Patents

Literature

61results about How to "Thin skin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compositions containing mixtures of tetrapeptides and tripeptides

ActiveUS6974799B2Reducing visible sign of agingImprove stateCosmetic preparationsToilet preparationsPersonal careTetrapeptide

Pharmaceutical, personal care and cosmetic compositions containing a tripeptide and a tetrapeptide are useful for treating visible signs of aging including wrinkles, stretch marks and dark circles.

Owner:SEDERMA SA

Foamed thermoplastic polyurethanes

InactiveUS7202284B1Improve cell structureExcellent surface appearanceCoatingsPolymer scienceMicrosphere

Process for the preparation of foamed thermoplastic polyurethanes characterized in that the foaming of the thermoplastic polyurethane is carried out in the presence of thermally expandable microspheres.

Owner:JPMORGAN CHASE BANK N A AS COLLATERAL AGENT +1

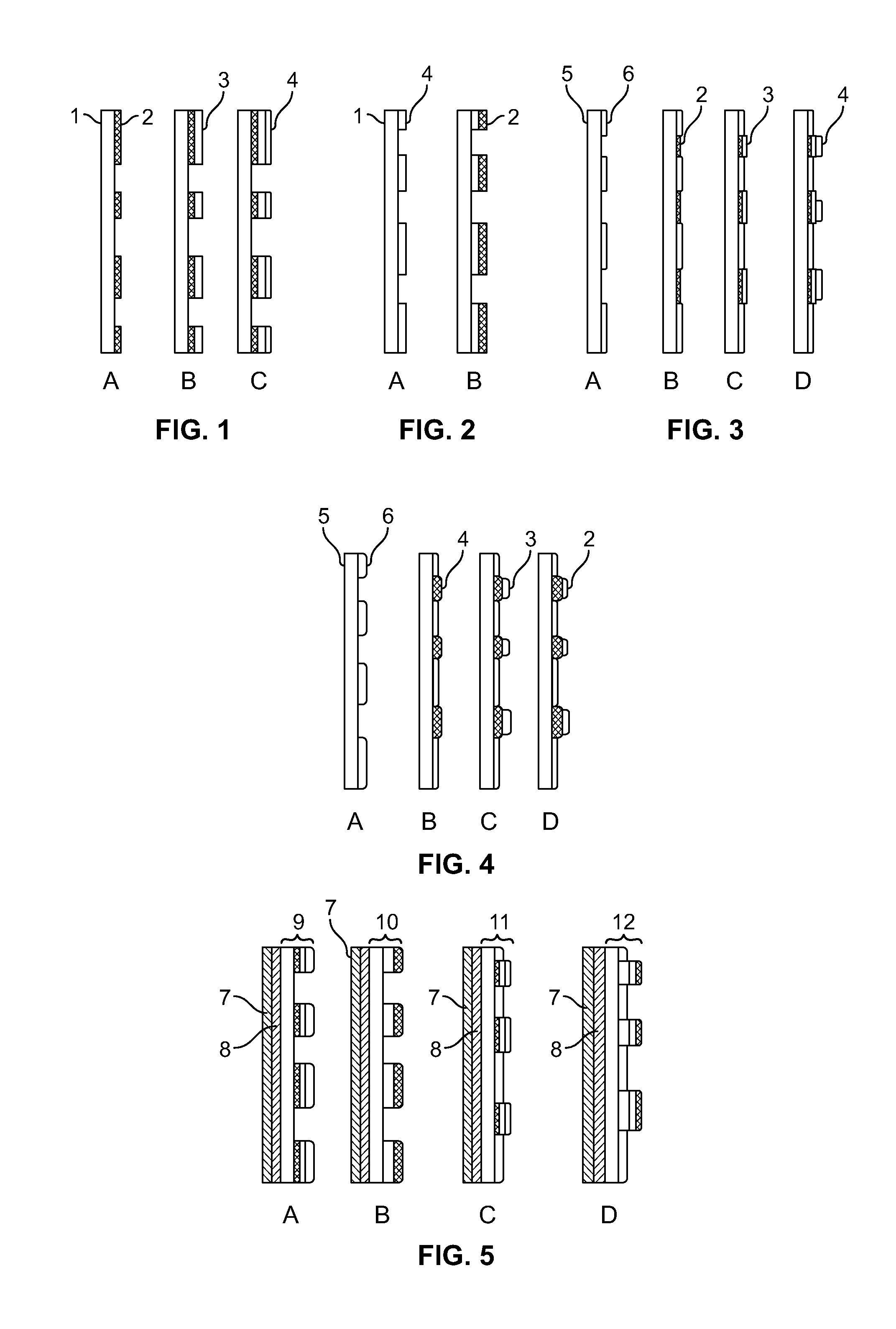

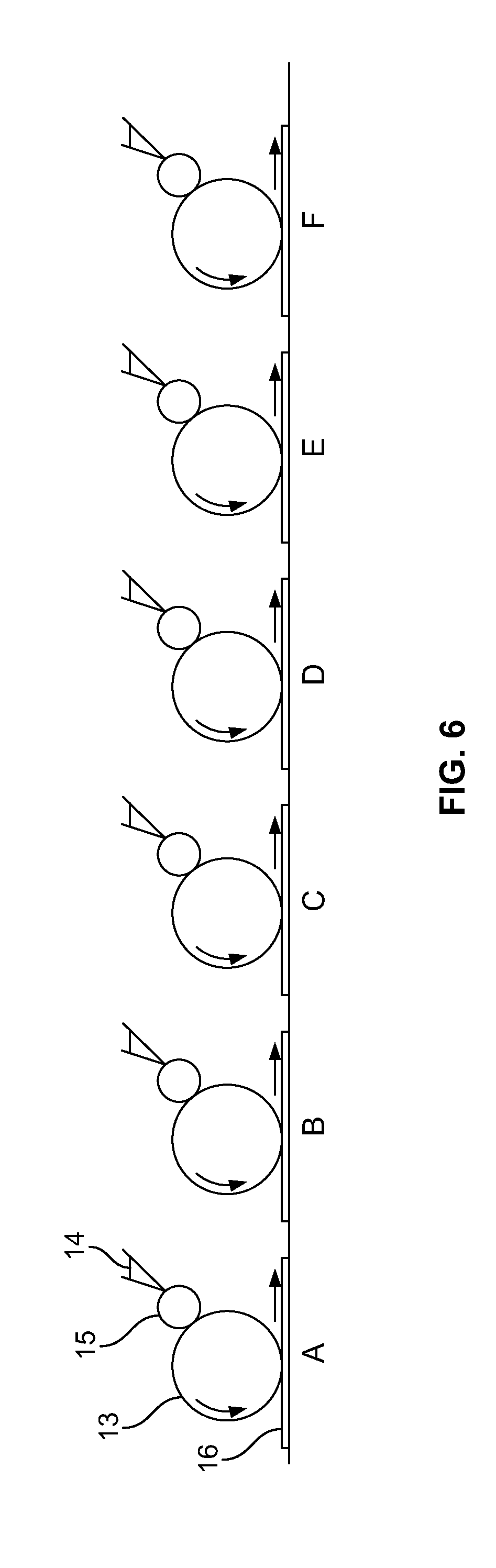

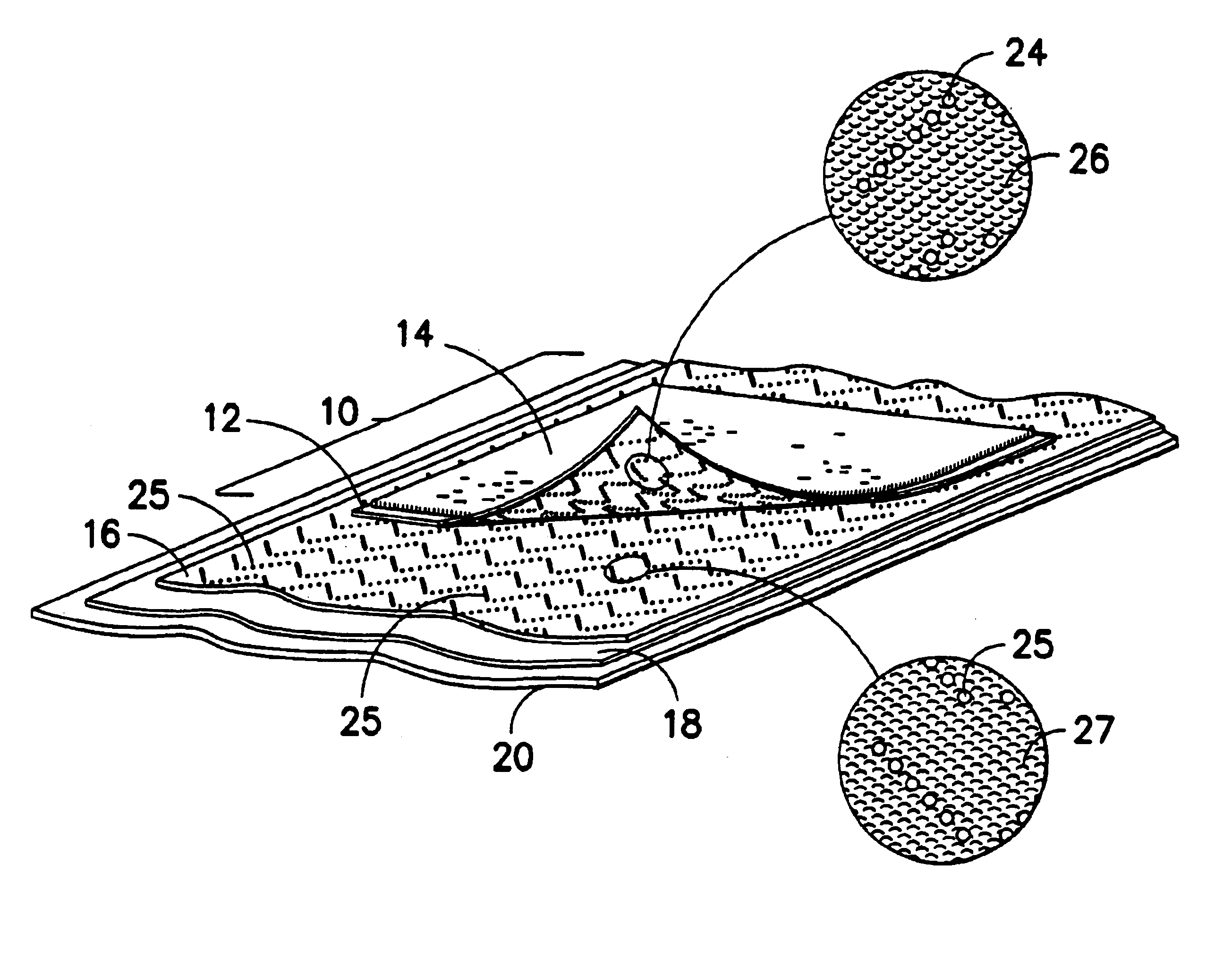

One-Way Graphics Materials and Methods

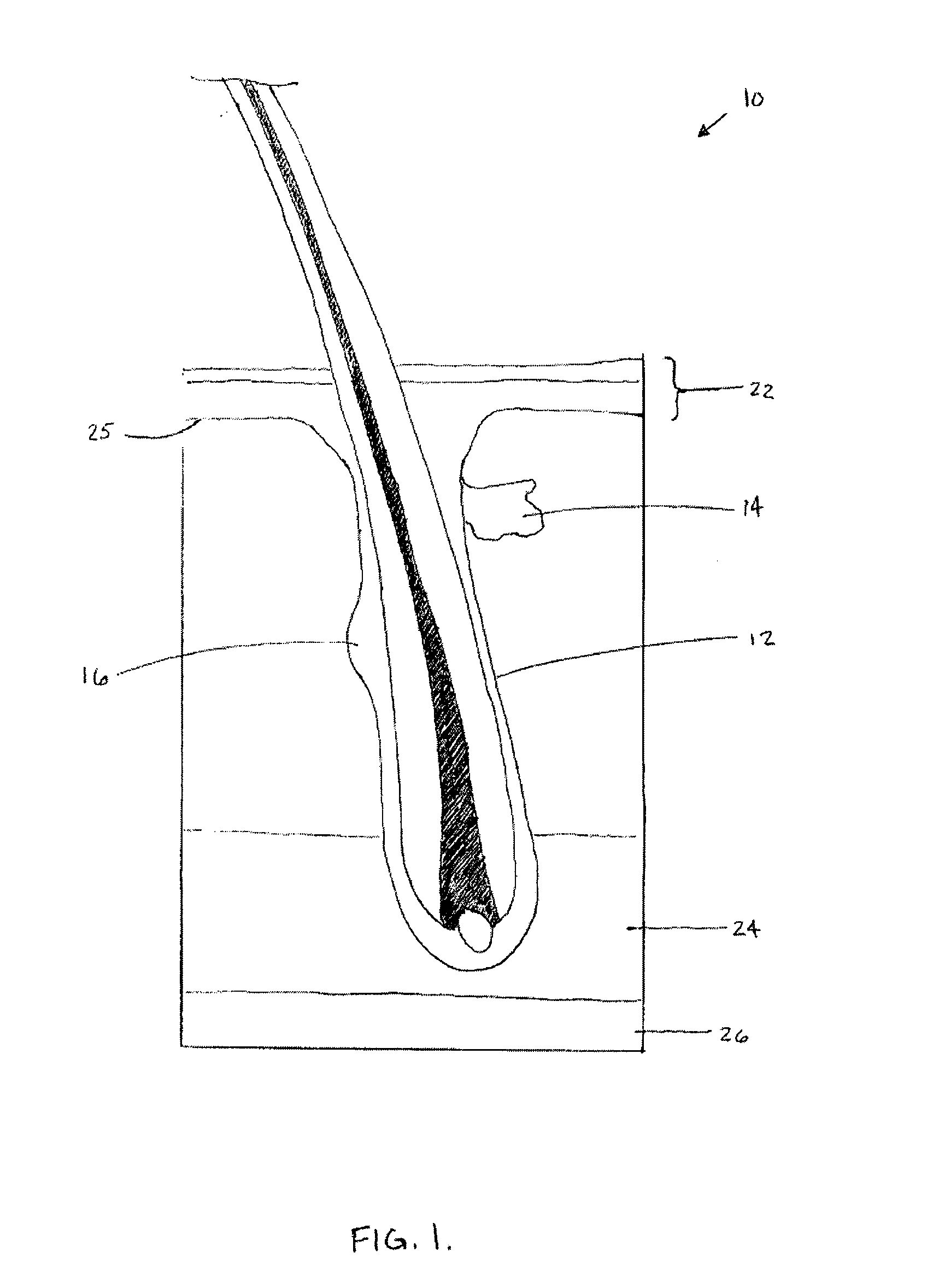

InactiveUS20130330486A1Thin skinStatic indicating devicesDecorative surface effectsGraphicsDisplay device

Included herein are base materials and methods for use in creation of one-way graphics, including a dye-receptive substrate with a pattern of ink-repellent material over the dye-receptive substrate. An image may be printed selectively onto the base material to leave a visual perforation pattern that allows vision through the printed image under appropriate illumination. Also disclosed are printing methods involving the application of variously ordered layers of light-absorbing, light-reflective, and image mediums to printing substrates with physically raised and lowered areas to create one-way graphics. The invention also includes new forms of one-way graphics, including lenticular and holographic one-way displays, and one-way displays having internal lighting sources.

Owner:MINDFLOW

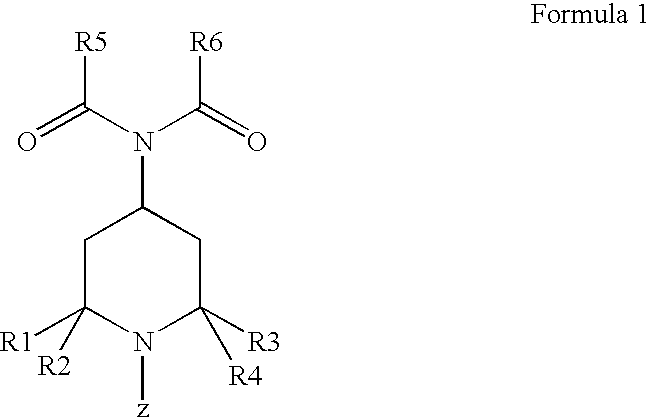

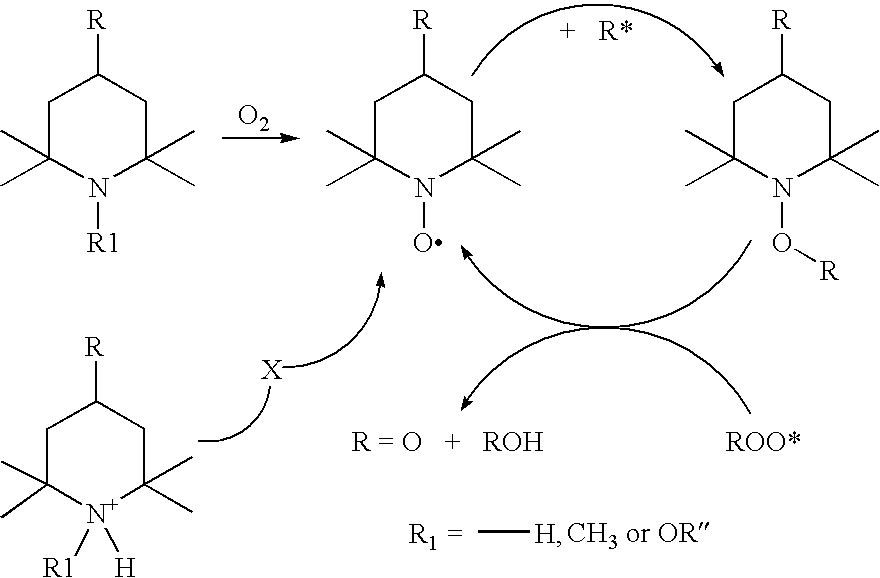

Dermocosmetic Preparations

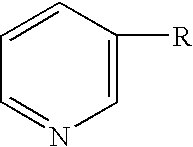

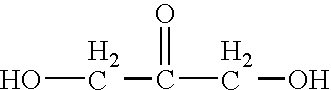

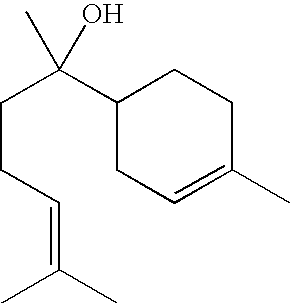

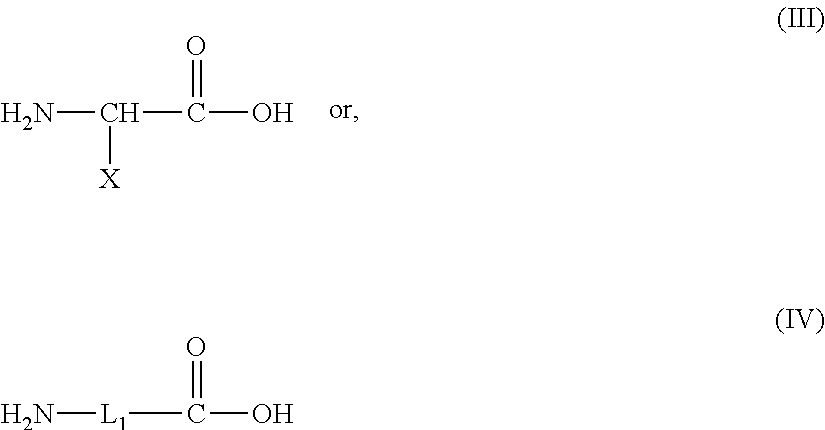

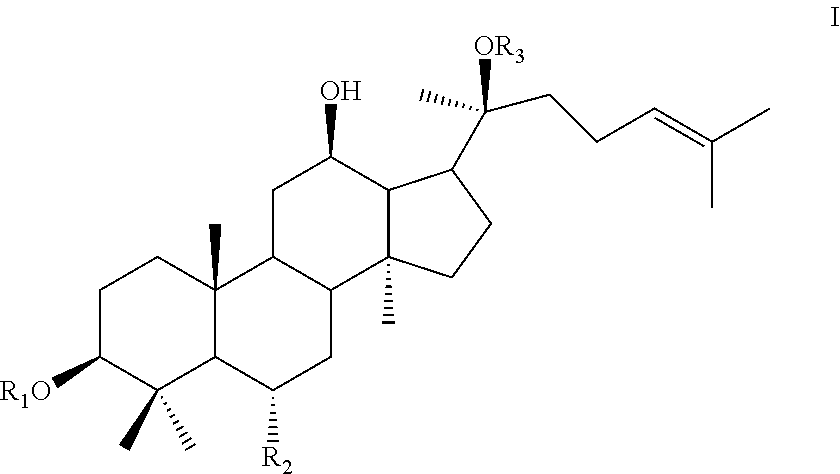

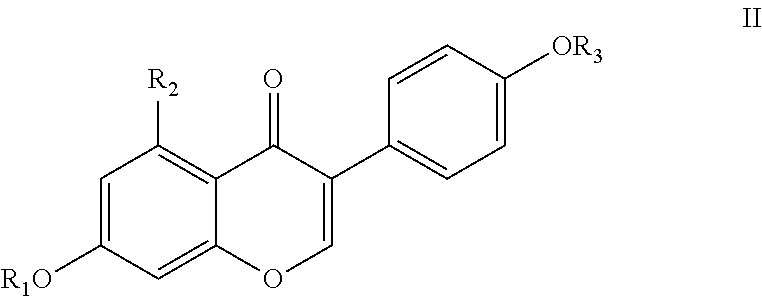

InactiveUS20080220031A1Reduce lossesPromote skin regenerationCosmetic preparationsHair cosmeticsArylAlkoxy group

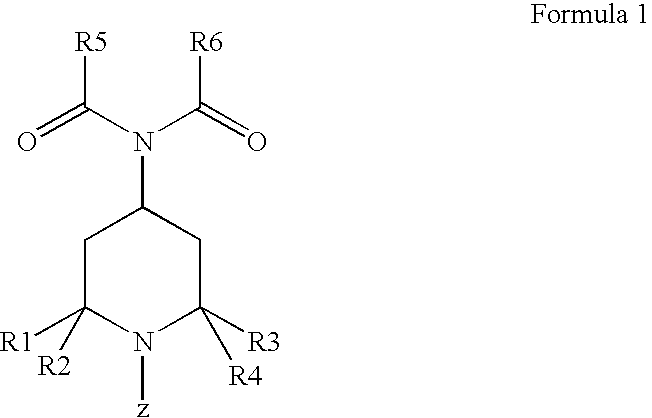

The present invention relates to dermocosmetic compositions comprising a compound comprising the structural element of the formula Iwhere the radical Z has the following meaning: H, C1-C22alkyl group, C6-C10-aryl group, C1-C22-alkoxy group or a C6-C10-O-aryl group substituted by a C1-C22-alkyl or C-C22-alkoxy group,and the radicals R1 to R6, independently of one another, have the following meaning: H, C1-C22-alkyl group, C6-C10-aryl group, O, OH, C1-C22-alkoxy group or a C6-C10-O-aryl group substituted by a C1-C22-alkyl or C1-C22-alkoxy group,it being possible for R5 and R6 to be bridged in such a way that a five- to eight-membered ring is formed and, in the case of a five-membered ring, this ring may be part of an oligomer as a result of covalent bonds at positions 3 and 4.The invention furthermore relates to the use of said compounds in dermocosmetic formulations and the use of the dermocosmetics according to the invention for reducing skin or hair damage caused by free radicals. The invention furthermore relates to the use of the compounds according to the invention for increasing the stability of dermocosmetic formulations.

