Patents

Literature

112 results about "Unit speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Units for Speed. The SI units for speed are m/s (meters per second). In everyday usage, kilometers per hour or miles per hour are the common units of speed. At sea, knots (or nautical miles) per hour is a common speed.

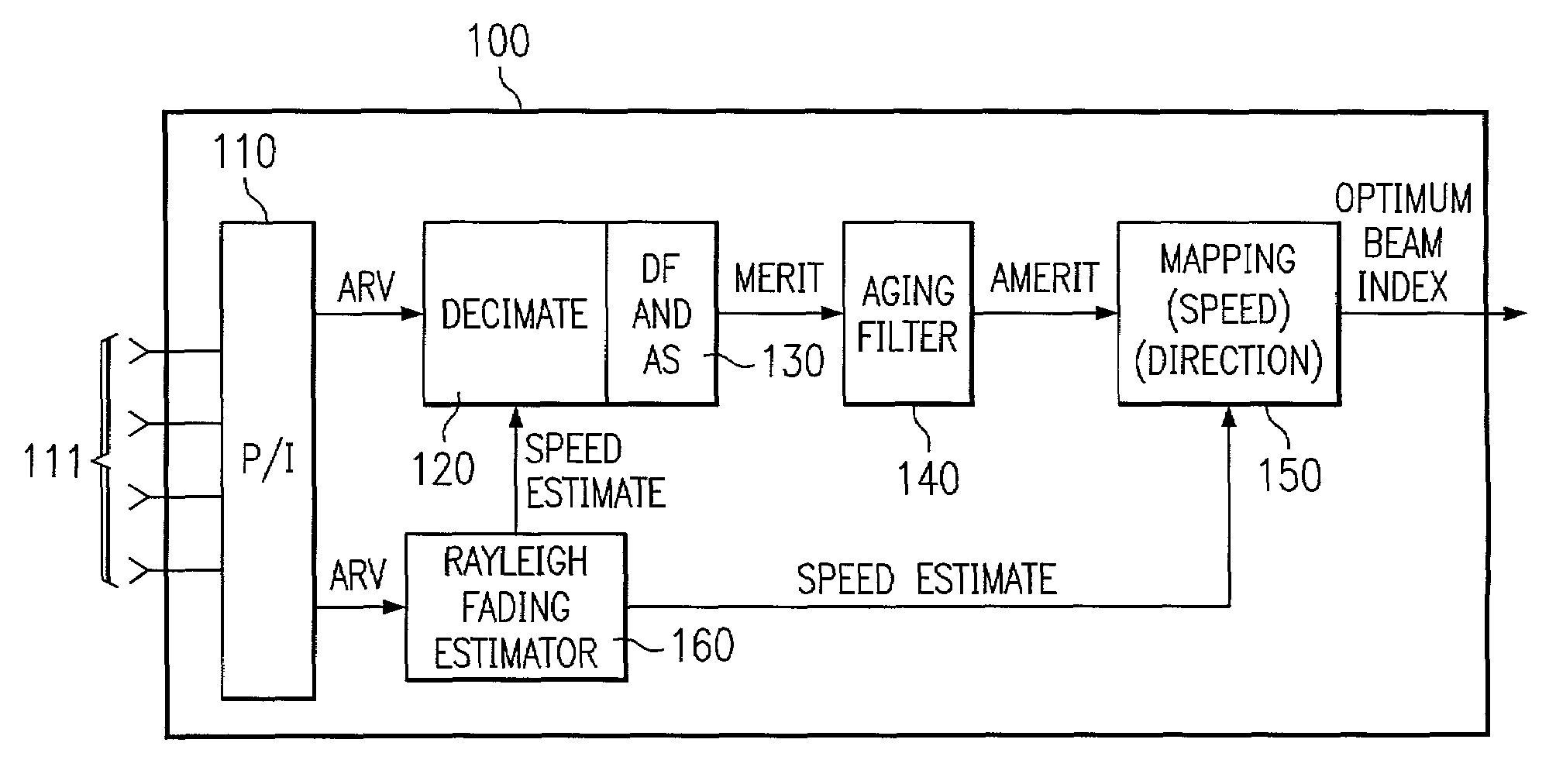

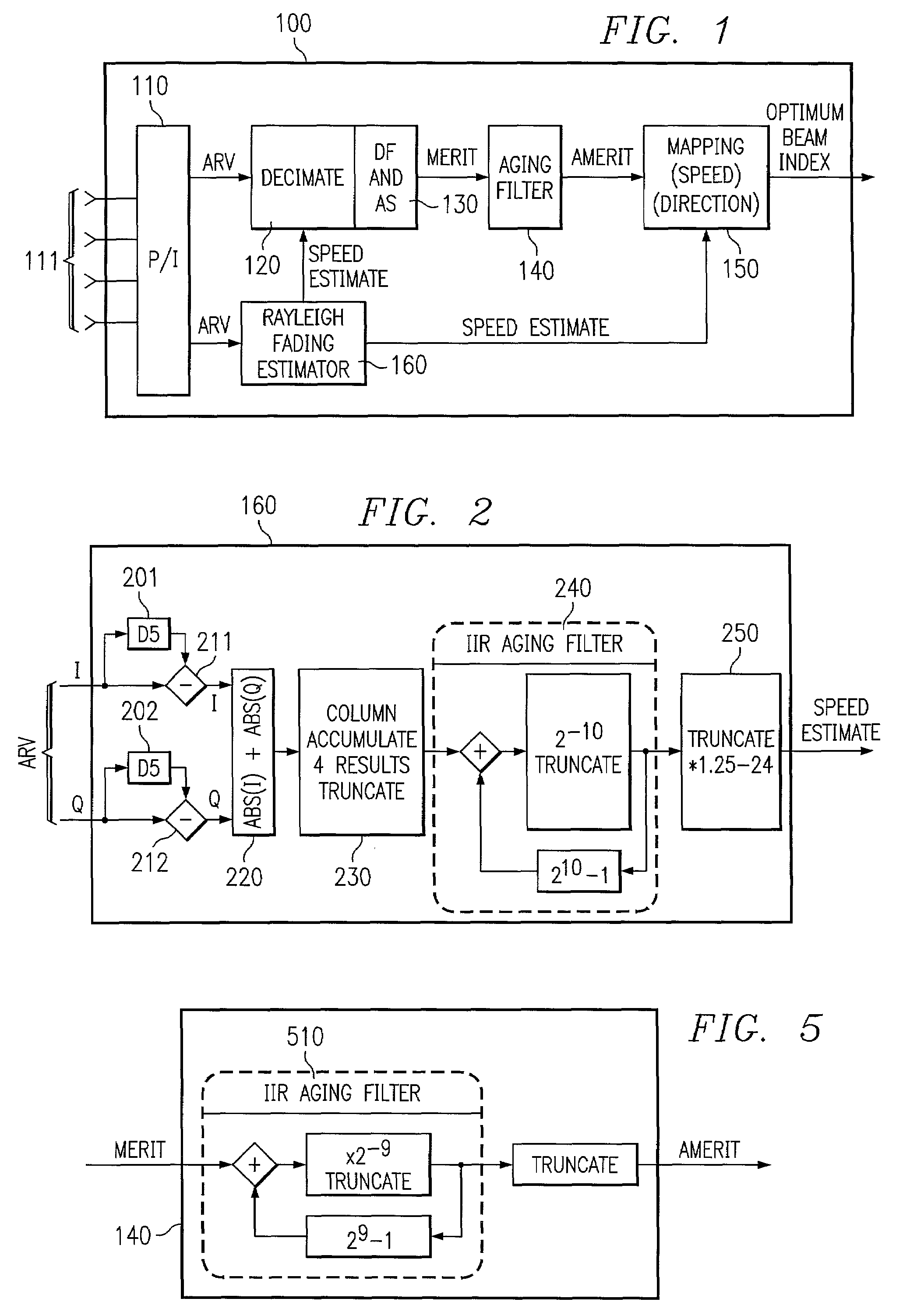

System and method for selecting optimized beam configuration

InactiveUS7117014B1Increase system capacityLimited amountPower managementSubstation equipmentTelecommunications linkUnit speed

Disclosed are systems and methods which provide communication links optimized with respect to particular subscriber units. Preferred embodiments utilize multiple information components with respect to the arrival of signals associated with target subscriber units in providing optimized communication links. Most preferably, direction information and information with respect to the signal spread experienced in the communication channel is used. Moreover, preferred embodiments utilize subscriber unit speed information in providing optimized communication link determinations.

Owner:F POSZAT HU

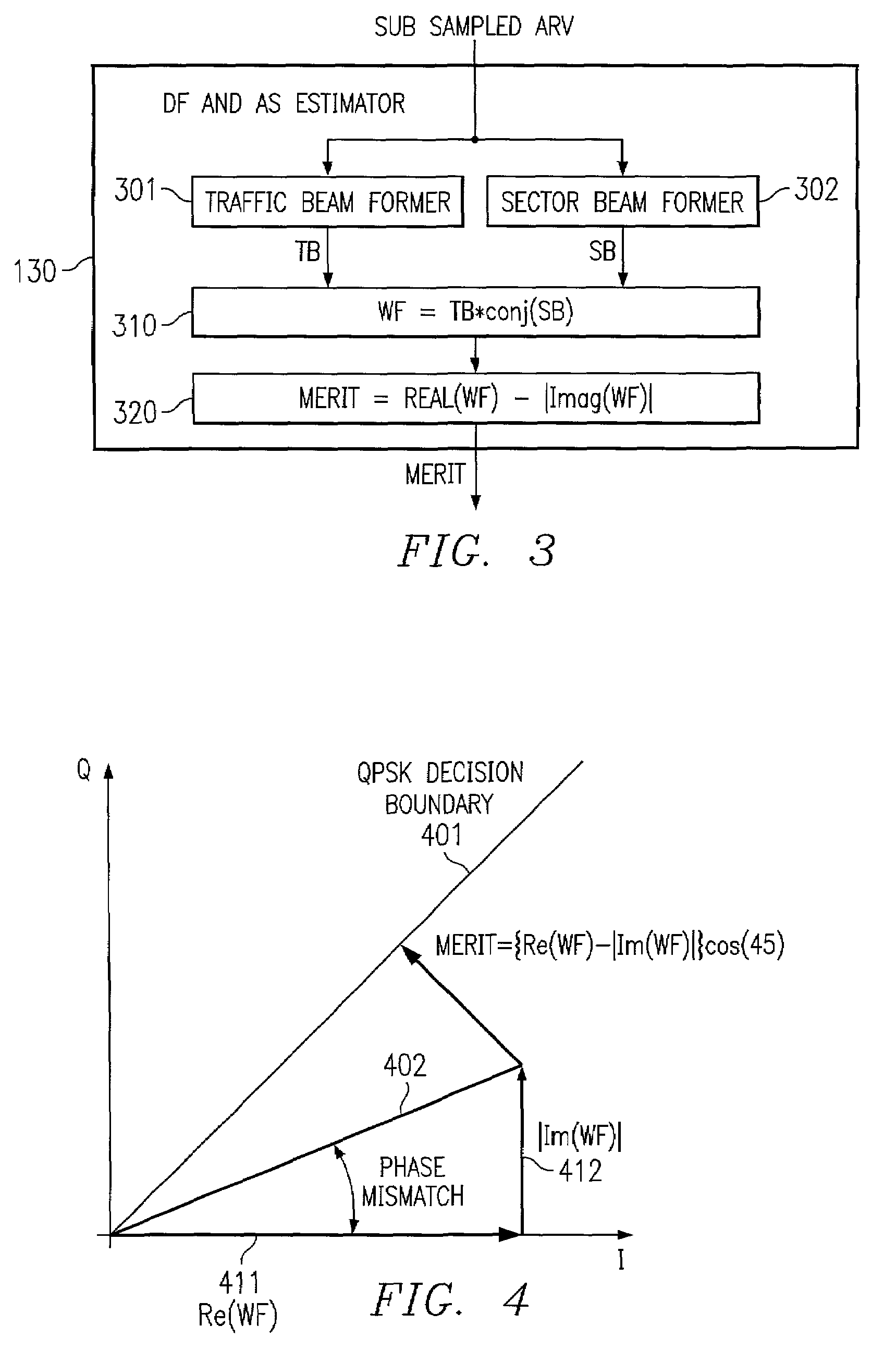

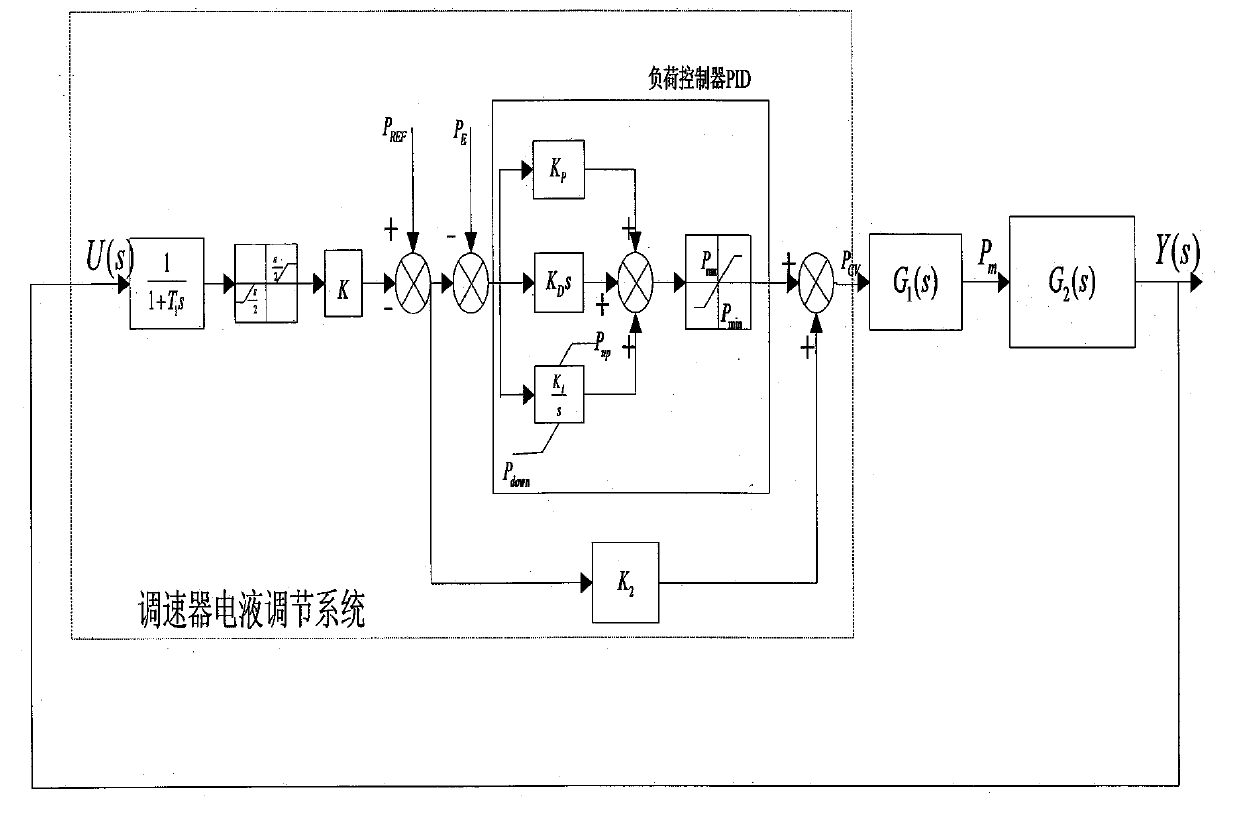

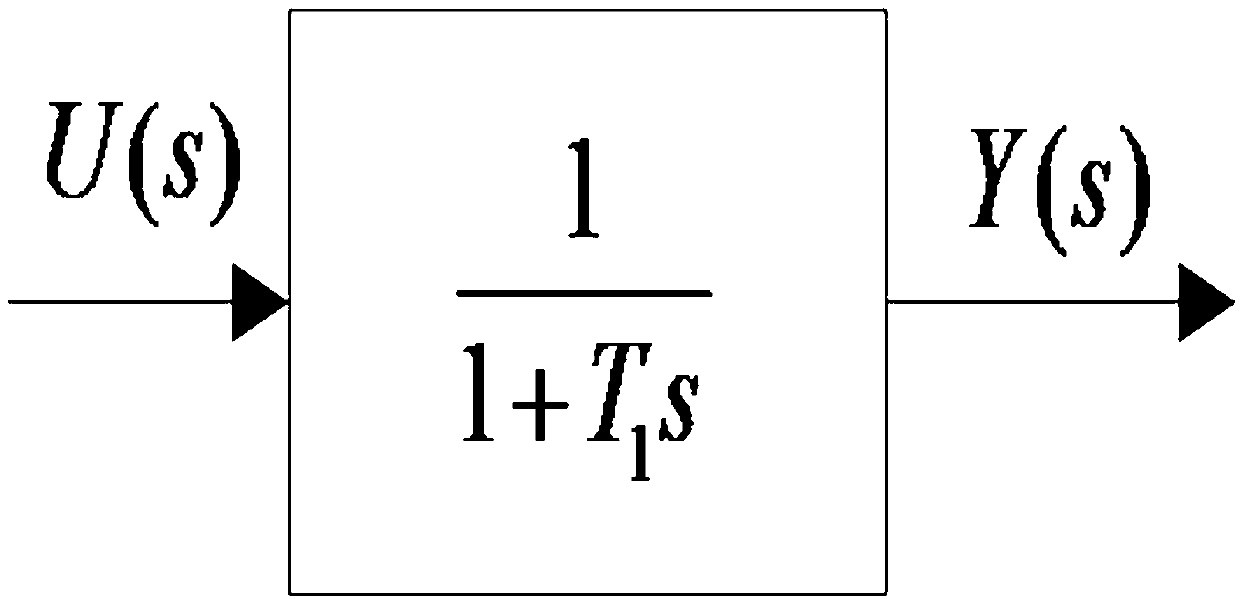

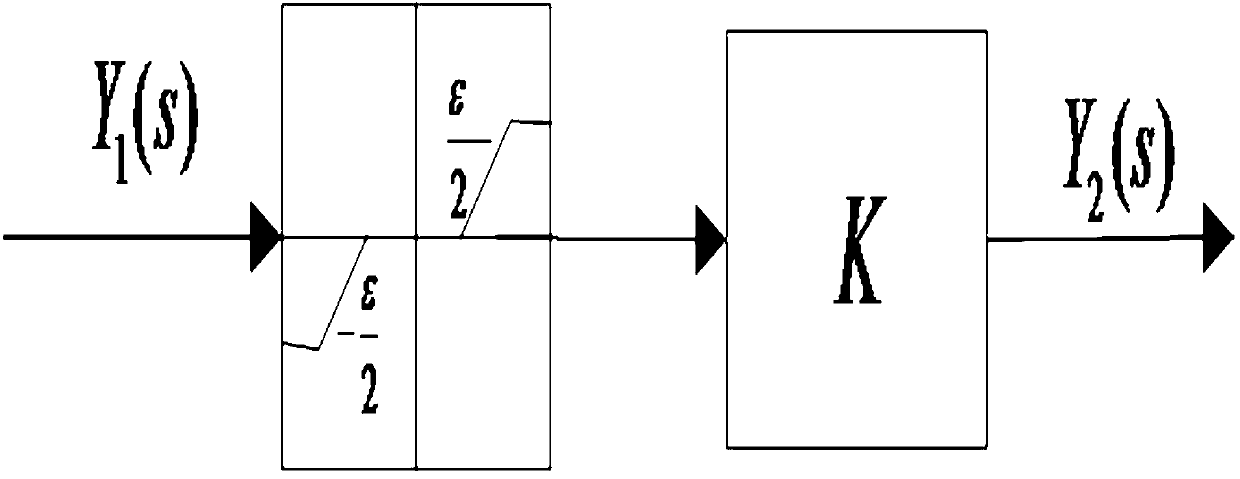

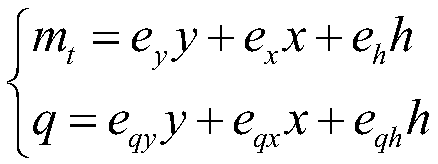

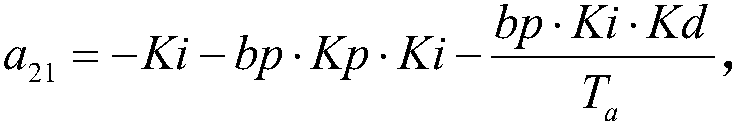

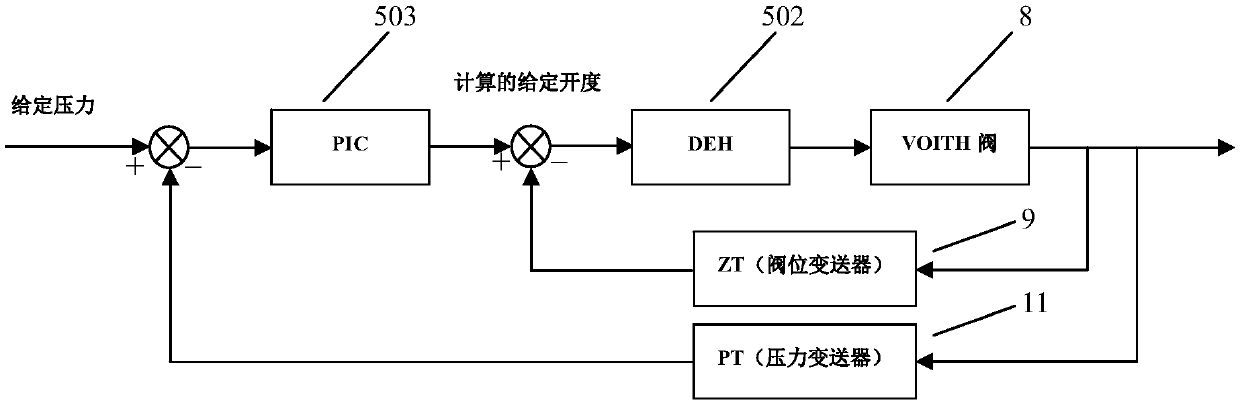

Automatic setting method for control parameters of water turbine speed regulating system

ActiveCN104533701AHigh precisionImprove dynamic qualityHydro energy generationMachines/enginesWater turbineUnit speed

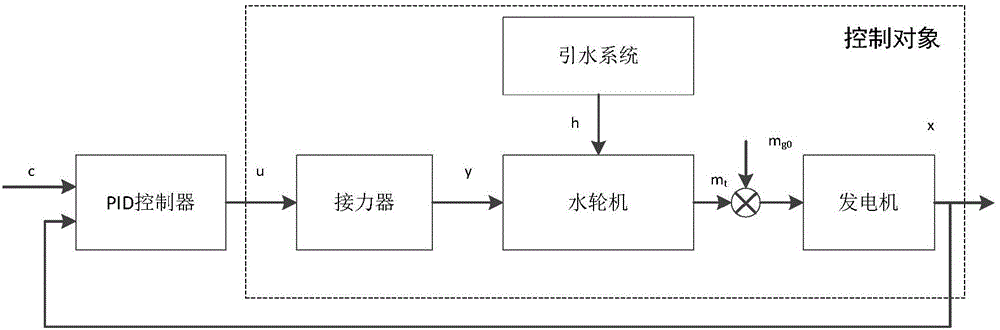

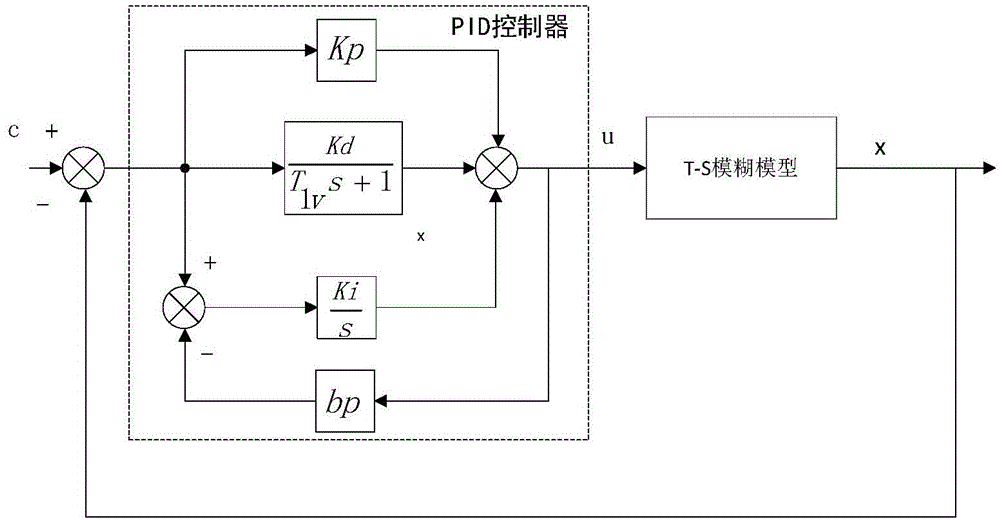

The invention relates to an automatic setting method for control parameters of a water turbine speed regulating system. According to the method, firstly, T-S fuzzy model identification is conducted on a control object of the water turbine speed regulating system of a real unit to obtain a high-precision simulation system of the water turbine speed regulating system; secondly, according to the simulation system, a target function with the PID control parameters as optimization variables is set up, and the target function is worked out through a gravitational search algorithm to obtain the optimal PID control parameters. Due to the fact that the precision of the set simulation system is high, the characteristics of the real unit can be really reflected, the control parameter optimization result obtained through the simulation system can be directly applied to the real unit, and the dynamic quality of the unit speed regulating system is effectively improved.

