Patents

Literature

51results about How to "Thinning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Synergetic composition for the treatment of psoriasis and other skin disorders and method therefor

InactiveUS20030185915A1ThinningSuppression problemBiocideUnknown materialsBULK ACTIVE INGREDIENTParapsoriasis

Synergetic compounded medication formula for the treatment of psoriasis, seborrhea, dermatitis, dandruff, eczema, acne, and other skin disorders. The present invention is to provide regenerative treatment of skin disorders recurrent in all areas of the body. The invention of this disclosure uses a well-known corticosteroid as an active ingredient, namely Triamcinolone acetonide, which when used in combination with a special formula is effective, easy to use, and less expensive than similar products available with a prescription in the market. A method for administering said composition to inhibit proliferation of psoriatic cell populations in the epidermis is disclosed

Owner:CARLO JAIME +3

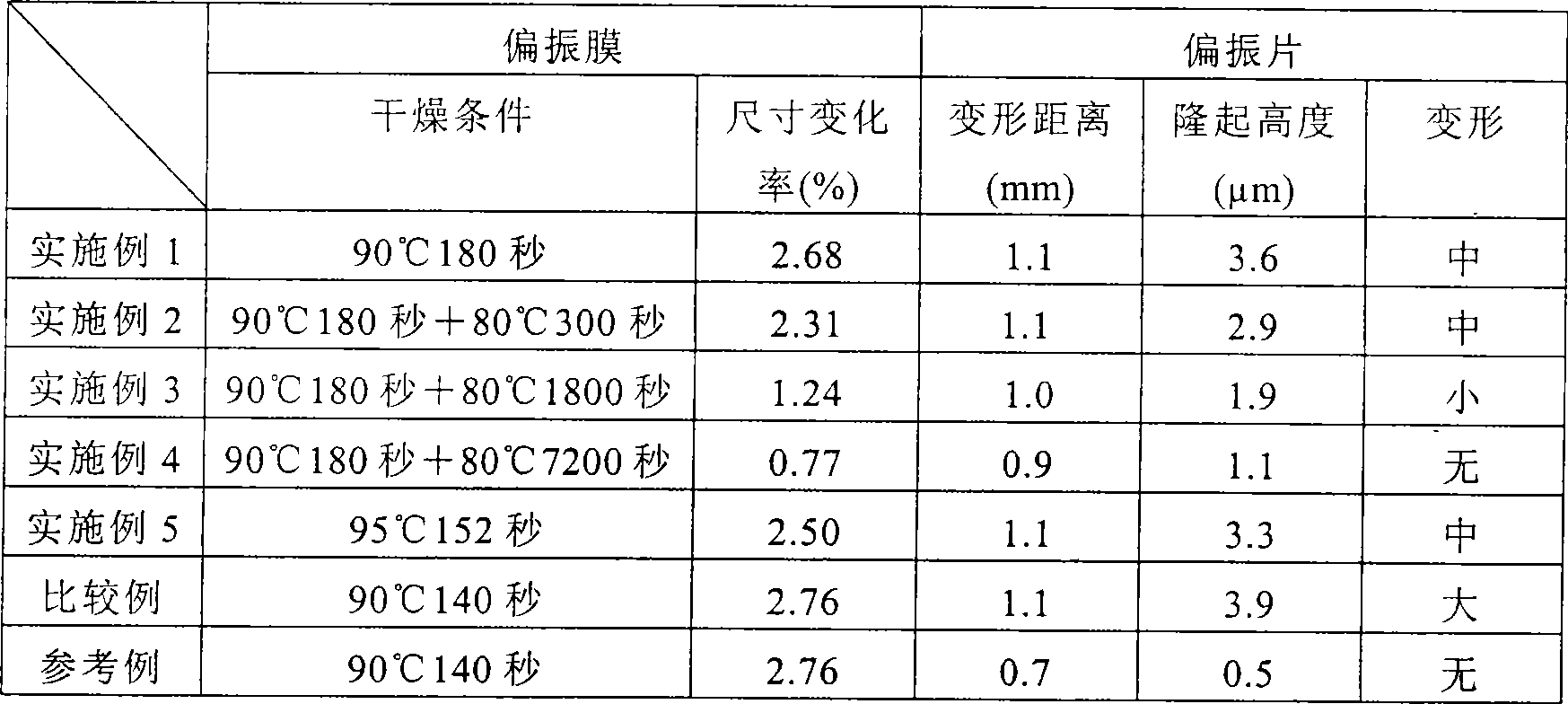

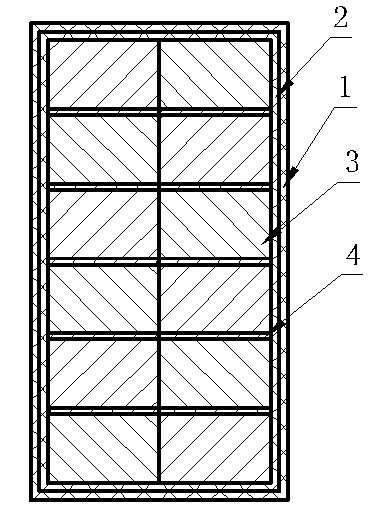

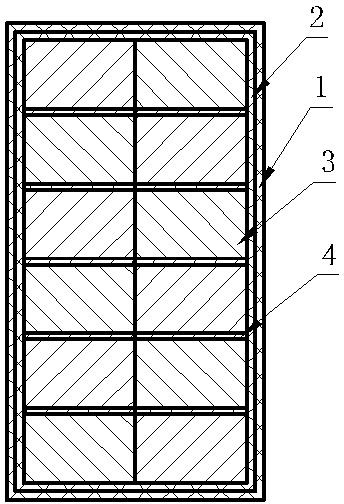

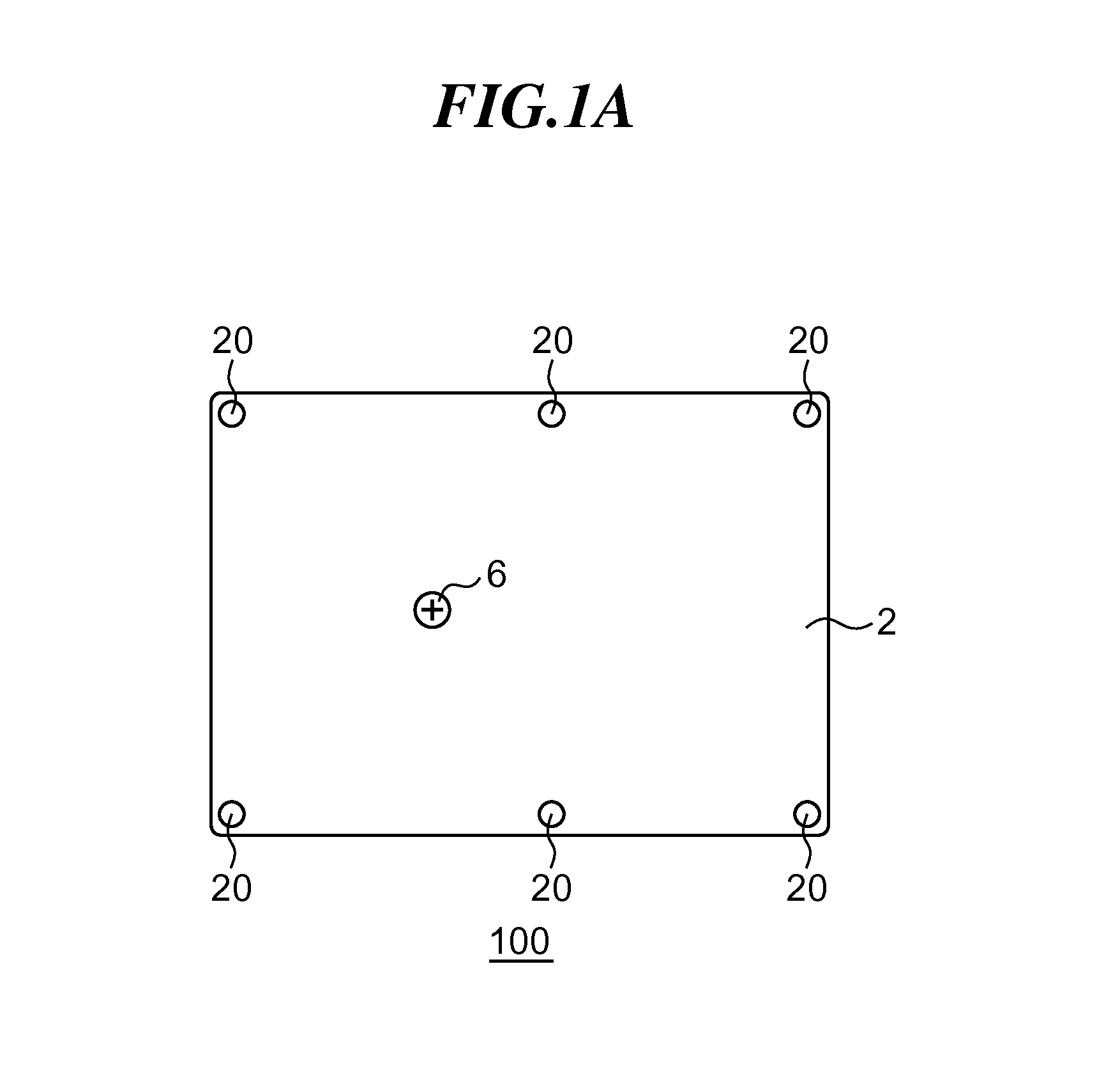

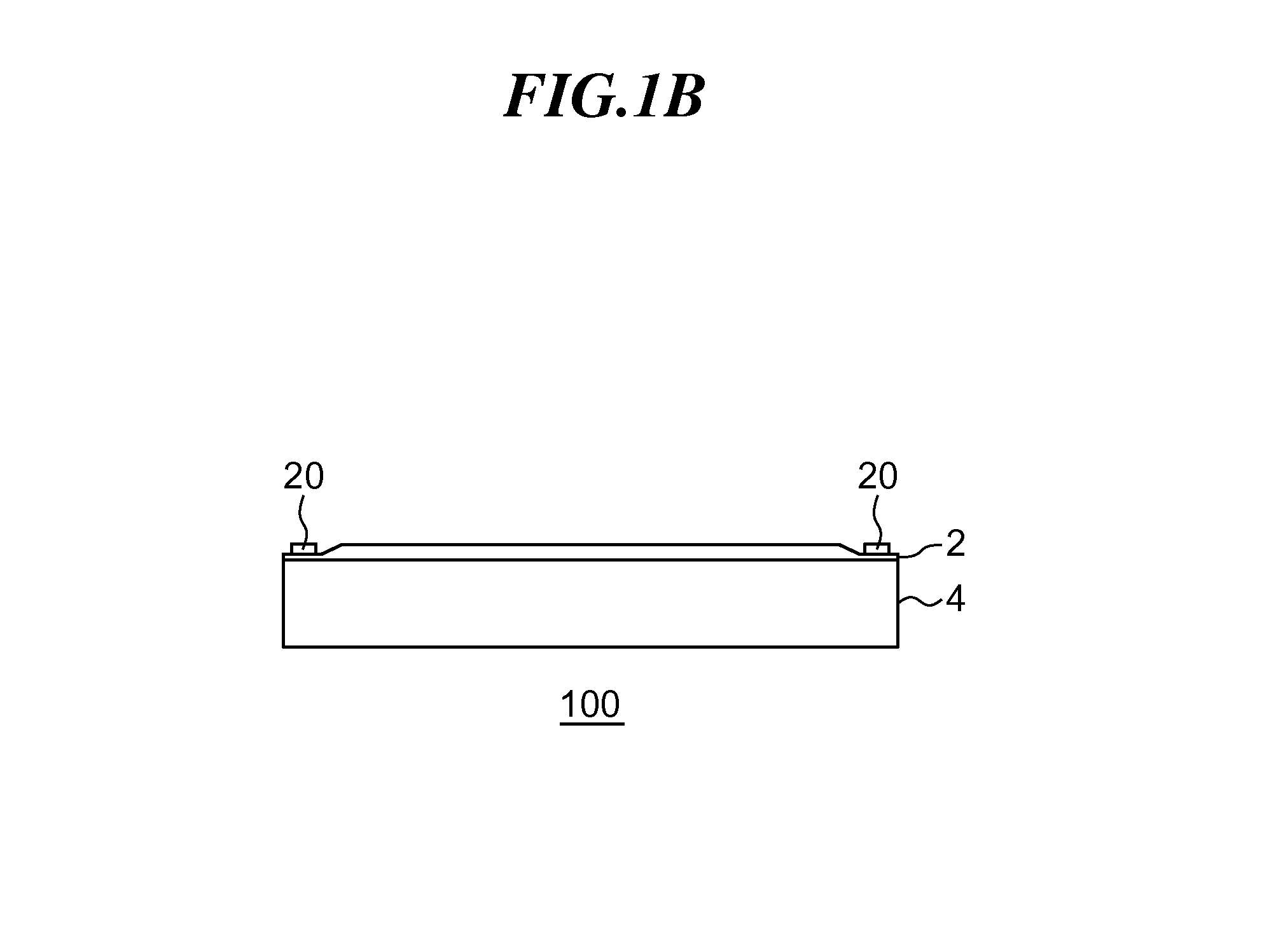

Method for preparing polaroid

InactiveCN101424766AThinningGood durabilitySynthetic resin layered productsPolarising elementsPolarizerCellulose acetate

The present invention provides a method for manufacturing a polarizing disc, wherein, a transparent protective film is laminated on only one surface of polarizing film which is formed by polyvinyl alcohol resin and has a dimension changing rate lower than 2.7through an adhesive layer. The transparent protective film is preferably cellulose acetate resin in the method for manufacturing a polarizing disc. Additionally, preferably the other surface of polarizing film is formed with an additive layer that is formed by acrylic resin.

Owner:SUMITOMO CHEM CO LTD

Polymer nickel cobalt manganese vanadium lithium power battery and preparation method thereof

InactiveCN102610852ALow toxicityLow costCell electrodesFinal product manufactureCurrent collectorPolymer gel

The invention discloses a polymer nickel cobalt manganese vanadium lithium power battery and a preparation method thereof. The polymer nickel cobalt manganese lithium vanadium power battery comprises a positive electrode, a negative electrode, a diaphragm, polymer gel electrolyte and a battery shell, wherein the positive electrode consists of a positive electrode active matter, an adhesive, a conducting agent and a positive electrode current collector, and nickel cobalt manganese vanadium lithium is adopted as the positive electrode active matter. The polymer nickel cobalt manganese vanadium lithium power battery disclosed by the invention has excellent electrochemical performance and can be better applied to electric bicycles, motorbikes, energy storage power stations and electric automobiles.

