Method for producing liquid crystal display

A liquid crystal display, black matrix technology, applied in instruments, nonlinear optics, optics, etc., to achieve the effects of high contrast, high portability, and increased color confusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

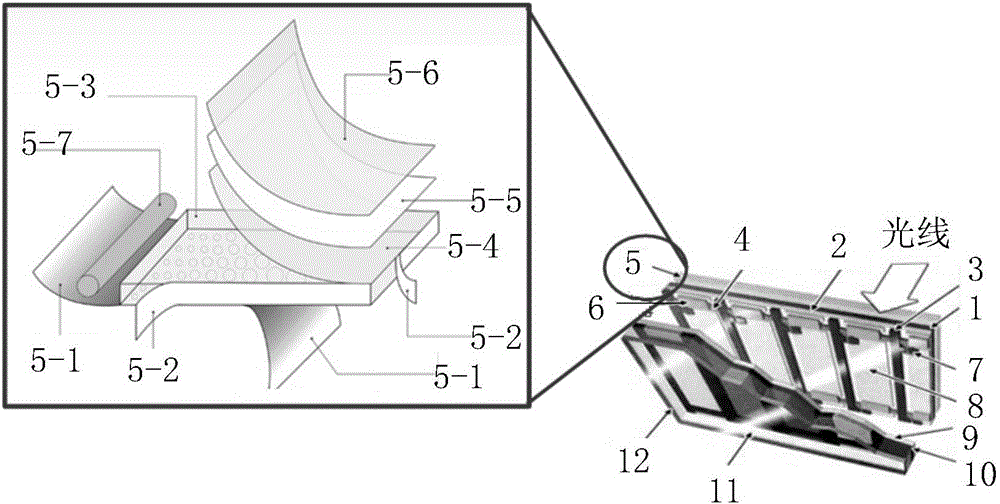

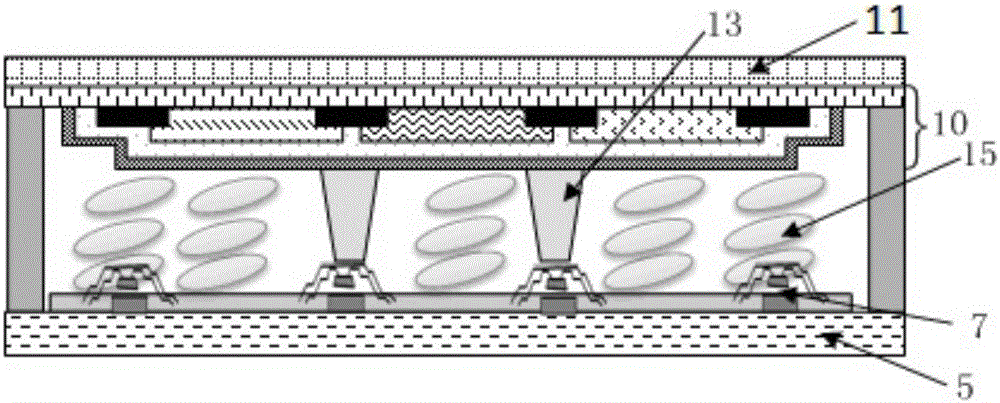

Examples

preparation example Construction

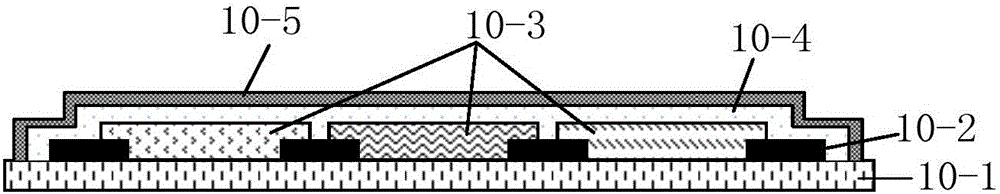

[0073] In the present invention, the preparation method of the color filter can be a conventional method in the field, for example, it can include: first, cleaning the glass substrate, then coating the BM photoresist, exposing and developing the BM to form a first black matrix; The photoresist was coated with a resin composition containing color pigments (C.I. Pigment Red 254 / C.I. Pigment Yellow 139=80 / 20), and then masked and UV exposed and developed to form a red base film on the substrate. The color pigment (C.I. Pigment Green 36 / C.I. Pigment Yellow 150=60 / 40) resin composition forms a green base film on the substrate; then the resin composition containing the color pigment (C.I. Pigment Blue 15:6) is coated on the substrate by a similar method. The blue base film is formed thereon, wherein the order of forming the red base film, the green base film and the blue base film is not necessarily carried out in the above-mentioned order.

[0074] In addition, the materials of the...

Embodiment

[0078] Silicon-based microparticles are silicon-based microparticles produced by Ube Nitto Company, Japan, and are made of aluminum silicate with alumina and silicon dioxide as the main components, and are purchased from Ube Nitto Company.

preparation example

[0080] Prepare red base film, green base film and blue base film according to the formula in Table 1 below. The specific preparation method of color filter is as follows: first, the glass substrate is cleaned, then BM photoresist coating, exposure and development of BM to form The first black matrix (the material of the first black matrix is similar to the material in the red base film, the first black matrix does not contain microparticles with light diffusion function, and the red pigment in the red base film is replaced with the same amount of carbon black) Then photoresist is coated with a resin composition containing color pigments (C.I. Pigment Red 254 / C.I. Pigment Yellow 139=80 / 20) on it, and then photomask and UV exposure and development are used to form a red base film on the substrate, using A resin composition containing a color pigment (C.I. Pigment Green 36 / C.I. Pigment Yellow 150=60 / 40) was formed on a substrate in a similar manner to form a green base film; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com