Owner:HUAZHONG UNIV OF SCI & TECH

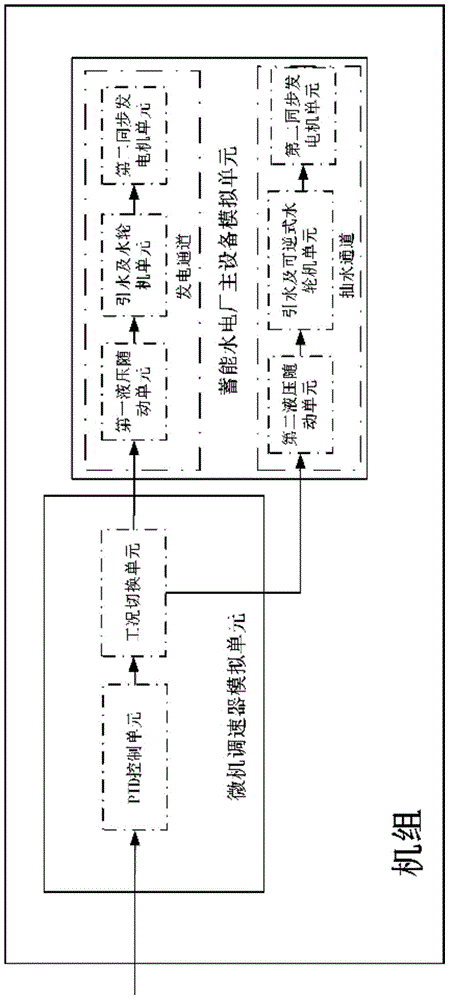

Speed regulating simulation system and method applicable to pumped storage unit

ActiveCN103606108AImplement co-simulationImplement characterization analysisData processing applicationsSoftware simulation/interpretation/emulationUnit speedLoad following power plant

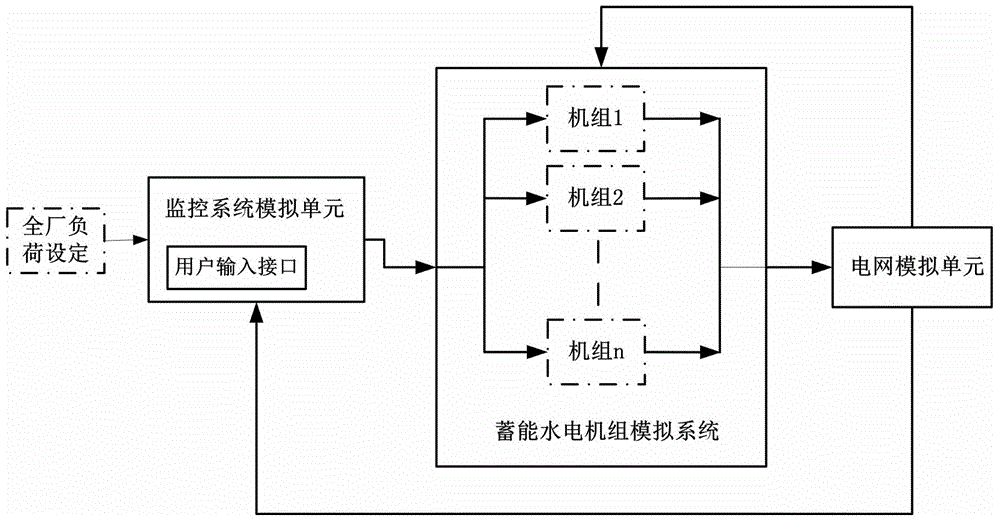

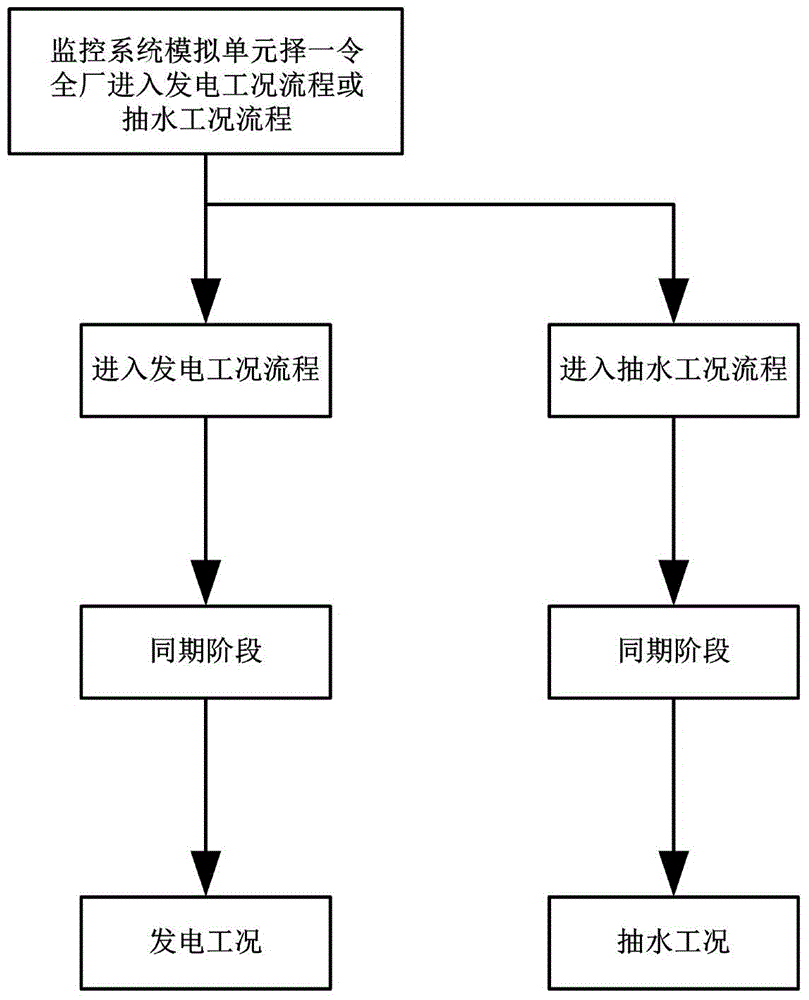

The invention provides a speed regulating simulation system applicable to a pumped storage unit and a speed regulating simulation method applicable to the pumped storage unit. The speed regulating simulation system applicable to the pumped storage unit is composed of a monitoring system simulation unit, a storage hydroelectric generating unit simulation system and a power grid simulation unit; and the speed regulating simulation system applicable to the pumped storage unit can realize a plurality of simulation modes such as real-time simulation, super real-time simulation and under real-time simulation of a pumped storage unit speed adjustment system through diversified simulation. With the speed regulating simulation system and method applicable to the pumped storage unit of the invention adopted, a whole power regulation loop of load setting, load regulation and load output of a pumped storage power station can be simulated authentically, and machine-network joint simulation based on a pumped storage unit speed regulating system model can be realized, and pumped storage unit characteristic analysis and power grid stability research under the background of a large power grid can be facilitated. Compared with other platforms which can only realize a single-unit plant-level speed adjustment system function, the speed regulating simulation system and method applicable to the pumped storage unit of the invention are advantageous in excellent functional performance and greater benefit for satisfying requirements of experiments, analysis researches and the like, and positive significance for the promotion of development and the improvement of production efficiency.

Owner:广东蓄能发电有限公司

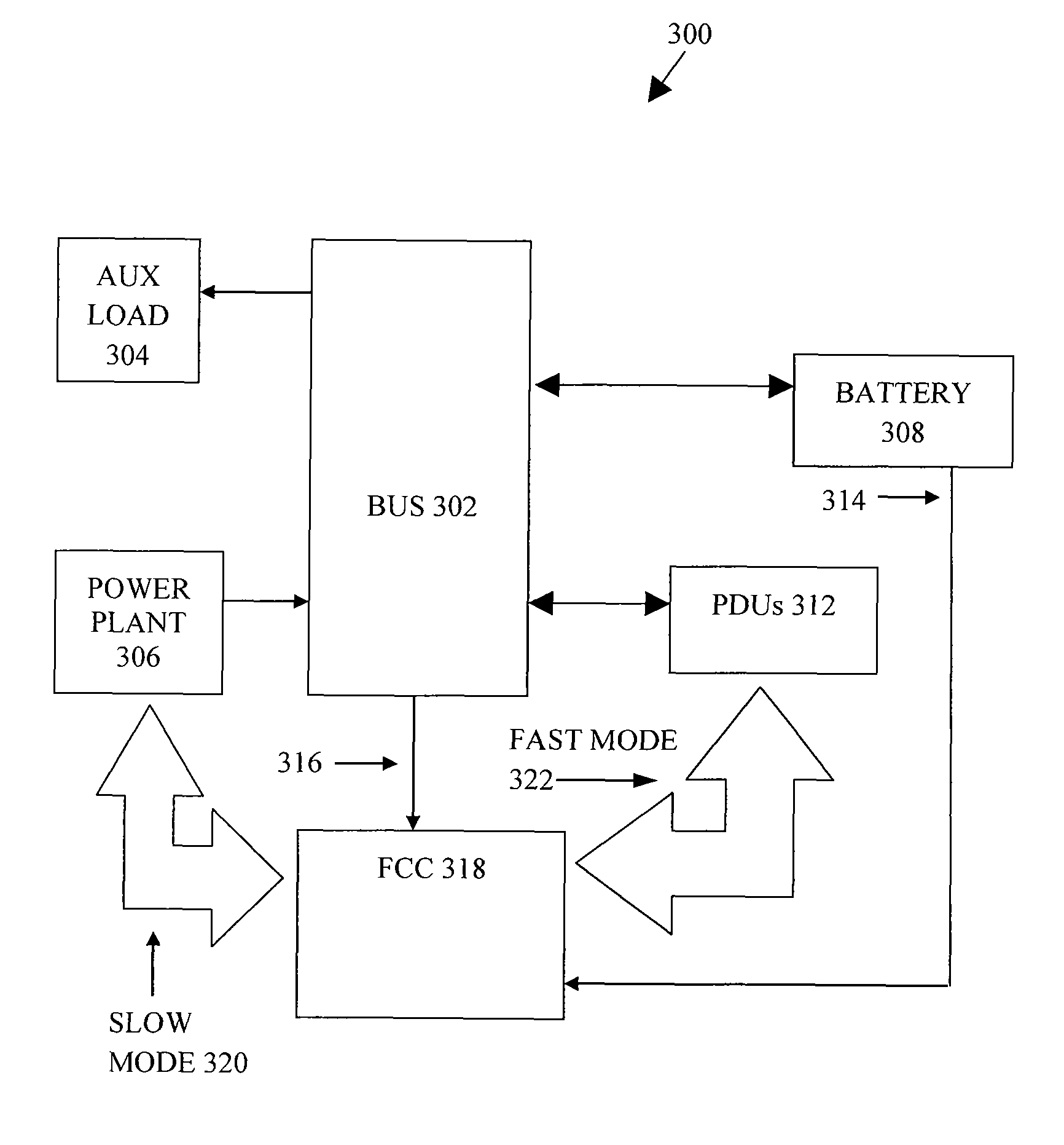

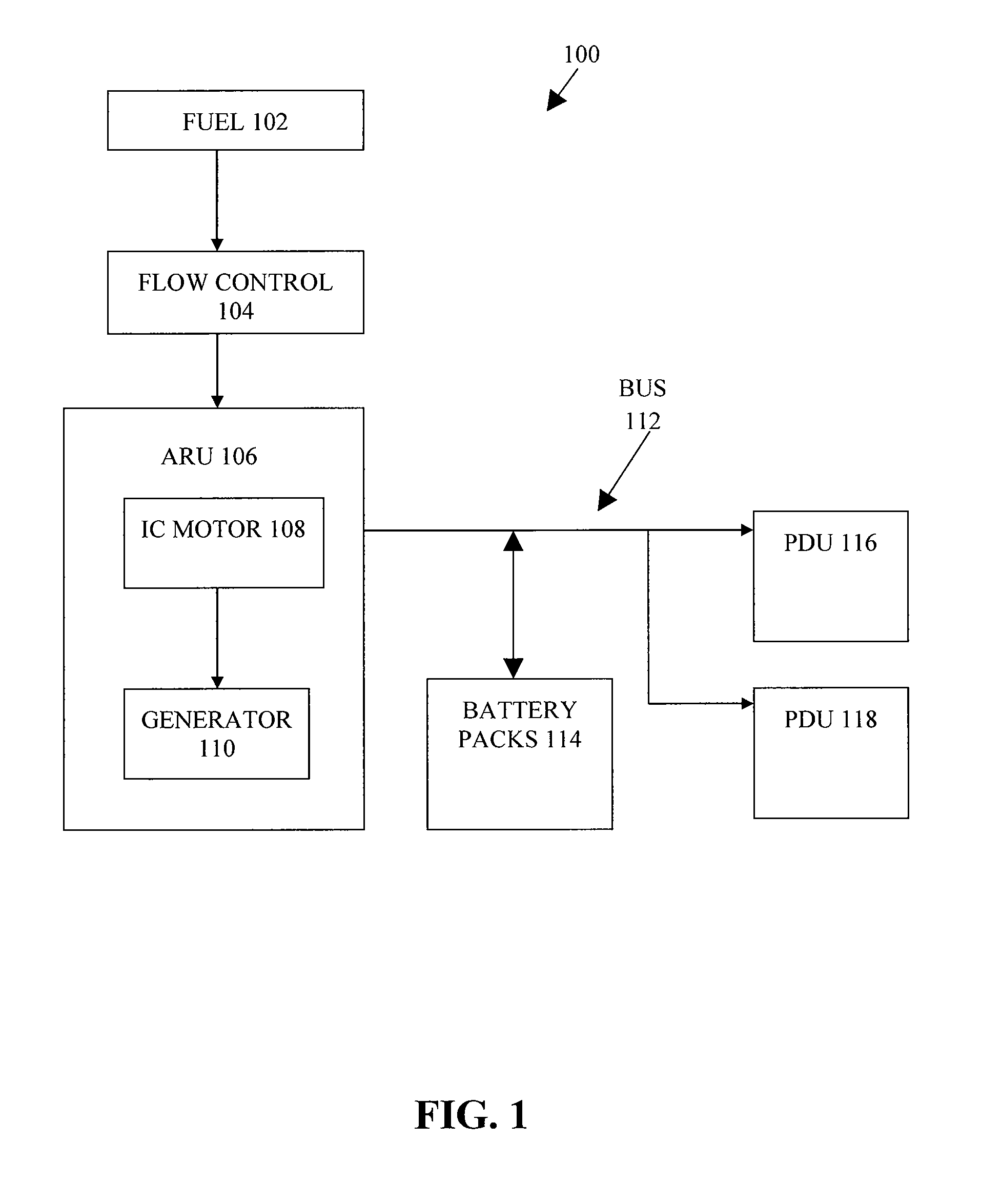

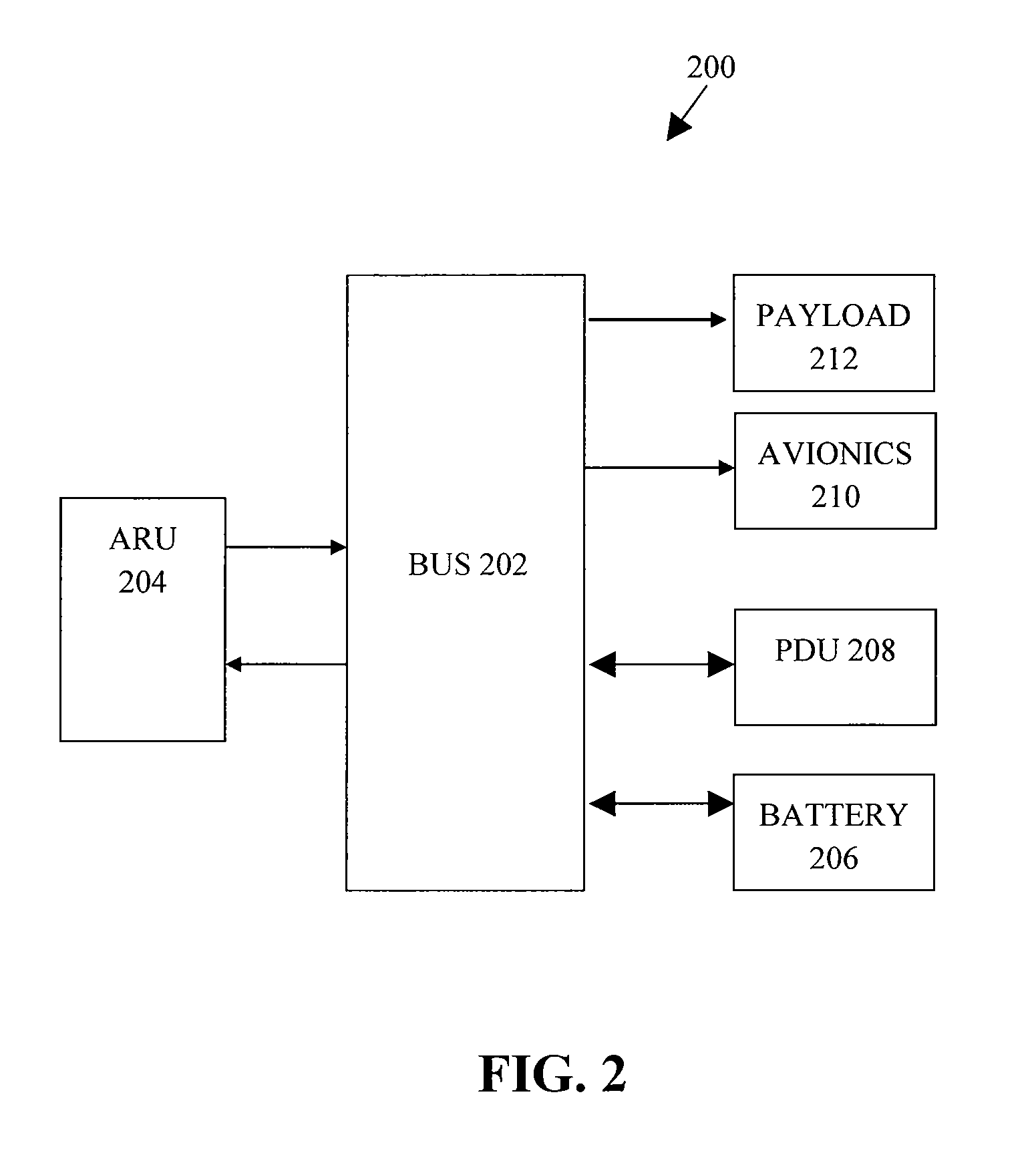

Aircraft power management

ActiveUS8296036B2Improve vehicle performanceRapid responseElectric power distributionPropellersPower stationUnit speed

An electric power management system of a vehicle may interconnect a power plant, a propeller drive unit, and a battery via a bus. A controller may direct the operation of the power plant and the propeller drive unit. In a slow control mode, the propeller drive unit may react slowly to small throttle change requests. In the slow control mode, the propeller drive unit may draw power completely or substantially from the power plant. Upon a throttle request to rapidly change propeller drive unit speed more than a threshold amount, the controller may direct that the propeller drive unit quickly obtain the requested speed by drawing power required from the battery in excess of that being generated from the power plant. Subsequently, the controller may direct that the power plant increase power generation to maintain the propeller drive unit at the new speed, and recharge or float the battery.

Owner:AEROVIRONMENT INC

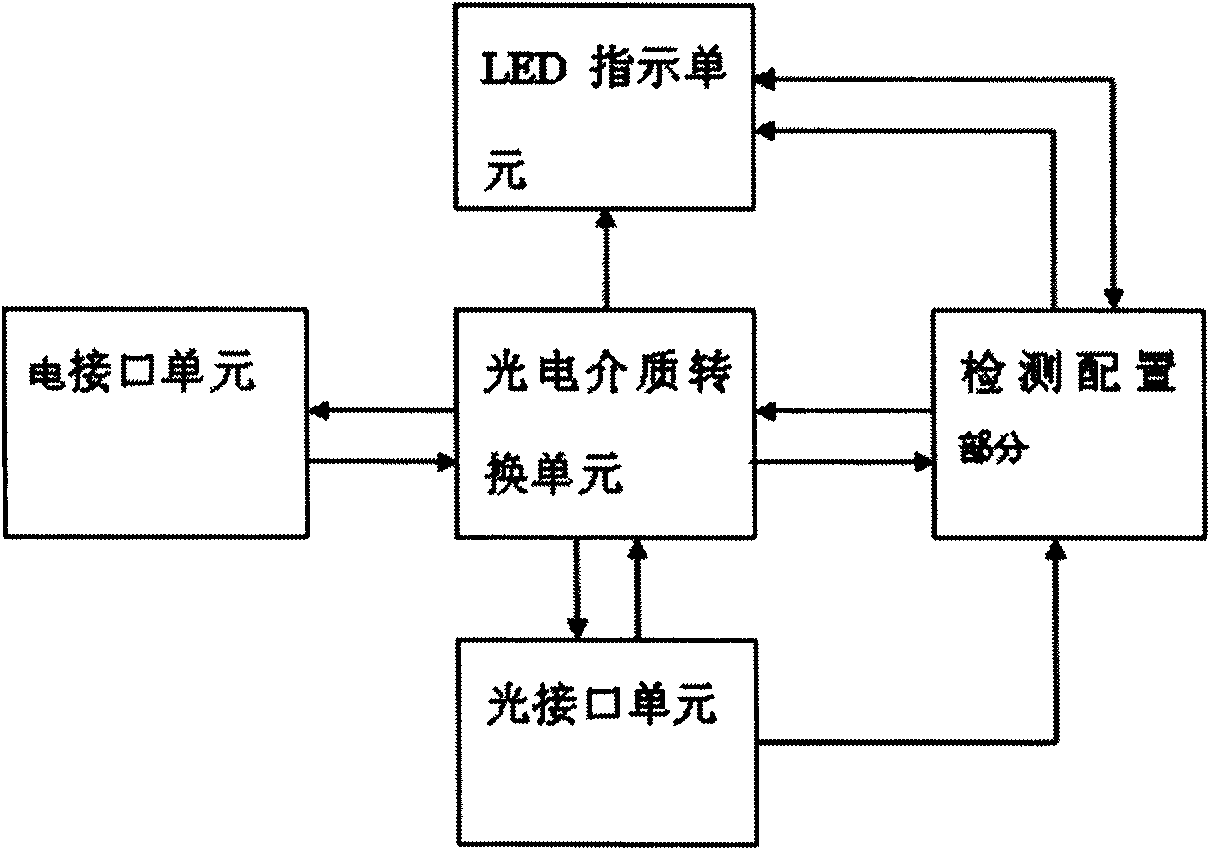

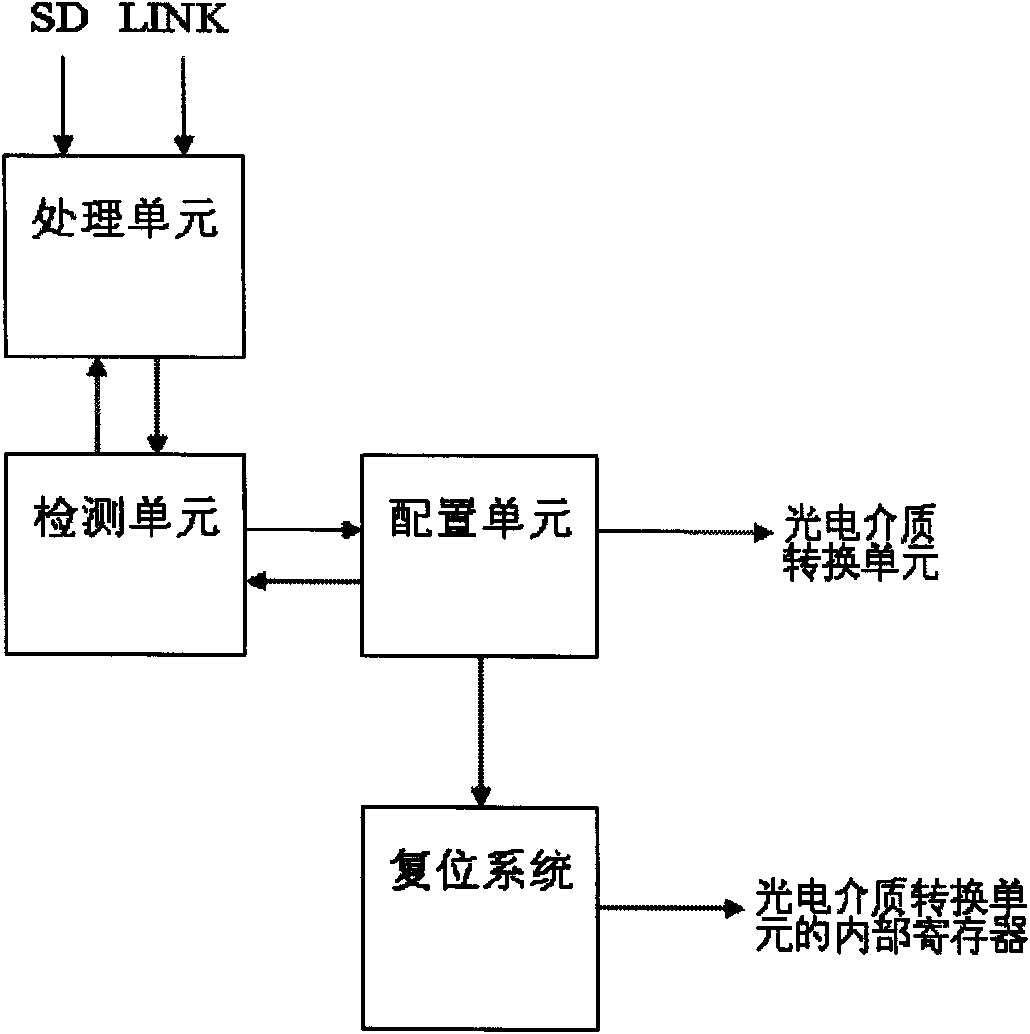

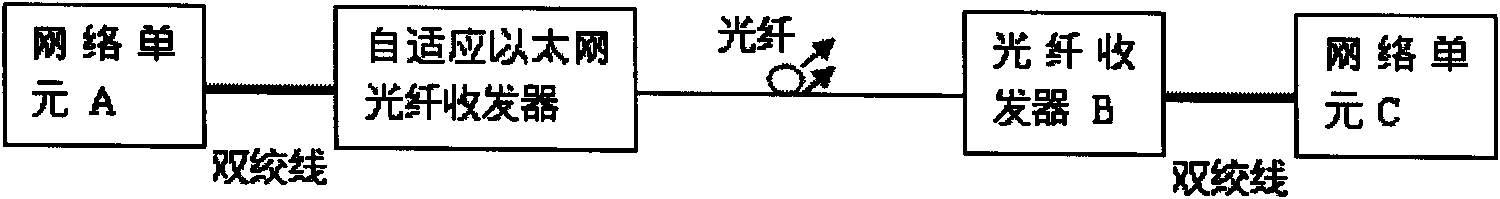

Optical port self-adaptive Ethernet network fiber optical transceiver and self-adaptive approach thereof

ActiveCN101610116AReduce operating costsNetwork engineering is convenientElectromagnetic transceiversFiberTransceiver

The invention provides an optical port self-adaptive Ethernet network fiber optical transceiver, comprising an electrical interface unit, an optical interface unit, an actinodielectric translation unit, a configuration unit, a detection unit and a resetting system; wherein the actinodielectric translation unit comprises an internal register, the detection unit and the configuration unit are electrically connected, the actinodielectric translation unit is electrically connected with the electrical interface unit, the optical interface unit, the configuration unit and the resetting unit respectively. The invention further provides the self-adaptive approach of the optical port self-adaptive Ethernet network fiber optical transceiver and provides the possibility of using fiber optical transceivers with different optical interface unit speeds in the same optical fiber link; the optical port self-adaptive Ethernet network fiber optical transceiver of the invention has wider application range than ordinary fiber optical transceivers, thus avoiding operating at low speed due to access to high-speed optical link; in addition, after the fiber optical transceiver at the other end of the optical fiber link is updated, namely the speed is increased, mutual communication among the fiber optical transceivers can still be carried out.