Owner:BASF AG

Methods and compositions for topical delivery

PendingUS20190105261A1Thin skinAvoid inconvenienceSalicyclic acid active ingredientsCosmetic preparationsActive agentMedicine

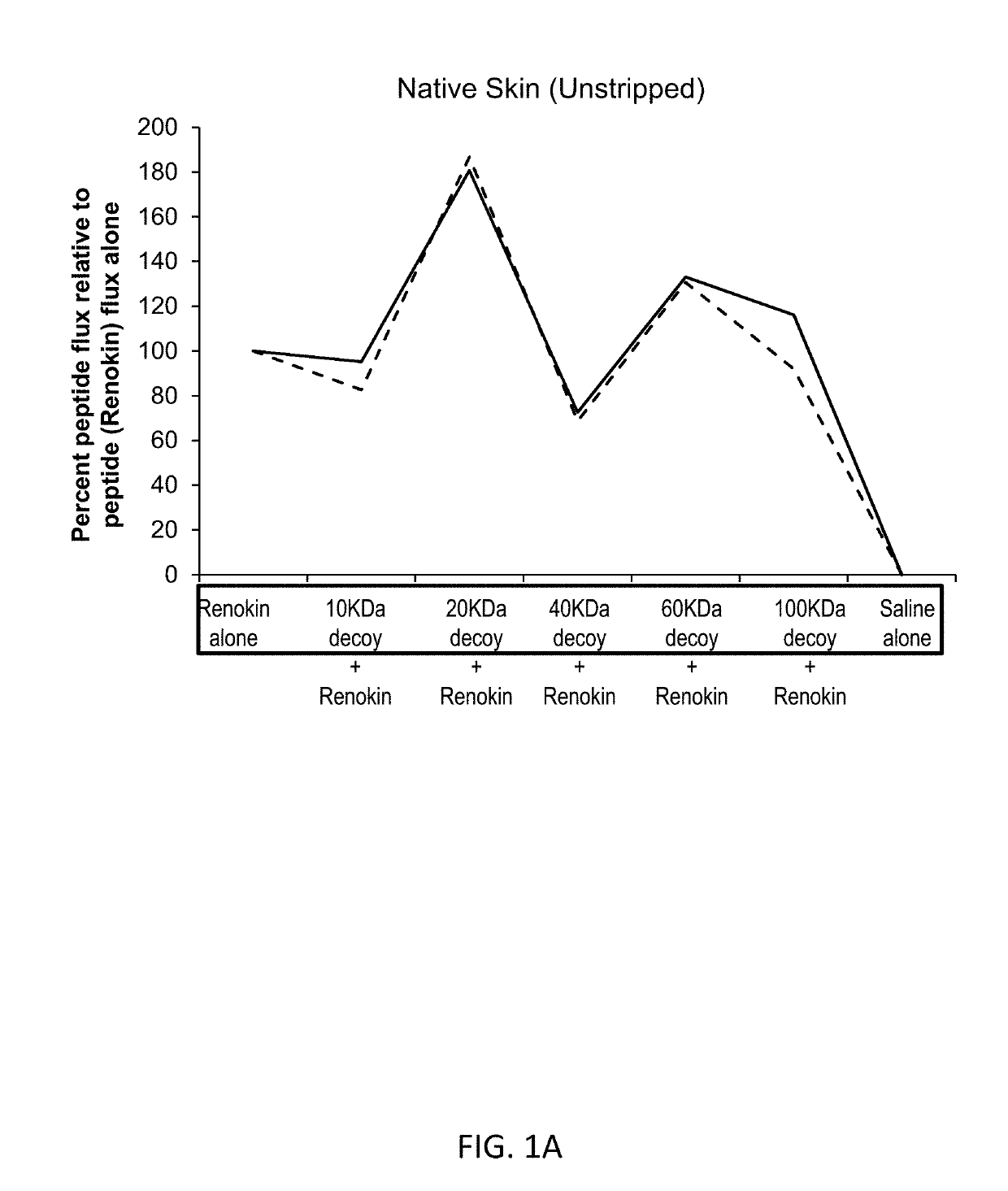

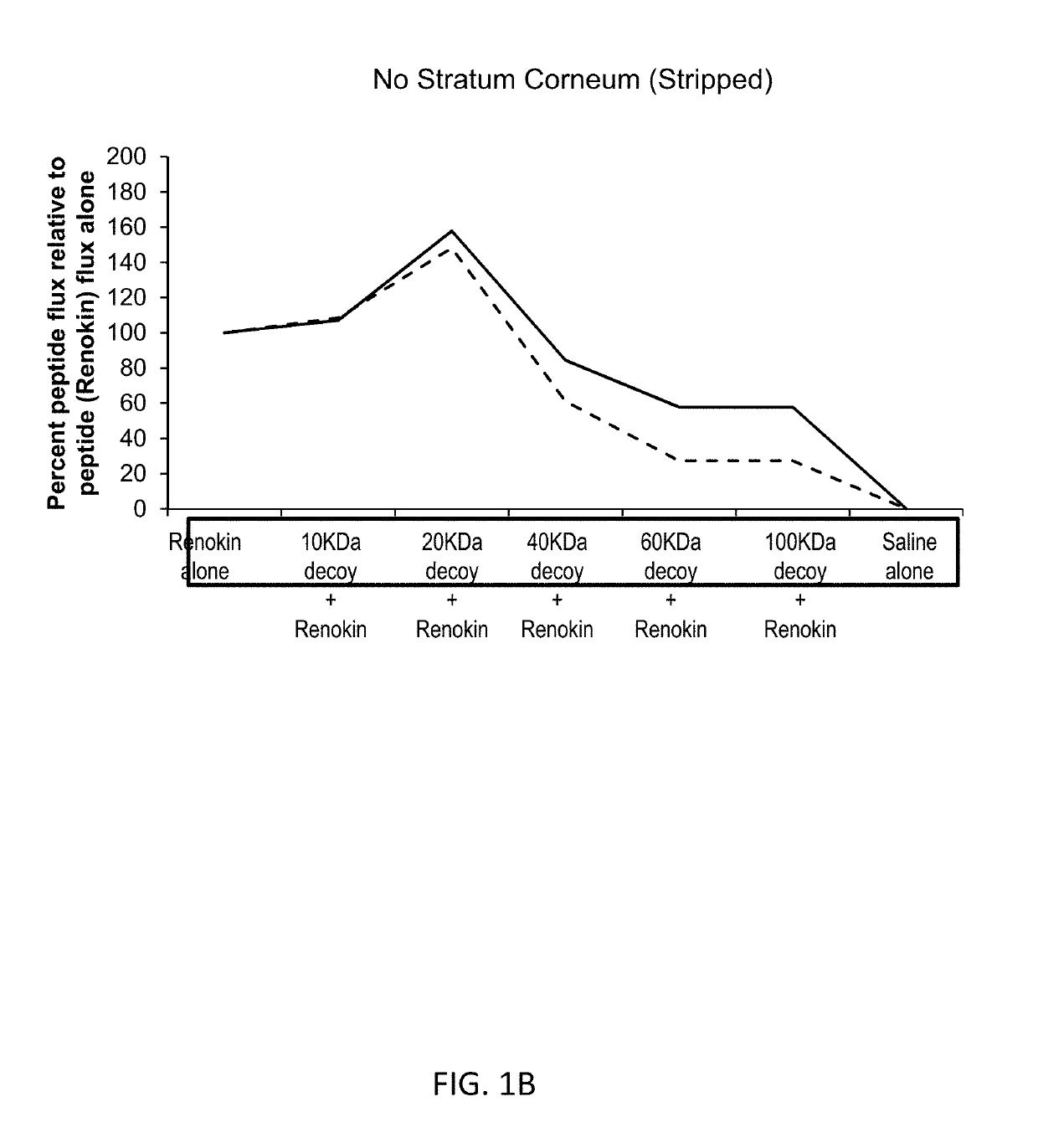

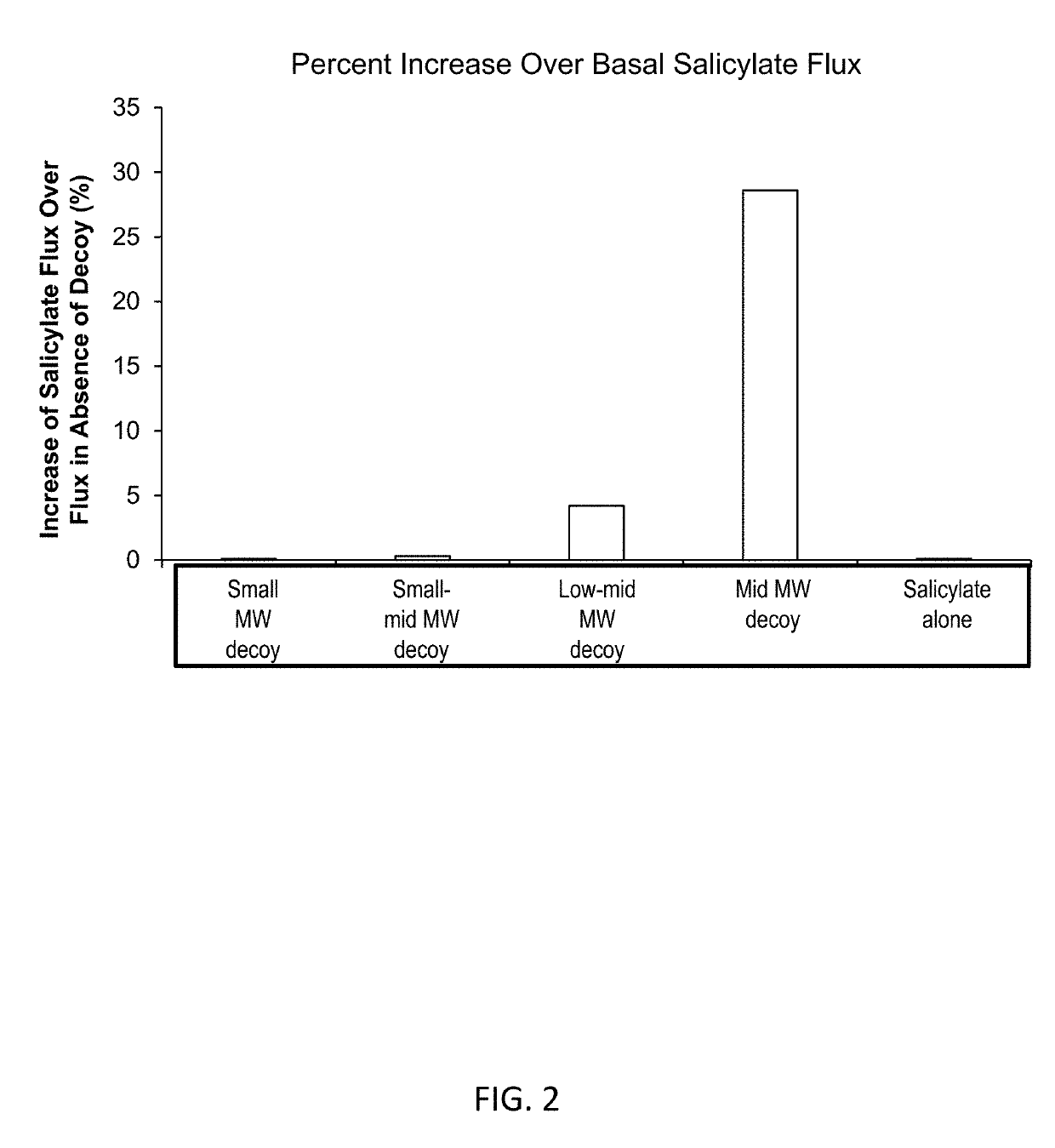

Compositions for topical delivery of an active agent and methods for using such compositions are described herein. Compositions include one or more active agents and about 0.001 wt. % to about 10 wt. % of a extracellular matrix component having average molecular weight of about 2,000 daltons to about 20,000 daltons. The extracellular components include hyaluronic acid, collagen, fibronectin, elastin, lectin, and fragments thereof and combinations thereof.

Owner:ILLUSTRIS PHARMA INC

Synergetic composition for the treatment of psoriasis and other skin disorders and method therefor

InactiveUS20030185915A1ThinningSuppression problemBiocideUnknown materialsBULK ACTIVE INGREDIENTParapsoriasis

Synergetic compounded medication formula for the treatment of psoriasis, seborrhea, dermatitis, dandruff, eczema, acne, and other skin disorders. The present invention is to provide regenerative treatment of skin disorders recurrent in all areas of the body. The invention of this disclosure uses a well-known corticosteroid as an active ingredient, namely Triamcinolone acetonide, which when used in combination with a special formula is effective, easy to use, and less expensive than similar products available with a prescription in the market. A method for administering said composition to inhibit proliferation of psoriatic cell populations in the epidermis is disclosed

