Luzhou-flavor yeast and manufacturing method thereof

A production method and a strong-flavor technology, applied in the field of winemaking, can solve the problems of cumbersome process, large dust pollution and high energy consumption in the crushing process, and achieve the effects of neat section, improved fermentation power, and plump and robust mycelium.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

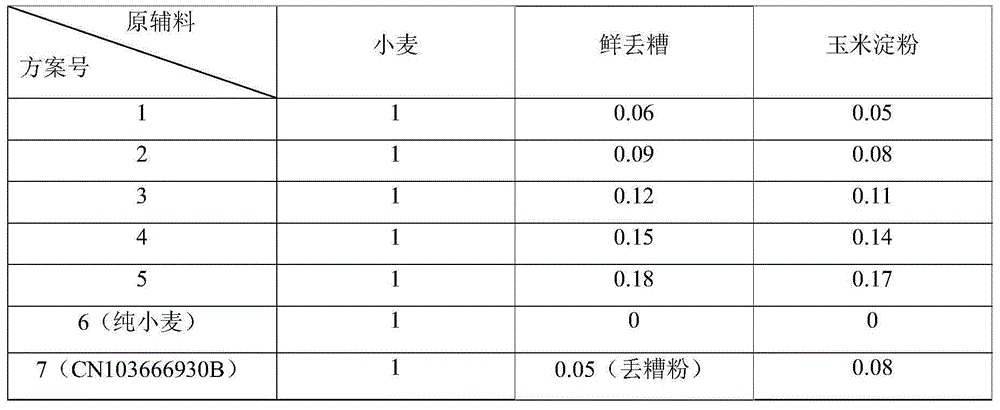

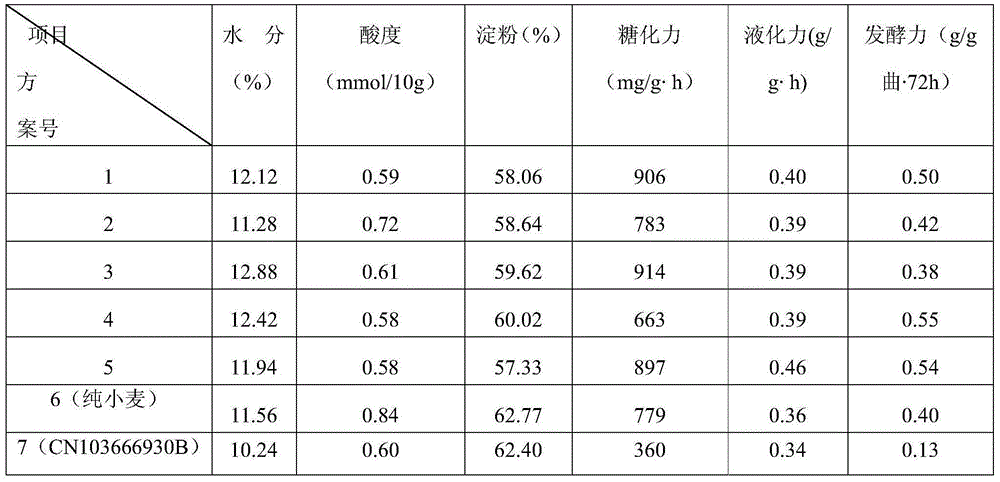

[0037] In this example, the crushed wheat, fresh grains, and cornstarch were uniformly mixed according to different proportions (see Table 1), pressed into koji, cultured for fermentation, koji turned, and stored in a warehouse.

[0038] Table 1 Proportion composition of different schemes

[0039]

[0040] (1) After moistening and crushing the wheat, add different proportions of fresh distilled grains and cornstarch according to Table 1 and mix evenly, and mix. When tempering, the water temperature is 80-87°C, the time for moistening is 4-24 hours, and the moisture content of the wheat after moistening reaches 12-14%. There is a crisp sound.

[0041](2) Requirements for mixing materials: the temperature of the water used during mixing is 25-40°C, and the water content after mixing is 38-40%. hand.

[0042] (3) Start the buckling machine to press the blank, the buckling time is 8s, the bending specification is (34+1) cm long, (21+1) cm wide, and (5.5-7.5) cm thick; the se...

Embodiment 2

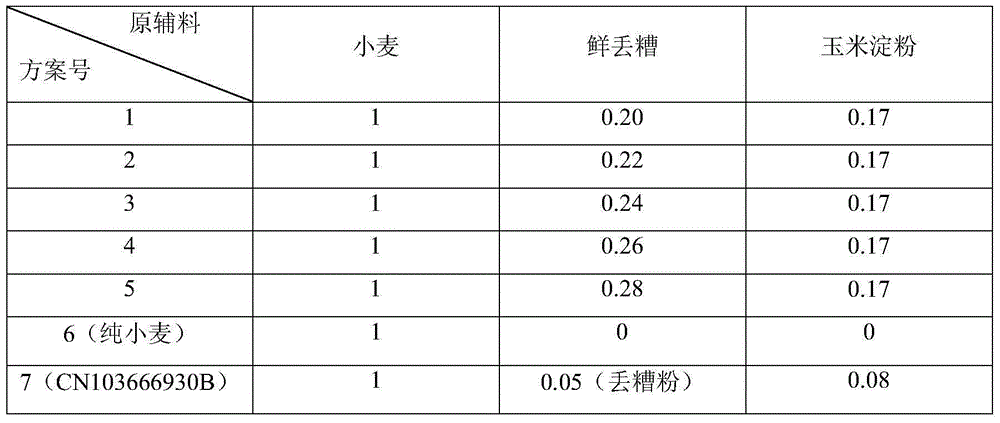

[0058] In this embodiment, the crushed wheat, fresh grains and cornstarch are mixed uniformly according to different proportions (see Table 4), pressed into koji, cultured for fermentation, koji turned, and stored in a warehouse.

[0059] Table 4 Proportion composition of different schemes

[0060]

[0061] (1) After tempering and crushing the wheat, add different proportions of fresh distilled grains and cornstarch according to Table 1 and mix evenly, and mix. When tempering, the water temperature is 80-87°C, the time for moistening is 4-24 hours, and the moisture content of the wheat after moistening reaches 12-14%. There is a crisp sound.

[0062] (2) Mixing requirements: the water used for mixing is cold water, and the water content after mixing is 38-40%; the sensory quality is that the bent material has uniform draft, no ash and pimples, and it is not sticky when kneaded into a ball.

[0063] (3) Start the buckling machine to press the blank, the buckling time is 8s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com