Patents

Literature

34results about How to "Avoid broken belt accidents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

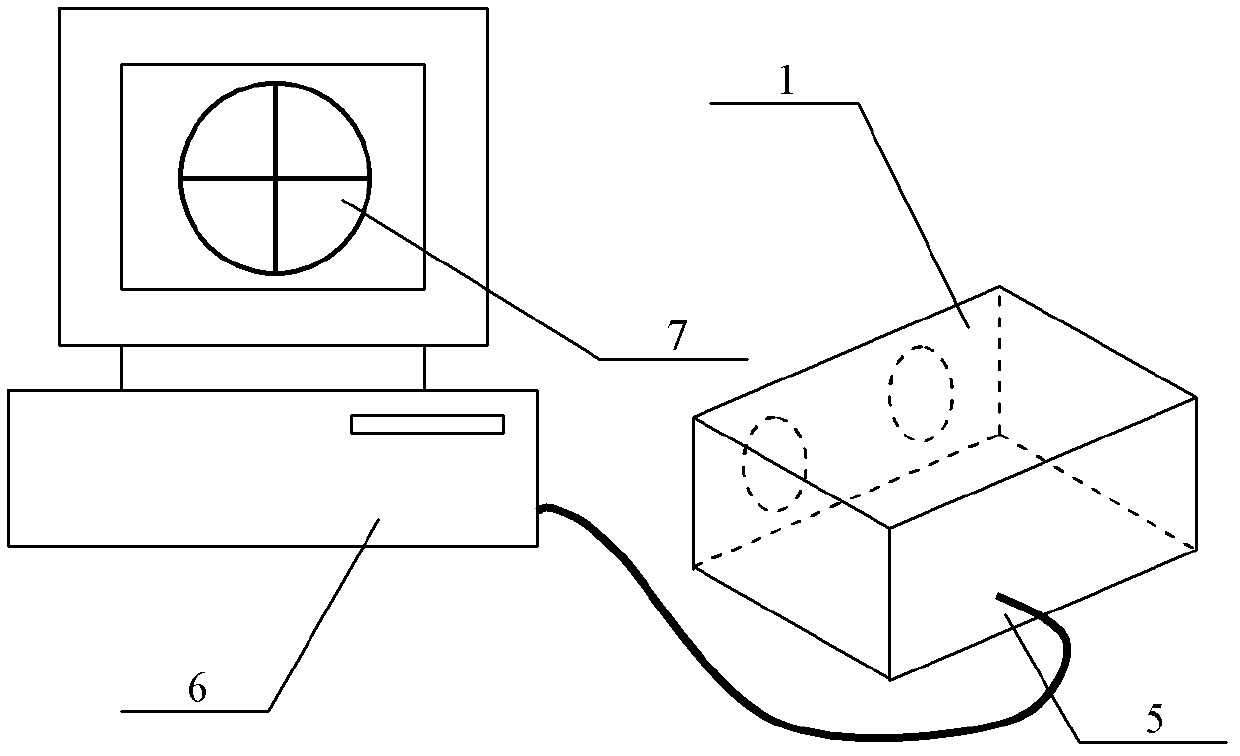

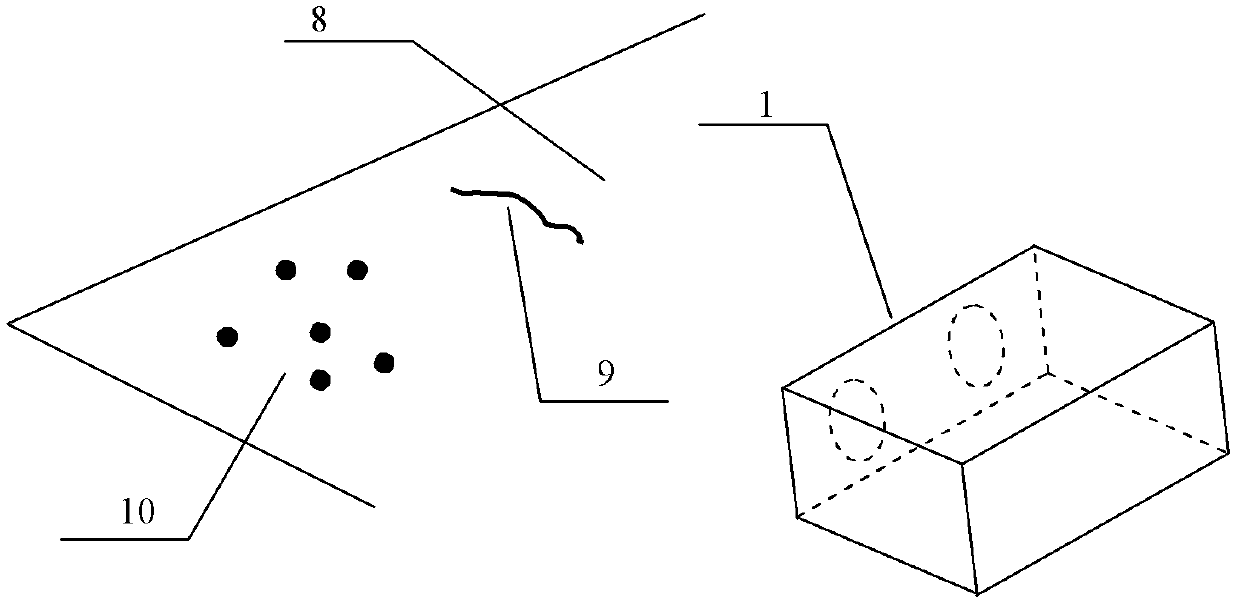

Stereoscopic vision on-line detection method for surface crack of stretched aluminum alloy plate

InactiveCN102565072AReal-time measurementGuaranteed reliabilityForce measurement by measuring optical property variationOptically investigating flaws/contaminationAlloyCcd camera

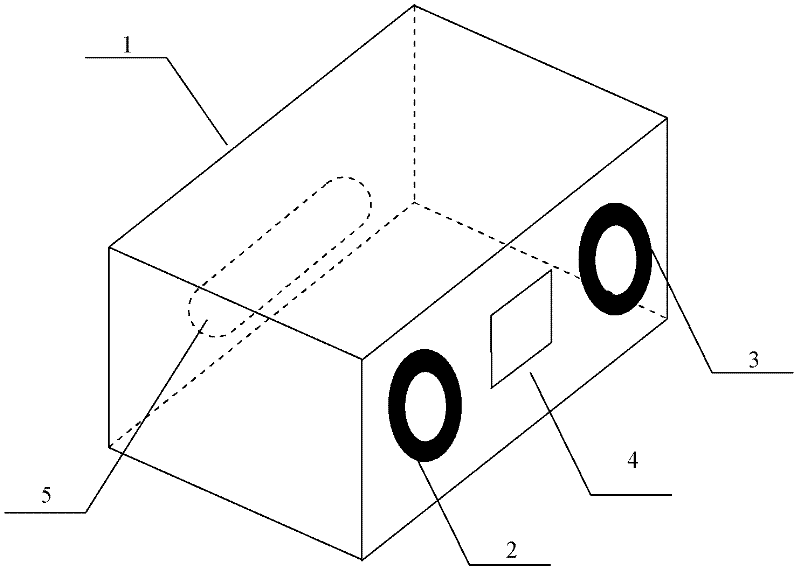

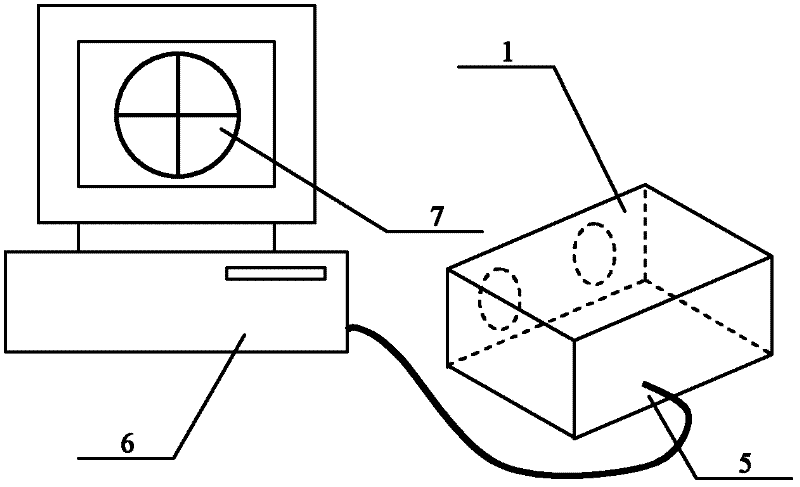

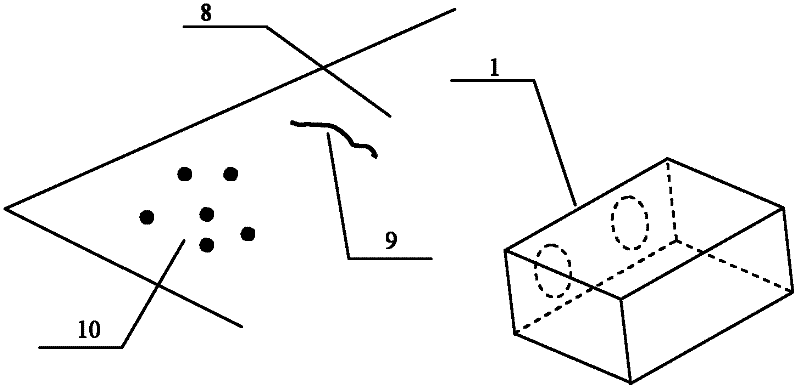

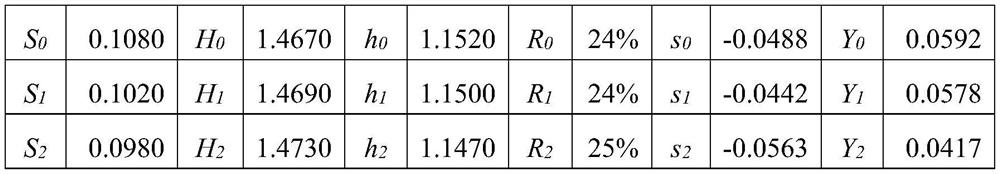

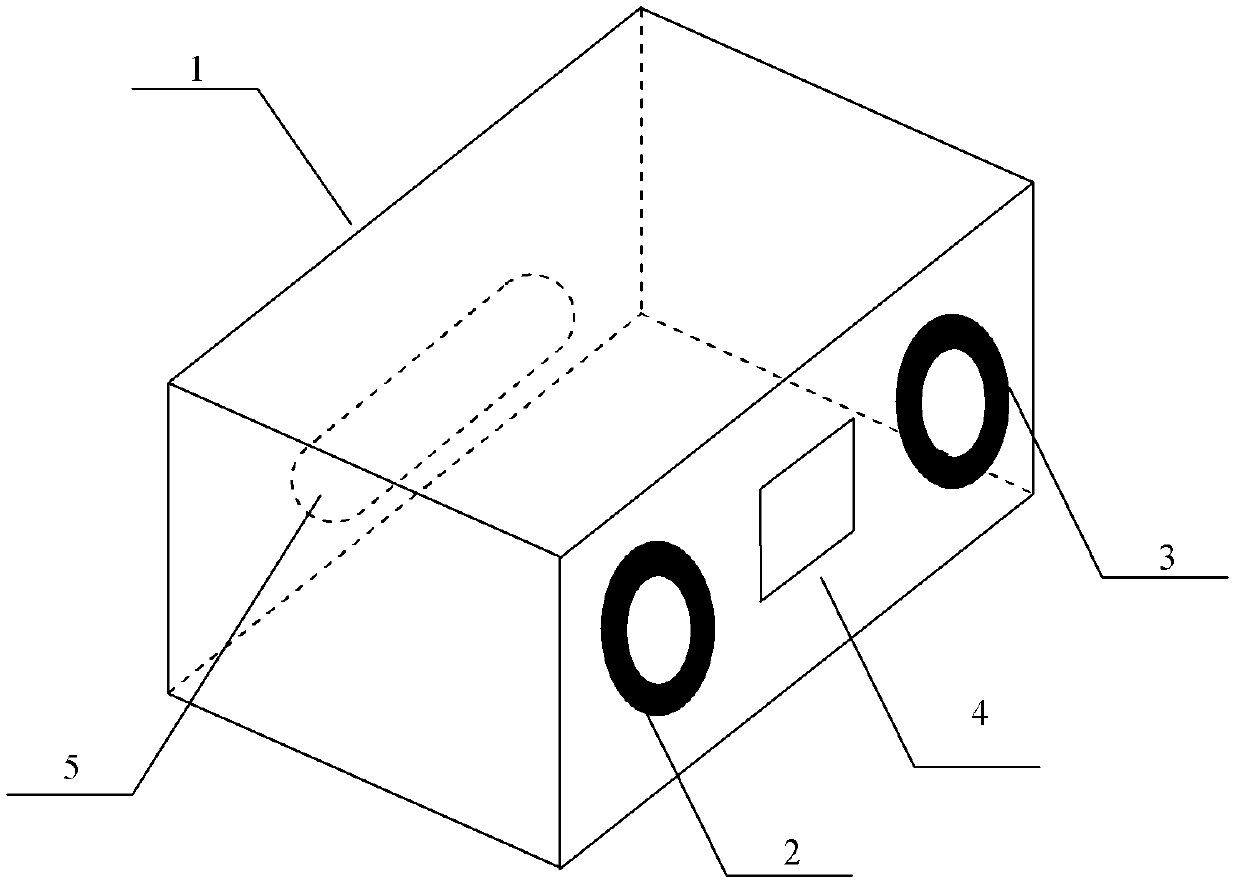

The invention discloses a stereoscopic vision on-line detection method for a surface crack of a stretched aluminum alloy plate. According to the vision detection method, two CCD (Charge Coupled Device) cameras are fixedly connected with equipment so as to keep the constant parameters of the relative position of the CCD cameras; a matched calibrating program is used for automatically finishing a calibrating operation for the parameters of the two cameras; and a special precise mechanical system is used for controlling and outputting focal length parameters of the cameras, so as to realize the precise measurement for space coordinate information of a small object. Accordingly, a real-time measuring algorithm for an area stress and a crack length on the basis of displacement of a surface texture feature point (detecting point) is provided. The measured stress level and crack length information are combined with a crack growth theory, so that the crack threatening estimation and the action forecasting are realized, the optimal stretching technical parameter is confirmed, the belt breaking accident is avoided during a stretching process, the safety of equipment and production personnel is ensured, the yield of products is increased and the application prospect in the panel processing field is wide.

Owner:CHONGQING UNIV

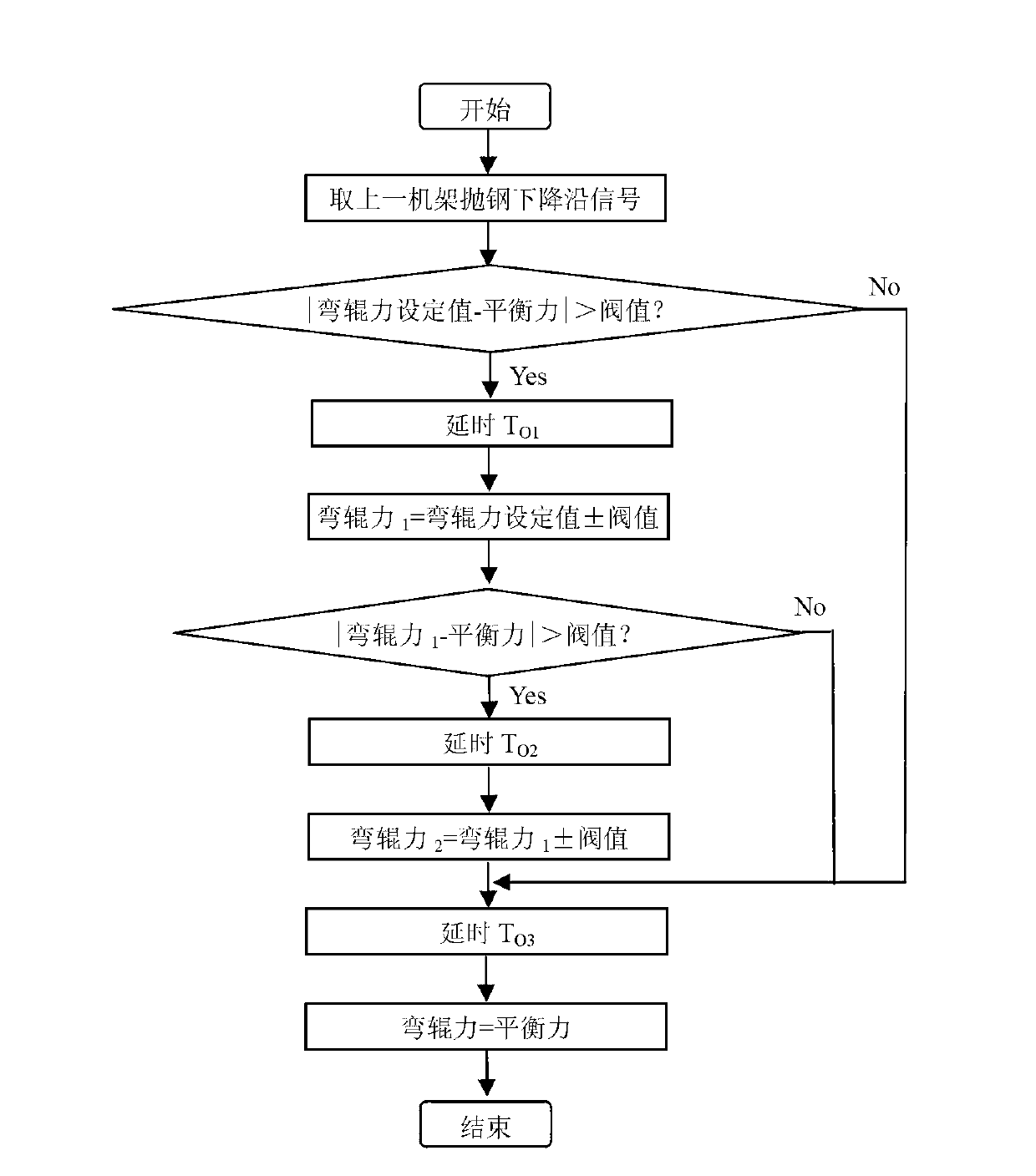

Method for controlling head and tail shapes of hot-rolled strip steel

ActiveCN102989787APrevent shape deterioration etc.Improve shape qualityRare end control deviceStructural engineeringStrip steel

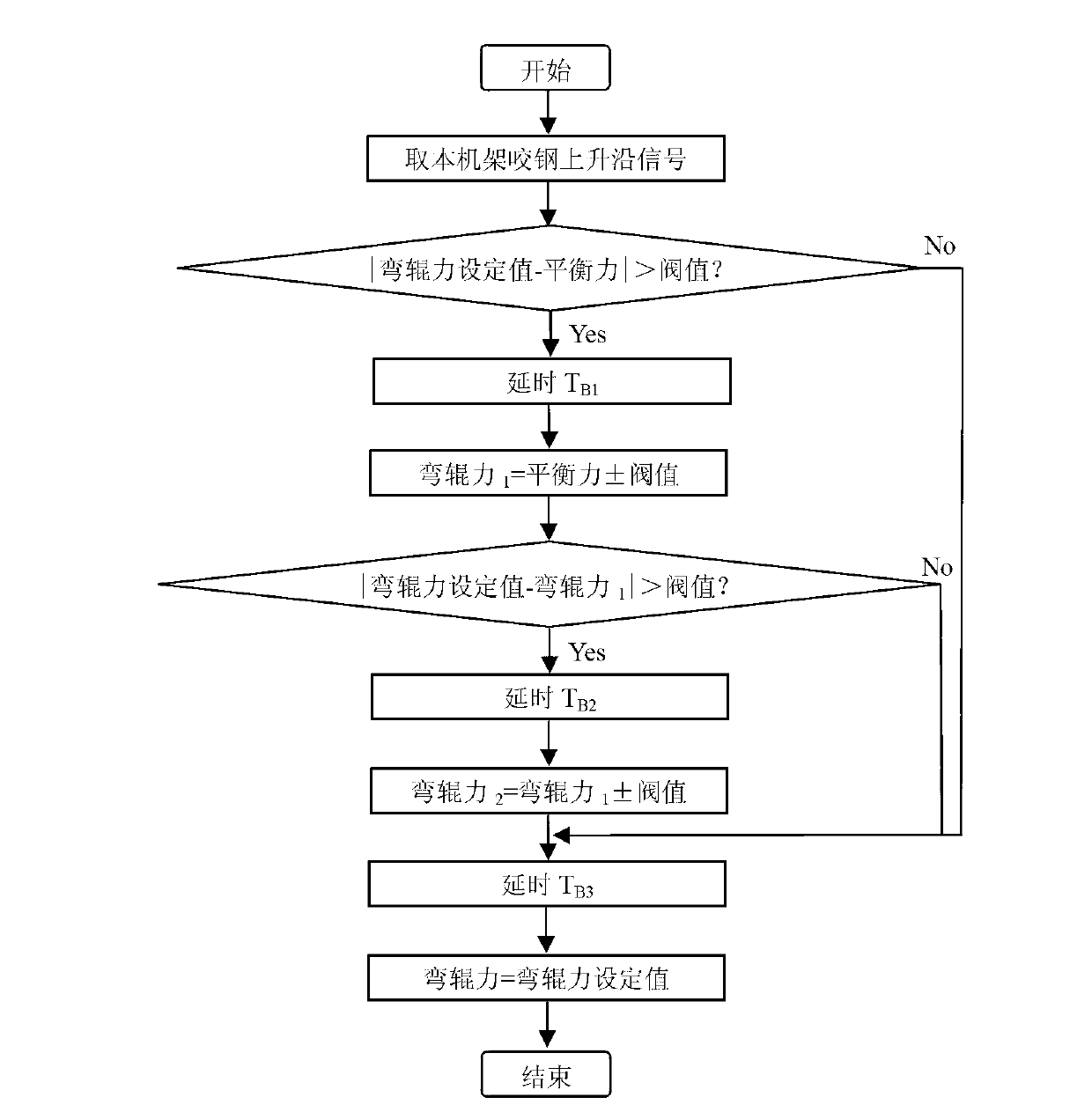

The invention provides a method for controlling the head and tail shapes of hot-rolled strip steel. For the control on the head shape of strip steel, the smooth switching between the balancing and roll bending of a rack is controlled through a steel biting rising edge signal of the rack; and for the control on the tail shape of the strip steel, the smooth switching between the roll bending and balancing of a follow-up rack is controlled through a steel throwing falling edge signal of an upstream rack. According to the invention, through the reasonable design on a hydraulic balancing and roll bending control scheme of a working roll of a rear finishing mill, phenomena such as the head and tail shapes of strip steel are deteriorated due to the instantaneous switching between balancing and roll bending, and the like can be effectively prevented, thereby improving the quality of head and tail shapes of the strip steel, avoiding the occurrence of creasing and strip breakage accidents, and reducing the production cost.