Owner:CARLO JAIME +3

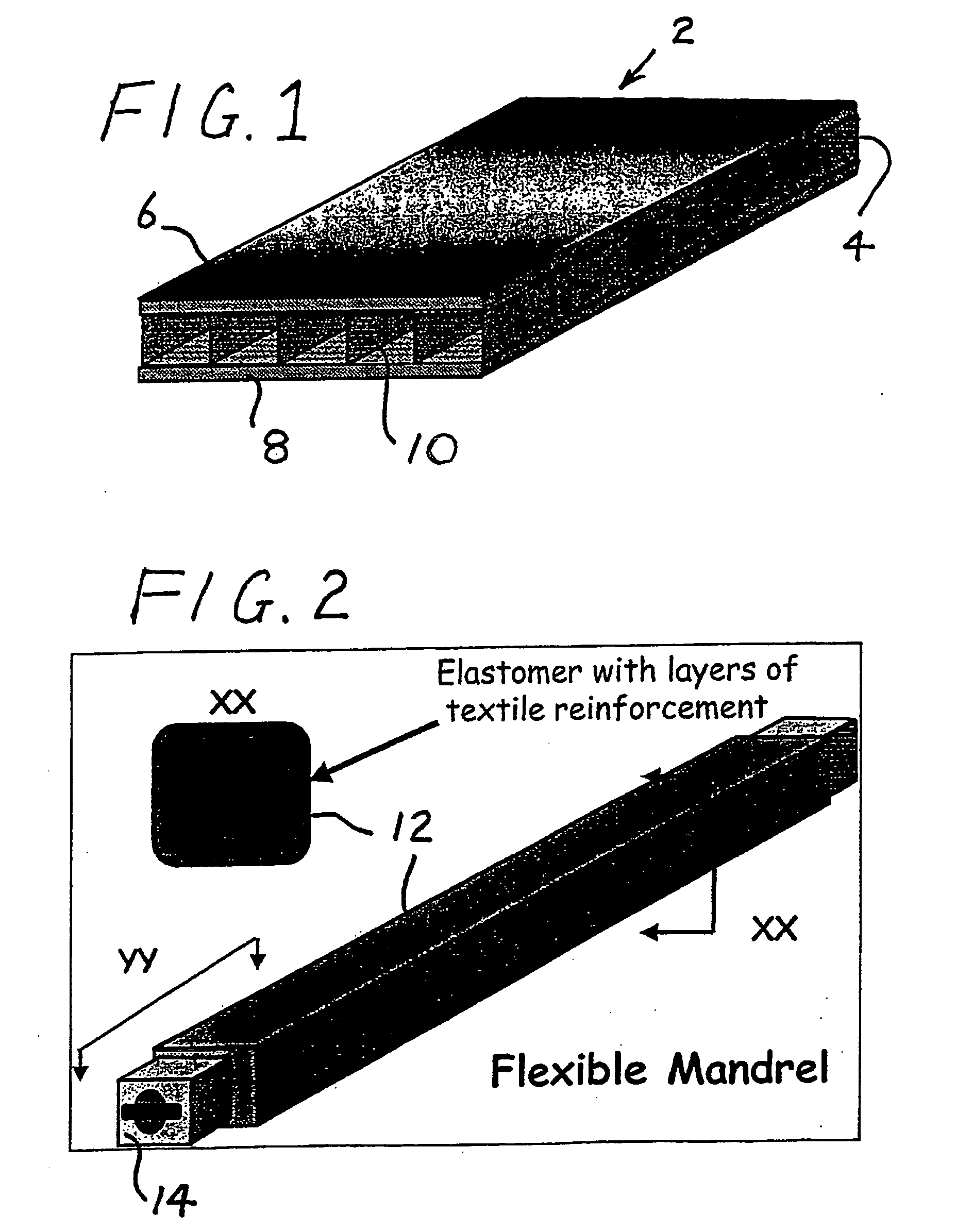

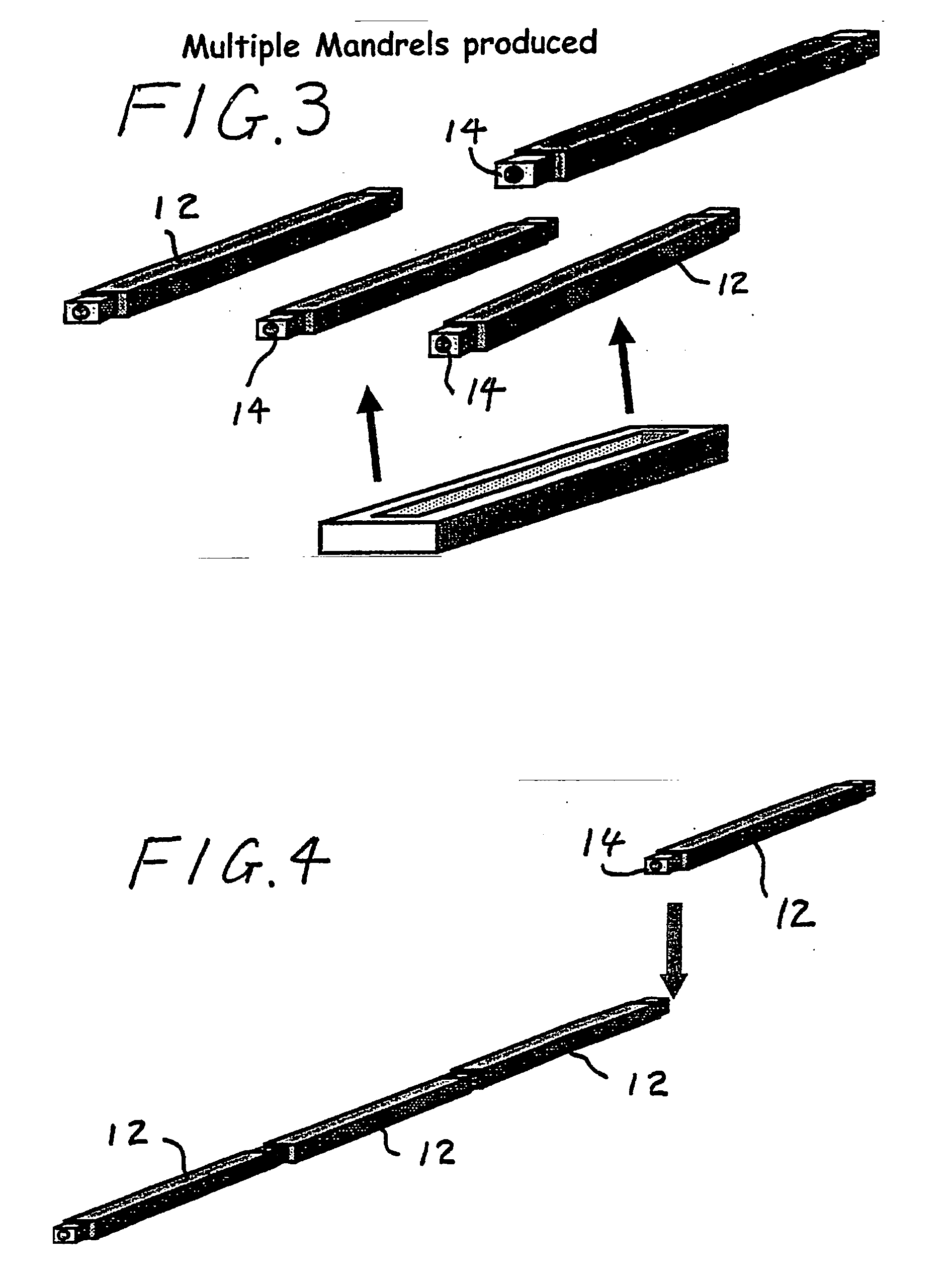

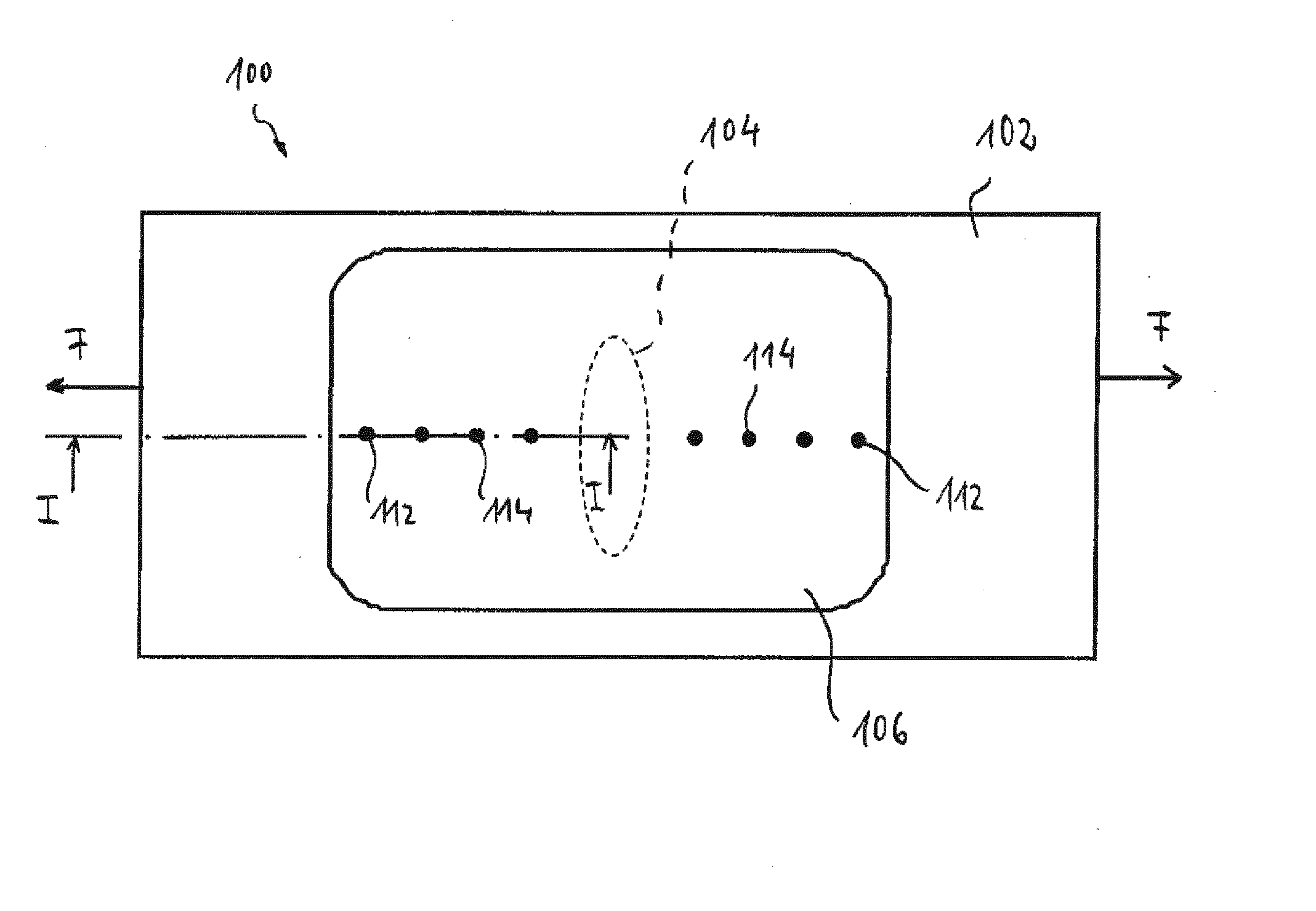

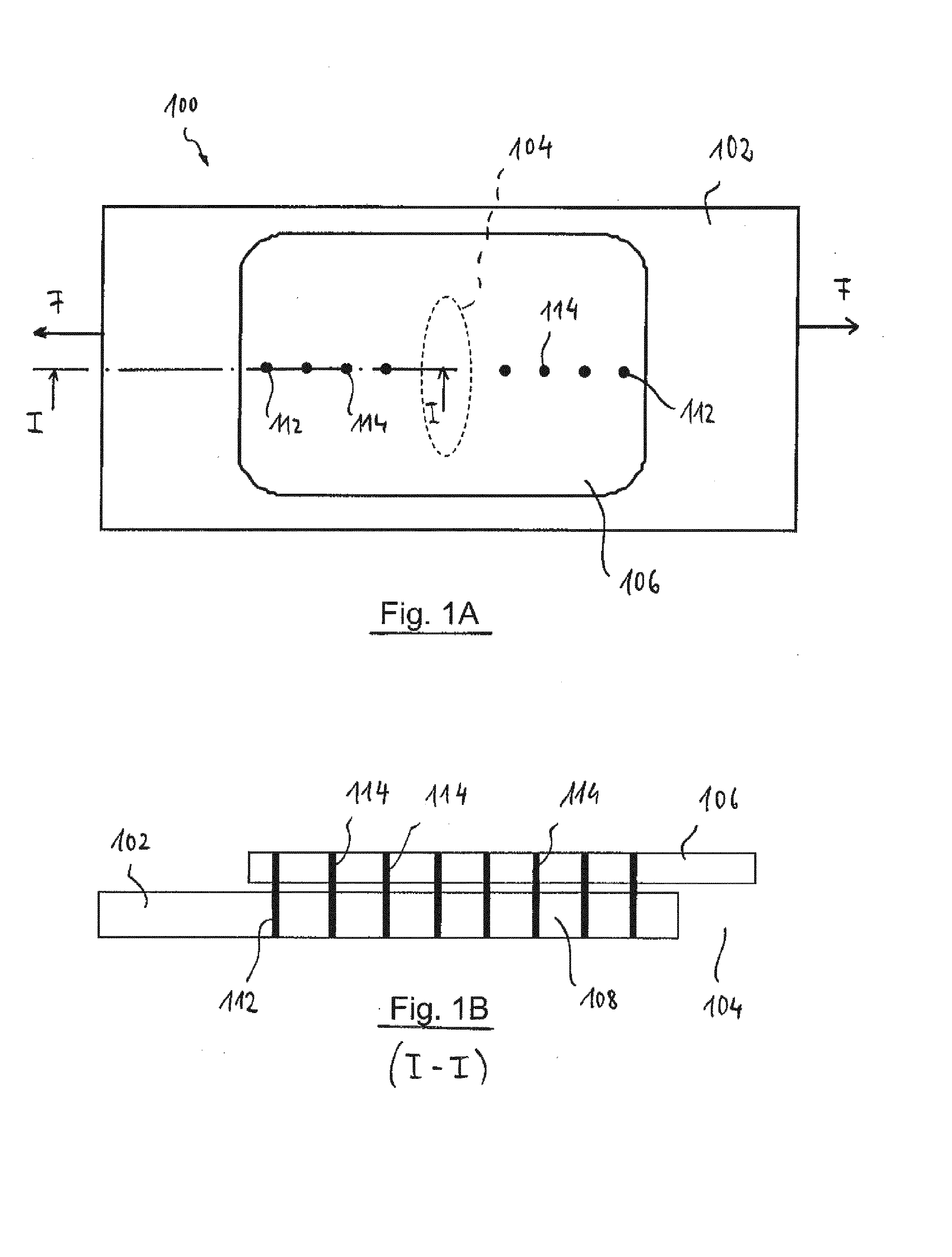

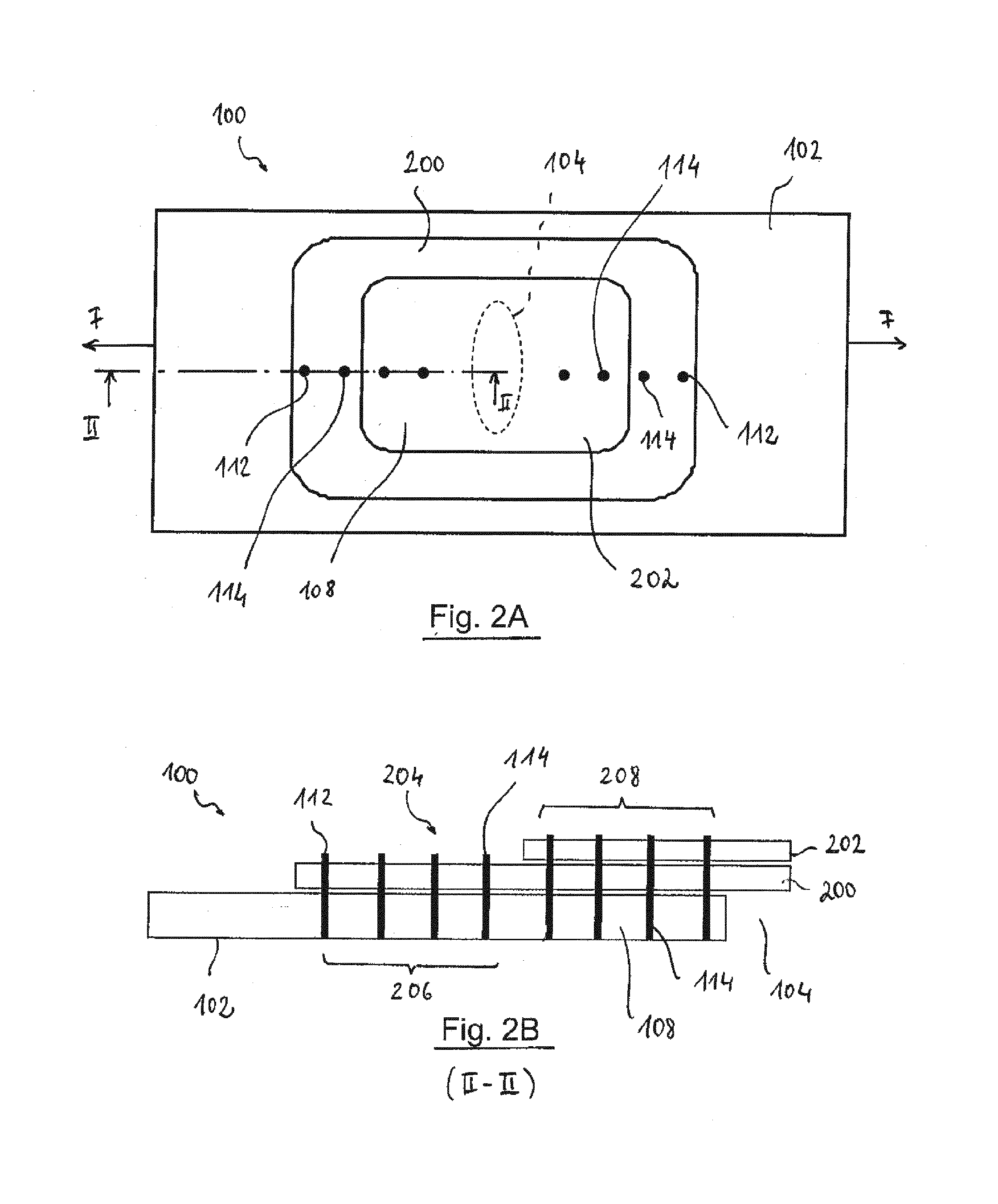

Fibre reinforced composite component

InactiveUS20060062973A1Expensive to produceReduce harmLayered productsEfficient propulsion technologiesEngineeringFiber-reinforced composite

A fibre reinforced composite component is provided having cured fibre reinforced wall elements which extend in side by side relation along the length or width of the component between the front face and the rear face and which are formed by setting up an assembly of mandrels in side by side disposition, which are clad with a reinforcing fibre material, curing the material after resin impregnation to form the wall elements, and removing the mandrels to form cells bounded or partly bounded by the wall elements.

Owner:SHORT BROTHERS

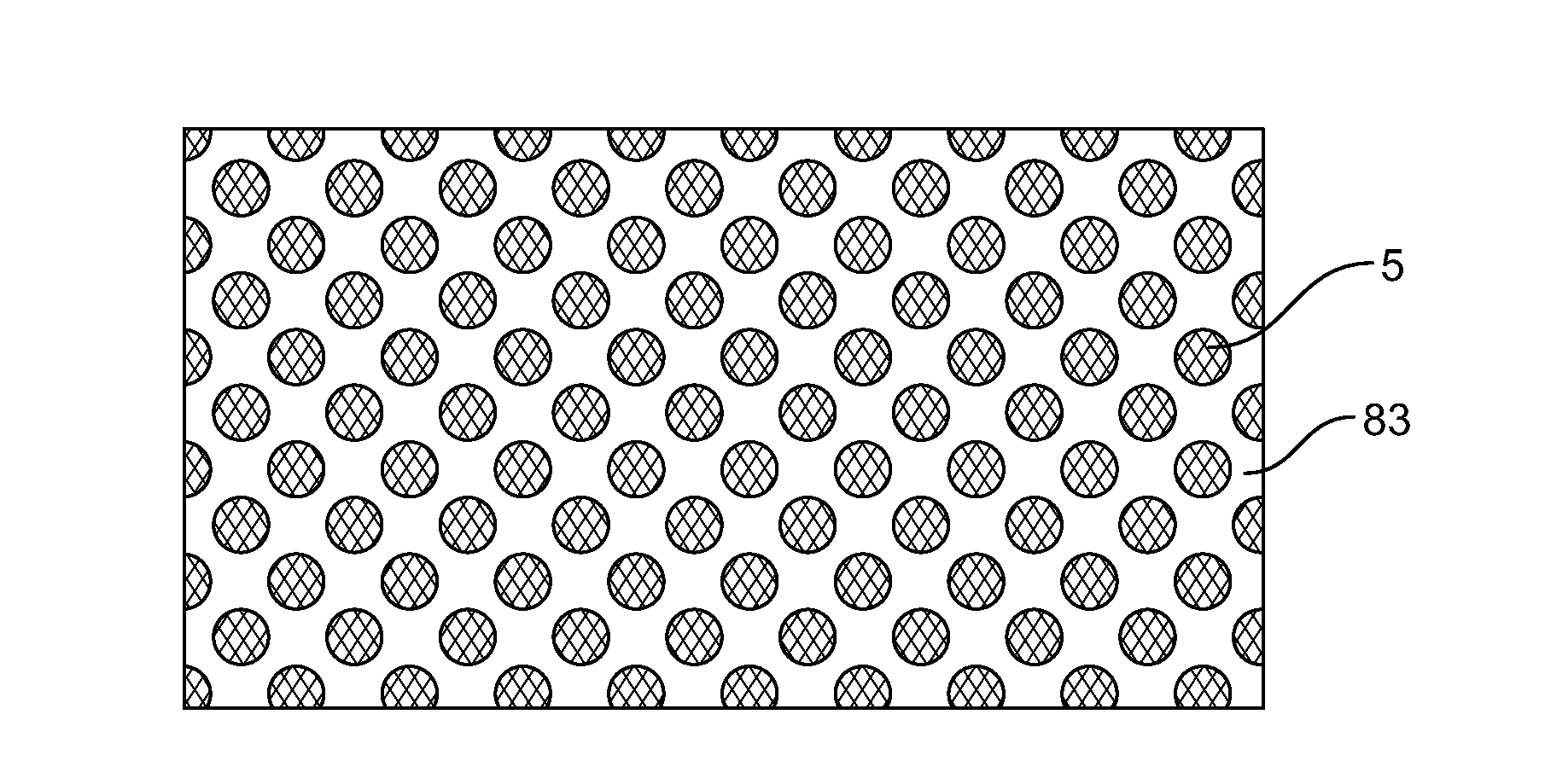

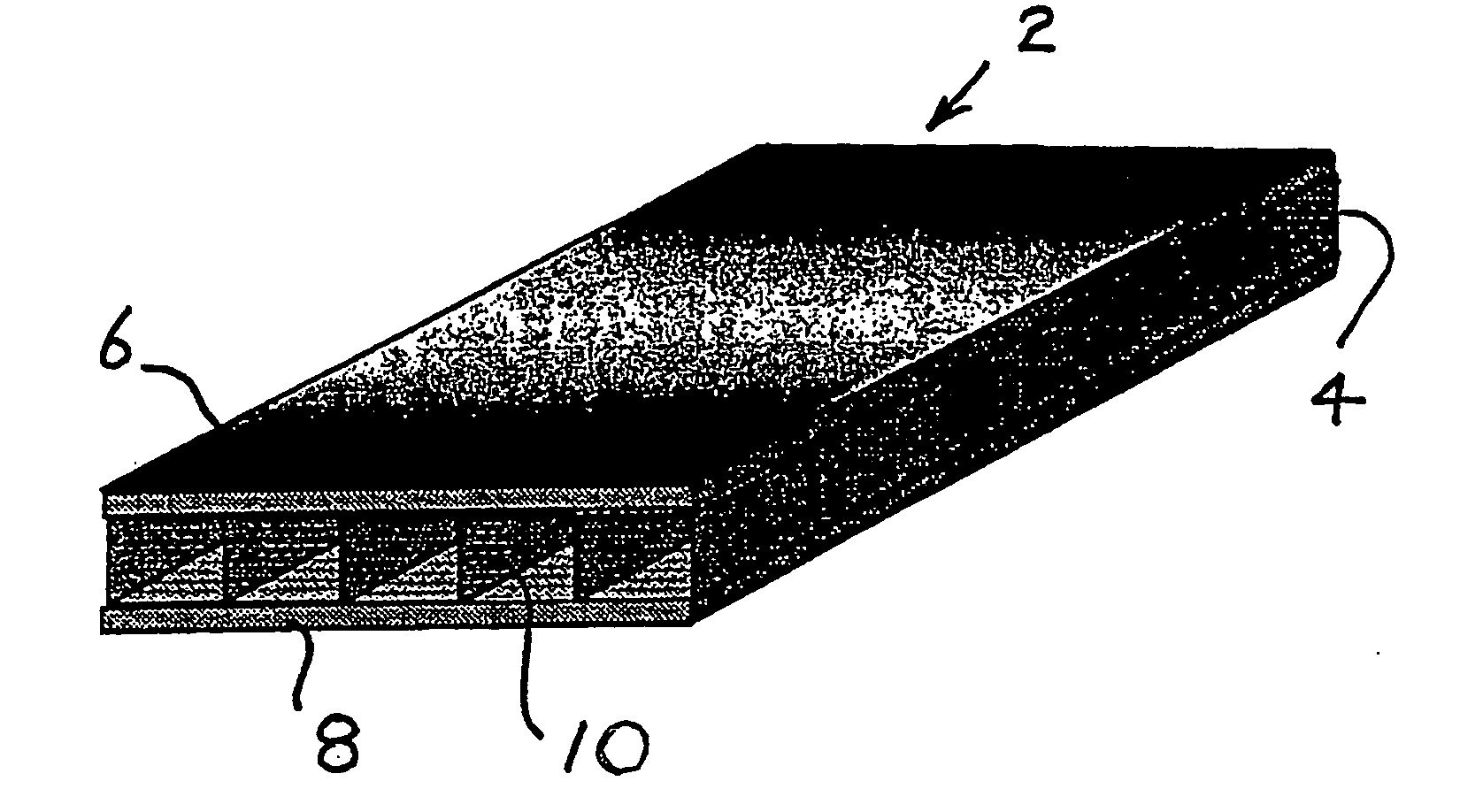

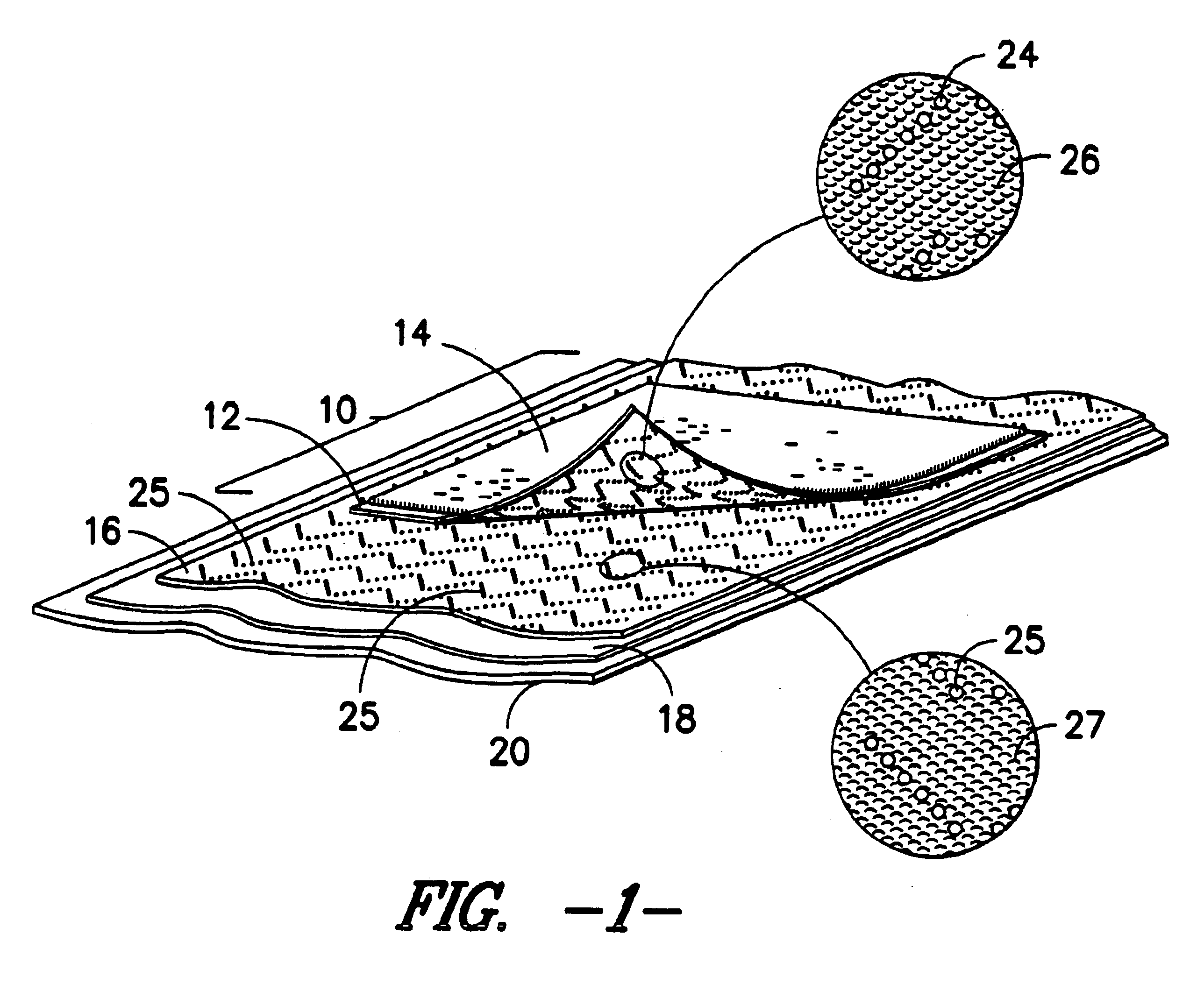

Cleat-forming woven fabric article for the manufacture of anti-creep floor mats

InactiveUS6787215B1Easily and efficiently producedThin skinKitchenware cleanersBathsVulcanizationFoam rubber

The present invention relates to specific methods of producing cleated rubber-backed floor mats (such as dust control or rubber mats) through the utilization of the combination of a perforated coated woven fabric article and a cushioned platen liner between the article and the metal platen of an in-line dust control mat manufacturing machine. Such a procedure permits a more efficient manner of producing cleated anti-creep dust control mats than previously followed. In particular, the fabric article is in the form of a conveyor belt and is preferably constructed from Teflon(R)-coated woven fiberglass which will not adhere to the tacky rubber component of the target mat and can withstand the extremely high vulcanization temperatures and pressures required during the production of a dust control mat. The cushioned platen liner, which is preferably comprised of or coated with silicon, is utilized as a separator between the metal platen of the manufacturing machine, as well as cushion for the molten rubber as it is pressed through the conveyor belt perforations during vulcanization. Such a cushioned liner material substantially eliminates any problems due to the force of the metal platen against the molten rubber as it passes through the article perforations. Further, a method for utilizing the conveyor belt to produce foam rubber cleated anti-creep mats is disclosed. The cleats of these mats have a thicker skin than the rest of the mat, thereby imparting enough strength and structural integrity so that the foam rubber mats may withstand the daily rigors of use, combined with periodic launderings. The produced mat as well as the woven fabric article / cushioned platen liner combination are also encompassed within this invention.

