Preparation method and application of saccharopolyspora sp. Inoculated raw wheat koji for brewing food

A technology of raw wheat koji and spore bacteria, applied in the direction of microorganism-based methods, biochemical equipment and methods, vinegar preparation, etc., can solve the problems of deteriorating flavor of brewed food, increasing production costs of enterprises, affecting the quality of brewed food, etc., to achieve Save the cost of brewing production, improve the economic benefits of the enterprise, and improve the effect of flavor and appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

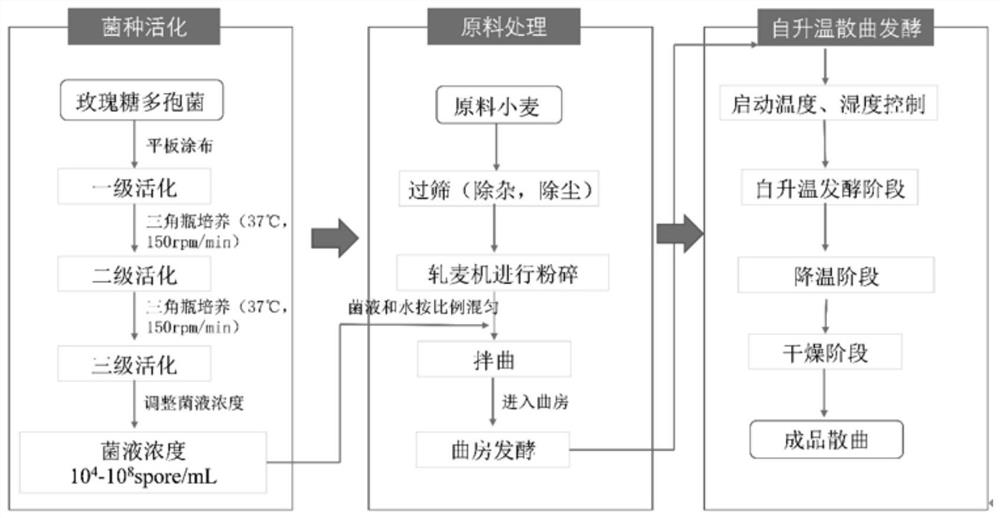

[0095] Embodiment 1: production technology of raw wheat koji (Sanqu) inoculated with Saccharopolyspora roseosa

[0096] See the process flow for inoculating raw wheat koji with Saccharopolyspora figure 1 ,Specific steps are as follows:

[0097] (1) Preparation of roseose polyspora bacteria liquid

[0098] Inoculate roseose polyspora F2014 into the actinomycetes culture medium, culture at a constant temperature of 37°C for 96 hours, then pick colonies from the plate and inoculate them into the actinomycetes liquid medium, and culture them on a shaker at 37°C and 150r / min for 48 hours , to prepare the seed solution;

[0099] Then the seed solution was transferred to the actinomycetes liquid medium according to the inoculum amount of 3% (v / v), and cultured on a shaker at 150 r / min at 37° C. for 96 hours to obtain Saccharopolyspora rosea bacteria solution.

[0100] (2) crush the red-skinned or yellow-skinned soft wheat produced in the year after sieving, the moisture content of...

Embodiment 2

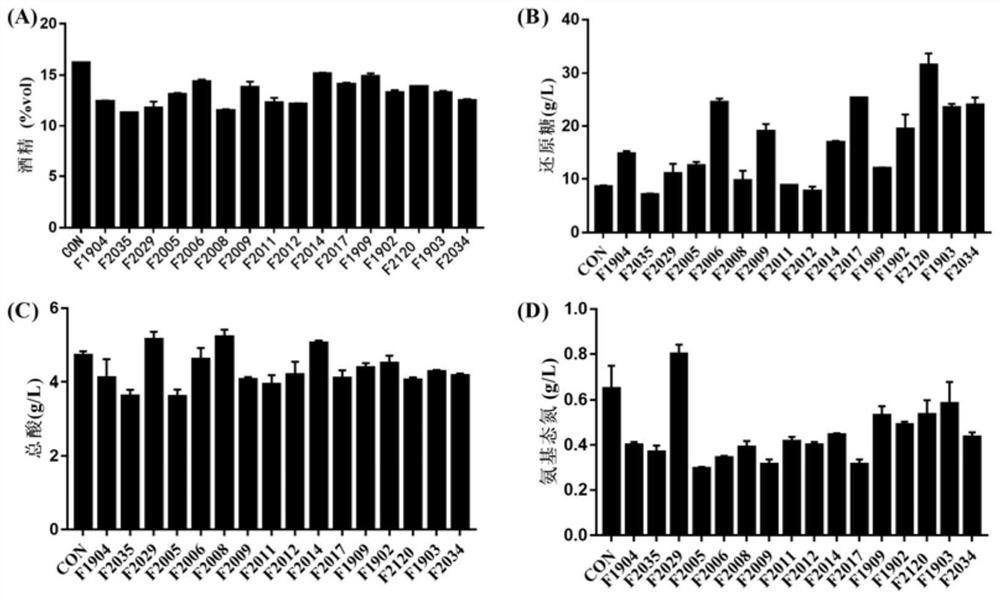

[0108] Example 2: Performance comparison of raw wheat koji inoculated with different polyspores in rice wine brewing

