Liquid crystal display television assembly structure

An assembly structure, a technology for LCD TVs, applied to TVs, color TVs, components of color TVs, etc., can solve the problems of inconvenient assembly of LCD TVs, thick LCD TVs, affecting production efficiency, etc., and achieve thickness change and compact layout structure. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

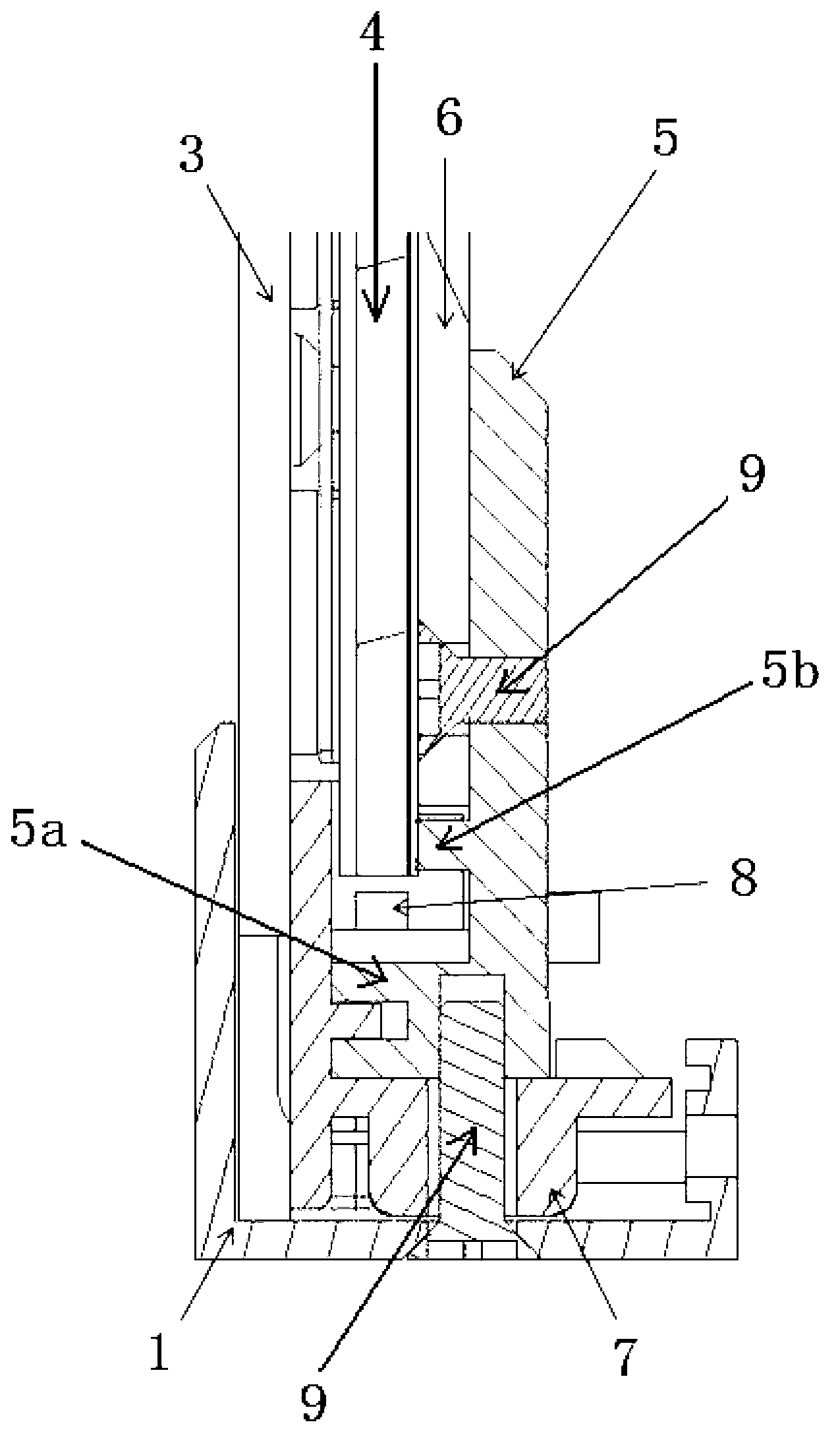

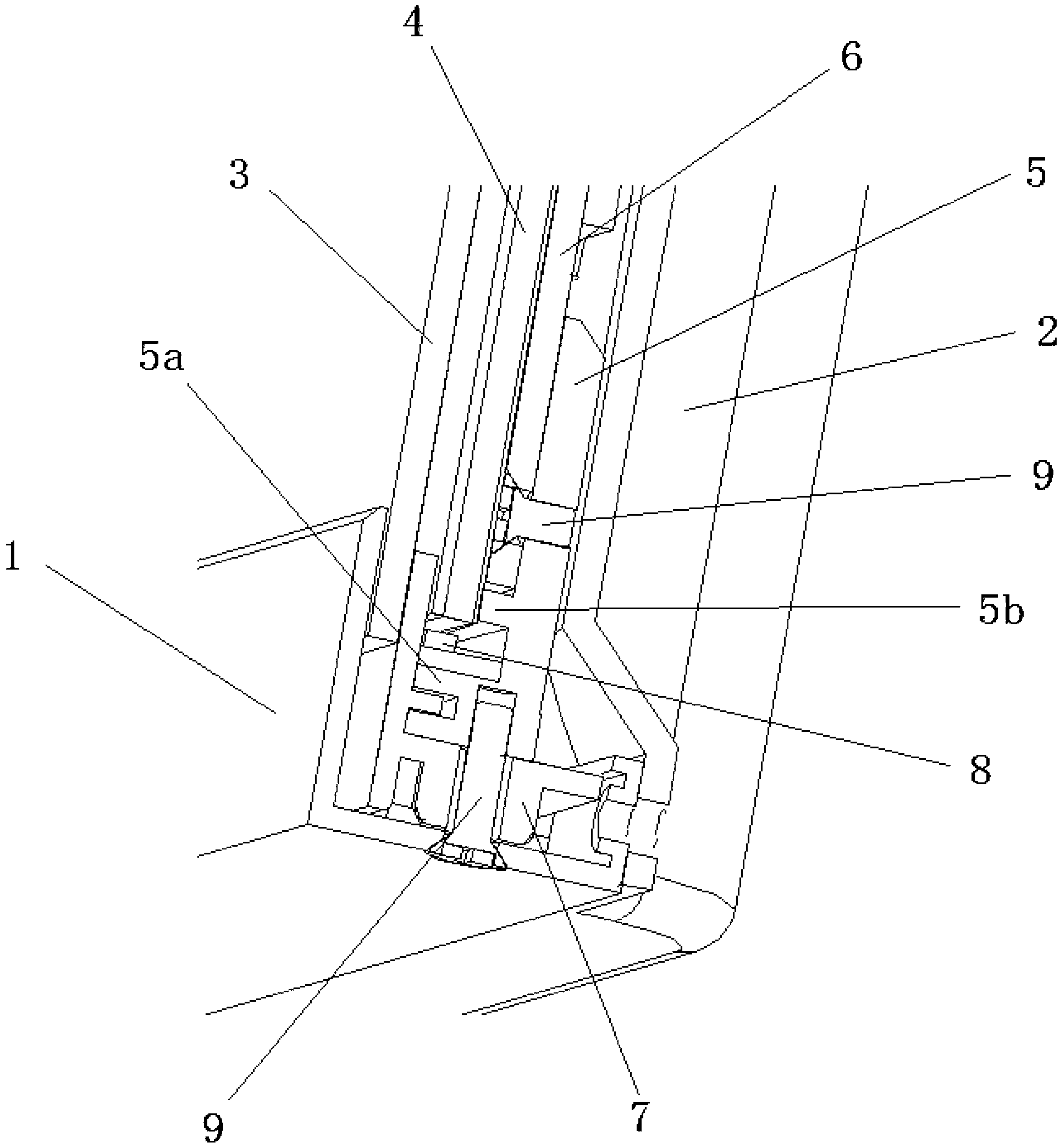

[0015] Example: Combine figure 1 , figure 2 Shown is a specific embodiment of the LCD TV assembly structure provided by the present invention, in which a liquid crystal panel 3, a backlight module 4, and a back panel 6 are sequentially arranged from front to back in the space formed by fixing the front shell 1 and the rear cover 2 and the heat dissipation plate 5, the back plate 6 is fixed by screws 9 and attached to the heat dissipation plate 5, and the bottom of the heat dissipation plate 5 is bent to form a base 5a extending forward to the bottom of the back plate 6 and the backlight module 4. In this embodiment, a plastic frame 7 is arranged on the outer periphery of the heat dissipation plate 5, and the top and both sides of the backlight module 4 are fixed to the plastic frame 7. The bottom of the front case 1, the plastic frame 7 and the base 5a are sequentially screwed together. 9 threading and fixing.

[0016] The backlight module 4 involved in this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com