Owner:MILLIKEN & CO

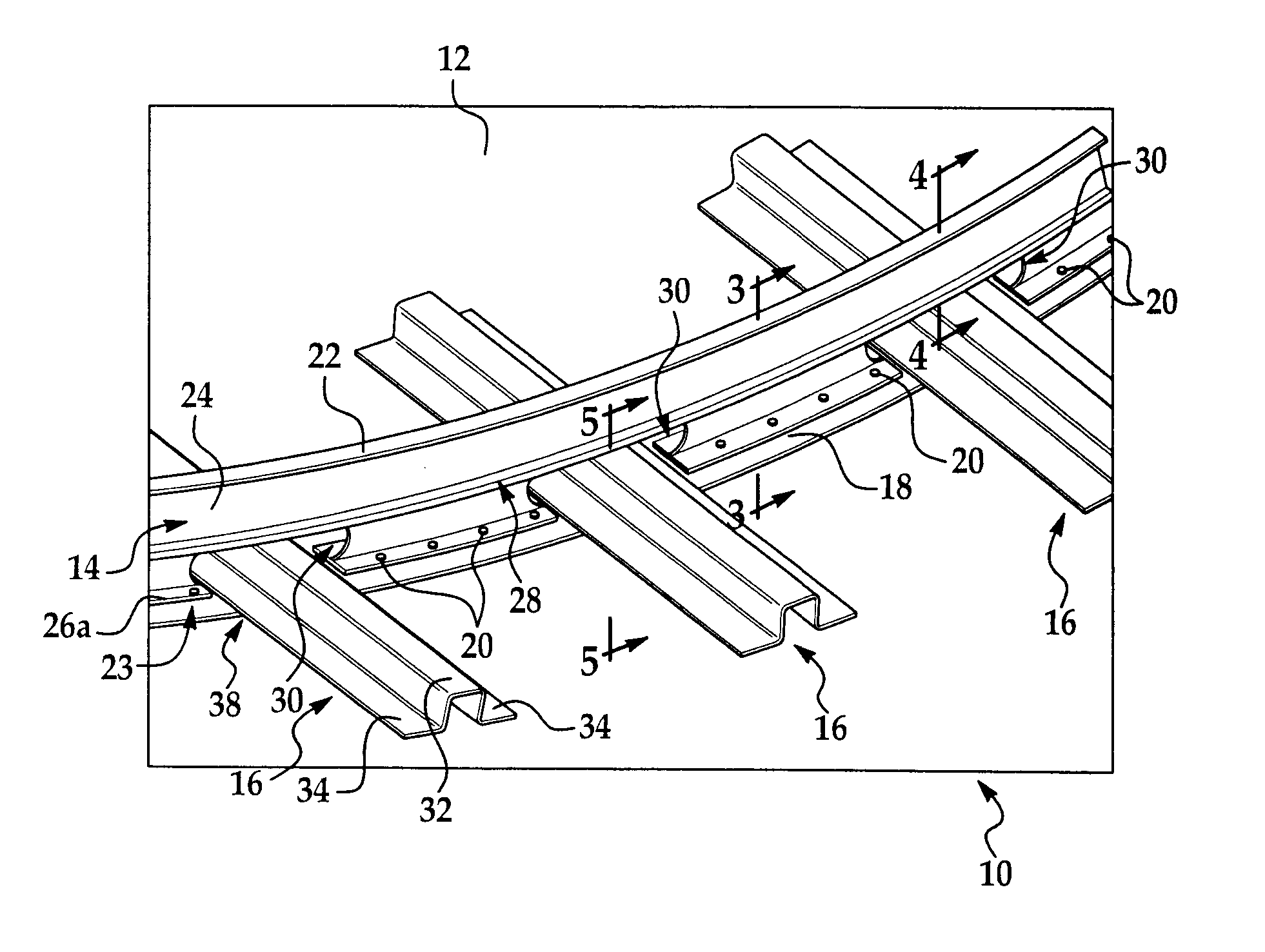

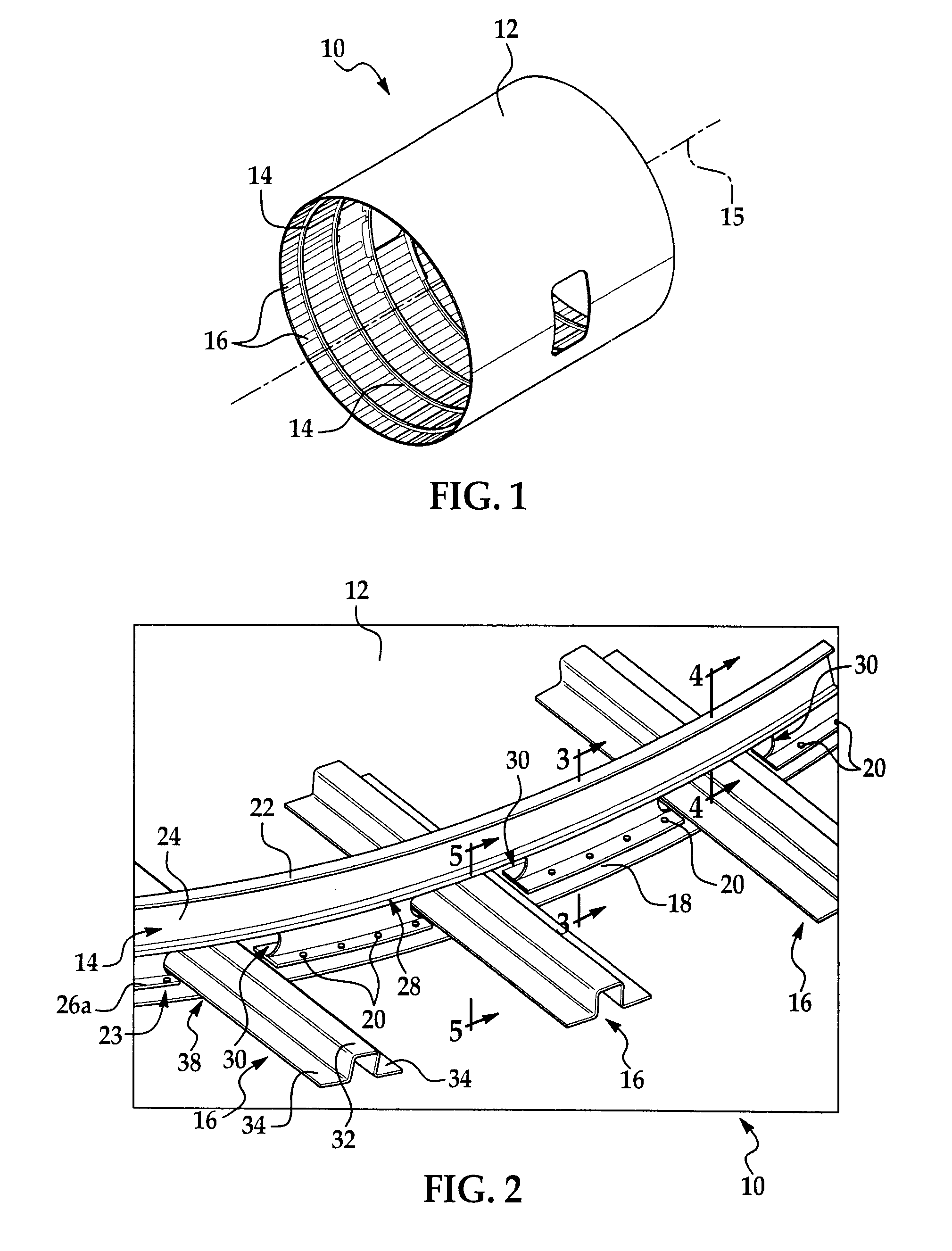

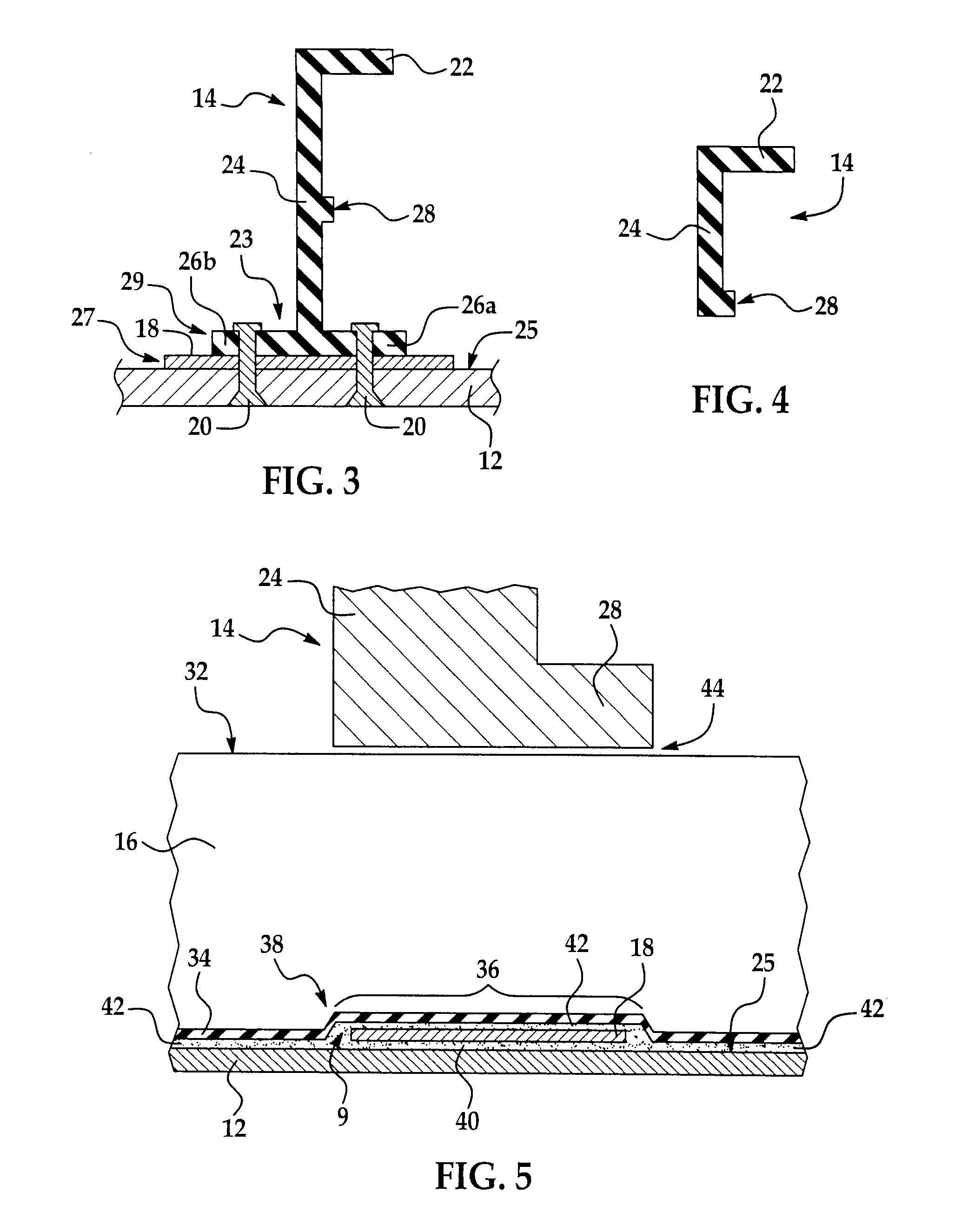

Bonded metal fuselage and method for making the same

A bonded metal fuselage for aerospace vehicles includes a monocoque structure having an outer metal skin, metal tear straps bonded to the outer skin and metal stringers bonded to the outer skin and to the tear straps. The outer chords of fuselage frames are fastened directly to tear straps and to the skin, obviating the need for clips to fasten the frames to the stringers.

Owner:THE BOEING CO

Peptides and Their Use in the Treatment of Skin

ActiveUS20160367463A1Improving oneImproving more signCosmetic preparationsToilet preparationsSkin treatmentsPeptide

Peptides (and derivatives thereof), topical compositions, and methods of diminishing signs of aging and / or improving health of human integuments are provided. The peptides are derived from human Growth Differentiation Factor 11 (GDF-11).

Owner:AVON PROD INC

Skin care compositions

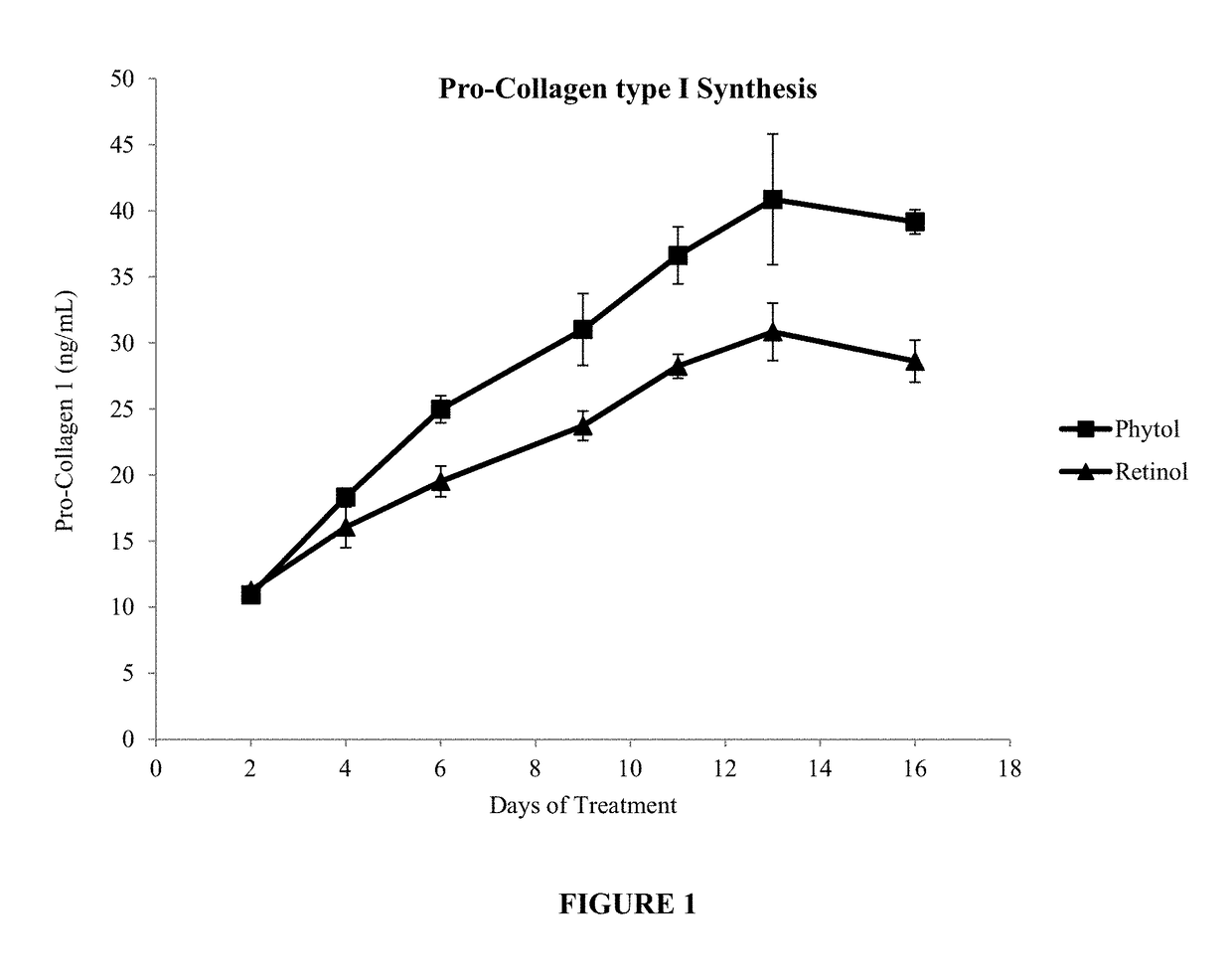

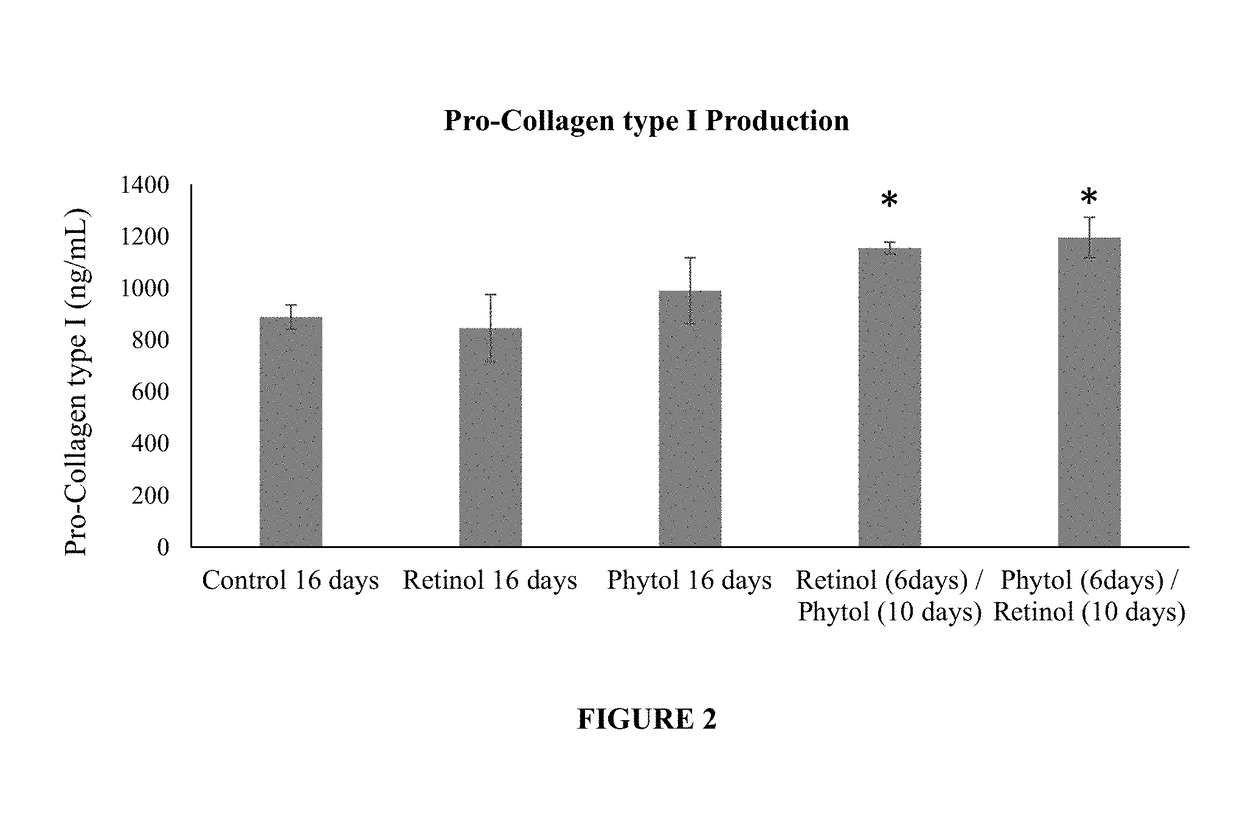

InactiveUS20130164265A1Increase synthesisIncrease skin hydrationCosmetic preparationsBiocideCuticleFibroblast migration

This invention provides compositions and methods of manufacturing such compositions that employ GRAS compounds which can act to promote the generation of stem, epidermal or other skin cells in the epidermis, activation of collagen synthesis, activation of hyaluronic acid synthesis, enhanced skin hydration, and dermal healing by stimulating stem cell and fibroblast migration to sites of needed repair. These compositions and methods are useful for rejuvenating the skin and for treating some skin-related aging or other dermal damaging conditions, including wrinkle reduction and treatment of minor dermal wounds.

Owner:FLAVIN DANA +1

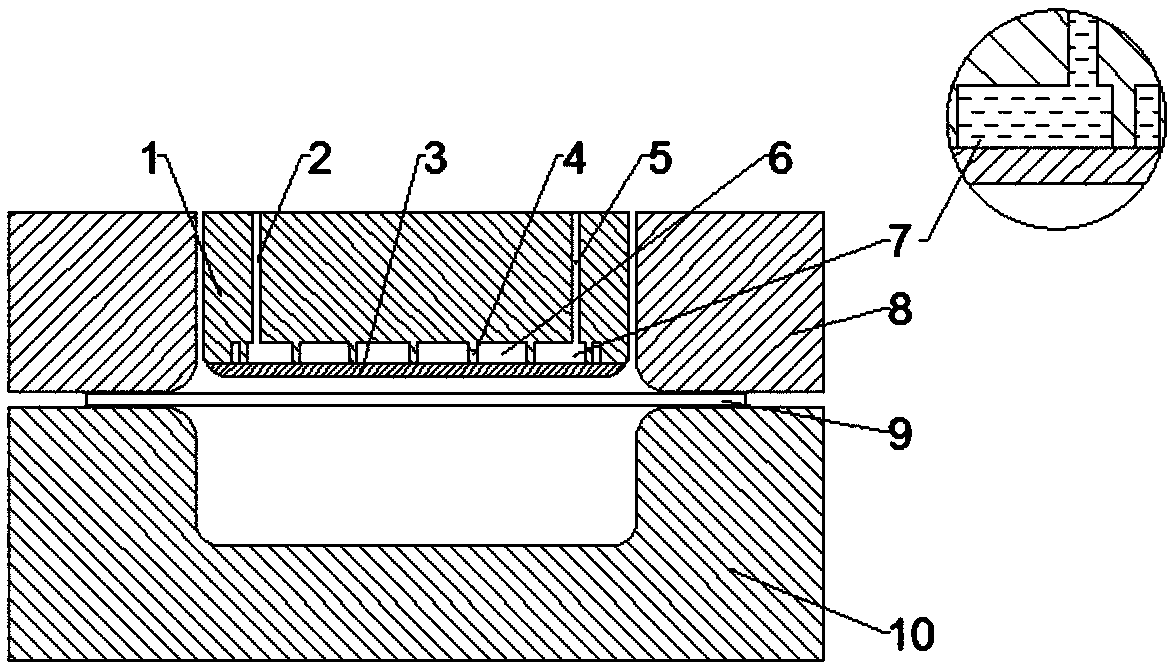

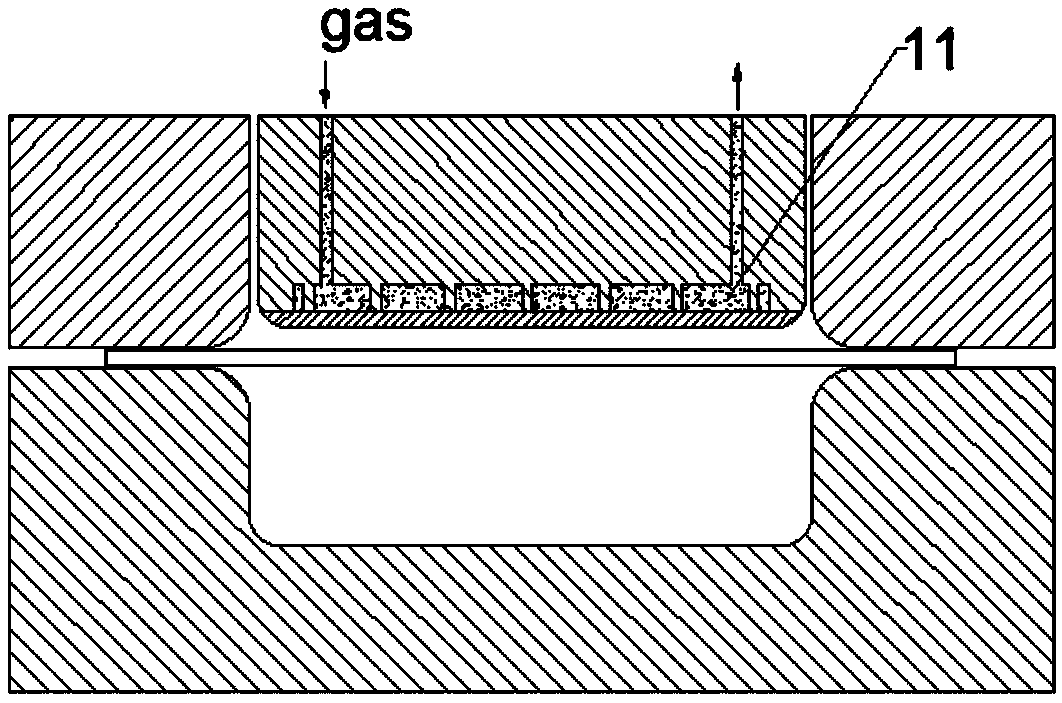

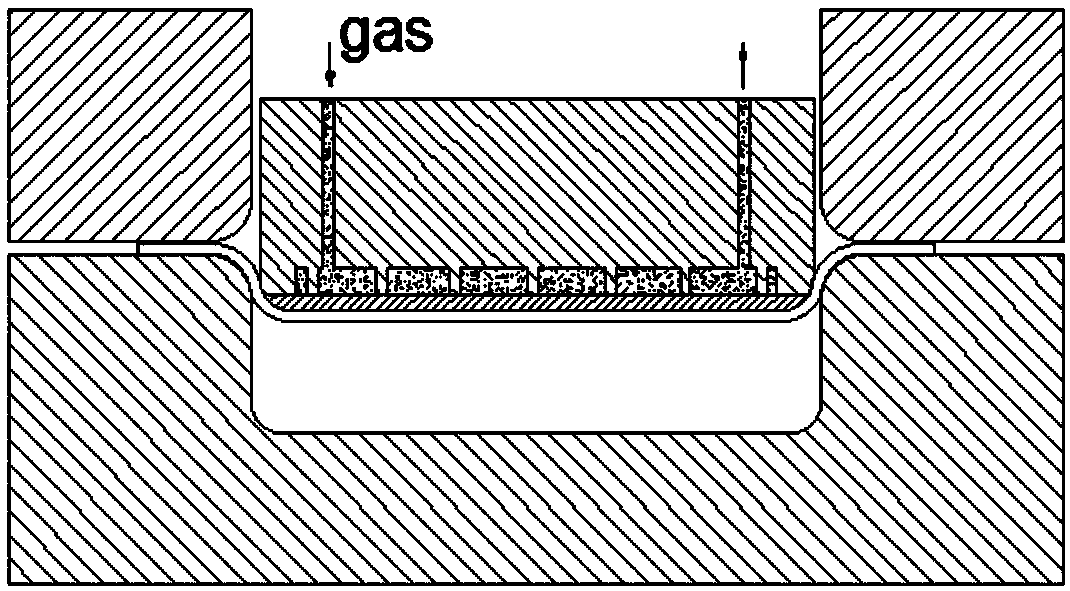

Mold for achieving in-mold rapid forming and quenching

The invention provides a mold for achieving in-mold rapid forming and quenching. The mold comprises an upper mold, a binder ring and a lower mold, the upper mold is composed of an inner solid mold core and a thin-walled skin, and interconnected grooves are formed between the inner solid mold core and the thin-walled skin. In the forming stage, no heat insulation material such as filler or fillinggas exists in the grooves, and a low-temperature medium is introduced into the grooves in the quenching stage. The mold has the advantages that the forming and quenching processes are relatively independent and have little influence on each other, the skin is small in wall thickness and small in heat capacity, the grooves are filled with the heat insulation materials, the problem that a hot plateblank and a cold mold are rapidly cooled after making contact during forming can be avoided, and rapid cooling and quenching of the formed hot plate blank can be achieved. The mold core is prepared from common mold materials through common machining equipment, the mold manufacturing period is short, and the cost is low. The mold can be used for achieving rapid forming and quenching of metal materials of different types and thicknesses.