Owner:ANGANG STEEL CO LTD

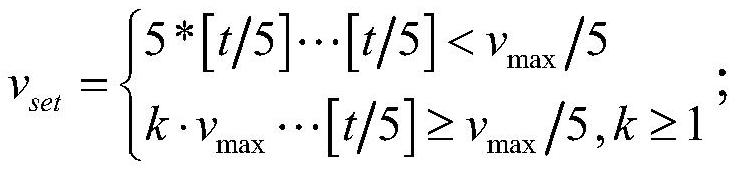

Pickling line tandem cold mill withdrawal and straightening machine control method

ActiveCN106424170ARealize automatic operationAvoid broken belt accidentsWork treatment devicesRoll mill control devicesMachine controlStrip steel

The invention discloses a pickling line tandem cold mill withdrawal and straightening machine control method. When the yielding strength of a target steel grade is smaller than or equal to 300 MPa, the ductility of a withdrawal and straightening machine is 2.3%-2.5%, and the engagement amount is 30 mm to 35 mm; when 300 MPa<the yielding strength<=450 MPa, the ductility is 1.8%-2.2%, and the engagement amount is 35 mm to 40 mm; when the yielding strength is larger than 450MPa, the ductility is set 0.5%-1.2%, and the engagement amount is 40 mm to 42 mm; and meanwhile according to the difference of the thickness or the width of front strip steel and rear strip steel, weld joint excessive withdrawal and straightening machine modes are divided into four kinds. By means of the pickling line tandem cold mill withdrawal and straightening machine control method, the withdrawal and straightening machine achieves automatic grouping control over steel grades in different yielding strength levels, normal withdrawal and straightening of the withdrawal and straightening machine can be guaranteed, the loads of the withdrawal and straightening machine can also be effectively reduced, normal pickling of the strip steel is guaranteed, and the withdrawal and straightening up-to-standard rate reaches 98% or above; and selection of the weld joint excessive withdrawal and straightening machine modes guarantees normal pickling of weld joint heads and tails, and the strip breakage accident caused by poor weld joint quality is avoided.