[0109] 1, the specific implementation method is the same as embodiment 1, the difference is that,

[0110] In the step (3) of Example 1, the roseose polyspora bacterium liquid is mixed with water according to the inoculation amount of 5% (v / m), and the final concentration of the bacterium liquid is adjusted to be 5 × 10 8 CFU / mL, to obtain bacterial suspension;

[0111] The bacterium suspension in the (4) of embodiment 1 is added in the wheat after pulverizing according to the amount of 25% (v / m); The start-up warming stage of cultivating koji: the koji room start-up temperature is 45 ℃, and the koji center temperature is at Slowly increase from room temperature to 45°C within 12 to 24 hours, and the other conditions are the same as in Example 1.

[0112] Using other Saccharopolyspora: F2005, F2006, F2008, F2120, F2009, F2011, F2012, F2017, F1902, F1903, F19...

Embodiment 3

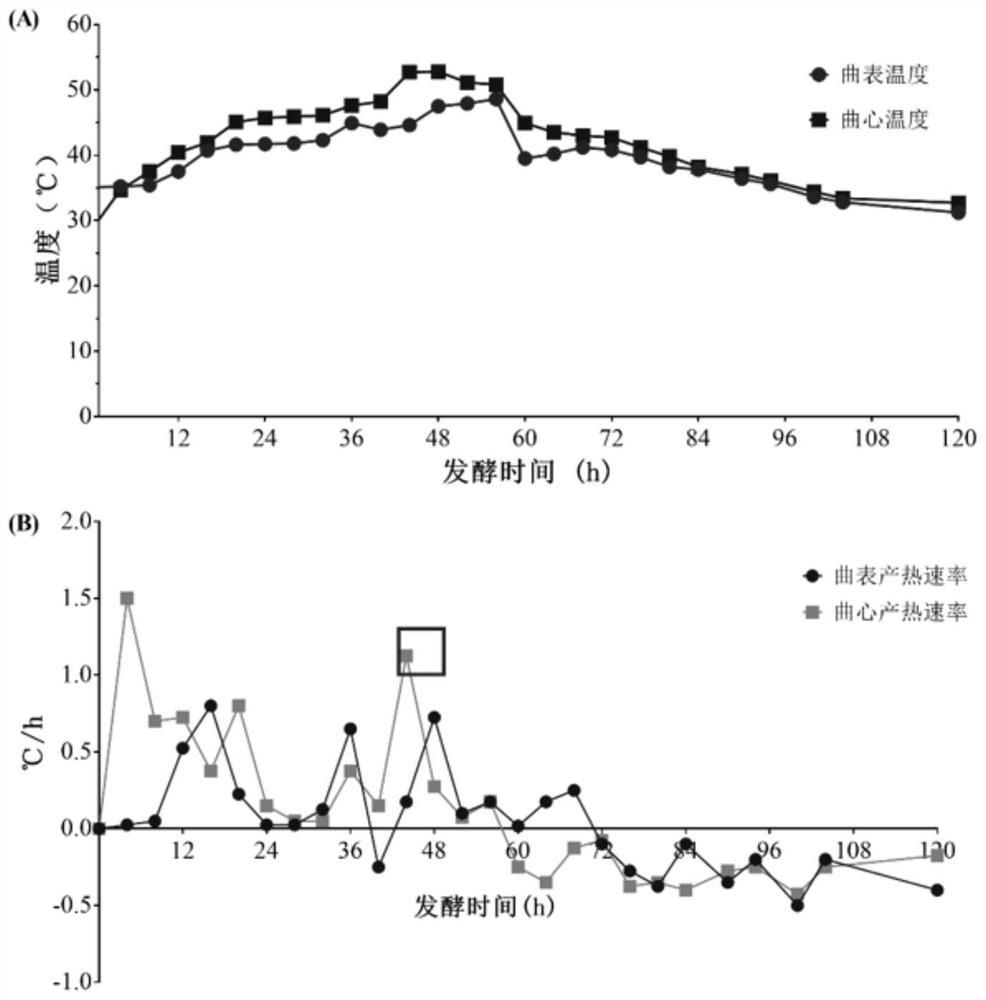

[0132] Embodiment 3: the optimization of rose sugar polyspora inoculation raw wheat koji (Sanqu) process

[0133] 1. Based on the koji making process in Example 1, the amount of water added in wheat koji, the amount of Saccharopolyspora inoculum, the fermentation temperature and the fermentation time were optimized respectively, and the response values of saccharification power and liquefaction power were evaluated indicators, which determine the optimal process parameters for each factor, such as Figure 5 shown.

[0134] (1) Moisture is one of the essential factors for the growth of microorganisms, and there is also an indirect relationship with the enzyme production of microorganisms. The specific implementation method is the same as embodiment 1,

[0135] The difference is that in step (3) of Example 1, the roseose polyspora bacterium liquid is mixed with water according to the inoculation amount of 5% (v / m), and the final concentration of the bacterium liquid is adjus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com