Owner:深圳市中星动力电池技术有限公司 +1

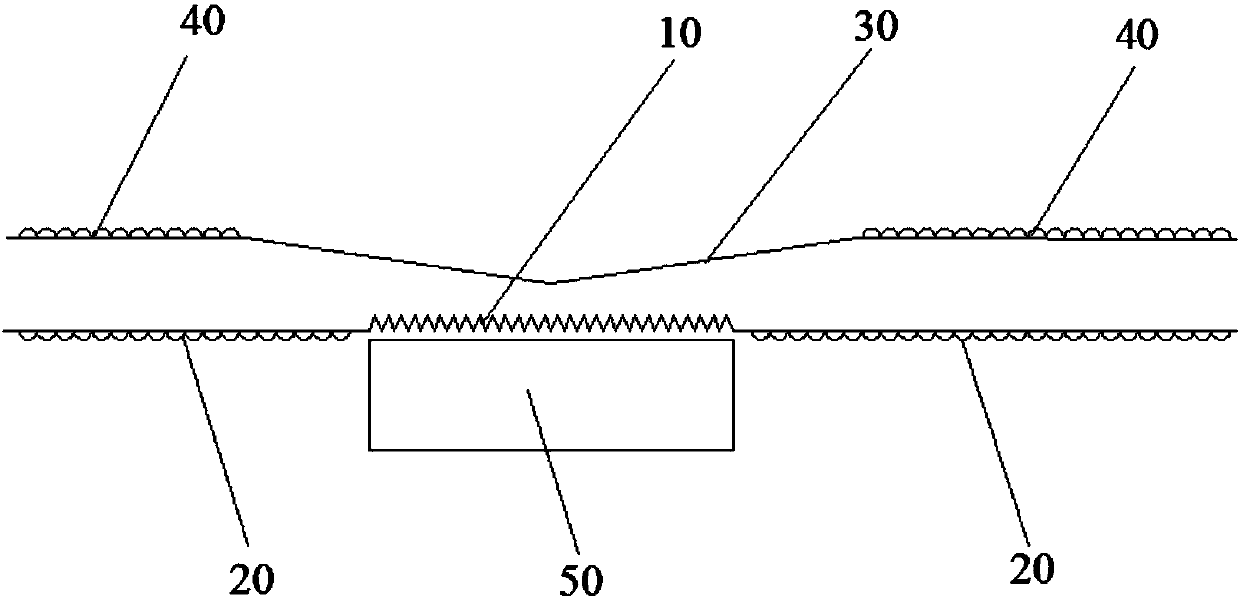

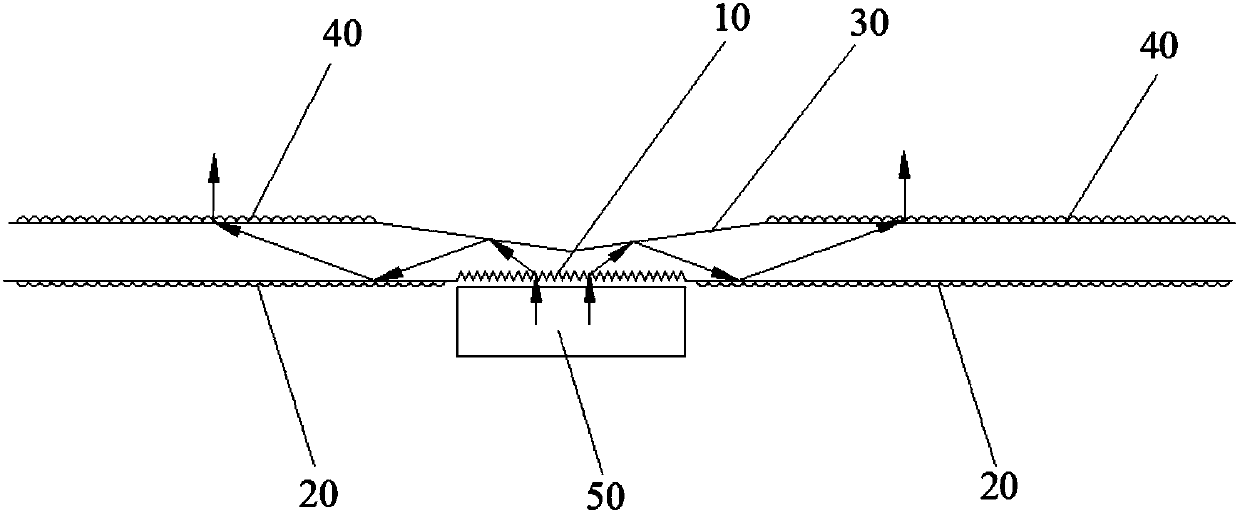

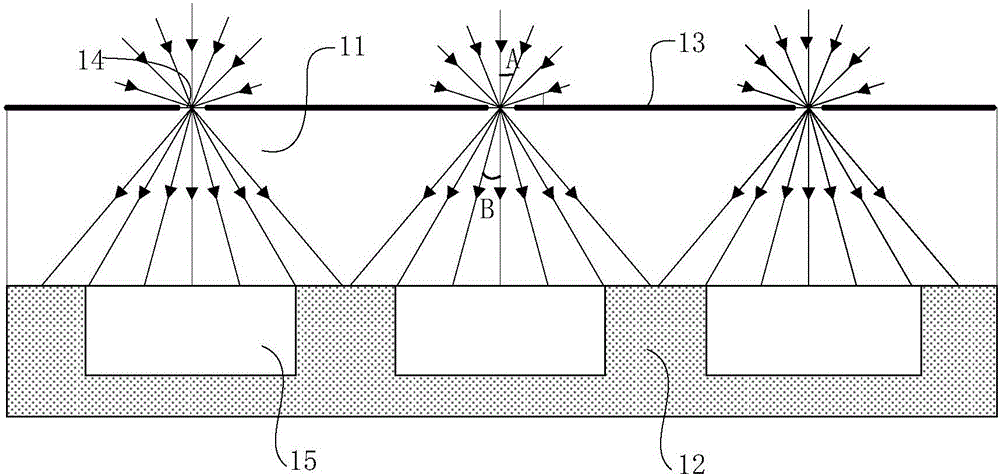

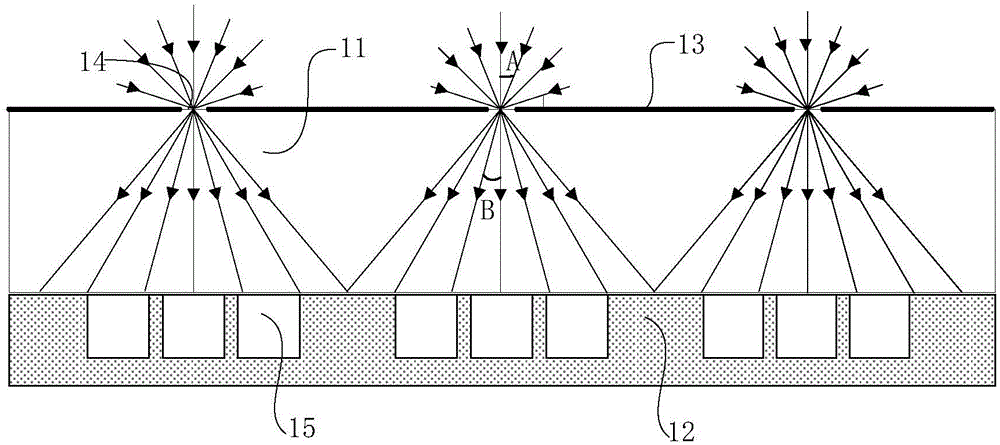

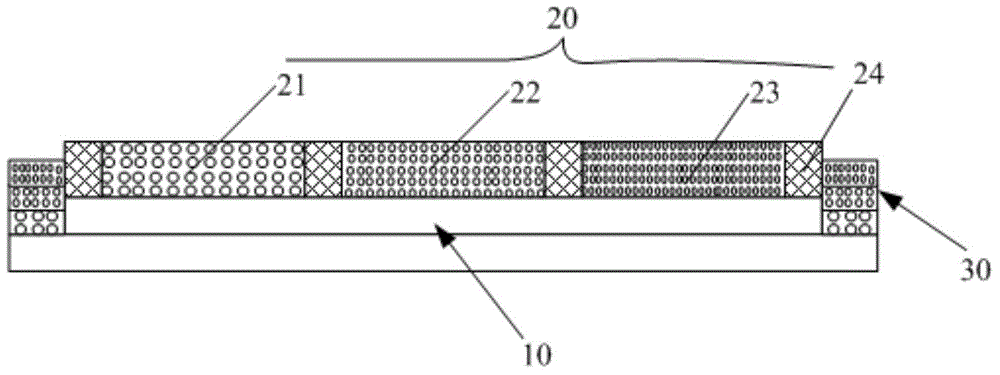

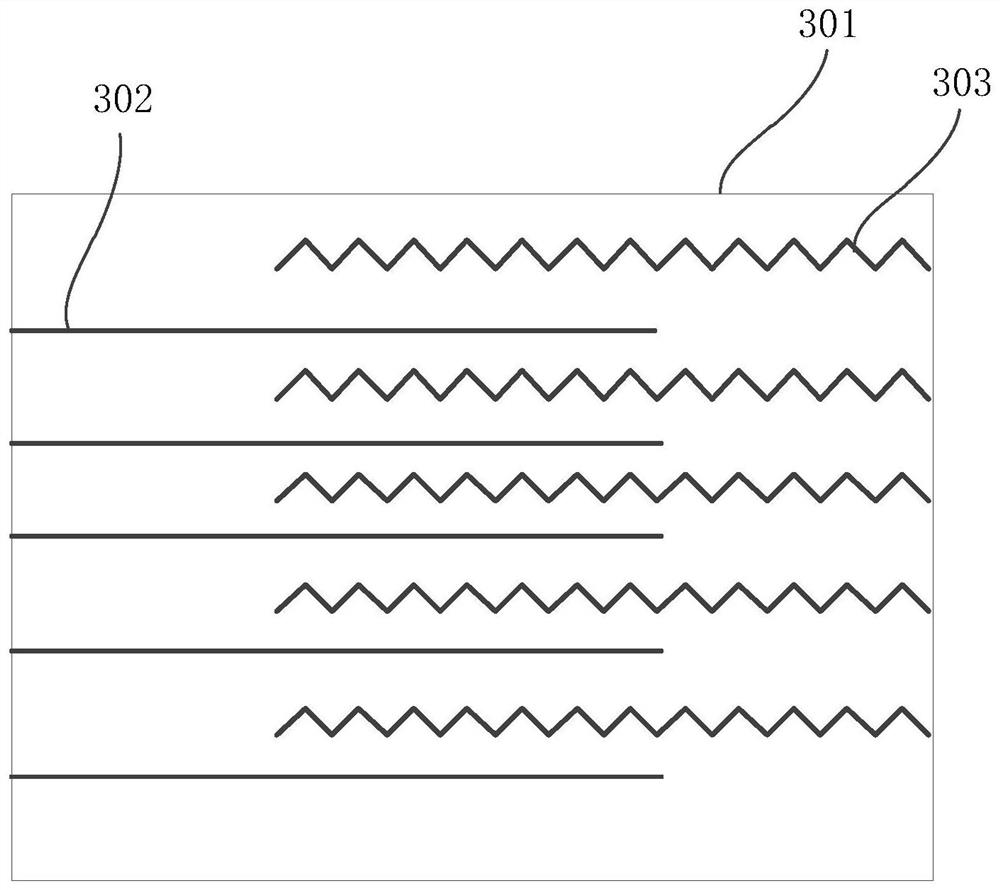

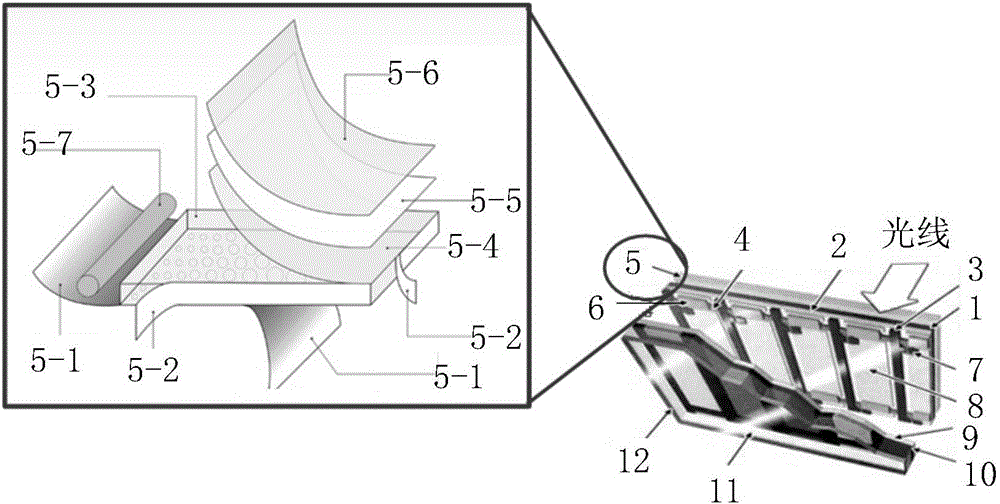

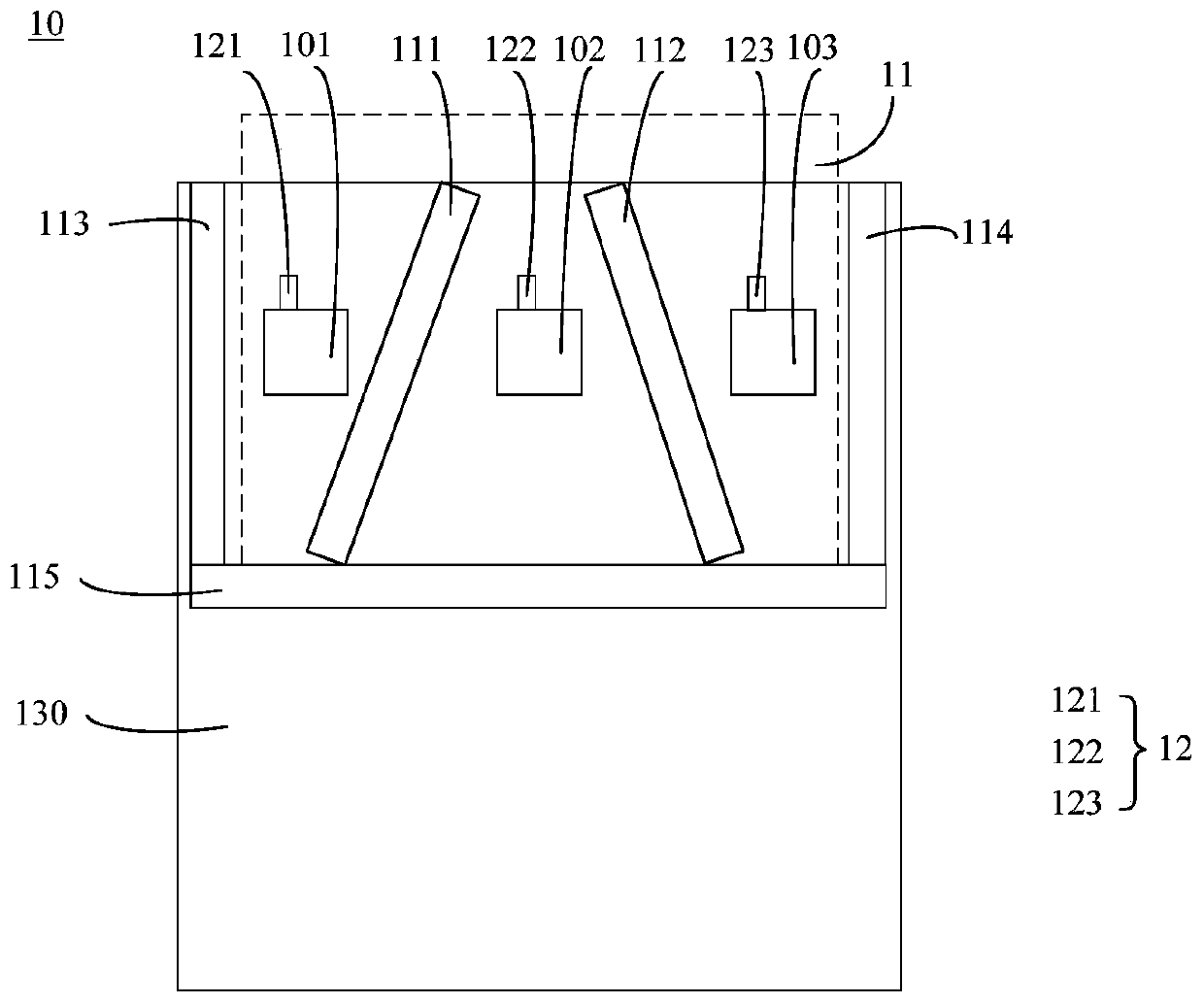

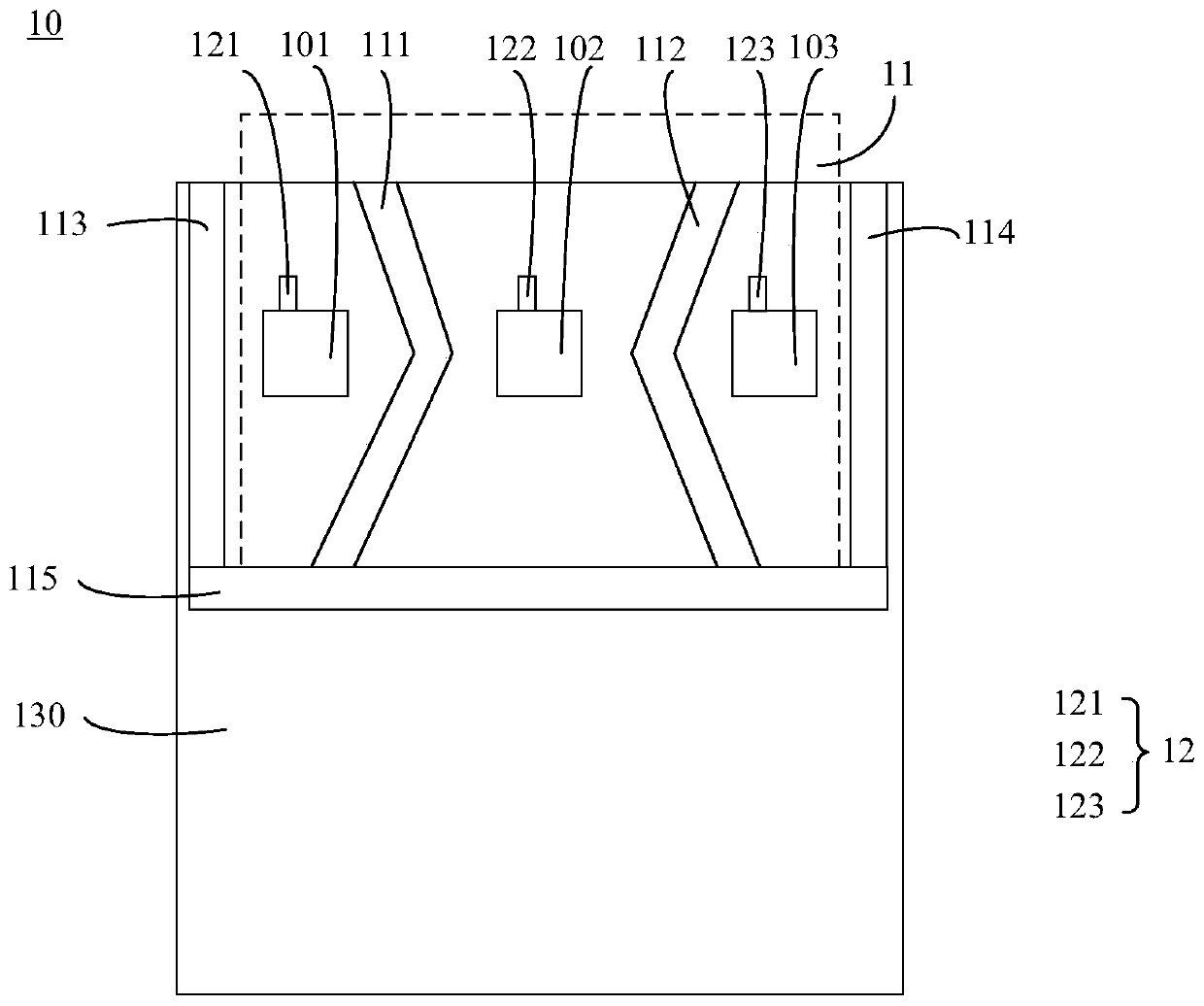

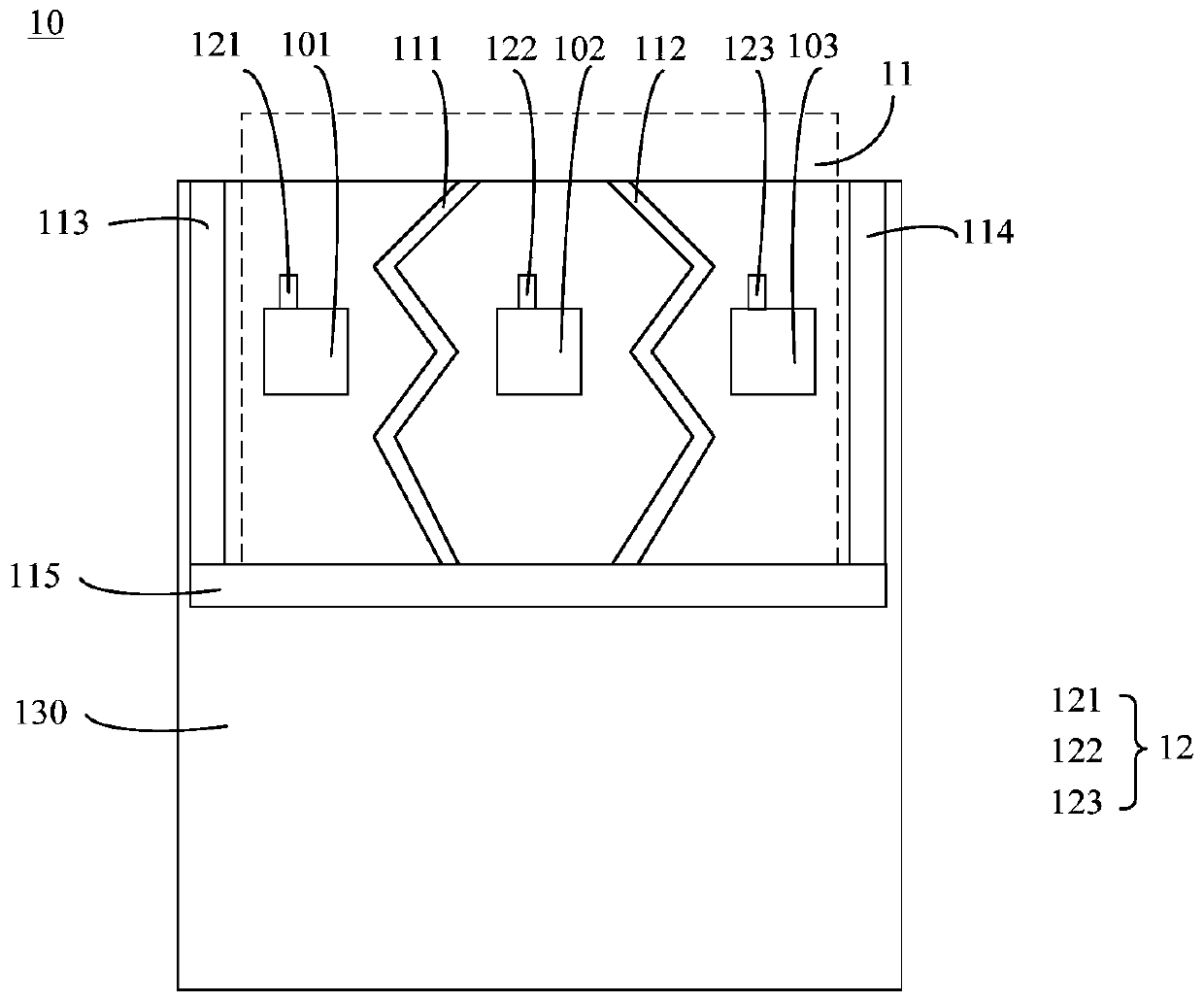

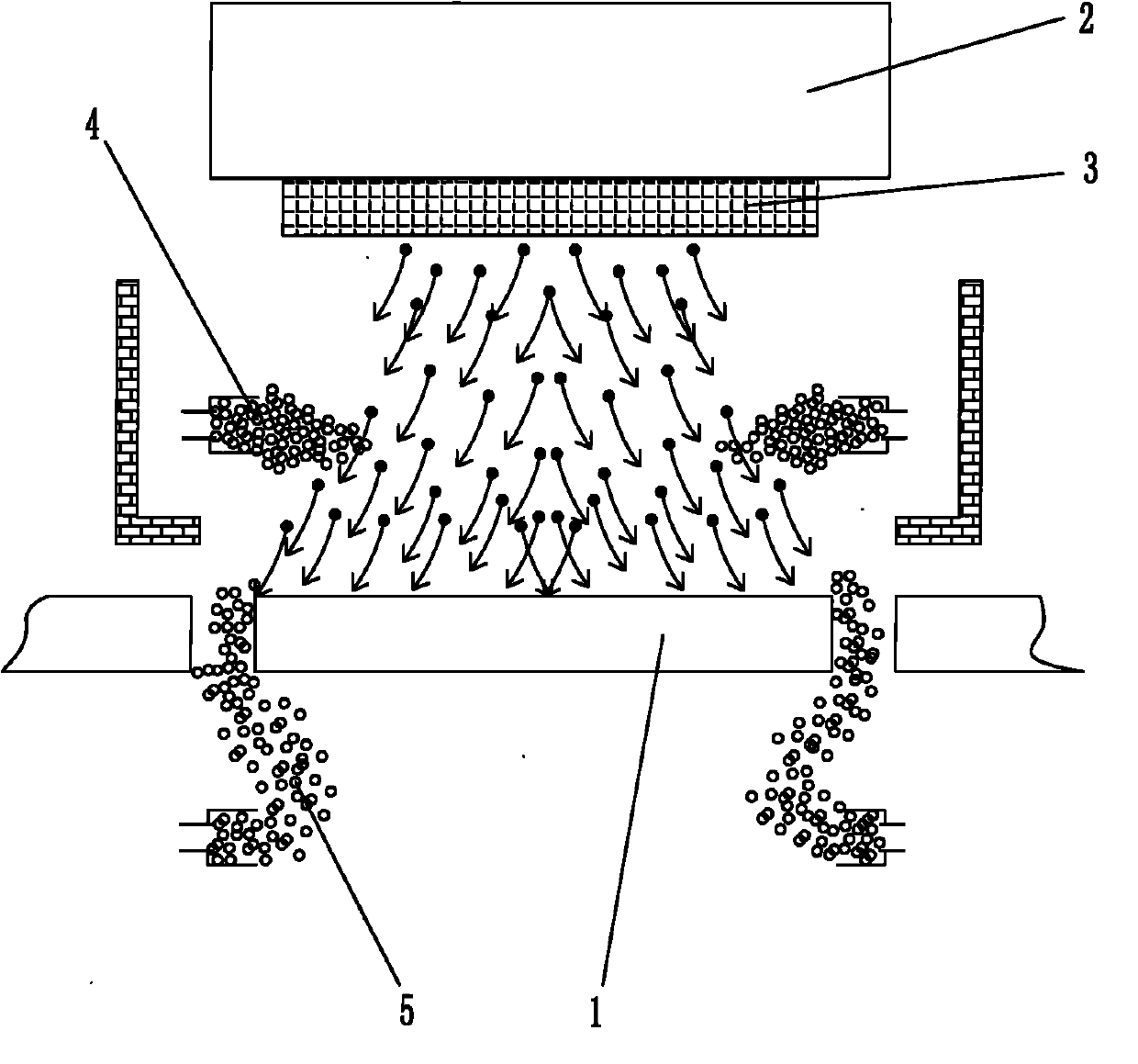

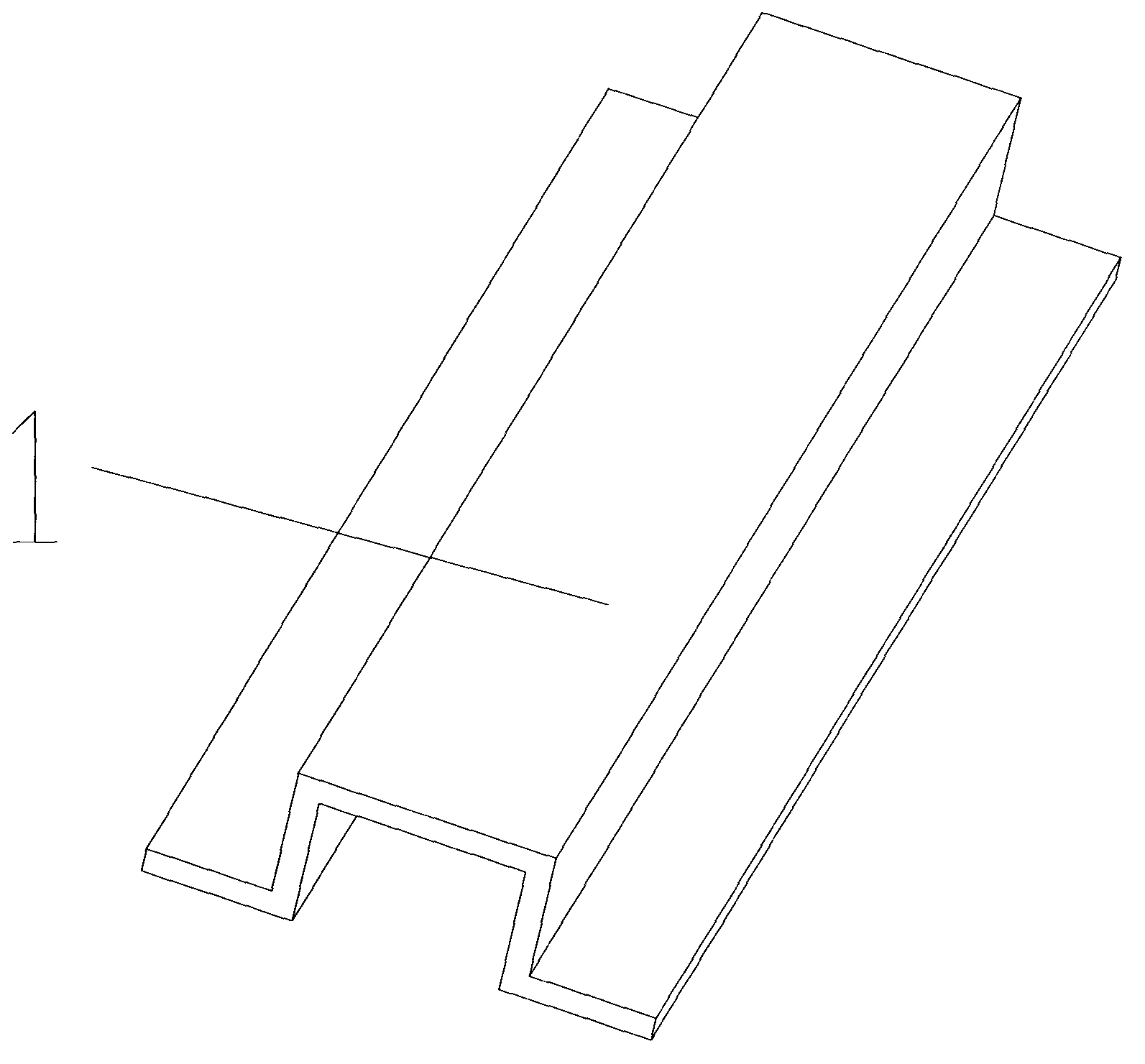

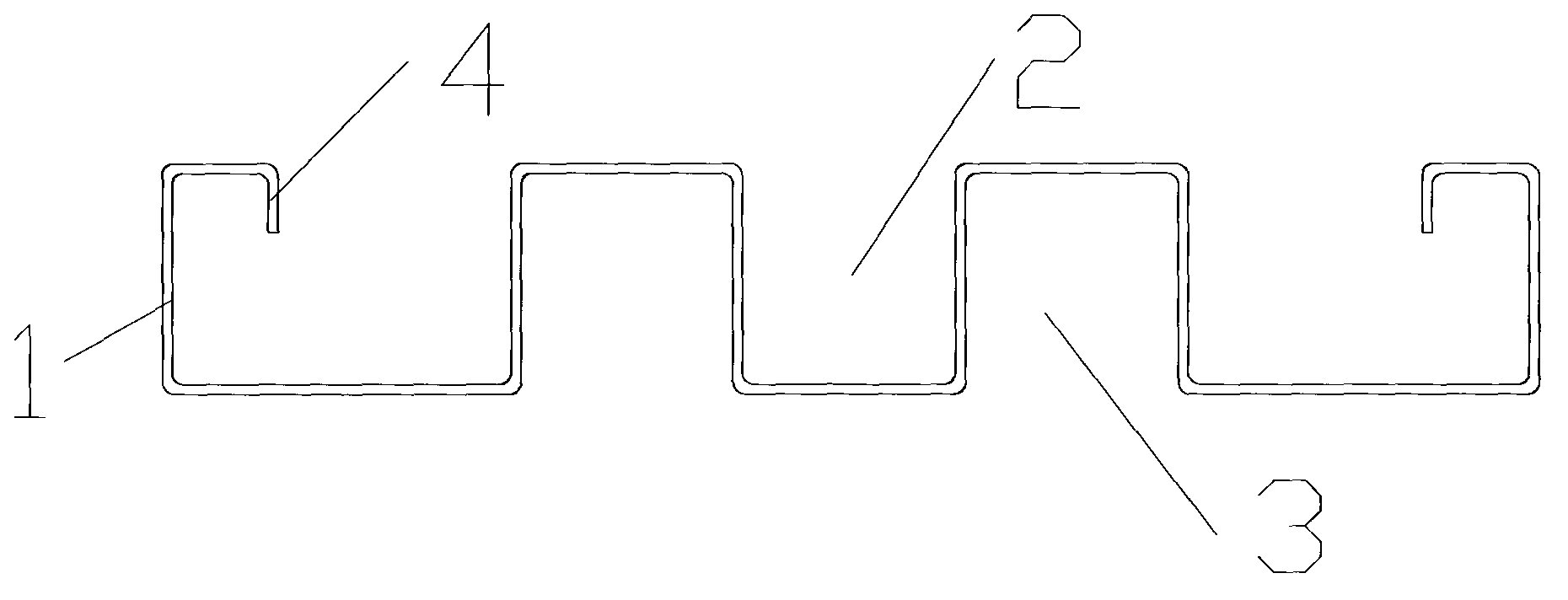

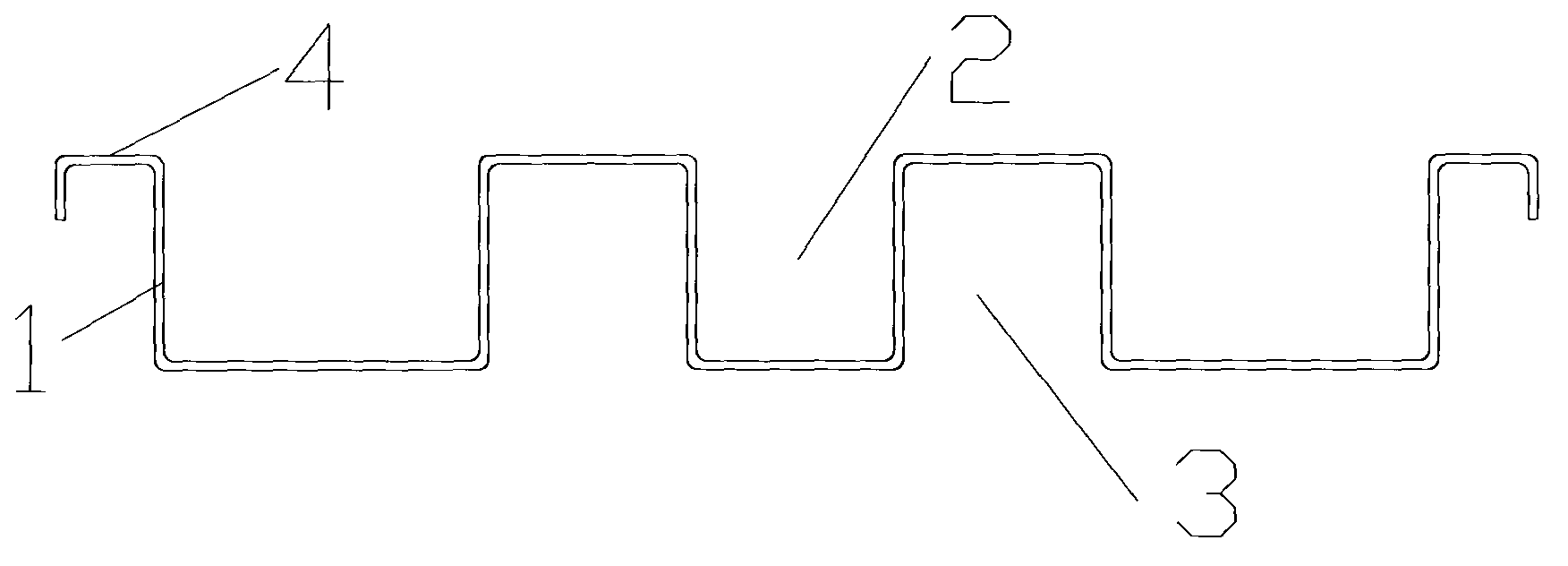

Light transmission plate and panel lamp

The invention discloses a light transmission plate and a panel lamp. An optical scattering structure and an optical reflecting structure are arranged on the lower surface of the light transmission plate; the optical reflecting structure surrounds the optical scattering structure; an optical polarizing structure and an optical condensing structure are arranged on the upper surface of the light transmission plate; the optical polarizing structure is matched with the optical scattering structure; the optical scattering structure is matched with a light source; light rays emitted by the light source are steered to enter the light transmission plate through a light ray scattering structure, and are deflected onto the optical reflecting structure through the optical polarizing structure; and theoptical reflecting structure enables the reflected light rays to irradiate to the optical condensing structure and to emit out through the optical condensing structure. The light transmission plate can be machined on a transparent plate; the light source, such as an LED and the like is directly bonded on the light transmission plate, so that the light rays emitted by the light transmission platecan be displayed as uniform planar light, the material cost is reduced, the utilization rate of light energy is increased, and the input power is reduced; and meanwhile, photoelectric products can bethinner, so that the demand space is reduced, and the use places and ranges are widened.