Owner:HANGANG GRP HANBAO IRON & STEEL

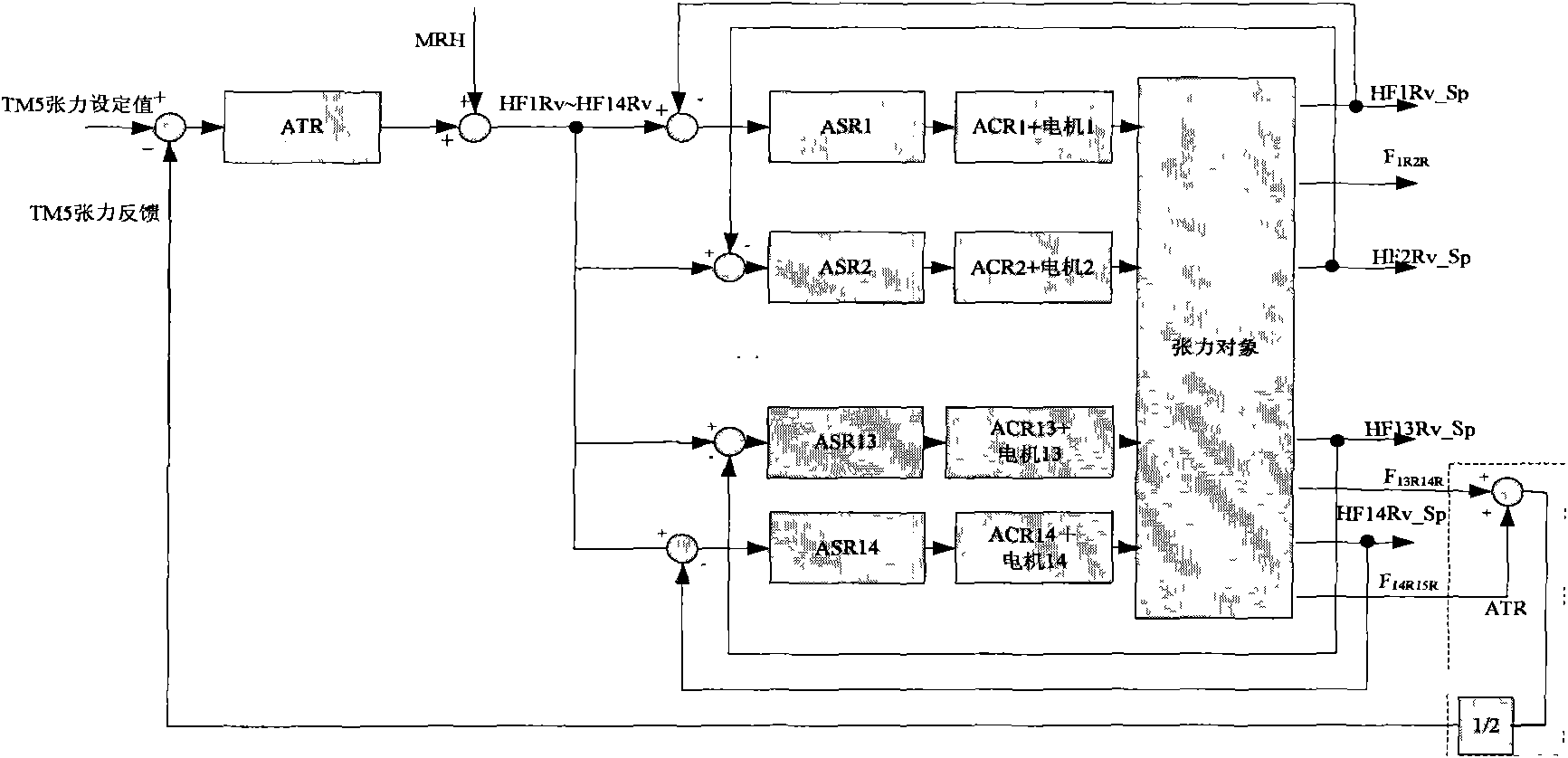

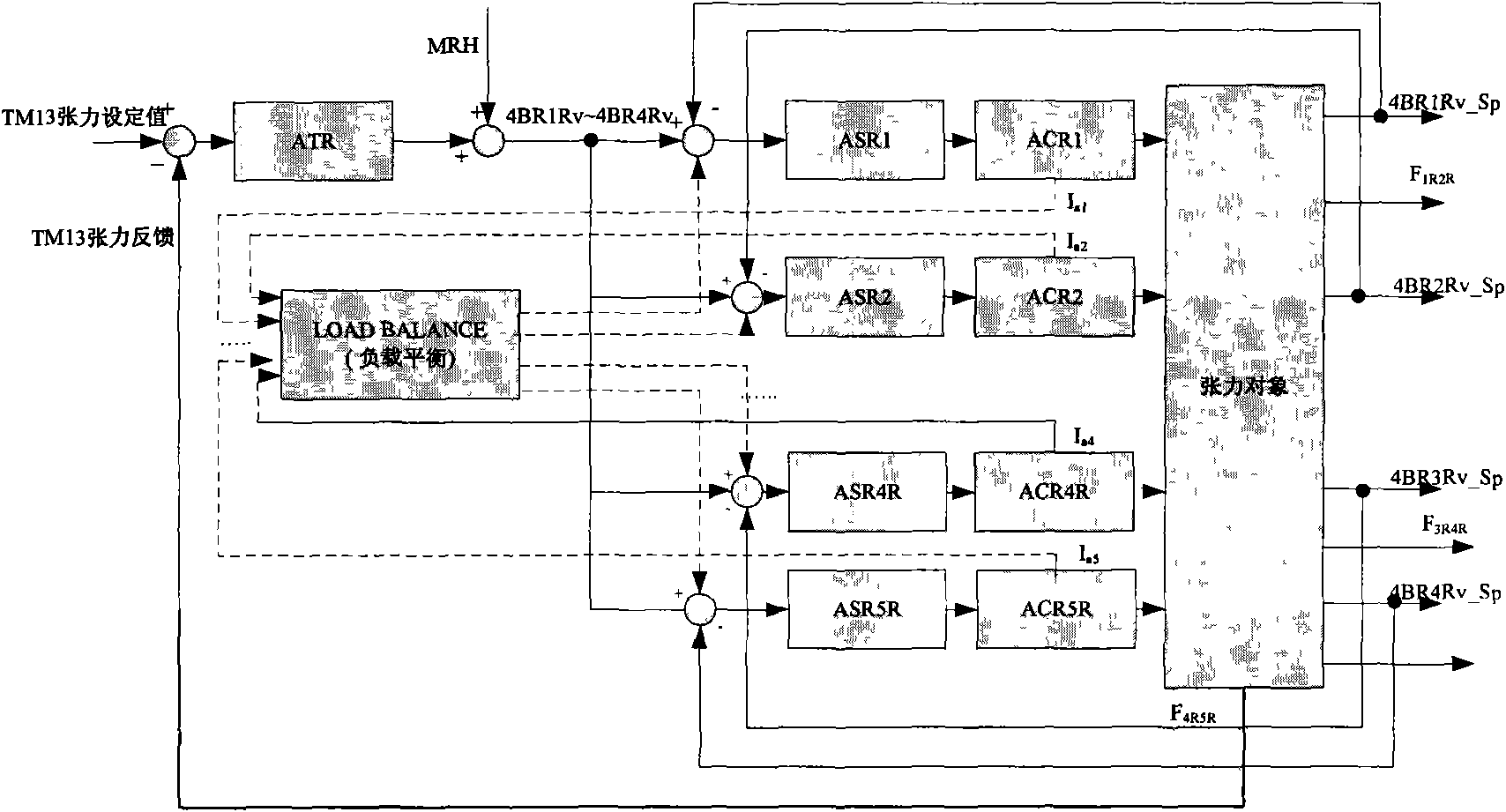

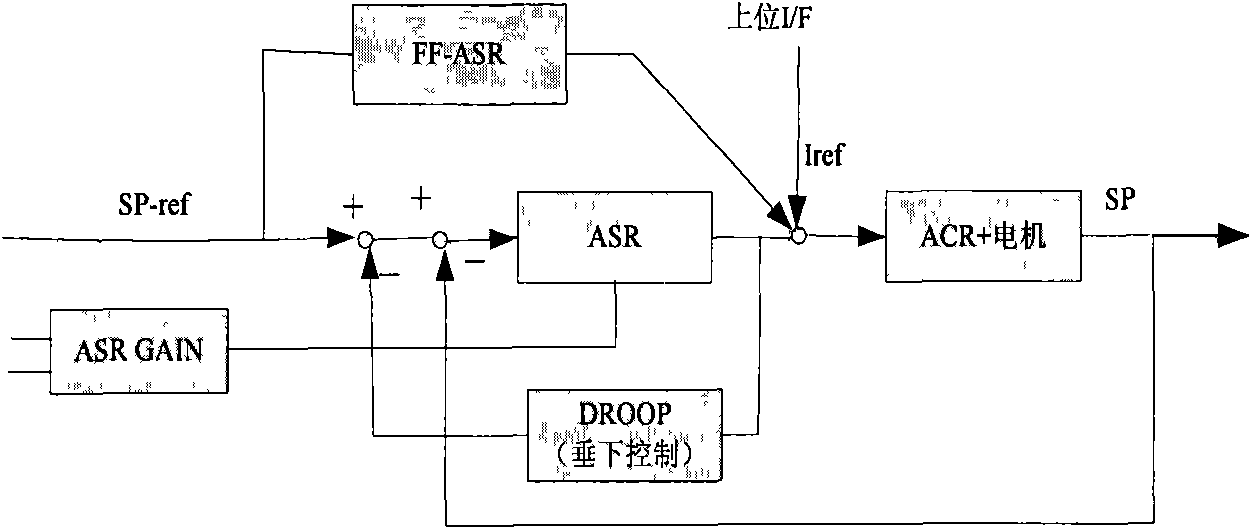

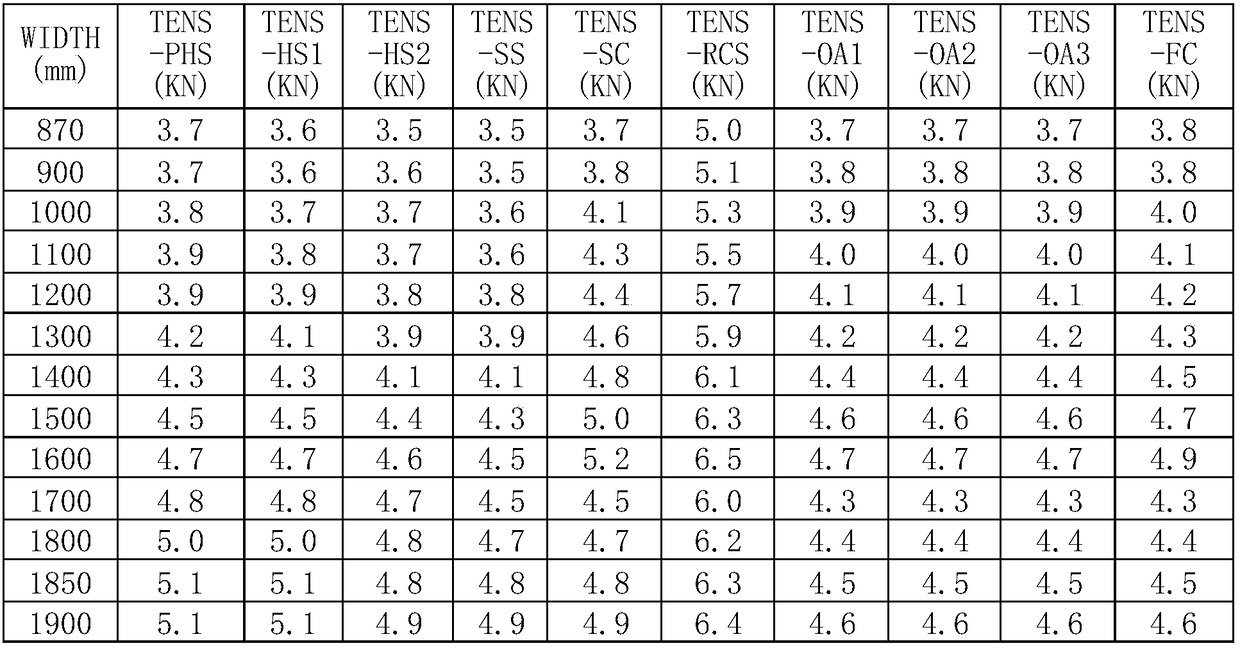

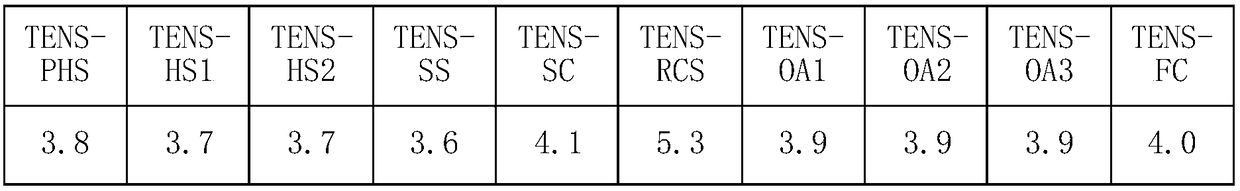

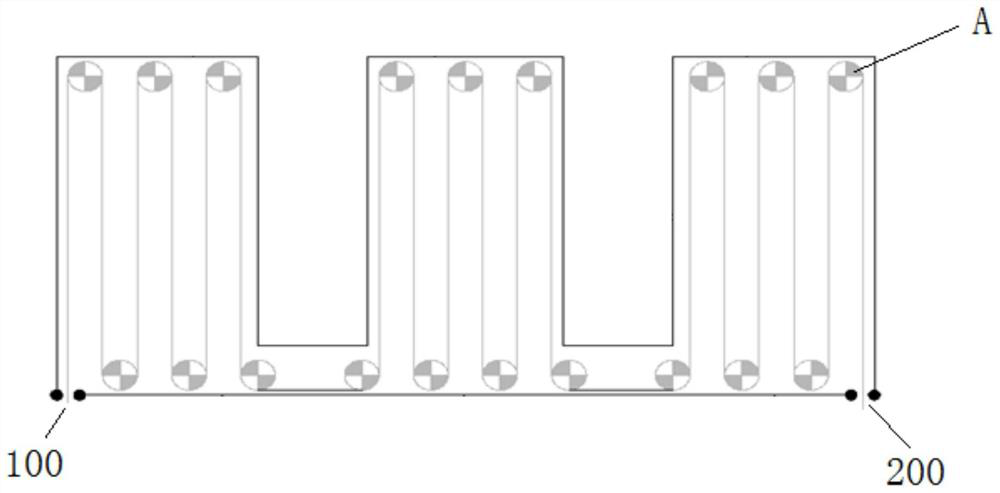

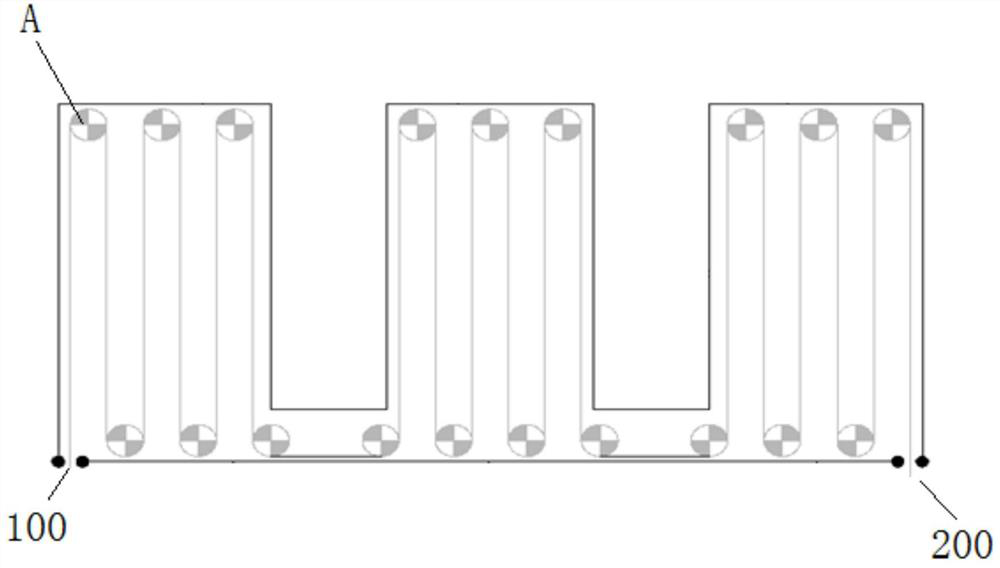

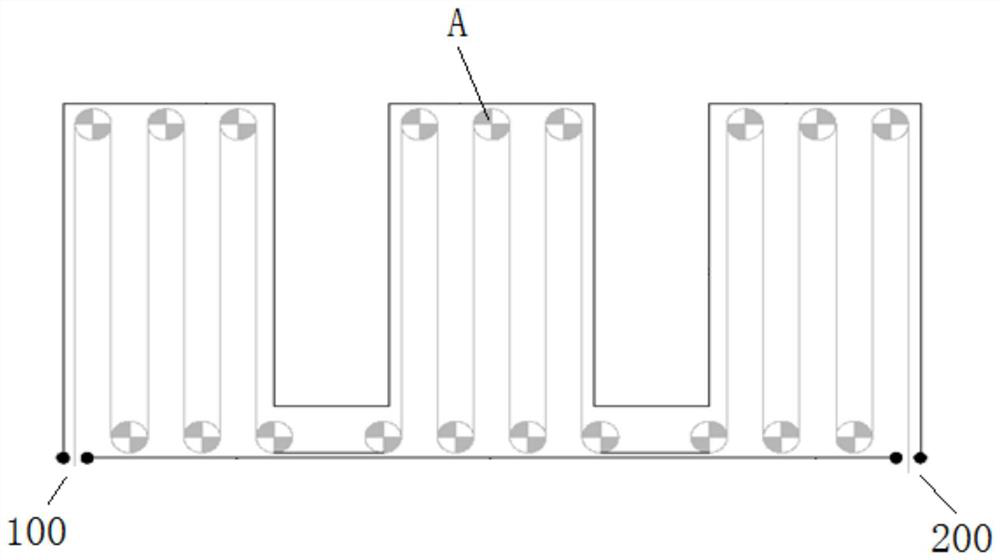

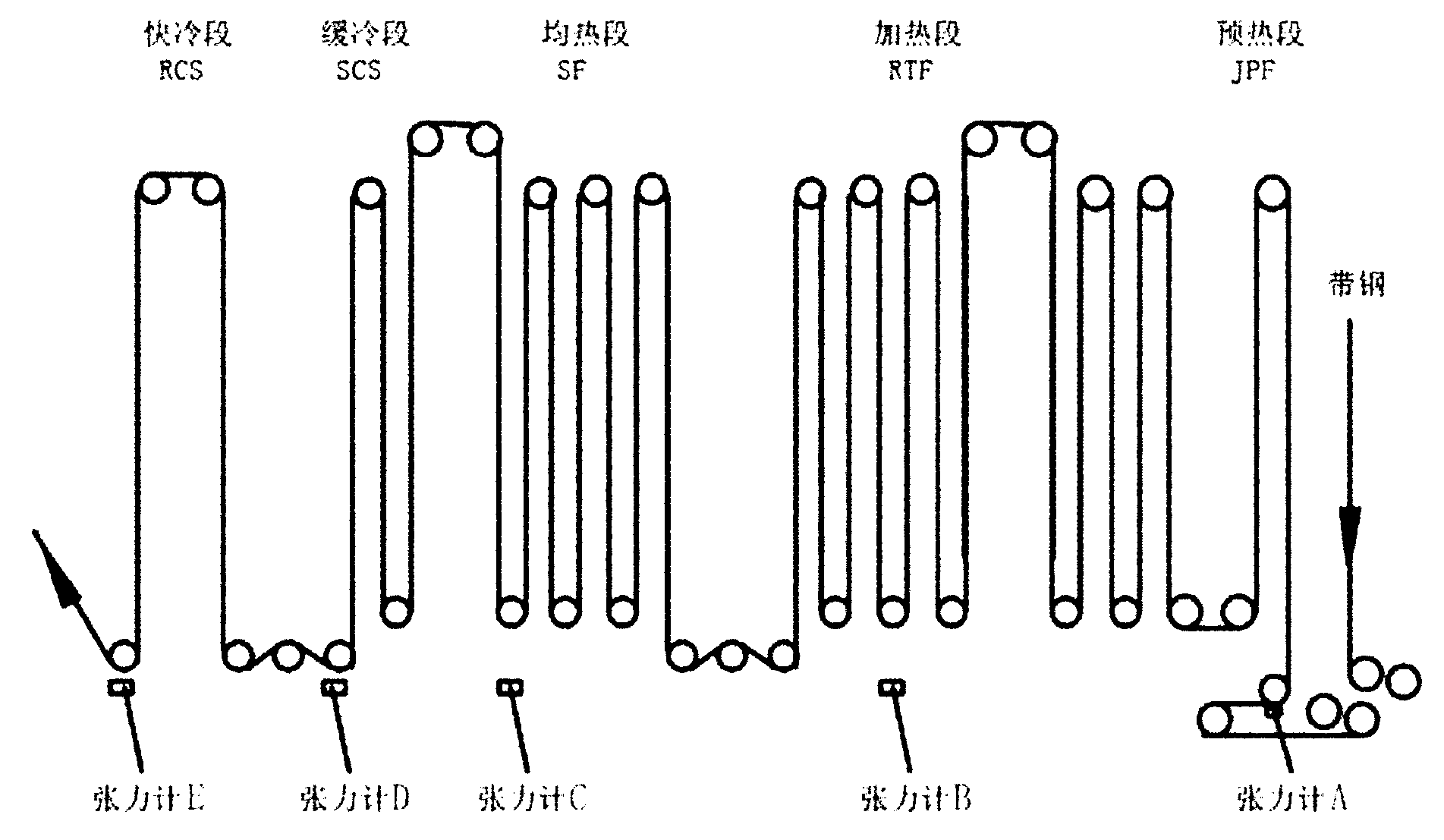

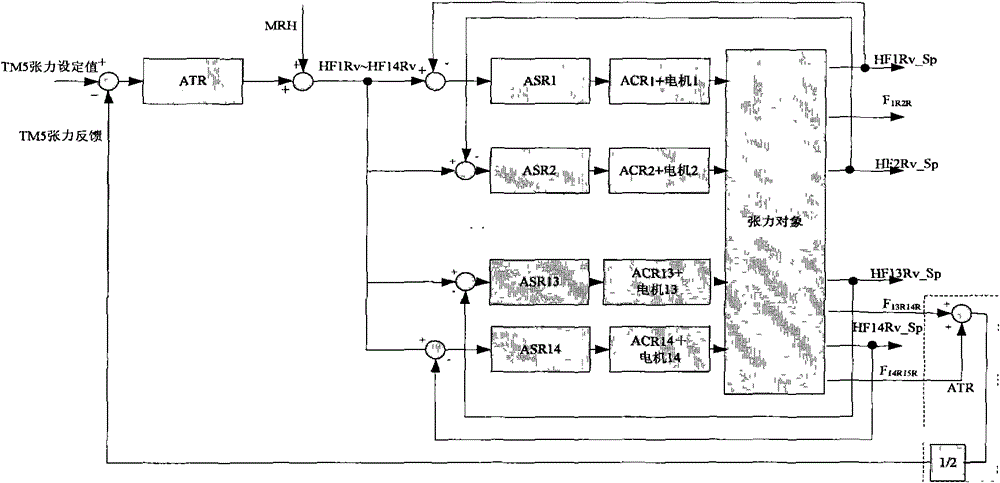

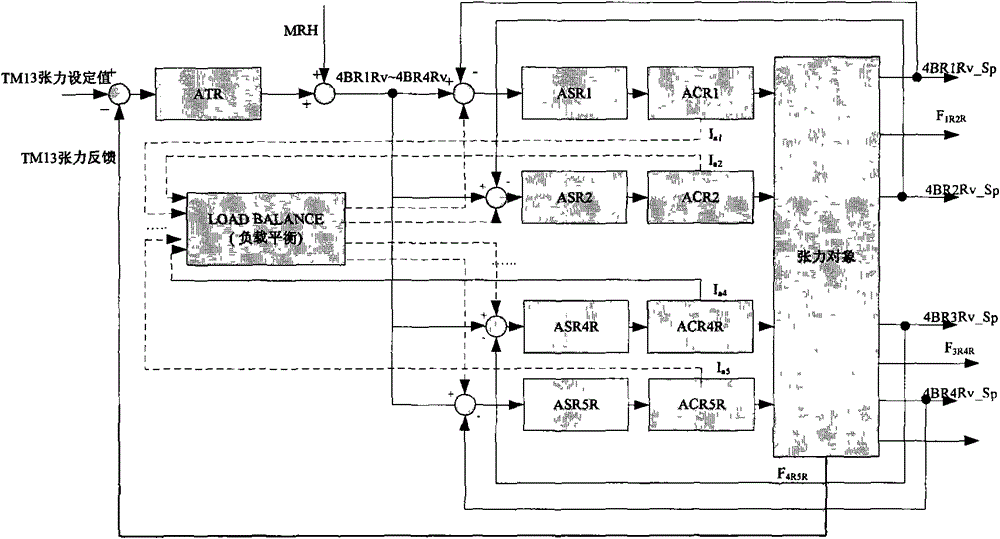

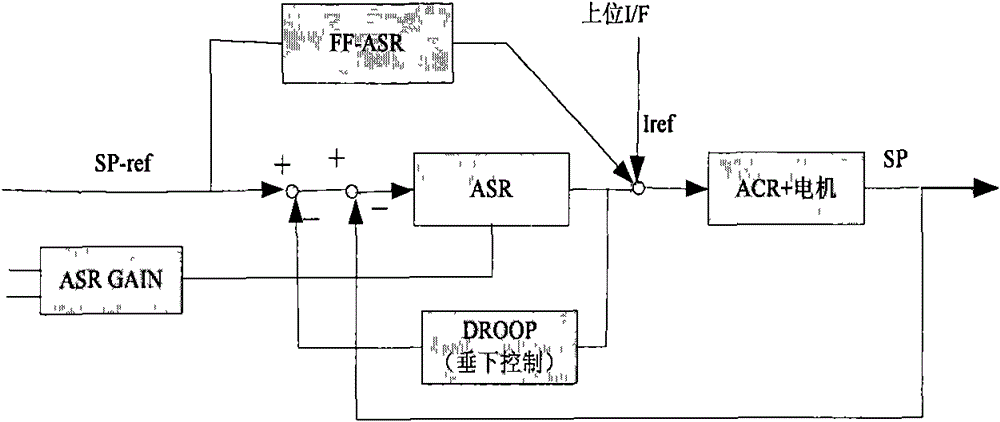

Soft-measuring method for tension of band steel between rollers of continuous annealing unit

ActiveCN102042893AAvoid broken belt accidentsAvoid Model ErrorsTension measurementLinear processFrequency domain

The invention discloses a soft-measuring method for the tension of band steel between rollers of a continuous annealing unit, comprising the following steps of: (1) acquiring process data; (2) preprocessing the process data; (3) constructing a soft-measuring model for combining a cascade observer with a neural network compensator; and (4) correcting the model. The moment current of a frequency converter corresponding to each roller between two tension measuring instruments, the speed and the boundary tension of each roller are used as the input quantity, the tension between every two rollers is calculated by the recursion in a cascade manner by adopting a frequency domain observer arithmetic, thus the indirect calculation and measuring on the tension of the band steel at the position where no tension measuring instrument is installed can be better realized, a favorable means is provided for the stability monitoring of the operation condition of the continuous annealing unit, high-precision calculation on the tension of the band steel at the position where no tension measuring instrument is installed is realized relatively accurately through compensating the nonlinear process characteristic and the unmodeled dynamics by applying a main model and neural network method, and a basis can be provided for the optimization on the control process parameter of tension in the continuous annealing unit.

Owner:BAOSHAN IRON & STEEL CO LTD

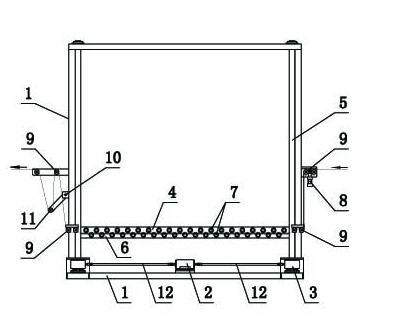

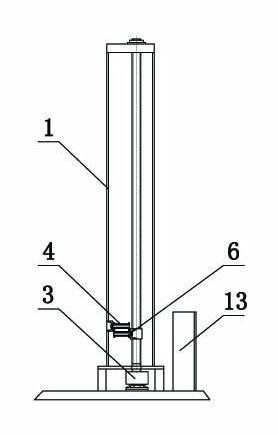

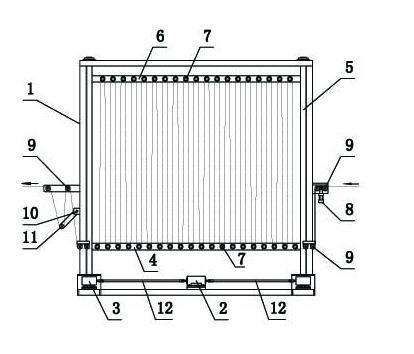

Steel strip and aluminium strip automatic storage machine

The invention relates to a steel strip and aluminium strip automatic storage machine, and belongs to the technical field of optical cable processing equipment. The steel strip and aluminium strip automatic storage machine is composed of a rack, a motor, speed variators, a fixing bracket, screw rods and a movable bracket, wherein the motor is fixedly installed at the middle part of the base of the rack, speed variators which are connected by a transmission shaft are installed at both ends of the base, the fixing bracket is installed at the lower part of the rack, screw rods which are connected with the speed variators are installed on upright columns at both sides of the rack, the movable bracket is installed on the screw rods, rotating guide wheels are installed on the fixing bracket and the movable bracket in a staggered way, and a strip pressing device, a potentiometric controller and a dance wheel are separately installed on outside of the upright columns of both sides of the rack. The steel strip and aluminium strip automatic storage machine moves up and down through the movable bracket, automatically stores the steel strip and aluminium strip on the storage machine and can control tension force when the strip is released to realize automatic strip storage and steady releasing operation, so as to solve the problem of the existing simple strip storage machine which requires manual control, and is prone to accidents of strip being wrung and broken. By adopting the steel strip and aluminium strip automatic storage machine, manpower resource is saved and production cost of optical cables is lowered.

Owner:HUBEI KAILE SCI & TECH

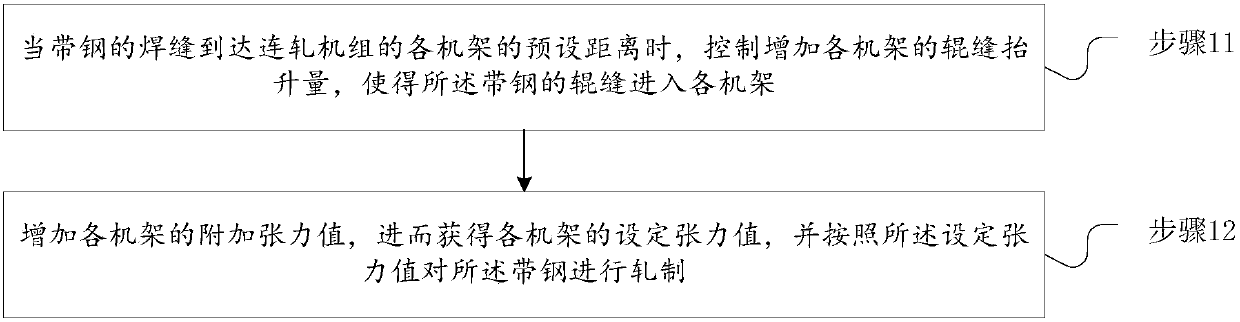

Rolling method for reducing edge cracking of continuous rolling mill

InactiveCN107900101AReduce rolling forceReduce tensile stressRoll force/gap control deviceTension/compression control deviceStrip steelWeld seam

The invention discloses a rolling method for reducing edge cracking of a continuous rolling mill. When a weld joint of a strip steel reaches the preset distance of all the racks of the continuous rolling unit, the lifting amount of a roller gap of each machine frame is controlled and enables the roller gap of the strip steel to enter into each machine frame, so the way of increasing the thicknessof the welding seam and reducing the rolling force of the welding seam area is achieved, edge split and strip breakage accidents caused by ultra-thin strip heads and excessively large rolling force can be avoided, and the smooth rolling is guaranteed. The additional tension value of each machine frame is increased, then the set tension value of each machine frame is obtained, the strip steel is rolled according to the set tension value, so that the tensile stress of the welding seam area is reduced, edge split can be avoided or reduced, so that the phenomenon of strip breakage caused by edge split of the front region and the rear region of the weld joint is avoided, and free rolling of the rolling mill is facilitated.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

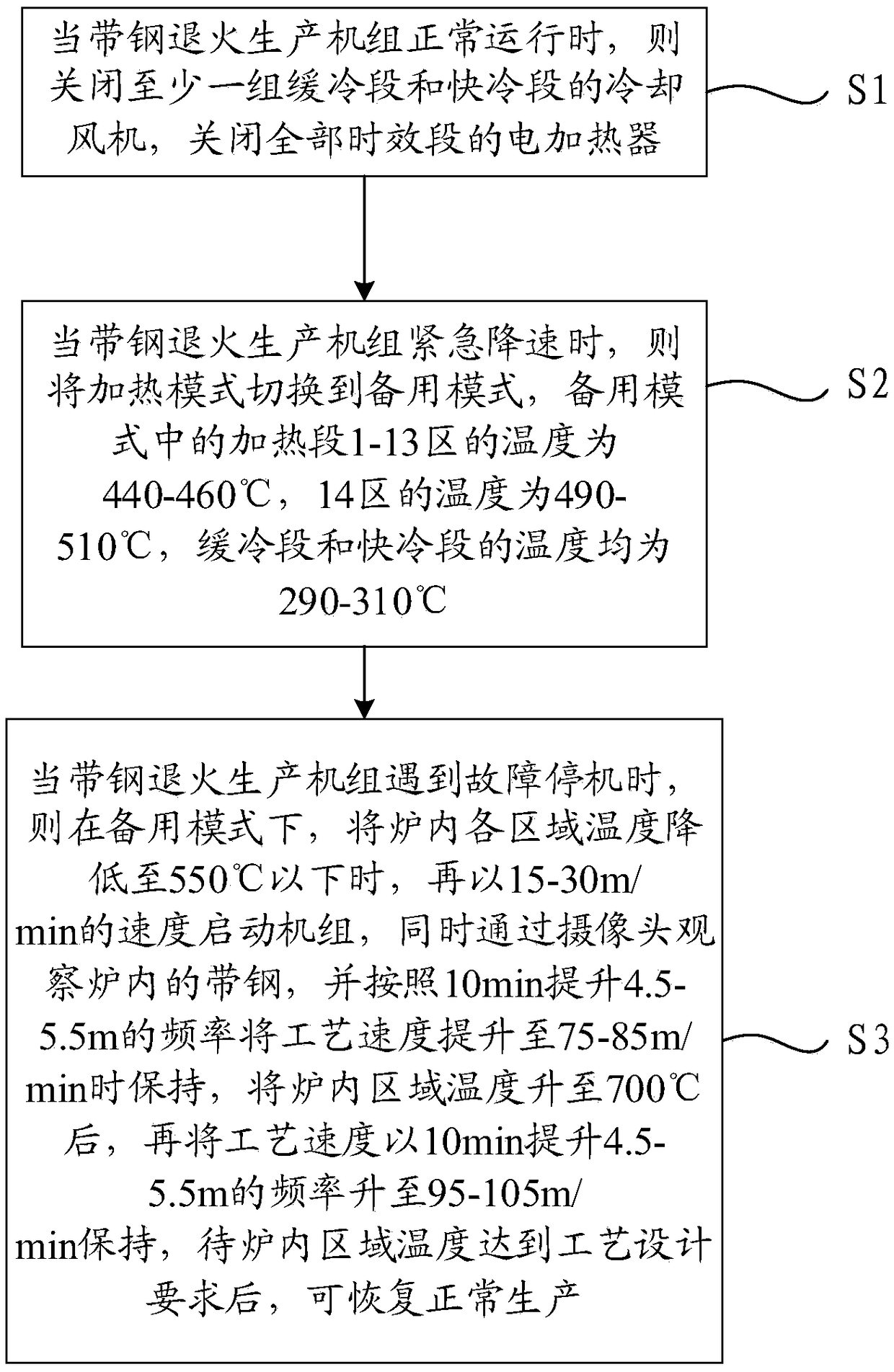

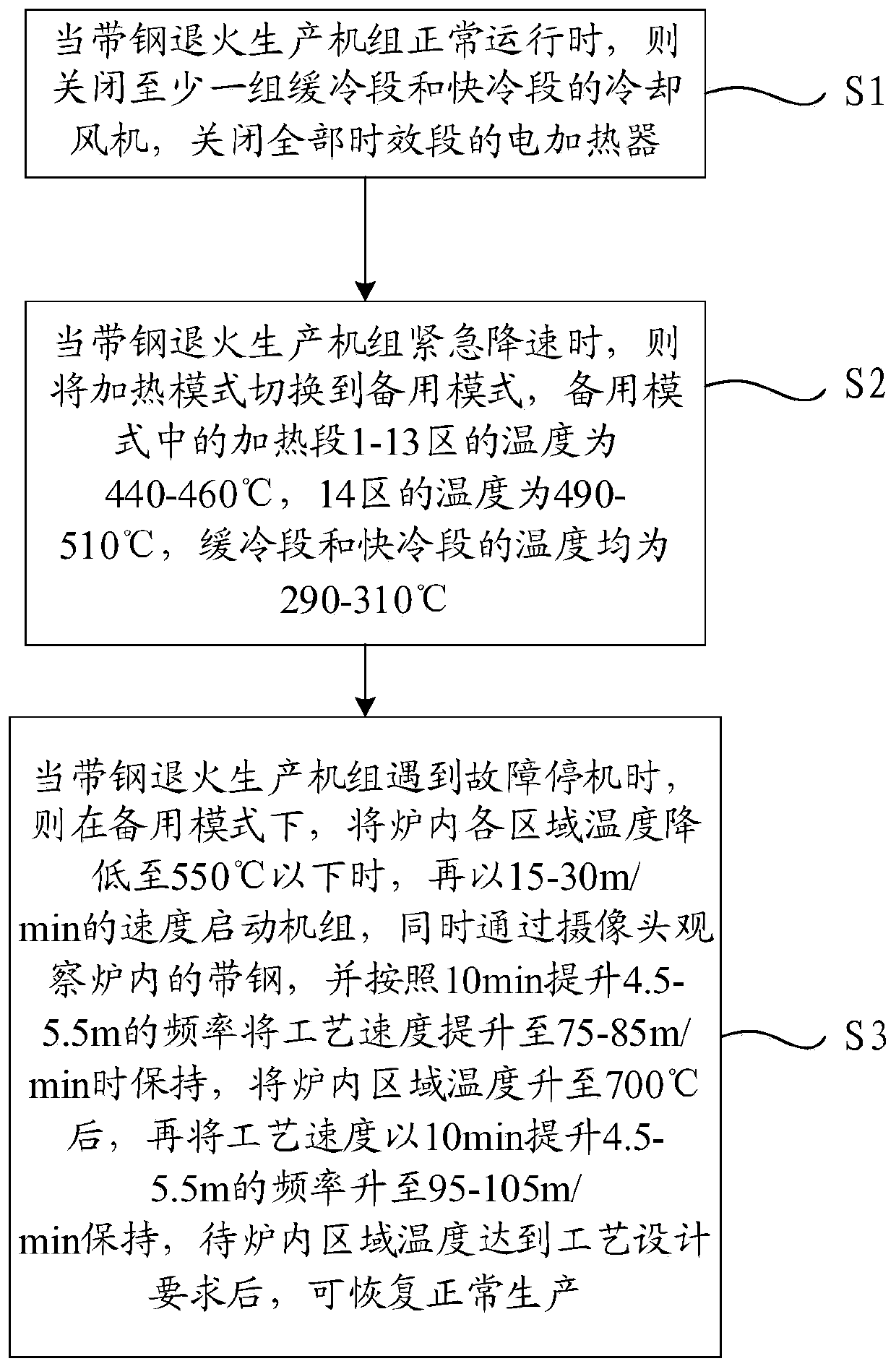

0.4 mm thin IF steel strip continuous annealing anti-wrinkling control method

ActiveCN109207711AStable productionReach the goal of cost reduction and efficiency increaseFurnace typesHeat treatment process controlStrip steelContinuous annealing

