A Method for Prediction of Strip Warp Suitable for Continuous Annealing Units

A continuous annealing unit and strip steel technology, applied in the field of metallurgical steel rolling, can solve problems such as the study of the force of the internal unit of the strip steel, the inability to realize the online prediction of the bending of the strip, and the inability to quantitatively give the bending trend of the strip steel. Minimize the effect of avoiding broken belt accidents and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

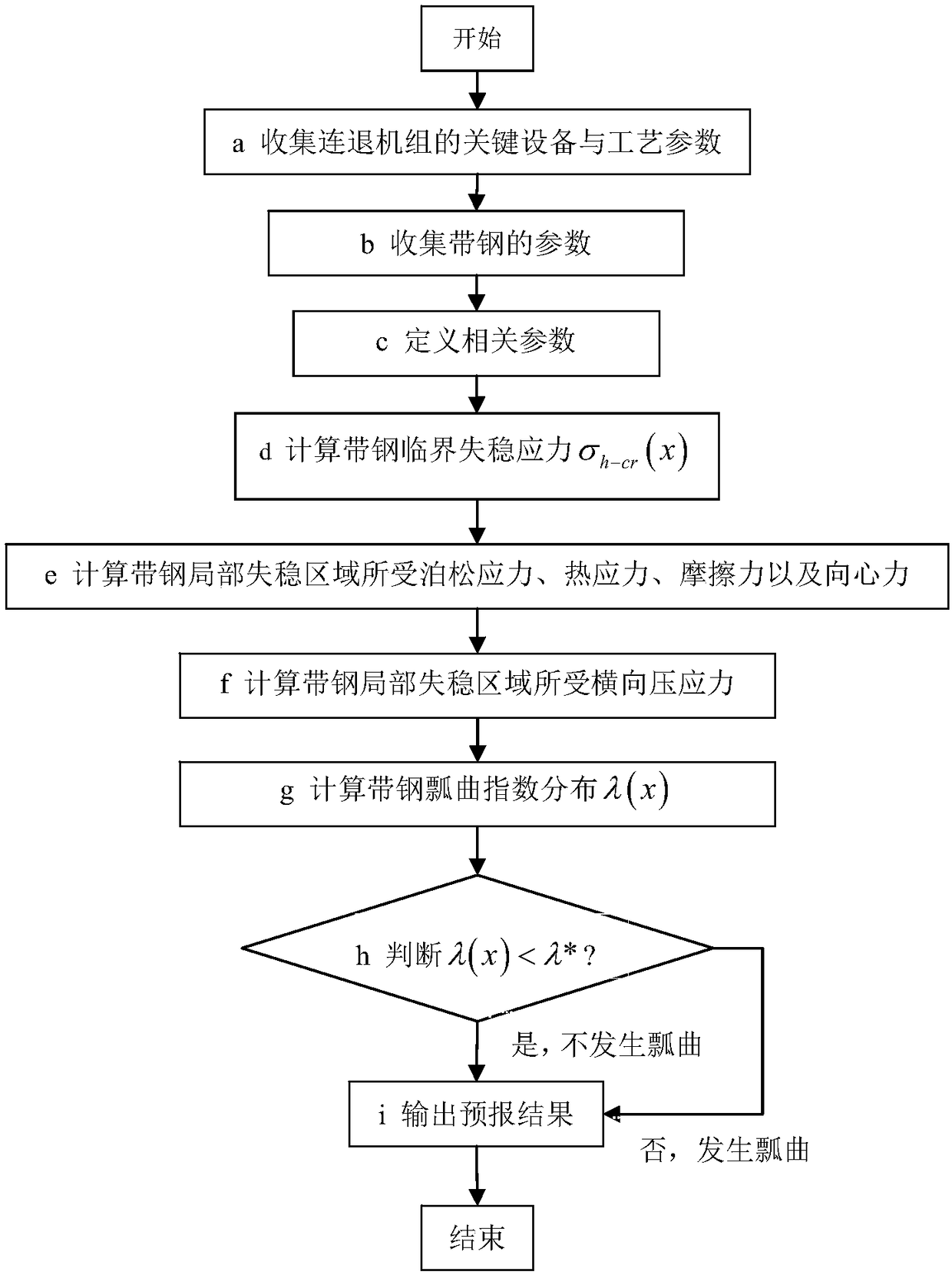

[0059] according to figure 1 The overall calculation flow chart of the strip bending prediction method suitable for the continuous annealing unit is shown. The steel strip is selected as CQ and the specification is 0.50mm×1500mm, and a certain pass of the soaking section of the continuous annealing unit in a domestic factory is taken as example:

