A method for controlling edge cracking of strip steel by crystallization roll shape

A technology for controlling strips and crystallization rolls, applied in rolling mill control devices, metal rolling, manufacturing tools, etc., to achieve large cost advantages, solve strip breakage accidents, and improve quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

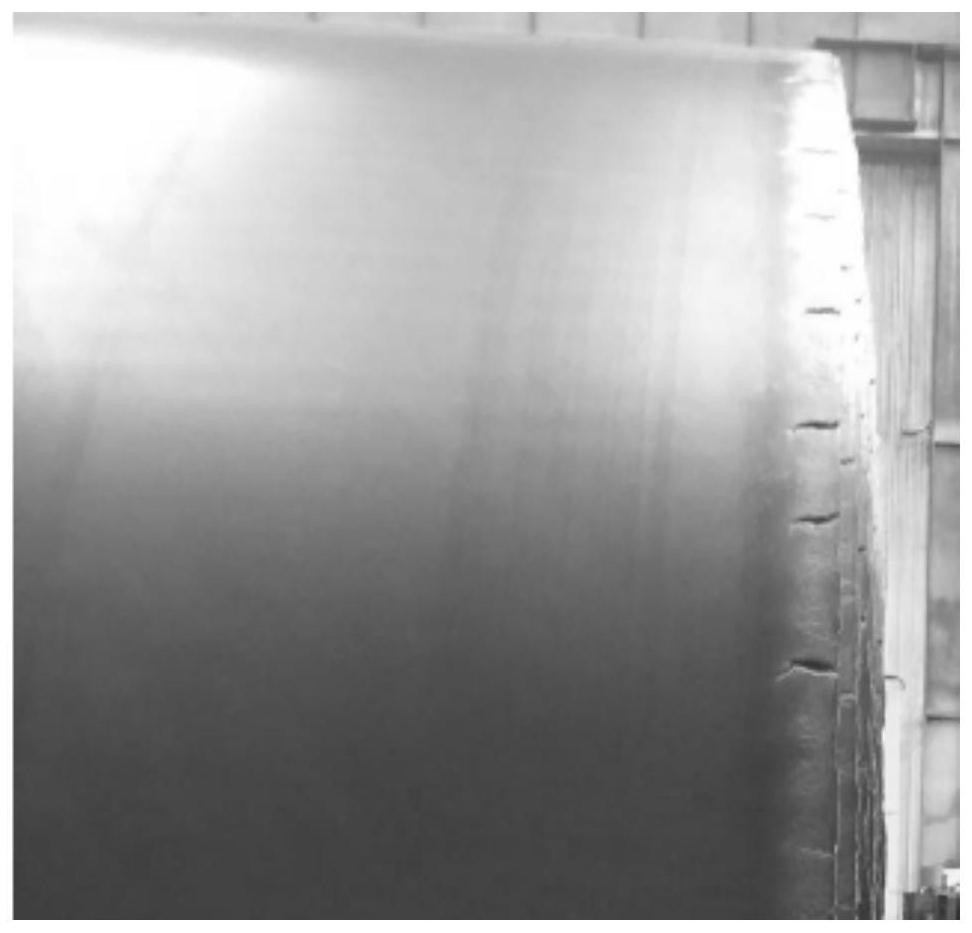

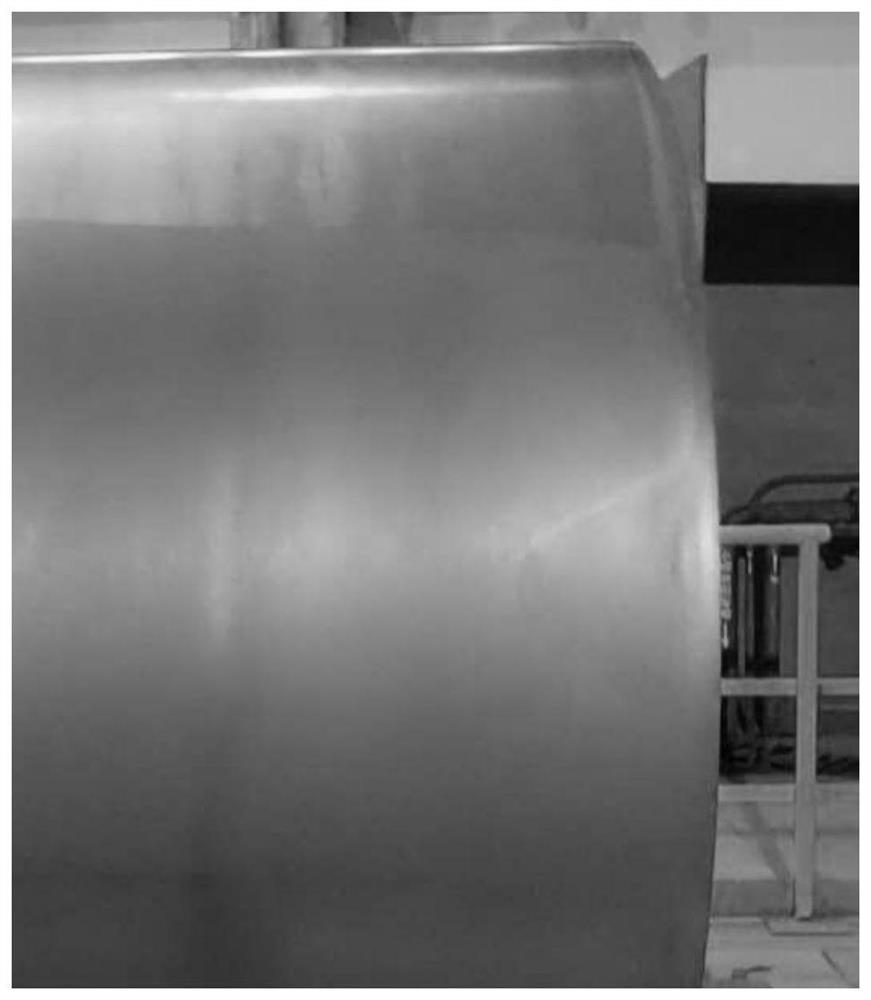

Image

Examples

Embodiment 1

[0030] In Example 1, the length of the strip edge crack along the width direction of the strip was determined to be 50mm, and the length of the edge roll shape of the crystallizing roll to be modified was determined to be 90mm; 1 point was taken for every 10mm distance, and the original crystallizing roll was The edge roll shape curve is discretized and selected within the range of the edge length of 90mm, and the discretized original roll shape value S is obtained. 0 , S 1 , S 2 ...S 9 ; Simultaneously obtain the thickness value H of the edge of the cast strip within the same length range 0 , H 1 , H 2 ...H 9 and the thickness of the strip is h 0 , h 1 , h 2 ...h 9 ; Obtain the thickness of the cast strip and the thickness of the rolled strip at the center position of the strip width to be 1.758mm and 0.9mm, and calculate the thickness reduction ratio R at the center position to be 48.8%; R i The value of and s i The values are shown in Table 1, and according to ...

Embodiment 2

[0034] In Example 2, it is determined that the length of the strip edge crack along the strip width direction is 35mm, and the length of the edge roll shape of the crystallization roll to be modified is determined to be 70mm; The edge roll shape curve is discretized and selected within the range of the edge length of 70mm, and the discretized original roll shape value S is obtained. 