Owner:深圳市巨联高科技有限公司

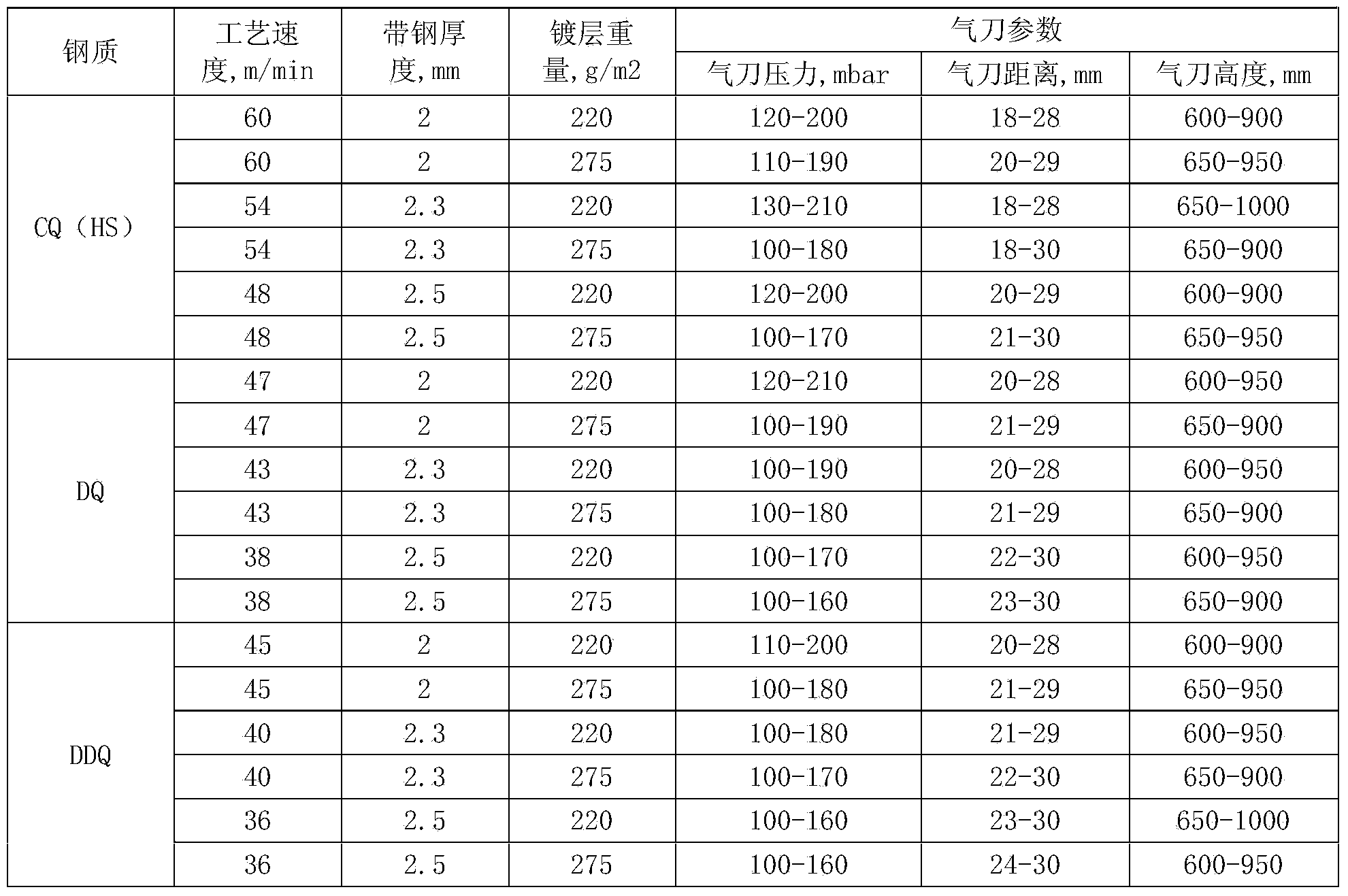

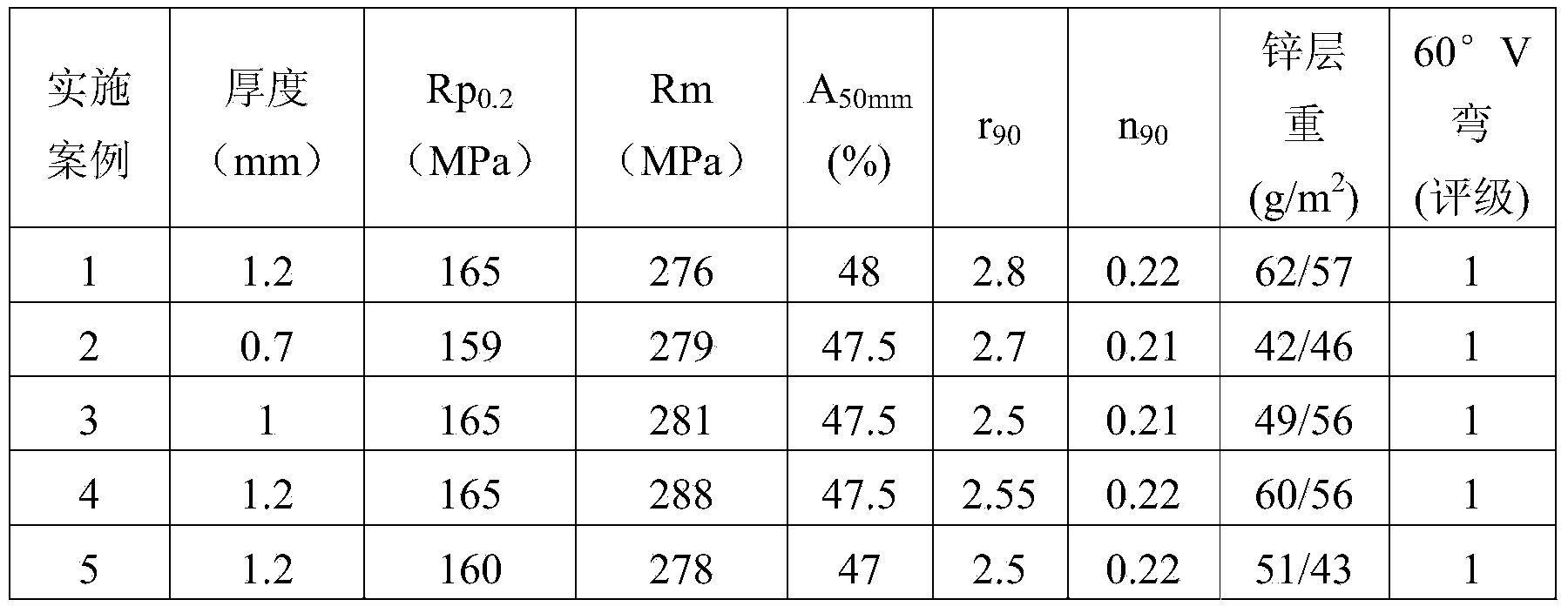

Method for controlling zinc flow ripples of heavy-weight material and thick-coating hot-galvanizing products

ActiveCN103966537AControl surface qualityImprove surface qualityHot-dipping/immersion processesUnit speedStrip steel

The invention relates to the field of hot galvanizing, in particular to a method for controlling zinc flow ripples of heavy-weight material and thick-coating hot-galvanizing products. The method is characterized in that aiming at the reasons caused by the defect of zinc flow ripples, the temperature of an injection medium is adjusted, the cooling capacity of the injection medium to strip steel is improved, and meanwhile technological parameters of an air knife are optimized, so that the purpose of controlling the defect of the zinc flow ripples is achieved; the specific parameters are selected as follows: 1, before production, indoor temperature of a draught fan is within the range between 0-10 DEG C; 2, parameters of the air knife are optimized: the distance between the lip of the air knife and the liquid surface is 600-1,000 mm, the distance between the lip of the air knife and the strip steel is 15-30 mm; according to the unit speed and coating depth, the pressure of the air knife is 100-300 mbar. Compared with the prior art, the method has the benefits as follows: surface quality of heavy-weight material and thick-coating hot-galvanizing products of which the heavy-weight material is not less than 2.0 mm and the thick coating is not less than 220 g / m<2> is effectively controlled, and the percent of pass is improved to 96.2 percent from 90.5 percent before implementation.

Owner:ANGANG STEEL CO LTD

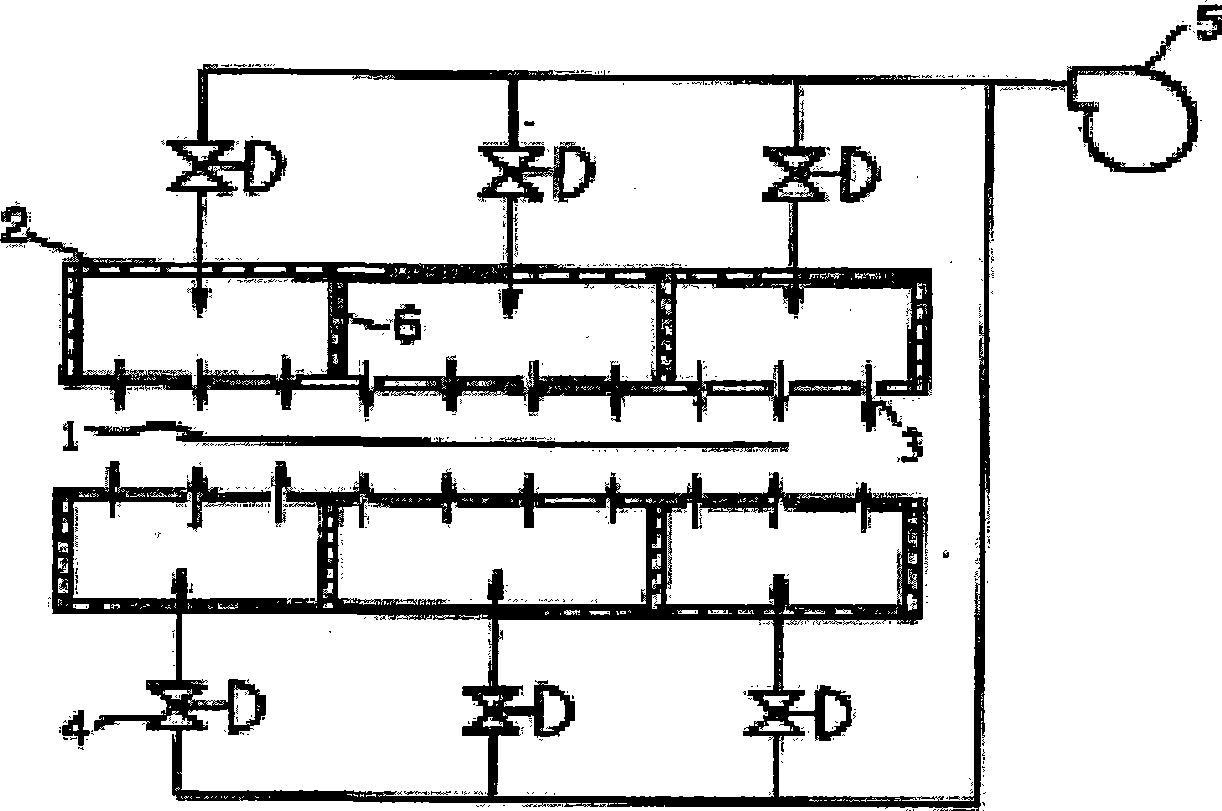

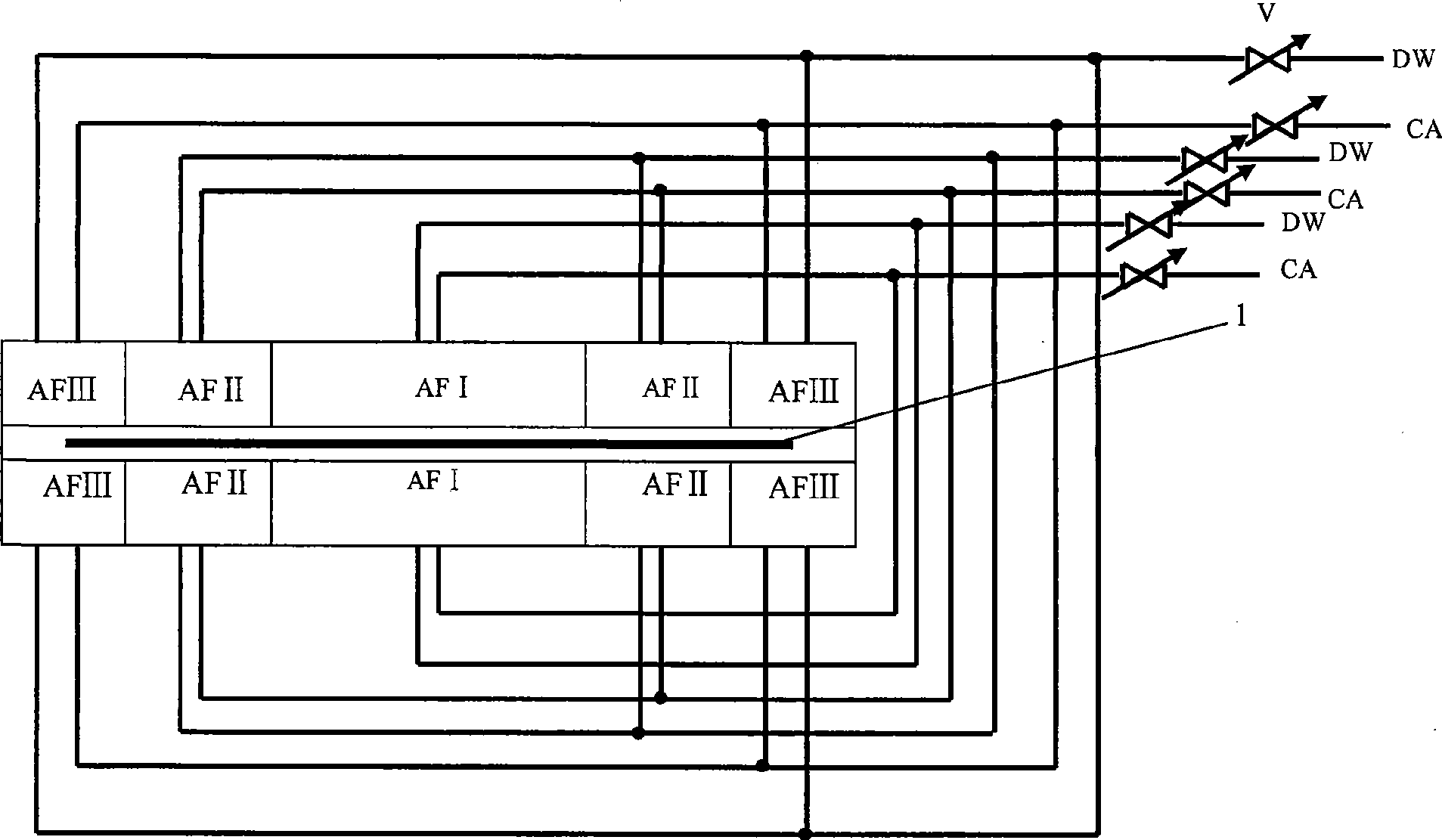

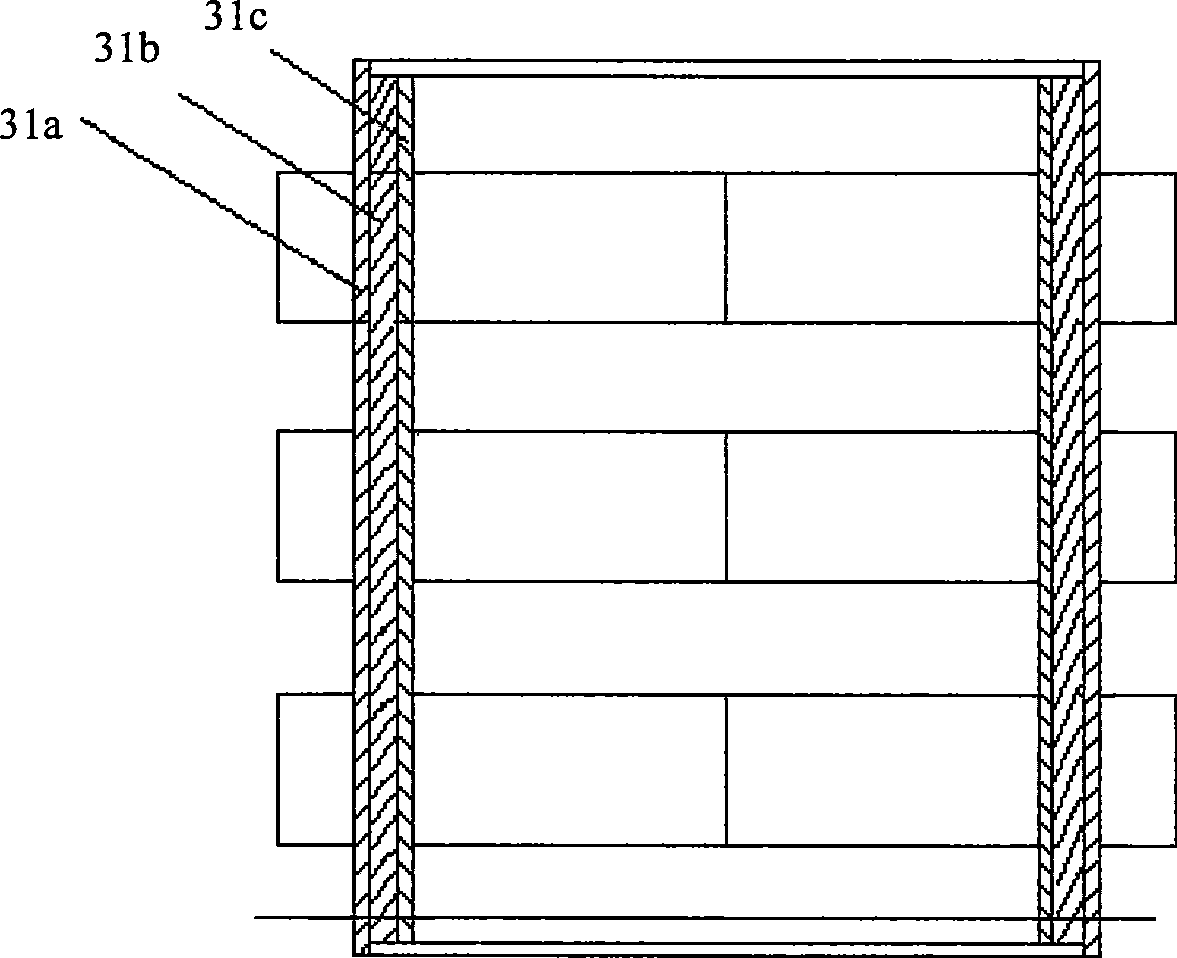

Alloying furnace cooling section strip steel cooling apparatus and cooling control method

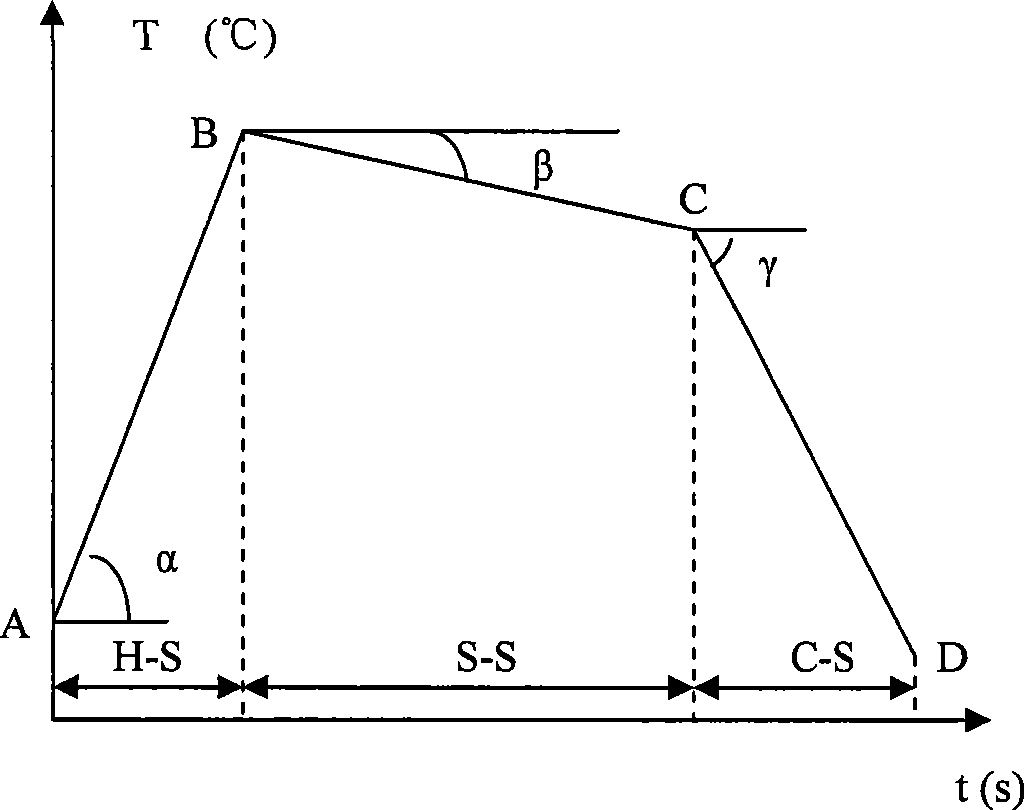

ActiveCN101376960AExcellent chalking resistanceLow costHot-dipping/immersion processesFurnace typesUnit speedStrip steel

The invention relates to an alloying furnace cooling section air blasting and air-spray cooling composite cooling device and a cooling regulation method; the cooling device controls different areas along the width direction of the strip steel, and the cooling speed is adjustable along the width of the strip steel; the device is divided into a lower section, a middle section and an upper section along the rolling direction of the strip steel; the middle section is in an alternative deployment way of air blasting cooling and air-spray cooling; the lower and the upper sections are in a pure cooling deployment way; and all sections are grouped in the rolling direction of the strip steel; each group of cooling way can be singly controlled by a switch. The device can regulate the cooling speed after the alloying of the strip steel within quite a large range according to the requirement of an alloying annealing curve even at maximum unit speed, so as to manufacture an alloyed hot-dip galvanized steel sheet with excellent cladding powder resistance, and the evenness of the cladding alloying is very good.