Owner:PEPNICE ELECTRONIC SCI & TECH CO LTD

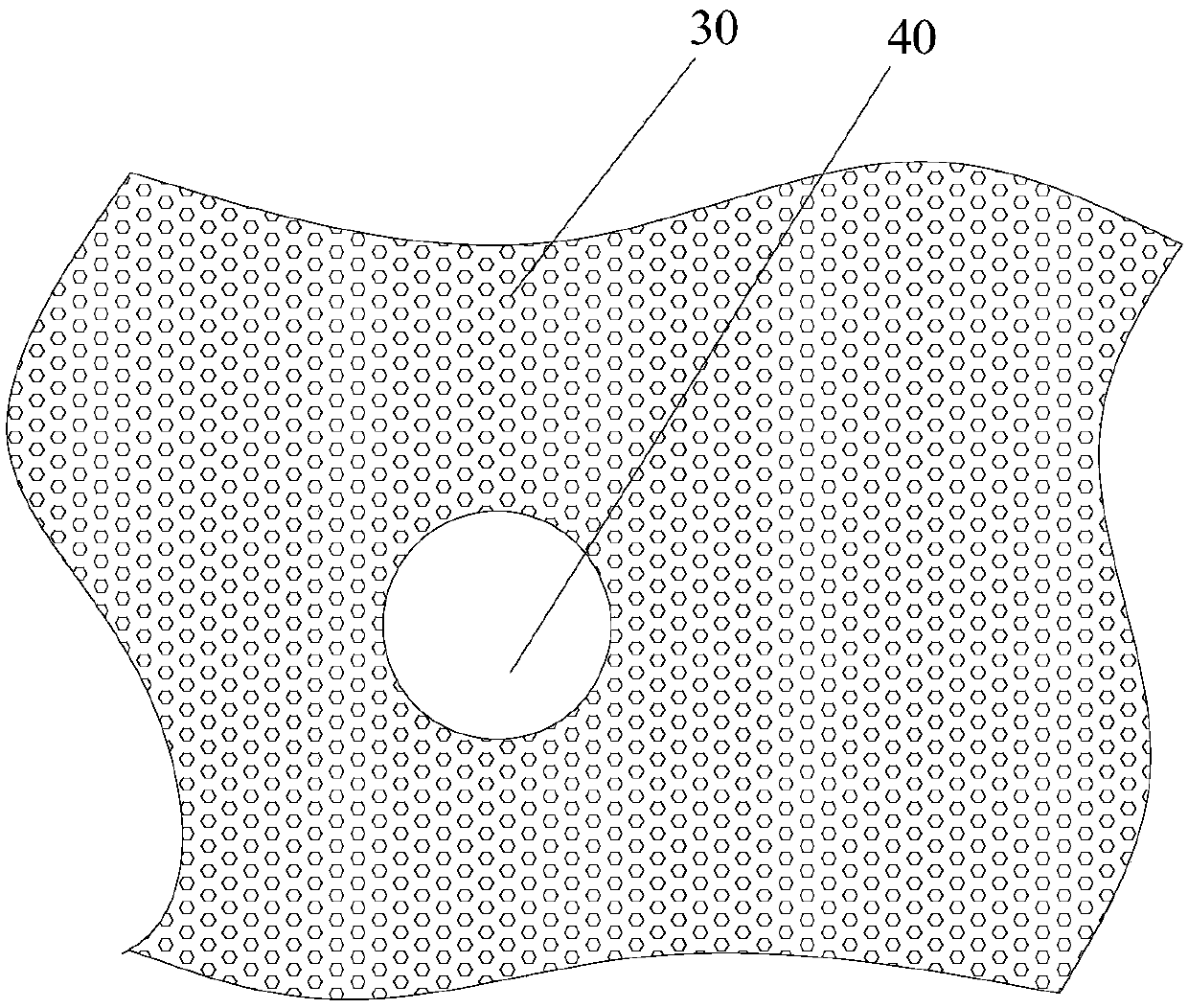

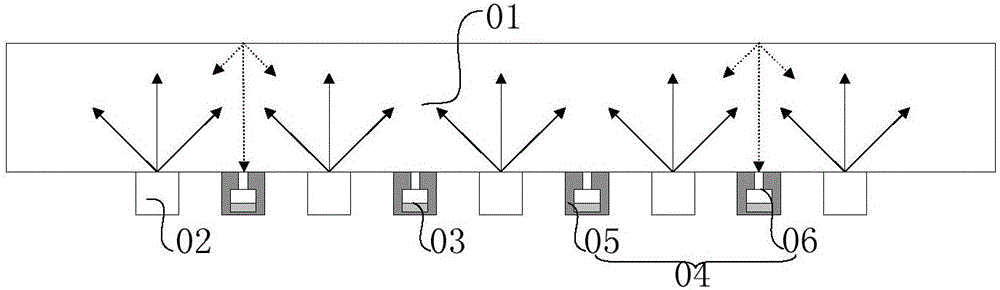

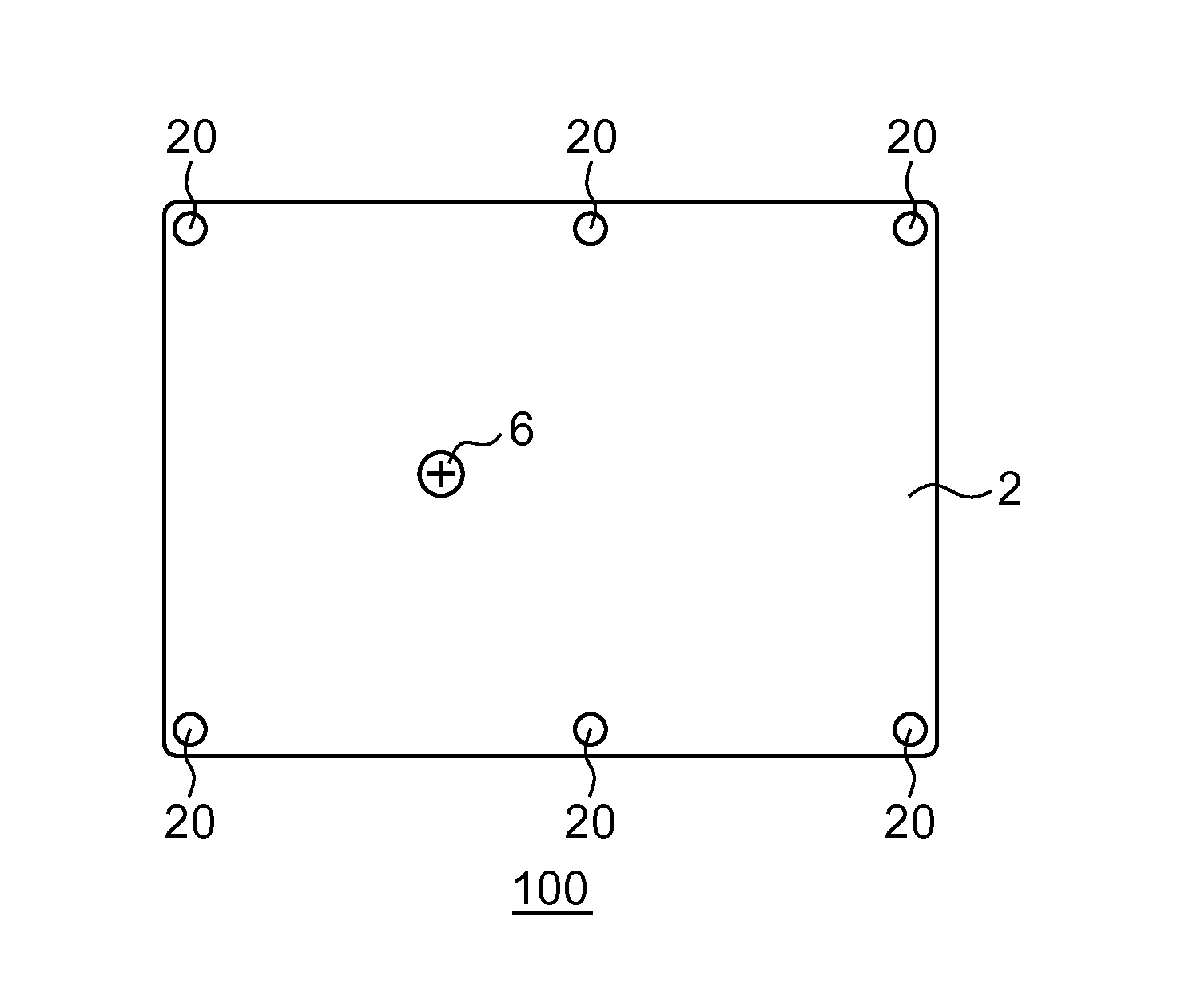

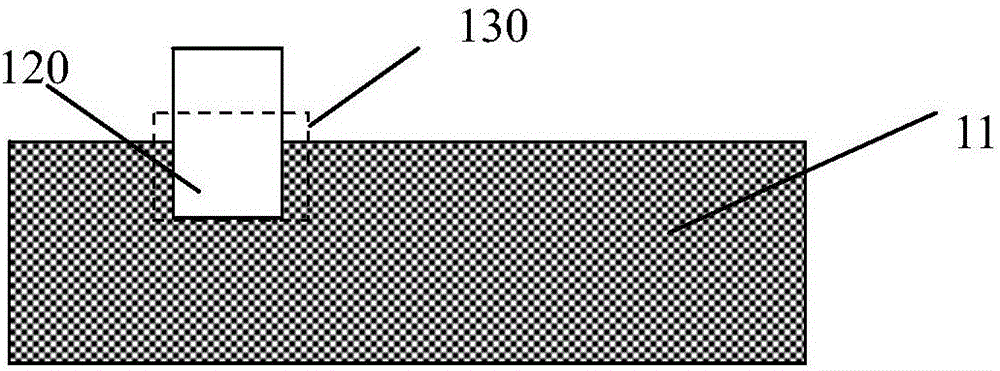

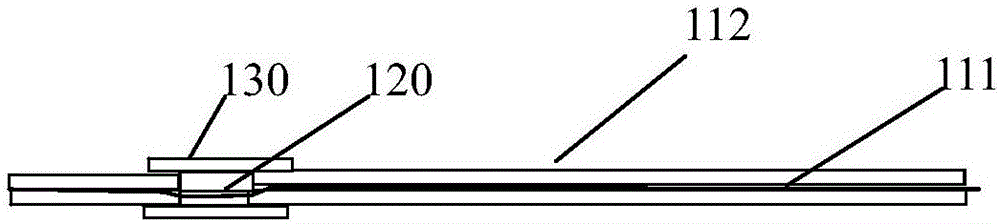

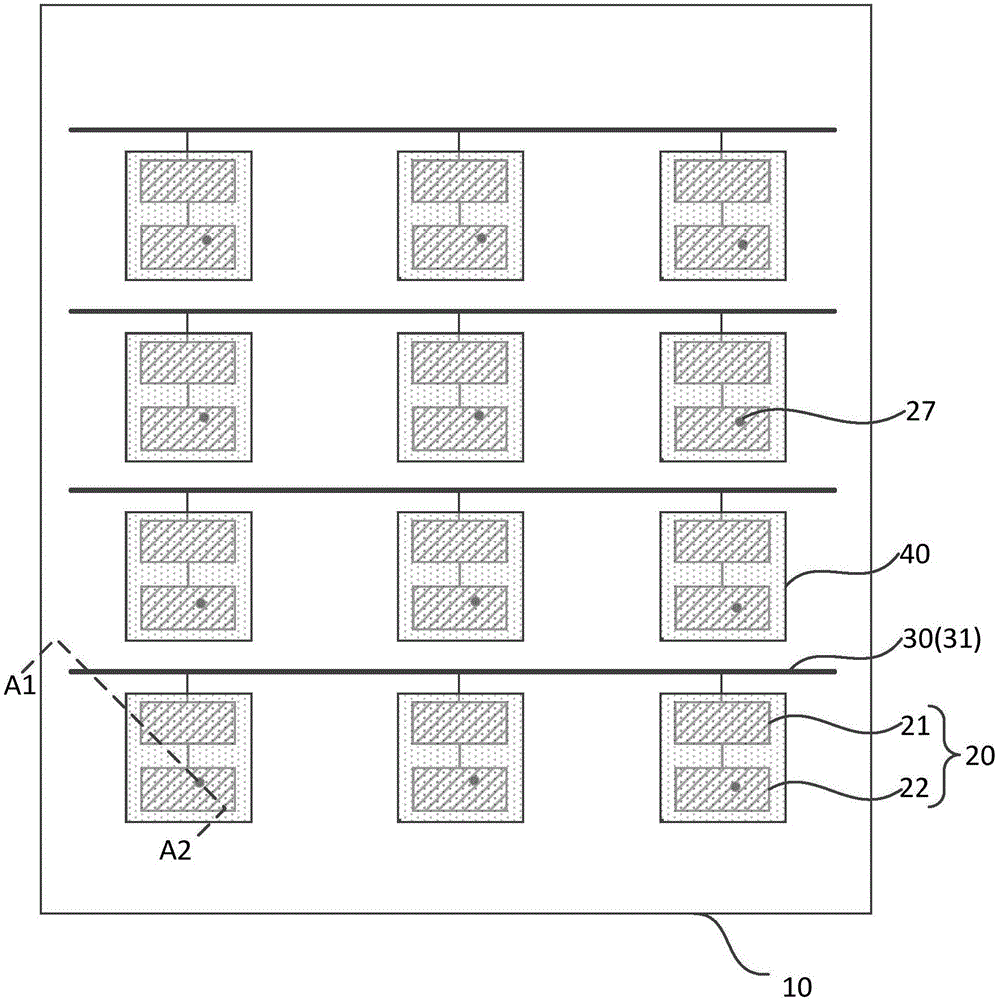

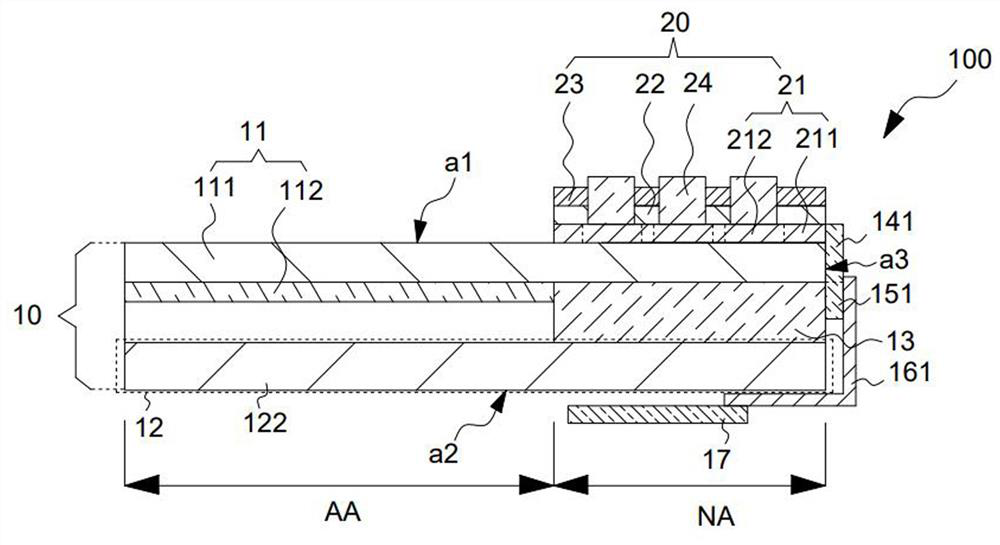

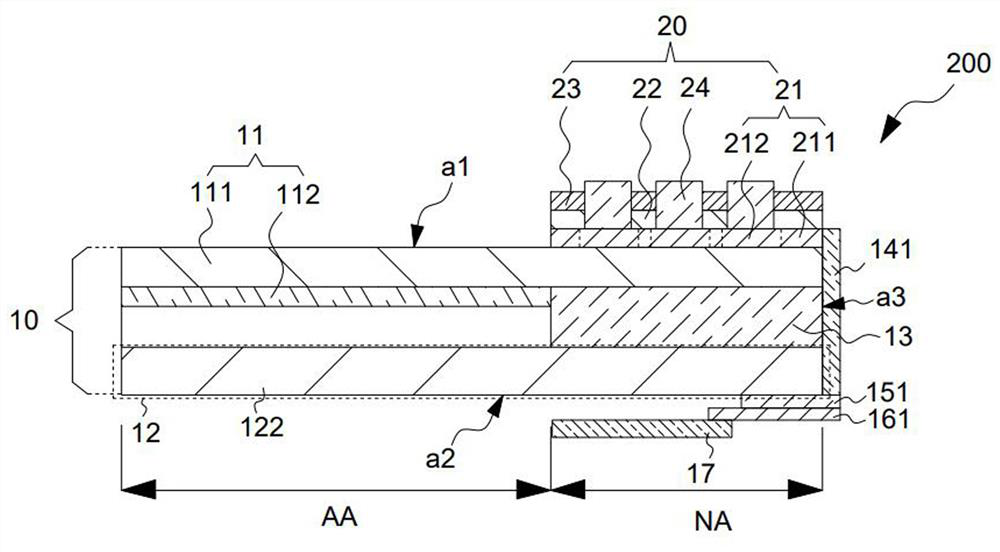

Image collector and fingerprint collection device

InactiveCN107437055AThinningThe production process is simplePrint image acquisitionFingerprintBlock layer

The invention provides an image collector and a fingerprint collection device. The fingerprint collection device comprises a transparent cover plate, an image sensor disposed below the transparent cover plate, and a light-blocking layer disposed on the upper surface of the transparent cover plate; a plurality of light transmitting holes are formed in the light blocking layer; the image-side field of view lambda of the light transmitting holes is equal to arcsin (n1 / n2), wherein n2 is larger than n1; and a distance d between the centers of the adjacent light transmitting holes is greater than or equal to the diameter Dimage of the image-side field of view of the light transmitting holes. According to the image collector of the invention, the size of the image-side field of view of the light transmitting holes is limited through transparent media with different refractive indexes; since the thickness of the light blocking layer for carrying the light transmitting holes is far more smaller than the thickness of the field of view diaphragm of light sensing picture elements, so that the thickness of the image collector provided by the invention can be greatly decreased; since an etching processing for obtaining the light transmitting holes in the light-blocking layer is simple than the manufacturing process of a field of view diaphragm, the image collector provided by the invention is simple in manufacture and low in cost.

Owner:渭南印象认知技术有限公司

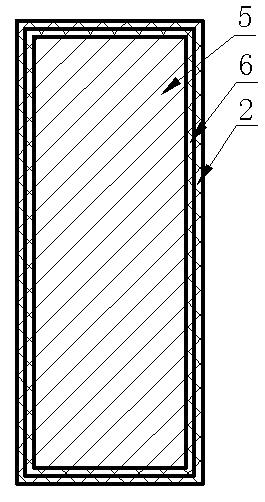

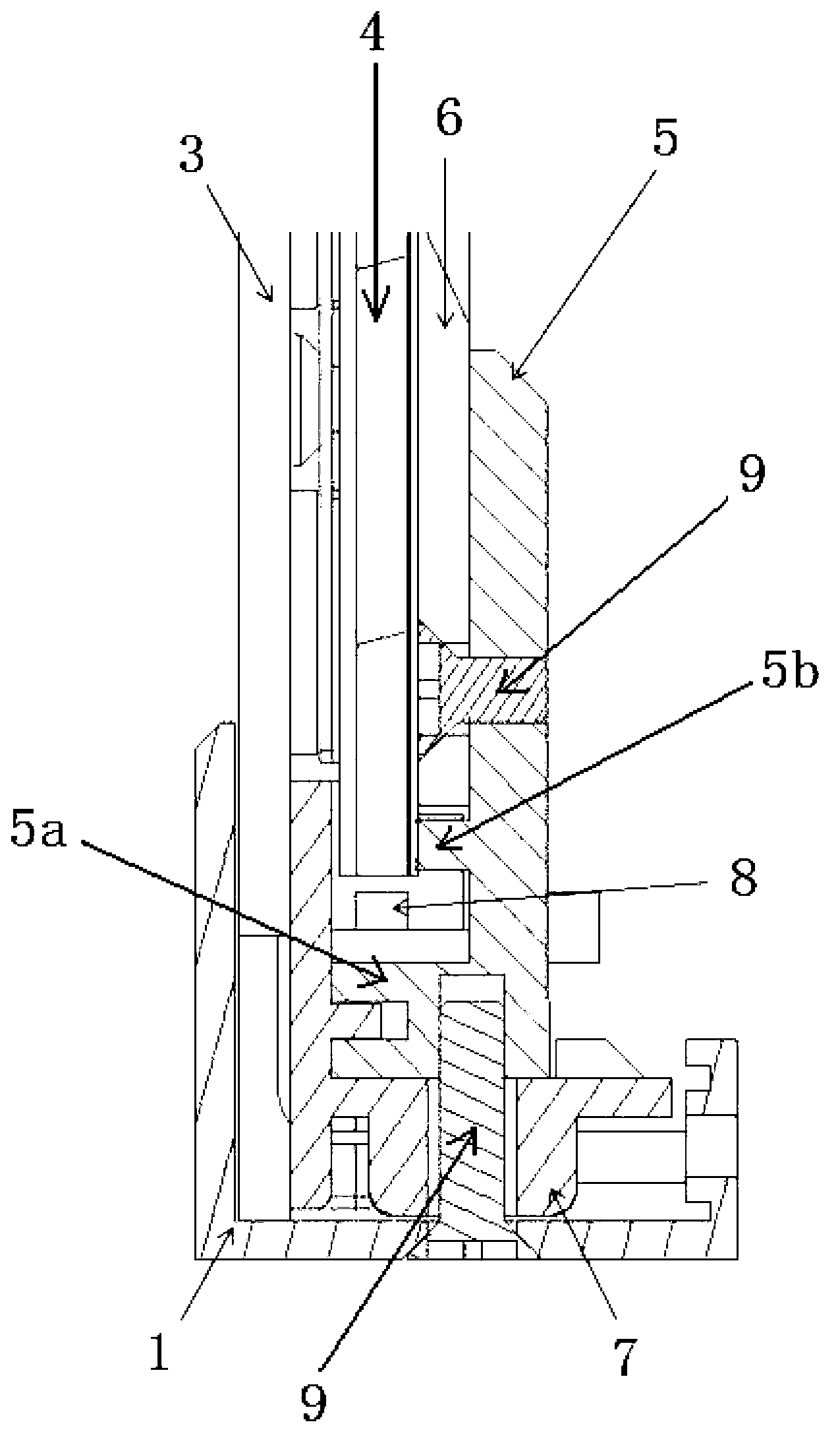

Insulating structure for 2MW wind driven generator

InactiveCN102185407AImprove electromechanical performanceThinningWindings insulation shape/form/constructionApplying solid insulationWind drivenVacuum pressure

The invention discloses an insulating structure for a 2MW wind driven generator. The insulating structure comprises a stator iron core, a rotor iron core, stator coils (3) embedded in the stator iron core, rotor coils (5) embedded in the rotor iron core, a mica tape coated and wound on the stator coils (3), nickel hydrazine nitrate (NHN) insulation (1) and a mica tap coated and wound on the rotor coils (5); inter-turn pads (4) are arranged among the stator coils (3); the stator iron core, the stator coils (3), the mica taps and the NHN insulation (1) are bonded together through solvent-free impregnated resin and vacuum pressure impregnation; and the rotor iron core, the rotor coils (5) and the mica tapes are bonded together through the solvent-free impregnated resin and the vacuum pressure impregnation. The invention has the advantages that: the electromechanical properties of the insulating structure can be improved, the aging speed of the insulating structure is slowed down, the service life of the insulating structure is long, the production cost is greatly reduced, and the problem of inter-turn insulation impact caused by a frequency converter is solved.