Owner:DALIAN UNIV OF TECH +1

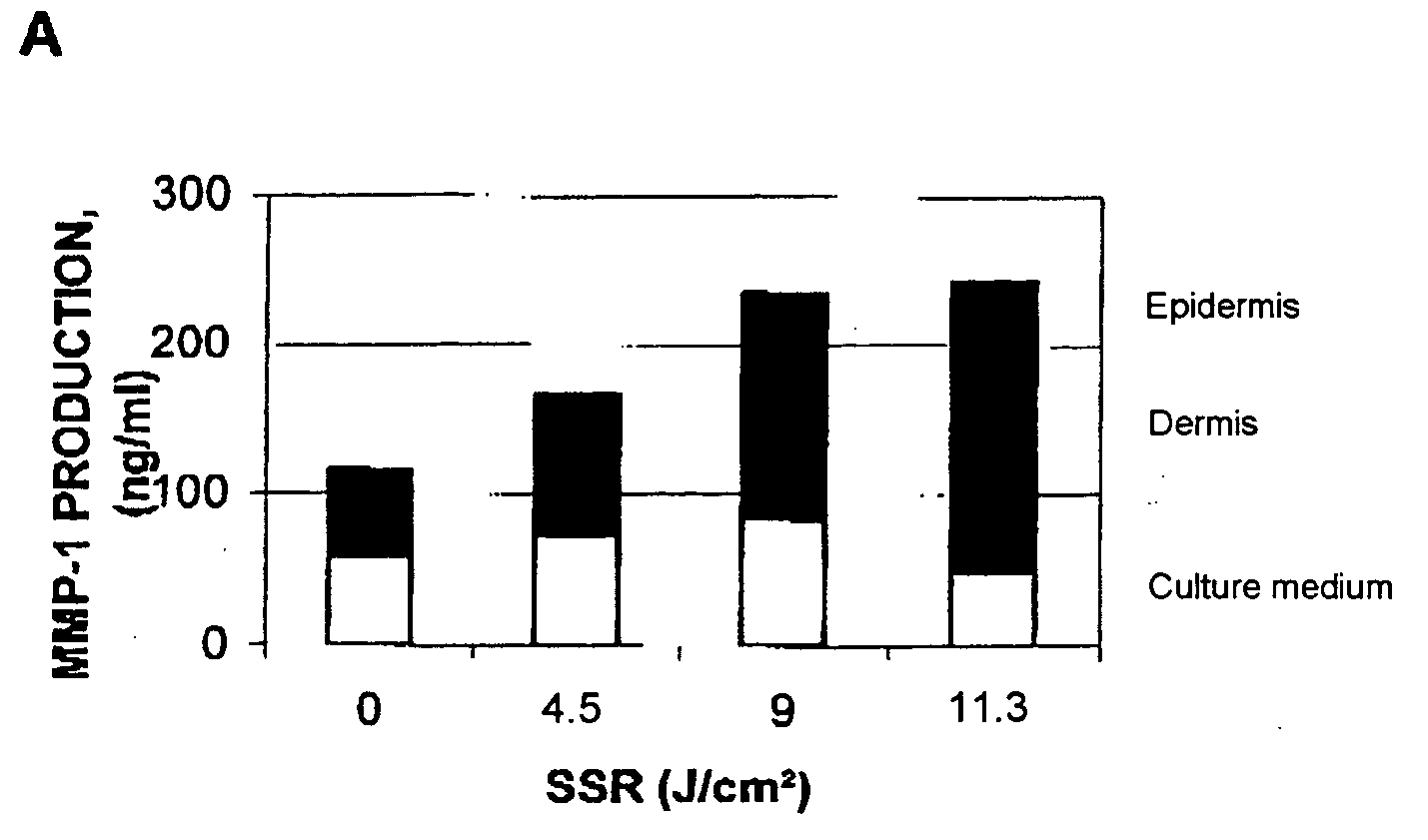

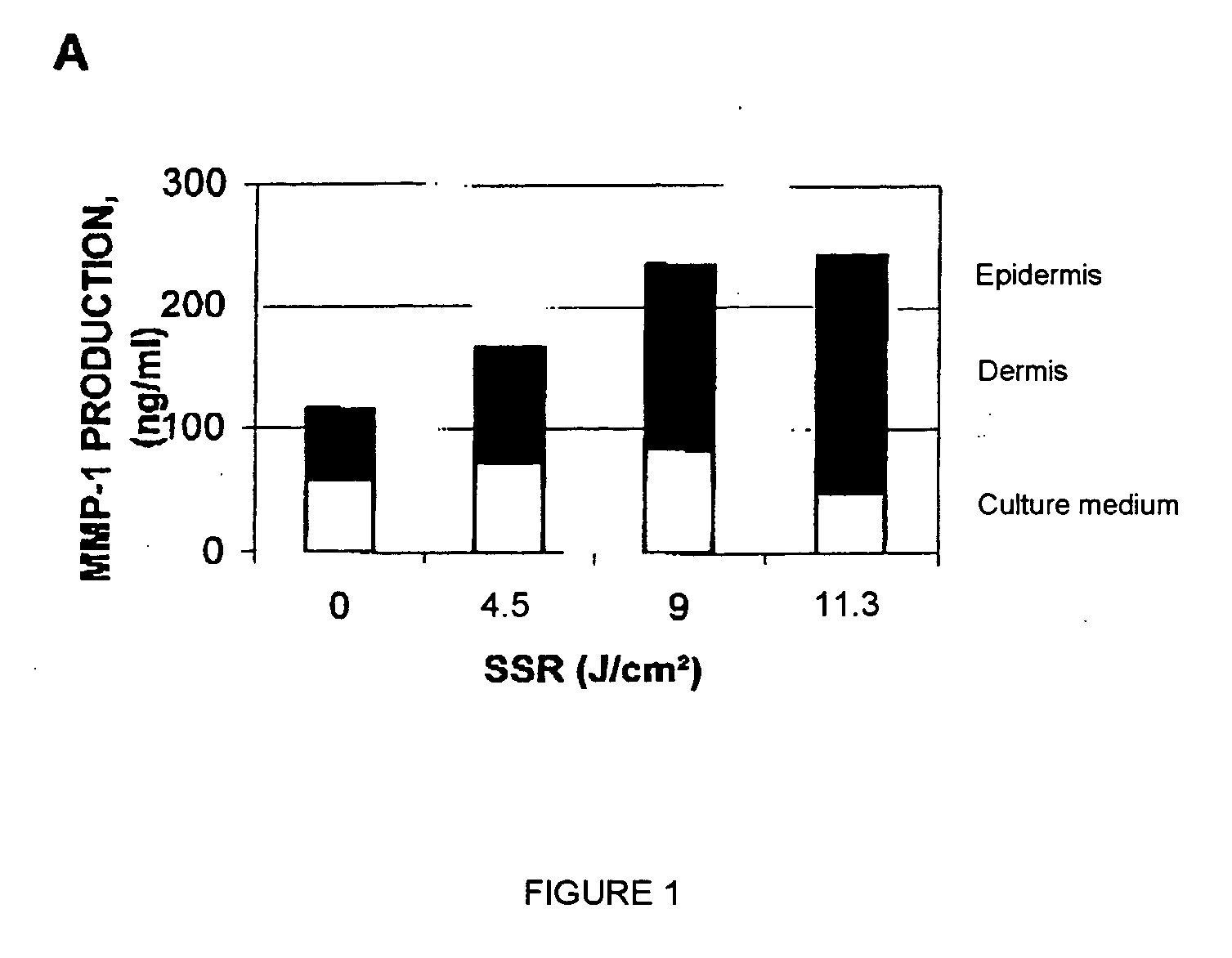

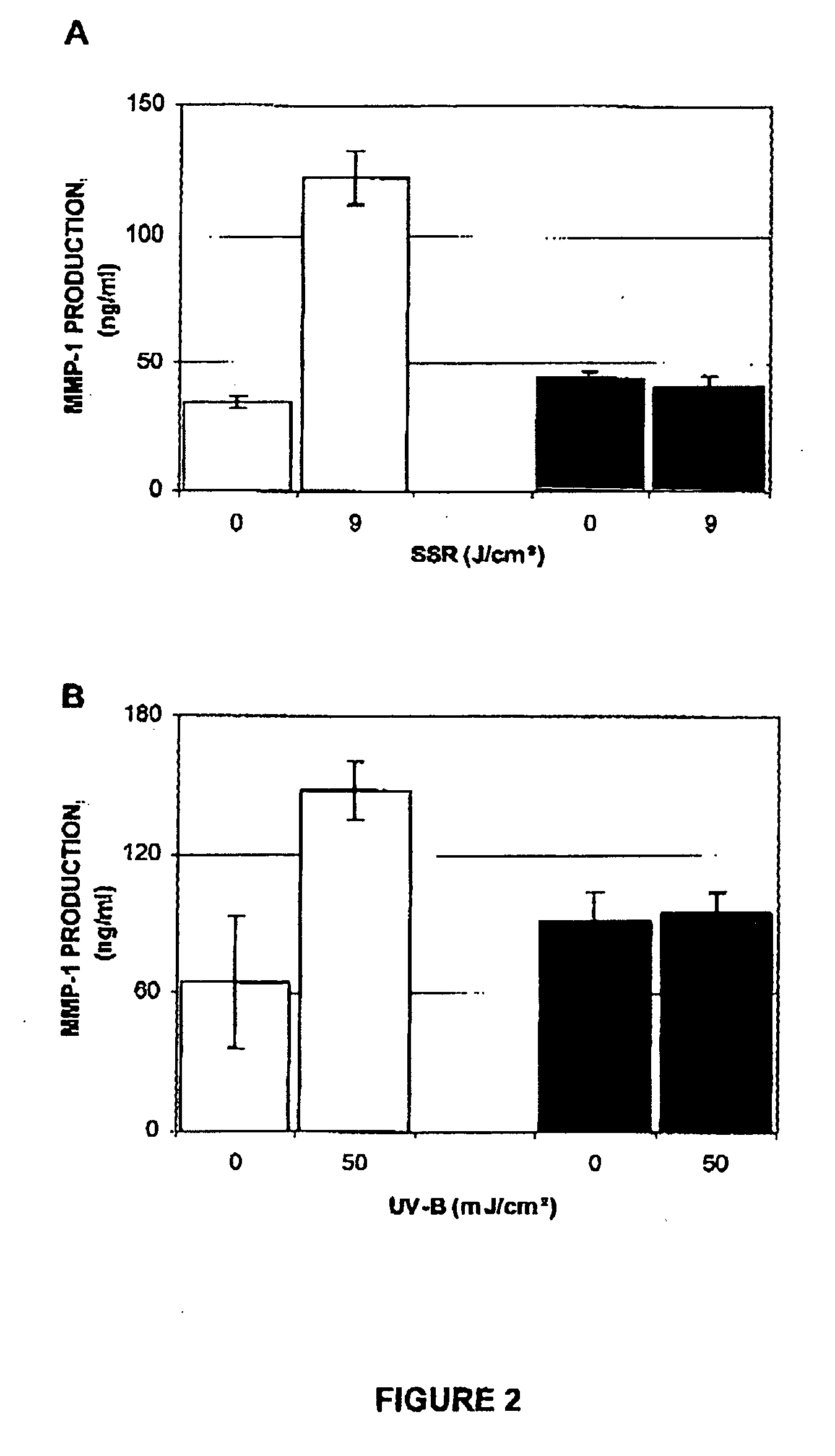

Preventing and/or combating collagen fiber degradation induced under conditions of natural exposure to sunlight

InactiveUS20050058611A1Efficient processEliminate the effects ofCosmetic preparationsHair cosmeticsFiberScalp

Cosmetic / dermatological compositions useful for preventing and / or combating the degradation of collagen fibers induced by solar radiation typically characterized by a UV-A / UV-B ratio ranging from 10 and 17, advantageously formulated for topical application onto the skin and / or scalp, contain a thus effective amount of at least one inhibitor of the production of photoinduced keratinocytic cytosoluble factors, notably sodium butyrate.

Owner:LOREAL SA

Steamed bun filled with soup

InactiveCN103652509AEnhance digestionStrengthen kidney and strengthen yangFood coatingFood preparationPearl barleySyzygium

The invention relates to a steamed bun and particularly relates to steamed bun filled with soup. The steamed bun is prepared from the following materials: flour, pork, sesame oil, astragalus membranaceus, Chinese yam, codonopsis pilosula, Chinese angelica, fructus amomi, tsaoko amomum fruit, syzygium aromaticum, cinnamon, pepper, bay leaves, tsaoko amomum fruit, endothelium corneum gigeriae galli, poria cocos, pearl barley, galangal, anise, fennel, dried ginger, radix linderae, hyacinth bean, lotus seed, longan and the like. The steamed bun has the advantages that in the processing process, various nutritional ingredients of the materials are better stored, and the characteristics of color, fragrance and flavor are embodied, so that the steamed bun is a good product with superior nutrition for dining tables and families and has the effects of being good in taste and comprehensive in nutrition, nourishing a human body and strengthening the body.

Owner:李瑞麟

Tetraploid watermelons producing small fruits

InactiveUS20060037110A1Thin skinMore edible fleshPlant cellsAngiosperms/flowering plantsTissue cultureCitrullus lanatus

Tetraploid watermelon inbreds are disclosed. The invention relates to the seeds and plants of the tetraploid watermelon inbreds, the methods of propagating the tetraploid inbreds through seeds and tissue culture. The invention also relates to methods of producing the triploid seedless watermelon seeds and plants by crossing the tetraploid inbreds with diploid watermelon inbreds, and to the triploid plants produced therefrom.

Owner:SYNGENTA PARTICIPATIONS AG

Crystal steamed creamy custard bun and preparation method thereof

InactiveCN103478512AIncrease varietyPrevent leakageFood coatingFood preparationPotato starchWheat starch

The invention discloses crystal steamed creamy custard buns and a preparation method thereof. The crystal steamed creamy custard buns comprises the following raw materials: wheat starch, mung bean starch, tapioca starch, potato starch, lotus root starch, colloid, salad oil, butter, white sugar, egg, milk, corn starch and custard powder. The preparation method comprises the following steps: steamed stuffed bun wrapper preparation; stuffing preparation; formed product preparation; cooking; packing, labeling and marketing. The crystal steamed creamy custard buns are characterized in that the steamed stuffed bun wrappers adopt a mixture of various starches, so that the prepared crystal steamed creamy custard buns are crystal, bright and translucent in appearance, and have low probability of leakage; the stuffing in the crystal steamed creamy custard buns is clear to see, thereby prompting appetite. The crystal steamed creamy custard buns are smooth to eat, are fine and smooth, tough and chewy and al dente, and are unique in taste. Moreover, not only the steamed stuffed bun wrappers but also the stuffing are rich in nutrition; the crystal steamed creamy custard buns are fragrant outside and tender inside, are thin in the steamed stuffed bun wrappers and full in stuffing, and breaks through the tradition. Besides, the types of the steamed stuffed bun are increased.

Owner:江拥军

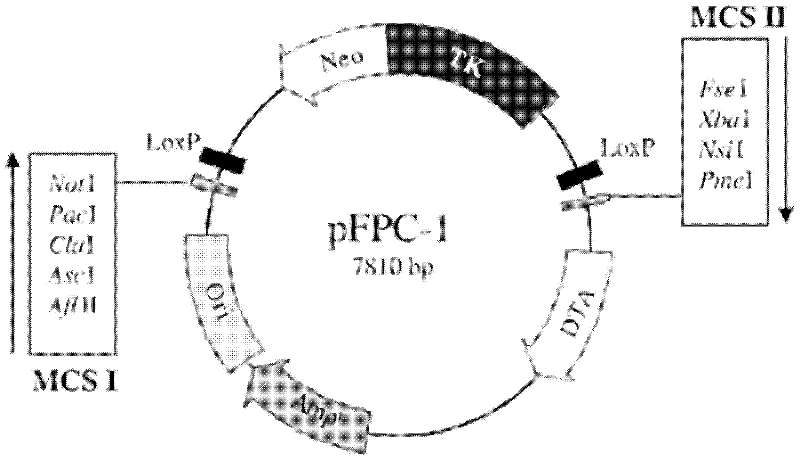

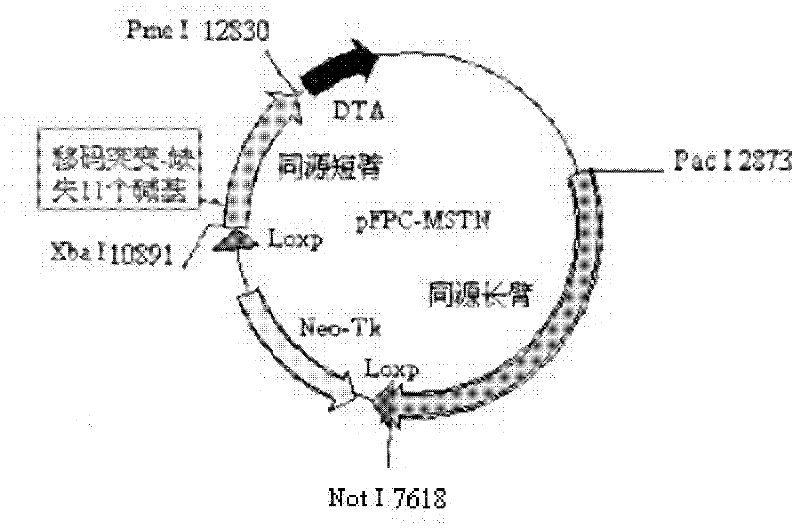

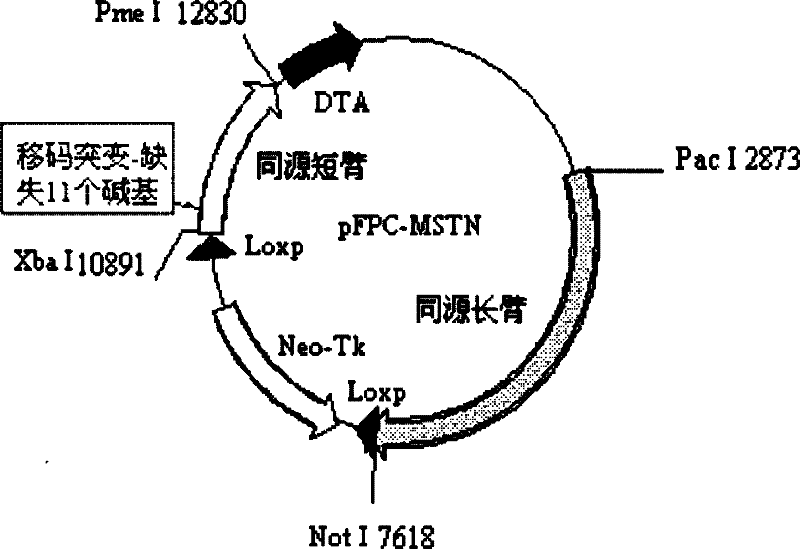

Method for introducing frame-shift mutation in MSTN (myostatin) genes of cattle

InactiveCN102653764AMuscular developmentReduce subcutaneous fatFermentationPlant genotype modificationMyostatinLong arm

The invention discloses a method for introducing frame-shift mutation in bovine MSTN (myostatin) genes. According to the method, a targeting vector for the frame-shift mutation of the bovine MSTN genes is established, and the frame-shift mutation is introduced into the third exon of the bovine MSTN genes by virtue of homologous recombination. The method comprises the following steps of: synthesizing a homologous short arm containing the frame-shift mutation of MSTN, and allowing the homologous short arm to be short of 11bp on the third exon to form the frame-shift mutation; synthesizing a homologous long arm of the MSTN, and inserting a vector pFPC-1 by virtue of a restriction enzyme cutting site to establish the targeting vector pFPC-MSTN of the frame-shift mutation in the bovine MSTN genes; and transfecting bovine somatic cells after the linearization of the targeting vector, and introducing the frame-shift mutation in the bovine MSTN genes by virtue of the homologous recombination. Transgenic cattle with the frame-shift mutation of the MSTN genes can be obtained in the production by virtue of the cells, thereby improving beef production traits of the cattle and improving the quality and yield of beef.

Owner:TIANJIN AGRICULTURE COLLEGE +1

Tetraploid watermelons producing small fruits

InactiveUS20080005814A1Thin skinMore edible fleshPlant genotype modificationAngiosperms/flowering plantsTissue cultureWATERMELON SEED

Tetraploid watermelon inbreds are disclosed. The invention relates to the seeds and plants of the tetraploid watermelon inbreds, the methods of propagating the tetraploid inbreds through seeds and tissue culture. The invention also relates to methods of producing the triploid seedless watermelon seeds and plants by crossing the tetraploid inbreds with diploid watermelon inbreds, and to the triploid plants produced therefrom.

Owner:SYNGENTA PARTICIPATIONS AG

Method for producing a connector, connector and aircraft or spacecraft

A method for producing a connector, in particular for repair, in particular in the field of aviation and aerospace, including the steps of: providing a base layer; attaching a first layer of fibre composite material having a first rigidity to the base layer; attaching a second layer of fibre composite material having a second rigidity to the first layer, offset therefrom, the second rigidity being greater than the first rigidity; and riveting the first layer to the base layer and riveting the second layer to the first layer and to the base layer.

Owner:AIRBUS OPERATIONS GMBH

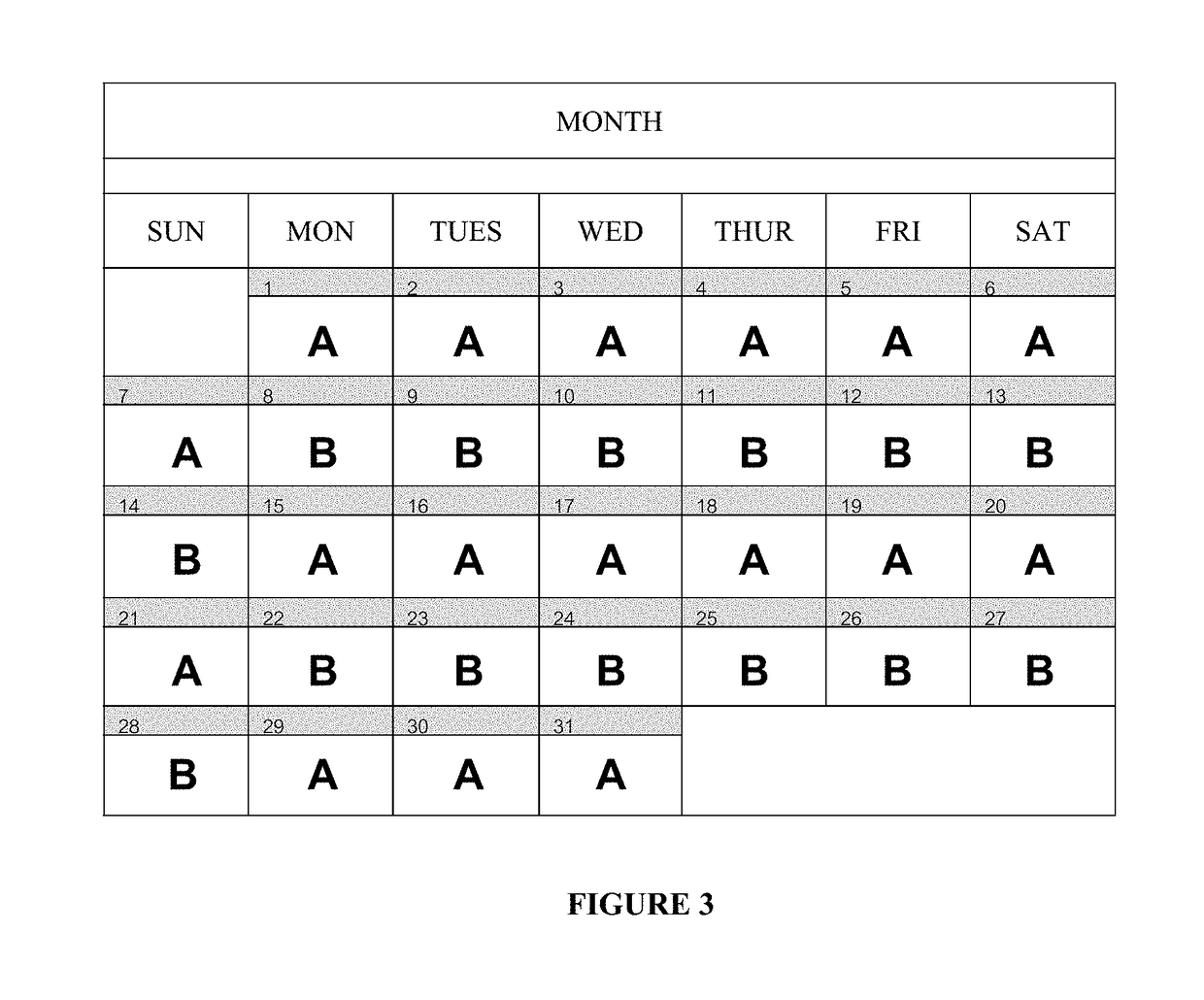

Methods for treating skin

ActiveUS10076479B1Reduce appearance problemsBeneficial to human healthCosmetic preparationsToilet preparationsMedicineTreatment modality

Provided are methods of treating skin with at least two alternating treatment modalities to improve the health and / or diminish signs of aging. Some methods according to the present invention may comprise topically applying at least two separate compositions, in a sequential, rotating, or alternating fashion to overcome adaptation, tolerance, or sensitization phenomena.

