Heating device and heating method for edges of steel coils

An edge heating and steel coil technology is applied in metal processing equipment, metal rolling, manufacturing tools, etc. It can solve the problems of poor production flexibility, difficulty in on-site management, and large floor space, so as to avoid loss and waste and shorten heating Time, the effect of reducing the footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

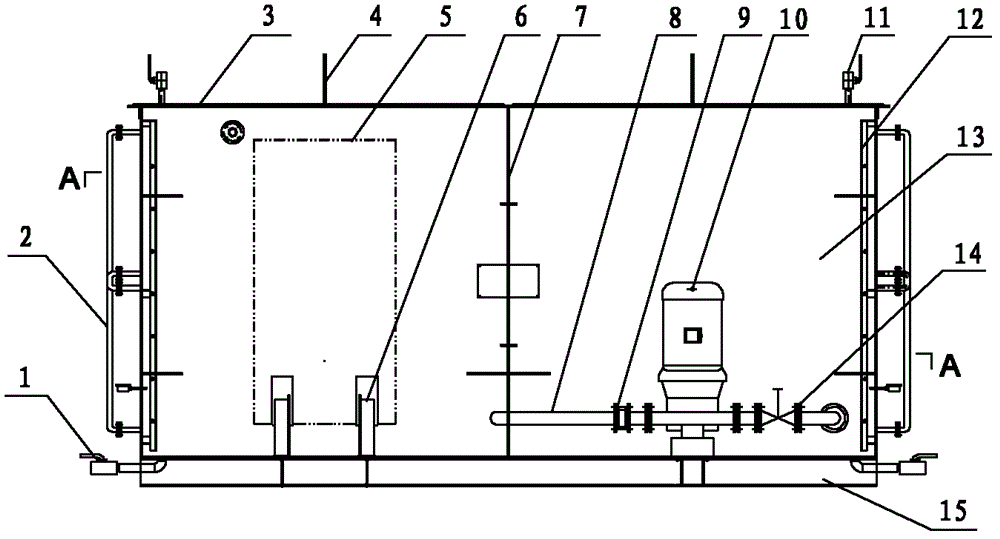

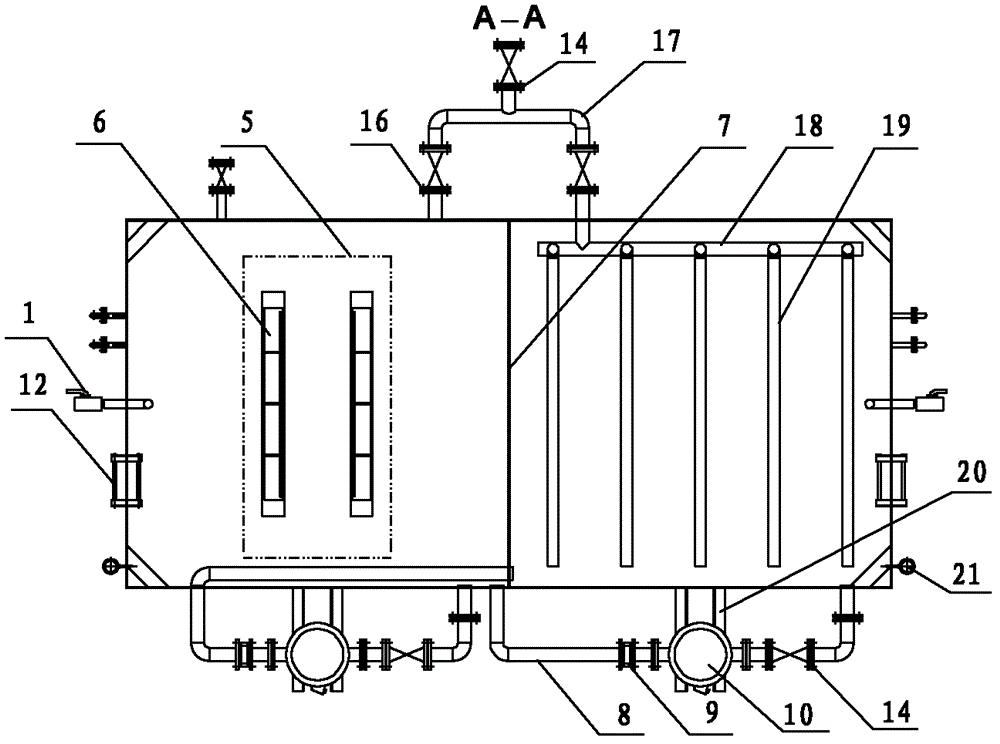

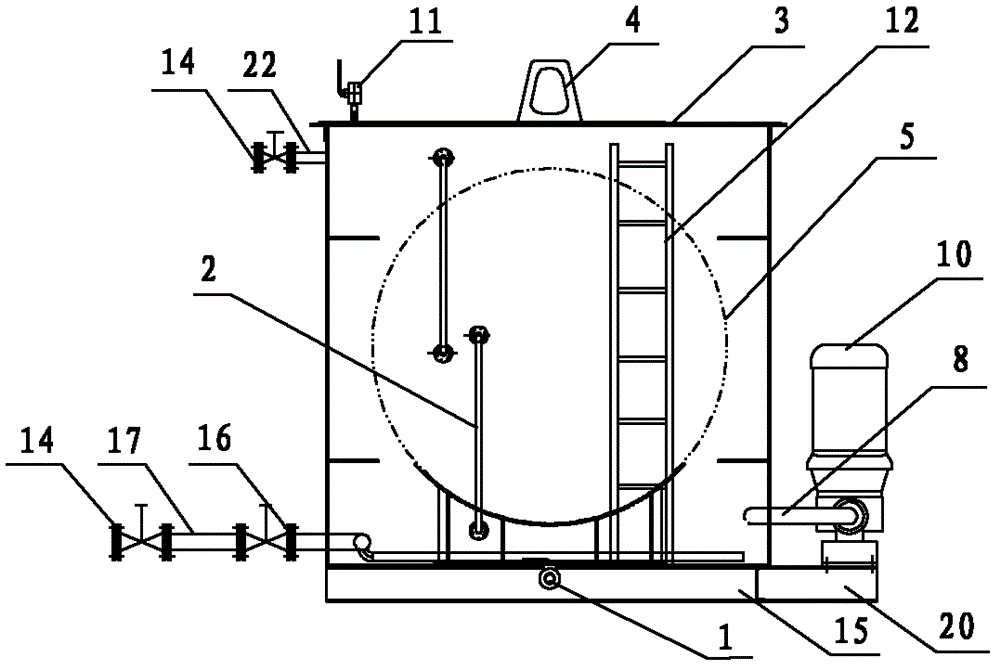

[0036] The coil edge heating device of the present invention is mainly composed of four parts: a water tank, a water circulation system, a steam heating system and an electric control system. The entire heating device is installed near the rolling mill to reduce heat loss.

[0037] The length, width and height of the water tank are 5000×2500×2500mm. A dividing plate 7 is welded in the middle of the water tank, and the water tank is evenly divided into two separate conjoined water tanks 12, and the conjoined water tanks 12 are fixed on the base 15.

[0038] The water circulation system mainly includes a hot water pump 10 , a circulating water pipe 8 , a check valve 9 and a stop valve 14 .

[0039] The steam heating system includes an air intake pipe 17, a shut-off valve 14, an electric gate valve 16, a horizontal pipe 18 and an exhaust pipe 19.

[0040] The electric control system is composed of an electric control box with electrical components and PLC.

[0041] Two conjoine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com