Owner:DONGFANG ELECTRIC CORPLESHAN NEW ENERGY EQUIP

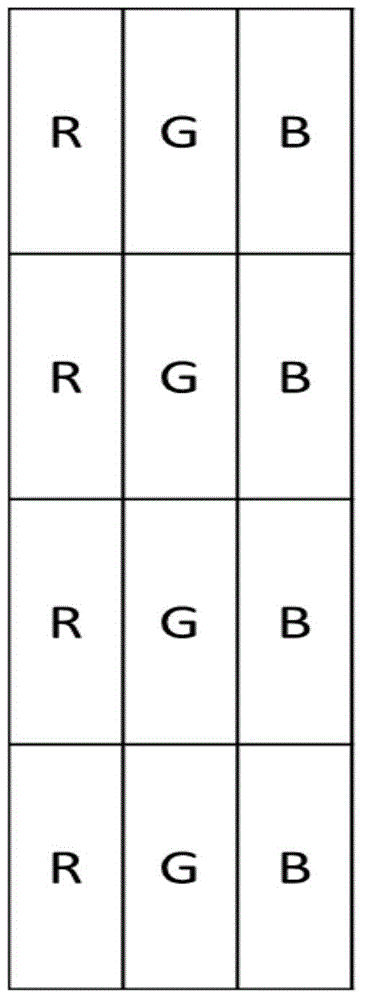

Liquid crystal composition, liquid crystal display panel and preparation method thereof

InactiveCN102876334AThinningReduce the driving voltageLiquid crystal compositionsNon-linear opticsEngineeringMolecular physics

The invention relates to a liquid crystal display panel, which comprises a first substrate, a second substrate, a liquid crystal molecular layer, a first liquid crystal cell layer and a second liquid crystal cell layer, wherein the second substrate is opposite to the first substrate; the liquid crystal molecular layer is provided with a plurality of liquid crystal molecules and arranged between the first substrate and the second substrate; the first liquid crystal cell layer is provided with a plurality of first liquid crystal cells and arranged between the first substrate and the liquid crystal molecular layer; and the second liquid crystal cell layer is provided with a plurality of second liquid crystal cells and arranged between the second substrate and the liquid crystal molecular layer. Besides, the invention also discloses a liquid crystal composition and a method for manufacturing the liquid crystal display panel. By the liquid crystal composition, the liquid crystal display panel is low in driving voltage, is thick and has good optical property; and by the manufacturing method, the liquid crystal display panel is high in yield and low in manufacturing cost.

Owner:CPT TECH GRP +1

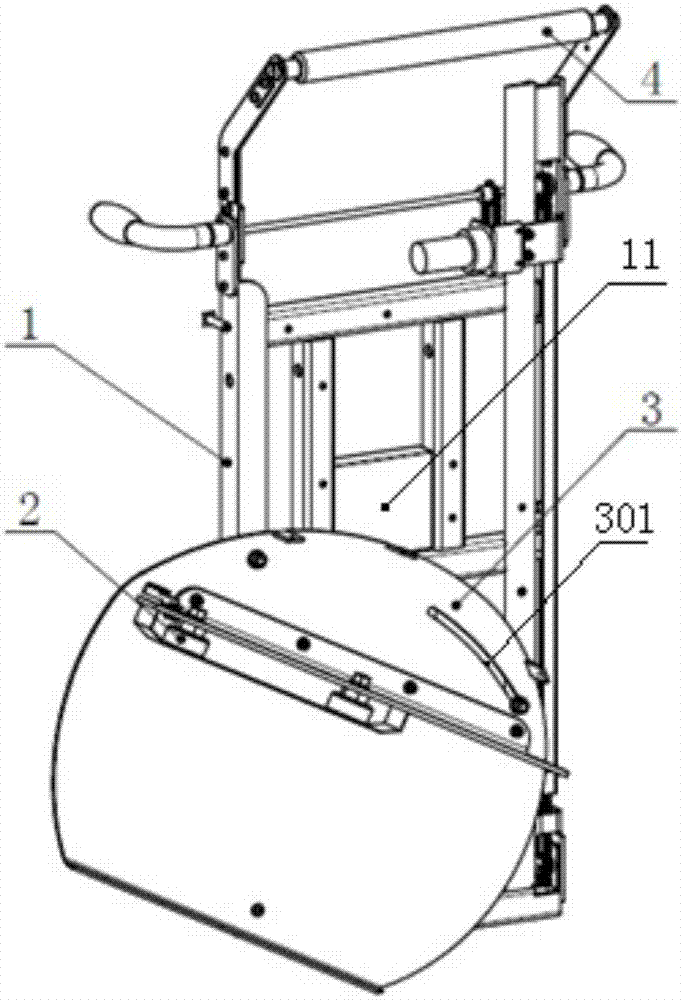

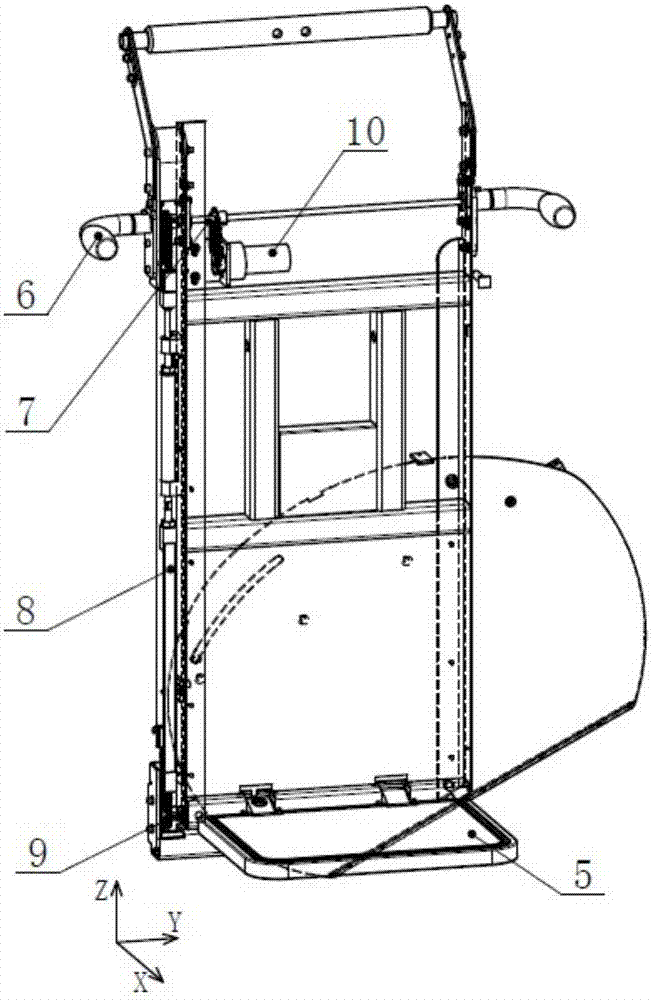

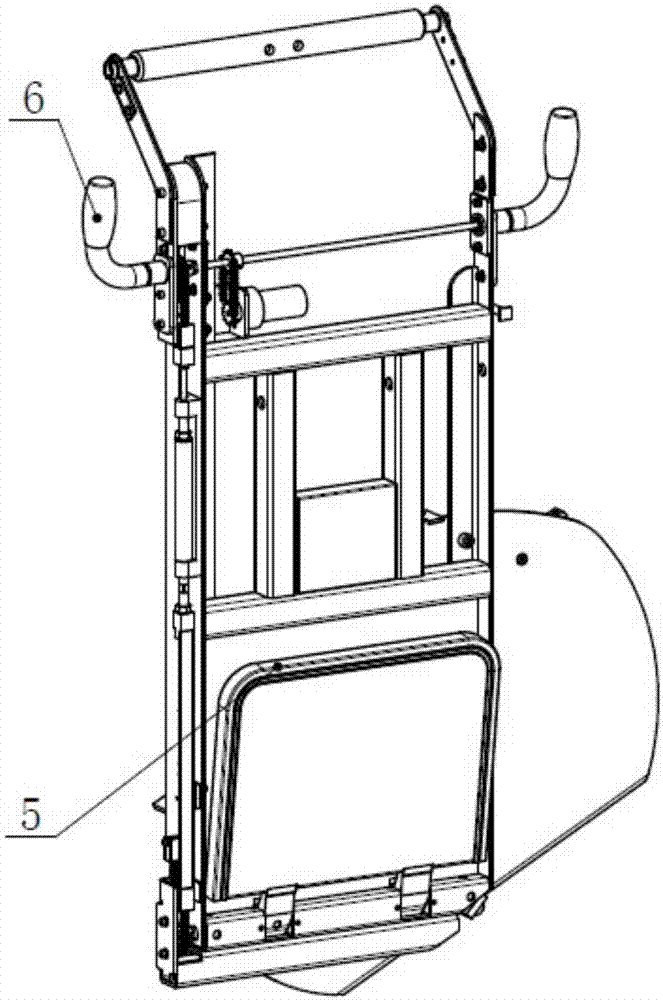

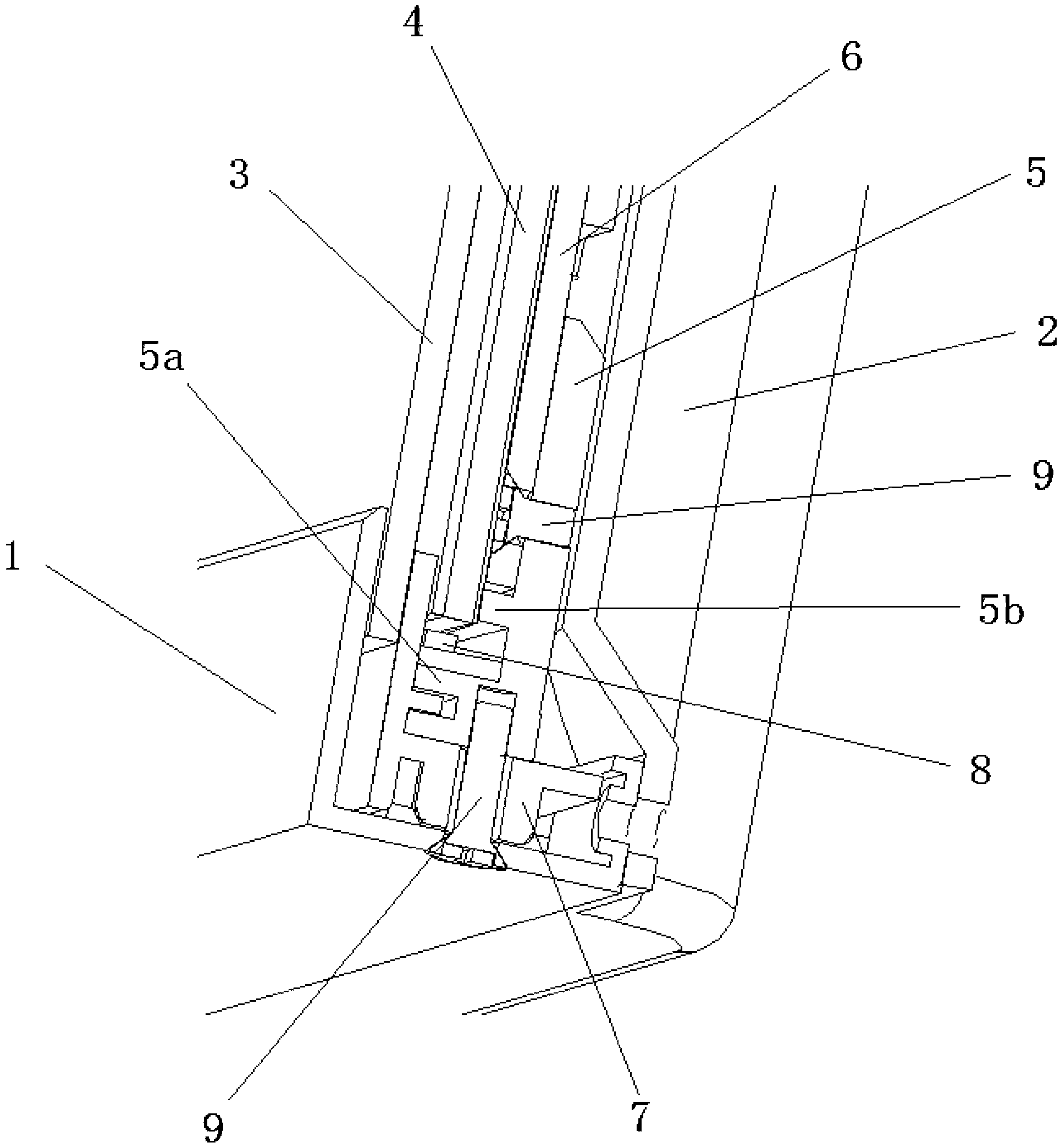

Bearing trolley applied to intelligent passageway moving device

The invention discloses a bearing trolley applied to an intelligent passageway moving device. The bearing trolley comprises a trolley frame, a balance plate, a roller train used for being assembled with a guide rail and a handrail used for being held, wherein the roller train is fixed to the balance plate, an angle adjusting mechanism is arranged on the balance plate, the balance plate is rigidly connected with the trolley frame through the angle adjusting mechanism, angles of the guide rail and the trolley frame are adjusted by the angle adjusting mechanism, a pedal capable of being folded upwards is arranged at the bottom of the trolley frame, and the pedal is hinged to the trolley frame. According to the bearing trolley disclosed by the invention, a roller assembly and the trolley frame are designed separately in a block mode, the angles of the guide rail and the trolley frame can be adjusted by the angle adjusting mechanism of the balance plate, the trolley frame and the unfolded pedal can keep horizontal, and the roller assembly can move on guide rails with different angles to be adaptive to different stair angles at the same time; furthermore, the bearing trolley has higher universality, small passageway space occupancy and a simplified structure; the pedal is thinner and light and convenient to fold, so that passageway space occupancy is further reduced.

Owner:NANJING KANGNI MECHANICAL & ELECTRICAL

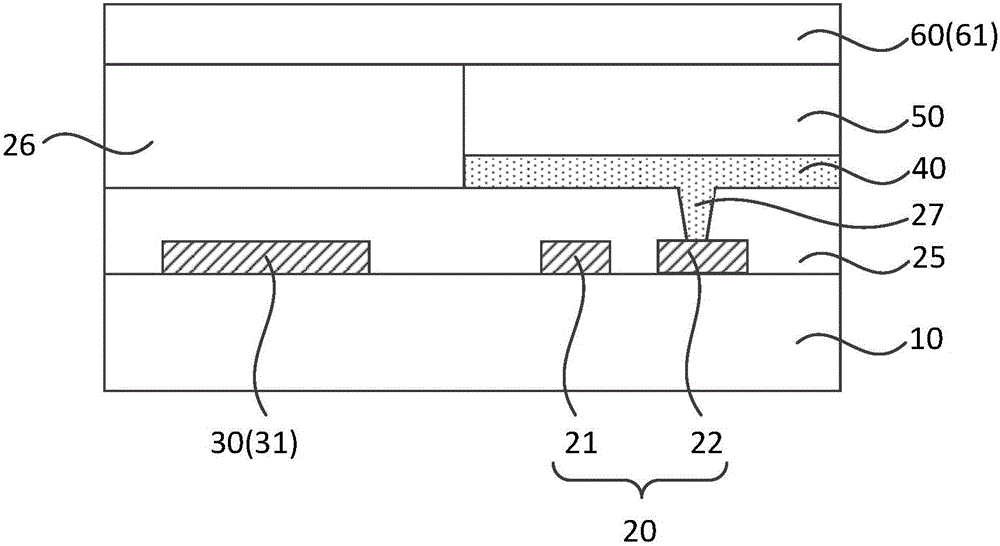

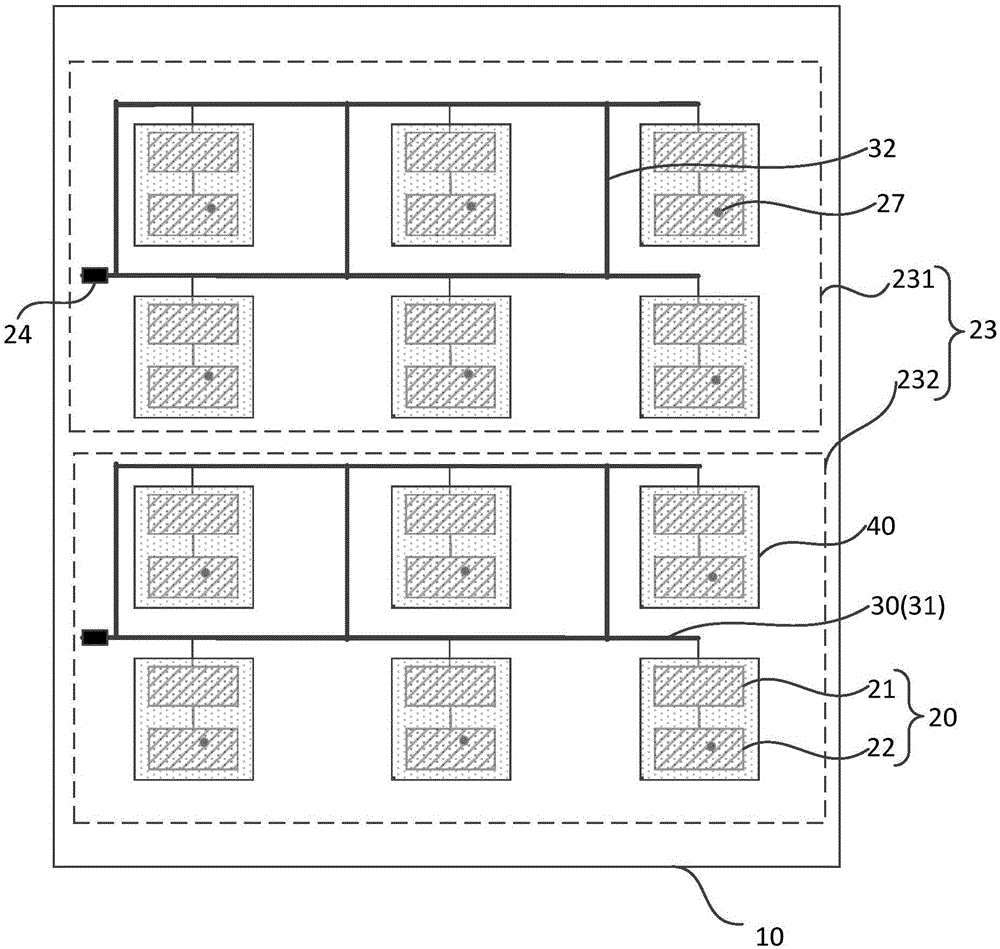

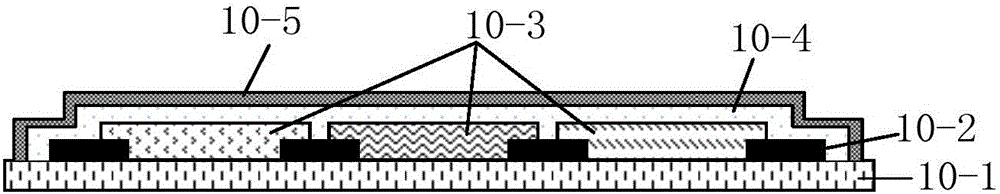

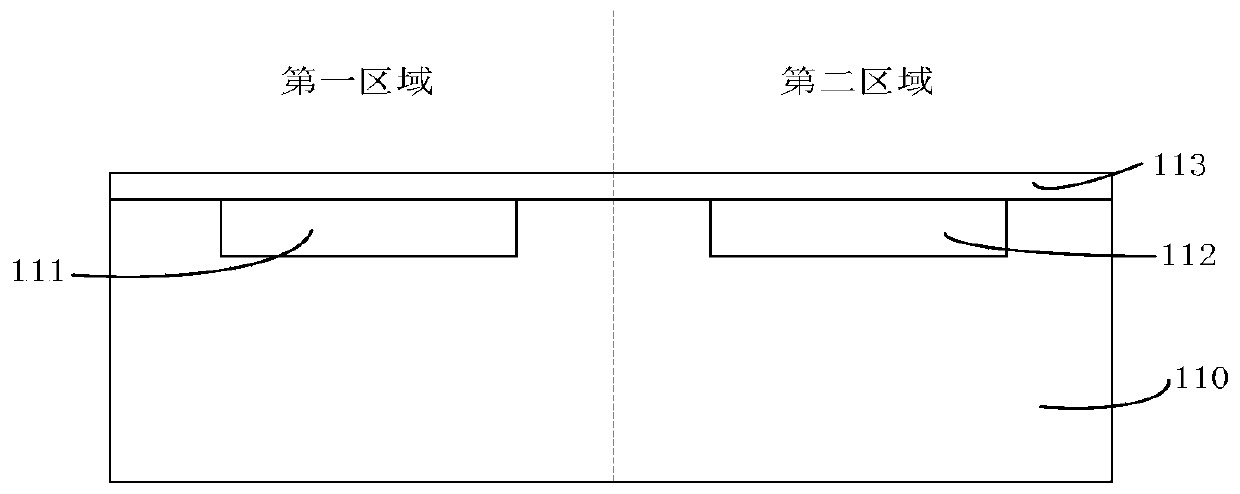

COA substrate and preparation method thereof as well as display device

InactiveCN105137648AThinningRealize thinner and lighterOptical filtersNon-linear opticsQuantum dotQuantum

The invention provides a COA substrate and a preparation method thereof as well as a display device, belonging to the technical field of display and solving the problem that the existing display device is relatively thick. The COA substrate provided by the invention comprises an array substrate, a colored optical filter layer which is arranged at the light emitting surface side of the array substrate, wherein the colored optical filter layer comprises optical filters with different colors, and the optical filters are prepared from quantum dot materials; quantum dots have orientation and are used for converting natural light into polarized light. As the optical filters of the colored optical filter layer of the COA substrate are prepared from the quantum dot materials, the quantum dots have orientation, and can be used for converting the natural light into the polarized light, so that the COA substrate is applied to a display panel, a polarizing film is not needed at the moment, so that the thickness of the display panel is reduced, and further, the lightness and thinness of the display device can be realized.

Owner:BOE TECH GRP CO LTD +1

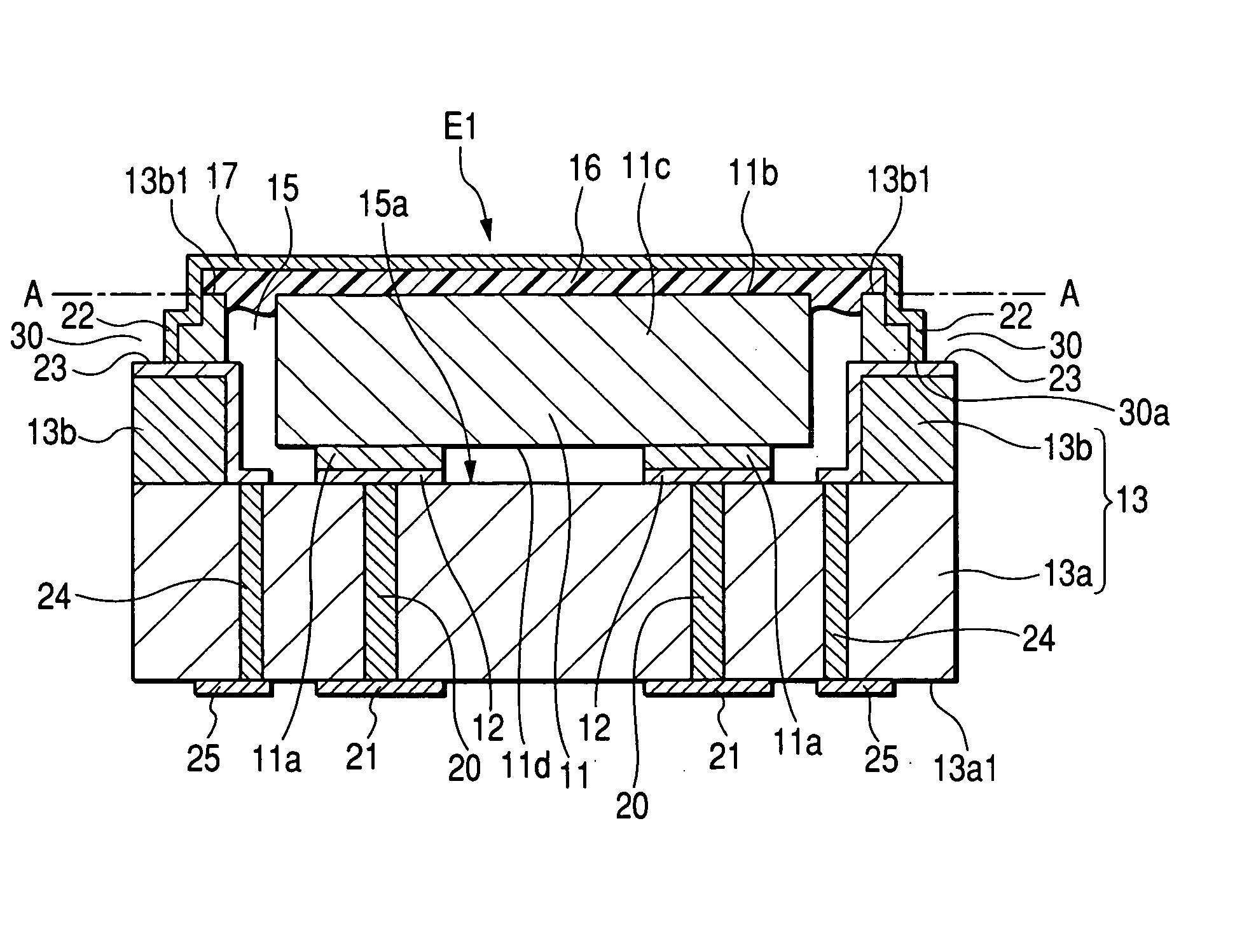

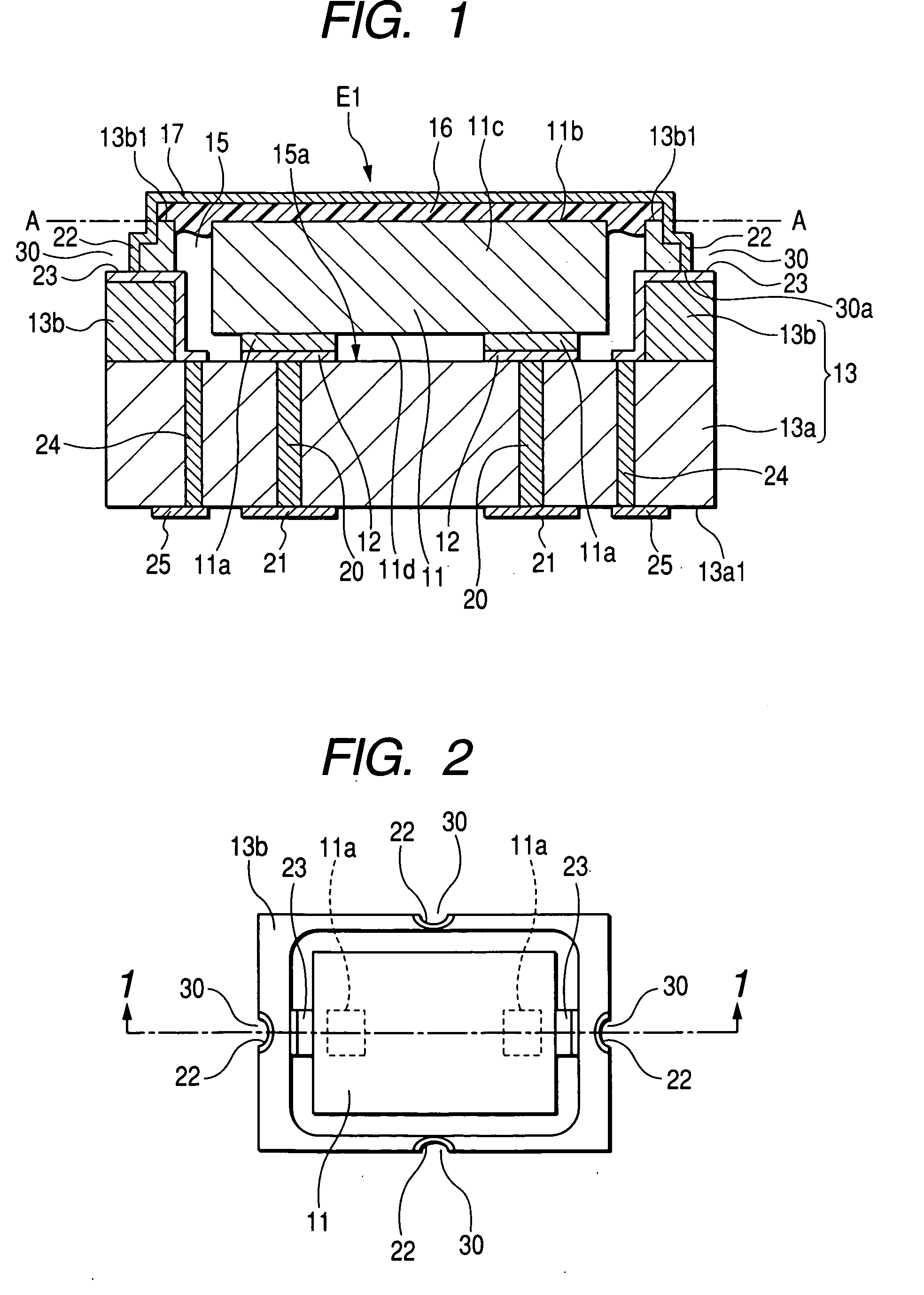

Rotating device

InactiveUS20140036391A1ThinningMaintaining and improving bearing rigidityShaftsRecord information storageAir liquid interfaceEngineering

A rotating device includes a sleeve which encircles a shaft, a housing which supports the shaft and which forms an annular supporting recess where the lower end of the sleeve enters together with the shaft, a ring member which is provided above the sleeve and which is fixed to the shaft in a manner encircling the shaft. A first gap between the sleeve and the shaft includes first and second radial dynamic pressure generating portions. An annular sleeve recess is formed in upper face of the sleeve. The ring member includes a ring entering portion that enters the sleeve recess in a non-contact manner. An outward gap in the radial direction where the ring entering portion and the sleeve recess face with each other in the radial direction includes a second air-liquid interface of a lubricant.