Owner:AVON PROD INC

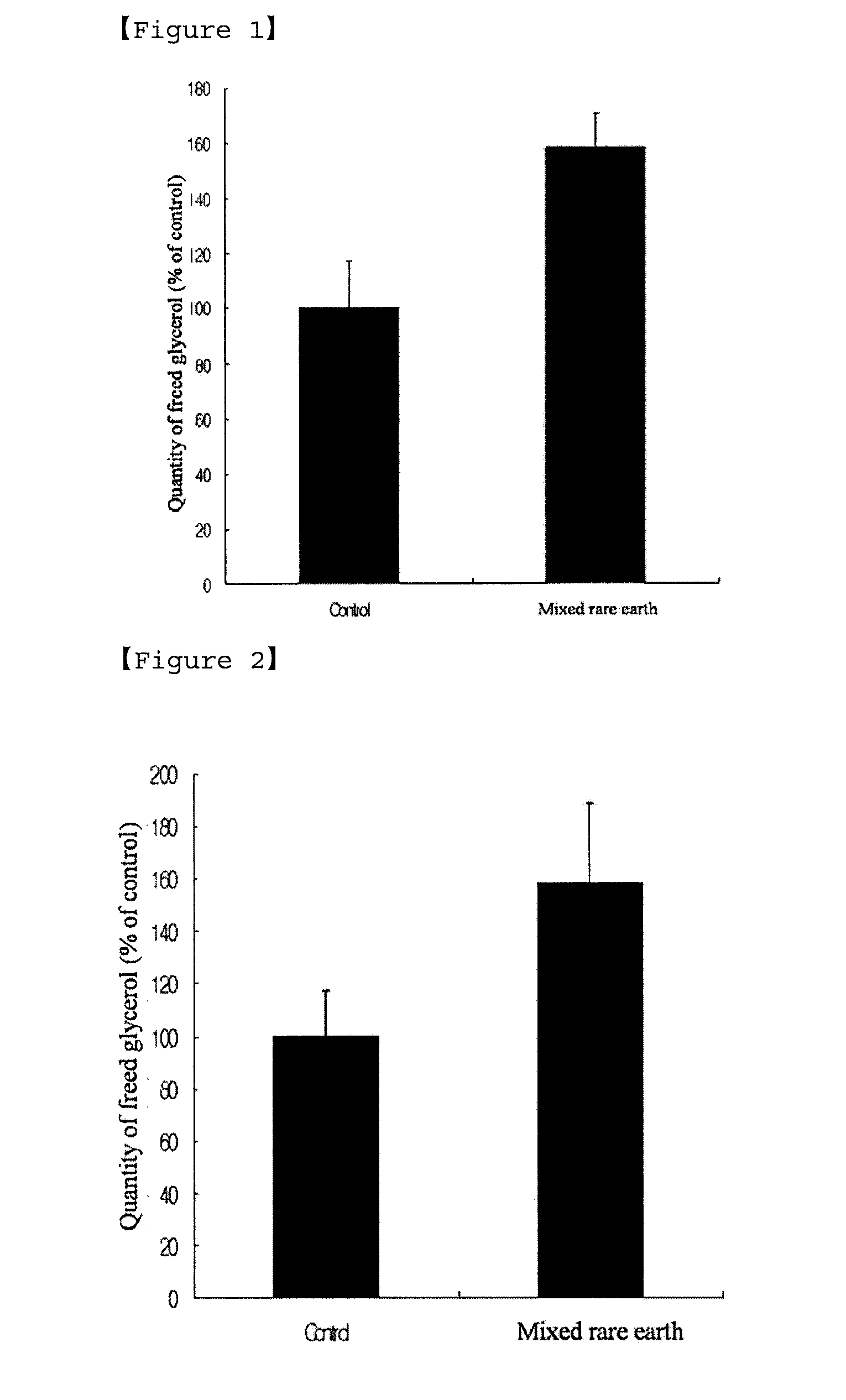

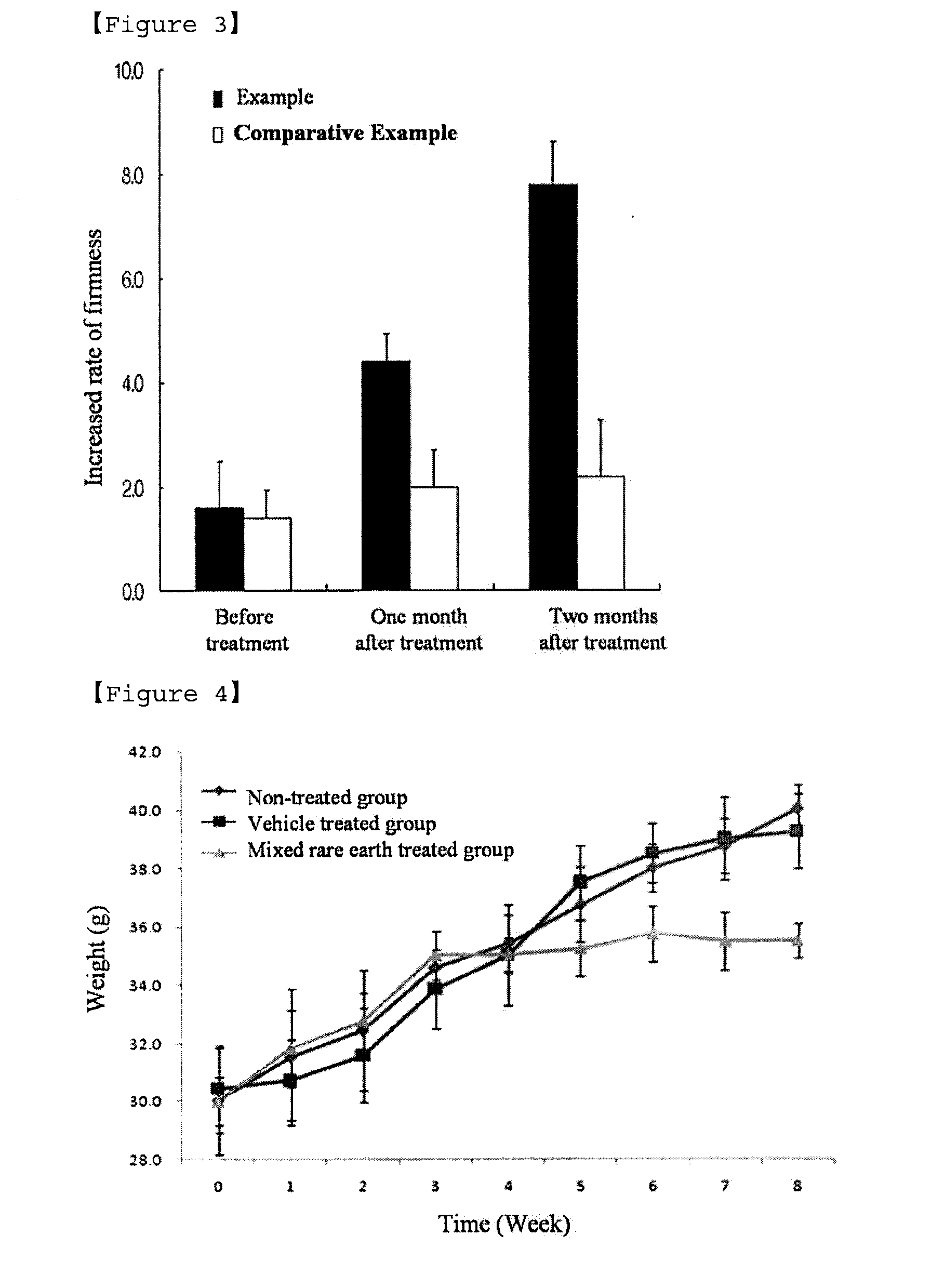

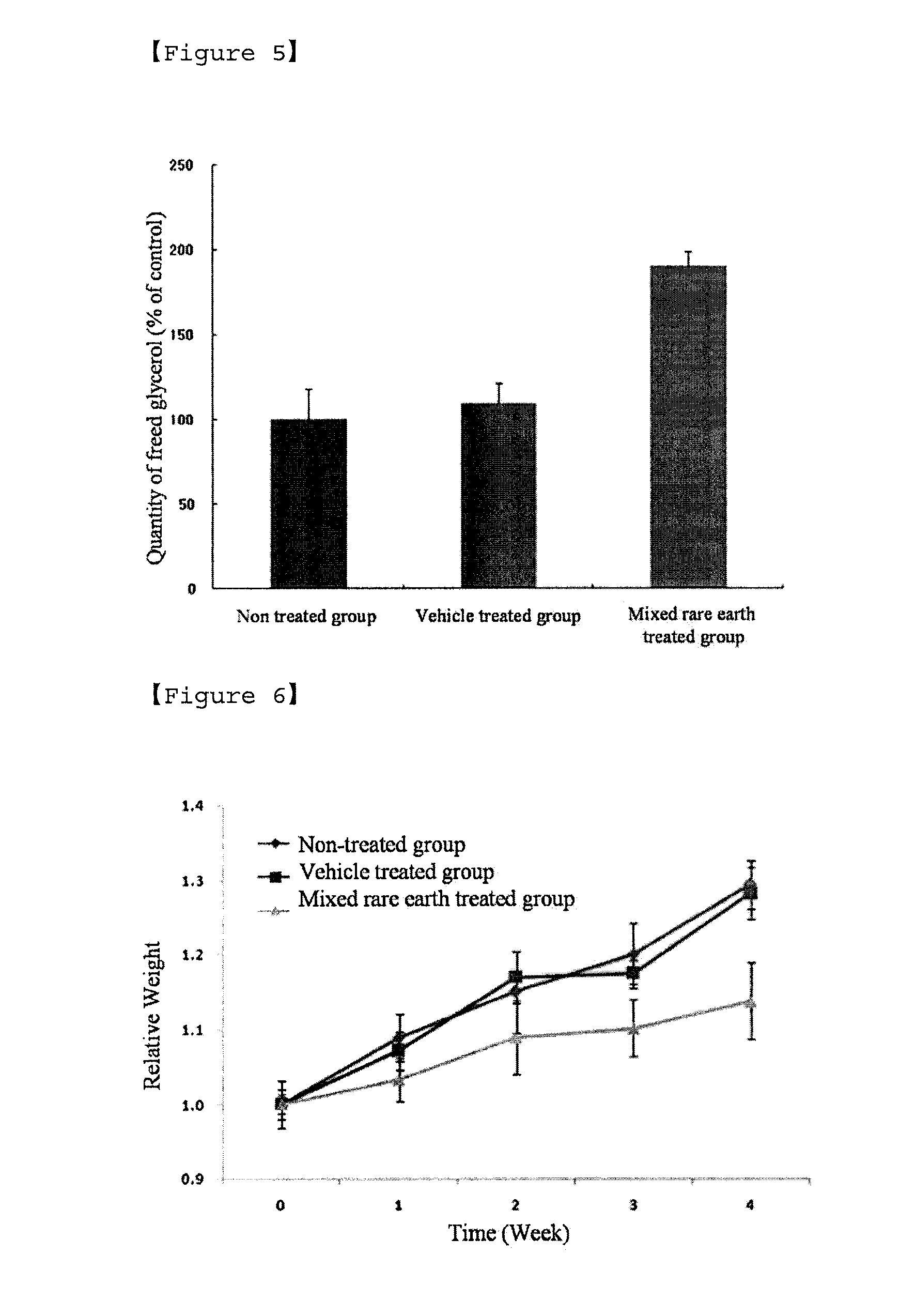

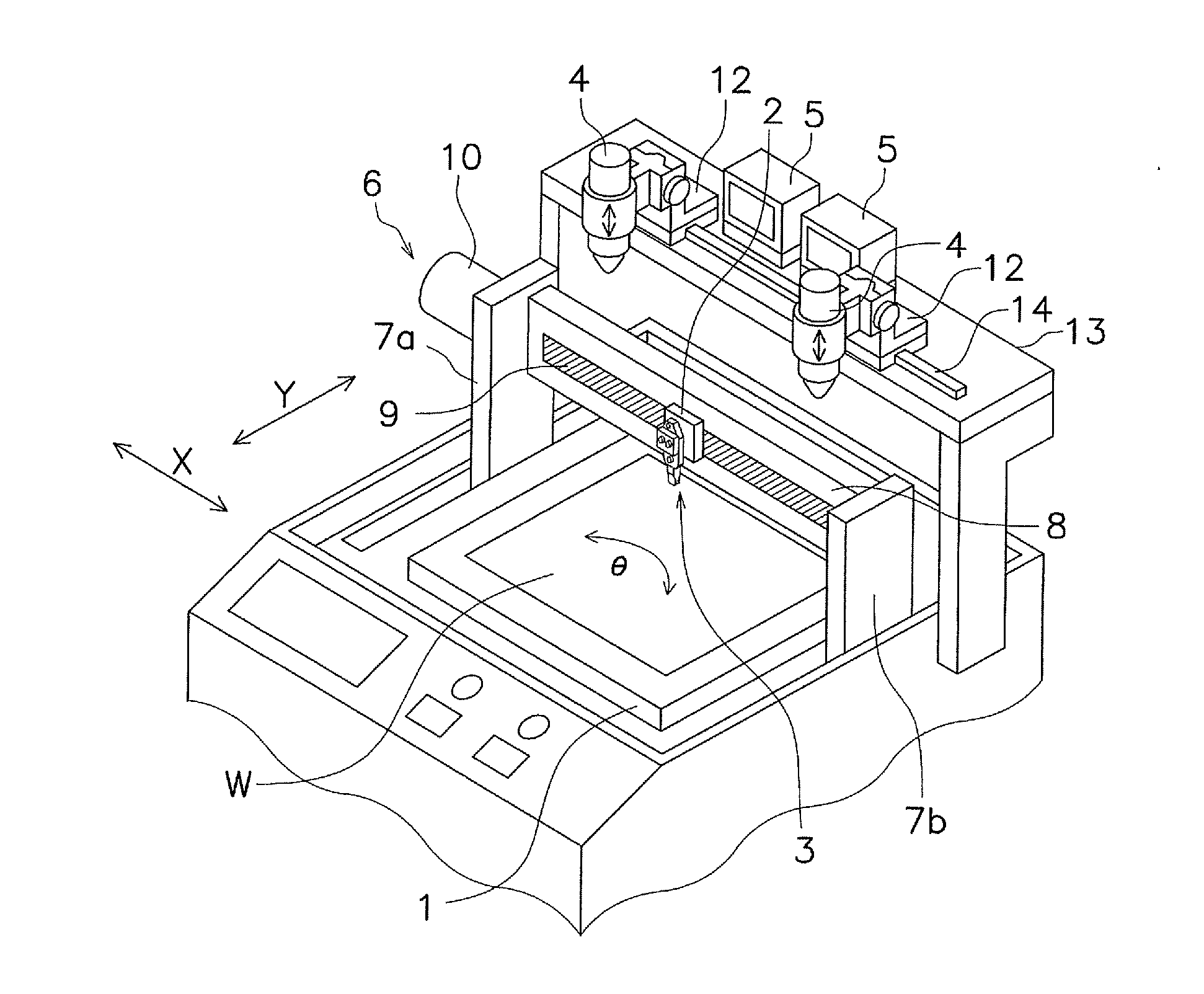

Uses of rare earth elements for slimming

InactiveUS20100239687A1Promote lipidolysisIncreasing fat oxidationCosmetic preparationsHeavy metal active ingredientsRare-earth elementLutetium

Disclosed is a use of rare earth element selected from the group consisting of lanthanum (La), cerium (Ce), praseodymium (Pr), neodymium (Nd), promethium (Pm), samarium (Sm), europium (Eu), gadolinium (Gd), terbium (Tb), dysprosium (Dy), holmium (Ho), erbium (Er), thulium (Tm), ytterbium (Yb), lutetium (Lu), scandium (Sc) and yttrium (Y), and a mixture thereof, or a salt or an oxide, for promoting lipidolysis, anti-cellulite, enhancing skin firmness, or for slimming.

Owner:TAEWUNG ELS INC

Peptides and their use in the treatment of skin

ActiveUS10034826B2Signs improvedIncreasing collagen and HA productionCosmetic preparationsPeptide/protein ingredientsSkin treatmentsPeptide

Embodiments of the invention are related generally to the methods of diminishing the signs of aging in and / or improving health of human integuments, such as skin, and compositions comprising peptides useful therefor. The compositions according to the invention may comprise one or more peptides or fragments or derivatives thereof derived from a growth factor, e.g., Growth Differentiation Factor 11 (GDF11), in a topically acceptable vehicle.

Owner:AVON PROD INC

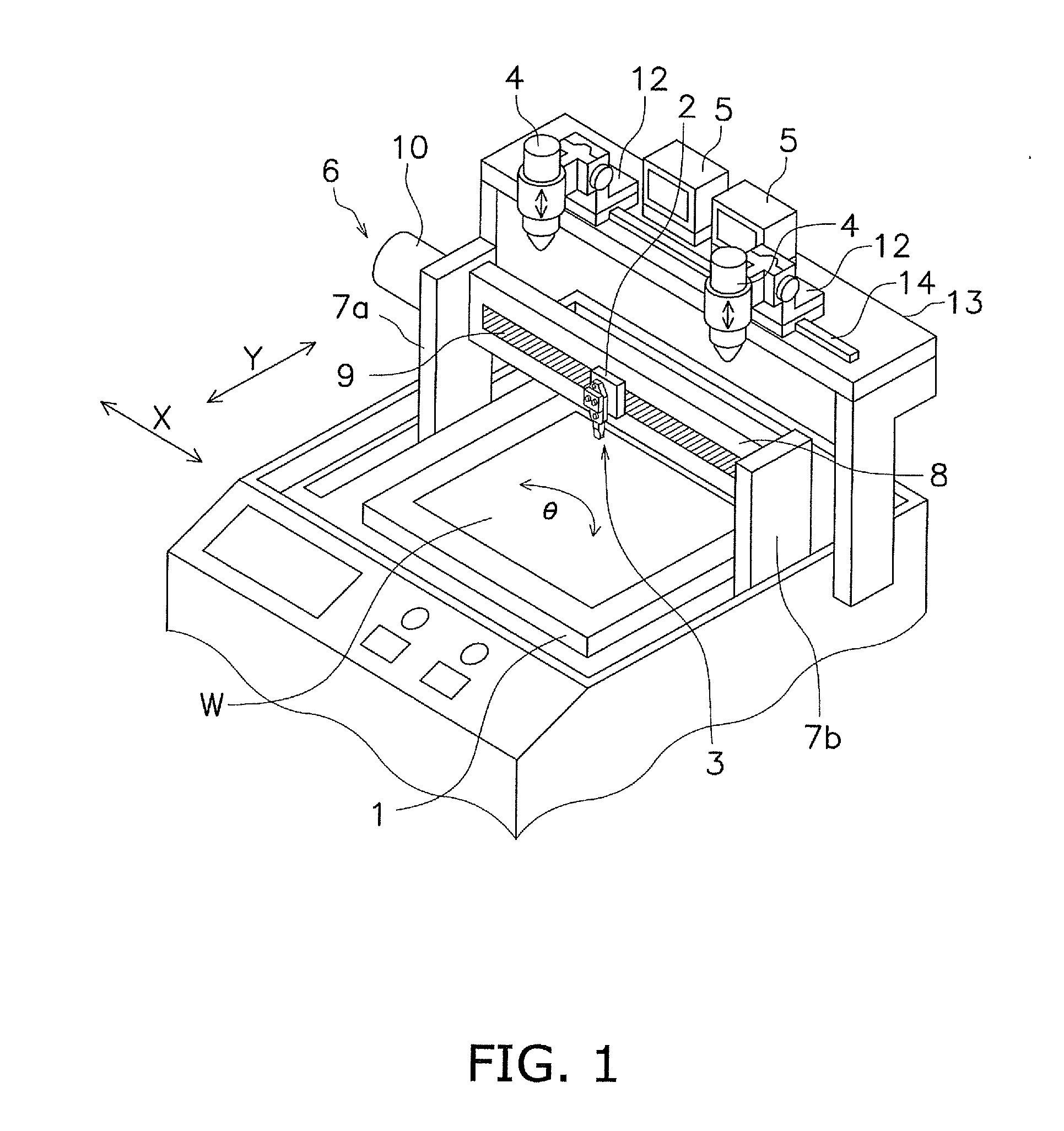

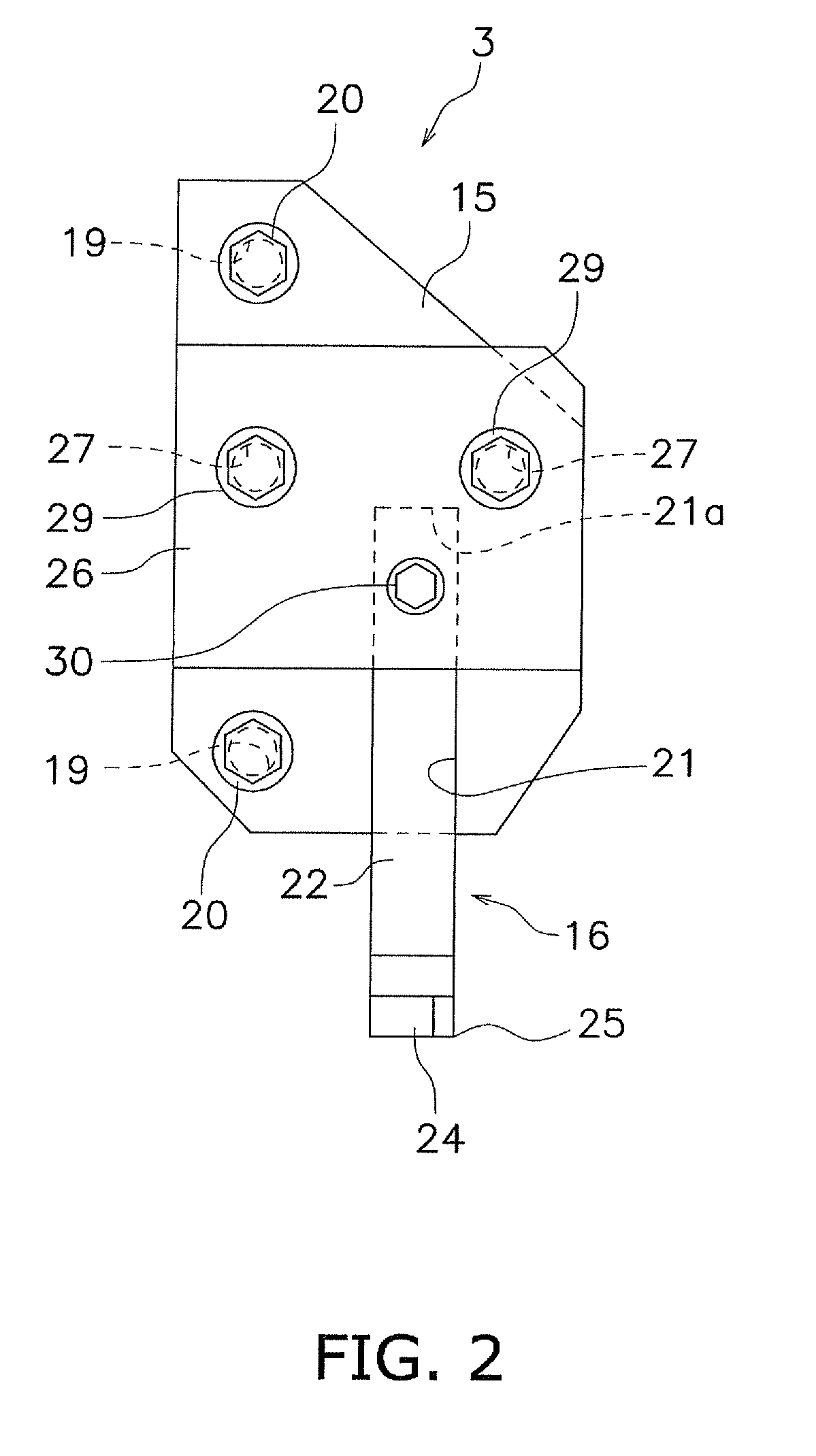

Groove machining tool for use with a thin-film solar cell

InactiveUS20110167979A1Precise positioningEasy to operateFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringMachine tool

There is provided a groove machining tool supported in a holder and caused to move together with the holder in relative fashion along a scheduled scribe line over an integrated thin-film solar cell substrate to form a groove. The groove machining tool includes a tool body supported in the holder, and a blade tip part formed in a distal part of the tool body. The blade tip part includes a blade extending along a direction intersecting a direction of movement of the tool, at a first end along the direction of movement of the tool. The blade is tilted backward from the direction of movement of the tool in relation to a direction orthogonal to the direction of movement of the groove tool, as viewed from a bottom face of the blade tip part.