The invention discloses a 0.4 mm thin IF steel strip continuous annealing anti-wrinkling control method, including steps of: a) during normal operation of a steel strip annealing production unit, shutting off cooling fans of at least one group of slow cooling sections and quick cooling sections, and shutting off electric heaters in all aging sections; b) during emergency speed down of the steel strip annealing production unit, switching heating mode into standby mode; c) when the steel strip annealing production unit is shutdown in failure, reducing the temperature of all zones in the furnaceto lower than 550 DEG C and increasing technical speed to 75-85 m / min with maintenance, then heating the temperature of the internal zone of the furnace to 700 DEG C, and increasing the technical speed to 95-105 m / min with maintenance, and when the temperature of the internal zone of the furnace reaches technical design requirement, returning to normal production. By means of the method, cold-wrinkling during production of the 0.4 mm thin IF steel strip is prevented, and accident of breaking of the steel strip is avoided. The method guarantees normal and stable production of the unit and reaches the object of reducing cost and increasing efficiency in enterprises.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

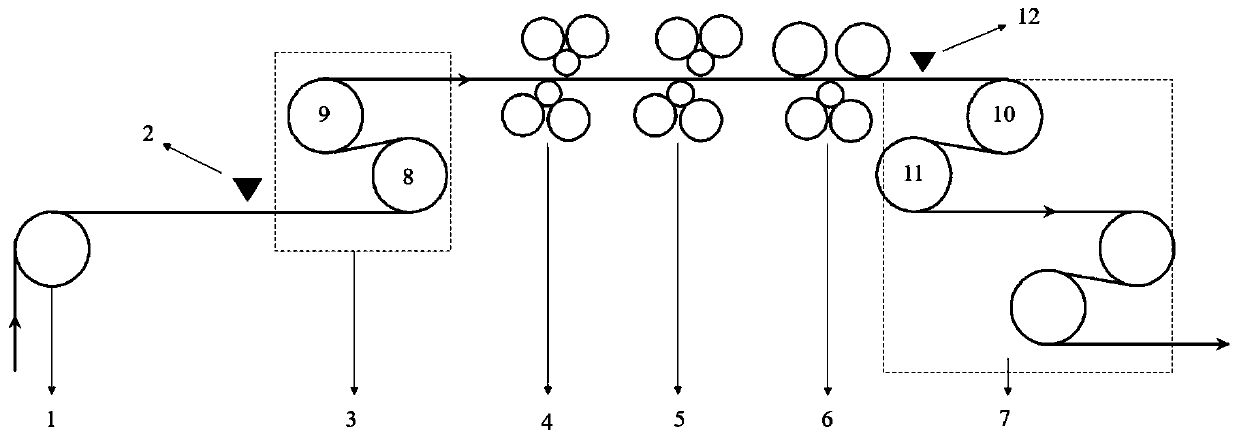

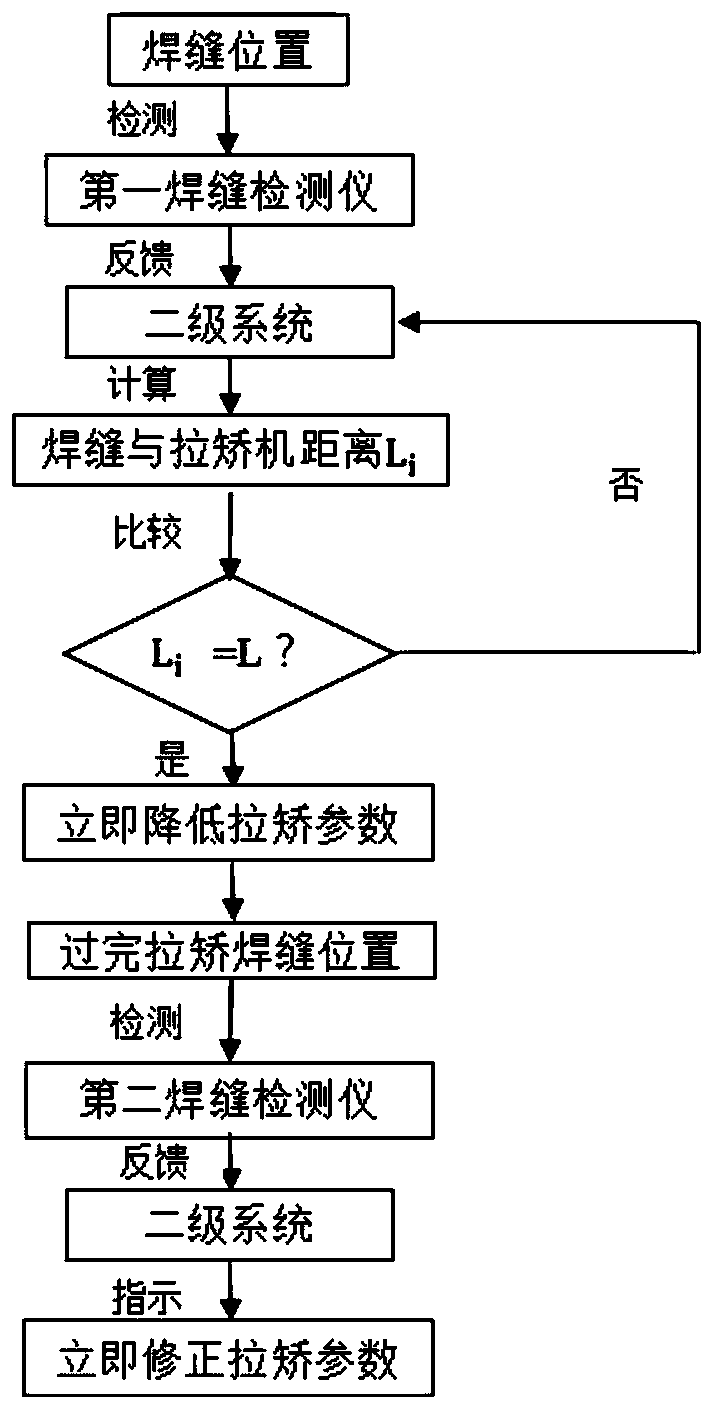

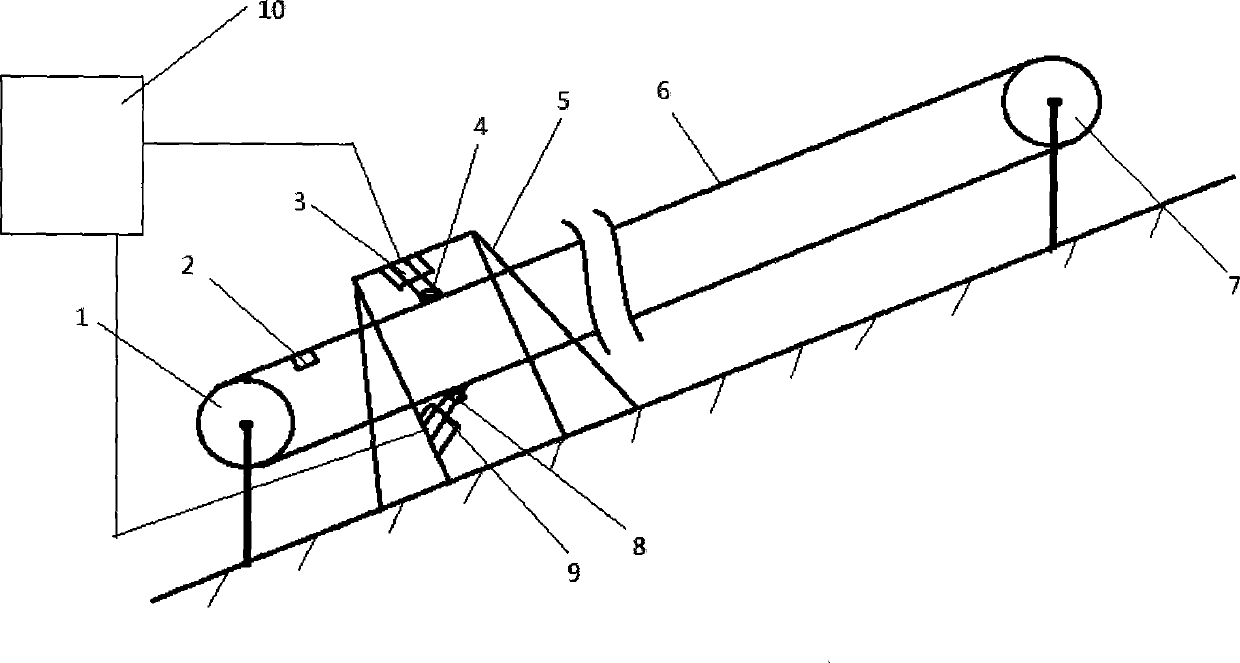

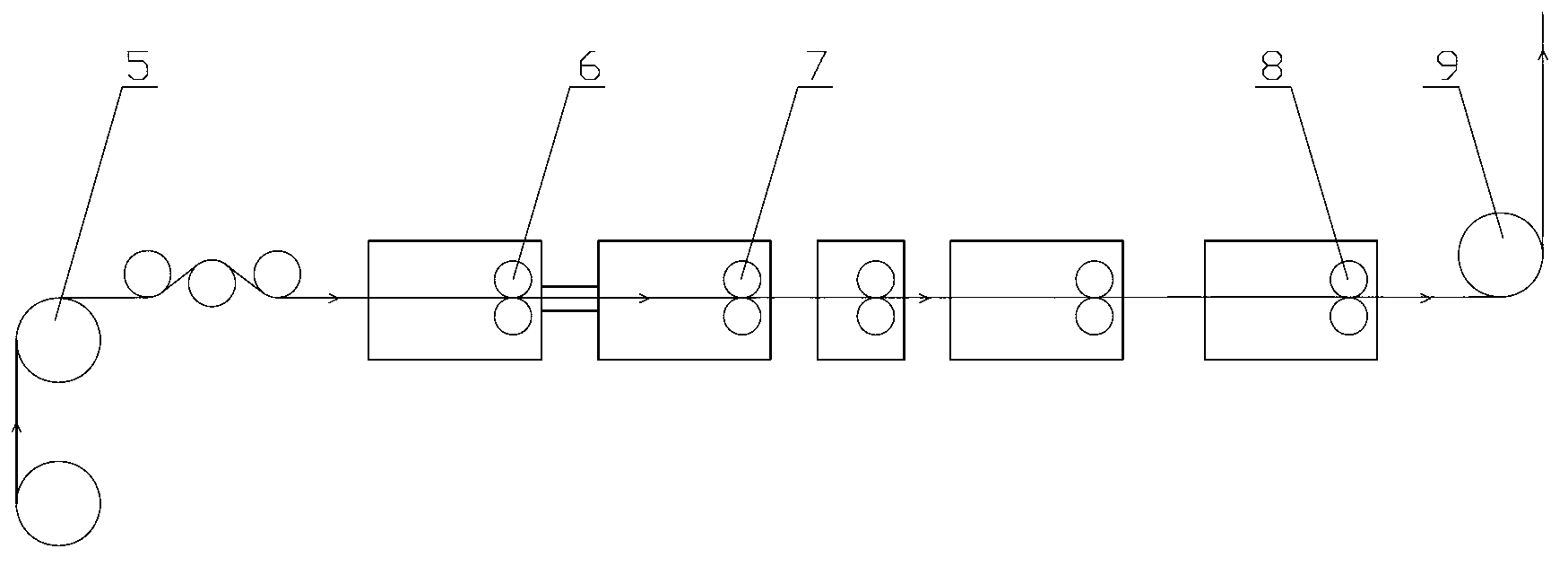

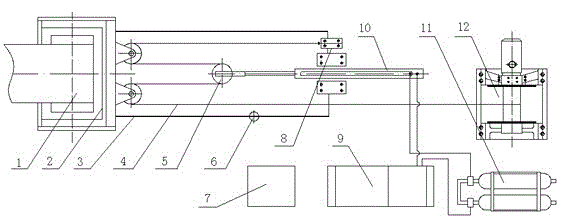

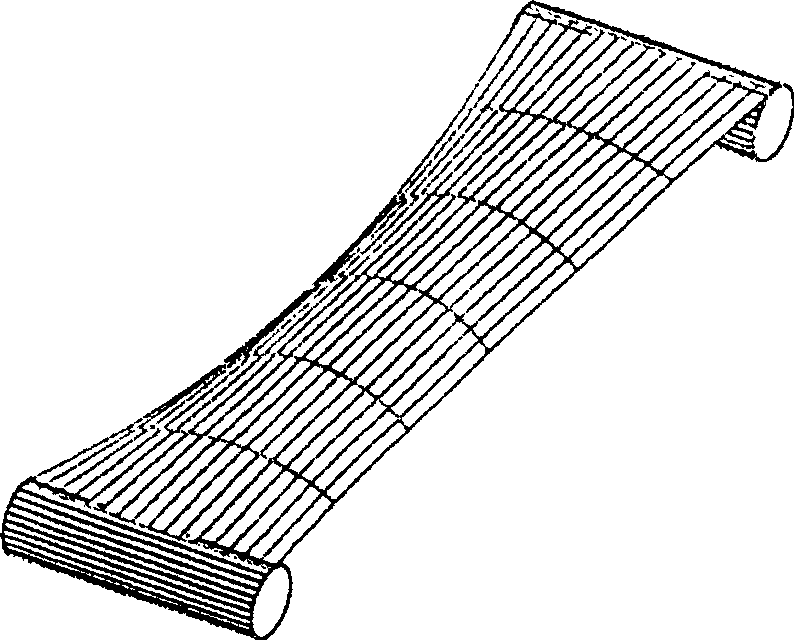

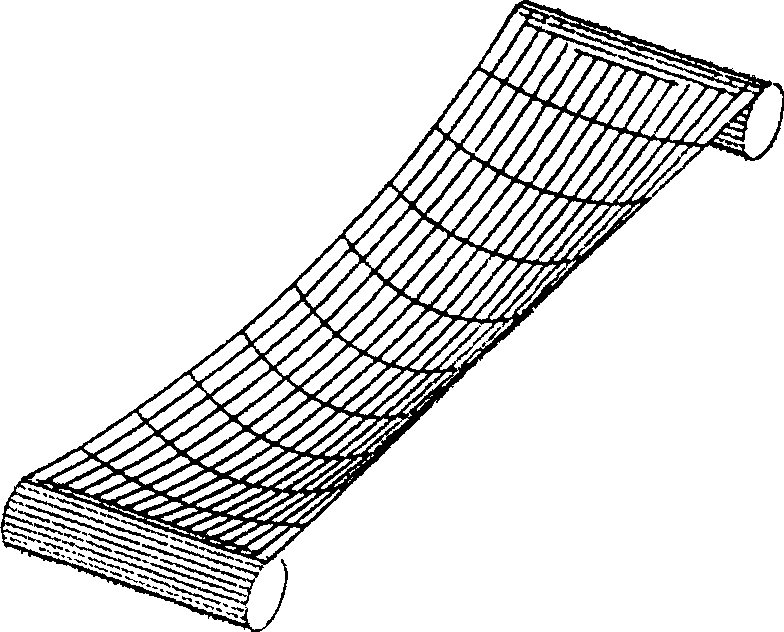

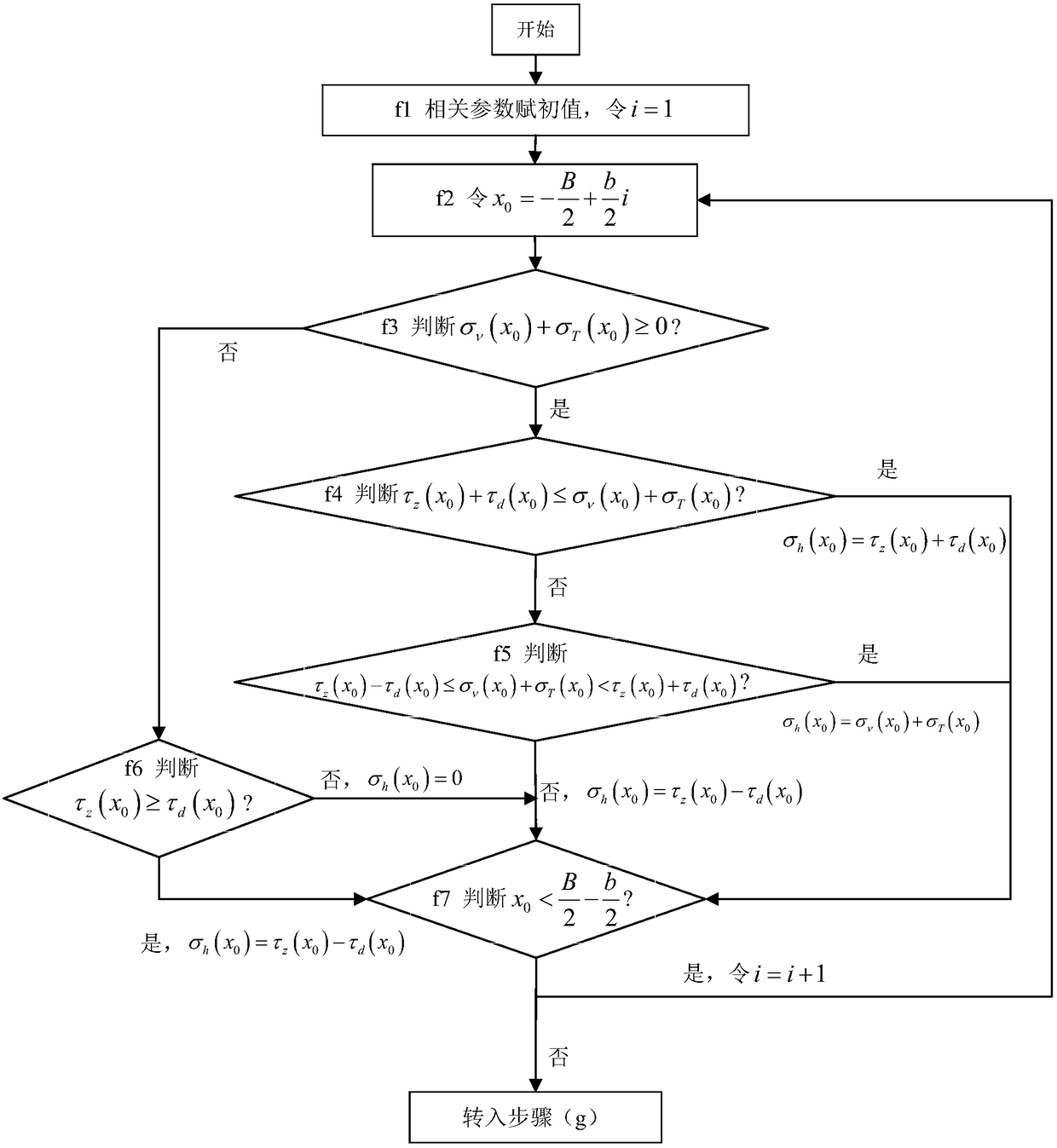

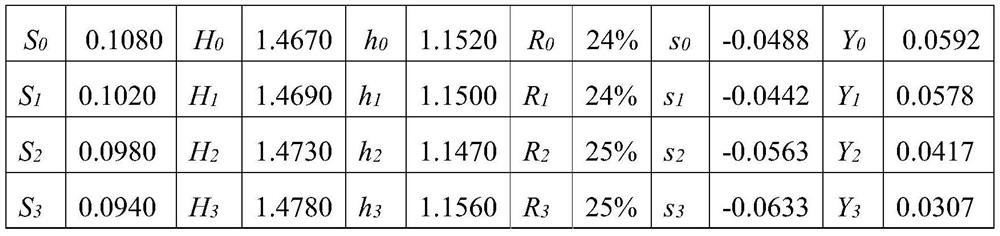

Stretching bending straightening mechanical system with self-adaptive function in case of pass through welding seam

PendingCN111185482AImprove yieldReduce the amount of resectionWork treatment devicesMeasuring devicesStructural engineeringStrip steel

The invention provides a stretching bending straightening mechanical system with a self-adaptive function in the case of pass through a welding seam, and belongs to the technical field of cold rolling. The system involves a turning roller, a first welding seam detector, an inlet tensioning roller group, a 1# bending roller group, a 2# bending roller group, a straightening roller group, a second welding seam detector and an outlet tensioning roller group, wherein the first welding seam detector is arranged behind the turning roller, the second welding seam detector is arranged behind the straightening roller group, the inlet tensioning roller group is arranged behind the first welding seam detector, the outlet tensioning roller group is arranged behind the second welding seam detector, andthe 1# bending roller group, the 2# bending roller group and the straightening roller group are arranged between the inlet tensioning roller group and the outlet tensioning roller group in sequence. The system can adapt to welding seams, passing through a stretching straightening machine, of strip steel with various strength, width and thickness specifications, and can realize automatic switchingof stretching straightening process parameters of the welding seam with poor welding quality according to the detected welding seam position, thereby reducing the workload on workers and improving theautomatic working capacity of the equipment.

