Velvet surface antibacterial PP (polypropylene) reinforced material and preparation method thereof

A surface antibacterial and reinforcing material technology, applied in the field of PP materials, to achieve the effects of excellent comprehensive performance, inhibition of bacterial growth, and convenient operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

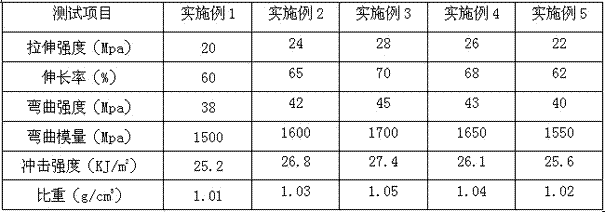

Examples

Embodiment 1

[0053] An antibacterial PP reinforced material with a velvet surface, which is composed of the following parts by weight:

[0054] 60 parts of PP resin

[0055] 3 parts of POE elastomer

[0056] 10 parts of filler

[0057] Surface active agent 2 parts

[0058] Antibacterial agent 0.5 parts

[0059] Lubricant 0.5 parts

[0060] 0.5 parts of weathering agent

[0061] Coupling agent 0.3 parts

[0062] 0.2 parts of antioxidant.

[0063] The filler is nano calcium carbonate with a particle size of 10 nm.

[0064] The surface active agent is Clariant FA14; the antibacterial agent is a silver salt antibacterial agent.

[0065] The lubricant is a mixture composed of OP wax and calcium stearate in a weight ratio of 1.2:1.

[0066] The weathering agent is an ultraviolet absorber UV-770; the coupling agent is a titanate coupling agent.

[0067] The antioxidant is a mixture composed of antioxidant 1010 and antioxidant 168 in a weight ratio of 1:0.8.

[0068] A preparation method of antibacterial PP reinforce...

Embodiment 2

[0073] The difference between this embodiment and the foregoing embodiment 1 is:

[0074] An antibacterial PP reinforced material with a velvet surface, which is composed of the following parts by weight:

[0075] 65 parts of PP resin

[0076] 4 parts of POE elastomer

[0077] 12 parts of filler

[0078] Surface active agent 2.5 parts

[0079] Antibacterial agent 0.8 parts

[0080] 0.8 parts of lubricant

[0081] 0.8 parts of weathering agent

[0082] 0.4 parts of coupling agent

[0083] 0.4 parts of antioxidant.

[0084] The filler is nano calcium carbonate with a particle size of 30 nm.

[0085] The lubricant is a mixture composed of OP wax and calcium stearate in a weight ratio of 1.4:1.

[0086] The antioxidant is a mixture composed of antioxidant 1010 and antioxidant 168 in a weight ratio of 1:0.9.

[0087] In the step (2), the processing parameters of the twin-screw extruder are: zone one temperature 178°C, zone two temperature 178°C, zone three temperature 188°C, zone four temperature 188...

Embodiment 3

[0089] The difference between this embodiment and the foregoing embodiment 1 is:

[0090] An antibacterial PP reinforced material with a velvet surface, which is composed of the following parts by weight:

[0091] 70 parts of PP resin

[0092] 5 parts of POE elastomer

[0093] 15 parts of filler

[0094] Surfactant 3 parts

[0095] Antibacterial agent 1 part

[0096] 1 part lubricant

[0097] 1 part of weathering agent

[0098] Coupling agent 0.5 parts

[0099] Antioxidant 0.5 parts.

[0100] The filler is nano calcium carbonate with a particle size of 50 nm.

[0101] The lubricant is a mixture composed of OP wax and calcium stearate in a weight ratio of 1.5:1.

[0102] The antioxidant is a mixture composed of antioxidant 1010 and antioxidant 168 in a weight ratio of 1:1.

[0103] In the step (2), the processing parameters of the twin-screw extruder are: a zone temperature of 180°C, a zone temperature of 180°C, a zone temperature of 190°C, a zone four temperature of 190°C, a zone five temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com