Owner:BAOSHAN IRON & STEEL CO LTD

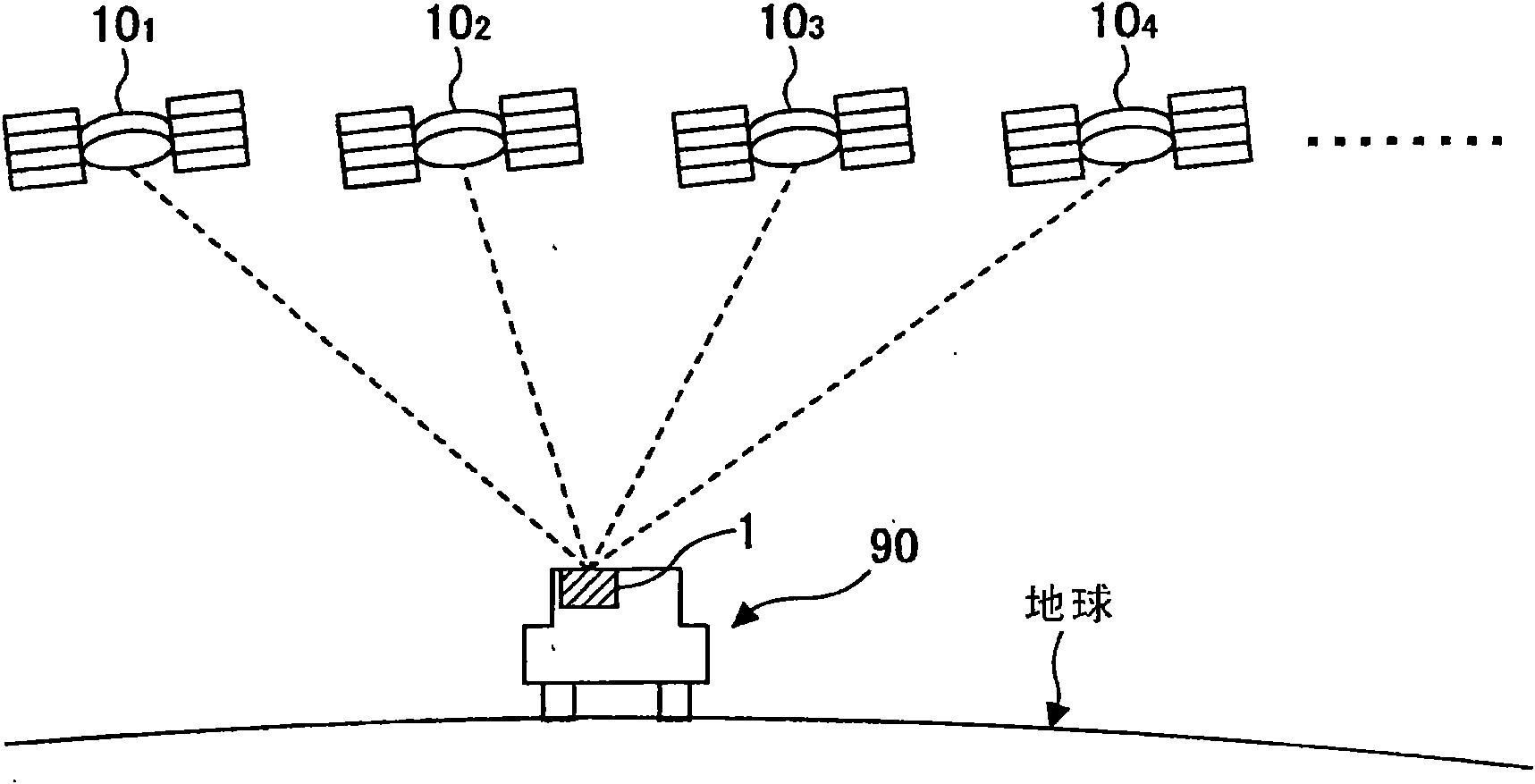

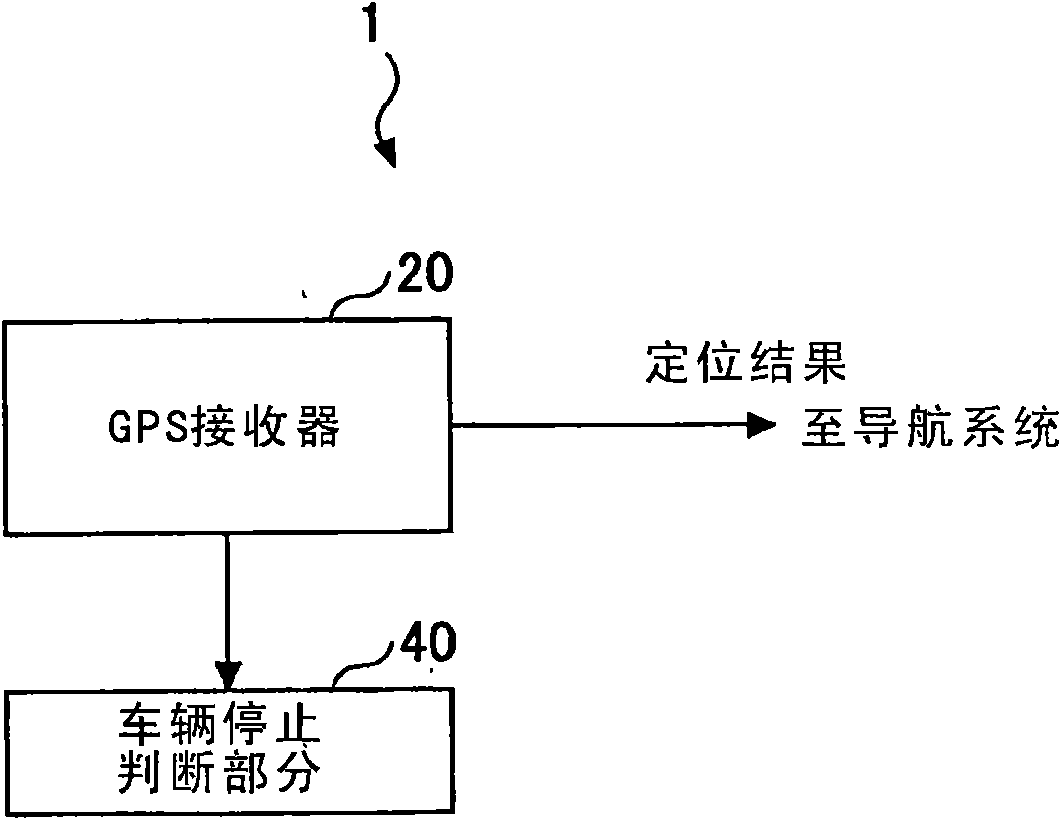

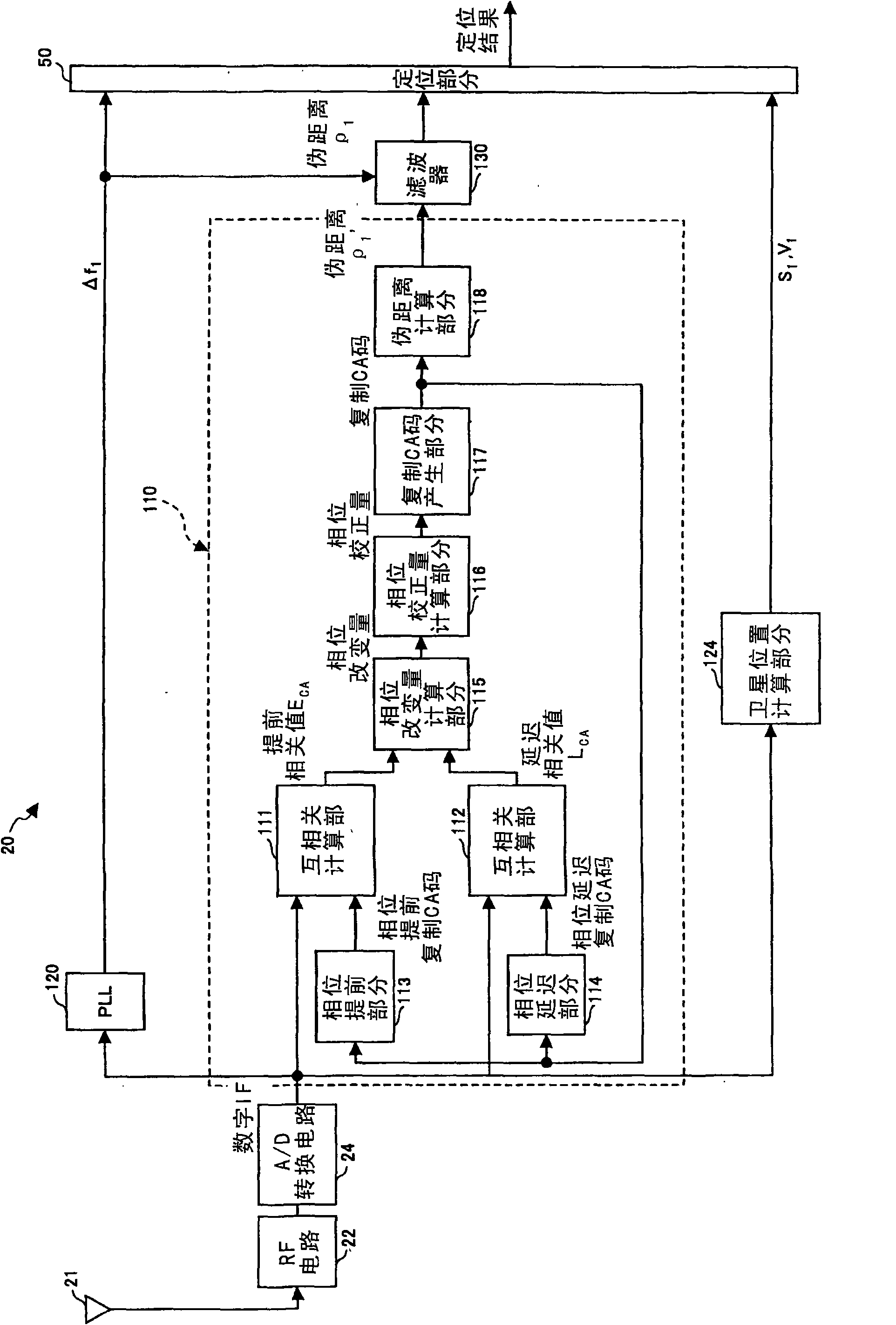

Mobile positioning apparatus

InactiveCN101606080AAppropriately weighted positioning calculationsPosition fixationSatellite radio beaconingUnit speedErrors and residuals

In a mobile-unit positioning device, phases of pseudo noise codes carried on satellite signals from satellites are observed at a mobile unit to measure a position of the mobile unit. A pseudo distance between one of the satellites and the mobile unit is measured for every satellite during a stop of the mobile unit using an observed value of the phase acquired during a stop of the mobile unit. An error index value indicating an error of the measured distance is computed based on the distances measured at points in time during a stop of the mobile unit. A weighting factor is determined based on the index value computed for every satellite. A weighted positioning computation using the determined weighting factor is performed to determine a position of the mobile unit during movement using an observed value of the phase acquired during movement. The invention also provides an another device capable of measuring position using an analogy method, in this case, the erro criterion is based on the error of the measured mobile unit speed not based on the pseudo distance.

Owner:TOYOTA JIDOSHA KK

Speed regulator parameter identification method combined with frequency locus and particle swarm optimization

ActiveCN103345546AConvenient and timely accessAvoid field testingSpecial data processing applicationsElectric power systemUnit speed

The invention relates to a speed regulator parameter identification method combined with a frequency locus and the particle swarm optimization. The speed regulator parameter identification method can be used for identifying parameters of a unit speed regulator. According to the speed regulator parameter identification method, an input and output model of a speed regulator system is set up, and identifiability of corresponding parameters is proved; an electromechanical transient simulating calculation module of the PSASP software is directly called through an interface, the speed regulator parameters are obtained, a simulation frequency curve after a power system is interfered is obtained, the speed regulator parameters are regulated based on the particle swarm optimization, and therefore the simulation frequency curve is close to an actual measurement frequency curve as much as possible; the optimized speed regulator parameters are obtained through repeated parameter optimization. According to the speed regulator parameter identification method, parameter identification of a speed regulating system can be finished only by utilizing a fault recording curve of a frequency and parameters of other components of the system, much troublesome on-spot tests can be avoided, and the relevant parameters of the speed regulator can be conveniently obtained by dispatch personnel in time.

Owner:STATE GRID CORP OF CHINA +1

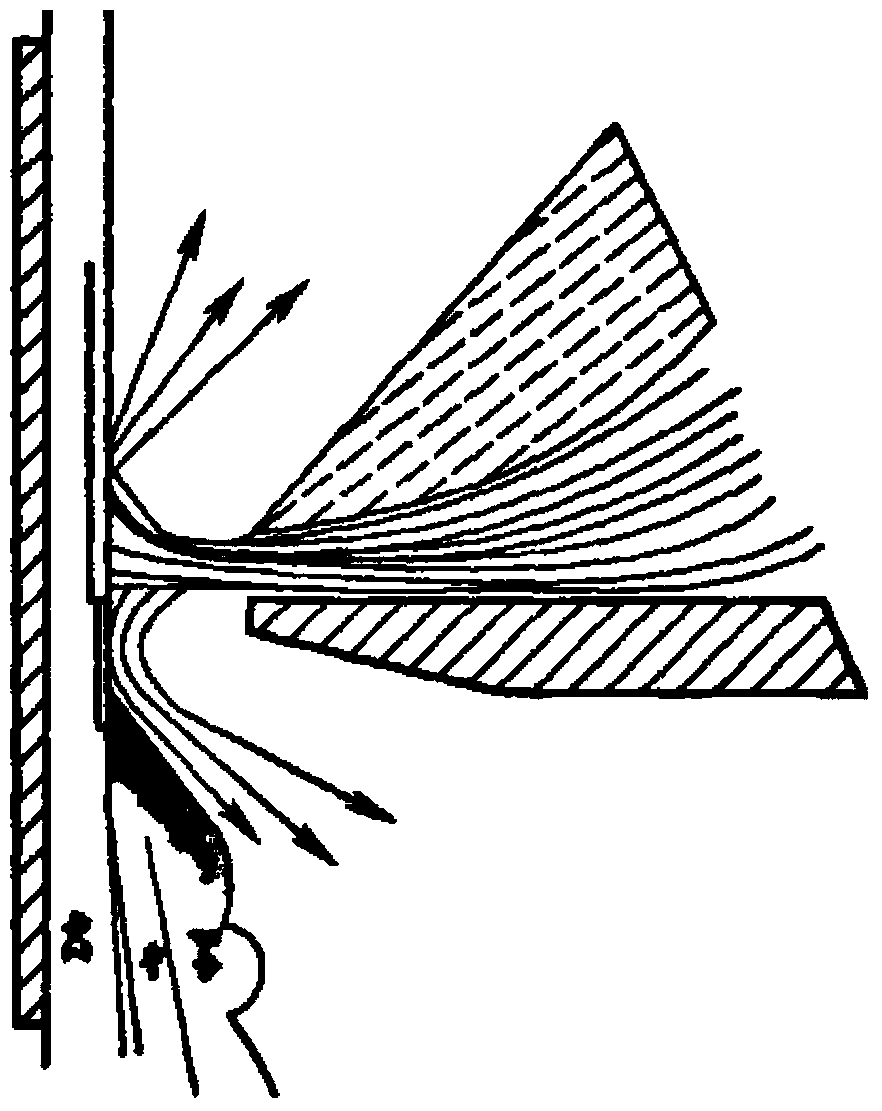

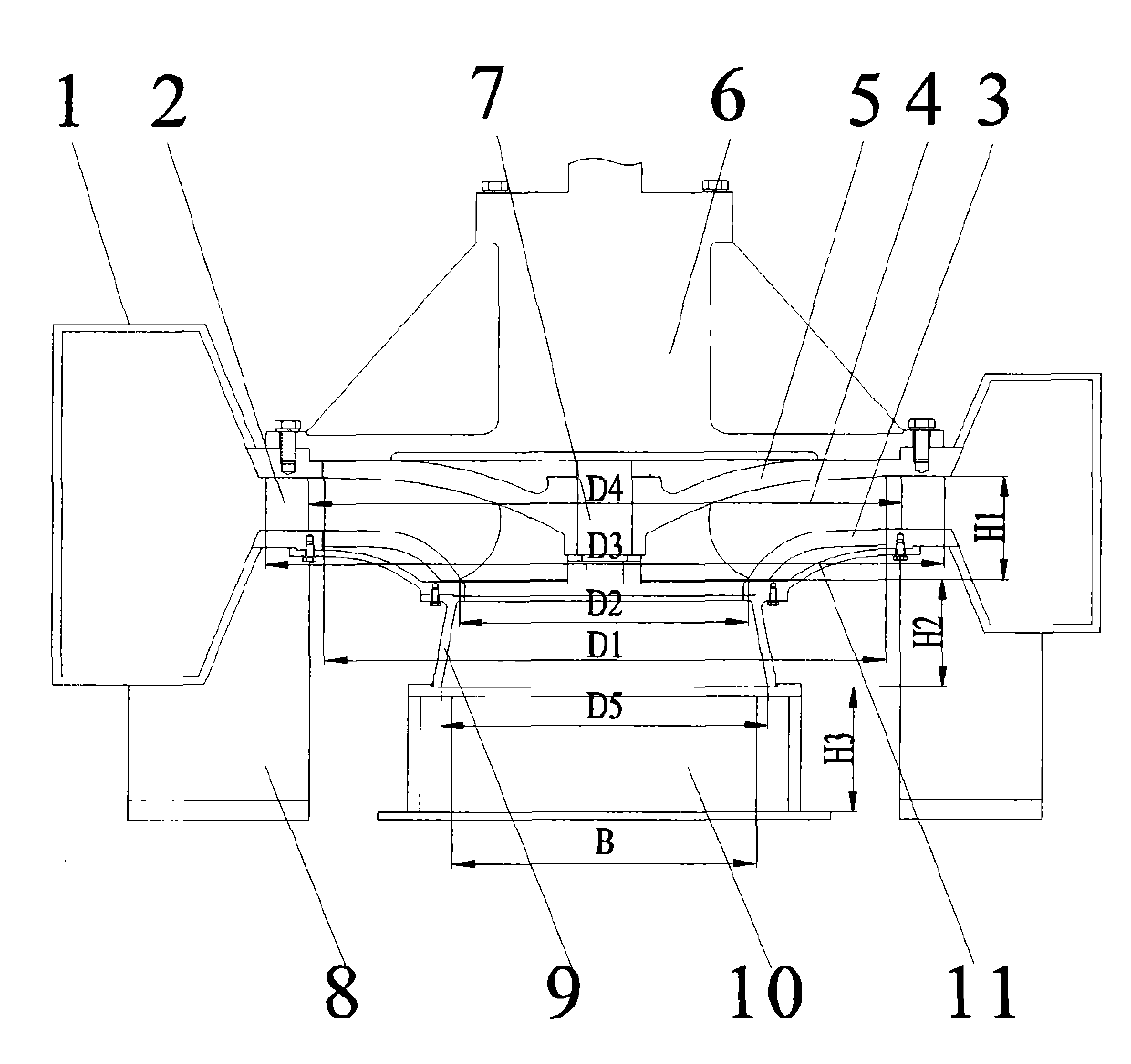

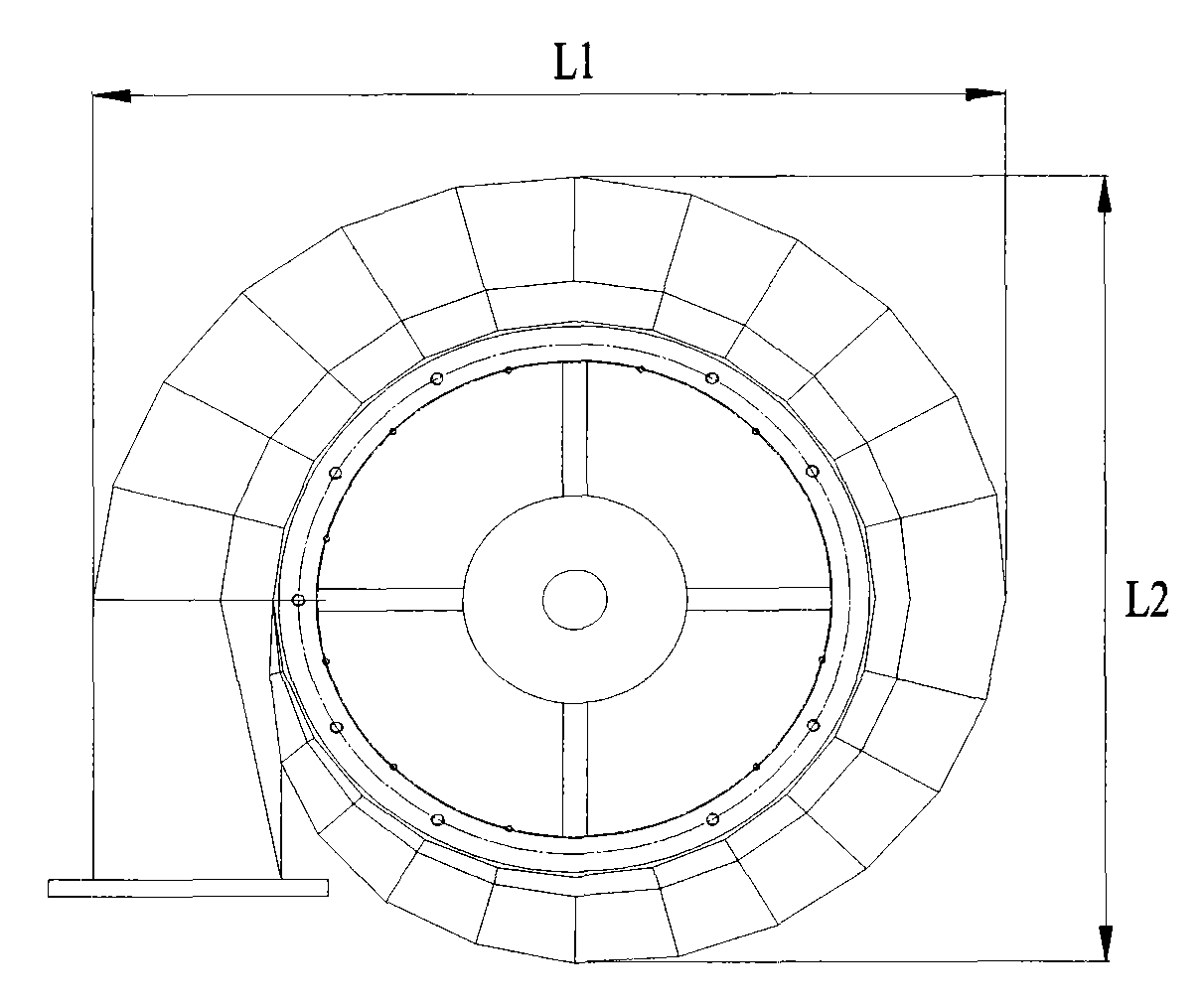

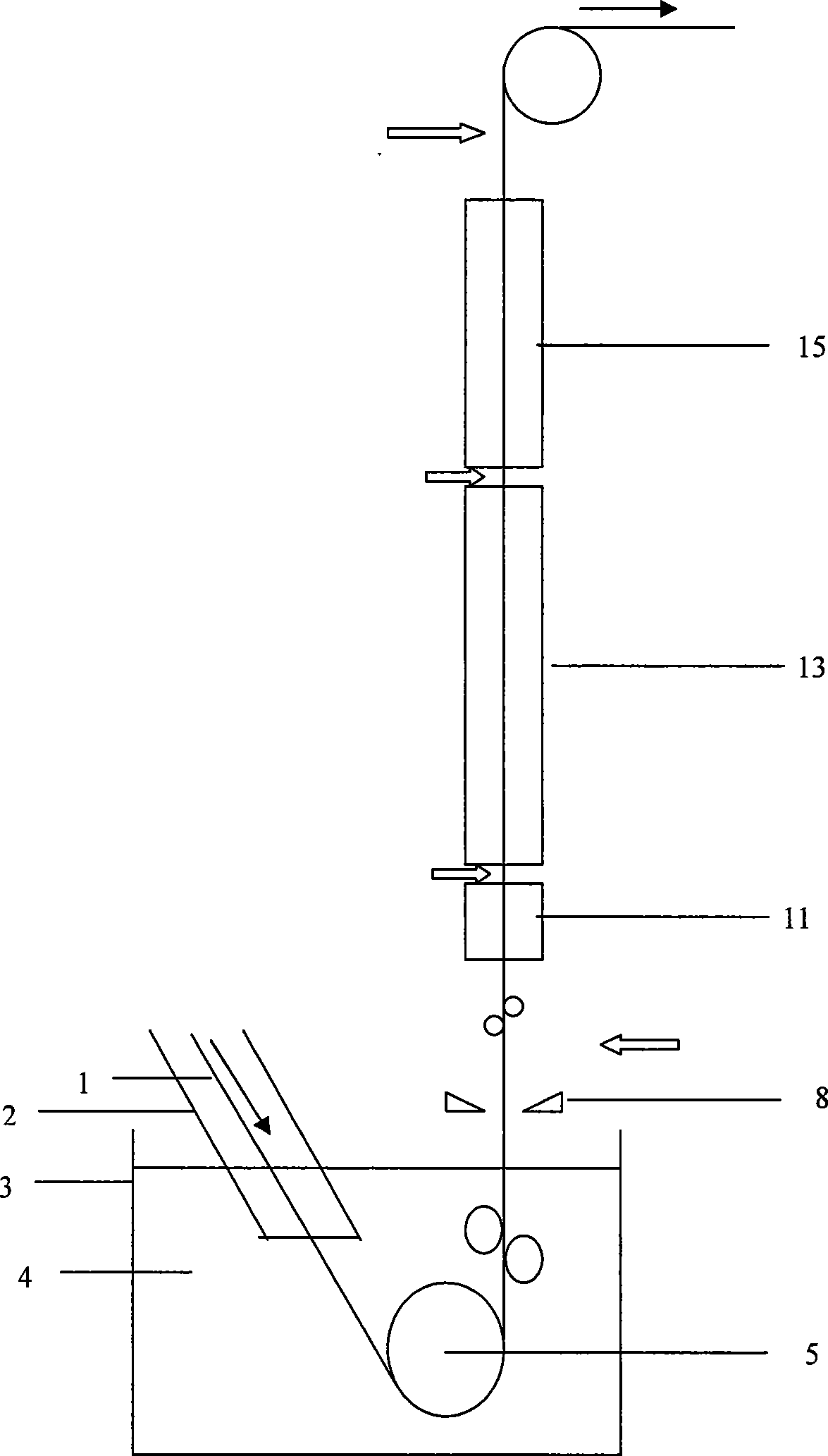

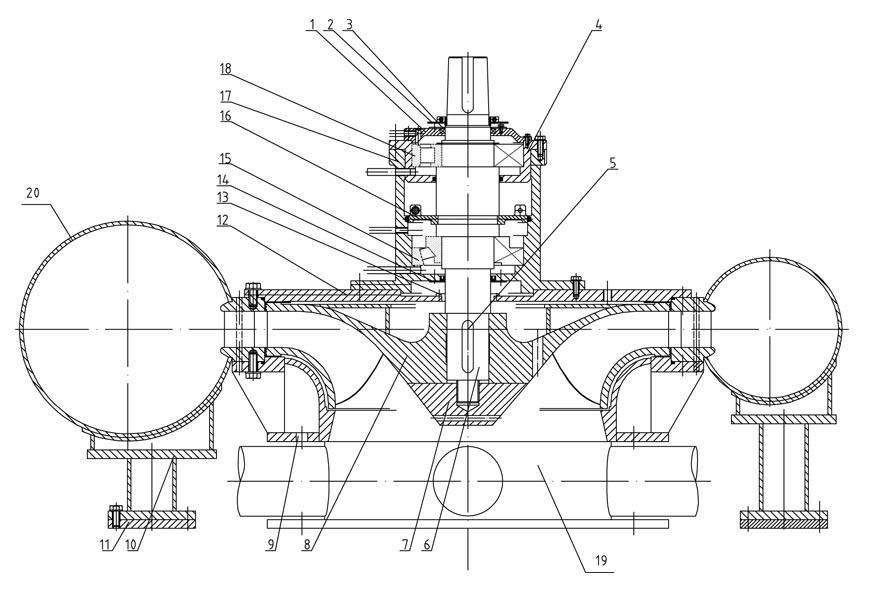

Direct connection low-speed small-scale mixed-flow turbine applied in hydrodynamic energy-saving cooling tower

InactiveCN101560940ASolve the problem of output speed controlSolve control problemsReaction enginesEngine componentsLow noiseLow speed

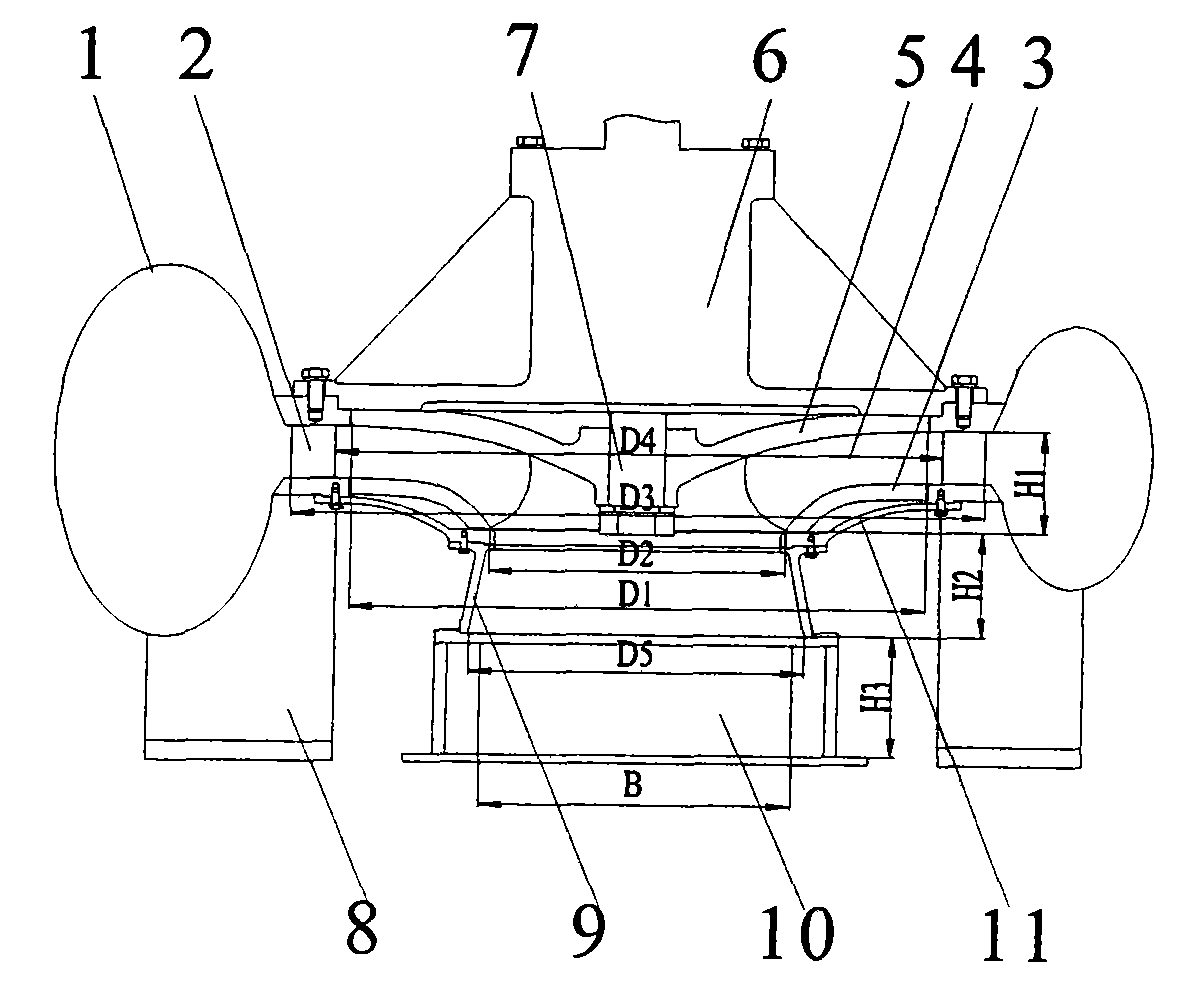

A direct connection low-speed small-scale mixed-flow turbine applied in a hydrodynamic energy-saving cooling tower, comprising a volute (1) for flooding water, a seating ring (2) provided with single row of guide vanes in a circular way, a runner (12), a straight-taper type water outlet pipe (9) and a side water outlet tank (10); wherein the seating ring (2) is arranged at the inner side of the volute (1), a water outlet port formed by guide vanes of the seating ring (2) is communicated with a water inlet port formed by curved vanes (4), a water outlet port formed by the curved vanes (4) is communicated with a water inlet port of the straight-taper type water outlet pipe (9), and an water outlet port of the straight-taper type water outlet pipe (9) is communicated with a water inlet port of the side water outlet tank (10). The turbine is characterized in that a shaft block (6) is arranged on the runner (12) and is internally provided with a shaft (7) which is directly mounted with a cooling fan blade; the value of the unit speed n11=nD1 / square root of H is 28-42, wherein n is the rated speed of the cooling fan blade, D1 is the diameter of a water inlet port of the runner (12), H is the hydraulic pressure for entering a tower. The invention has the advantages of small size, high efficiency and low noise.