Owner:UNIV OF SCI & TECH BEIJING

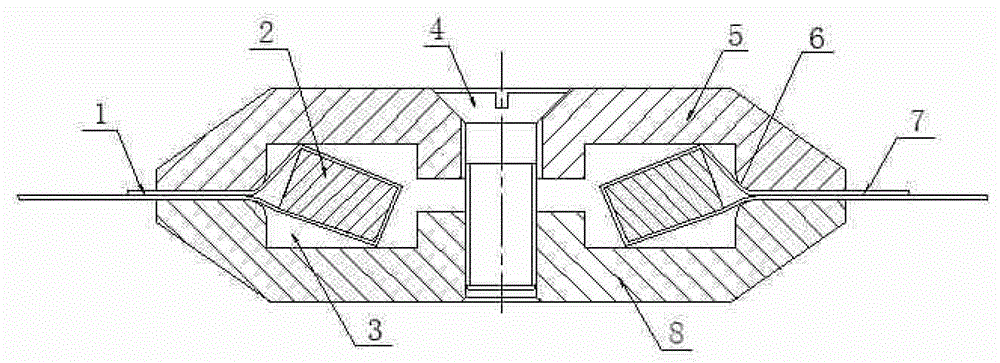

Breakage protection device for belt conveyor

InactiveCN103771108APrevent heavy loads from slippingAvoid broken belt accidentsControl devices for conveyorsHydraulic cylinderHydraulic pump

The invention provides a breakage protection device for a belt conveyor. The breakage protection device for the belt conveyor comprises a driving drum, a reversing drum and a conveyor belt sleeved therebetween, wherein a support is arranged above the conveyor belt; an upper pressing beam vertical to the upper end surface of the conveyor belt is arranged in the middle of the support; the other end of the upper pressing beam is connected with a piston end of an upper hydraulic oil cylinder; a lower pressing beam for pressing the lower end surface of the conveyor belt is arranged in the middle of the support; the other end of the lower pressing beam is connected with a piston end of a lower hydraulic oil cylinder; the upper hydraulic oil cylinder and the lower hydraulic oil cylinder are connected with a hydraulic pump station through oil pipes respectively; a sensor for detecting reverse running condition of the conveyor belt is arranged below the conveyor belt at an interval; a controller is connected at the output end of the sensor; the output end of the controller is connected with the hydraulic pump station. Before breakage of the conveyor belt, the conveyor belt is stopped so as to prevent a heavy load thereon from sliding down, so that a breakage accident of the belt conveyor running in an inclined way can be effectively prevented and the safety of mine production is ensured.

Owner:王刚

A 0.4mm Thin Strip IF Steel Continuous Stripping Anti-Wrinkle Control Method

ActiveCN109207711BStable productionReach the goal of cost reduction and efficiency increaseFurnace typesHeat treatment process controlProcess engineeringContinuous annealing

The invention discloses a 0.4 mm thin IF steel strip continuous annealing anti-wrinkling control method, including steps of: a) during normal operation of a steel strip annealing production unit, shutting off cooling fans of at least one group of slow cooling sections and quick cooling sections, and shutting off electric heaters in all aging sections; b) during emergency speed down of the steel strip annealing production unit, switching heating mode into standby mode; c) when the steel strip annealing production unit is shutdown in failure, reducing the temperature of all zones in the furnaceto lower than 550 DEG C and increasing technical speed to 75-85 m / min with maintenance, then heating the temperature of the internal zone of the furnace to 700 DEG C, and increasing the technical speed to 95-105 m / min with maintenance, and when the temperature of the internal zone of the furnace reaches technical design requirement, returning to normal production. By means of the method, cold-wrinkling during production of the 0.4 mm thin IF steel strip is prevented, and accident of breaking of the steel strip is avoided. The method guarantees normal and stable production of the unit and reaches the object of reducing cost and increasing efficiency in enterprises.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

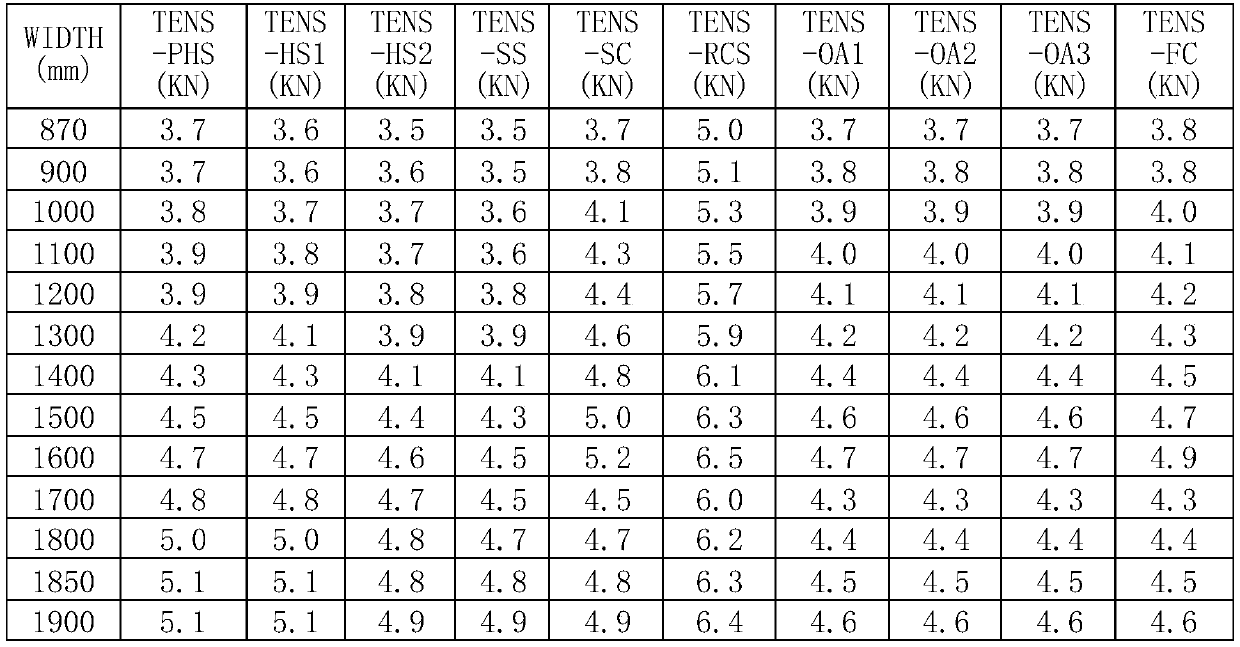

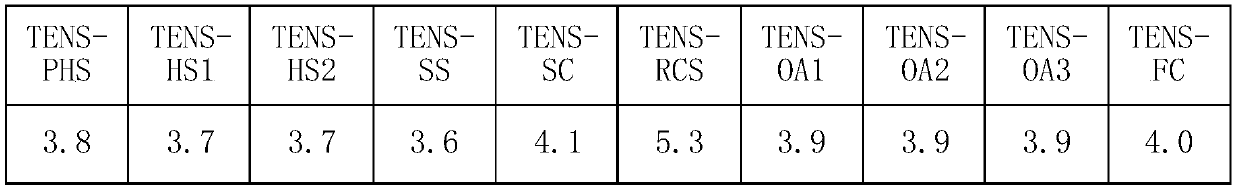

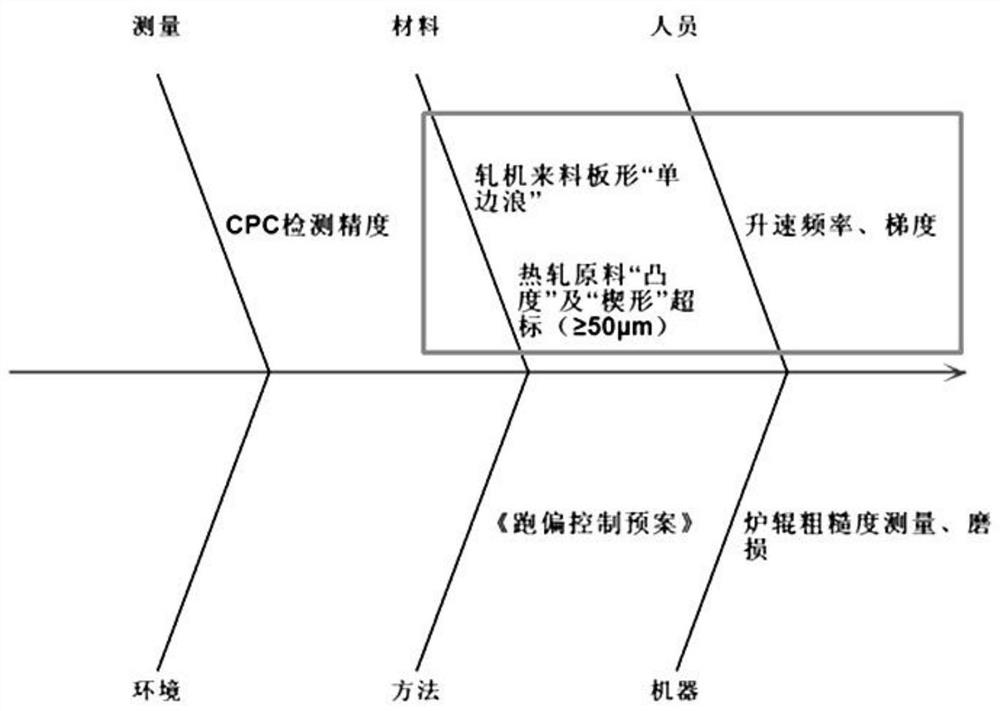

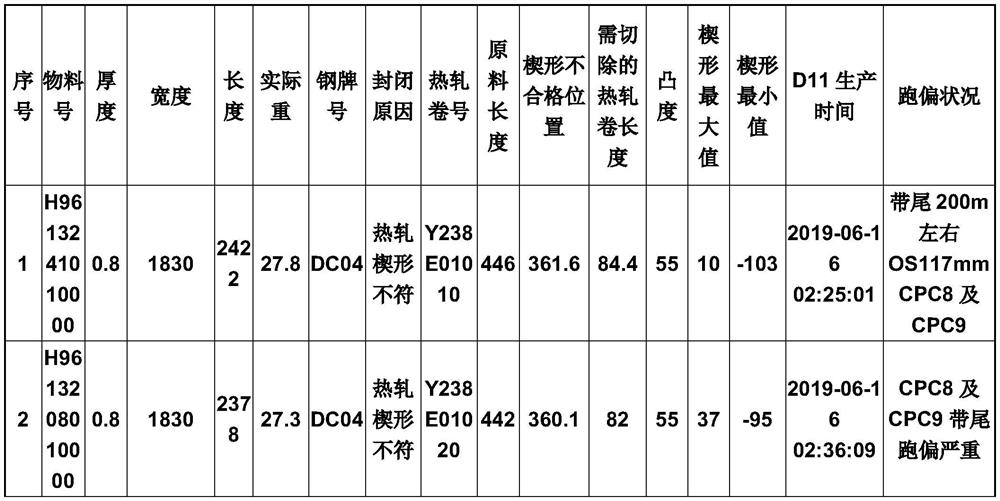

Method for controlling deviation of wide materials of continuous annealing unit

InactiveCN111850280AReduce the risk of going off trackAvoid broken belt accidentsFurnace typesHeat treatment furnacesMicrometerEngineering

The invention belongs to the technical field of steel rolling heat treatment, and particularly relates to a method for controlling deviation of wide materials of a continuous annealing unit. The method comprises the following steps of 1) controlling the plate shape of an incoming material of a rolling mill; 2) controlling a convexity value and a wedge-shaped value of a hot-rolled strip steel; andconducting closed discharge or repairing and cutting off on a steel coil with the convexity value less than 40 micrometers or the convexity value larger than 80 micrometers and the wedge-shaped valuelarger than 50 micrometers; 3) cutting off a seriously defective part of the strip shape in the head and tail areas of the steel coil, and sealing the steel coil with a poor strip shape of the whole coil; and 4) controlling the deviation of a strip steel furnace area, specifically, when the temperature of the furnace area is reduced to 700 DEG C or below, controlling a strip steel speed at a deviation position to enable the strip steel to crawl out of the furnace at the speed of V less than or equal to 30m / min, and increasing the speed of the furnace area only after the deviation amount of thestrip steel is less than or equal to 50mm. According to the method, the strip steel deviation risk is reduced, and the strip breakage accident in the furnace is avoided.

Owner:ANGANG STEEL CO LTD

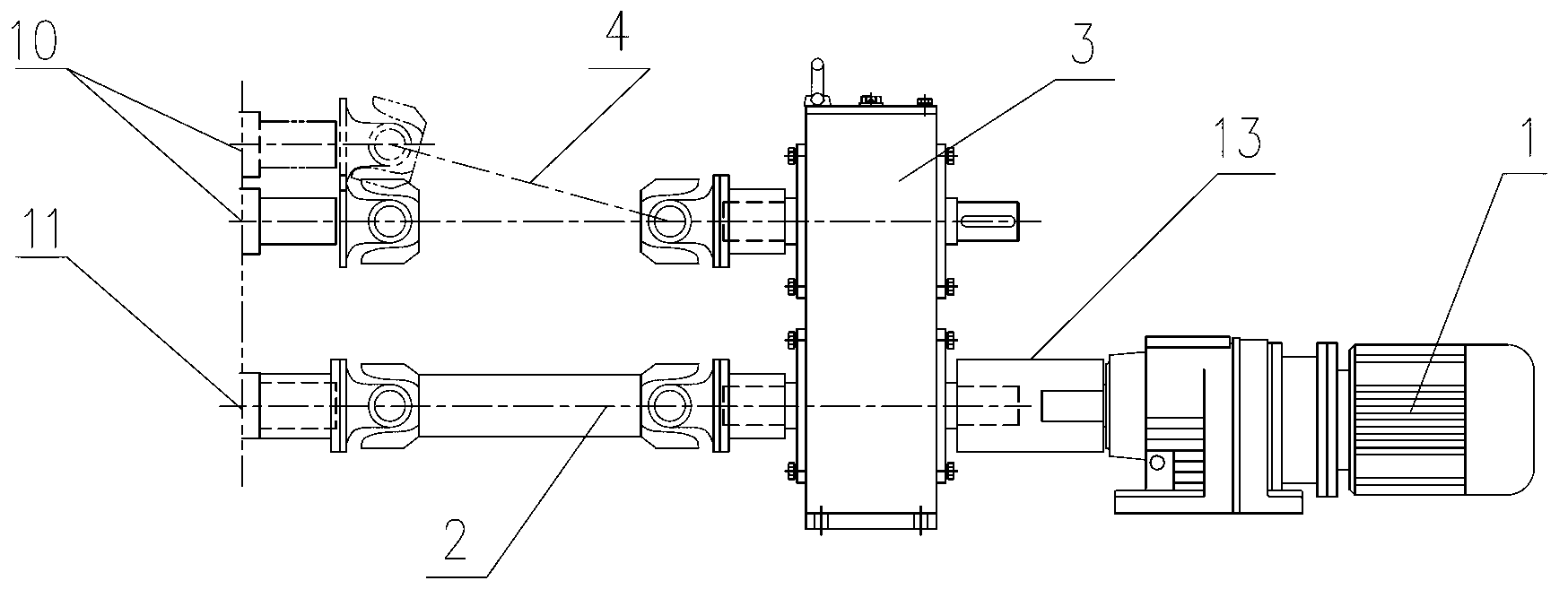

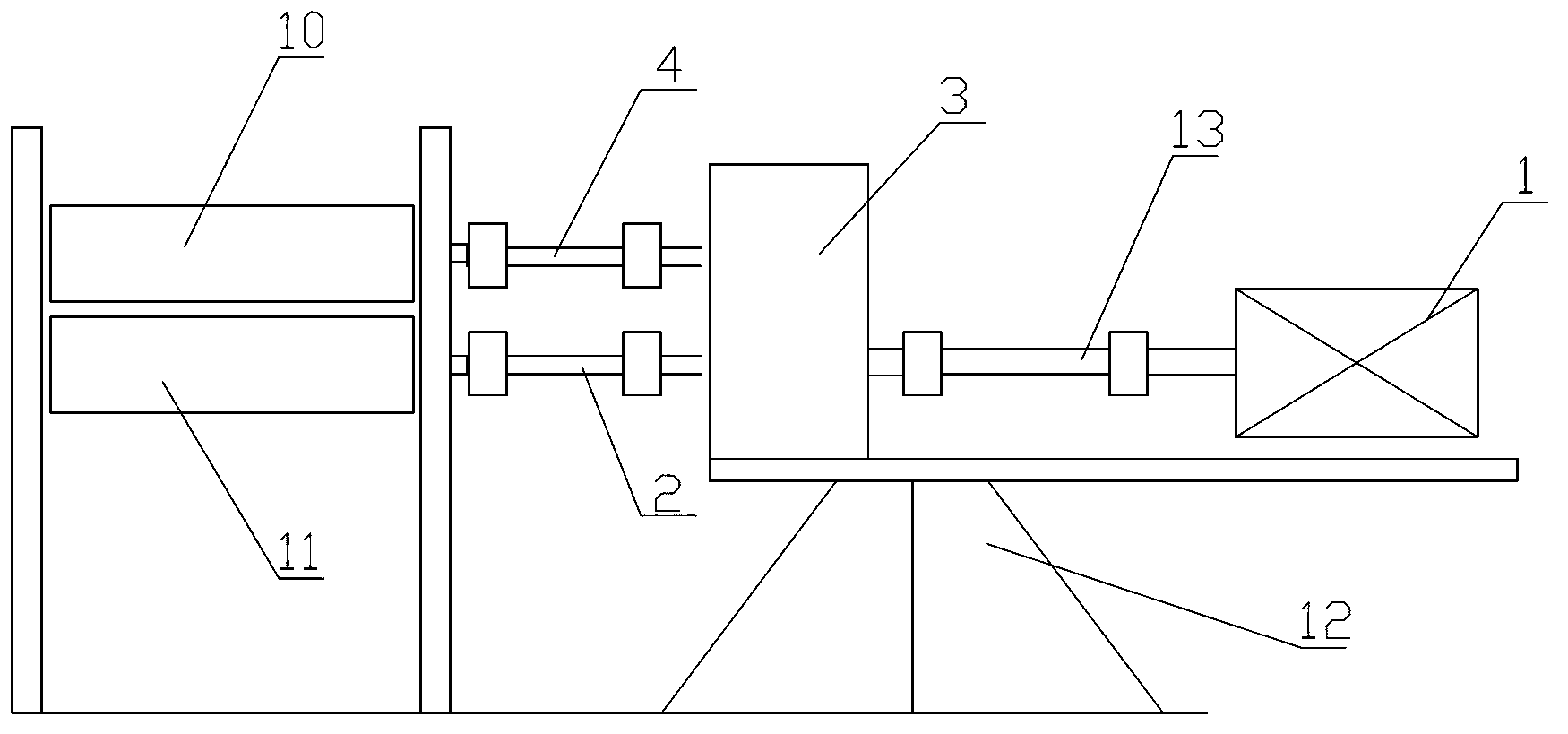

Device and method for preventing alkali wash section of continuous annealing line from off-tracking

The invention relates to device and method for preventing an alkali wash section of a continuous annealing line from off-tracking. The device comprises a variable frequency motor, a shaft coupler, a gear case and wring rollers, wherein the wring rollers comprise an upper wring roller and a lower wring roller; the gear case is arranged between the wring rollers and the shaft coupler; one end of the shaft coupler is connected with the output end of the variable frequency motor; the other end of the shaft coupler is connected with the input end of the gear case; the output end of the gear case is connected with the upper wring roller through a joint type shaft coupler I; the output end of the gear case is connected with the lower wring roller through a joint type shaft coupler II; and the variable frequency motor drives the shaft coupler to rotate. The off-tracking prevention method comprises the following steps that: a steel strip passes through the wring roller of the alkali section, and passes through between the upper wring roller and the lower wring roller which are used as driving rollers. The device and the method provided by the invention has the advantages that the steel strip is prevented from off tracking on the alkali section, so that waste products and wastes of various energies can be reduced; and meanwhile, the strip breakage accident is prevented from occurring, so that the production can be smoothly carried out. The production efficiency is improved, and the spare consumption is reduced.

