Stretching bending straightening mechanical system with self-adaptive function in case of pass through welding seam

A technology of stretching, bending, straightening and mechanical systems, which is applied in the field of cold rolling, can solve the problems of prone to broken belt accidents, reduce the production efficiency of enterprises, and reduce the economic benefits of enterprises, so as to improve the automatic working ability of equipment and improve the safety of equipment operation Sexuality and the effect of increasing the economic benefits of the enterprise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0019] The invention provides a stretching bending straightening mechanical system with self-adaptive function through welding seam.

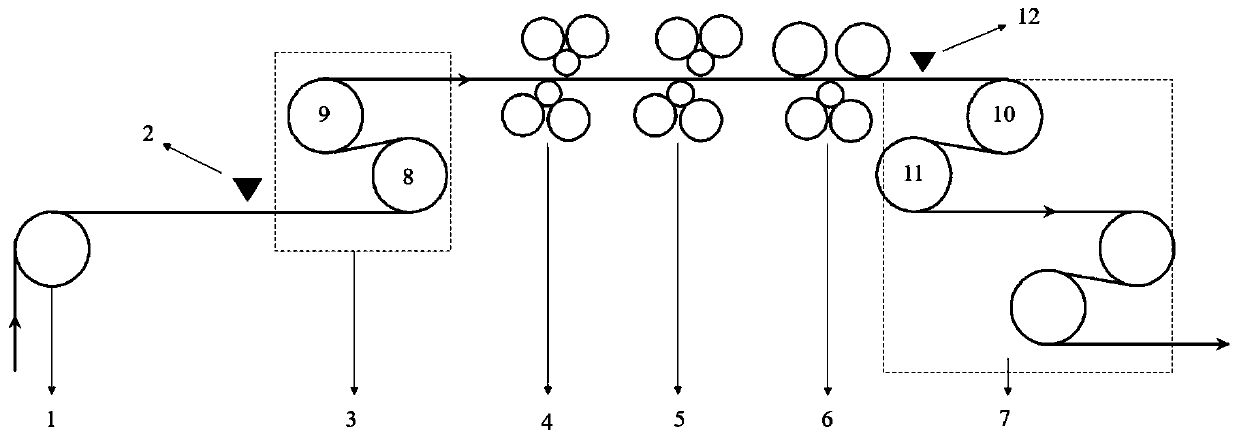

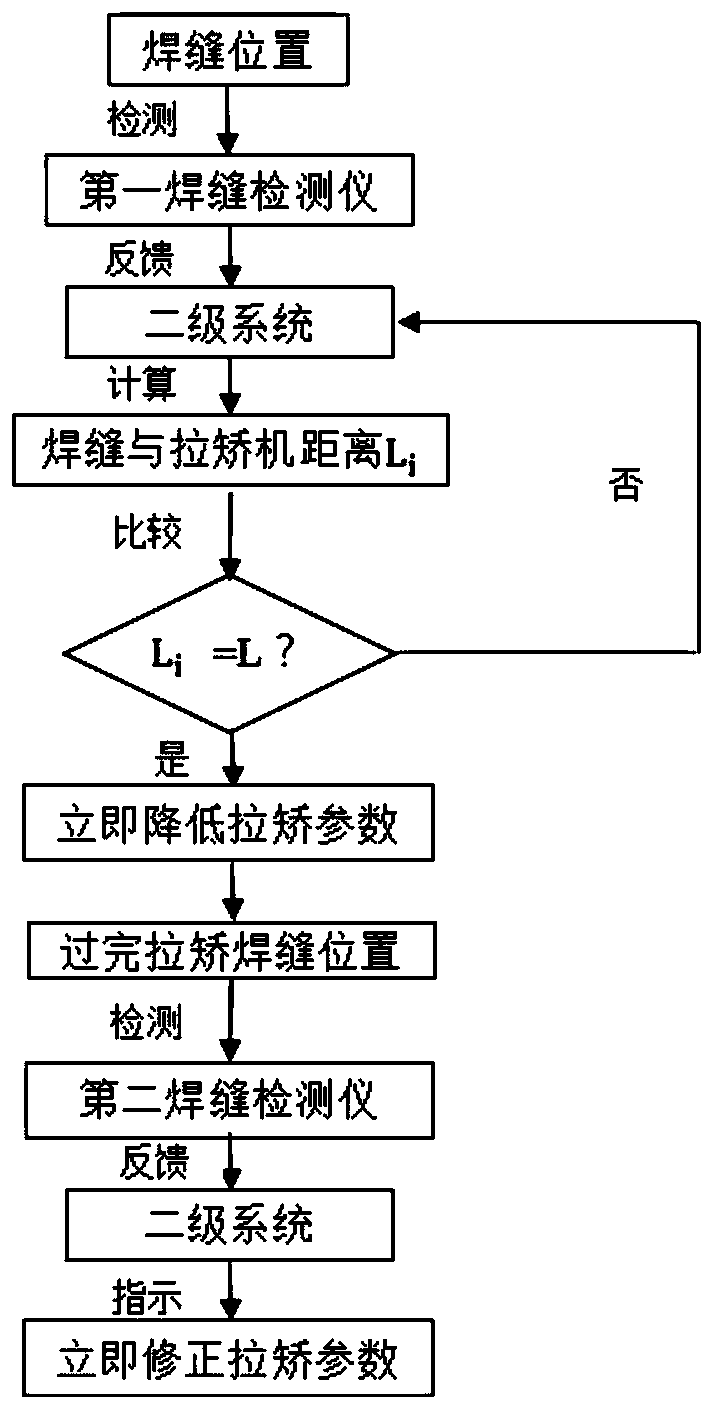

[0020] Such as figure 1 As shown, the system includes steering roller 1, first weld detector 2, entrance tension roller group 3, 1# bending roller group 4, 2# bending roller group 5, straightening roller group 6, second weld inspection 12 and the exit tension roller group 7, the first weld detector 2 is installed behind the steering roller 1, the second weld detector 12 is installed behind the straightening roller group 6, and the entrance is installed behind the first weld detector 2 Tensioning roller group 3, the exit tensioning roller group 7 is set behind the second weld detector 12, and 1# bending roller group 4 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com