Production method for high-frequency thin-ribbon silicon steel

A production method and thin strip technology, applied in the field of steel rolling, can solve the problems of long production cycle, deterioration of cold workability, increased difficulty in production control, etc., and achieve the effect of improving work efficiency, avoiding the increase of cold brittleness, and having favorable effects of isotropy of finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

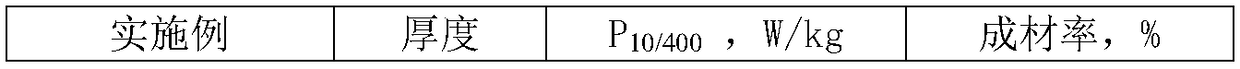

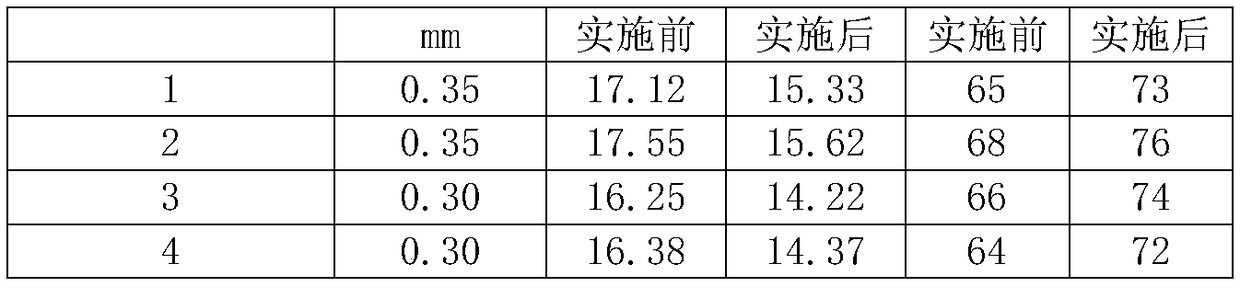

Examples

Embodiment 1

[0027] The mass percentage content of the main alloy (silicon + manganese + aluminum) is 3.81%, of which 2.95% Si, 0.53% Al, 0.33% Mn;

[0028] After refining and decarburization, use silicon deoxidation, carry out silicon alloying, and then carry out aluminum alloying; composition control: S: 0.0085%, N: 0.0050%, (Ni+V+Ti): 0.022%; continuous casting superheat 25 ℃, casting speed 0.5m / min, columnar crystal ratio 56%; furnace temperature for hot rolling: 450℃, heating temperature 1100℃, heating time 220 minutes.

Embodiment 2

[0030] The mass percentage content of the main alloy (silicon + manganese + aluminum) is 4.01%, of which 2.75% Si, 0.83% Al, 0.43% Mn;

[0031] After refining and decarburization, use silicon deoxidation, carry out silicon alloying, and then carry out aluminum alloying; composition control: S: 0.0105%, N: 0.0035%, (Ni+V+Ti): 0.025%; continuous casting superheat 20 ℃, casting speed 0.9m / min, columnar crystal ratio 67%; furnace temperature for hot rolling: 390℃, heating temperature 1150℃, heating time 190 minutes.

Embodiment 3

[0033] The mass percentage content of the main alloy (silicon + manganese + aluminum) is 4.70%, of which 3.32% Si, 1.13% Al, 0.25% Mn;

[0034] After refining and decarburization, use silicon deoxidation, carry out silicon alloying, and then carry out aluminum alloying; composition control: S: 0.0010%, N: 0.0045%, (Ni+V+Ti): 0.018%; continuous casting superheat 30 ℃, casting speed 0.6m / min, columnar crystal ratio 75%; furnace temperature for hot rolling: 490℃, heating temperature 1120℃, heating time 210 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com