Owner:NANJING XINGFEI COOLING EQUIP

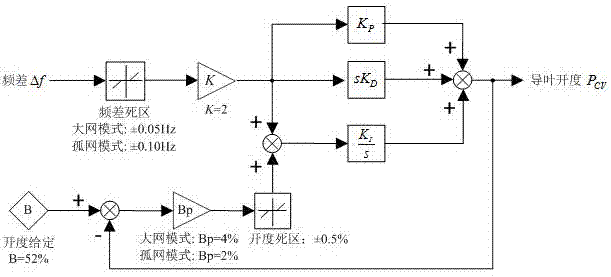

A unit speed regulation system control parameter setting method considering frequency modulation and stability constraints

The invention provides a unit speed regulation system control parameter setting method considering frequency modulation and stability constraints. The method comprises the following steps: S1) carrying out analysis on stability of a possible isolated-network-operation hydropower unit speed regulation control system; S2) obtaining a range of control parameters with primary frequency modulation performance constraint of a unit being taken into consideration; S3) under the premise of meeting small disturbance stability, giving a range of control parameters of the unit speed regulation system; S4) obtaining unit prime motor and speed regulation system measured parameters through actual measurement modeling, and obtaining overlap based on the ranges of the control parameters and applying the data to simulation analysis verification instances of the setting method; and S5) for a primary frequency modulation parameter setting range and a small interference stability parameter stability range, carrying out overall consideration, and finally, obtaining a parameter value range capable of meeting both frequency modulation performance requirements and small interference stability requirements, and carrying out setting on the unit speed regulation system model parameters. The method can obtain parameter values meeting both requirements under the premise of meeting double-term index requirements.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +2

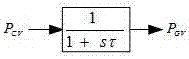

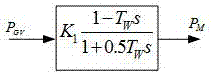

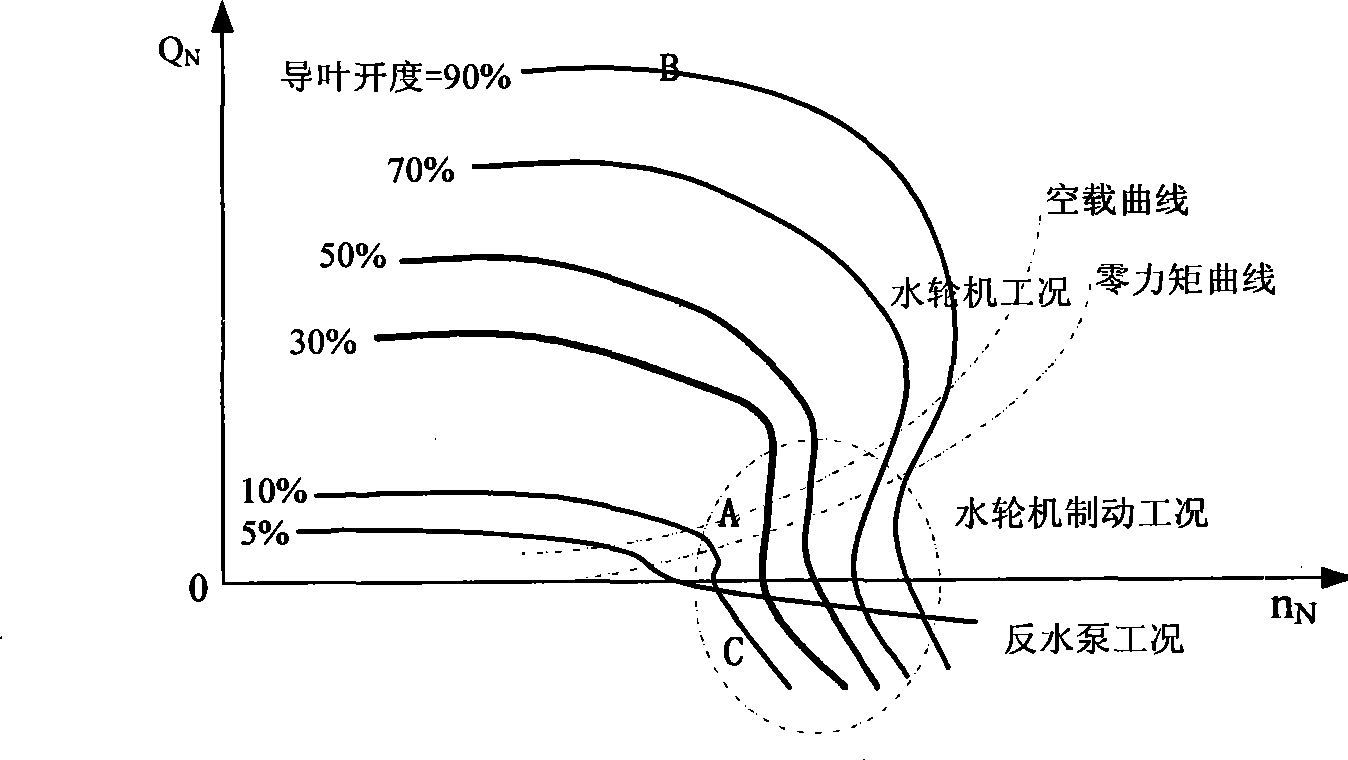

Parameter identification method for linear model of pump turbine

ActiveCN108763831AHigh degree of fitSure easyGeometric CADCharacter and pattern recognitionNerve networkWater turbine

The present invention discloses a parameter identification method for a linear model of a pump turbine. The method comprises the following steps: coupling an approximate elastic water hammer model ofa water diversion system, an IEEE six-parameter model of the pump turbine, a generator motor system model and a PID governor model to obtain a linear model of a pumped storage unit speed control system under the power generation condition, and constructing a linear mapping model of the pumped storage unit speed control system; determining the upper and lower boundaries of to-be-identified parameters of the pumped storage unit speed control system, and obtaining parameter identification sample data; using a BP nerve network method to train the parameter identification sample data, and establishing a BP neural network parameter identification model; and taking running measured data of the pumped storage unit speed control system as the input of the BP neural network parameter identificationmodel, and solving to obtain a parameter identification result of the pumped storage unit speed control system. According to the method disclosed by the present invention, not only linear model parameters can be determined easily and the accuracy of the data is relatively ideal, but also the method has the advantages of less difficulty in obtaining samples and better flexibility in selecting samples.

Owner:STATE GRID CORP OF CHINA +2

Method for rolling ultra-thin cold-rolled tinning black plate

ActiveCN105251768AImprove shape qualityIncrease rolling speedRoll force/gap control deviceTension/compression control deviceElectricityLow speed

Disclosed is a method for rolling an ultra-thin cold-rolled tinning black plate. As for a tinning black plate of MRT-3 and MRT-4 steel types and with band steel inlet width being 800-850 mm, inlet thickness being 1.7-1.8 mm and rolling thickness being 0.17-0.18mm, a five-rack acid pickling cold continuous rolling unit is used for production; a distribution mode with relatively balance motor power is used for rolling loads; the rolling reduction of each rack is determined according to the motor power model calculated value of each rack; the cold continuous rolling tension system, the cold continuous rolling working roller and middle roller bending system, the low-speed rolling process additional tension system, the roller technological parameters and the rolling process emulsion technological parameters are reasonably set, so that the unit speed is optimized, the rolling loads of all the racks are distributed in balance, the unit rolling speed and the equipment productivity are improved, and energy and electricity consumption of the unit is greatly reduced; the production cost is reduced, and good plate shape quality of an outlet cold-rolled plate is guaranteed.

