A 0.4mm Thin Strip IF Steel Continuous Stripping Anti-Wrinkle Control Method

A control method and continuous retreat technology, applied in heat treatment process control, manufacturing tools, furnaces, etc., can solve problems such as very large impact on unit stable operation, broken belt accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

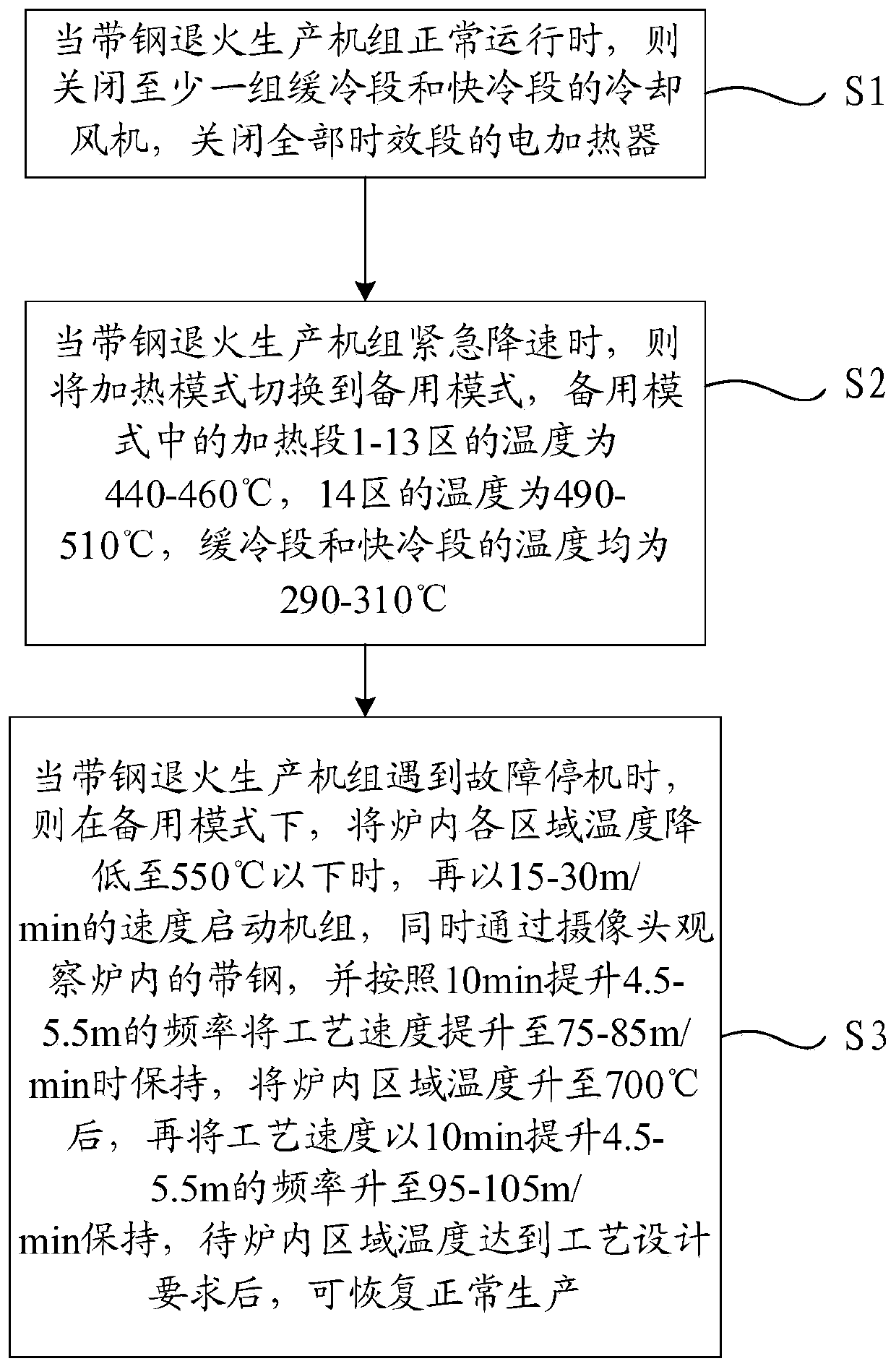

Method used

Image

Examples

Embodiment 1

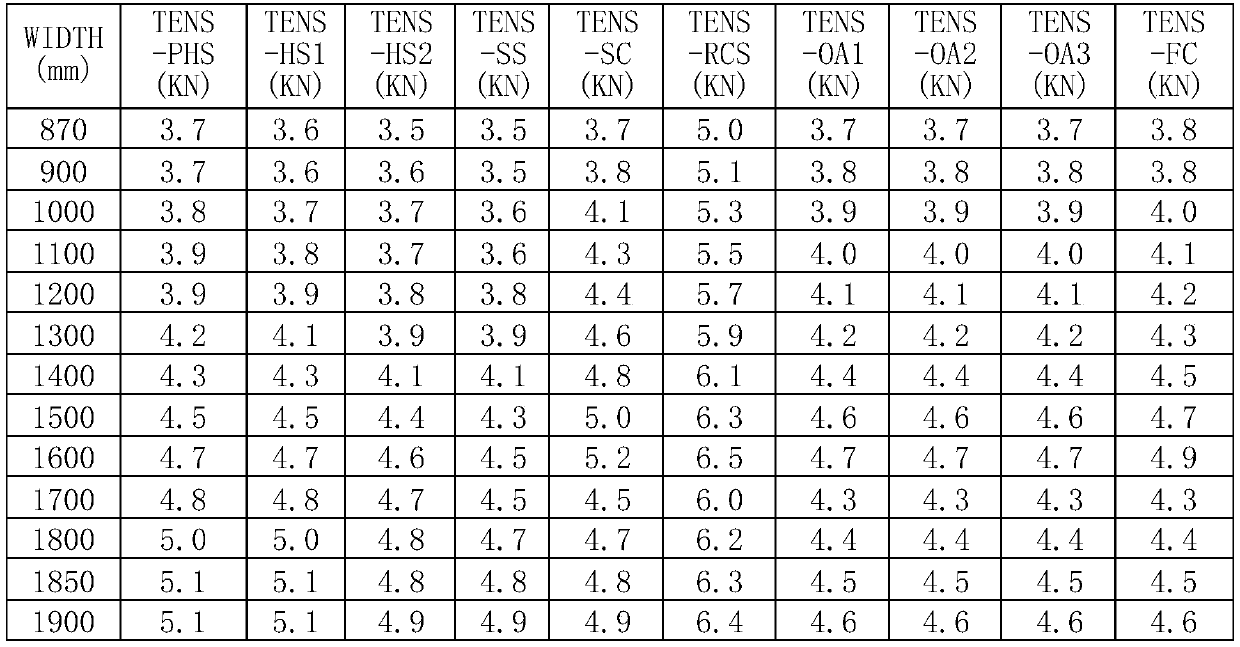

[0047] Production variety: DC04, specification: 0.4*1024mm, the tension process in the furnace is shown in Table 2.

[0048] The process parameter base of each section tension in the furnace in table 2 embodiment 1

[0049]

[0050] Turn off the first pair of fans in the slow cooling section and the second pair of fans in the fast cooling section, turn off all the electric heaters in the aging section, and adjust the unit speed to 200m / min. After the above adjustments, the surface of the strip steel is smooth and there is no cold wrinkle.

Embodiment 2

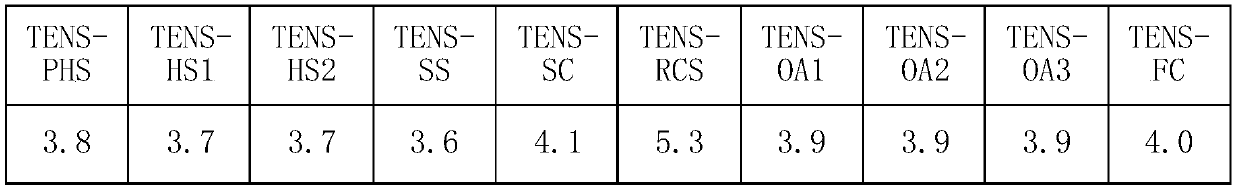

[0052] Production variety: DC04, specification: 0.4*1320mm, the tension process in the furnace is shown in Table 3.

[0053] The process parameter base of each section tension in the furnace in table 3 embodiment 2

[0054]

[0055] Due to the roll change failure of the export tempering machine, the export was full, and the furnace area slowed down to shutdown.

[0056] When the unit slows down, switch the heating mode to the Standby mode in advance, that is, the standby mode. The Standby temperature heating section 1-13 zone is 450°C, 14 zone is 500°C, and the slow cooling section and the fast cooling section are both 300°C; The cooling fans in the slow cooling section, fast cooling section and final cooling section are all turned off, and the tension of each section in the furnace is reduced by 20%. At this time, the strip steel in the furnace has no wrinkles or deviation; Tension, when the standby mode reduces the temperature in the furnace area to below 550°C, start th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com