Owner:ANGANG STEEL CO LTD

Automatic-control rubber belt hydraulic tightening device

The invention discloses an automatic-control rubber belt hydraulic tightening device, which comprises a hydraulic pump station, a control box, a tightening oil cylinder and an energy storage station, wherein a control host machine, a digital control circuit and a random function module are arranged in the control box; and the digital control circuit and the random function module are connected with the control host machine. The automatic-control rubber belt hydraulic tightening device is compact in structure, light in weight, small in impact force and stable and reliable in starting, the carrying tensile force can be changed randomly, and therefore, the phenomena including belt breakage, belt abrasion and the like can be avoided. Meanwhile, the automatic-control rubber belt hydraulic tightening device is flameproof and safe.

Owner:扬州市神威机械设备有限公司

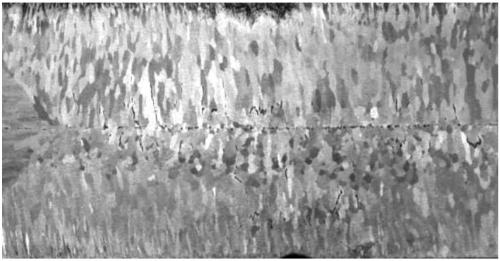

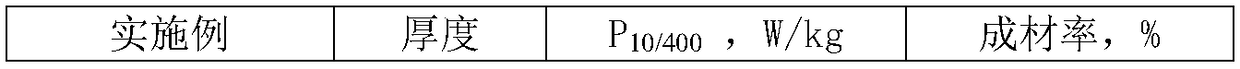

Production method for high-frequency thin-ribbon silicon steel

InactiveCN109082605AIsotropic favorableReduce smeltingTemperature control deviceMetal rolling arrangementsNiobiumManganese

The invention provides a production method for high-frequency thin-ribbon silicon steel. The production method is applicable to cold rolled non-oriented silicon steel of which the content of a main body alloy of silicon, manganese and aluminum is greater than 2.5%, and comprises the following steps: 1) carrying out refining decarbonization, silicon deoxidation, silicon alloying and aluminum alloying; 2) controlling contents of harmful elements, namely controlling that the content of sulfur is less than or equal to 0.020%, the content of nitrogen is less than or equal to 0.0100%, and the overall content of niobium, vanadium and titanium is less than or equal to 0.025%; 3) controlling a superheat degree for 15-50 DEG C and a pull speed within 0.3-1.2m / min in a continuous casting process, andcontrolling that the ratio of columnar crystal of a cast blank is greater than or equal to 50%; 4) controlling a feeding temperature greater than or equal to 300 DEG C for cast blank hot rolling, andheating with a neutral or reductive atmosphere, wherein the heating temperature is less than or equal to 1200 DEG C, and the heating control is controlled within 180-240 minutes. A finished product thinning effect and an effect of reducing eddy-current loss of high-frequency magnetization are achieved. Production control difficulties of overall procedures are reduced, and technical difficulties of higher alloy contents and thinner products are also avoided.

Owner:ANGANG STEEL CO LTD

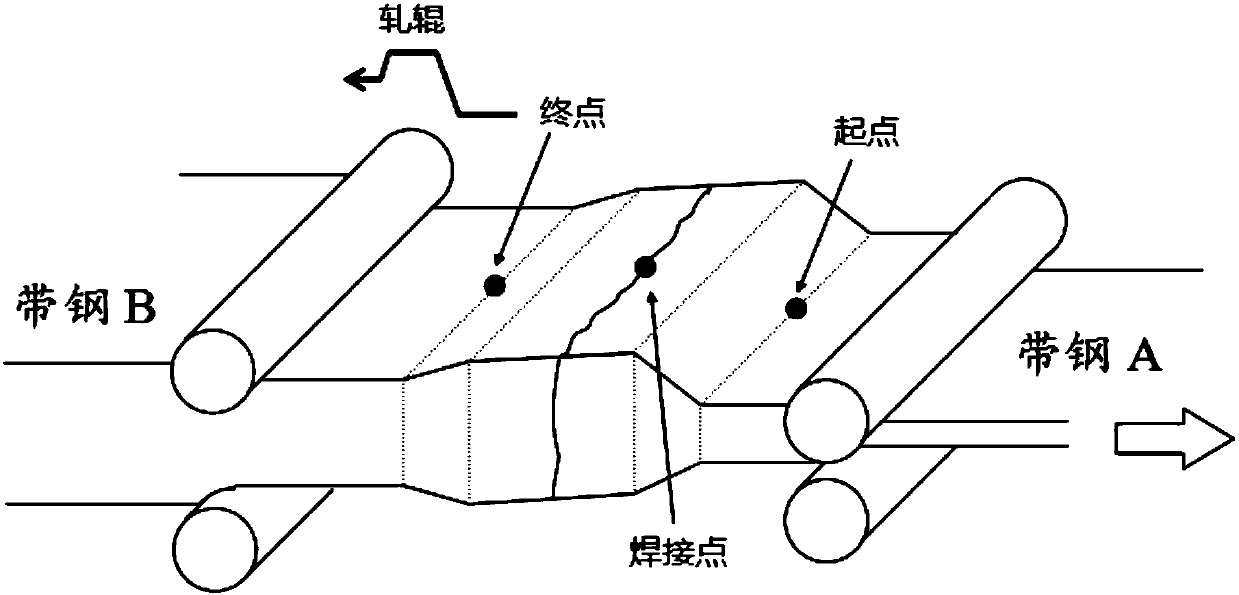

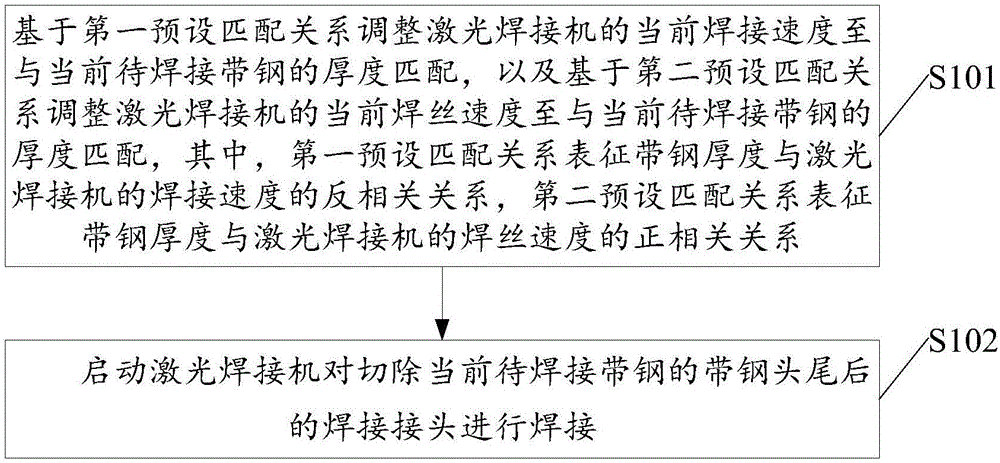

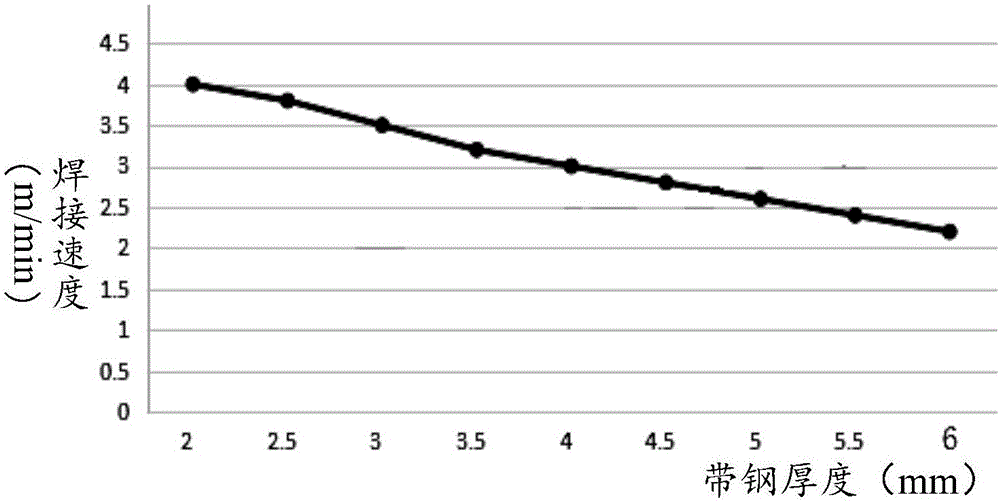

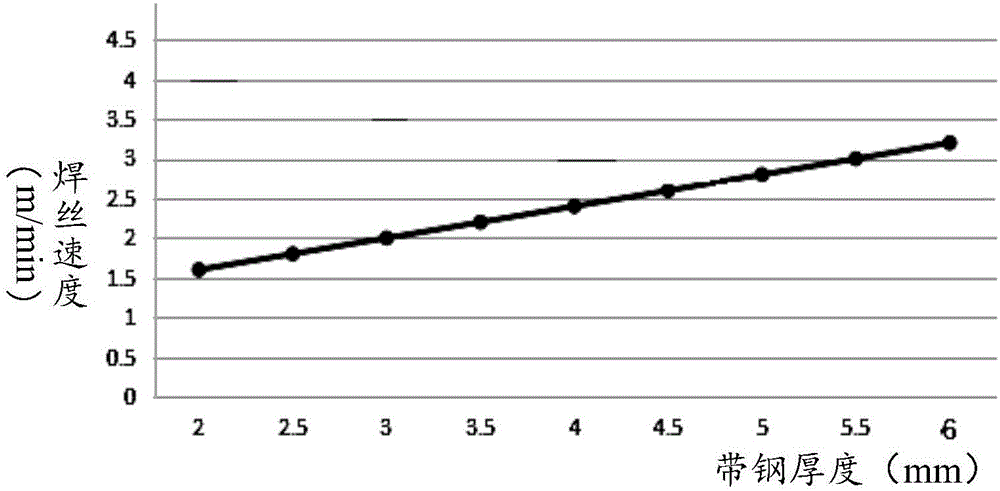

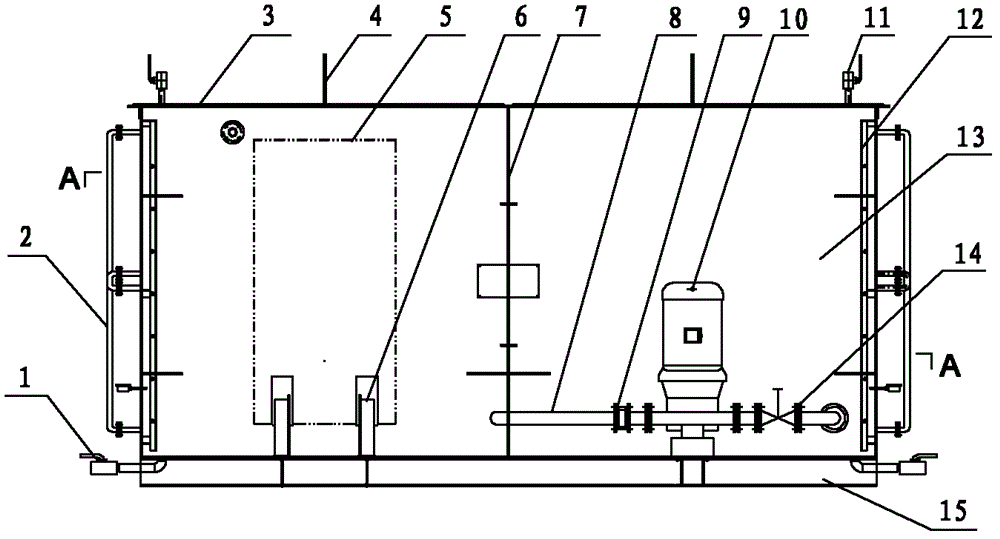

Laser welding method and laser welding device

ActiveCN106392326AAvoid broken belt accidentsReduced welding speedWelding/soldering/cutting articlesMetal working apparatusLaser solderingPositive correlation

The invention discloses a laser welding method and a laser welding device, and is applied to the field of cold continuous rolling. The laser welding method comprises the steps that on the basis of the first preset matching relation, the current welding speed of a laser welding machine is adjusted to be matched with the thickness of current to-be-welded strip steel, and on the basis of the second preset matching relation, the current welding wire speed of the laser welding machine is adjusted to be matched with the thickness of the current to-be-welded strip steel, wherein the first preset matching relation represents the inverse correlation of the strip steel thickness and the welding speed of the laser welding machine, and the second preset matching relation represents the positive correlation of the strip steel thickness and the welding wire speed of the laser welding machine; the laser welding machine is started to weld a welding joint after the head and the tail of the current to-be-welded strip steel are cut. The technical problem that during rolling production of an existing DP980 steel ball in a continuous rolling unit, strip breakage happens is solved, and the continuous rolling production requirement is met.

Owner:BEIJING SHOUGANG COLD ROLLED SHEET

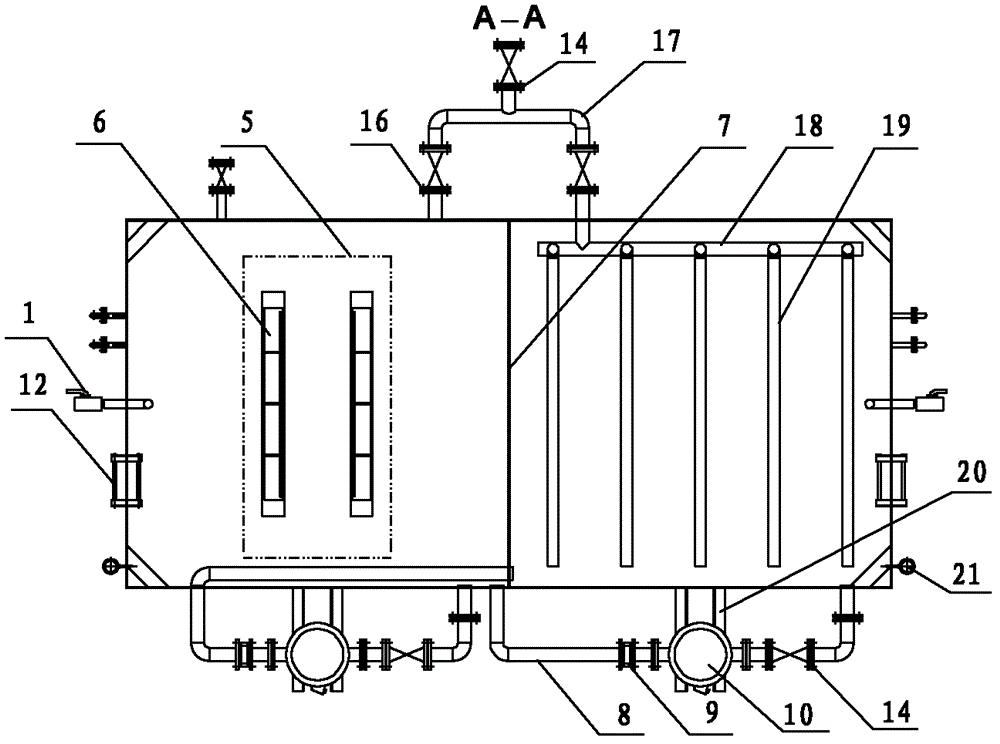

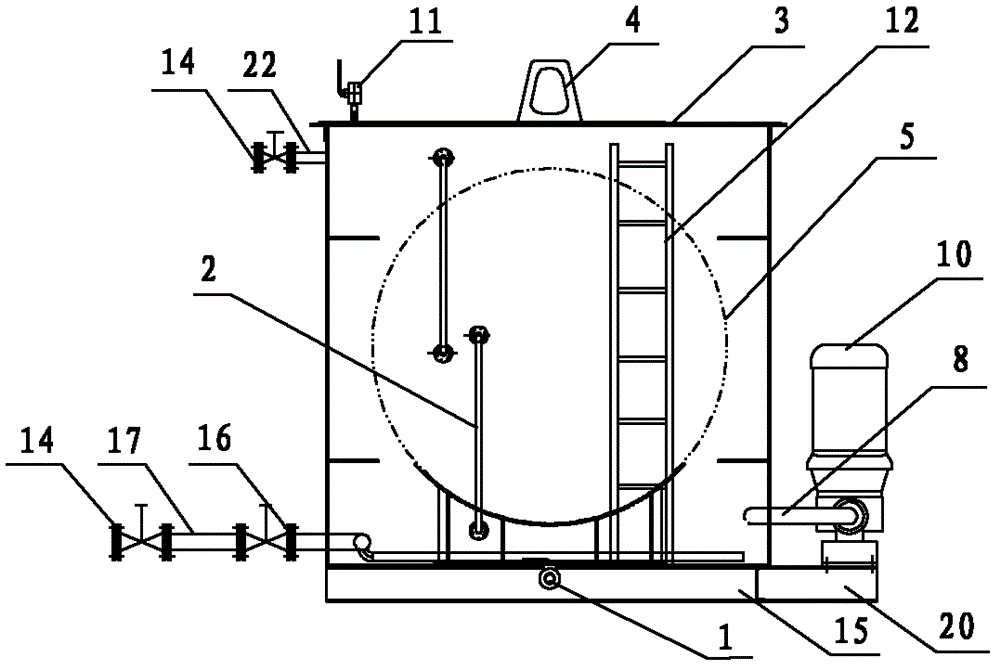

Heating device and heating method for edges of steel coils

ActiveCN102950158BTake advantage ofAvoid wastageWork treatment devicesMetal rolling arrangementsWater circulationEngineering

The invention provides a heating device and a heating method for edges of steel coils. The heating device comprises a water circulation system, a steam heating system, an electric control cabinet and a heating device, wherein the water circulation system comprises a hot water pump, a circulating water pipe, a check valve and a stop valve, the steam heating system is provided with an air inlet pipe, an electric gate valve, a transverse pipe and drain pipes, the electric control cabinet is provided with electrical elements and a PLC (programmable logic controller), and the heating device comprises connected water tanks with covers. The heating device and the heating method have the advantages that water is heated by steam, the steel coils are heated by hot water, the hot water is recycled, accordingly, water consumption can be greatly reduced, and the occupied area and the engineering investment are reduced; the heating efficiency is improved, steel coil heating time is greatly shortened, different heating temperatures can be adopted for the different steel coils, steel coil heating flexibility is improved, the rolling star temperature of the steel coils is assuredly kept higher than 50 DEG C under the condition that the heating time is shorter than 40 minutes, and requirements of rolling rhythm are met completely; and the quality of edges of rolled strip steel is effectively improved, the shortcoming of edge crack is overcome, and strip breakage accidents of the steel coils are stopped.

Owner:ANGANG STEEL CO LTD

Method for preventing band-break during continuous annealing process of band steel and its control system

ActiveCN100471961CTimely control the speed of passing through the boardAvoid broken belt accidentsFurnace typesHeat treatment furnacesControl systemStrip steel

This invention provides a method preventing strip band-breaking during continuous annealing and its control system. It measures the panel data between the decoiler and the entry loop of the continuous annealing machine to assure the technique parameter. The control system includes: the panel testing unit equipped between the decoiler and the entry loop of the continuous annealing machineto test the panel data of the strip; the control unit connecting the panel testing unit and continuous annealing machine to assure the technique parameter according to the tested panel data and control the continuous annealing machine according to the technique parameter. In this invention, because the strip panel form has been tested before going into the annealing furnace, so it can control the panel-through speed, tensility and correction angle of the strip in time, effectively avoid the band-breaking accident. In addition, because the testing equipment is in front of the entry of the furnace, so the equipment and testing are convenient.