Owner:ANGANG STEEL CO LTD

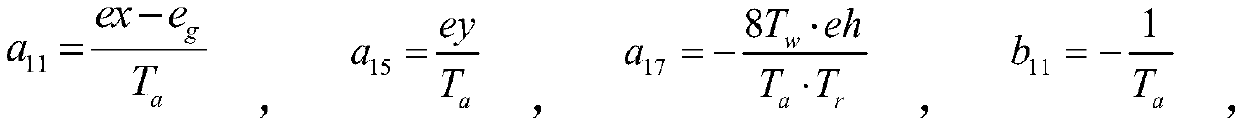

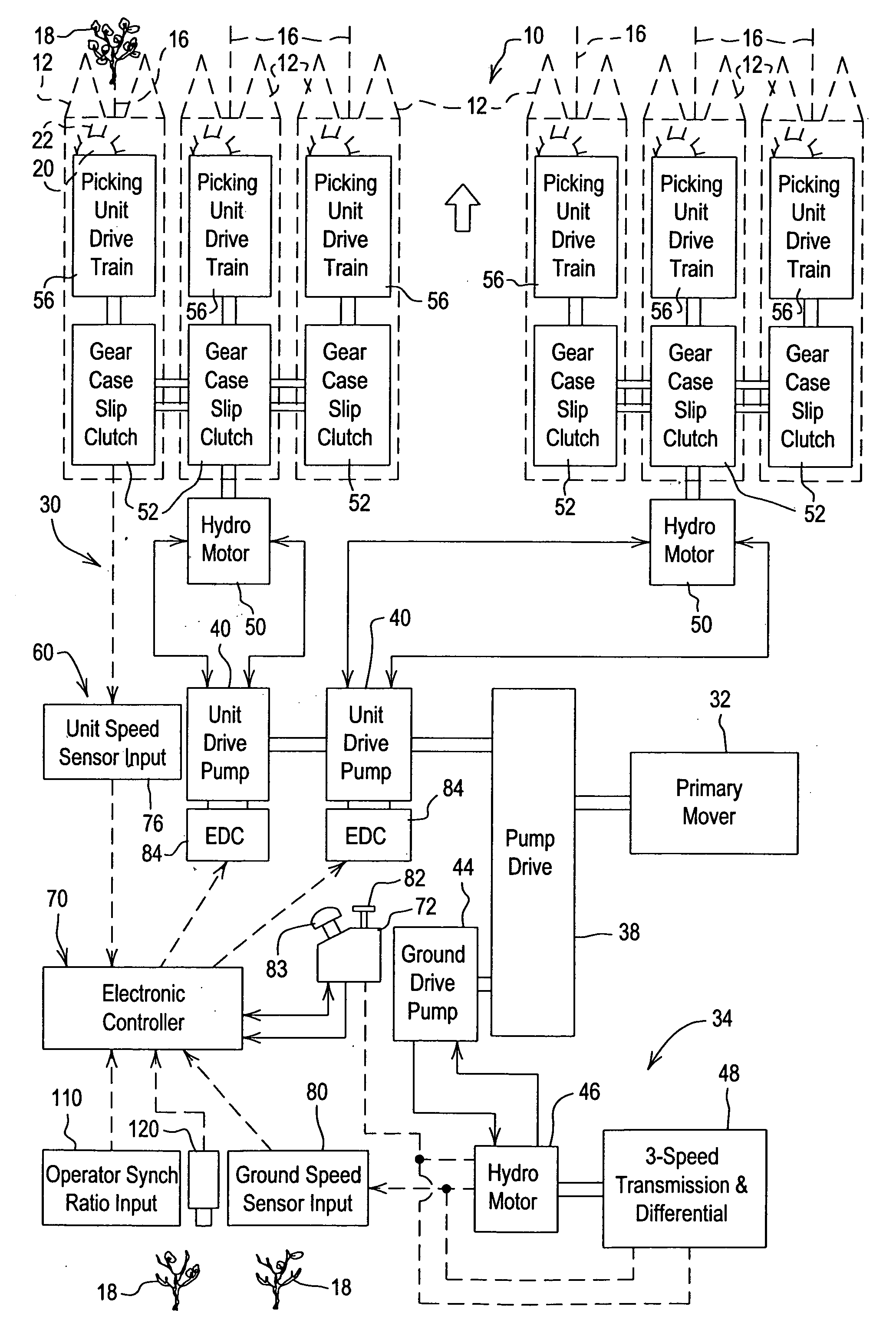

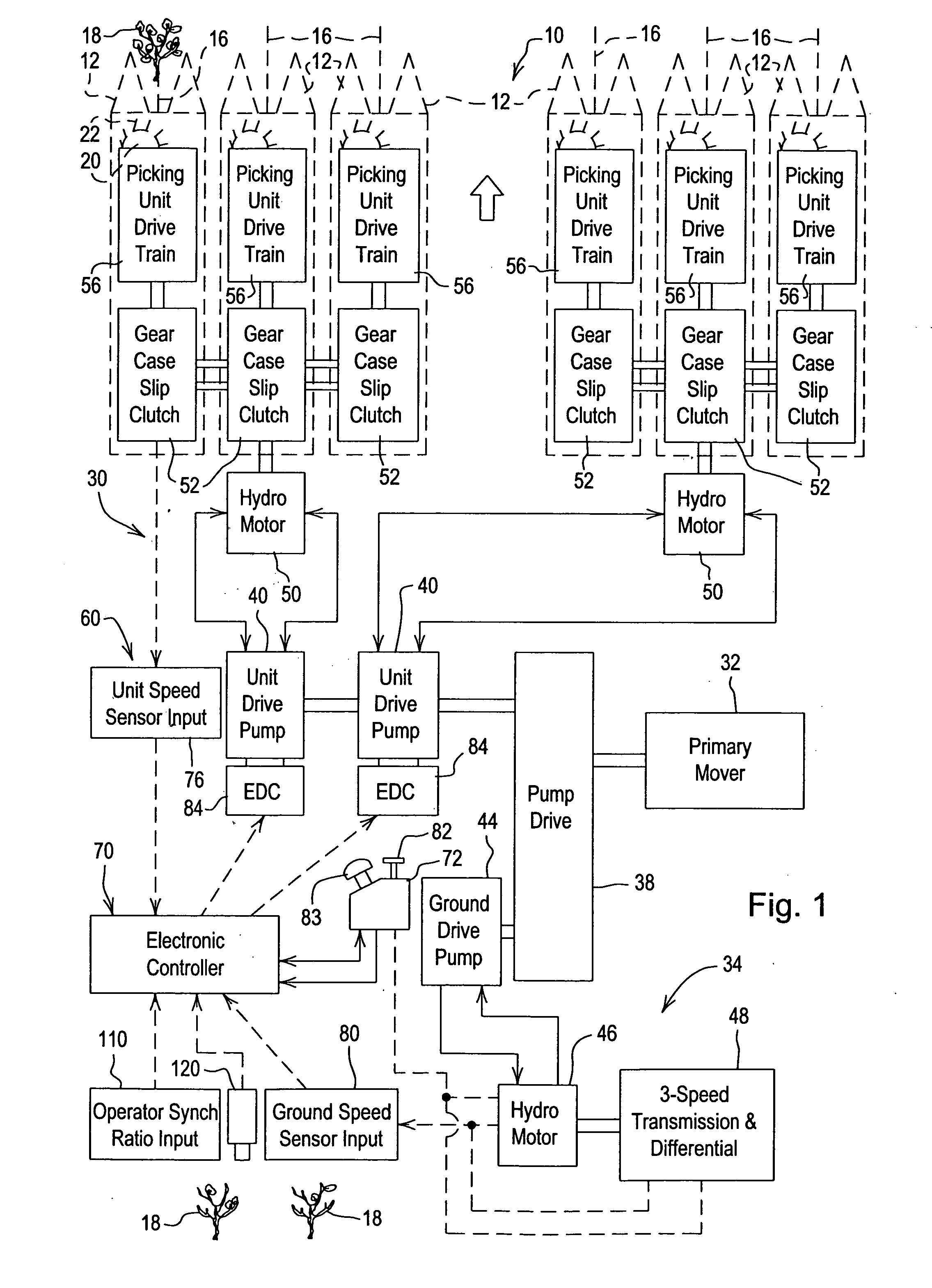

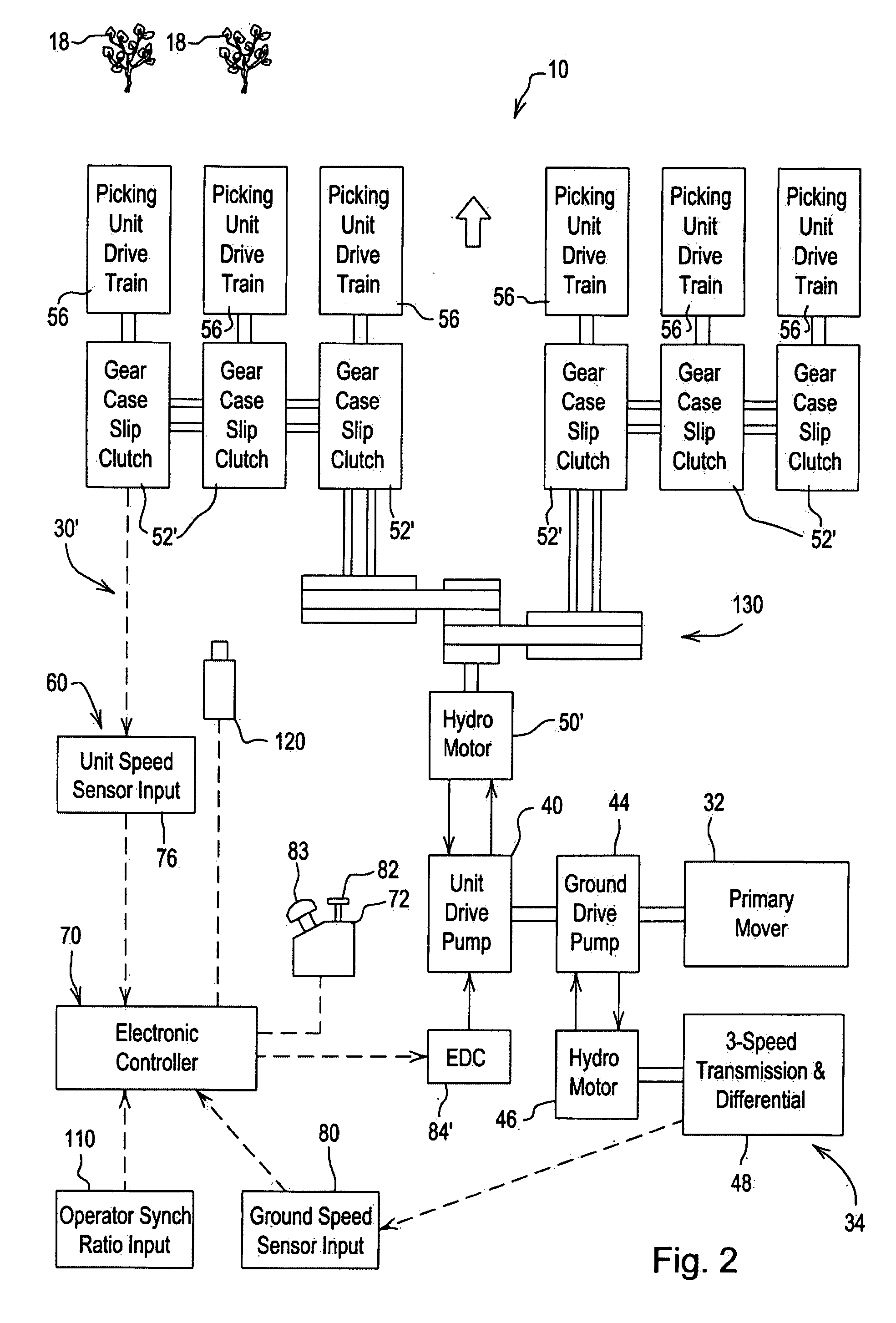

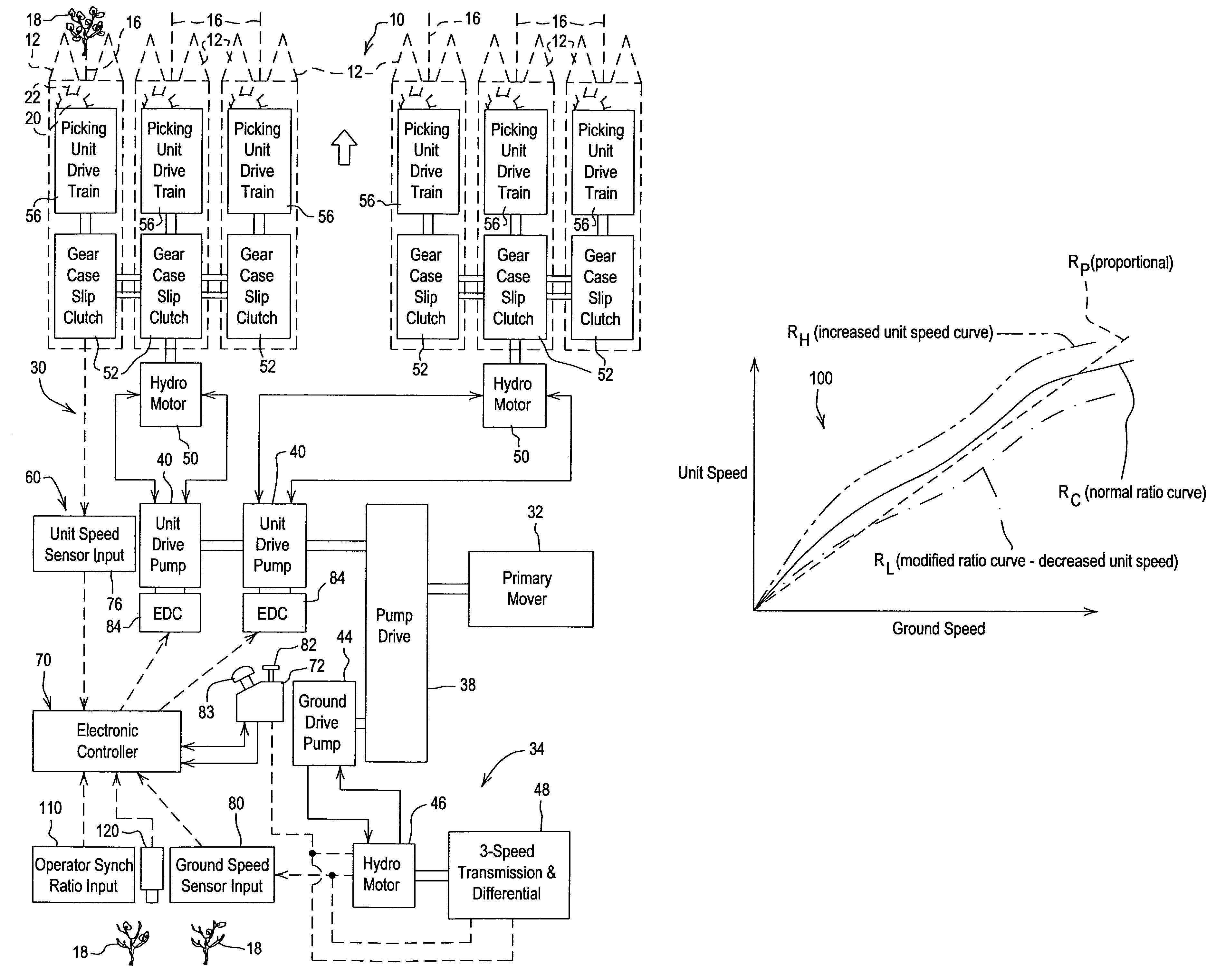

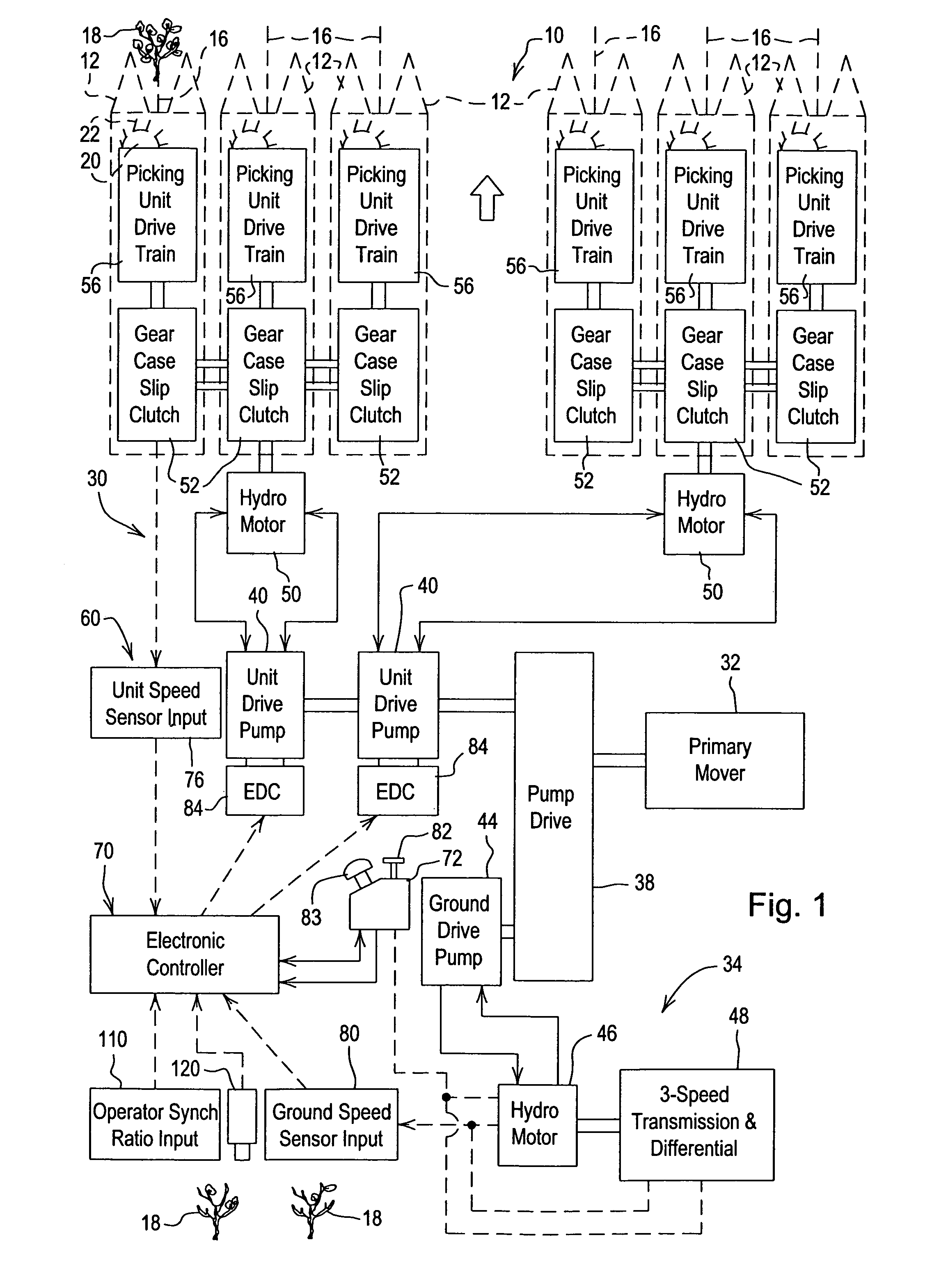

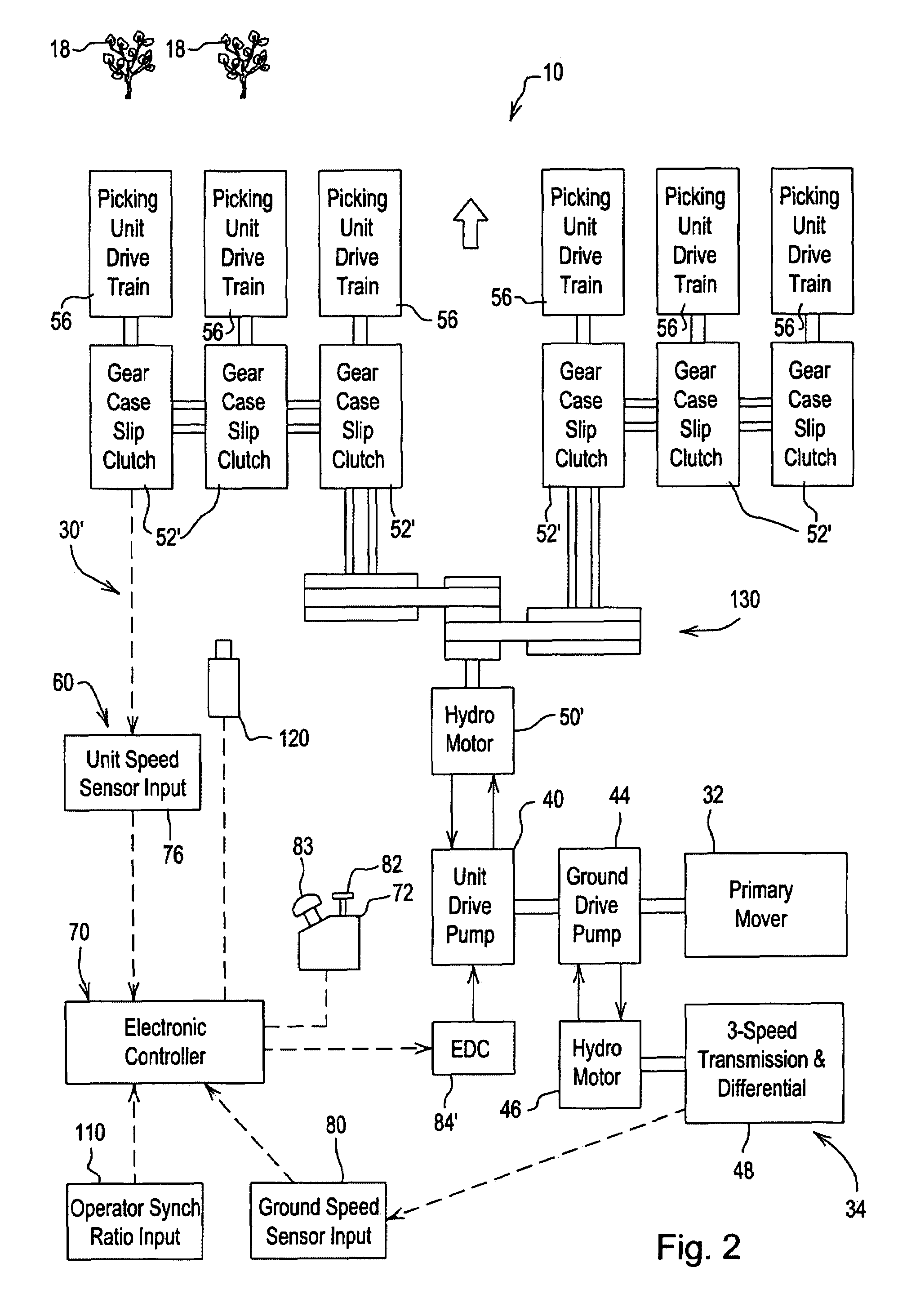

Cotton harvester row unit speed synchronization control

ActiveUS20080046154A1Optimize drive structureOvercome problemsAnalogue computers for trafficMowersProduction rateElectronic controller

An electronic controller with a sensed ground speed input calculates appropriate cotton harvester row unit speed based on harvester ground speed and a preset ground speed versus a unit speed curve. The controller includes an automatic or manual ratio adjustment input. The ratio adjustment input allows the unit speed to be increased or decreased from the preset speed. The controller reads row unit speed via unit speed sensors and sends a signal to the unit speed actuator or electronic drive control (EDC) on a hydro, variable sheave, or other variable drive device to adjust unit speed to the calculated value. A detector or field vision device such as a camera responsive to cotton on the plants provides a signal to the automatic ratio adjustment input to change the ratio for increased productivity and reduced machine wear.

Owner:DEERE & CO

Cotton harvester row unit speed synchronization control

ActiveUS7386380B2Optimize drive structureOvercome problemsAnalogue computers for trafficMowersProduction rateElectronic controller

An electronic controller with a sensed ground speed input calculates appropriate cotton harvester row unit speed based on harvester ground speed and a preset ground speed versus a unit speed curve. The controller includes an automatic or manual ratio adjustment input. The ratio adjustment input allows the unit speed to be increased or decreased from the preset speed. The controller reads row unit speed via unit speed sensors and sends a signal to the unit speed actuator or electronic drive control (EDC) on a hydro, variable sheave, or other variable drive device to adjust unit speed to the calculated value. A detector or field vision device such as a camera responsive to cotton on the plants provides a signal to the automatic ratio adjustment input to change the ratio for increased productivity and reduced machine wear.

Owner:DEERE & CO

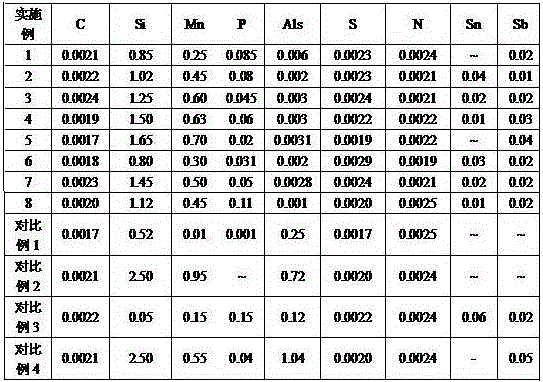

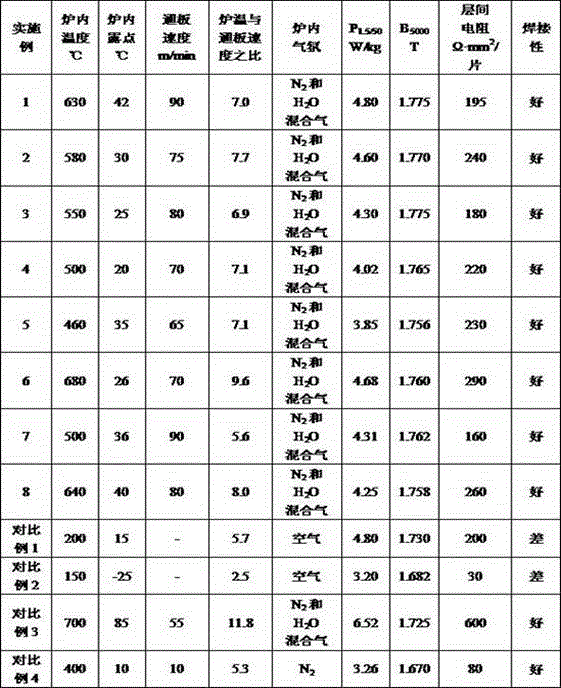

Non-oriented electrical steel good in weldability and magnetism and production method

ActiveCN106756491AGuaranteed MagneticMaintain interlayer resistanceSolid state diffusion coatingPorosityElectrical steel

Non-oriented electrical steel good in weldability and magnetism is composed of, by weight, 0-0.0030% of C, 0.8%-1.7% of Si, 0.2%-0.8% of Mn, 0-0.0050% of S, 0.01%-0.15% of P, 0-0.030% of Al, 0-0.0050% of N, 0-0.05% of Sn and / or Sb. A production method comprises the steps that steel making, hot rolling, pickling and cold rolling are conducted, and then the thickness of a finished product is achieved; after the finished product is subjected to annealing, bluing treatment is conducted; and sampling, reeling, packaging and inspection are conducted. According to the non-oriented electrical steel good in weldability and magnetism and the production method, the weldability of the product is improved while interlamination resistance is kept, weld porosity, broken welding and other defects are decreased; through control over the atmosphere, temperature and dew point of oxidation and bluing, unit speed and bluing temperature of a non-oriented electrical steel sheet, the interlamination resistance is improved, meanwhile, magnetism deterioration caused by surface oxidation can be reduced to the smallest extent, and the magnetism of the finished product is ensured, specifically, a 0.50 mm sheet B50 is larger than or equal to 1.75 T, and P1.5 / 50 is smaller than or equal to 5.0 W / kg.

Owner:武汉钢铁有限公司

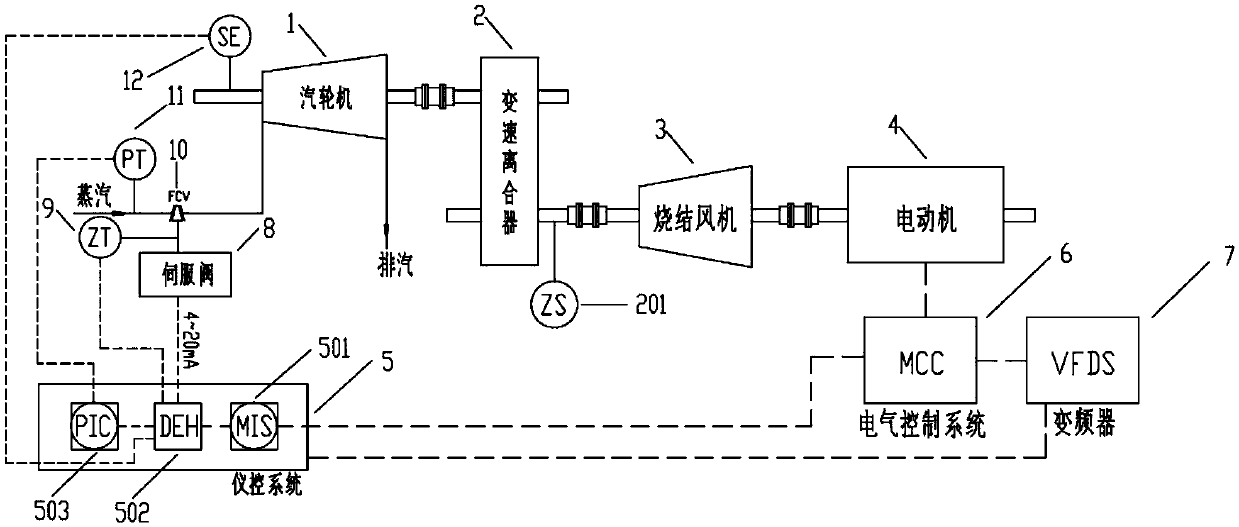

SHRT unit frequency converter and steam turbine rotating speed synchronous automatic adjusting control method

ActiveCN109519232AStable currentTroubleshoot fault trip issuesPump controlEngine startersFrequency changerPower flow

The invention discloses an SHRT unit frequency converter and steam turbine rotating speed synchronous automatic adjusting control method. The method comprises the steps that firstly, the rotating speed adjusting rate A is set in a frequency converter; secondly, the working condition is detected in real time, if a unit needs to be subjected to rotating speed rising running, the third step is executed, and if the unit needs to be subjected to rotating speed reduction running, the fourth step is executed; thirdly, the unit rotating speed decreasing running control is carried out, the frequency converter sends out a speed reduction preparing instruction to a DEH, a steam turbine is switched to the rotating speed adjusting mode from the power adjusting mode, after switching is finished, an instrument control system judges whether the unit meets the speed reduction condition, if the unit meets the speed reduction condition, the DEH feeds back the speed reduction allowing signal to the frequency converter, and after the frequency converter receives the allowing signal, the unit speed reduction adjusting is executed; fourthly, unit rotating speed increasing running control is carried out.According to the method, manual intervene is not needed, the problem that in the speed adjusting process, due to current fluctuation of an electric motor, the frequency converter fails and is shut down is solved, and meanwhile, the frequency converting adjusting SHRT unit generates the giant economic benefits for an enterprise.