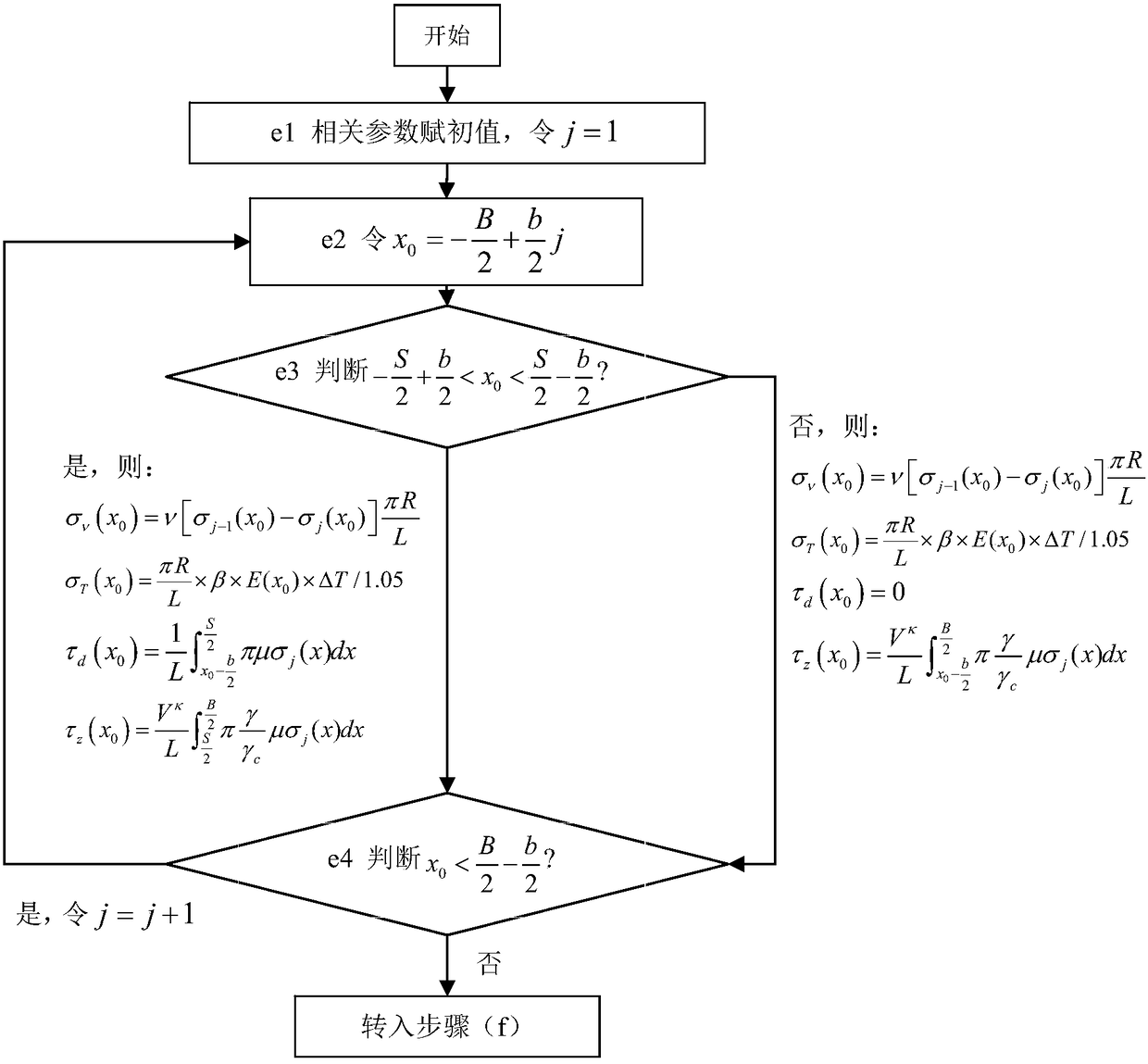

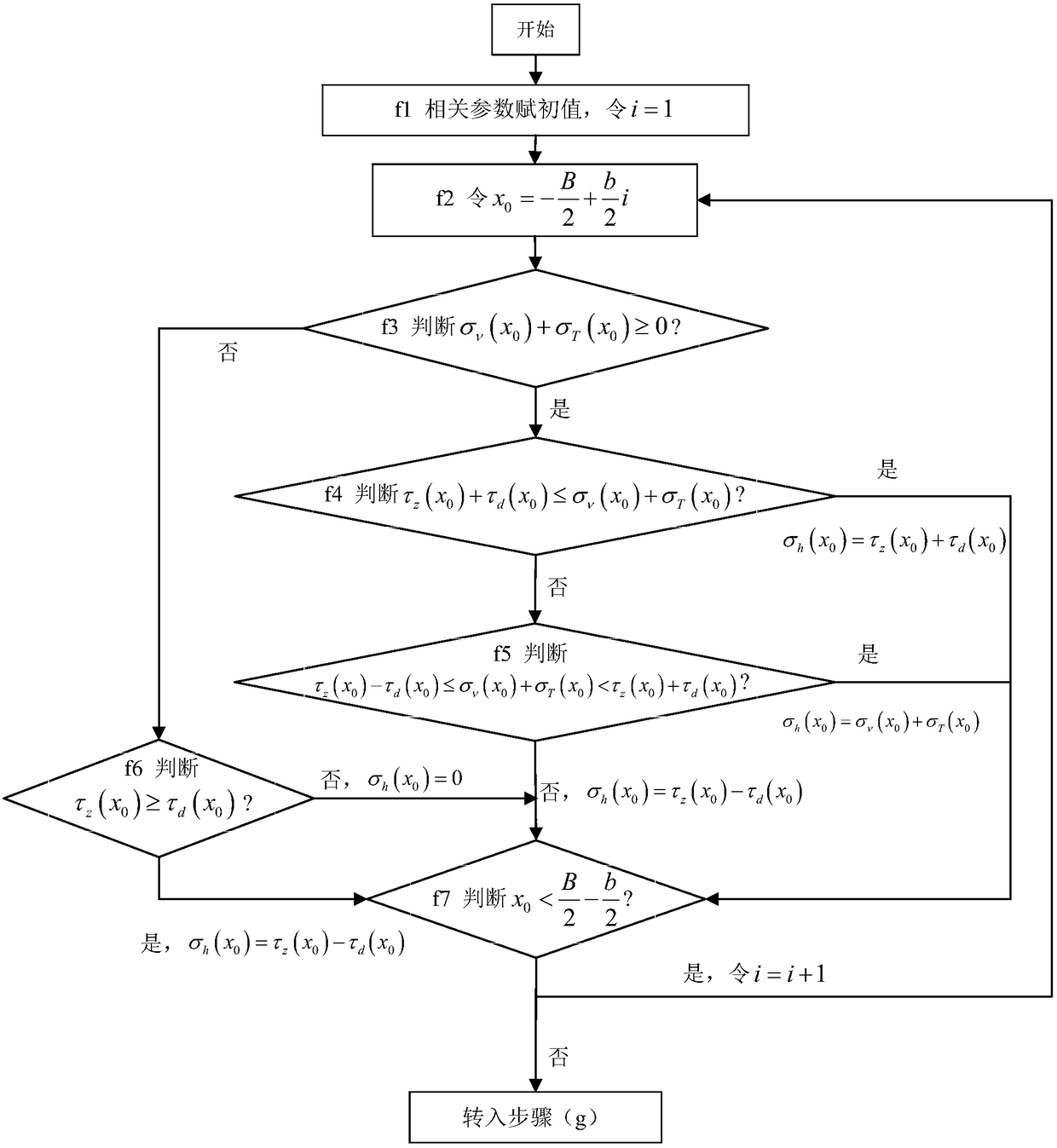

[0060] First, in step 1, the key equipment and process parameters of the continuous annealing unit are collected, mainly including: furnace roll radius R=450mm, furnace roll straight section length S=600mm, furnace roll taper γ=0.002rad, critical taper γ c = 0.004rad, unit speed V = 6m / s, speed influence coefficient κ = 0.12, friction coefficient μ between strip steel and furnace roll = 0.15;

[0061] Subsequently, in step 2, the parameters of the strip are collected, mainly including: strip width B=1500mm, strip thickness h=0.5mm, tension distribution σ of the current process section j (x) (such as Figure 4 shown), the tension d...

Embodiment 2

[0081] Select the strip steel whose steel type is CQ and whose specification is 0.50mm×1500mm, and take a certain pass in the slow cooling section of a continuous annealing unit in a domestic factory as an example:

[0082]First, in step 1, the key equipment and process parameters of the continuous annealing unit are collected, mainly including: furnace roll radius R=450mm, furnace roll straight section length S=400mm, furnace roll taper γ=0.003rad, critical taper γ c = 0.004rad, unit speed V = 6m / s, speed influence coefficient κ = 0.12, friction coefficient μ between strip steel and furnace roll = 0.15;

[0083] Subsequently, in step 2, the parameters of the strip are collected, mainly including: strip width B=1500mm, strip thickness h=0.5mm, tension distribution σ of the current process section j (x) (such as Figure 12 shown), the tension distribution σ of the previous process section j-1 (x) (such as Figure 13 shown), the temperature distribution T(x) of the current pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com