Owner:MITSUBOSHI DIAMOND IND CO LTD

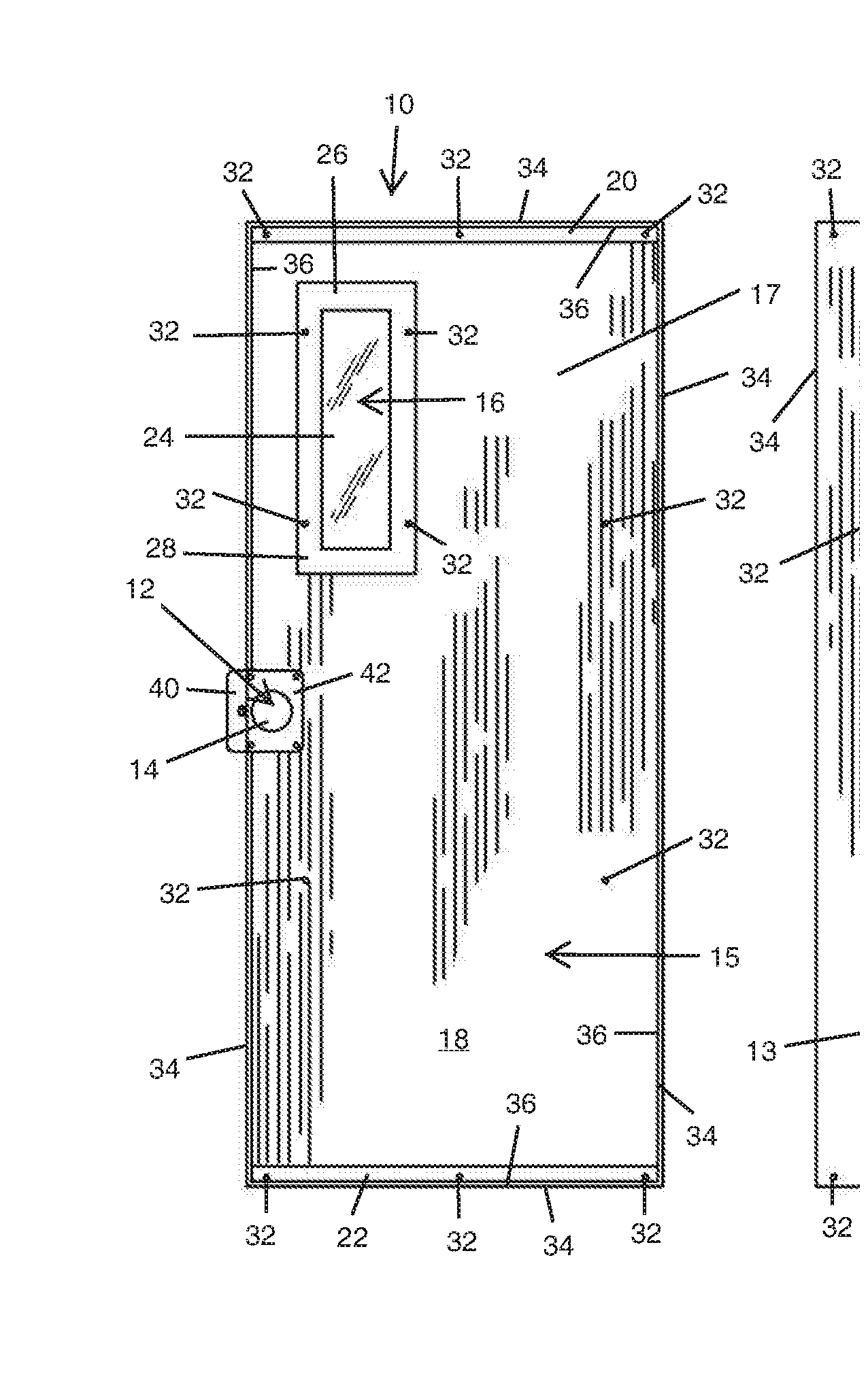

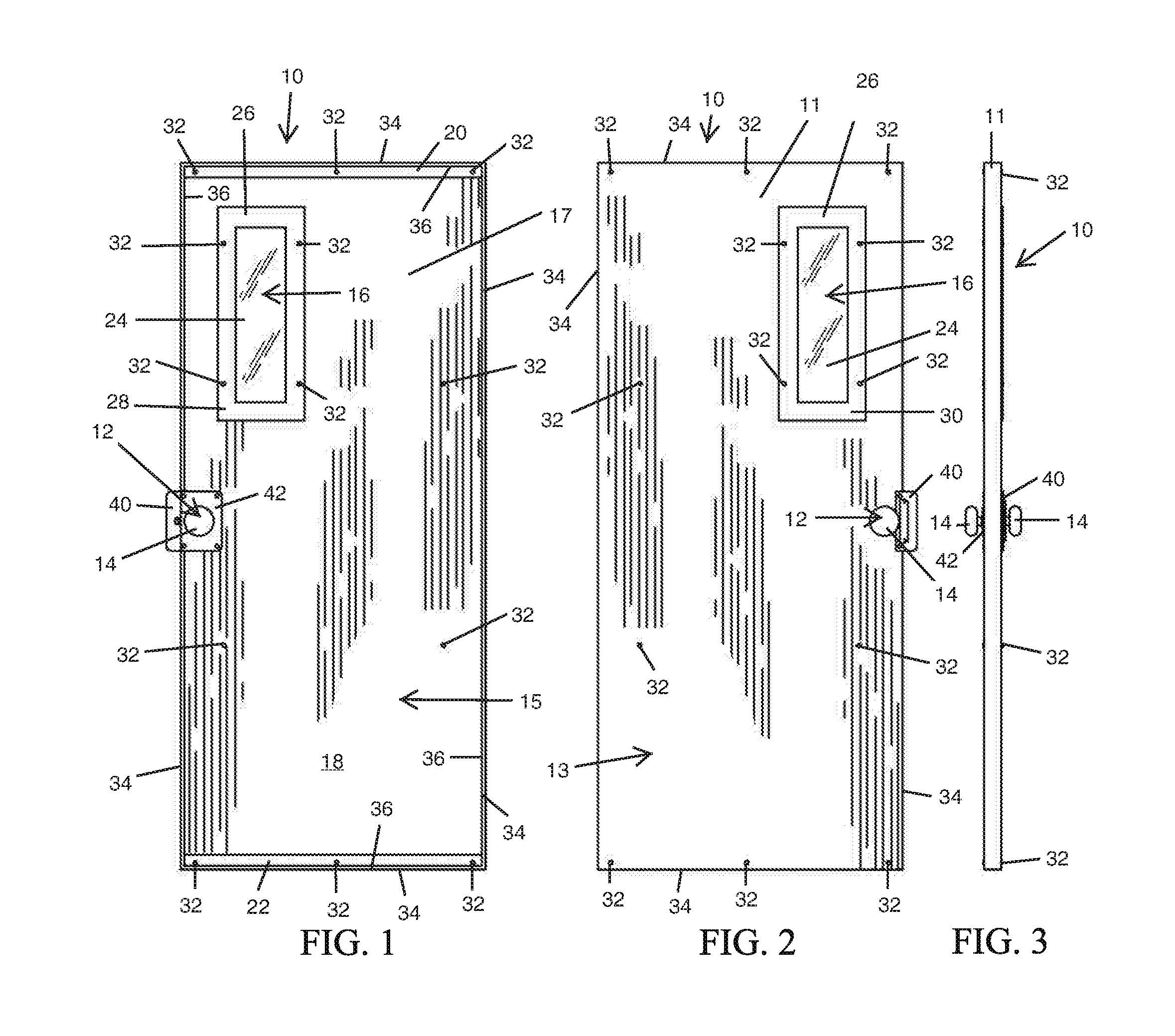

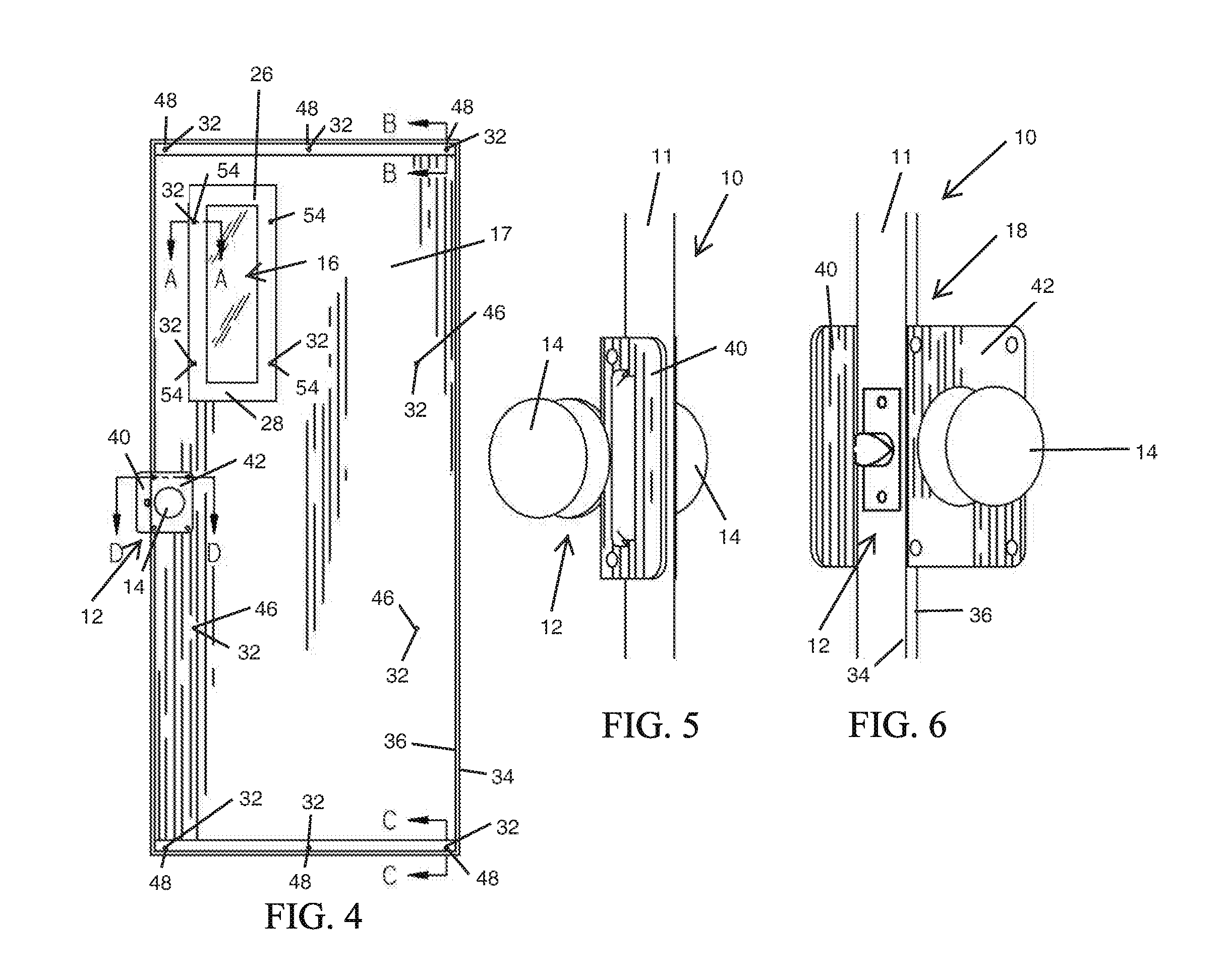

Classroom retrofit barriers

A ballistic door providing barrier-of-entry shielding blocks a doorway in certain emergency situations to shield against active shooters, while not inhibiting, impeding, or changing the safe egress through the ballistic door. A ballistic assembly may be secured to the non-threat side of an existing door, by retrofit installation or by new construction installation. The ballistic assembly has a ballistic skin, a top ballistic skin clamp, and a bottom ballistic skin clamp. The top and bottom ballistic skin clamps secure the ballistic skin against the non-threat side of the door. The ballistic door has at least a N.I.J. Level IIIA of protection against gunfire.

Owner:DAW TECH

Composite enzyme modifier dedicated to flour for making ultra soft bread

A powdered compound enzyme as the modifier dedicated for supersoft bread is proportionally prepared from fungal alpha-amylase, xylanase, glucose oxidase, transglutaminase and soybean powder.

Owner:HEBEI AGRICULTURAL UNIV.

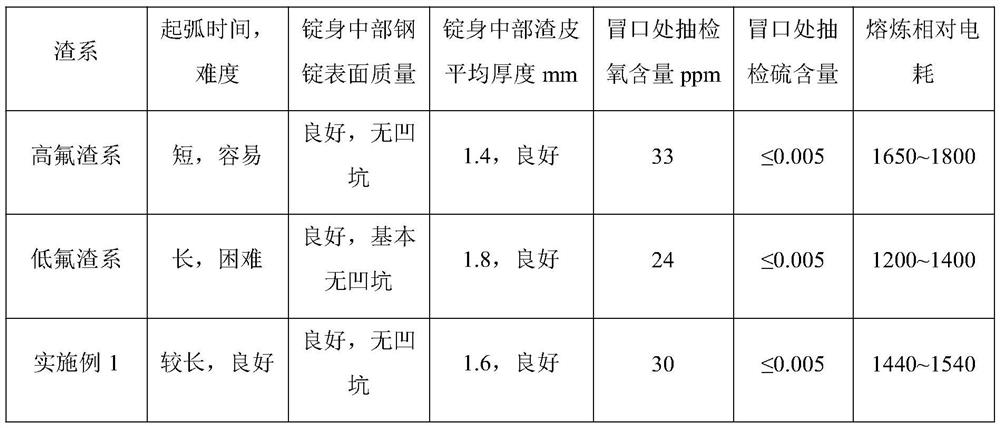

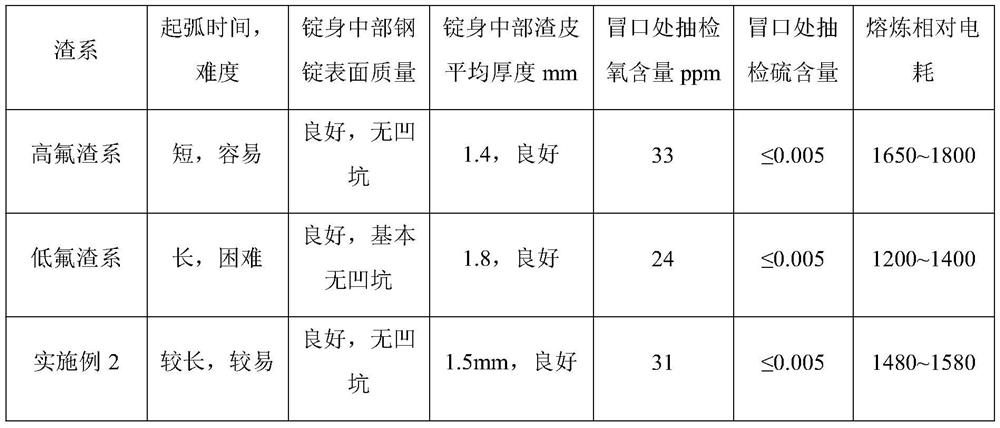

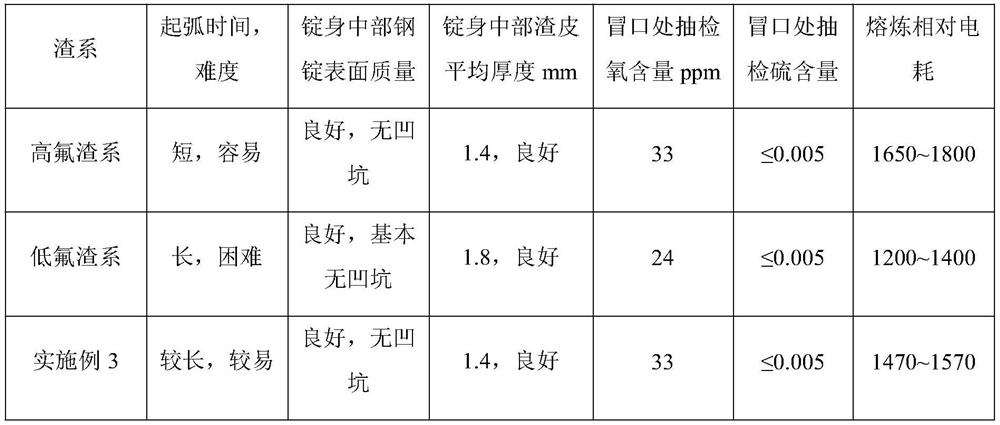

Medium-high fluorine slag system for electroslag remelting of B-containing rotor steel ingot and use method

The invention relates to a medium-high fluorine slag system for electroslag remelting of a B-containing rotor steel ingot and a use method, belongs to the technical field of electroslag special metallurgy, and is used for solving the problems of high energy consumption and high fluorine slag volatilization pollution of an existing B-containing electroslag remelting slag system. The medium-high fluorine slag system comprises the following components in percentage by mass: 40.26-46.79% of CaF2, 23.07-33.99% of Al2O3, 22.25-24.83% of CaO, 3-5% of MgO, 0.5-1.5% of B2O3 and the balance impurities, wherein SiO2 in the impurities is less than 0.5%. The medium-high fluorine slag system reduces the high fluorine slag volatilization pollution, and is low in power consumption and excellent in comprehensive metallurgical performance in use.

Owner:CENT IRON & STEEL RES INST

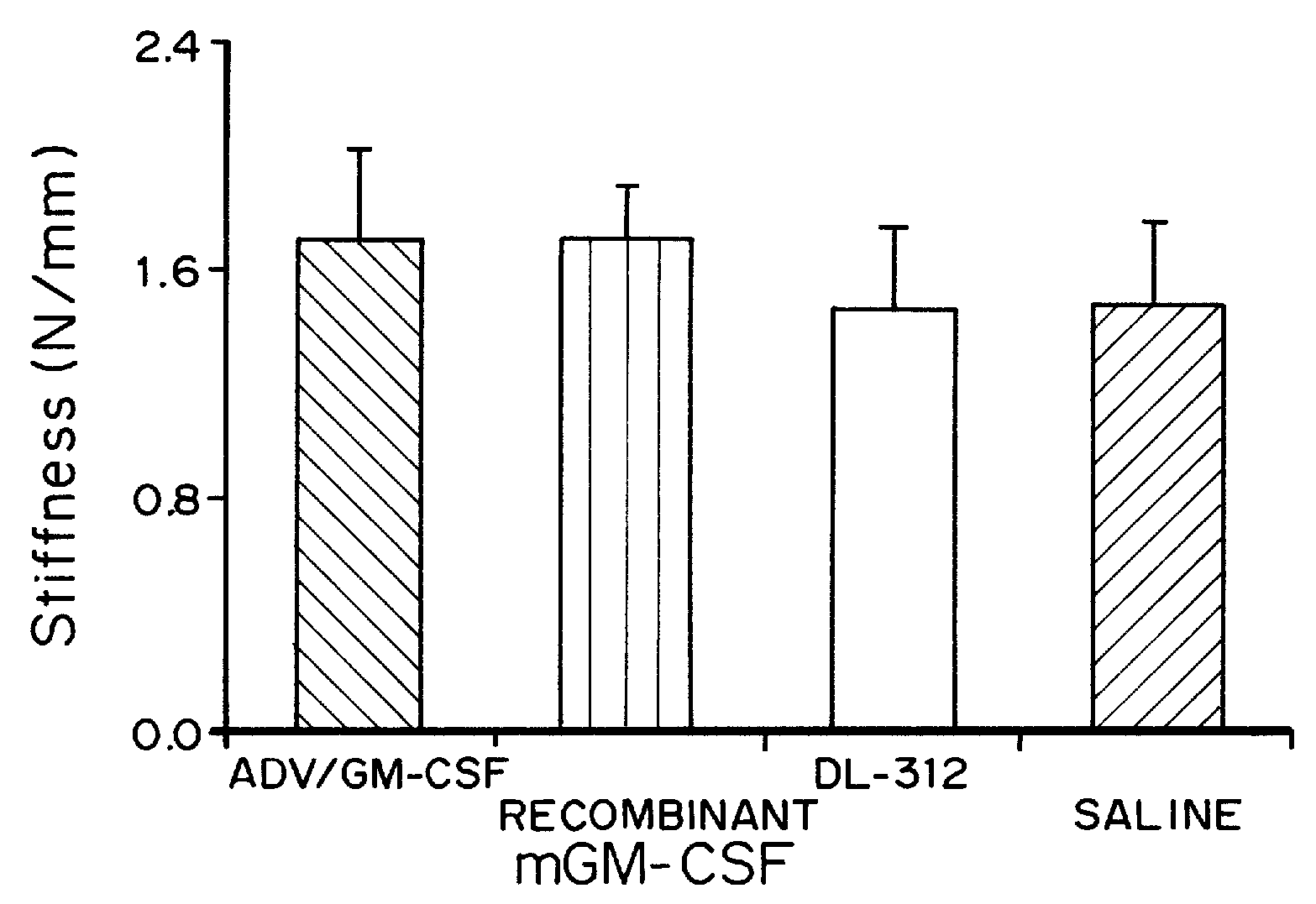

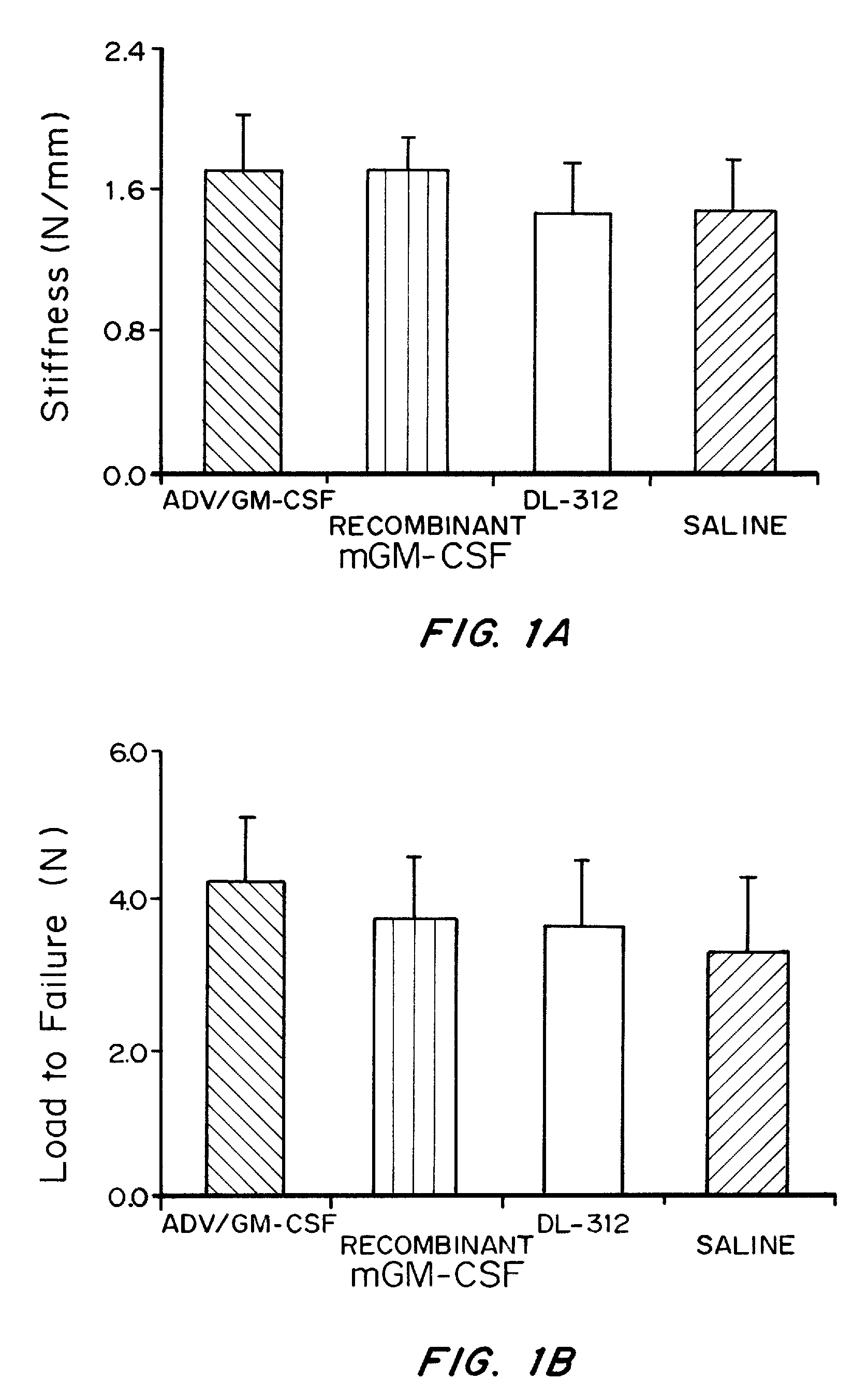

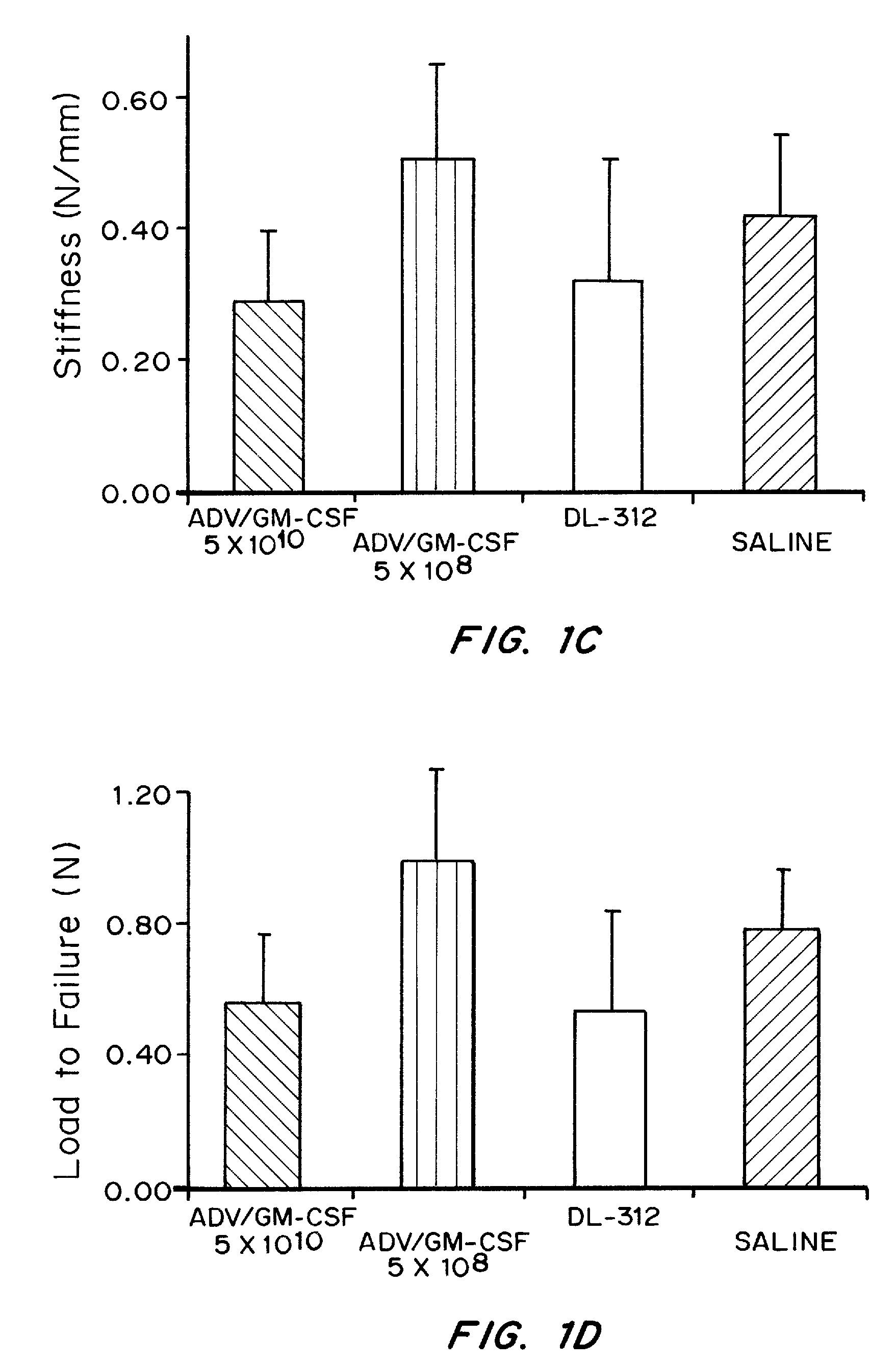

Gm-csf cosmeceutical compositions and methods of use thereof

ActiveUS20090191156A1Promotes fibroblast proliferationPromotes collagen productionBiocideOrganic active ingredientsDiseaseSustained Release Formulations

It has been discovered that granulocyte macrophage colony stimulating factor (“GM-CSF”) promotes migration of activated (but not differentiating) keratinocytes to wound sites. It was also discovered that GM-CSF increases the quantity and improves the quality of collagen. This growth factor specifically increases migration of keratinocytes of the “wound” phenotype but does not have significant effects upon differentiated keratinocytes. Examples demonstrate reversal of skin impairment in multiple animal models of diabetic skin imparment when provided in an effective amount over an effective time period. The examples also demonstrate the efficacy of the formulations in cosmetic applications. A preferred formulation is a sustained release formulation that delivers sufficient growth factor to the skin and the underlying tissue thereof to increase the rate of keratinocyte migration, as well as collagen deposition and fibroblast proliferation, in the skin to promote rejuvenation of skin injuries resistant to repair due to underlying disease, such as diabetes, or aging.