Owner:XIAN SHAANGU POWER

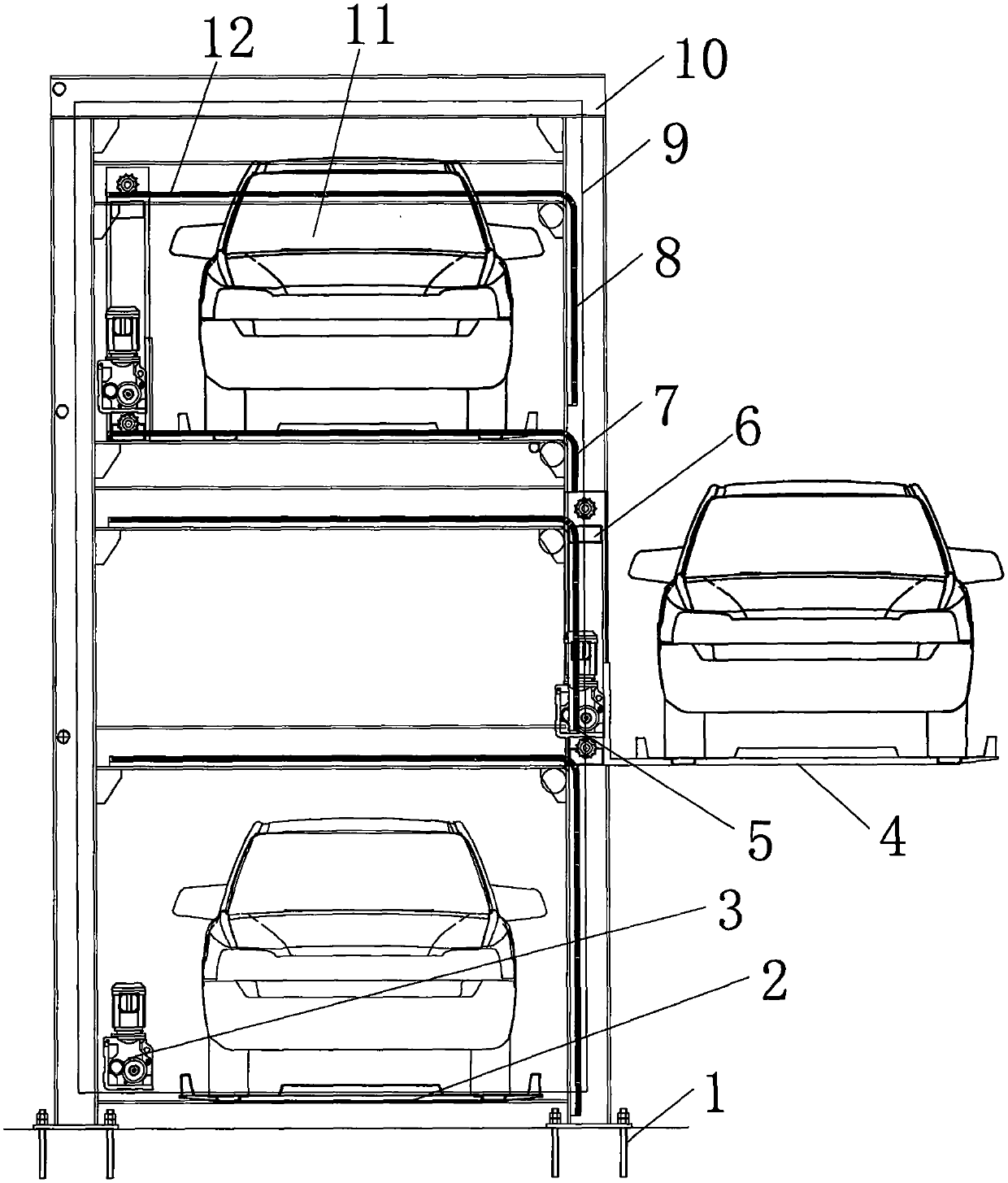

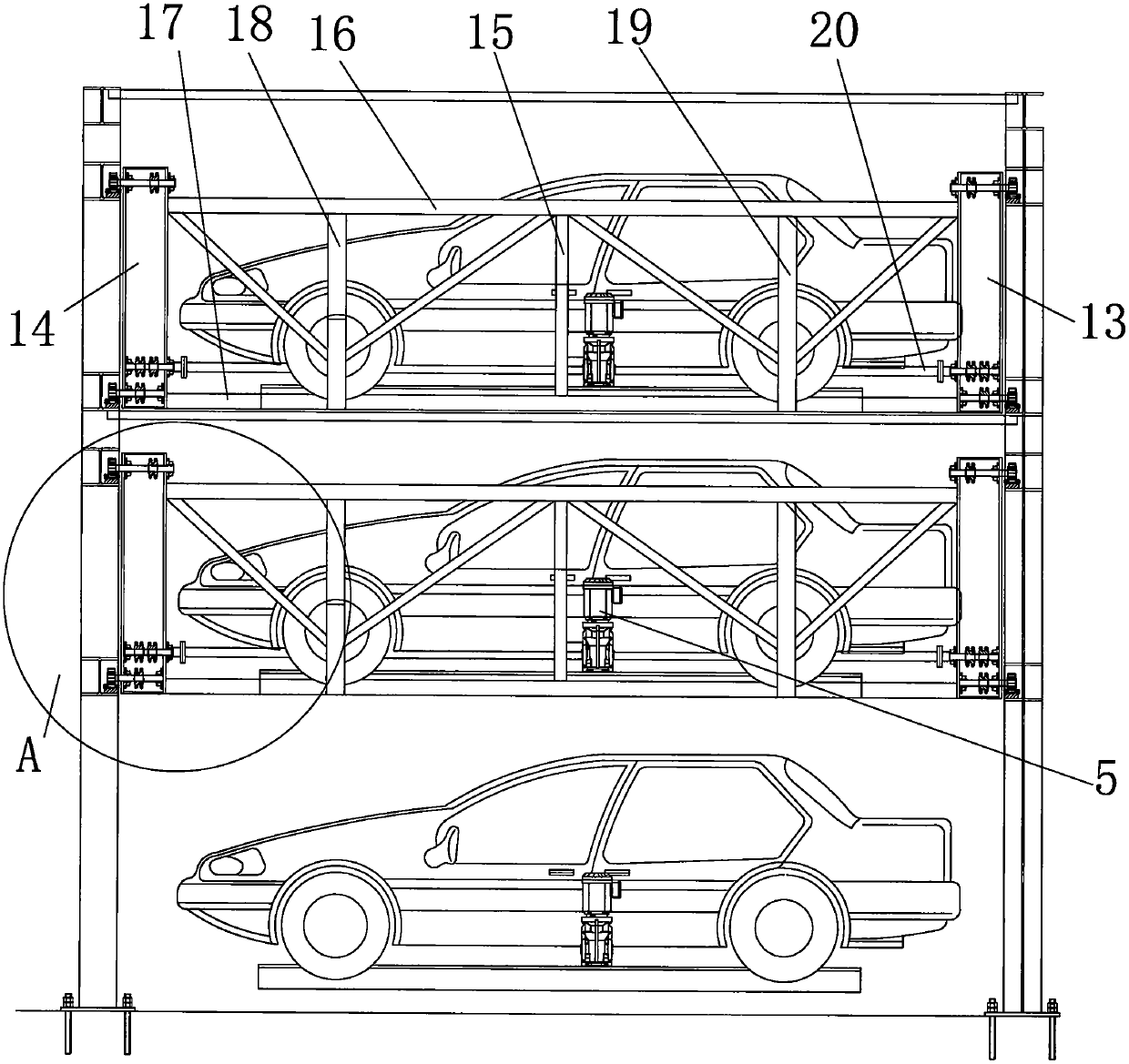

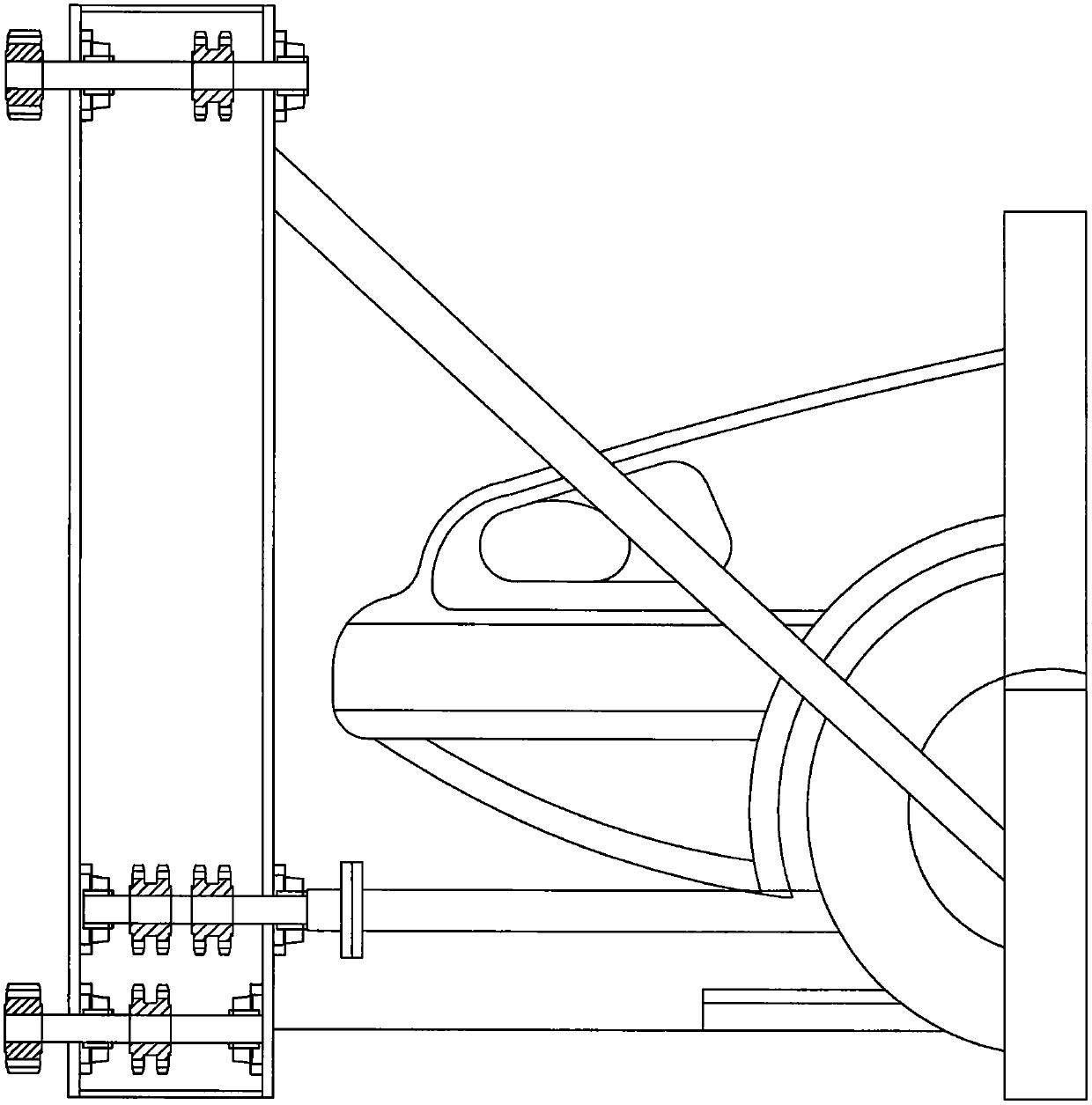

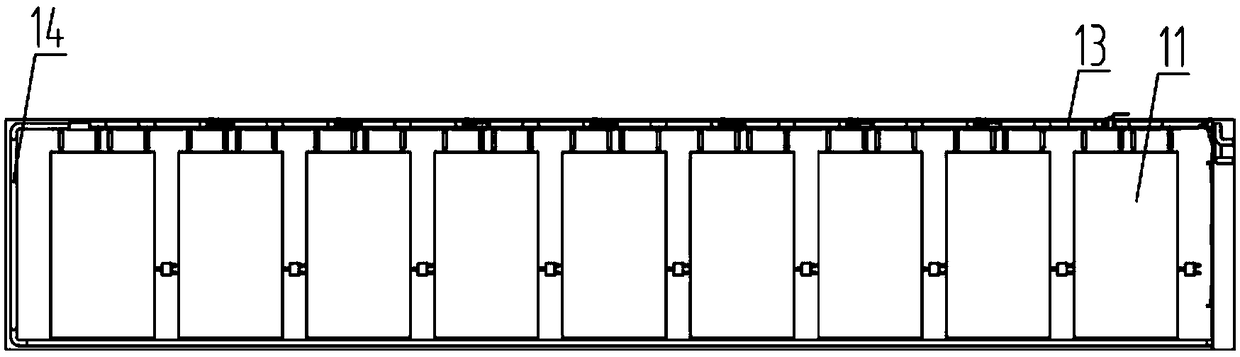

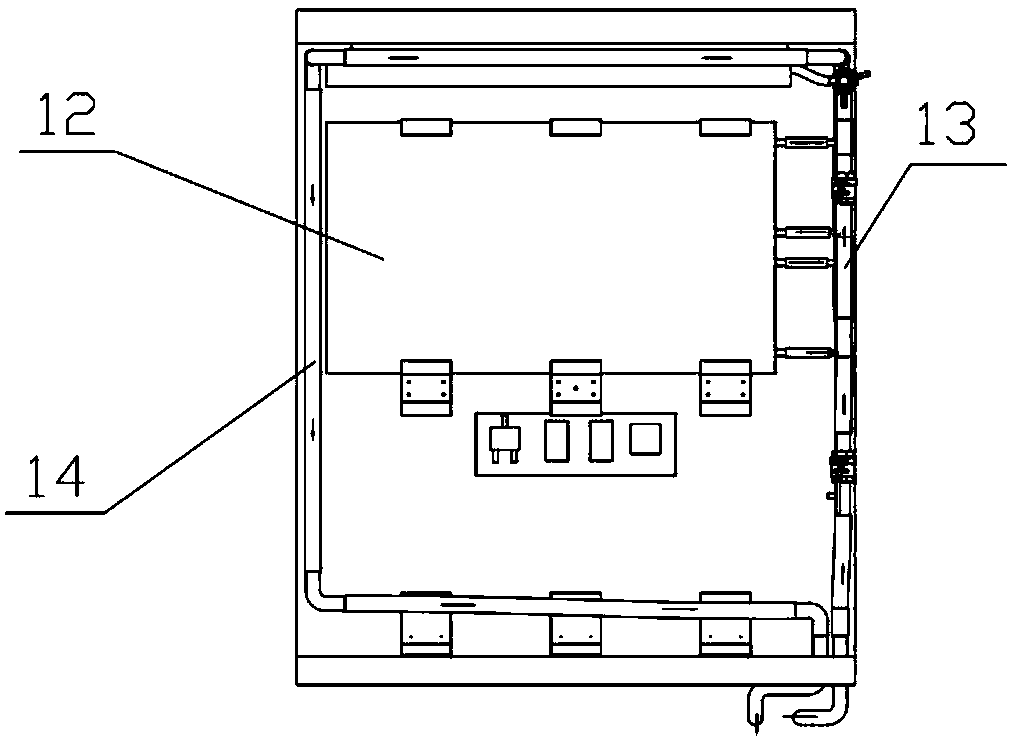

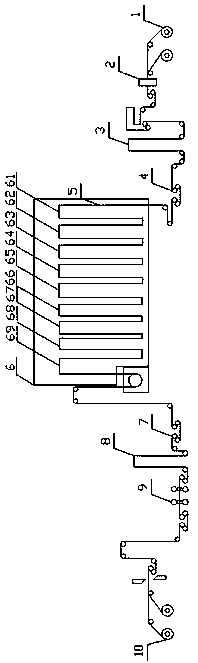

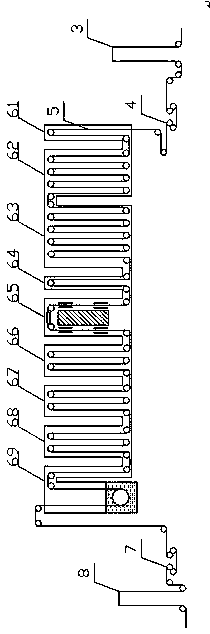

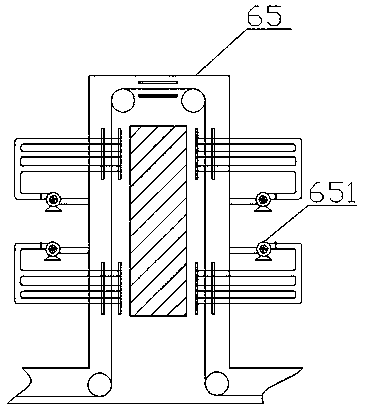

Drawer type lifting stereo garage

The invention discloses a drawer type lifting stereo garage. The drawer type lifting stereo garage comprises a garage body, wherein the garage body comprises four upright columns, wherein four upright columns are divided into a plurality of individual units by cross beams arranged horizontally to construct individual spaces for accommodating cars; the first floor of the individual unit comprises a ground car carrying board and a ground car carrying board transverse shifting device; each of the second floor and floors above the second floor of the individual unit comprises an air car carrying unit, an air car carrying car unit driving device, an air car carrying car unit speed reducer, an air car carrying car unit transmission component and an air car carrying car unit track. The drawer type lifting stereo garage occupies small area, and is flexible in installation and low in power consumption, 100% to 600% of parking spaces are increased, each parking space is an individual unit which can operate independently and the other parking spaces can be used when one parking space is broken down, the operating speed is high, and the car can be directly driven in and out without turning round.

Owner:黄永军

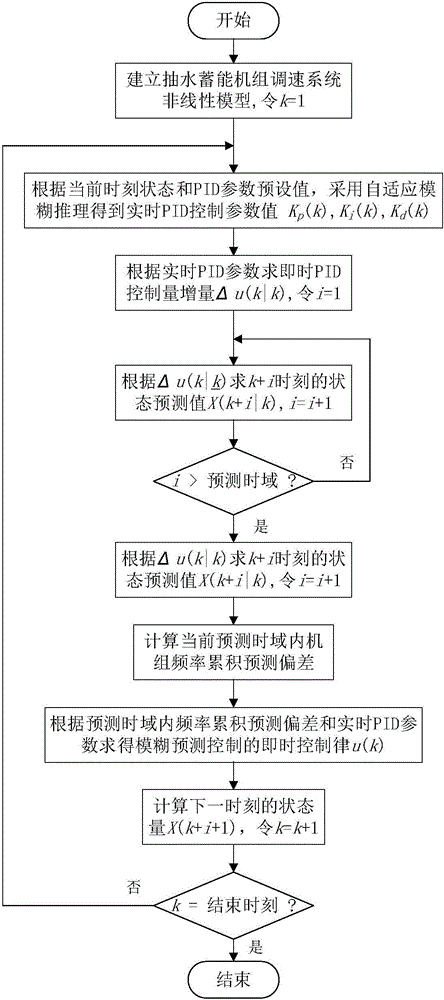

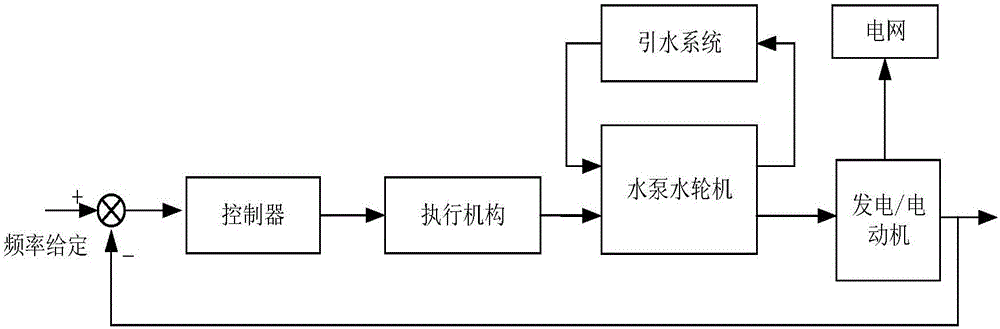

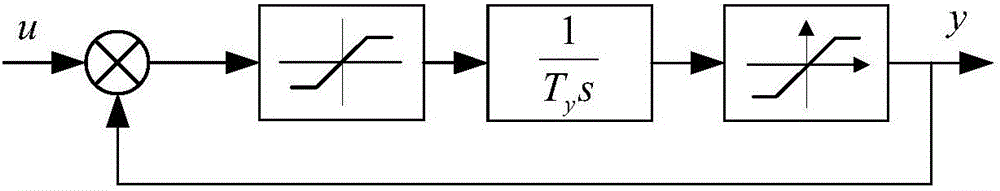

Quick non-linear fuzzy predictive control method for speed regulating system of pumped storage unit

ActiveCN106014849AEasy to adjustGood working condition adaptabilityActive/predictive/anticipative controlHydro energy generationTransient stateFuzzy pid control

The invention discloses a quick non-linear fuzzy predictive control method for a speed regulating system of a pumped storage unit. The quick non-linear fuzzy predictive control method includes the three steps of fuzzy PID parameter self-adaption, online rolling prediction and control law computing. By the adoption of the control method, the function that the fuzzy PID control parameters are adjusted automatically along with the working conditions is achieved, the future system state is predicted through a pumped storage unit speed regulating system non-linear model built in a controller by means of the online rolling prediction method, and the future system state quantity deviation information is considered when a real-time control law is set. By the adoption of the quick non-linear fuzzy predictive control method, the requirements of the control process of the pumped storage unit under different working conditions can be met, the control precision of the unit is improved effectively, and the transient state performance of the operating process of the unit is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

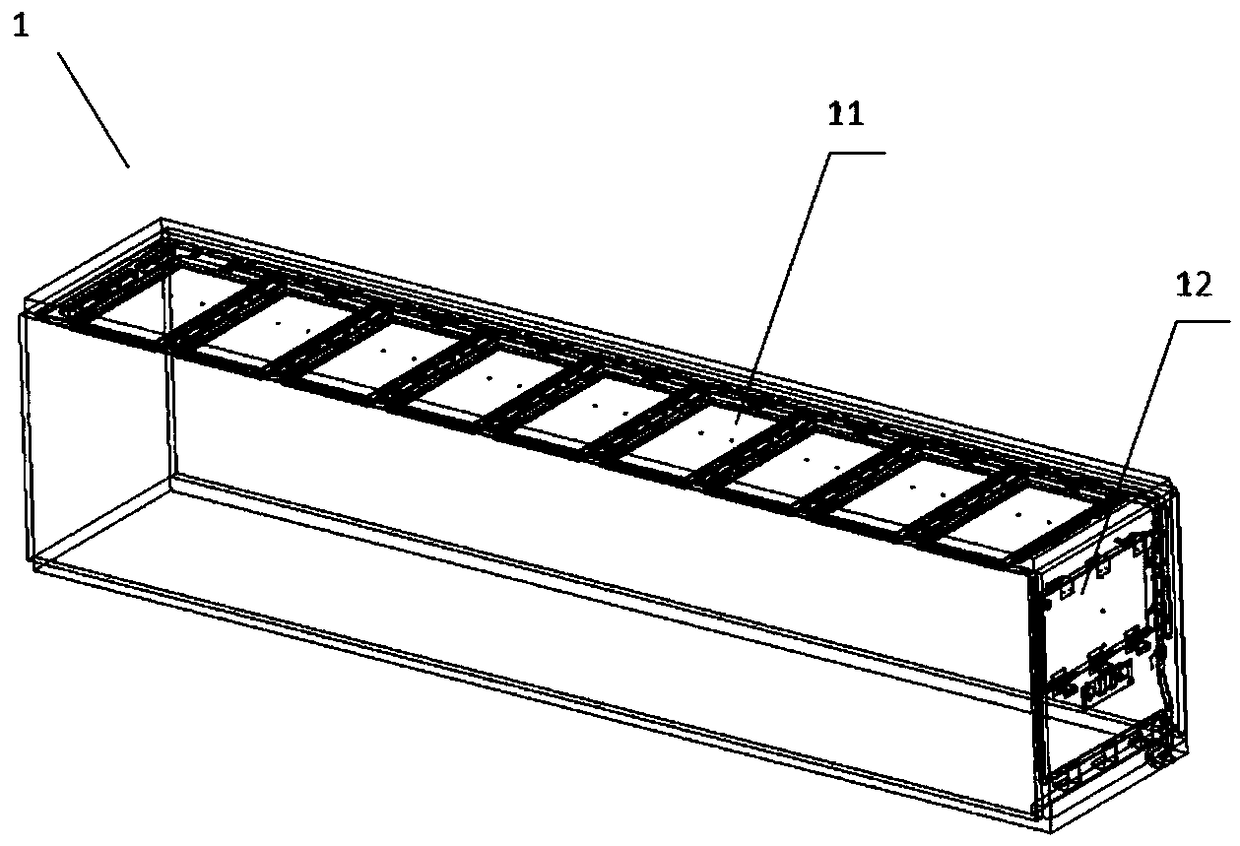

Energy storage unit

InactiveCN109099739ARapid cold storageAir-treating devicesRefrigerated goods vehiclePlate heat exchangerUnit speed

The invention provides an energy storage unit. The energy storage unit comprises a shell body (111), a phase change material and a heat exchanger (112). The interior of the shell body (111) limits thespace for accommodating the phase change material. The heat exchanger (112) is arranged for heat exchange with the phase change material, and the heat exchanger (112) includes at least one set of heat transfer units. The cross sections of the heat transfer units include circular portions (1122) and a plurality of scattering lines (1121) around the circular portions. The energy storage unit with the heat transfer units speeds up the cold storage process of the internal phase change material of the energy storage unit, and can realize the rapid cooling of the energy storage unit.

Owner:CRRC SHIJIAZHUANG CO LTD +1

Rapid shutdown control method for thin plate in vertical continuous annealing unit

ActiveCN110551889ASmall thermal inertiaReduce plate temperature differenceFurnace typesHeat treatment process controlUnit speedStrip steel

The invention relates to a rapid shutdown control method for a thin plate in a vertical continuous annealing unit. The control method includes the following steps of S1, switching an annealing furnaceto a cooling mode, and controlling the temperature of the annealing furnace; S2, reducing the speed of the unit (speed control); S3, reducing the tension of the unit (tension control); S4, when the unit speed is reduced to be below 400 mpm, pressing down a stop button; S5, after the unit is stopped, eliminating the tension of strip steel in an annealing furnace section and conveying the strip steel into annealing furnace so as to ensure the slackness of the strip steel before entering the annealing furnace and after exiting from the annealing furnace. According to the scheme, through reasonable adjustment of the speed and tension of the unit, the fluctuation of the tension in the furnace is reduced while the stable speed reduction of the unit is ensured, and the problem that the strip steel is stressed unevenly in the width direction under the action of large tension and thus generates ridge buckles is solved by adopting small tension control under the condition that stable running and non-deviation of the strip steel in the speed reduction process are ensured.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

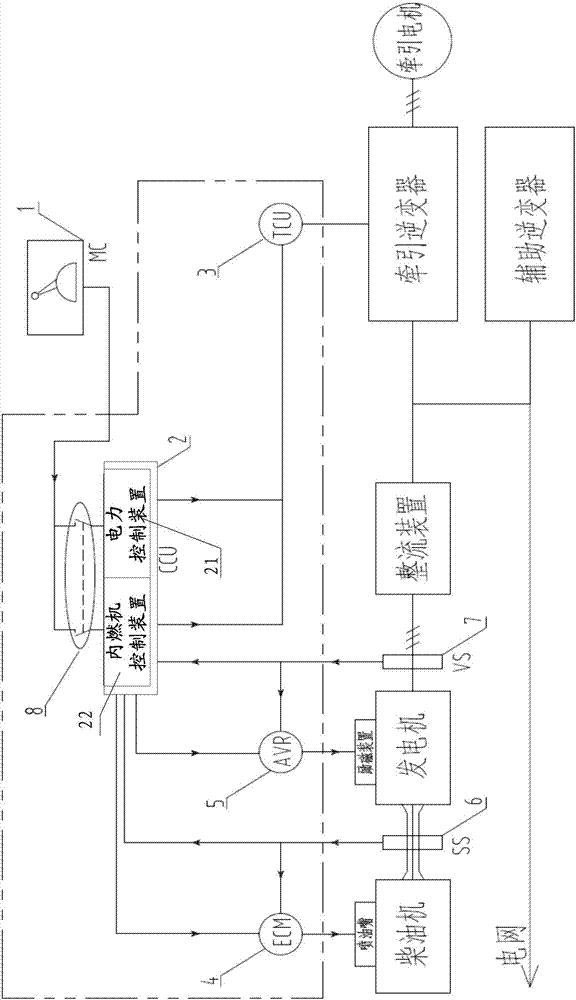

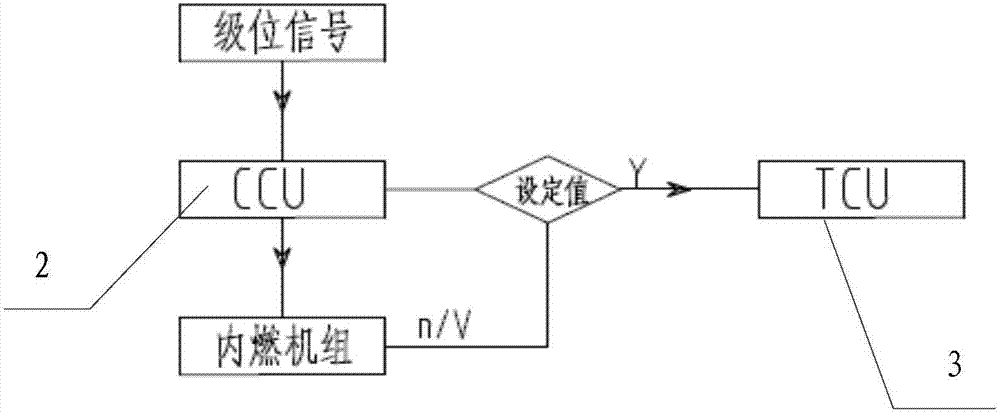

Double-energy-source alternating current transmission locomotive control system and locomotive with system

ActiveCN107150695ARealize regulationEasy to controlPropulsion using engine-driven generatorsRailway transportPower inverterCombustion

The invention discloses a double-energy-source alternating current transmission locomotive control system, which comprises an electric power control device, an internal combustion engine control device, a driver controller and a sensor, wherein the electric power control device and the internal combustion engine control device are both connected with an inverter control device; the driver controller is used for controlling either the internal combustion engine control device or the electric power control device to work; the sensor is used for detecting the rotating speed of a diesel engine or the voltage of a power generator; the sensor is connected with the internal combustion engine control device; when the rotating speed of the diesel engine and the voltage of the power generator both reach the set values, the internal combustion engine control device controls the inverter control device to regulate the output power. The electric power control device and the internal combustion engine control device are controlled through the same driver controller so as to realize the work of the locomotive in two modes including the internal combustion mode and the electric power mode; in the internal combustion engine power supply mode, the passive regulation of the powder in the prior art can be avoided, so that the machine unit speed regulation control and power control can be realized. The invention also provides a locomotive comprising the double-energy-source alternating current transmission locomotive control system.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

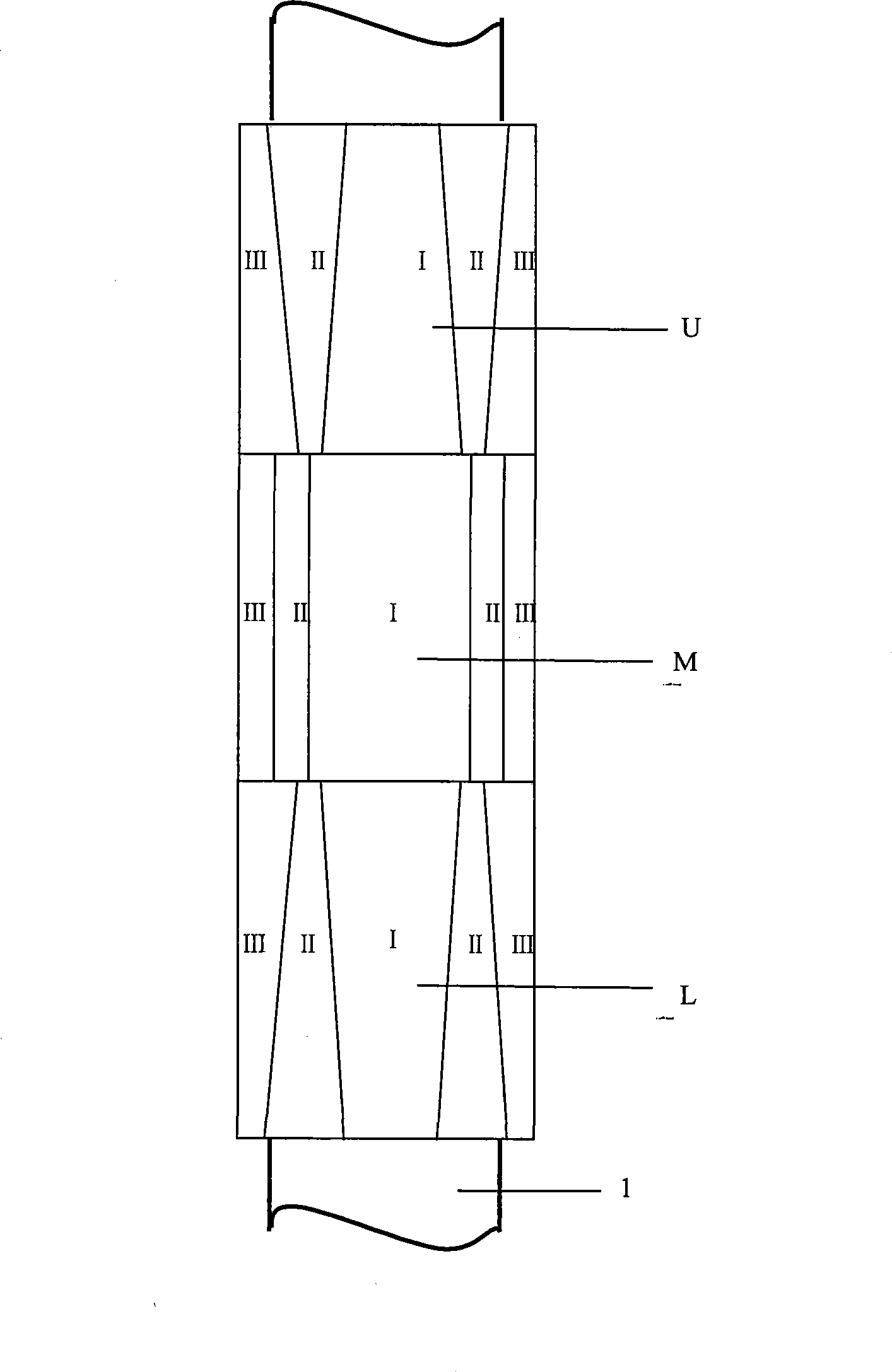

Alloying soaking furnace capable of realizing hot dip galvanizing coating alloying annealing curve free inclination of soaking temperature

ActiveCN101376959AAdjust and control temperatureExcellent chalking resistanceHot-dipping/immersion processesFurnace typesUnit speedStrip steel

The invention relates to a device for realizing the free inclination and heat evenness of an alloying furnace heat evenness section cladding alloying annealing curve; with a window which can be opened and closed on the furnace wall, the device can regulate the heat preserving performance and radiation rate of an alloying furnace, so that the alloying heat evenness temperature of a unit can realize inclination from high temperature to low temperature under any production condition including the precondition of maximum hourly output, and the free inclination of heat evenness temperature can be realized at lower unit speed or under the lower hourly output precondition by regulating the heating power of the heat evenness section. The device which can regulate the cooling speed of the alloying furnace heat evenness section strip steel and the adjustment to the heating power at the heat evenness section can realize the goal of the cladding alloying inclination heat evenness annealing of the heat evenness temperature of different alloyed products from high temperature to low temperature under different process conditions (e.g. different product specifications, unit speed, heat evenness temperature, etc.). In the alloyed hot-dip galvanized steel sheet manufactured by the device, the V-bend powder resistance of the cladding can reach Grade 2 to Grade 3.