Owner:BAOSHAN IRON & STEEL CO LTD

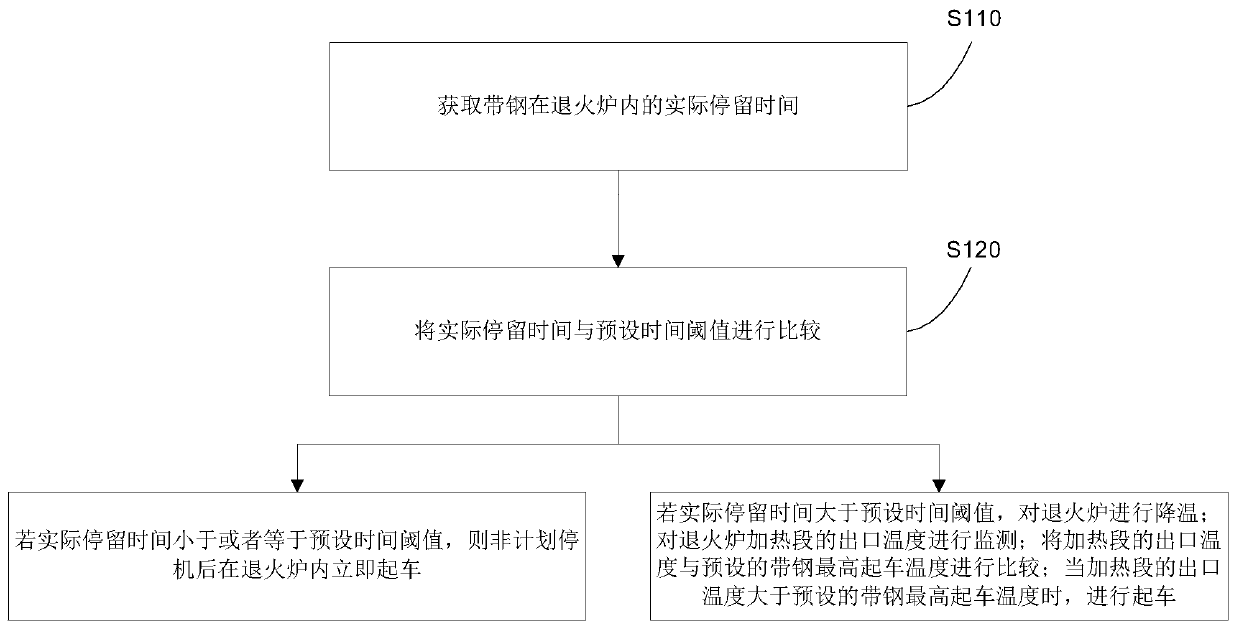

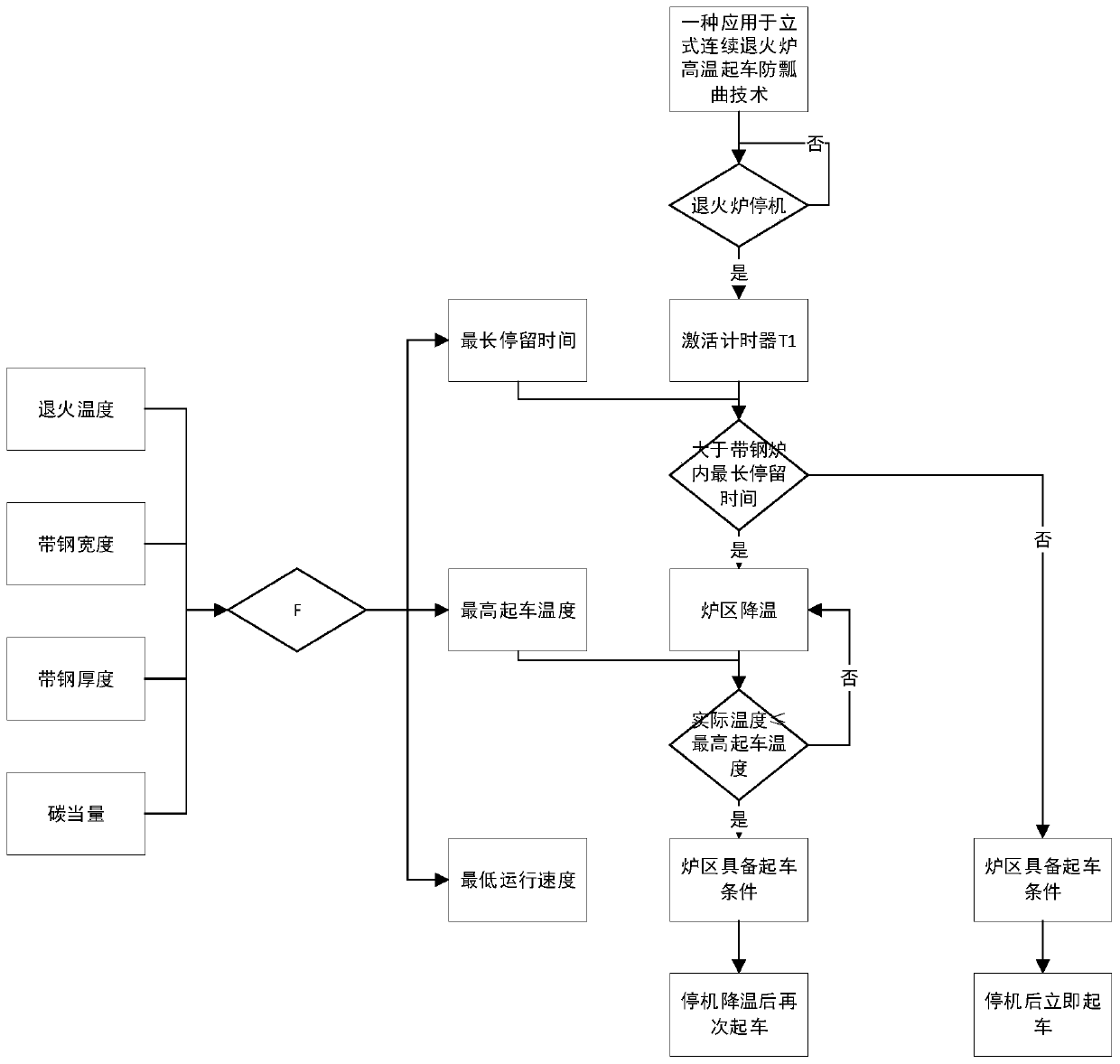

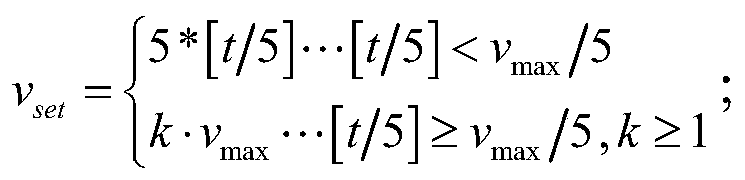

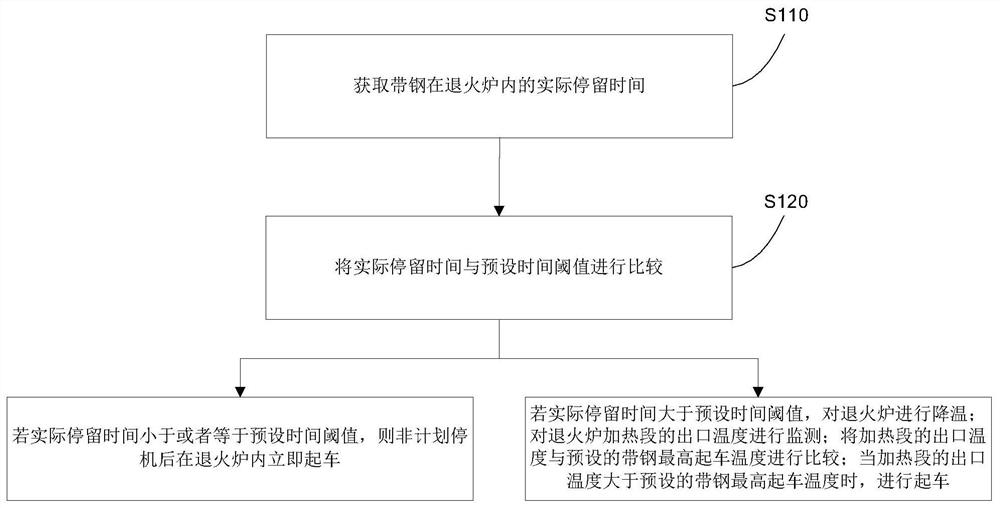

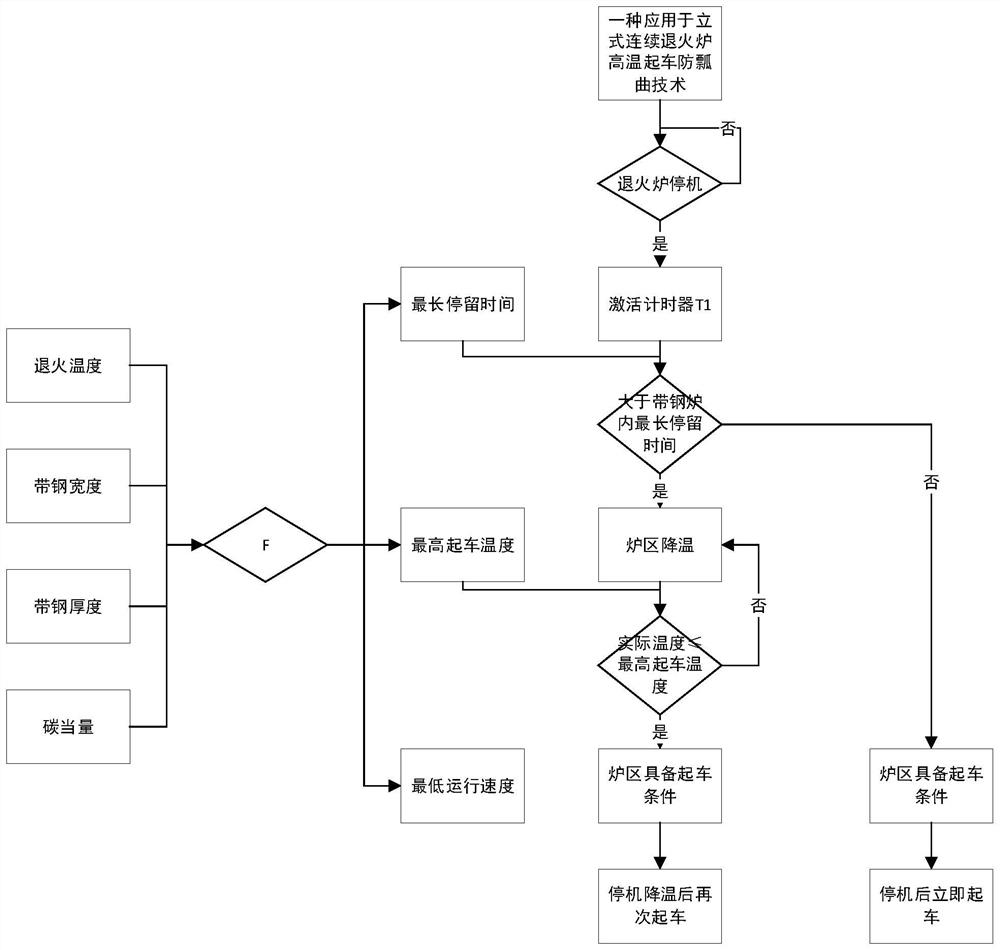

Anti-deflection start-up method of annealing furnace

ActiveCN110331276ASolve the technical problems of Yi Piao QuAvoid warping defectsFurnace typesHeat treatment process controlRetention timeStrip steel

The invention discloses an anti-deflection start-up method of an annealing furnace. The anti-deflection start-up method of the annealing furnace comprises the following steps: acquiring the actual retention time of belt steel in the annealing furnace and then comparing the actual retention time with a preset time threshold value; and if the actual retention time is less than or equal to the presettime threshold value, performing start-up in the annealing furnace at once after unplanned shutdown. In order to avoid generation of "deflection" defect on the surface of the belt steel caused by thefact that the temperature difference of the belt steel and a furnace roller is increased when the temperature of the belt steel is reduced continuously, a furnace area adopts "rapid speed-up" operation at the moment until the speed of the belt steel is more than the minimum safe operation speed. If the actual retention time is more than the preset time threshold value, start-up can be conducted after the temperature is reduced, the furnace area adopts "stepped speed-up" until the belt steel which stays in a heat area in the furnace completely deviates from a heating section and a soaking section, "stepped speed-up" is to enable the temperature of the belt steel and the temperature of the furnace roller to tend to be consistent as much as possible, and occurrence of the belt breaking accident in the furnace caused by serious deflection during start-up of materials liable to deflect is avoided.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

The Method of Shutdown and Tension Reduction of Large Strip Steel Continuous Annealing Furnace

ActiveCN111500848BDegree of reductionAvoid broken belt accidentsFurnace typesHeat treatment process controlStructural engineeringStrip steel

The invention discloses a method for stopping and reducing the tension of a large-scale continuous annealing furnace for strip steel. By controlling the order and direction of each furnace roller's final stop rotation, the steel strip in the furnace is in a sagging state. When the temperature of the annealing furnace returns to room temperature , the steel belt is not easy to be tensioned due to cold shrinkage or the tension degree can be reduced, which is beneficial to avoid the occurrence of broken belt accidents caused by parking.

Owner:CHONGQING CISDI THERMAL & ENVIRONMENTAL ENG CO LTD +1

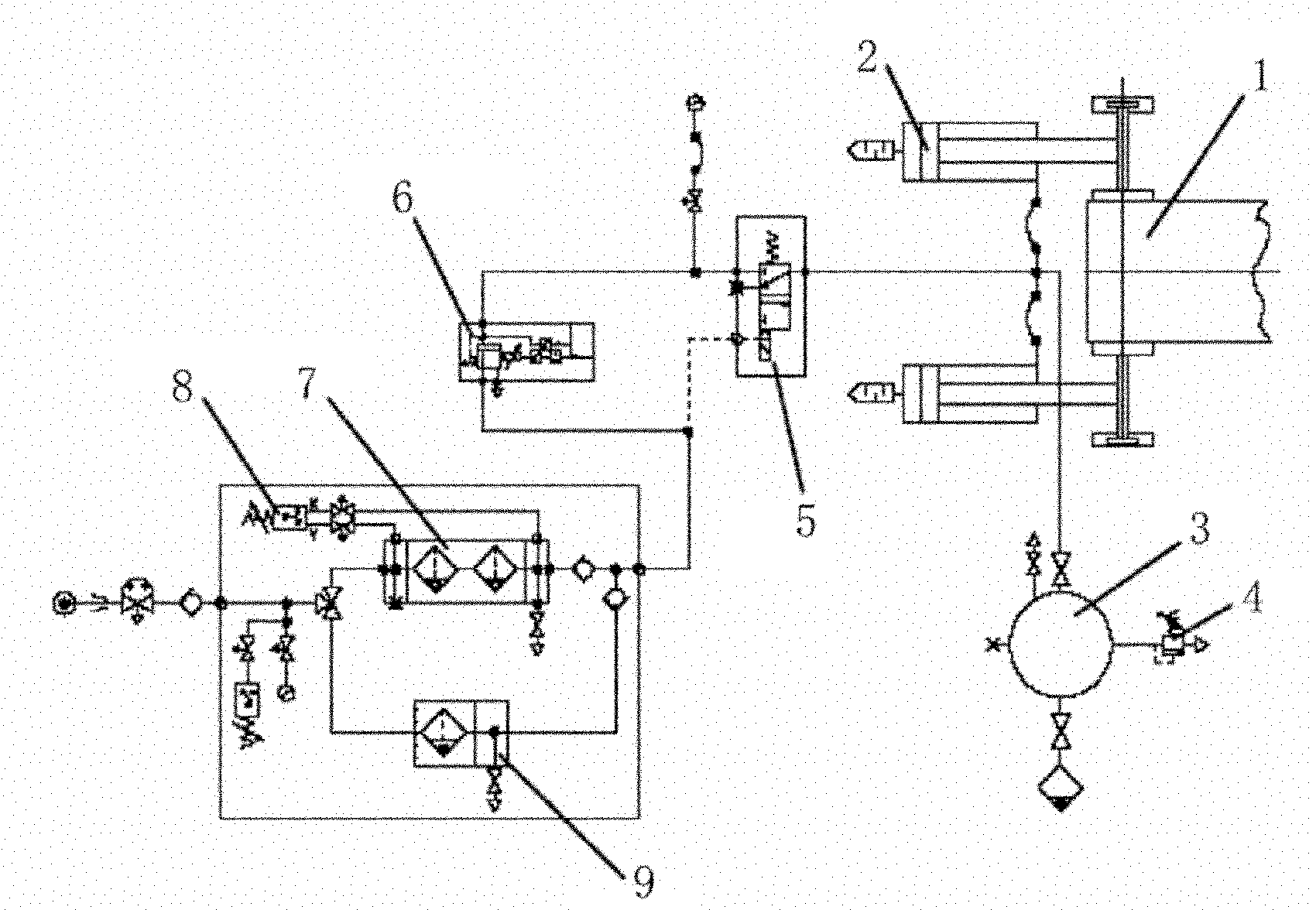

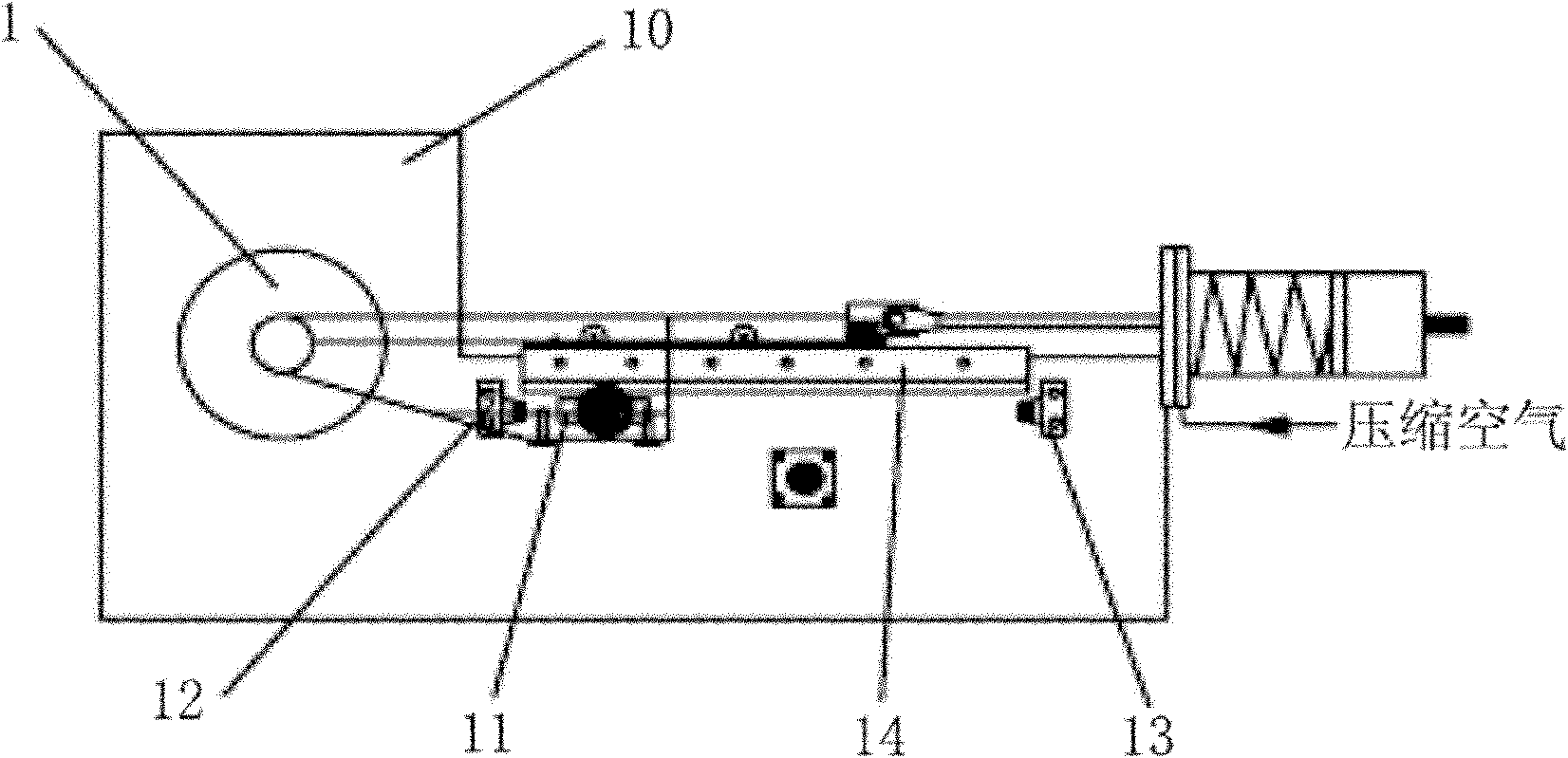

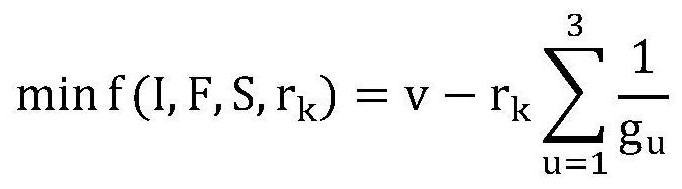

Control system and control method of dancer roll

ActiveCN102650891BAvoid broken belt accidentsReduce labor intensitySimultaneous control of multiple variablesControl systemRisk stroke

The invention relates to a control system and a control method of a dancer roll, wherein the control system comprises a guide rail, a position sensor and a pneumatic control system; a movable frame used for bearing the dancer roll is arranged on the guide rail; the position sensor is used for detecting the stroke variation between a target position and an initial position of the dancer roll; the pneumatic control system is used for providing tensile force to shift the dancer roll to the target position; and the pneumatic control system at least comprises a pneumatic proportional valve. The control method comprises a step of controlling the tensile force of the dancer roll and a step of controlling the position of the dancer roll, wherein the step of controlling the tensile force comprises the following steps of: a, calculating a pressure set value of the dancer roll, and b, converting the pressure set value of the dancer roll into a pressure set value of the pneumatic proportional valve; and the step of controlling the position also comprises the following steps of: a, recognizing the position of the dancer roll, and b, converting the difference value between a position set value and an actual value of the dancer roll into a speed compensation value of a unit idler roller.