Owner:NEW YORK UNIV

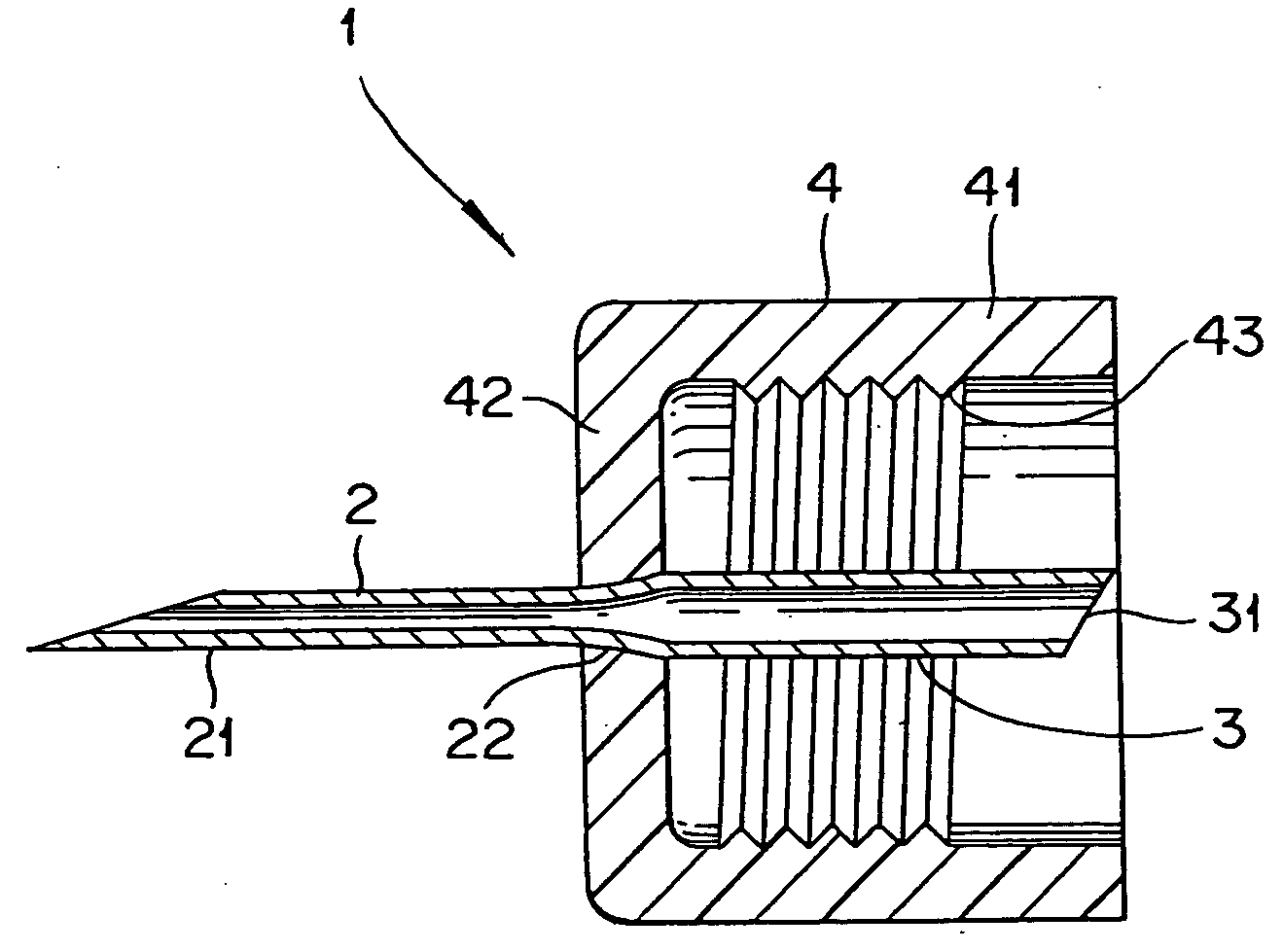

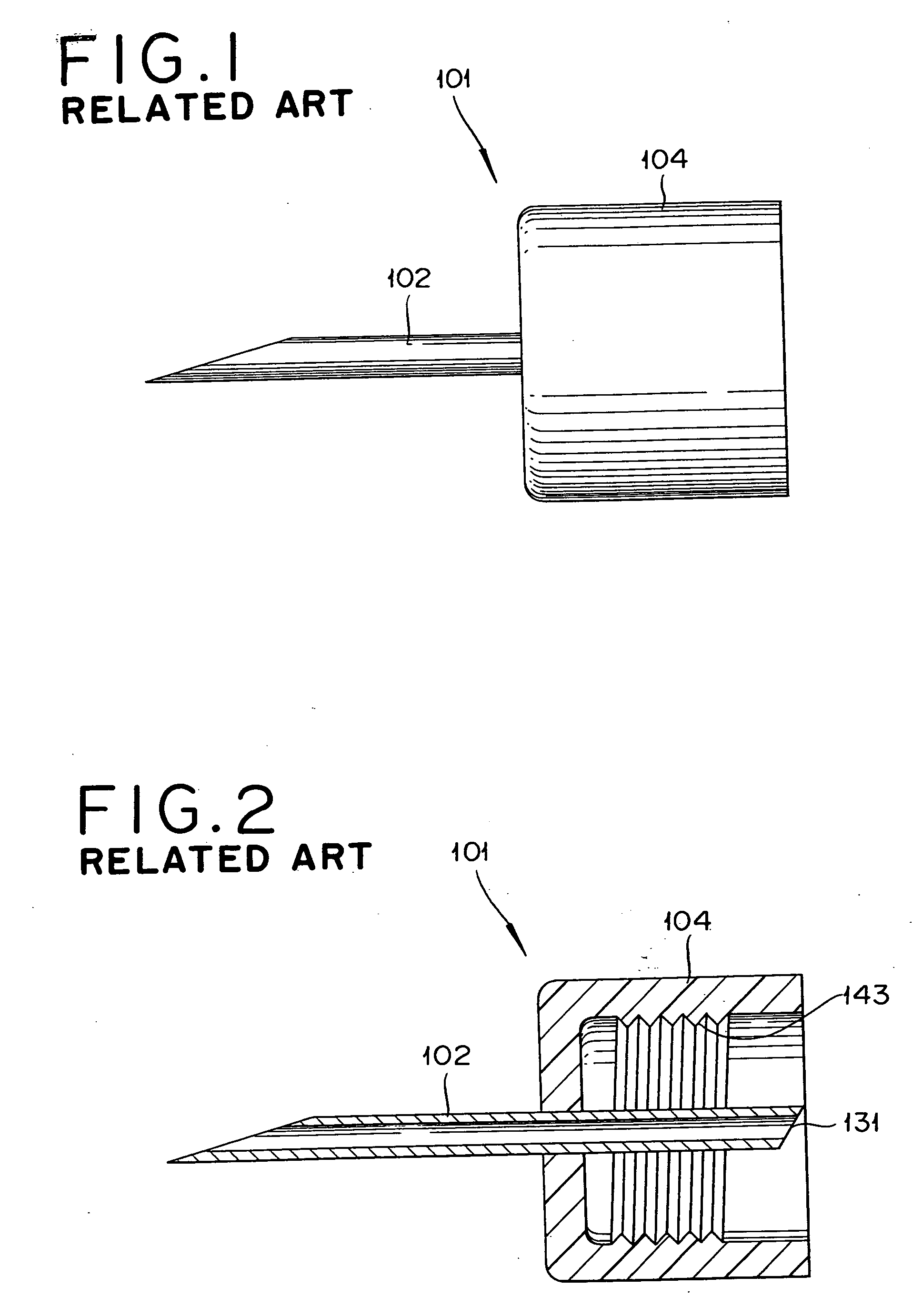

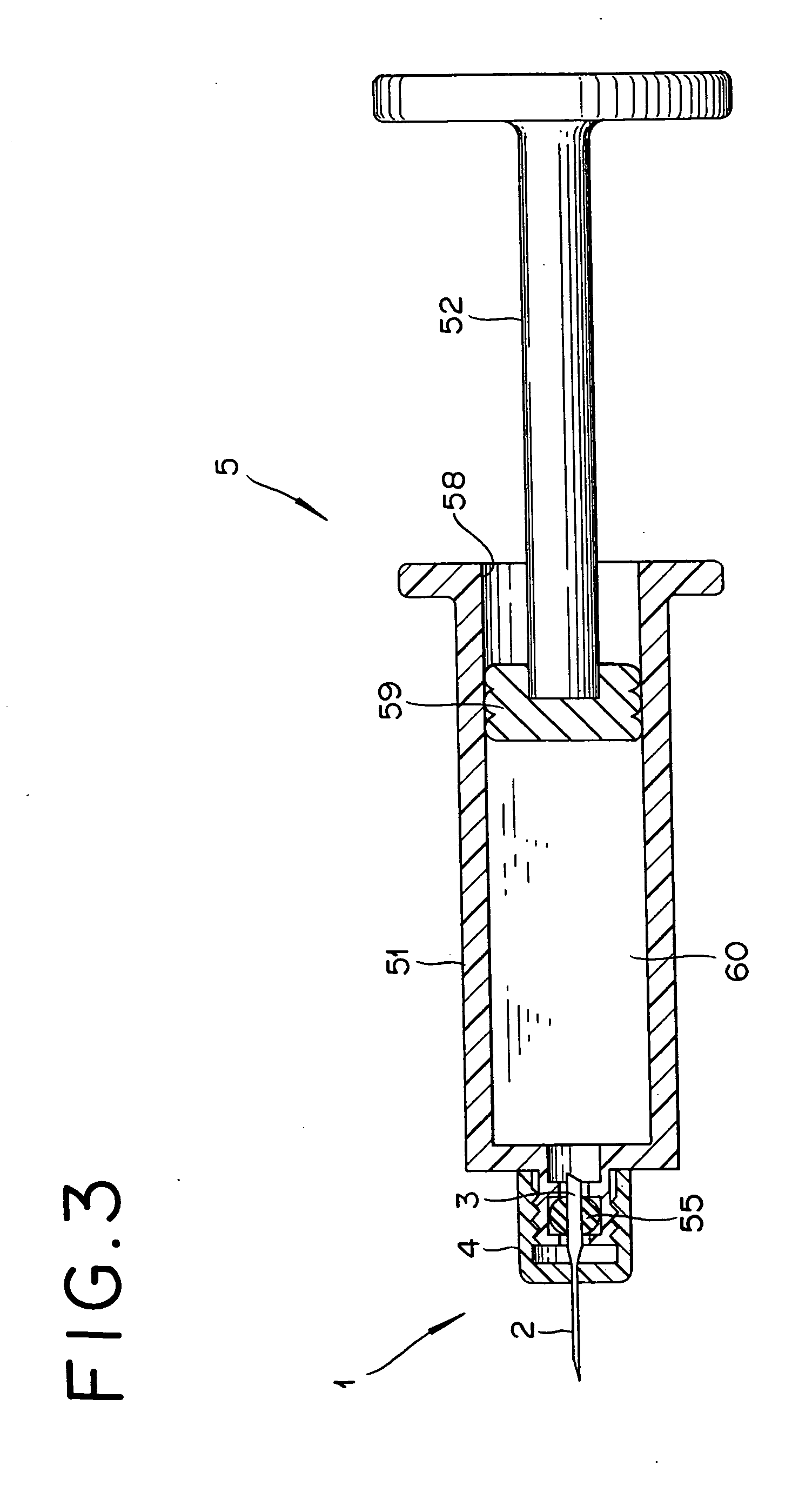

Injection needle and injection apparatus

InactiveUS20050096603A1Relieve painHigh strengthAmpoule syringesInfusion needlesDrug injectionInjection device

A drug injection needle 1 comprises a puncturing needle part 2 that has a puncturing part 21 that is capable of puncturing a body, a drug introducing needle part 3 that is capable of communicating with the inside of the drug container, and a housing 4 that supports the puncturing needle part 2 and the drug introducing needle part 3 in such a way as to allow the liquid drug to flow between the needle parts 2 and 3. The outer diameter of the puncturing part 21 is not more than 0.254 mm. The outer diameter of the drug introducing needle part 3 is larger than at least that of the vicinity of the distal end of the puncturing part 21 of the puncturing needle part 2, and a cutting edge 31 is formed at the end of the drug introducing needle part 3 for penetrating through an elastic member that is provided to seal the drug injection port of the drug container.

Owner:TERUMO KK

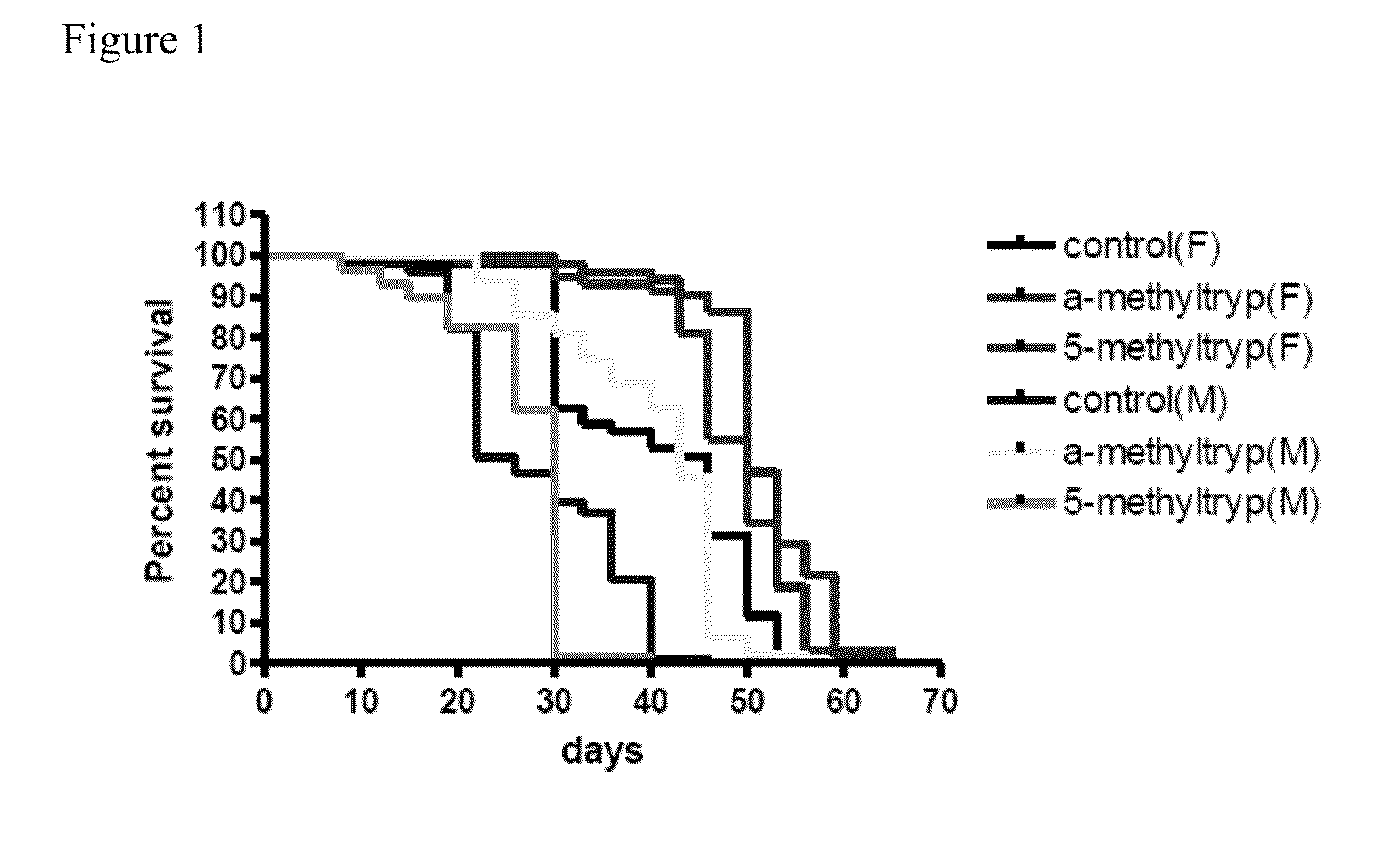

Compositions and methods for prolonging lifespan

InactiveUS20130101580A1Extend your lifeAvoid conversionBiocideNervous disorderBiologyKynurenine pathway

The present invention relates to therapeutic targets for aging. In particular, the present invention relates to the inhibition of the kynurenine pathway of tryptophan metabolism to extend lifespan or provide anti-aging benefits.

Owner:OXENKRUG GREGORY +1

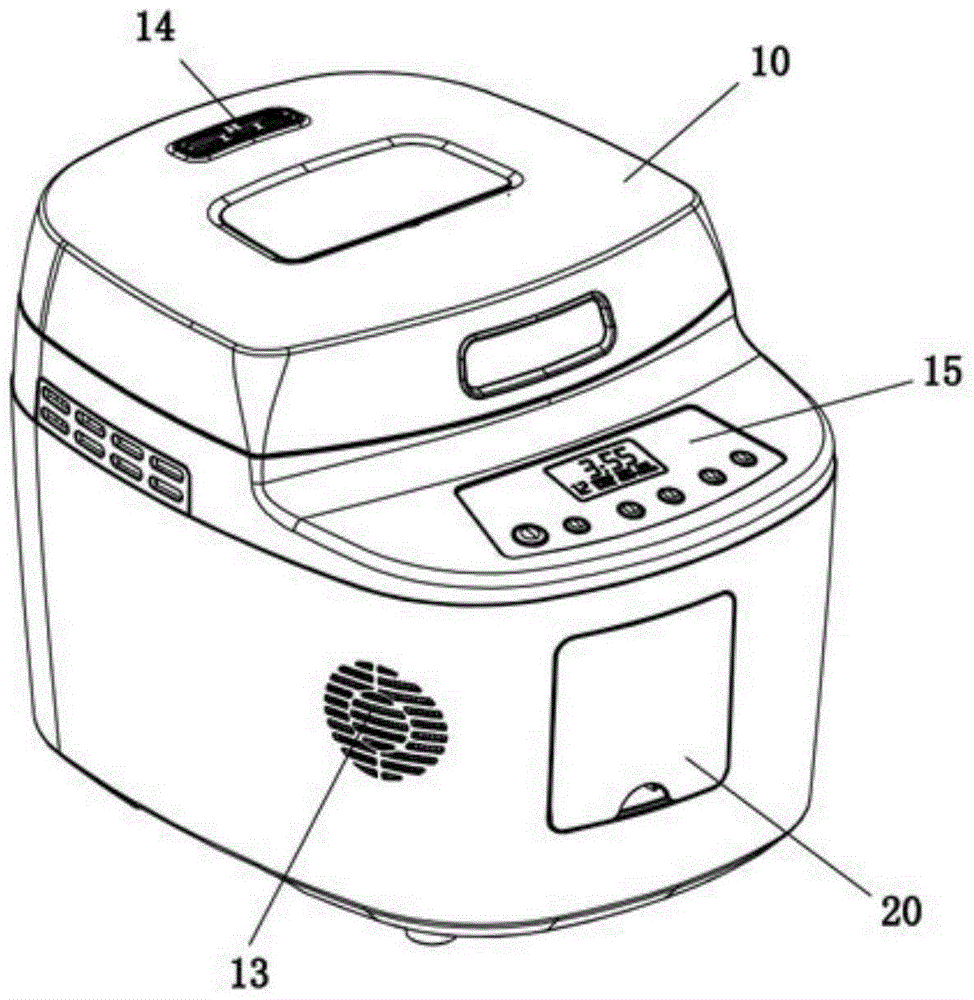

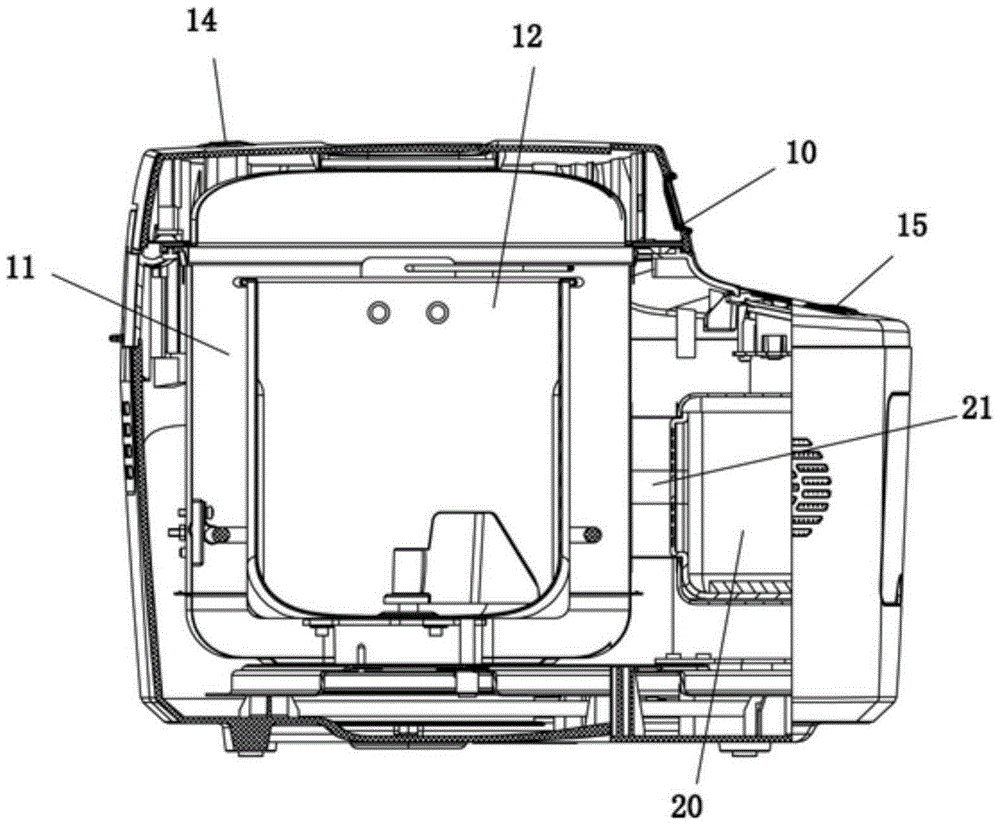

Temperature and moisture adjustable type bread maker

The invention relates to the technical field of bread makers, in particular to a temperature and moisture adjustable type bread maker. The bread maker comprises a main unit, wherein a braking chamber formed by an oven body is arranged inside the main unit, a bread barrel is arranged inside the baking chamber, and a moisturizing device is also installed in the main unit and used for changing the temperature and moisture of the baking chamber during fermentation. By the adoption of the bread maker, moisture and temperature during dough fermentation can be adjusted, the side effects caused by moisture and temperature on fermentation are avoided, and baked bread is made to taste better.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com