Owner:SAMSUNG ELECTRO MECHANICS JAPAN ADVANCED TECHNOLOGY CO LTD

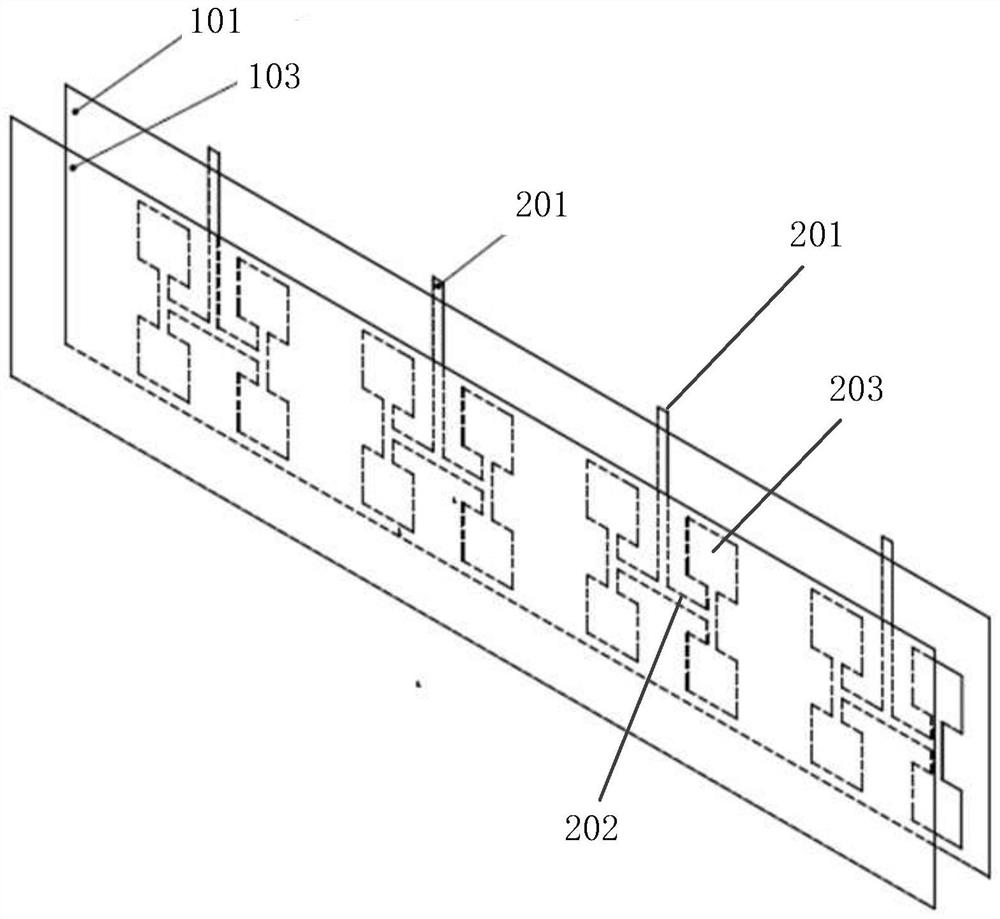

Preparation method for tab-embedded type electrode plate, electrode plate and lithium ion battery

PendingCN106450494AIncrease energy densityThinningFinal product manufactureSecondary cellsEngineeringLithium electrode

The invention discloses a winding type winding. The winding type winding comprises a positive electrode, a negative plate and a diaphragm, wherein the positive plate comprises a positive electrode plate and a positive electrode tab; the negative plate comprises a negative electrode plate and a negative electrode tab; the upper and lower side faces, except reserved blank regions, on the positive electrode plate and the negative electrode plate are both coated with electrode powder; the reserved blank regions are positioned on the edges of the electrode plates, and are corresponding to the positive electrode tab or the negative electrode tab in terms of size; the positive electrode tab or the negative electrode tab is correspondingly welded in the corresponding reserved blank regions; the front and back side surfaces, in the welding position of the positive electrode tab, of the positive electrode plate are correspondingly coated with positive electrode protection adhesive tapes to accommodate the positive electrode reserved blank region therein; and two corresponding adjacent positive electrode plates of the negative electrode tab and adjacent surfaces of the negative electrode tab are coated with negative protection adhesive tapes respectively so as to cover the negative electrode reserved blank region therebetween.

Owner:天津聚元新能源科技有限公司

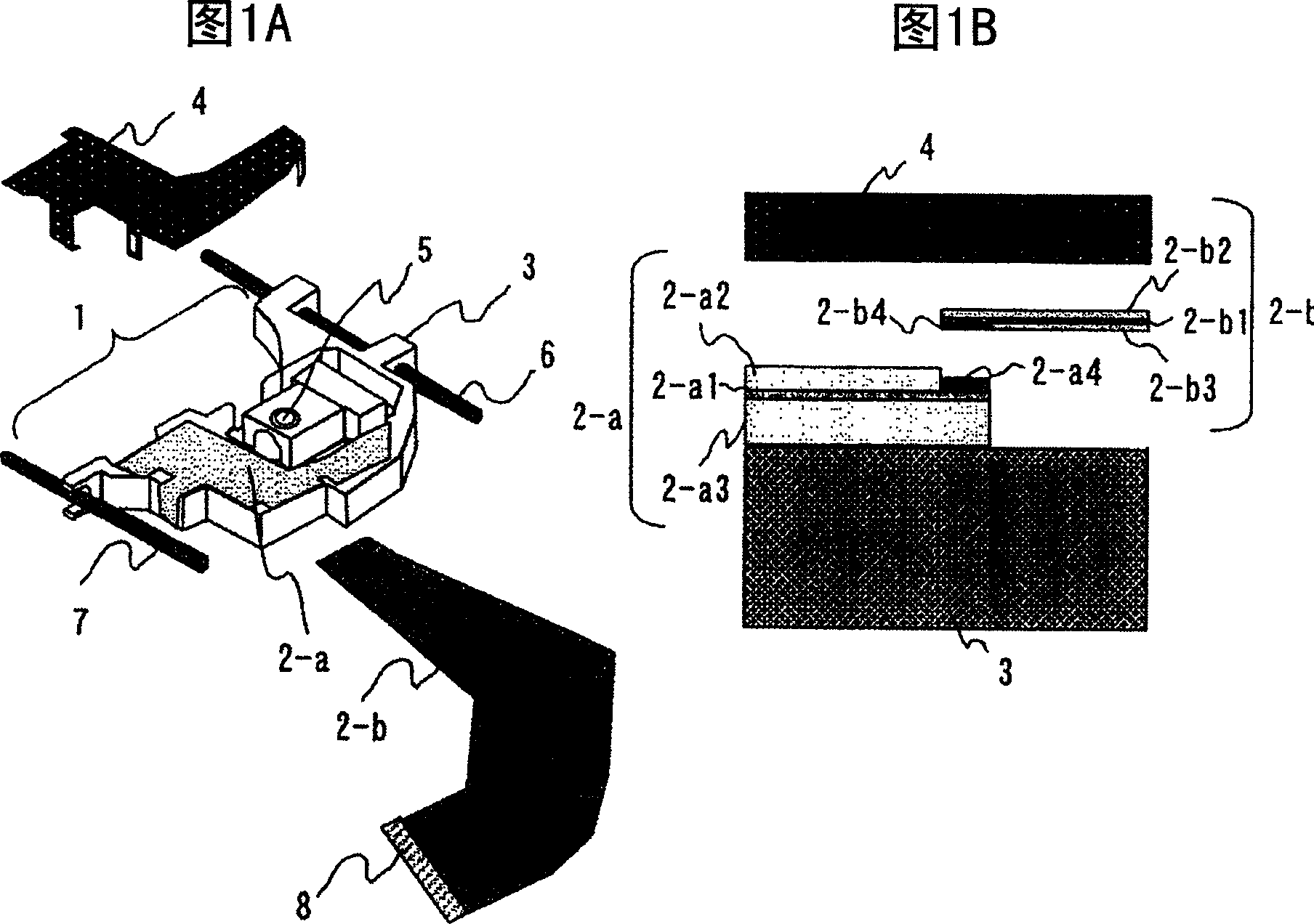

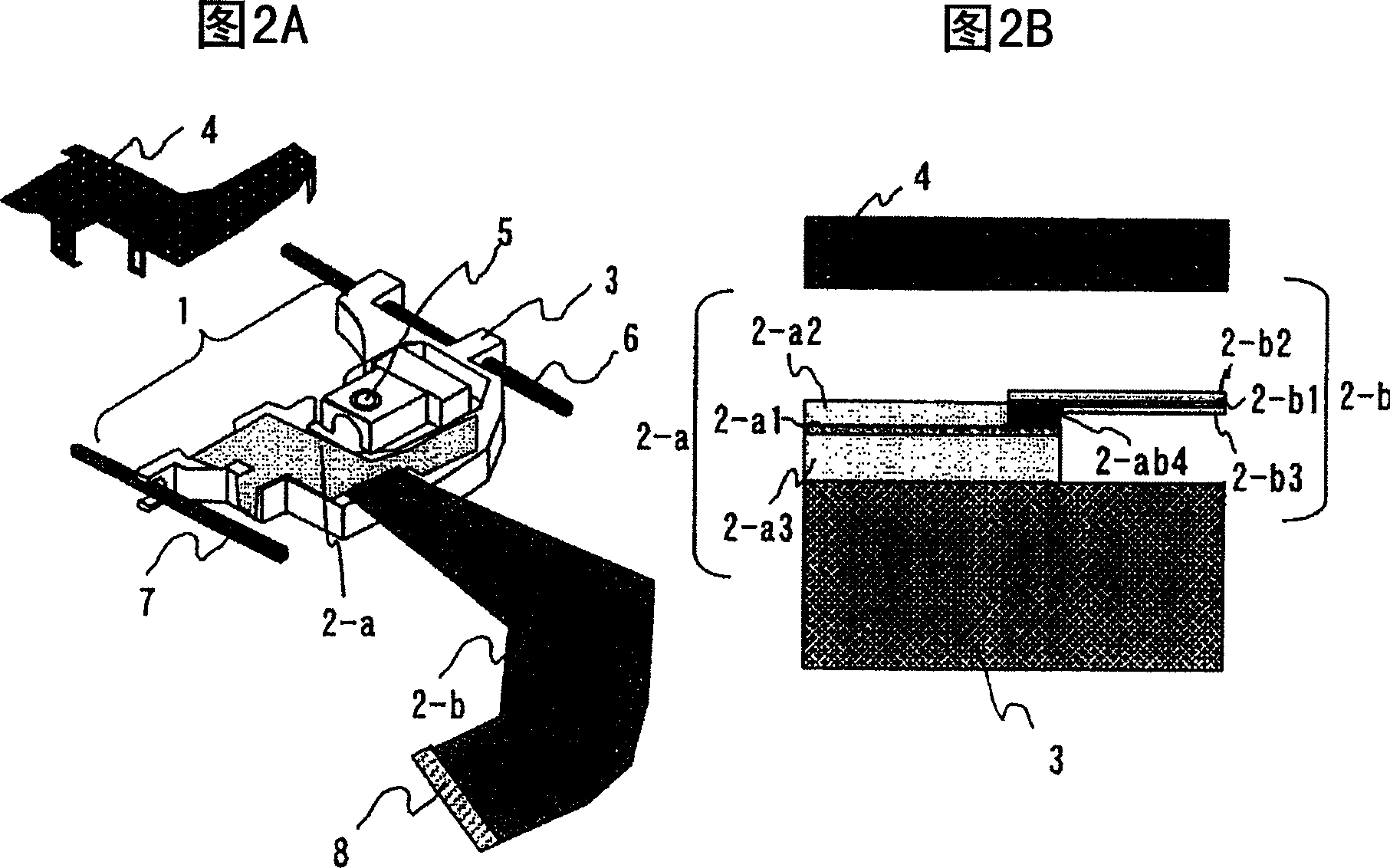

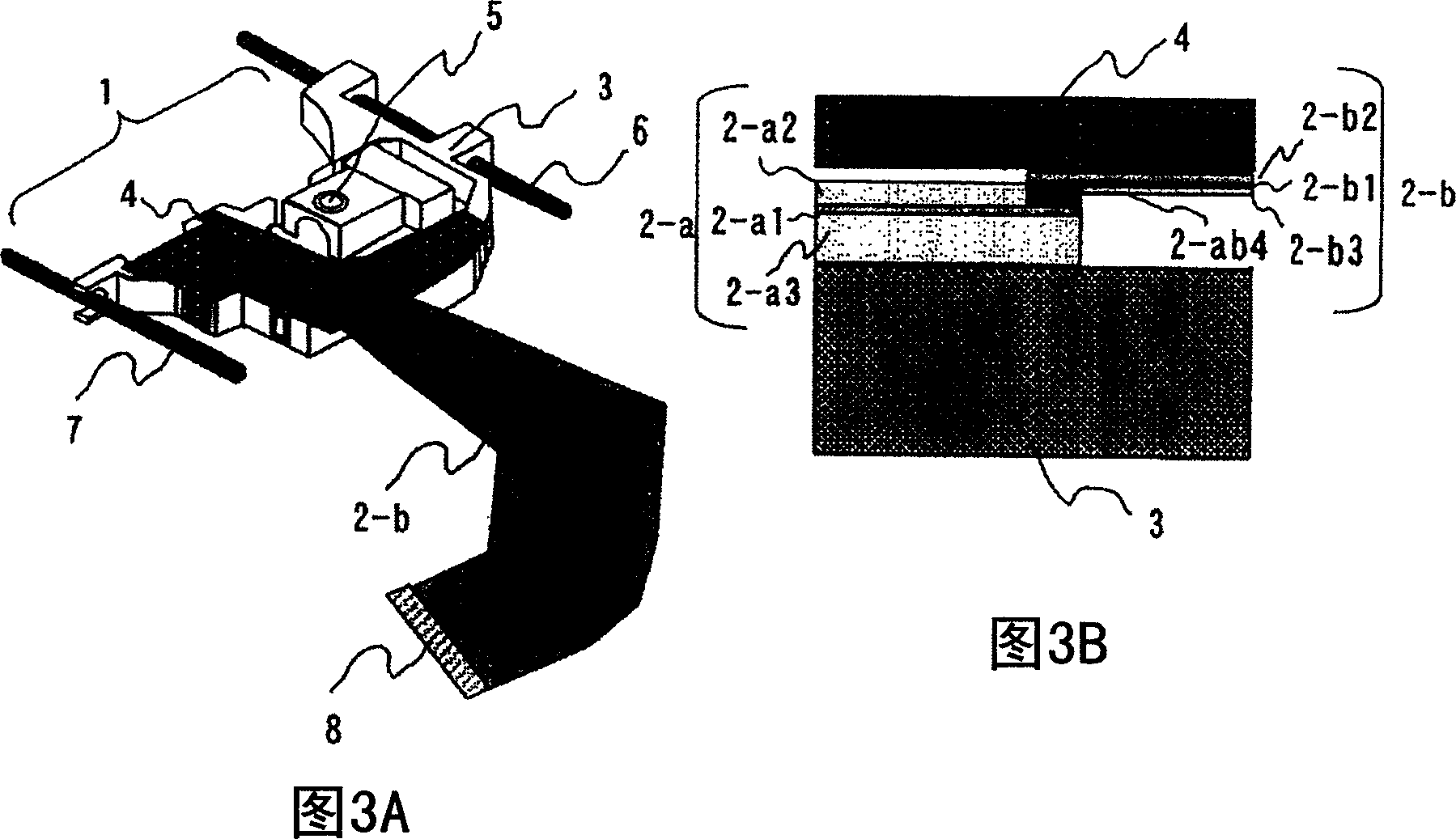

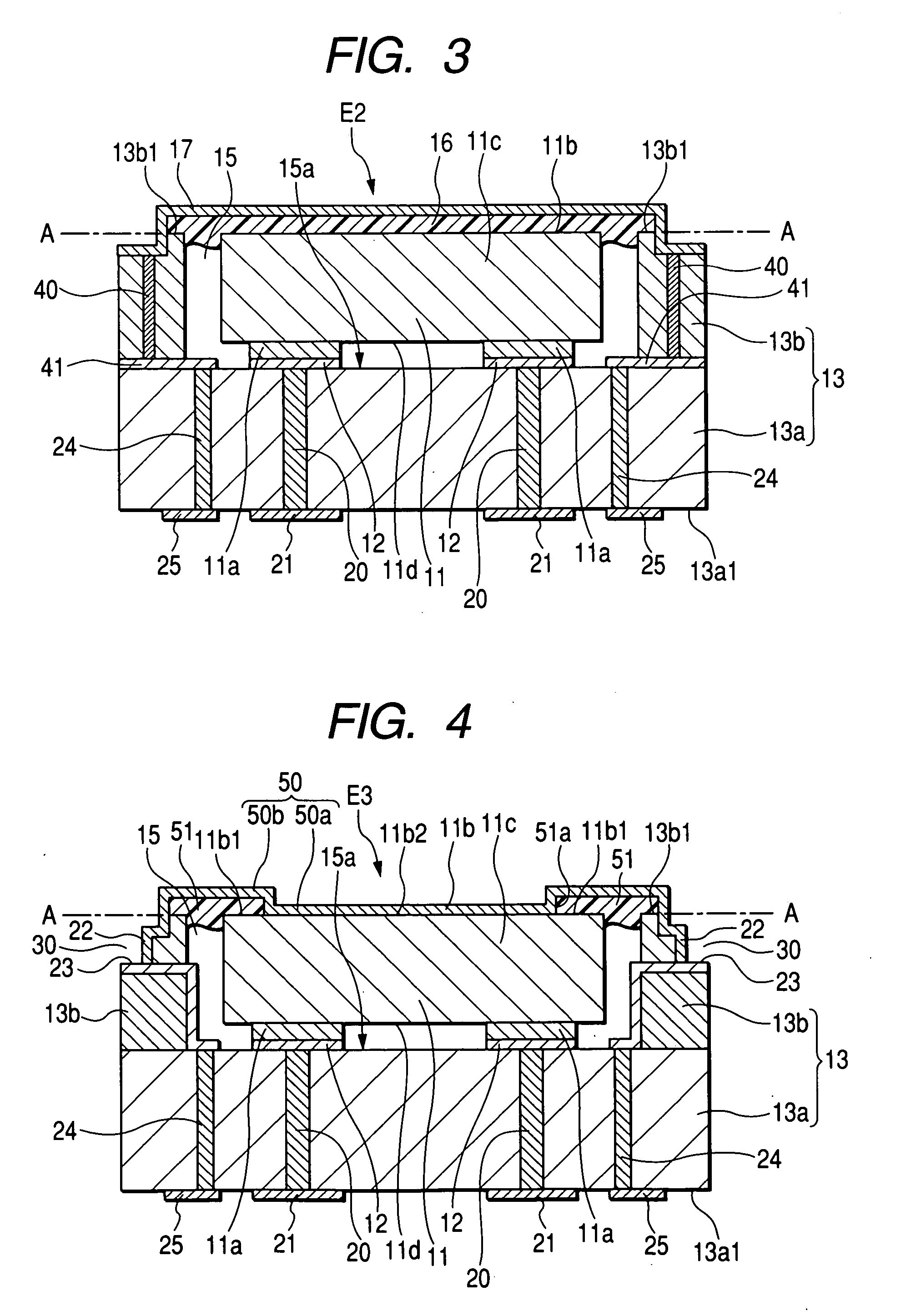

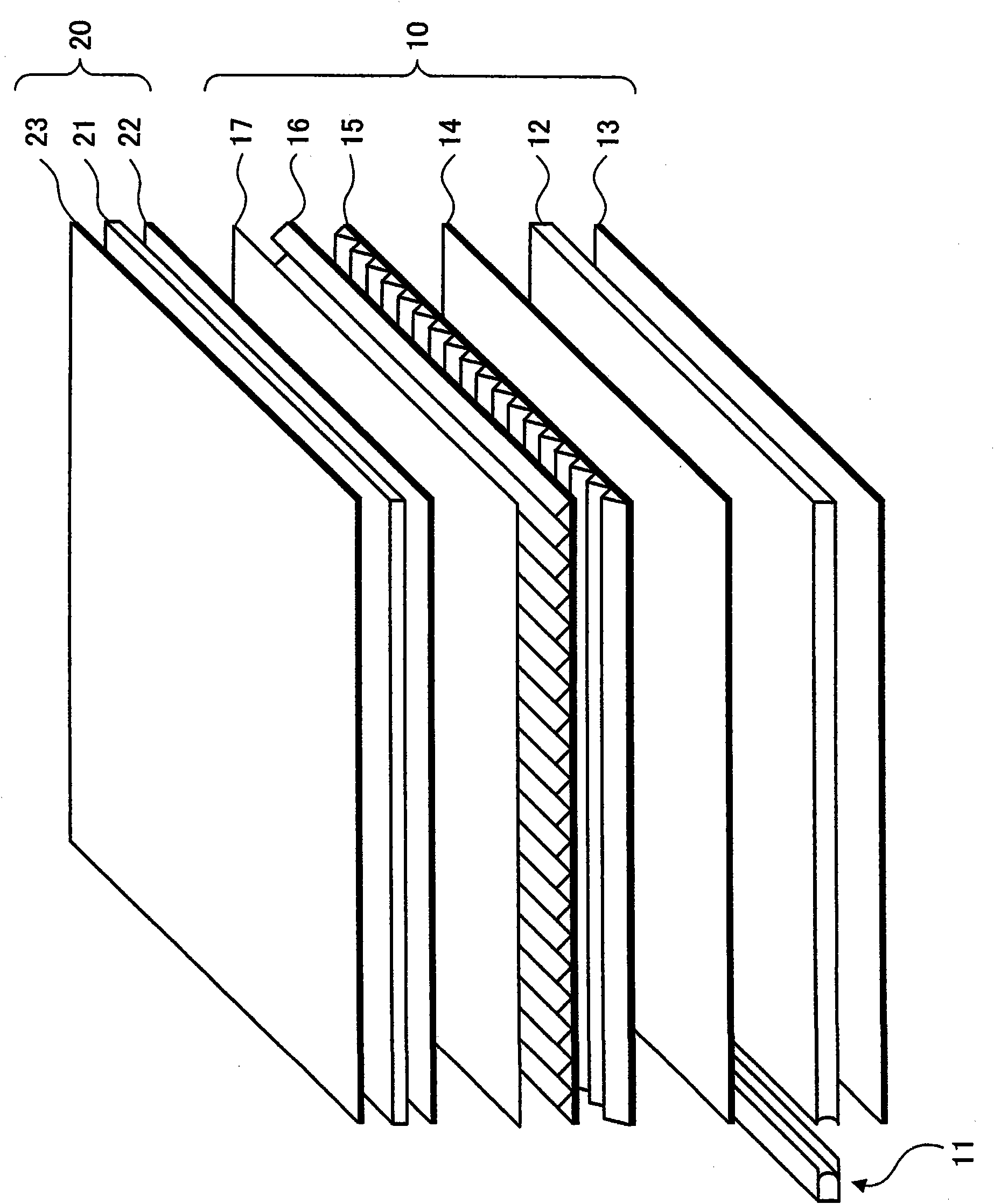

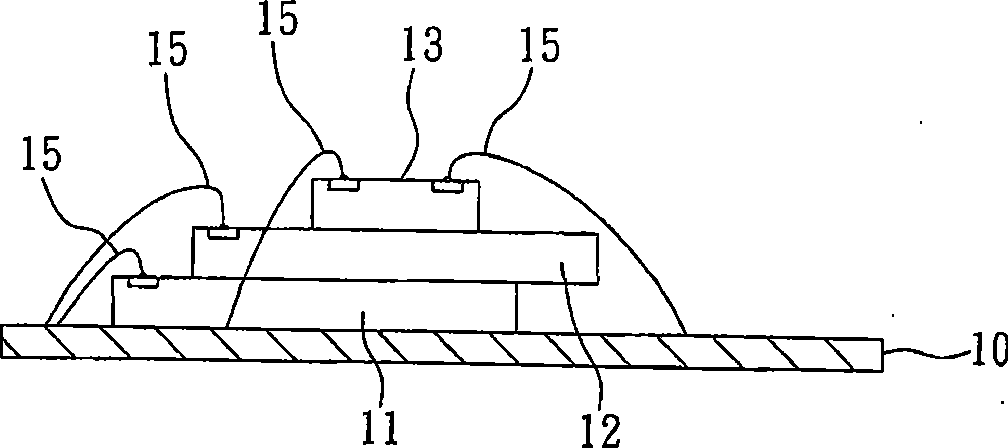

Optical disk drive apparatus

InactiveCN1822135AAchieve thinnerRealize the ability to meet the thinningCoupling device connectionsPrinted circuit aspectsElectrical conductorOptical disc

