Nutritional health-care yellow rice wine and brewing method thereof

A nutritional and yellow rice wine technology, which is applied in the direction of medical formula, alcohol beverage preparation, plant raw materials, etc., can solve the problem of many sour and bitter substances, achieve the effect of improving nutritional value, stable quality, and inhibiting the growth of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

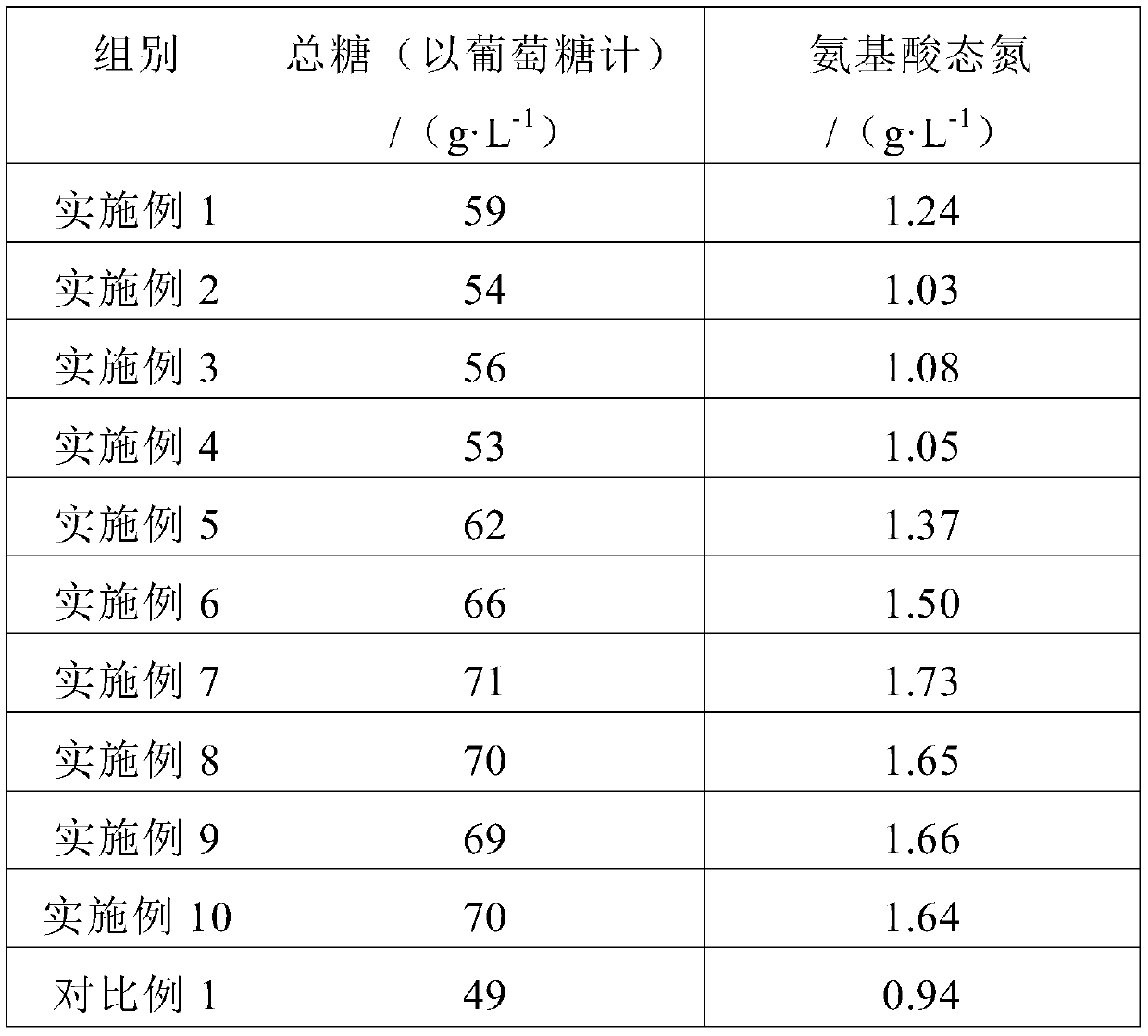

Examples

preparation example Construction

[0054] The preparation method of the acetic acid-sodium acetate buffer solution is as follows: add 3.86g of glacial acetic acid and 2.93g of sodium acetate into 1L of distilled water, and mix well.

[0055] The preparation method of 2-hydroxypropyltrimethylammonium chloride chitosan refers to the preparation method of Example 1 in the invention patent application number CN200910144393.

[0056] Resistant dextrin, CAS number: 9004-53-9, food grade, was purchased from Shandong Jurong Bioengineering Co., Ltd.

[0057] The extruding equipment is a DS32-II extrusion experimental twin-screw extruder, which was purchased from Jinan Dingrun Machinery Equipment Co., Ltd.

[0058] The rubber mill equipment is JMF-80 rubber mill, which was purchased from Guangzhou Hengdong Machinery Equipment Technology Co., Ltd.

[0059] The regenerated cellulose dialysis bag, with a diameter of 6.4 mm and a molecular weight cut-off of 3500 Da, was purchased from Shanghai Lianmai Bioengineering Co., Lt...

Embodiment 1

[0065] A brewing method of nutritional health-care rice wine, comprising the following steps:

[0066] Ⅰ. Raw material pretreatment: mix rice and glutinous rice in a mass ratio of 3:2 to obtain a mixture, then add distilled water with a mass of 18% of the mixture and soak for 14 hours to obtain a pretreated raw material;

[0067] Ⅱ. Rice steaming: Put the pretreated raw materials at 100°C for steam cooking, wherein the thickness of the pretreated raw materials is 20cm, the steam pressure is 0.1MPa, the cooking time is 30min, and cooled to 25°C to obtain steam Raw materials processed;

[0068] Ⅲ. Fermentation: Add red yeast rice, wheat koji, and plant additives to the steam-treated raw materials, and mix well. The mass ratio of the steam-treated raw materials, red yeast rice, wheat yeast, and plant additives is 1:0.06:0.02:0.09, Ferment at 25°C for 24 days, stirring once every 4 days to obtain fermented material;

[0069] Ⅳ. Treatment of fermented material: Filter the ferment...

Embodiment 2

[0076] It is basically the same as Embodiment 1, the difference is only in:

[0077] The preparation method of the plant additive is as follows: mix the leaves of the false eagle claw and the Herba Polygonum at a mass ratio of 1:1, dry at 50° C. for 5 hours, and pulverize to 80 mesh to obtain the raw material powder, and then mix them at a ratio of 1:10 ( g / mL) to the raw material powder, add 35wt% methanol aqueous solution, extract at 80°C for 3h, filter through 200 mesh filter cloth to obtain the filtrate, then place the obtained filtrate at 50°C, and the absolute pressure is 0.05MPa Concentrated to a water content of 8wt% under certain conditions to obtain a plant additive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com