Owner:BAOSHAN IRON & STEEL CO LTD

A start-up method for annealing furnace to prevent warping

ActiveCN110331276BLarge temperature differenceAvoid broken belt accidentsFurnace typesHeat treatment process controlMechanical engineeringSafe operation

The invention discloses an anti-deflection start-up method of an annealing furnace. The anti-deflection start-up method of the annealing furnace comprises the following steps: acquiring the actual retention time of belt steel in the annealing furnace and then comparing the actual retention time with a preset time threshold value; and if the actual retention time is less than or equal to the presettime threshold value, performing start-up in the annealing furnace at once after unplanned shutdown. In order to avoid generation of "deflection" defect on the surface of the belt steel caused by thefact that the temperature difference of the belt steel and a furnace roller is increased when the temperature of the belt steel is reduced continuously, a furnace area adopts "rapid speed-up" operation at the moment until the speed of the belt steel is more than the minimum safe operation speed. If the actual retention time is more than the preset time threshold value, start-up can be conducted after the temperature is reduced, the furnace area adopts "stepped speed-up" until the belt steel which stays in a heat area in the furnace completely deviates from a heating section and a soaking section, "stepped speed-up" is to enable the temperature of the belt steel and the temperature of the furnace roller to tend to be consistent as much as possible, and occurrence of the belt breaking accident in the furnace caused by serious deflection during start-up of materials liable to deflect is avoided.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

A kind of control method of tension leveler of pickling mill

ActiveCN106424170BGuaranteed normal tensionReduce loadWork treatment devicesRoll mill control devicesMachine controlStrip steel

The invention discloses a pickling line tandem cold mill withdrawal and straightening machine control method. When the yielding strength of a target steel grade is smaller than or equal to 300 MPa, the ductility of a withdrawal and straightening machine is 2.3%-2.5%, and the engagement amount is 30 mm to 35 mm; when 300 MPa<the yielding strength<=450 MPa, the ductility is 1.8%-2.2%, and the engagement amount is 35 mm to 40 mm; when the yielding strength is larger than 450MPa, the ductility is set 0.5%-1.2%, and the engagement amount is 40 mm to 42 mm; and meanwhile according to the difference of the thickness or the width of front strip steel and rear strip steel, weld joint excessive withdrawal and straightening machine modes are divided into four kinds. By means of the pickling line tandem cold mill withdrawal and straightening machine control method, the withdrawal and straightening machine achieves automatic grouping control over steel grades in different yielding strength levels, normal withdrawal and straightening of the withdrawal and straightening machine can be guaranteed, the loads of the withdrawal and straightening machine can also be effectively reduced, normal pickling of the strip steel is guaranteed, and the withdrawal and straightening up-to-standard rate reaches 98% or above; and selection of the weld joint excessive withdrawal and straightening machine modes guarantees normal pickling of weld joint heads and tails, and the strip breakage accident caused by poor weld joint quality is avoided.

Owner:HANGANG GRP HANBAO IRON & STEEL

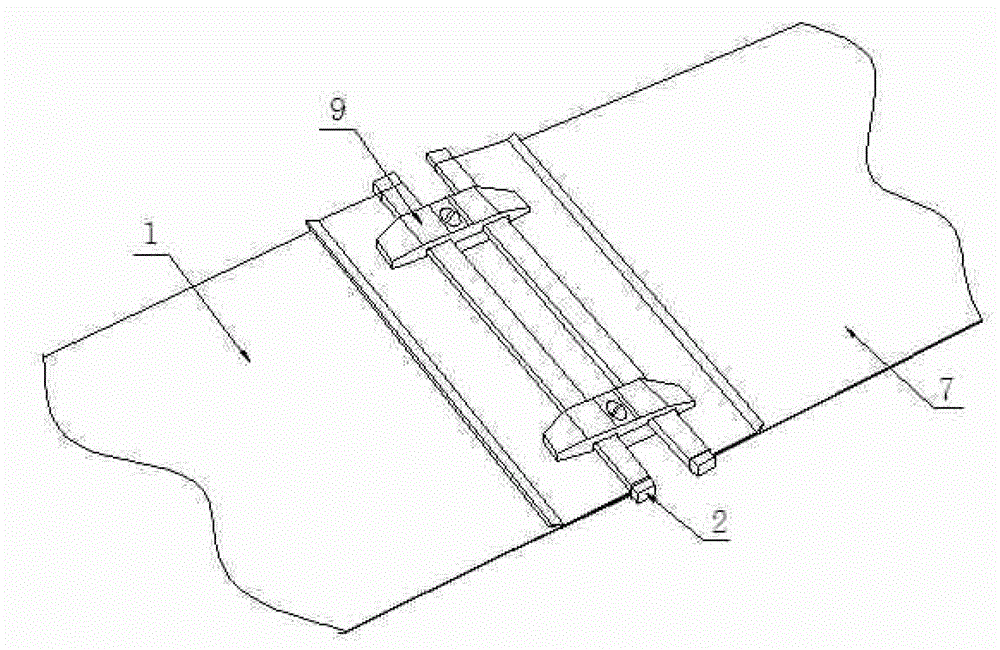

Steel belt butt-joint device and butt-joint method thereof

ActiveCN103277379BLower the altitudeEasy to passSheet joiningMetal rolling arrangementsButt jointUnit operation

The invention provides a steel belt butt-joint device and a butt-joint method thereof. The steel belt butt-joint device and butt-joint method thereof comprises at least two groups of end covers, a base and a countersunk bolt. Two through grooves are formed on the working faces formed by the end covers and the base, and two rectangular through holes are formed after opposite buckling. When steel belt butt joint is performed, a hand hammer is utilized to fix steel belts on a reinforced square steel rod, belt heads and belt tails are placed into the through holes, the countersunk bolt is fastened appropriately to exert tensile force on the belt heads and the belt tails respectively and then is fastened after tightening to exert tensioning force, and the belt heads and the belt tails are firmly clamped on inner walls of the through holes through the reinforced square steel rod. The height of the butt-joint device can be reduced, so that the butt-joint device can conveniently and smoothly pass through the sealing roller position and other narrow regions, and belt breakage accidents are avoided. The steel belts are formed through single-layer extrusion, so that the labor intensity is reduced, the operation time is shortened, and the operation efficiency is improved by more than 30%. Friction resistance is increased through external force, the locking effect is guaranteed, the steel belt connecting success rate and the unit operation rate are improved, and the production cost is reduced. The steel belt butt-joint device is simple in structure, convenient to operate and strong in applicability.

Owner:ANGANG STEEL CO LTD

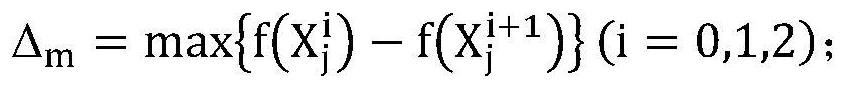

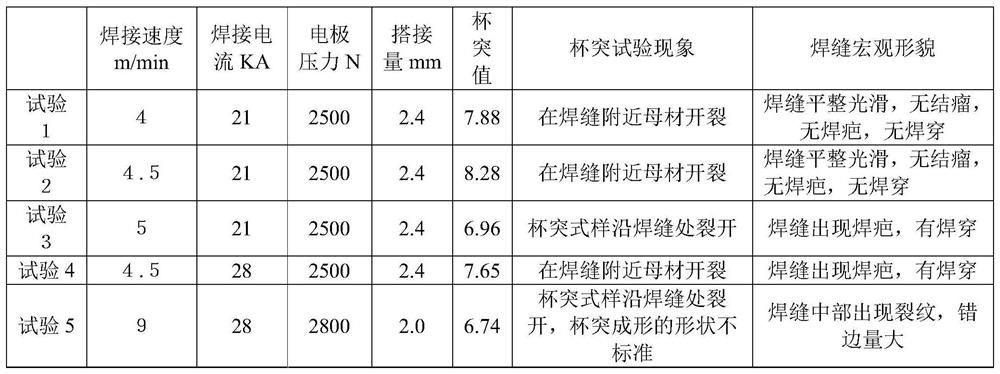

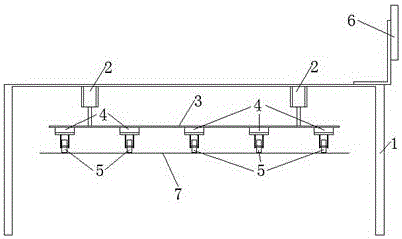

A method for obtaining process parameters of resistance seam welding and a welding method

ActiveCN110064830BIncrease productivityPrevent splashPressure electrodesEngineeringMaterial resources

The invention discloses a method for obtaining process parameters of resistance seam welding and a welding method, and belongs to the field of welding. Among them, the acquisition method of resistance seam welding process parameters and the fastest welding speed are determined through the following steps: based on the finite element method, a narrow overlap resistance seam welding temperature field / stress field calculation module is established; according to the narrow overlap resistance seam welding temperature field / The stress field calculation module extracts the nugget size and plastic ring size given the welding current, electrode pressure and overlap amount; using the nugget size and plastic ring size as constraints, the fastest welding speed is solved. This invention obtains the nugget size and plastic ring size as constraints through the narrow overlap resistance seam welding temperature field / stress field calculation module, and can solve the fastest welding speed on the premise of ensuring welding quality and avoiding belt breakage accidents. The present invention does not need to go through multiple field tests, which is beneficial to saving time, manpower and material resources.

Owner:马钢(合肥)钢铁有限责任公司

Tension on-line detecting device

InactiveCN106595909AAvoid broken belt accidentsEasy to adjustForce measurementEngineeringPressure sensor

Owner:江苏大力神科技股份有限公司

Soft-measuring method for tension of band steel between rollers of continuous annealing unit

ActiveCN102042893BAvoid broken belt accidentsAvoid Model ErrorsTension measurementFrequency changerMeasuring instrument

The invention discloses a soft-measuring method for the tension of band steel between rollers of a continuous annealing unit, comprising the following steps of: (1) acquiring process data; (2) preprocessing the process data; (3) constructing a soft-measuring model for combining a cascade observer with a neural network compensator; and (4) correcting the model. The moment current of a frequency converter corresponding to each roller between two tension measuring instruments, the speed and the boundary tension of each roller are used as the input quantity, the tension between every two rollers is calculated by the recursion in a cascade manner by adopting a frequency domain observer arithmetic, thus the indirect calculation and measuring on the tension of the band steel at the position where no tension measuring instrument is installed can be better realized, a favorable means is provided for the stability monitoring of the operation condition of the continuous annealing unit, high-precision calculation on the tension of the band steel at the position where no tension measuring instrument is installed is realized relatively accurately through compensating the nonlinear process characteristic and the unmodeled dynamics by applying a main model and neural network method, and a basis can be provided for the optimization on the control process parameter of tension in the continuous annealing unit.

Owner:BAOSHAN IRON & STEEL CO LTD

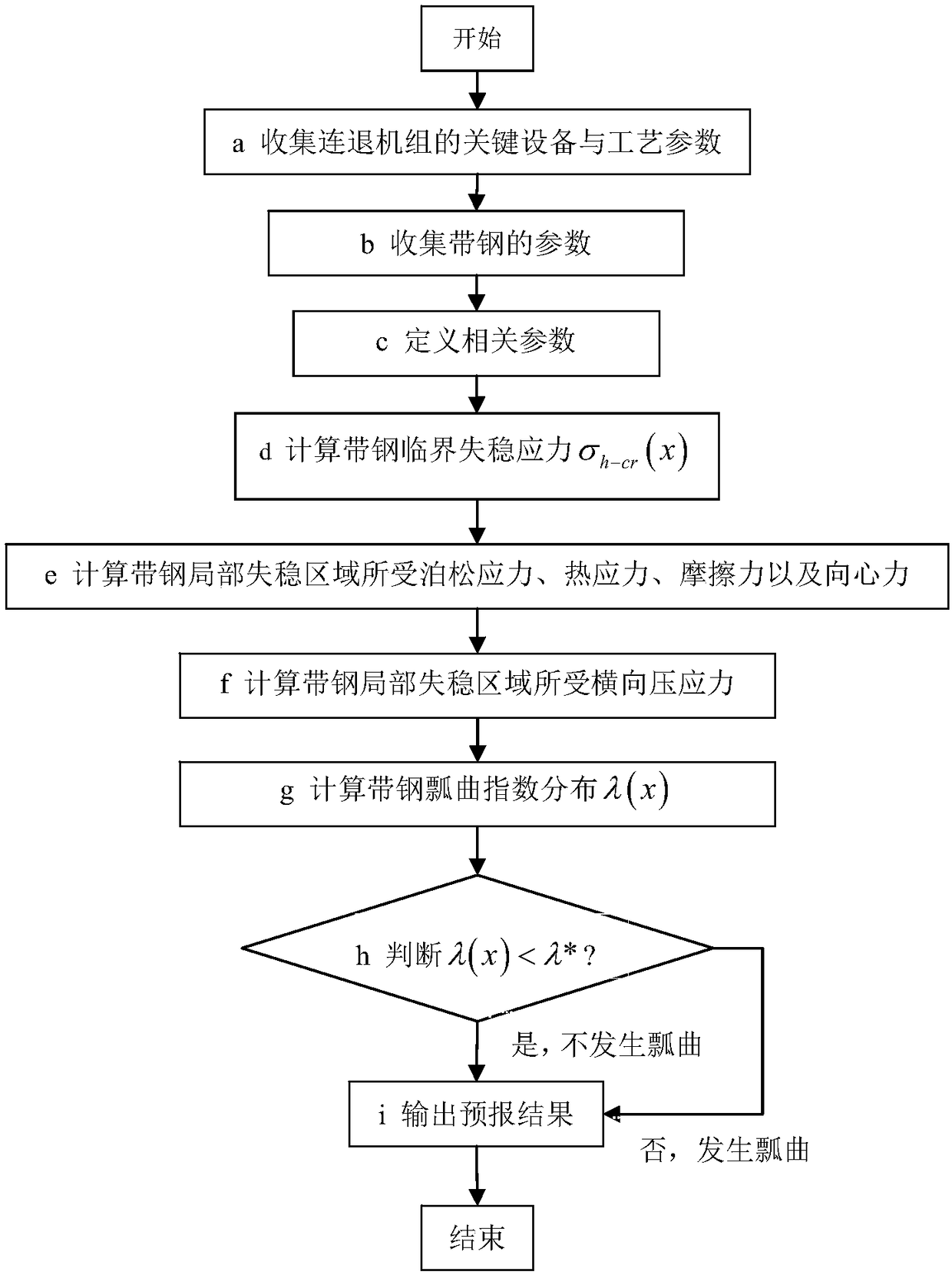

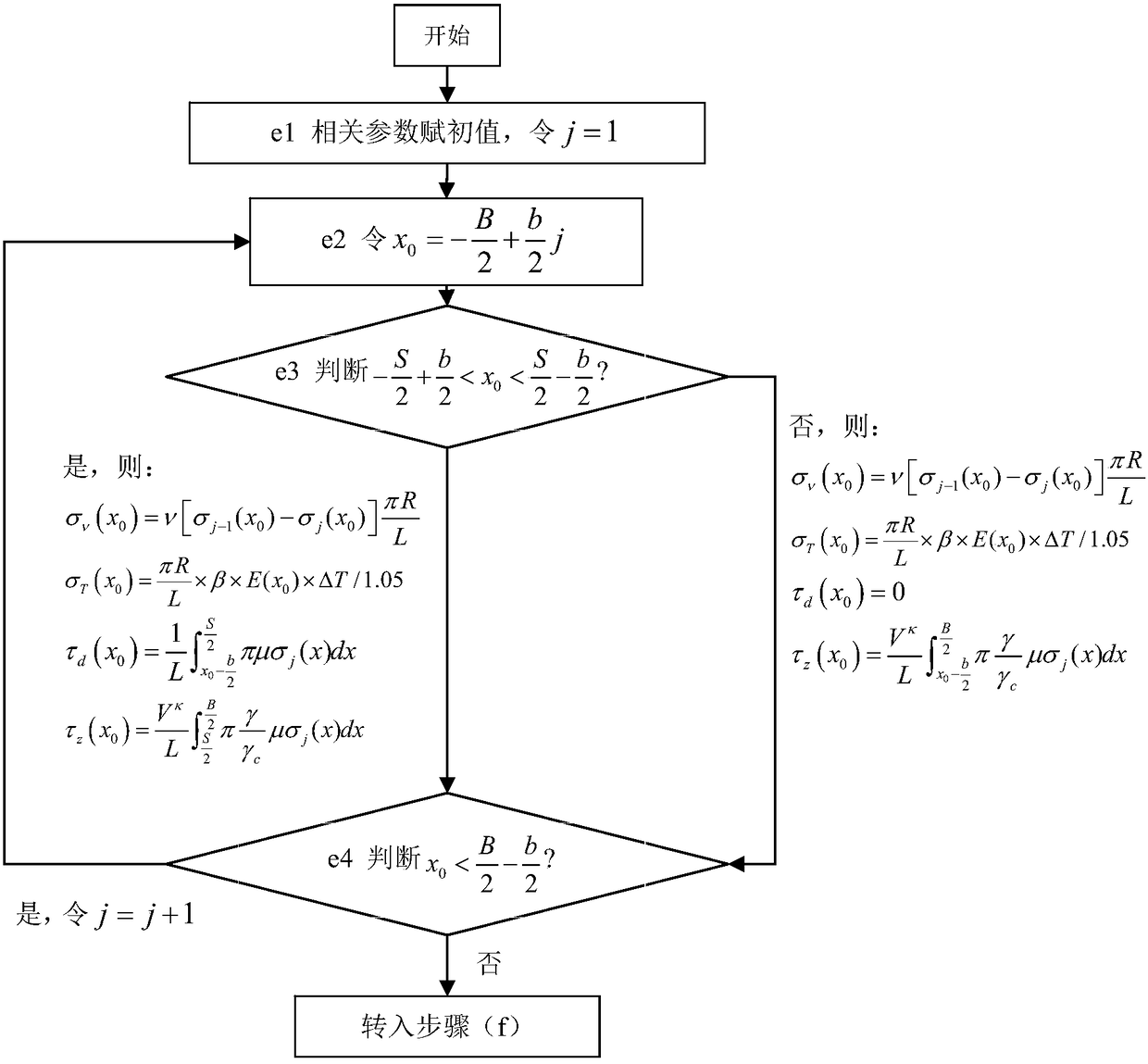

A Method for Prediction of Strip Warp Suitable for Continuous Annealing Units

ActiveCN106055870BForecast realizedRun at high speedFurnace typesHeat treatment process controlInstabilityStrip steel

Owner:唐山格诺金属科技有限公司

A method for controlling edge cracking of strip steel by crystallization roll shape

ActiveCN112296097BSolve the edge crack defectAvoid crackingRoll mill control devicesMetal rolling arrangementsStructural engineeringStrip steel

A method for controlling the edge cracking of strip steel through the roll shape of a crystallizing roll, comprising the steps of discretizing the edge roll shape curve of the original crystallizing roll, the thickness curve of the cast strip, and the thickness curve of the rolled strip, and calculating the center position of the strip steel width direction. Control the thickness reduction ratio of the strip edge area, and obtain the corrected crystallization roll edge roll shape value according to the roll shape optimization variables, etc., and perform curve fitting on the discretized roll shape value to obtain a new The crystallization roll edge roll shape curve. The invention controls the thickness of the edge part of the cast strip by changing the shape of the edge part of the crystallization roll, and controls the width direction of the strip steel during the hot rolling process, especially the thickness reduction ratio of the center region and the edge region, and improves the hot rolling process. The rolling balance in the width direction of the strip solves the defect of the edge crack of the double-roll cast strip, improves the quality of the strip edge, and solves the problems of broken strip and poor production continuity caused by the edge crack defect.

Owner:SHAGANG GROUP +2

Method for controlling edge cracking of strip steel through crystallization roller shape

ActiveCN112296097ASolve the edge crack defectAvoid crackingRoll mill control devicesMetal rolling arrangementsReduction ratioStructural engineering

A method for controlling edge cracking of strip steel through a crystallization roller shape includes the steps that discretization point taking is performed on an edge roller shape curve, a cast strip thickness curve and a rolled strip thickness curve of an original crystallization roller, the thickness reduction ratio of the center position in the width direction of the strip steel is obtained through calculation, the thickness reduction ratio of the edge area of the strip steel is controlled, a corrected crystallization roller edge roller shape value is obtained according to the roller shape optimization variable and the like, and curve fitting is performed on the discretized roller shape value to obtain a new crystallization roller edge roller shape curve. According to the method, thethickness of the edge of a cast strip is controlled by changing the roller shape of the edge of the crystallization roller, the thickness reduction ratio of the strip steel in the width direction, especially in the central area and the edge area, in the hot rolling process is controlled, the rolling balance of the strip steel in the width direction in the hot rolling process is improved, the defect of edge cracks of the double-roller cast strip steel is overcome, the edge quality of the strip steel is improved, and the problems of strip breakage and poor production continuity caused by edge cracking defects are solved.

Owner:SHAGANG GROUP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com