Owner:HITACHI MEDIA ELECTORONICS CO LTD

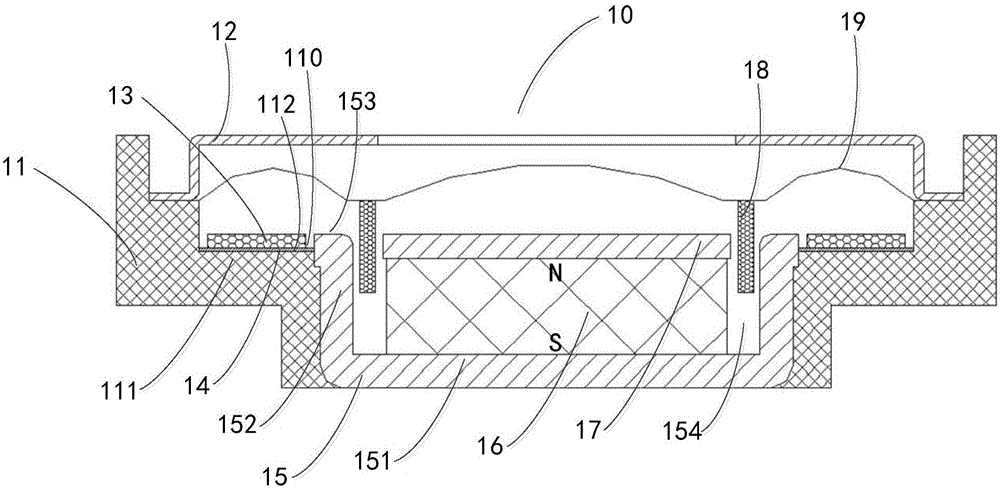

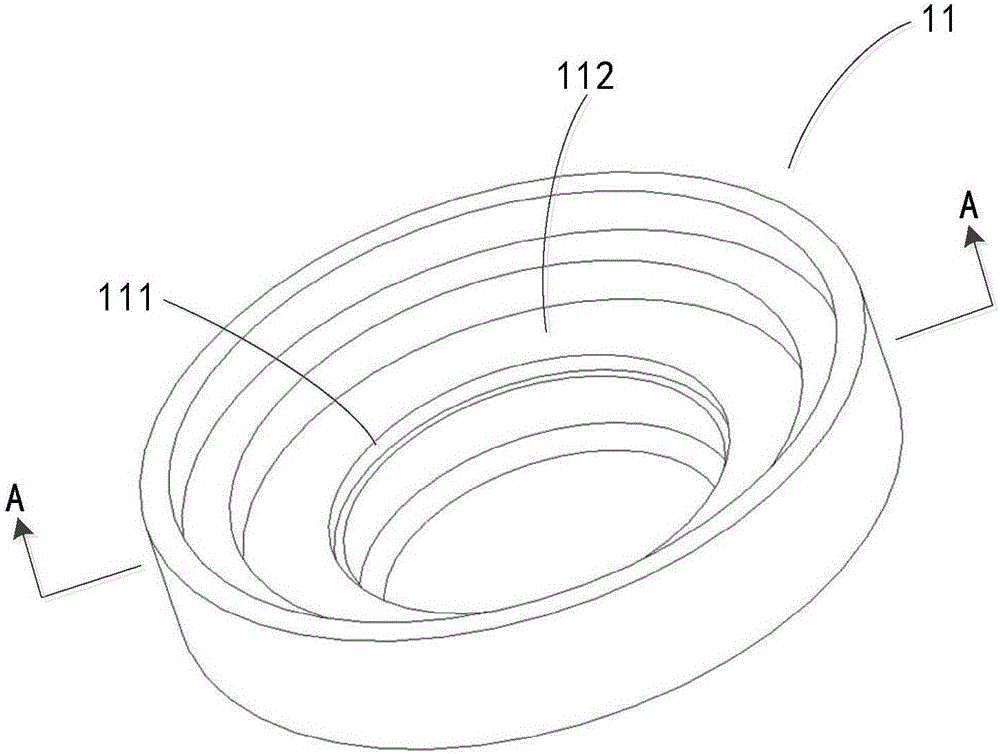

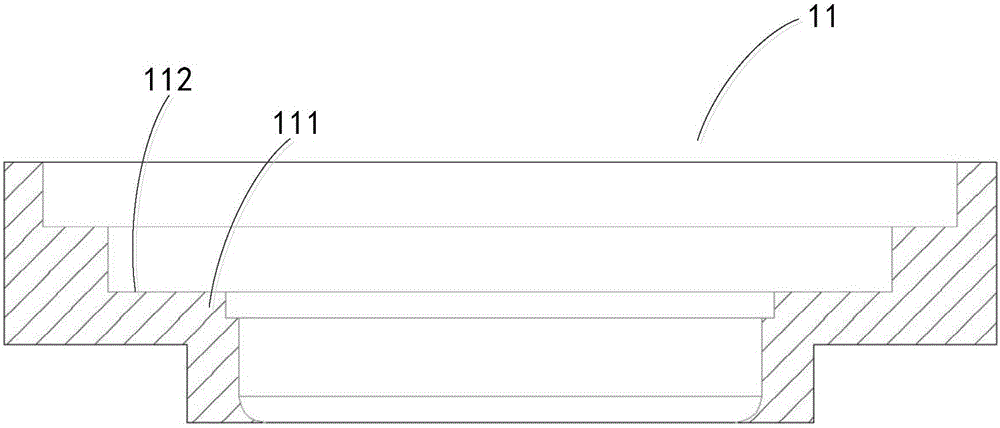

Loudspeaker and terminal

InactiveCN106210997ADoes not increase thicknessReduce thicknessElectrical transducersHearing aidEngineering

The embodiment of the invention provides a loudspeaker. The loudspeaker comprises a hearing-aid coil and a bracket, the bracket is provided with a sunken part, the hearing-aid coil is installed in the sunken part. Through the adoption of the scheme, the hearing-aid coil is installed in the sunken part on the bracket, so that the hearing-aid coil does not occupy the extra space, the thickness of the loudspeaker cannot be increased. Compared with the prior art, the thickness of the loudspeaker can be reduced, the thinning of the terminal of the loudspeaker is facilitated.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

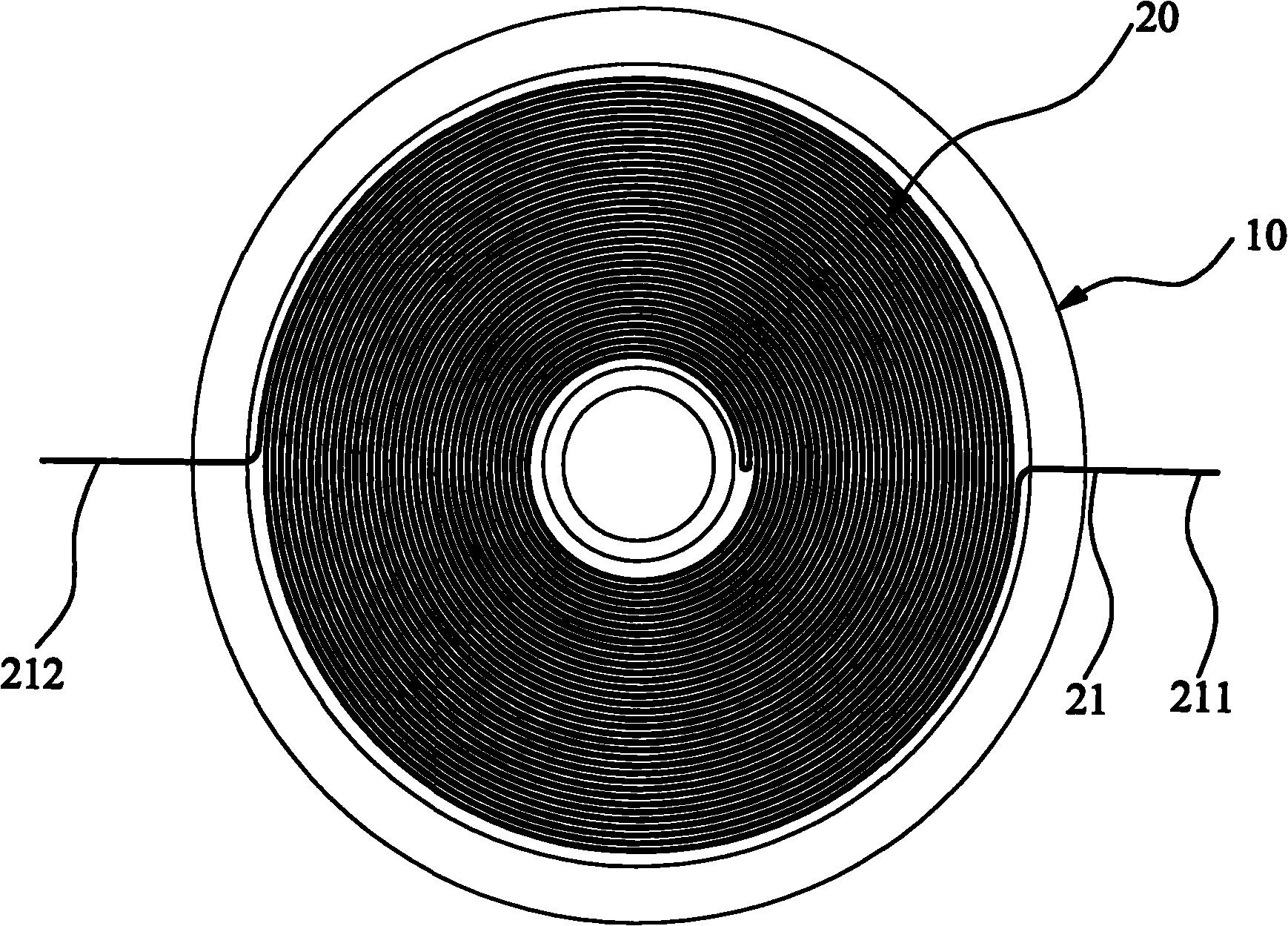

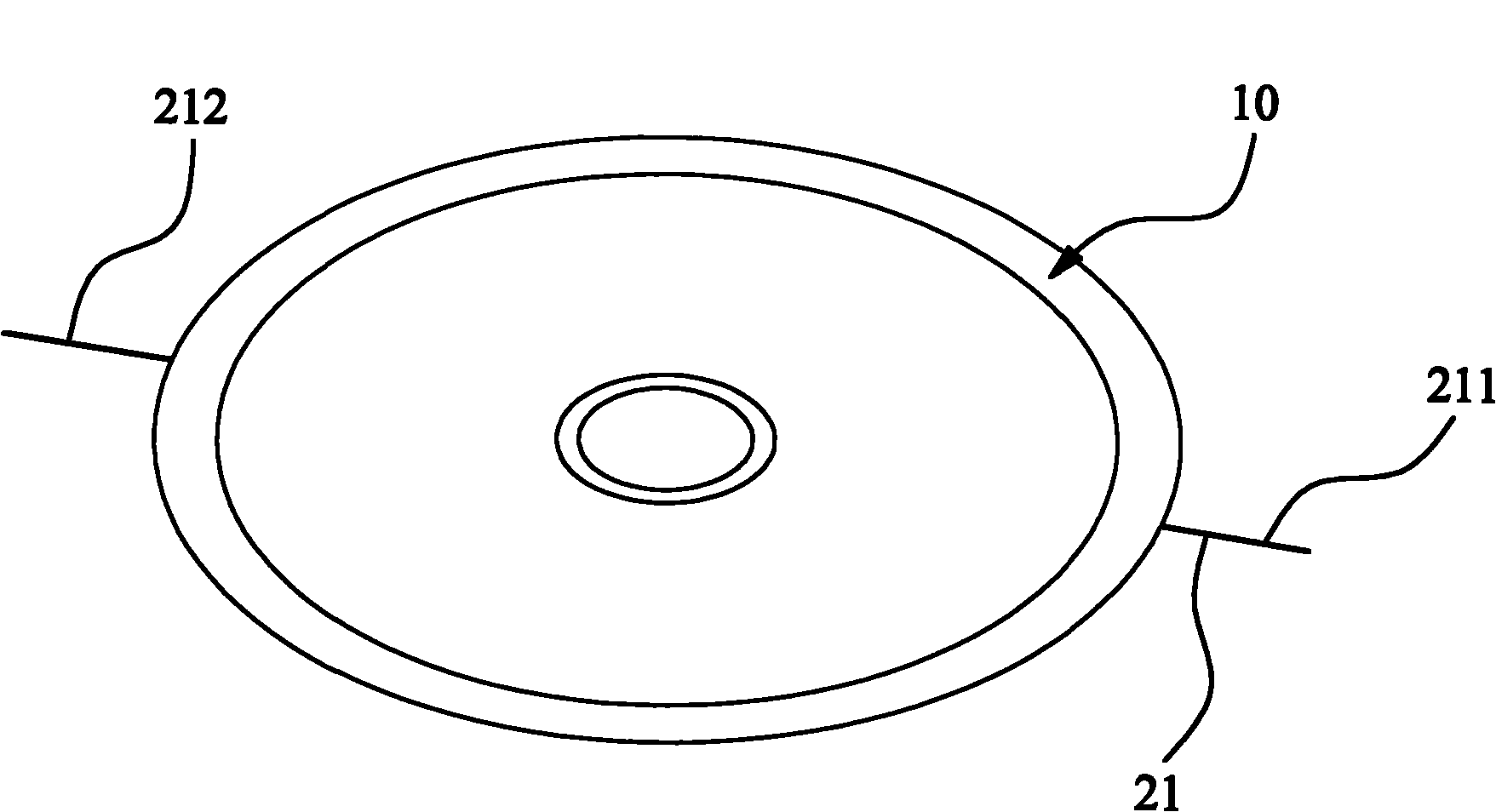

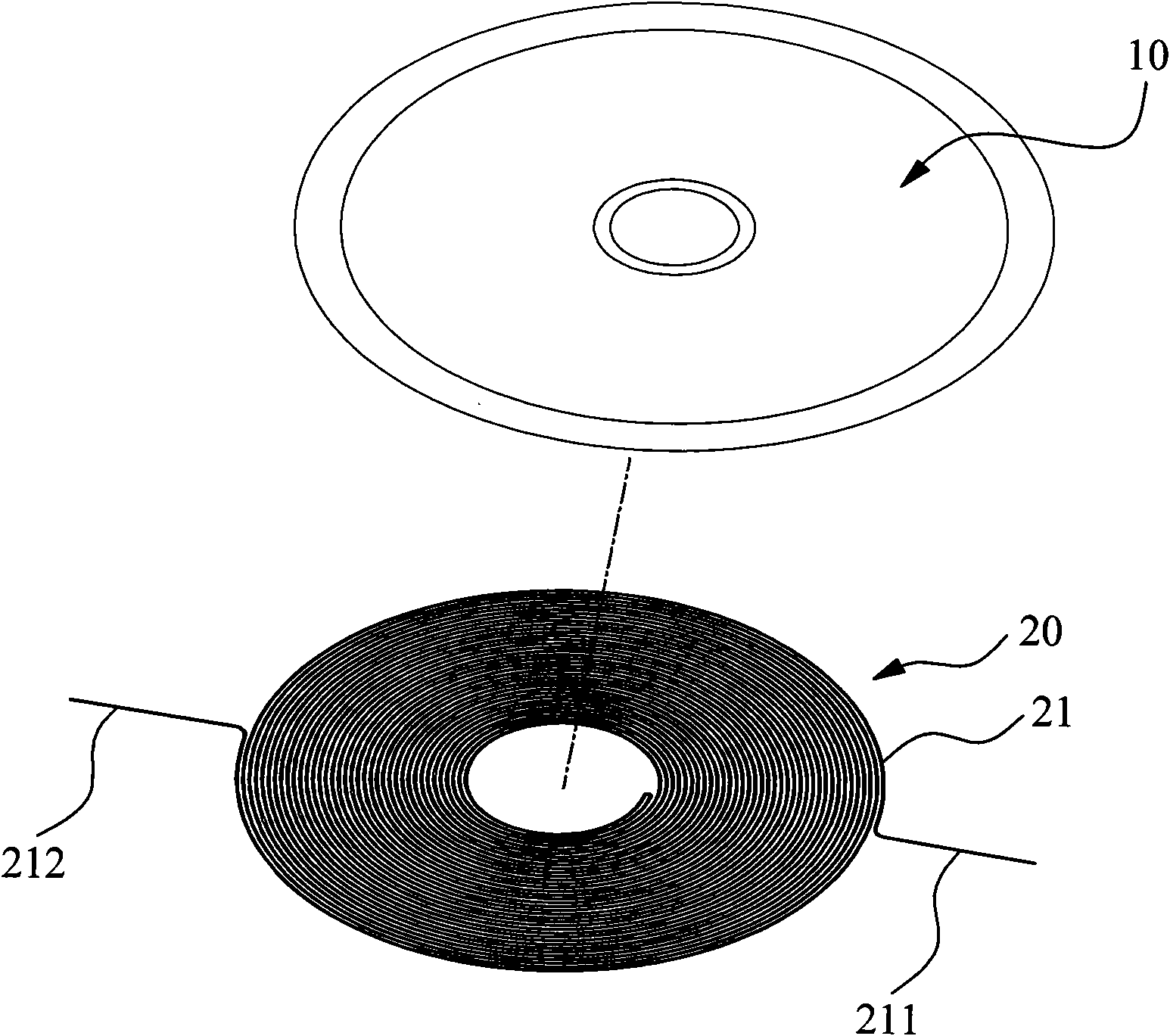

Compound voice diaphragm group

The invention discloses a compound sound film group comprising a voice diaphragm and a voice coil, wherein the voice coil is fixed on one surface of the voice diaphragm, and the voice coil is a plane-type single-layer coil spirally and tightly coiled by an enamelled wire; thereby, the voice diaphragm is formed by the plane-type single-layer coil spirally and tightly coiled by the enamelled wire, and the voice coil is compounded and shaped on the surface of the voice diaphragm; the height of the voice coil depends on the diameter of the enamelled wire so that the overall thickness of the compound sound film group is greatly reduced; simultaneously, gaps do not need to be arranged among magnetic circuits of the voice coil, thus, the contour dimensions of a horn and a receiver can be made smaller so as to meet the demand that electronic products in electronic product markets are miniaturized; moreover, the impedance can be directly and easily regulated according to the coiled number of turns of the coil and the diameter of the enamelled wire and is not limited, which is beneficial to all-frequency band passing and offers powerful support to manufacture the horn or the receiver with better tone quality and frequency response characteristic.

Owner:DONGGUAN TRANSOUND ELECTRONICS

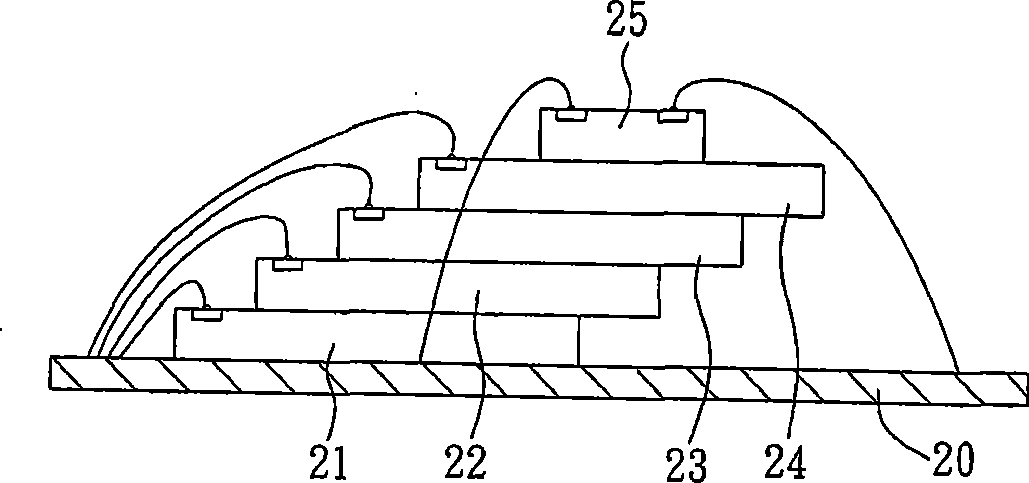

Electronic part and method of manufacturing the same

InactiveUS20050167137A1ThinningThinning electronic partImpedence networksSemiconductor/solid-state device detailsMiniaturizationEngineering

An electronic part which can be miniaturized is provided. A bottom surface of a substrate of an electronic element is positioned on the same virtual plane of an upper surface of a sidewall portion of a case body, and a seal material is covered thereon. Accordingly, a gap between the seal material and the bottom surface of the electronic element is not formed, and thus the electronic part can easily be made thin. Also, since the seal material is formed by a resin, even when positions of the bottom surface of the substrate and an upper surface of the sidewall portion are deviated, the deviation can be easily absorbed.