0 , S 1 , S 2 ...S 10 ; Simultaneously obtain the thickness value H of the edge of the cast strip within the same length range 0 , H 1 , H 2 ...H 10 and the thickness of the strip is h 0 , h 1 , h 2 ...h 10 ; Obtain the thickness of the cast strip and the thickness of the rolled strip at the center of the strip width to be 1.8mm and 1.2mm, and calculate the thickness reduction ratio R at the center position to be 33.3%; R i The value of and s i The value of is shown in Table 2, and according to the original roll shape and Y i =S i +s i The new crystallization roll edge roll shape valu...

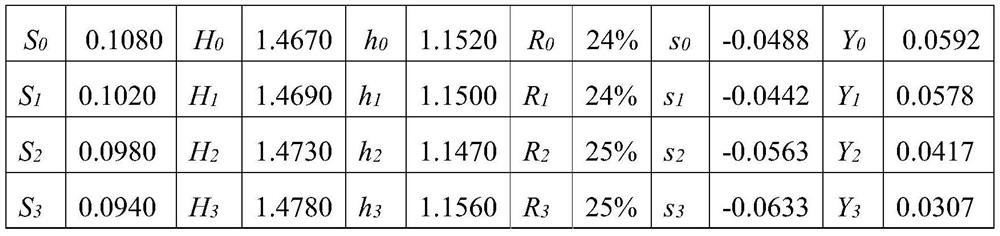

Embodiment 3

[0039]In Example 3, it is determined that the length of the strip edge crack along the width direction of the strip is 15mm, and the length of the edge roll shape of the crystallization roll that needs to be modified is determined to be 20mm; The edge roll shape curve is discretized and selected within the range of the edge length of 20mm, and the discretized original roll shape value S is obtained. 0 , S 1 , S 2 ...S 4 ; Simultaneously obtain the thickness value H of the edge of the cast strip within the same length range 0 , H 1 , H 2 ...H 4 and the thickness of the strip is h 0 , h 1 , h 2 ...h 4 ; Obtain the thickness of the cast strip and the thickness of the rolled strip at the center position of the strip width to be 1.75mm and 0.8mm, and calculate the thickness reduction ratio R at the center position to be 54.2%; R i The value of and s i The value of is shown in Table 3, and according to the original roll shape and Y i =S i +s i Obtain the new crystalliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com