Owner:ALPS ALPINE CO LTD

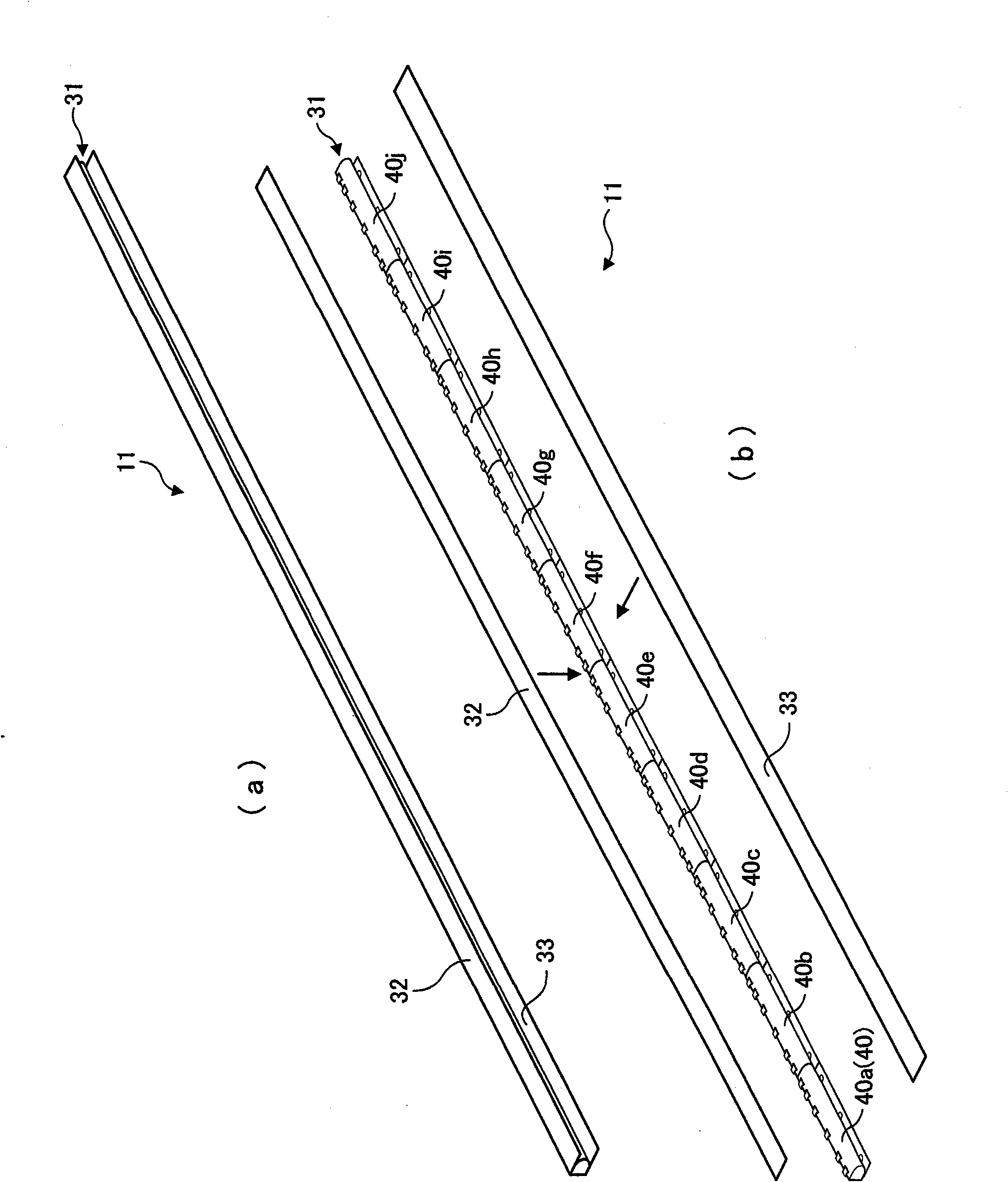

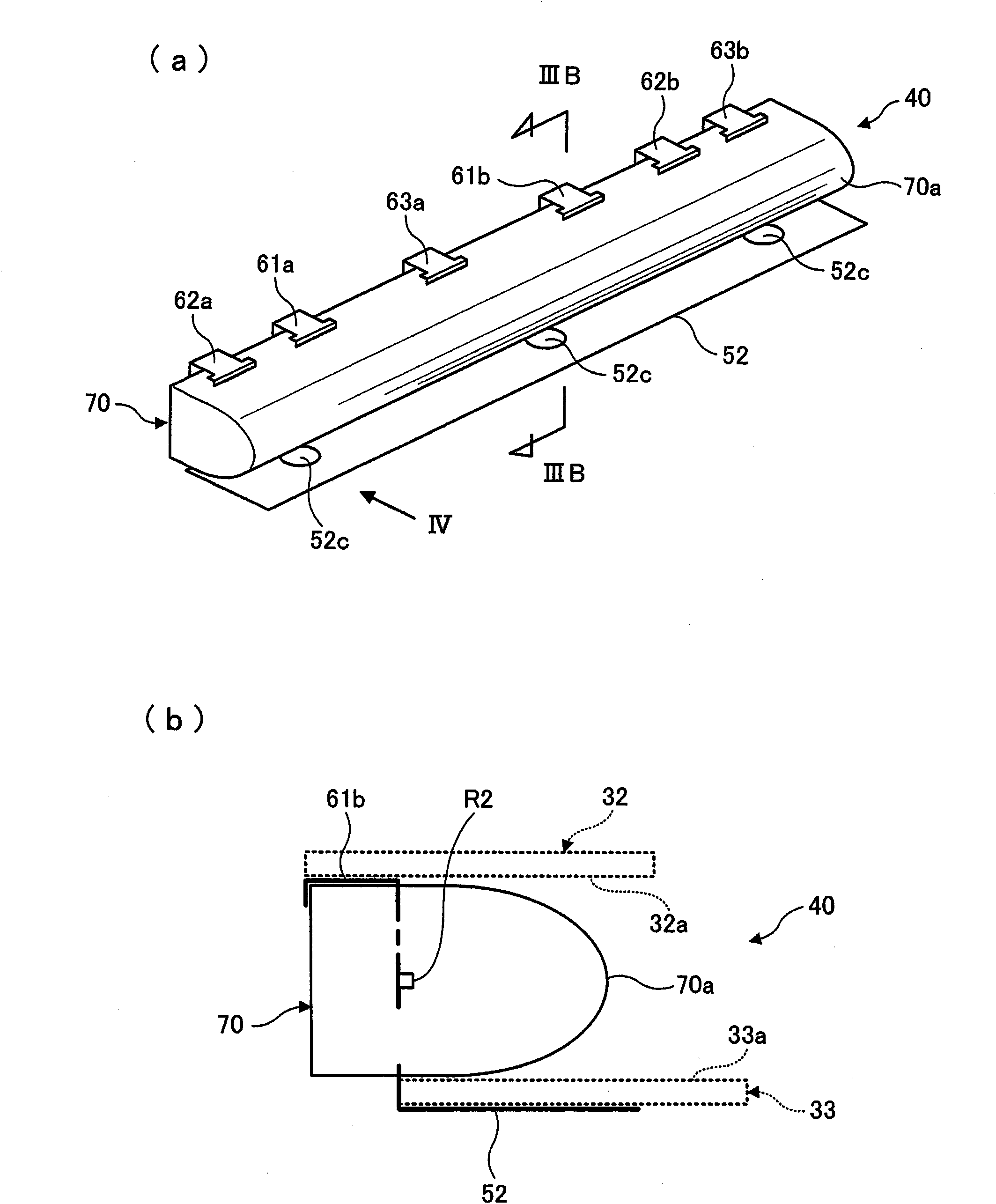

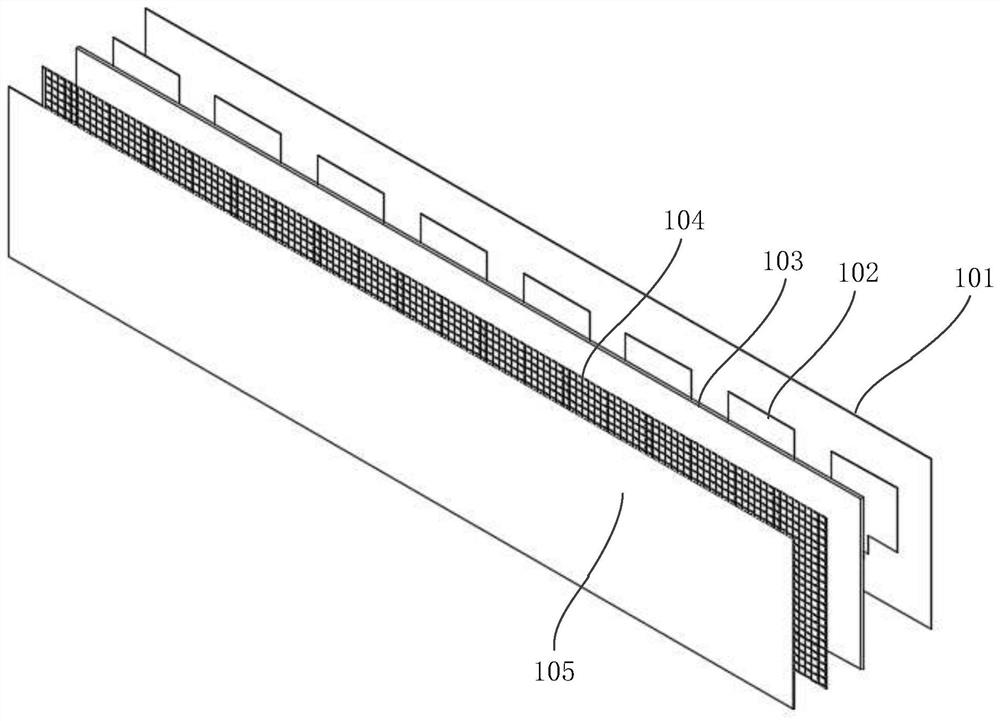

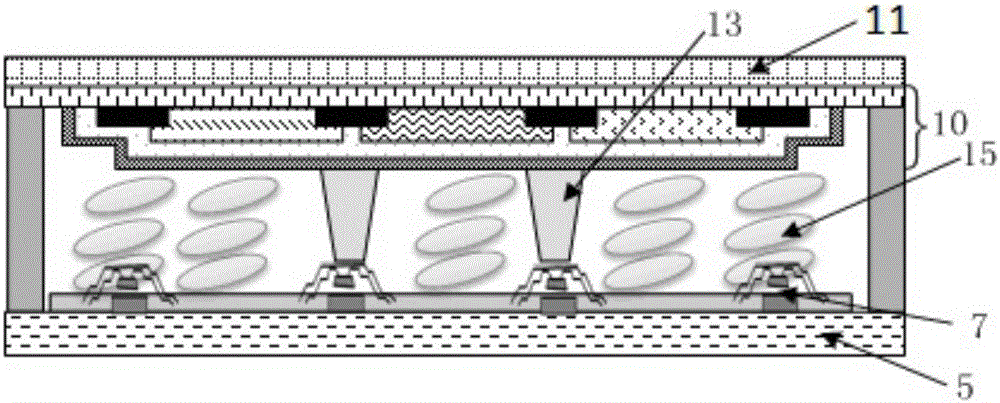

Light emitting device, display device and manufacturing method of the light emitting device

InactiveCN101803046ASuppression of light fluctuationSuppresses temperature fluctuationsMechanical apparatusPoint-like light sourceLead electrodeThinning

The invention provides a light emitting device, a display device and a manufacturing method of the light emitting device. A light emitting module (40) comprising eight LEDs emitting red, green and blue light; electric conductor parts (60) electrically connected to the respective LEDs and constitute power feeding routes to the respective LEDs; a heat conductor part (50) provided so as to be electrically insulated from the electric conductor parts (60) and constitute heat dissipating routes for heat generated in the respective LEDs; and a lenses (70) which seal the respective LEDs along with portions of the respective electric conductor and heat conductor parts (60, 50). Bending process is applied to each of the electrodes of the electric conductor parts (60) which are exposed from the lens (70) such as a red positive lead electrode portion (61a) and a heat dissipating portion (52) etc. in the heat conductor part (50) which is exposed from the lens (70). Accordingly, temperature change in the light emitting elements and accompanying light intensity change are suppressed, and at the same time, thinning of the light emitting device comprising the light emitting elements is achieved.

Owner:SHOWA DENKO KK

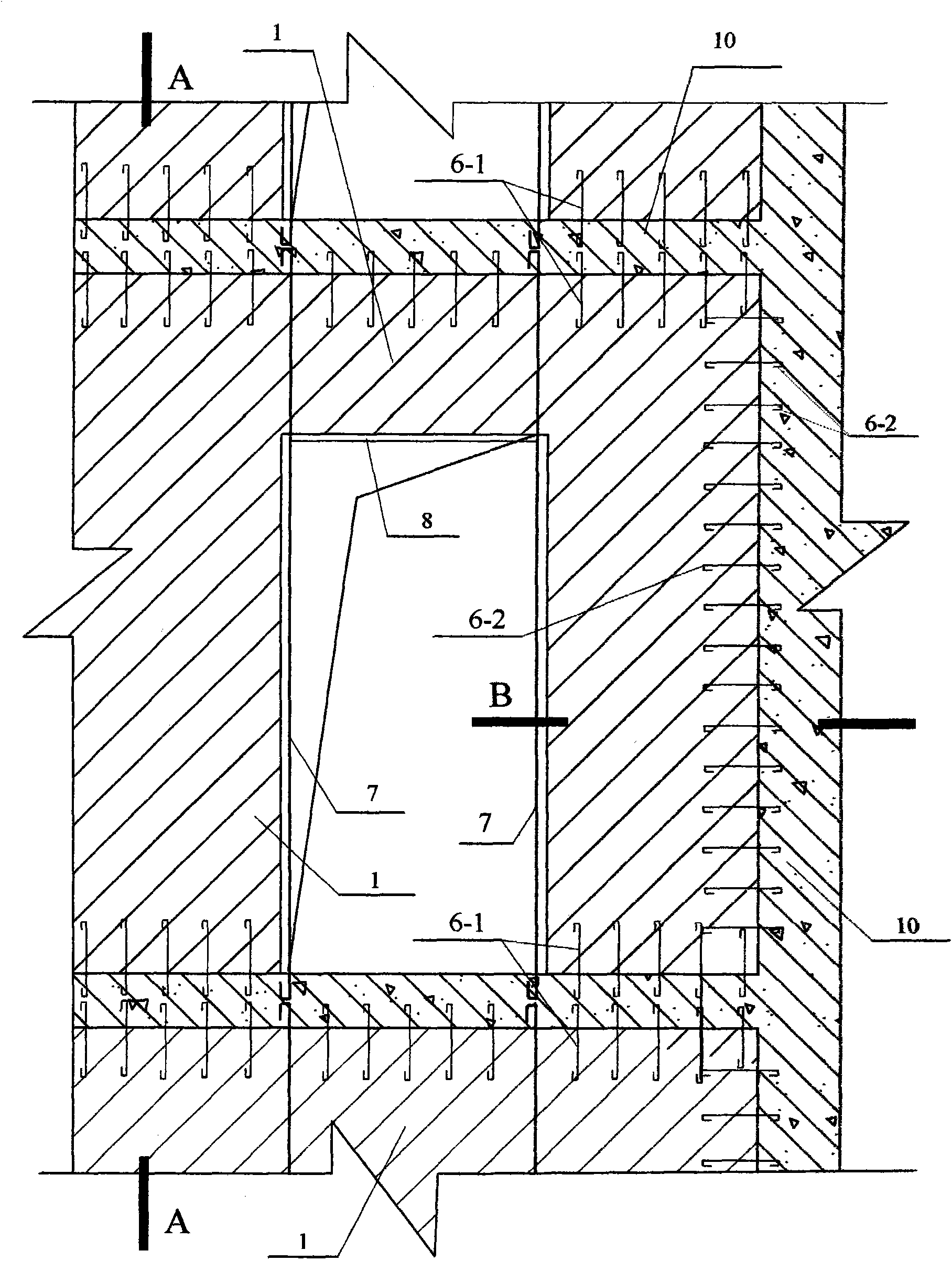

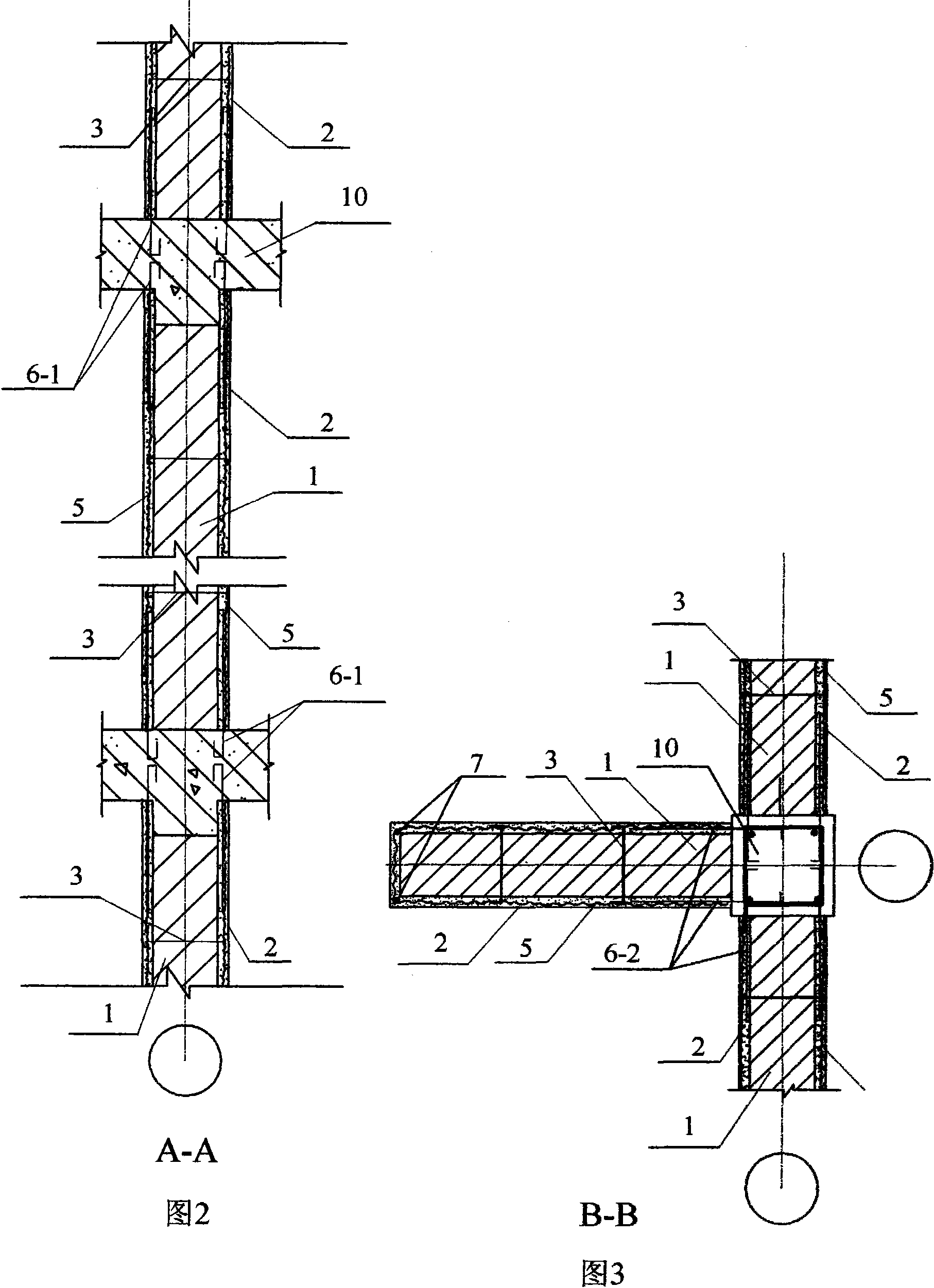

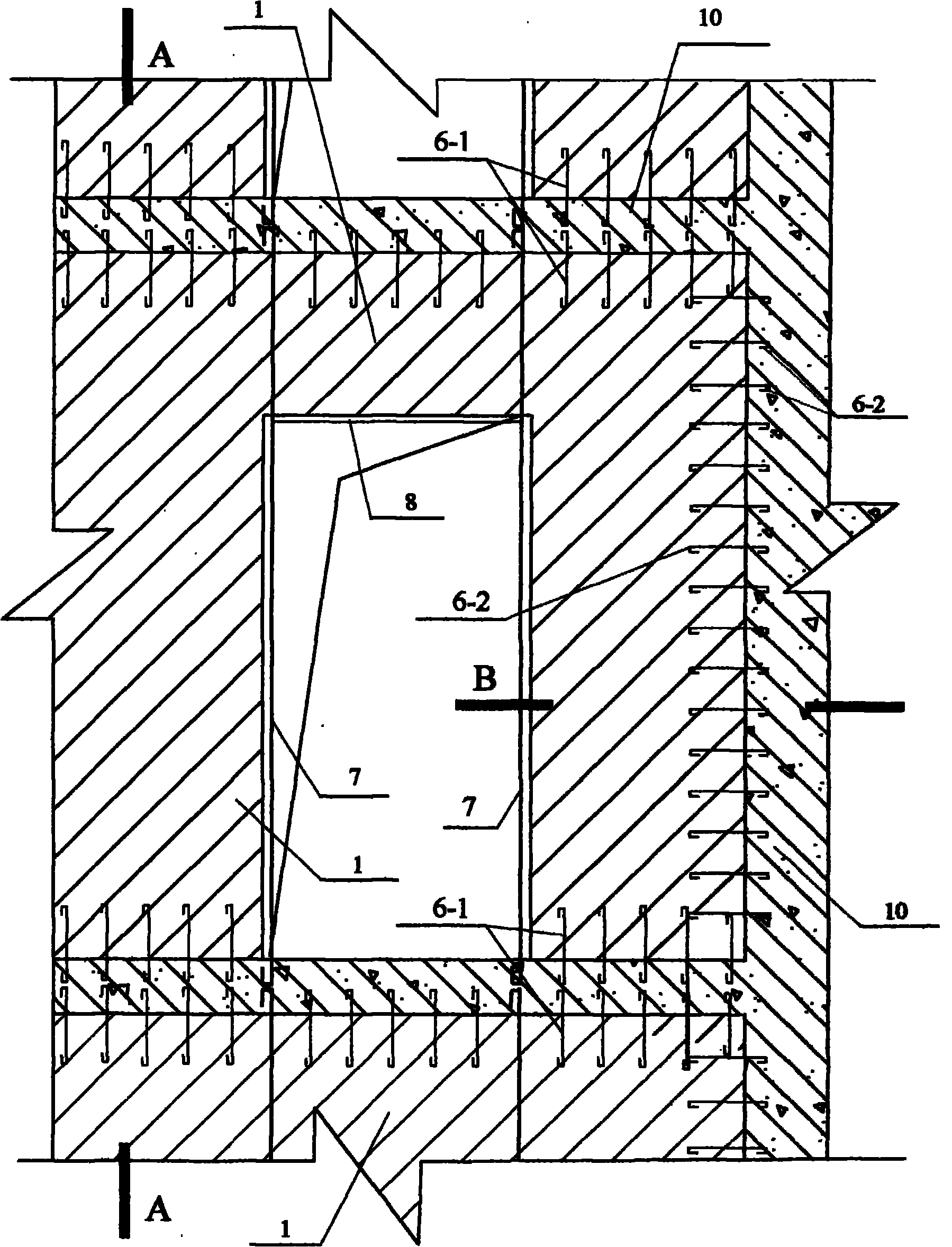

Composite masonry wall

InactiveCN101775856AImprove shear resistanceThinningWallsBuilding reinforcementsSteel barCement mortar

A composite masonry wall relates to a building composite wall and aims at the problem that the existing masonry has low shearing resistance bearing capacity. The building composite wall comprises a masonry wall, an external floated coat, a tie bar, alkali-resisting meshes or a metal net bamboo or a reinforcement net, a vertical anchoring steel bar and a building main body structure, wherein the masonry wall is a bearing masonry; the external floated coat is a cement mortar surface course or a fine stone concrete pavement; the building main body structure is a concrete or reinforced cement combination or a steel structural girder or plate or pillar or wall; the tie bar is arranged in the mortar layer of the masonry wall; the tie bar vertically passes through the masonry wall and is mutually pulled with alkali-resisting meshes at both sides or the metal net or the reinforcement net; the vertical anchoring steel bar is anchored with the building main body structure; and the vertical anchoring steel bar and the alkali-resisting meshes or the metal net or the reinforcement net are buried in the external floated coat, or the alkali-resisting meshes are adhered on the surface of the external floated coat, thus forming the composite bearing masonry wall with lath and plaster at both sides. The building composite wall is beneficial to the building seismic resistance, reduces the construction costs and increases the indoor usable floor area.

Owner:吴淑环

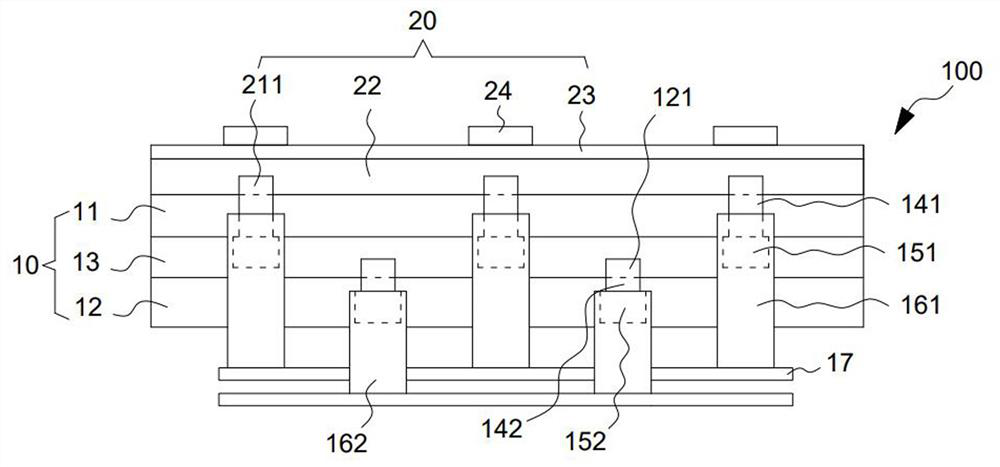

Display panel, integrated pressure induction display device and driving method

ActiveCN106527791AThinningLow production costStatic indicating devicesInput/output processes for data processingElectricityDisplay device

The embodiment of the invention discloses a display panel, an integrated pressure induction display device and a driving method. The display panel comprises a substrate; multiple pixel circuits formed on the substrate; at least a driving line which is electrically connected with the multiple pixel circuits and is reused as a first pressure induction electrode; multiple first electrodes which are formed on the multiple pixel circuits are arranged in one-to-one correspondence with the pixel circuits and are electrically connected with the corresponding pixel circuits; and organic light-emitting layers and second electrodes formed on the first electrodes. The second electrodes are multiplexed as multiple second pressure detection electrodes; and the first pressure induction electrode and the second pressure detection electrodes are used for detecting a pressure induced by the display panel. By utilizing the technical scheme of the invention, the thickness of the organic light-emitting display panel with a pressure detection function can be reduced, and the manufacturing cost of the organic light-emitting display panel can be lowered.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

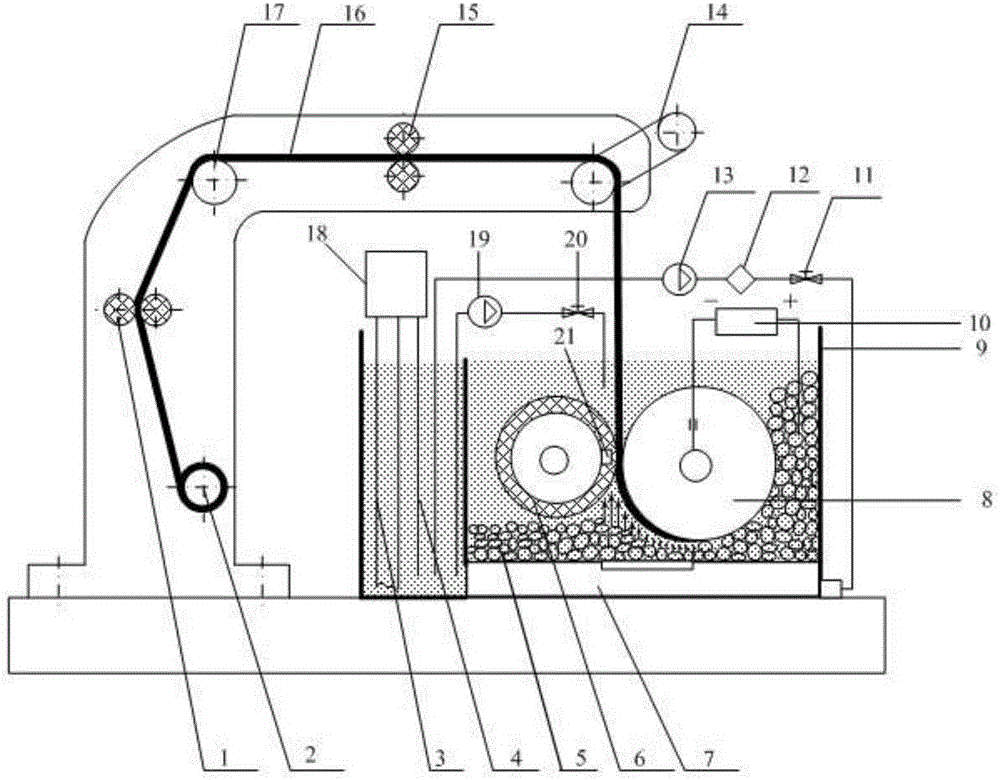

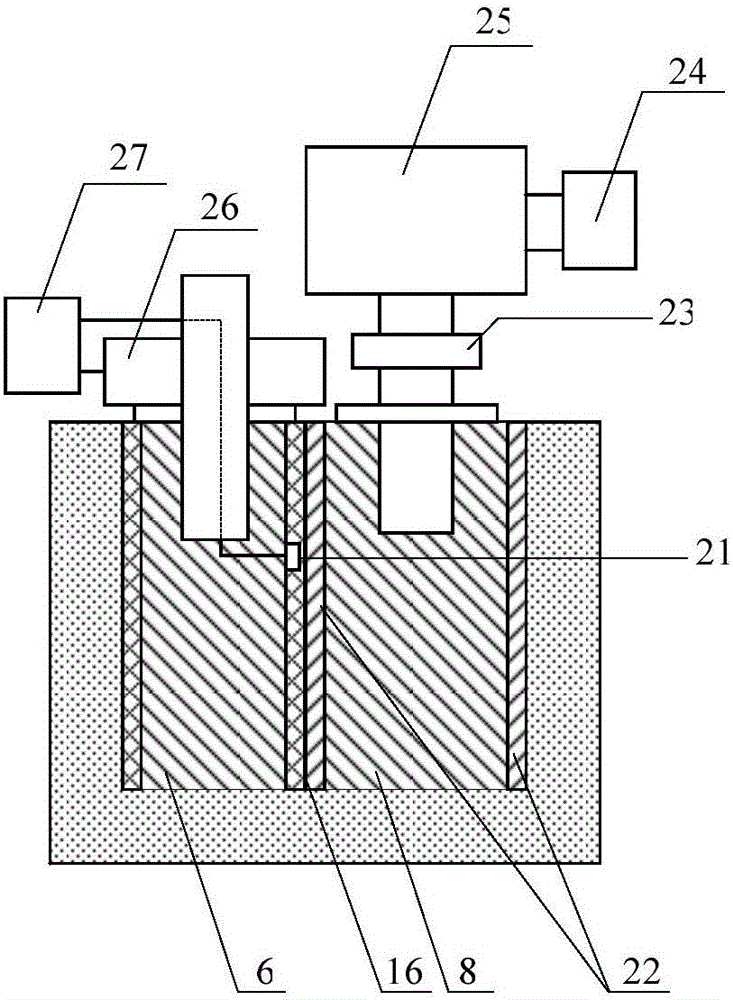

Electric casting manufacturing device and process of carbon fiber reinforced metal

ActiveCN106521563AAccelerate the liquid phase mass transfer processThinningElectroforming processesFibre reinforcementFiber bundle

The invention relates to an electric casting manufacturing device and a process of carbon fiber reinforced metal. Carbon fibers are wound on the surface of a cathode core mold under the condition of flexible pressing for electric casting formation. Under driving of a rotating motor and a guider, the carbon fibers are continuously wound and fully paved on the whole cathode core mold, and meanwhile, metal nickel is continuously deposited on the cathode core mold and the carbon fibers. In the process, a flexible pressing device is always tightly bonded on the surface of the cathode core mold. A water sucking material on the surface of the flexible pressing device can permeate electric casting liquid into the carbon fiber bundle to increase compactness of a prepared electric casting layer; and the flexible pressing device can remove hydrogen bubbles generated by the reaction and other impurities through the effects of extrusion and friction on the cathode core mold and the carbon fibers. The device needed by the process comprises an electric casting system, a carbon fiber winding system and a flexible pressing system. The device and the process can prominently reduce internal holes and surface defects of a carbon fiber reinforced metal electric casting layer, and prominently improve the quality and the mechanical performance of the prepared carbon fiber reinforced metal electric casting layer.

Owner:WUXI VOCATIONAL & TECHN COLLEGE

Method for reducing thickness of hexagonal boron nitride two-dimensional thin film

ActiveCN105648419AThinningQuality improvementChemical vapor deposition coatingBoron nitrideParticulate material

The invention relates to a method for reducing the thickness of a hexagonal boron nitride two-dimensional thin film. At present, a hexagonal boron nitride atomic layer thin film can grow through a chemical vapor deposition method, but growth quality of the hexagonal boron nitride atomic layer thin film is not high, for example, the domain size of single crystals is small and scattered boron nitride particles or continuous granular films exist on the surface layer of the thin film, and performance and application of boron nitride thin films are affected. According to the method, a boron nitride thin film is synthesized first through the chemical vapor deposition method, then particles in the surface layer of the thin film are removed through heat treatment in different atmospheres, and the high-quality hexagonal boron nitride two-dimensional thin film with the thickness being reduced is obtained. The method is beneficial to reduction of the thickness of the boron nitride thin film and improvement of quality of the thin film.

Owner:江苏中商碳素研究院有限公司

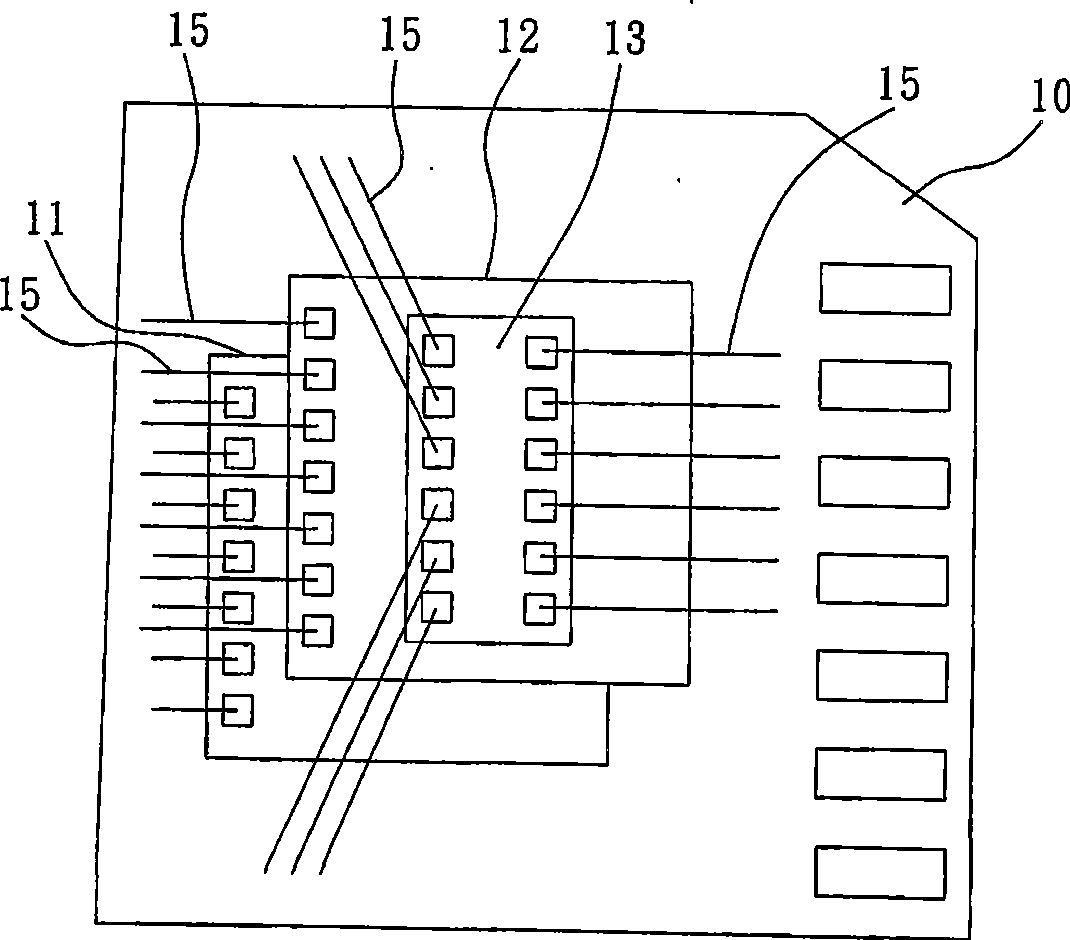

Multi-chip stacking structure and preparation thereof

ActiveCN101452861AIncrease the number of stacked layersAvoiding the problem of increasing structural heightSemiconductor/solid-state device detailsSolid-state devicesState of artChip stacking

The invention discloses a multichip stacking structure and a method for manufacturing the same. The multichip stacking structure comprises a first chip set which is provided with a plurality of first chips and is connected with a chip bearing piece in a stepped mode; the first chip of the topmost layer of the first chip set is connected with a second chip so that the first chip and the second chip are in electric connection with the chip bearing piece through a welding wire; adhesive film over wire technology (Film over Wire, FOW) is utilized to stack a third chip alternated with an insulating adhesive film on the first chip and the second chip so that the insulating adhesive film covers part of the welding wire end of the first chip of the topmost layer of the first chip set and at least one part of the second chip and is in electric connection with the third chip and the chip bearing piece through the welding wire, thereby solving the problem that when the second chip with planar dimension far less than that of the first chip is directly stacked on the first chip in the prior art, the height of the whole structure and the difficulty of wire welding operation are increased.

Owner:SILICONWARE PRECISION IND CO LTD

Vehicle glass, vehicle and control method of vehicle

PendingCN112693288AThinningEasy to installWindowsWindscreensAutomotive engineeringElectrically conductive

The invention provides vehicle glass, a vehicle and a control method of the vehicle, the vehicle glass is laminated glass, the laminated glass comprises a first glass panel, a middle layer and a second glass panel which are stacked in sequence, and the middle layer is provided with an electric heating piece and a transparent antenna; the transparent antenna comprises a first protective layer, an antenna oscillator, a substrate layer, a reflecting layer and a second protective layer which are sequentially stacked, wherein the substrate layer is made of fluororesin; the reflecting layer is formed by etching based on a conductive plate, an etching area and a non-etching area are obtained after the conductive plate is etched, the non-etching area forms the reflecting layer, the etching area is provided with a heat insulation layer, and the heat insulation layer comprises a transparent conductive oxide layer; the antenna oscillator is formed by arranging a plurality of antenna assemblies obtained by etching, the middle layer is provided with ETC antennas, and the ETC antennas are respectively arranged between two adjacent antenna assemblies; and on the premise that the ETC antenna needs to be installed on the middle layer of the automobile glass, the thickness of the middle layer of the automobile glass is reduced.

Owner:上海联净复合材料技术有限公司

Mixed connection panel and splicing panel

ActiveCN113763837AIncrease the display areaReduce borderSolid-state devicesIdentification meansLight-emitting diodeMaterials science

The invention discloses a mixed connection panel and a splicing panel. The mixed connection panel comprises a display panel and a light emitting diode substrate, and the display panel comprises a display area and a non-display area arranged on the peripheral side of the display area. The light emitting diode substrate is formed on the display panel. The light emitting diode substrate is located in the non-display area. According to the embodiment of the invention, the light-emitting diode substrate is prepared in the non-display area of the display panel, so that the overall display area of the mixed-connection panel is increased, and the light-emitting diode substrate is prepared on the display panel, so that the effect of thinning the light-emitting diode substrate is achieved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Method for producing liquid crystal display

InactiveCN105807480AThinningIncrease aesthetics and portabilityNon-linear opticsChemistryDiffusion function

The invention relates to the field of liquid crystal display, and discloses a method for producing a liquid crystal display, comprising: configuring the liquid crystal display to include: a color filter, a columnar spacer and a second black matrix, the color filter includes a color layer, located The first black matrix between the color base films of the color layer and the protective layer covering the color layer, the second black matrix is located on the opposite side of the first black matrix, and the columnar spacers are located between the protective layer and the second black matrix, The color layer includes a red base film layer, a green base film layer and a blue base film layer arranged horizontally in sequence, and the color layer contains microparticles with a light diffusion function; the width of the second black matrix is configured to be greater than the width of the first black matrix , and determine the second black matrix width according to various known parameters. The liquid crystal display produced by the method of the invention has high contrast ratio, high-quality picture display and high portability.

Owner:TUNGHSU KUNSHAN DISPLAY MATERIAL CO LTD +2

Cover plate and display device

ActiveCN110267181AThinningReduce thicknessPiezoelectric/electrostrictive transducersEngineeringSurface plate

The invention provides a cover plate and a display device, the cover plate comprises a protection part, a sound production part and a connection terminal, the sound production part is arranged at one side of the protection part, and the sound production part is provided with an exciter; and the connecting terminal is connected with the exciter and is used for transmitting an external driving signal to the exciter so as to drive the exciter to vibrate and produce sound. The sound production part and the protection part are integrated in the same layer, so that the cover plate plays a role in protecting the display panel and vibrating to produce sound at the same time, an exciter does not need to be additionally arranged, and the thickness of the display device is reduced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Liquid crystal display television assembly structure

ActiveCN102843536ACompact layoutThinningTelevision system detailsColor television detailsPhysicsEngineering

The invention discloses a liquid crystal display television assembly structure. The liquid crystal display television assembly structure comprises a front shell, and a liquid crystal display panel, a backlight module, a heat dissipation plate, a backboard and a rubber frame all arranged in a space formed by fixing a rear cover. The liquid crystal display television assembly structure is characterized in that the liquid crystal display panel, the backlight module, the backboard and the heat dissipation plate are orderly arranged from the front to the back in the space, the backlight module is fixed through the rubber frame, and the rubber frame is fixed with the heat dissipation plate; the backboard is fixed and attached on the heat dissipation plate, the bottom of the heat dissipation plate is bent to form a base, the base extends forwards to a part below the backboard and the backlight module, and the base is fixed with the bottom of the front shell. In comparison with the routine techniques, the heat dissipation plate is moved to the rear part of the backboard, the internal layout structure of a liquid crystal display television is more compact, the liquid crystal display television can be thinner. Simultaneously, the liquid crystal display television assembly structure is simple and convenient to assemble, and can improve the production efficiency, reduce the labor charges and lower the production cost.

Owner:SUZHOU VICTORY PRECISION MFG

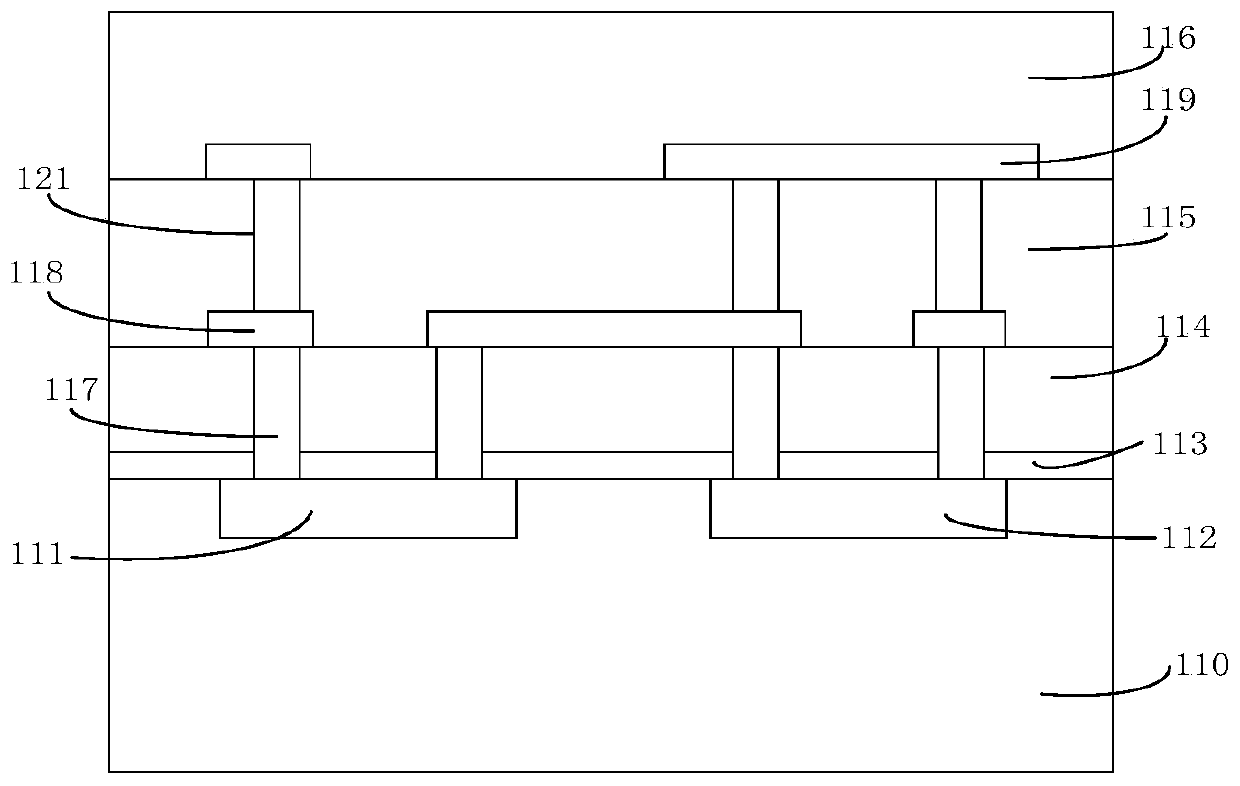

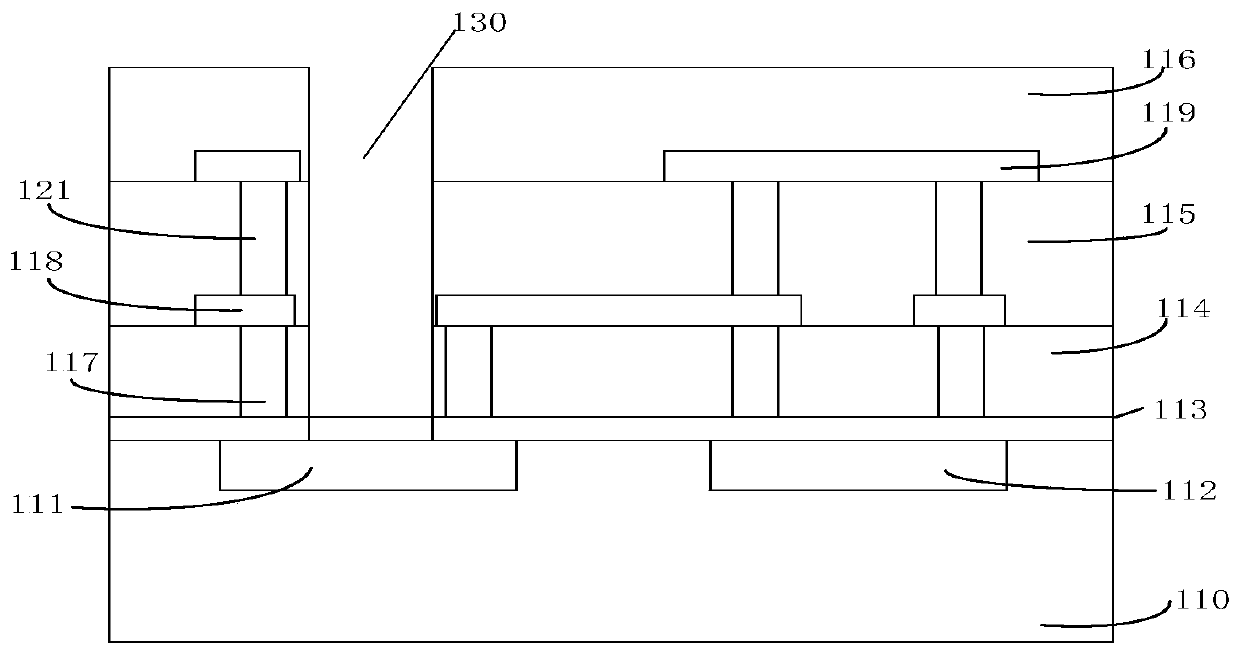

Optoelectronic integrated device and manufacturing method thereof

PendingCN111463226AThinningSmall attenuationSolid-state devicesRadiation controlled devicesPhysicsIntegrated devices

The invention discloses a photoelectric integrated device and a manufacturing method thereof. The method comprises the steps: providing a semiconductor substrate at least comprising a photoelectric device; forming a first dielectric layer on the first surface of the semiconductor substrate; forming an insulating layer on the first dielectric layer; forming a first opening in the insulating layer to expose the first dielectric layer above the photoelectric device region; and forming a second dielectric layer on the exposed first dielectric layer, wherein the first dielectric layer and the second dielectric layer are anti-reflection layers. According to the photoelectric integrated device provided by the invention, light can enter the photoelectric device only through the anti-reflection layer, so that excellent optical characteristics be acquired, and the manufacturing cost is reduced.

Owner:SILERGY SEMICON TECH (HANGZHOU) CO LTD

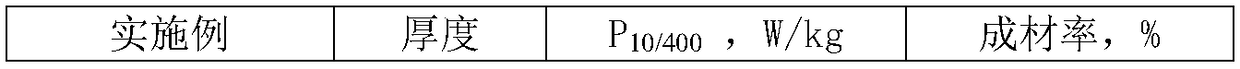

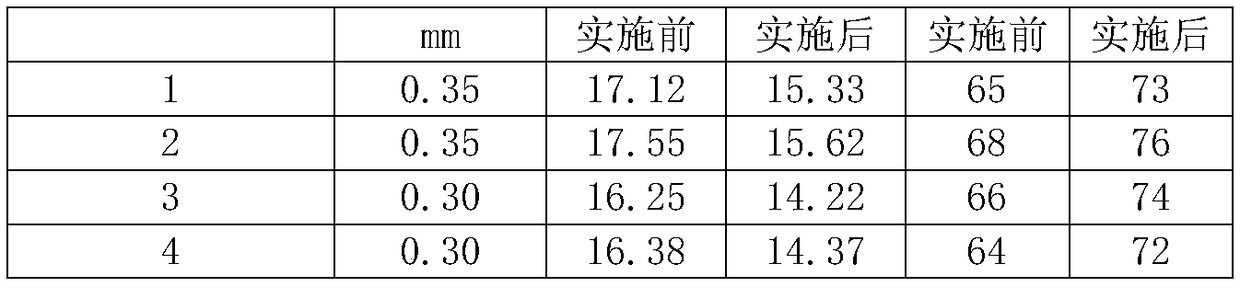

Production method for high-frequency thin-ribbon silicon steel

InactiveCN109082605AIsotropic favorableReduce smeltingTemperature control deviceMetal rolling arrangementsNiobiumManganese

The invention provides a production method for high-frequency thin-ribbon silicon steel. The production method is applicable to cold rolled non-oriented silicon steel of which the content of a main body alloy of silicon, manganese and aluminum is greater than 2.5%, and comprises the following steps: 1) carrying out refining decarbonization, silicon deoxidation, silicon alloying and aluminum alloying; 2) controlling contents of harmful elements, namely controlling that the content of sulfur is less than or equal to 0.020%, the content of nitrogen is less than or equal to 0.0100%, and the overall content of niobium, vanadium and titanium is less than or equal to 0.025%; 3) controlling a superheat degree for 15-50 DEG C and a pull speed within 0.3-1.2m / min in a continuous casting process, andcontrolling that the ratio of columnar crystal of a cast blank is greater than or equal to 50%; 4) controlling a feeding temperature greater than or equal to 300 DEG C for cast blank hot rolling, andheating with a neutral or reductive atmosphere, wherein the heating temperature is less than or equal to 1200 DEG C, and the heating control is controlled within 180-240 minutes. A finished product thinning effect and an effect of reducing eddy-current loss of high-frequency magnetization are achieved. Production control difficulties of overall procedures are reduced, and technical difficulties of higher alloy contents and thinner products are also avoided.

Owner:ANGANG STEEL CO LTD

Method for eliminating edge effect of coated glass

InactiveCN102021523AThinningAddressing edge effectsVacuum evaporation coatingSputtering coatingEdge effectsNitrogen

The invention discloses a method for eliminating the edge effect of coated glass. The method comprises the following steps of: depositing atoms of a target material on the surface of glass by using a magnetron sputtering method; distributing argon on a sputtering channel of the target material, which is arranged above the glass; distributing process gas for slowing sputtering below the glass, wherein the process gas for slowing sputtering can be oxygen or nitrogen. In the invention, on the basis of no change of the original equipment and method, the gas (oxygen or nitrogen, and the like) for slowing sputtering is only distributed below the glass and can enter a sputtering area only from edges of the glass because of the blocking of the glass, and thus, the speed of sputtering at the edges of the glass can be slowed, the thickness of films at the edges can be thinned, and finally the problem of edge effect of the coated glass can be solved.

Owner:吴江南玻华东工程玻璃有限公司

Reinforcing rib

InactiveCN103016947AThinningReduce weightElongated constructional elementsEngineeringUltimate tensile strength

The invention relates to a reinforcing rib, which comprises a reinforcing rib body. The end parts of the left end and the right end of the reinforcing rib body are symmetrically provided with hook structures; the middle part of the reinforcing rib body is provided with concave parts and convex parts at intervals; and the hook parts at the left end and the right end are arranged on the inner side or the outer side of the reinforcing rib body. The reinforcing rib is installed on an elevator decoration panel and is generally made of a galvanized iron plate. Test results show that the thickness and weight of the reinforcing rib can be reduced; and the strength of the elevator decoration panel can be increased, the effective load on the unit area of the elevator decoration panel can be increased, and the loading capacity of the unit area of an elevator can be improved.

Owner:苏州市相城区江南电梯装潢厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com