Owner:BAOSHAN IRON & STEEL CO LTD

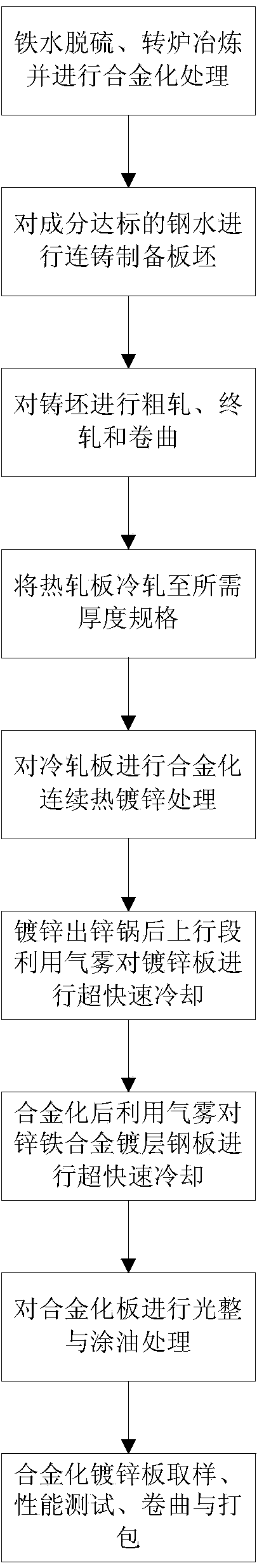

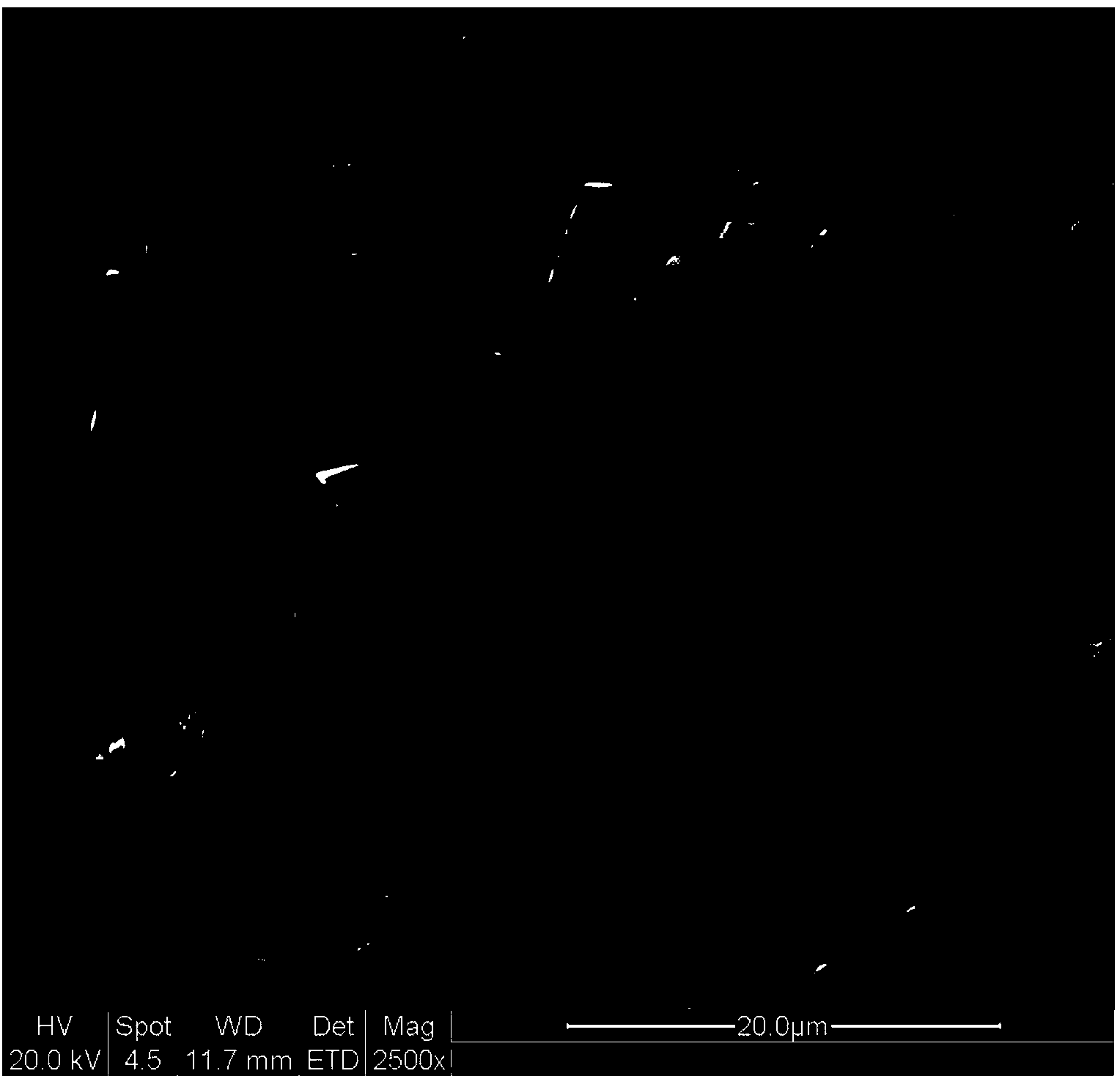

Method for producing steel plate with extra deep drawing iron and zinc alloy plating layer

InactiveCN104342541AImproved chalking resistanceCompact structureHot-dipping/immersion processesSheet steelUnit speed

The invention discloses a method for producing a steel plate with an extra deep drawing iron and zinc alloy plating layer. The method comprises the following steps of (1) desulfurizing, smelting in a converter furnace, and alloying; (2) continuously casting to prepare a slab; (3) setting the rough milling temperature of a casting blank as 1060-1100 DEG C, the final rolling temperature as 890-920 DEG C, and the coiling temperature as 680-730 DEG C; (4) performing cold rolling; (5) alloying a cold rolling sheet, performing continuous hot galvanizing treatment, setting the unit speed as 90-100 m / min, the heating temperature as 830-850 DEG C and the temperature of a quick cooling section as 500-520 DEG C, cooling a galvanized plate at an upward section after the galvanized plate is taken out of a zinc pot, setting the cooling speed as 40-60 DEG C / s, alloying, cooling the steel plate, and setting the cooling speed as 30-50 DEG C / s. The method has the advantages that the plating layer at the surface of the ultra deep drawing GA (galvanized alloy) plate has dense structure, and is free from obvious cracks and deficiencies, the crystal grain of iron and zinc alloy on the surface of the plating layer is fine and small, the size distribution is uniform, the chalking-resistant property of the alloying plating layer is excellent, and the method can be widely applied to the production field of automobile steel.

Owner:武钢集团有限公司

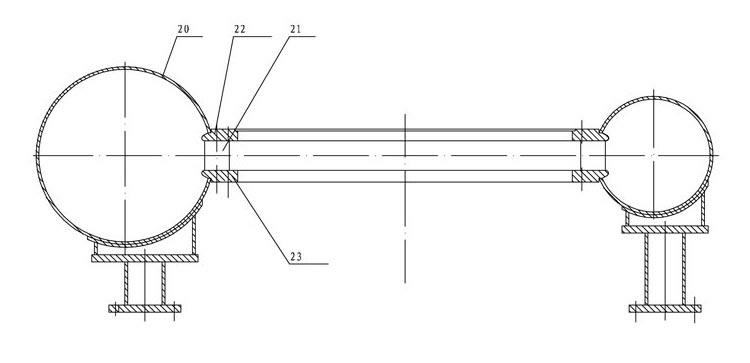

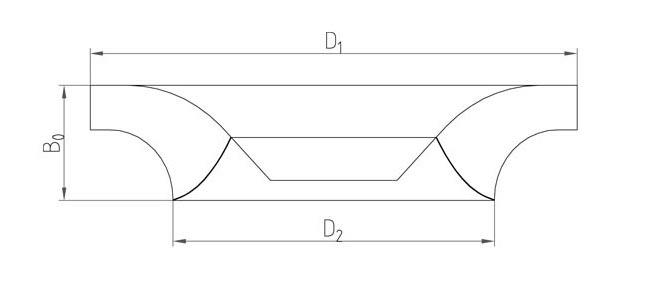

Mixed flow type water turbine with ultralow specific speed and high efficiency for cooling tower special belt water distributer

InactiveCN102213177ALow specific speedLow unit speedHydro energy generationReaction enginesCooling towerMixed flow

The invention relates to a mixed flow type water turbine with ultralow specific speed and high efficiency for a cooling tower special belt water distributer and relates to a novel energy-saving hydrodynamic device used for a cooling tower. The novel energy-saving hydrodynamic device comprises a rotating wheel, a main shaft, a bearing device, a stand ring, a base ring and cover plates, wherein the lower part of the base ring is connected with a water distributor, and the stand ring is formed by welding an volute, a guide vane, the upper cover plate and the lower cover plate into a whole. The mixed flow type water turbine provided by the invention has the characteristics of novel structure, stable operation, small noise, large flow capacity, high efficiency, energy conservation and environmental friendliness; the rotating wheel and each overflowing part of the water turbine are subjected to optimum design by adopting a CFD (computational fluid dynamic) three-dimensional flow turbulence unsteady constant analogue method, the geometric parameter of the rotating wheel and guide vane of the water turbine is set as follows: the ratio of the rotating wheel inlet diameter D1 to the rotating wheel outlet diameter D2 is equal to 1.508, the ratio of the rotating wheel height B0 to the rotating wheel inlet diameter D1 is equal to 0.20, the relative height of the guide vane O is equal to 0.09D1, the rotating wheel performance indexes meet the conditions that the specific speed ns=(50-70) m.kW, the unit speed n11=(45-55) r / min, the efficiency eta m=(88.5%-90.5%); and the key problem that the rotating wheel specific speed of the existing water turbine is overhigh and can not be matched with the cooling tower fan parameters if not being regulated by the planetary reducer is solved.

Owner:辽宁海思达科技发展有限公司

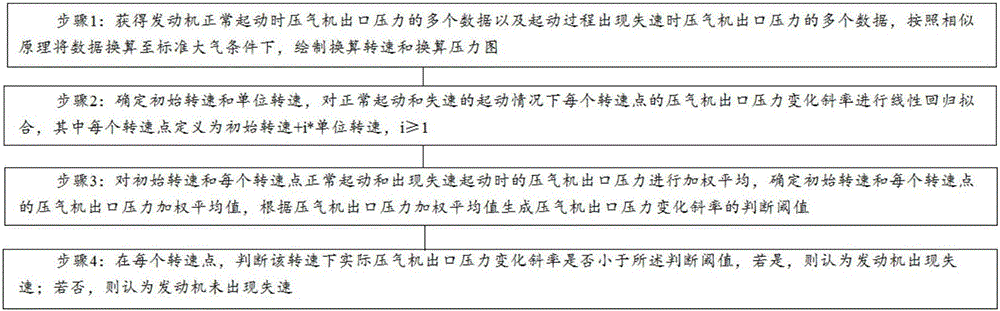

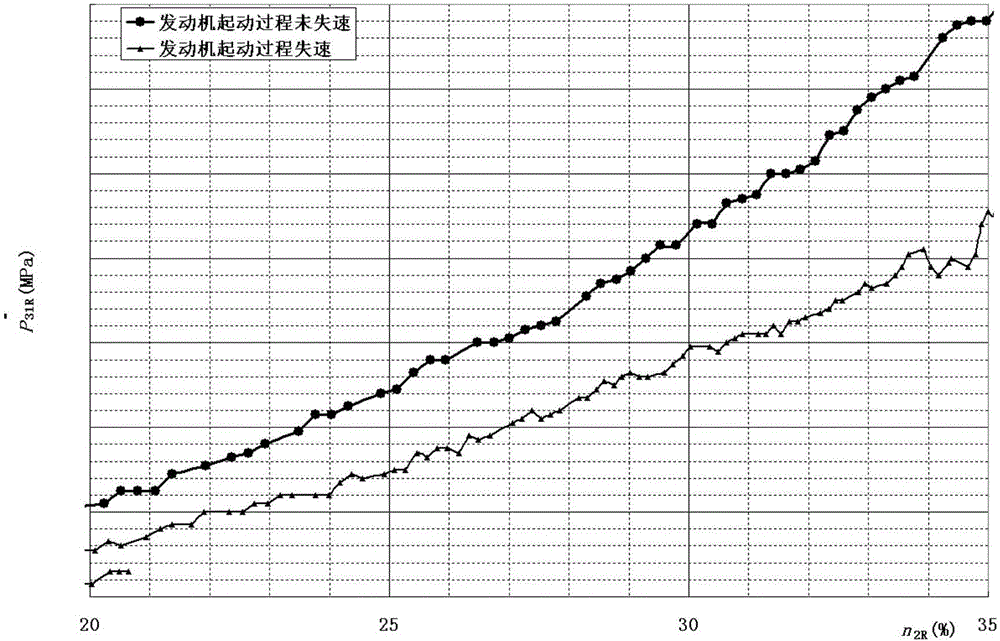

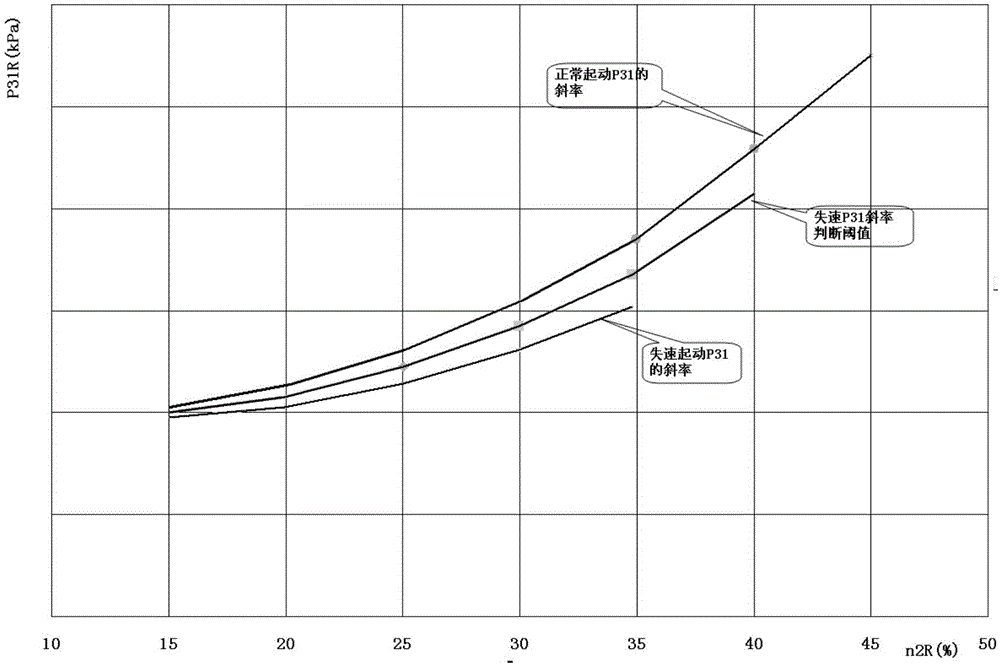

Method for judging stall during aero-engine starting

The invention discloses a method for judging stall during aero-engine starting. The method includes the steps of firstly, drawing corrected speed and corrected pressure graphs; secondly, determining initial speed and unit speed, and performing linear regression fitting; thirdly, performing weighted averaging on compressor discharge pressure of the initial speed and each speed point during normal starting and stall starting, and generating the judging threshold of a compressor discharge pressure change slope; fourthly, judging whether compressor discharge pressure change slope of the speed is smaller than the judging threshold or not, and if so, determining that engine stall occurs; if not, determining that engine stall does not occur. The method has the advantages that the method is designed according to the other feature, namely compressor discharge pressure lowering, of engine starting stall, and theoretically the stall can be distinguished once the stall occurs.

Owner:AECC SHENYANG ENGINE RES INST

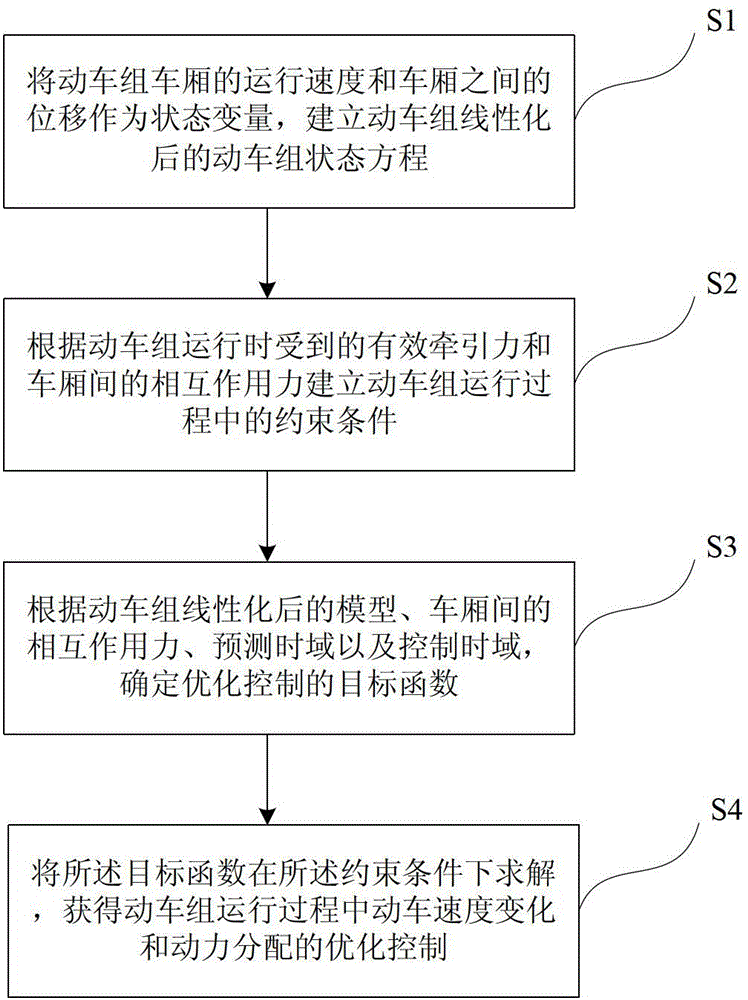

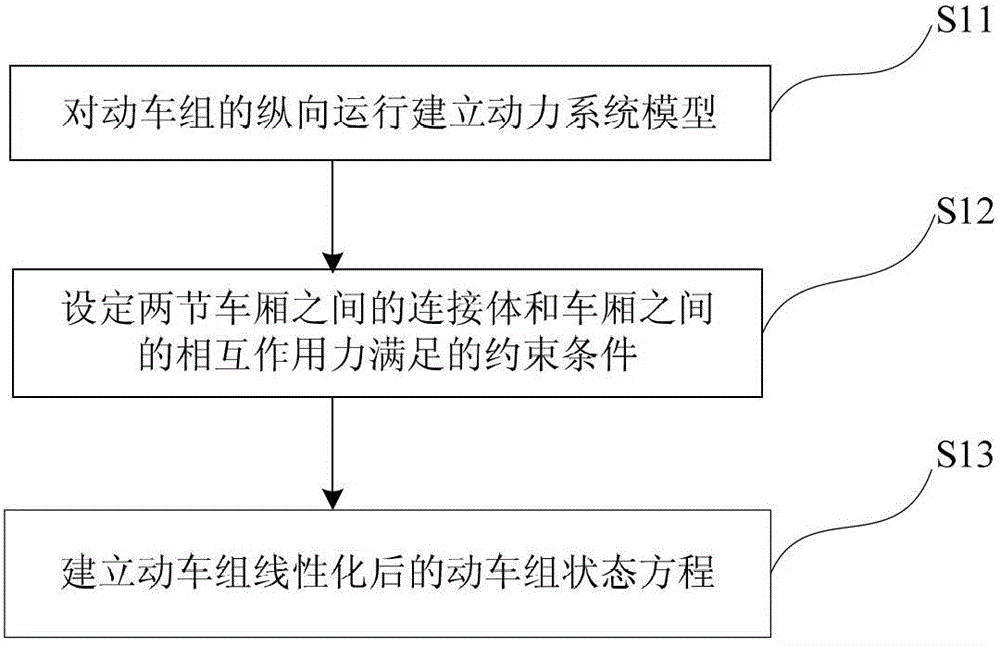

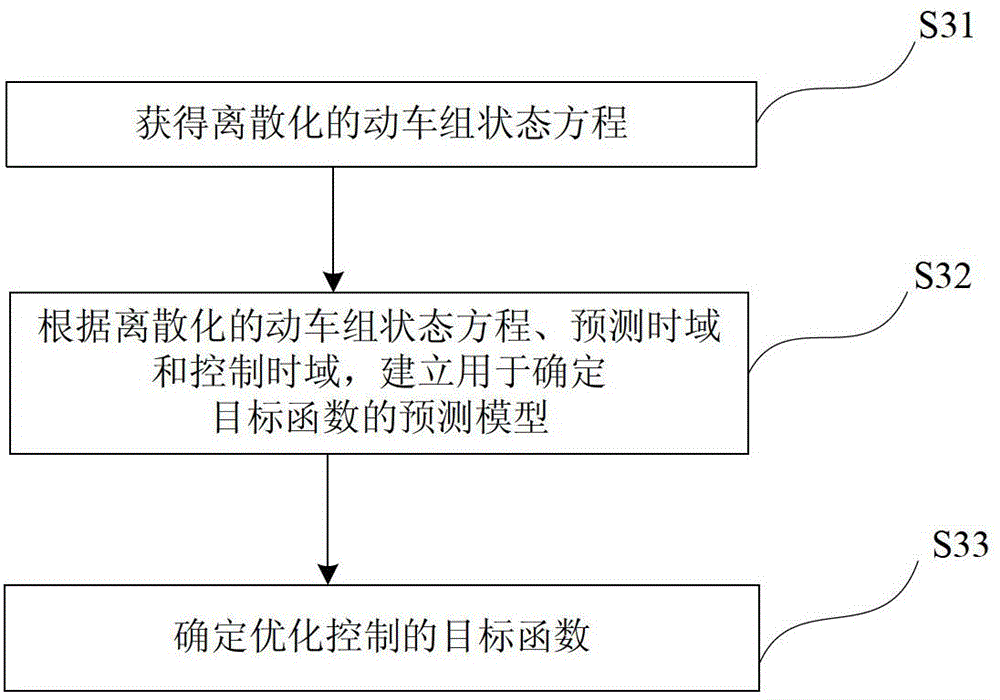

Motor train unit power optimizing prediction and control method based on model

InactiveCN102880772AStay Energy Efficient and EconomicalImprove power distribution efficiencyAerodynamics improvementSpecial data processing applicationsTime domainBody compartment

The invention provides a motor train unit power optimizing prediction and control method based on a model. The motor train unit power optimizing prediction and control method comprises the following steps of: S1) taking a running speed of a motor train unit compartment and displacement between compartments as state variables, and establishing a motor train unit state equation after a motor train unit is lineated; S2) establishing a constraint condition in a running process of the motor train unit according to an effective tractive force borne during running of the motor train unit and an interaction force between the compartments; S3) according to the model after the motor train unit is lineated, the interaction force between the compartments, a prediction time domain and a control time domain, determining an optimizing control target function; and S4) solving the target function under the constraint condition so as to obtain optimizing control of motor train unit speed variation and power distribution in the running process of the motor train unit. According to the motor train unit power optimizing prediction and control method based on the model disclosed by the invention, motor train unit power distribution model predication and control can be realized, power distribution is optimized according to variation of a motor train unit speed in the running process of the motor train unit, so that energy saving and economy can be kept when the motor train unit runs, and power distribution efficiency is improved.

Owner:SHANGHAI JIAO TONG UNIV

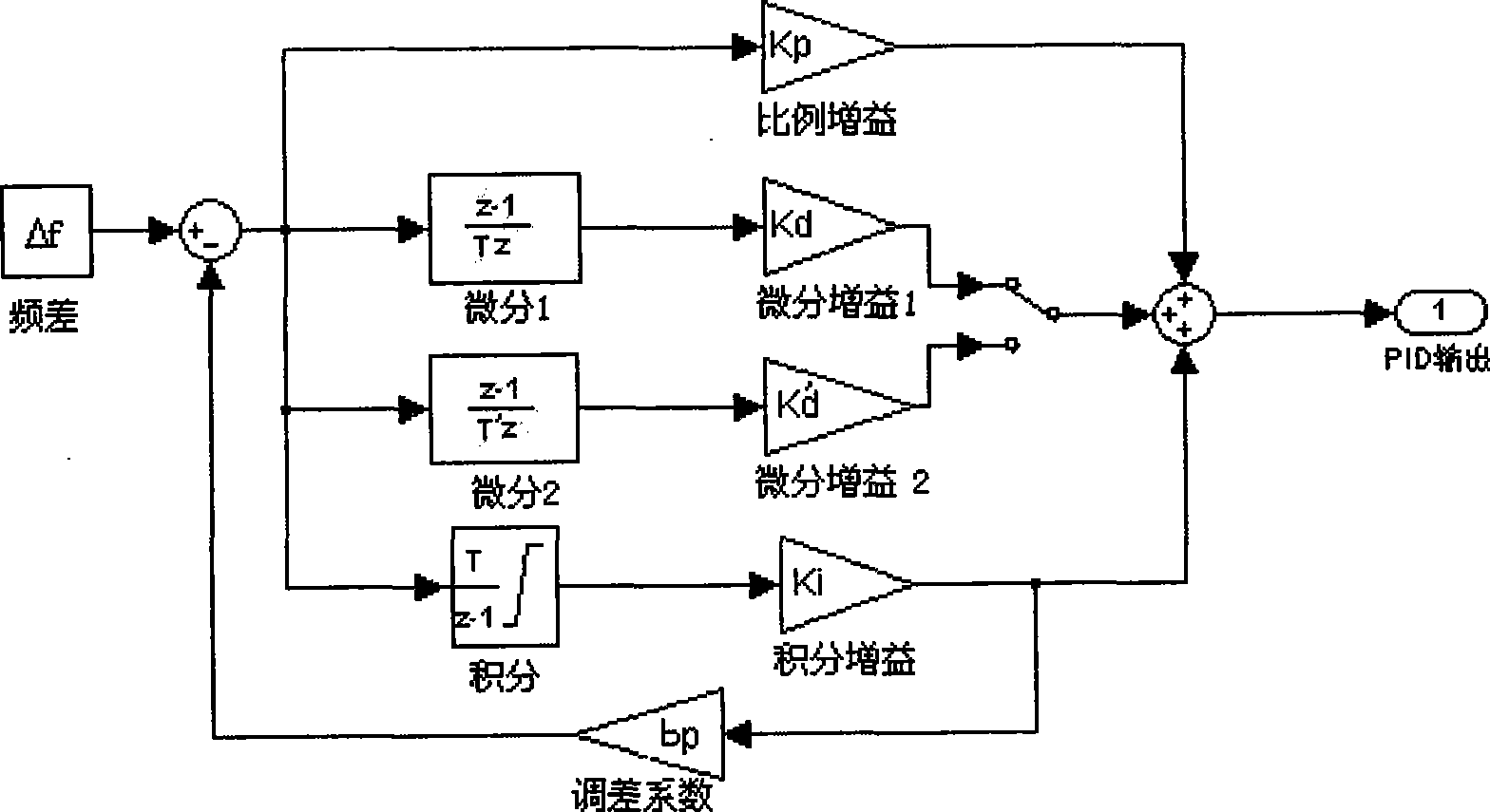

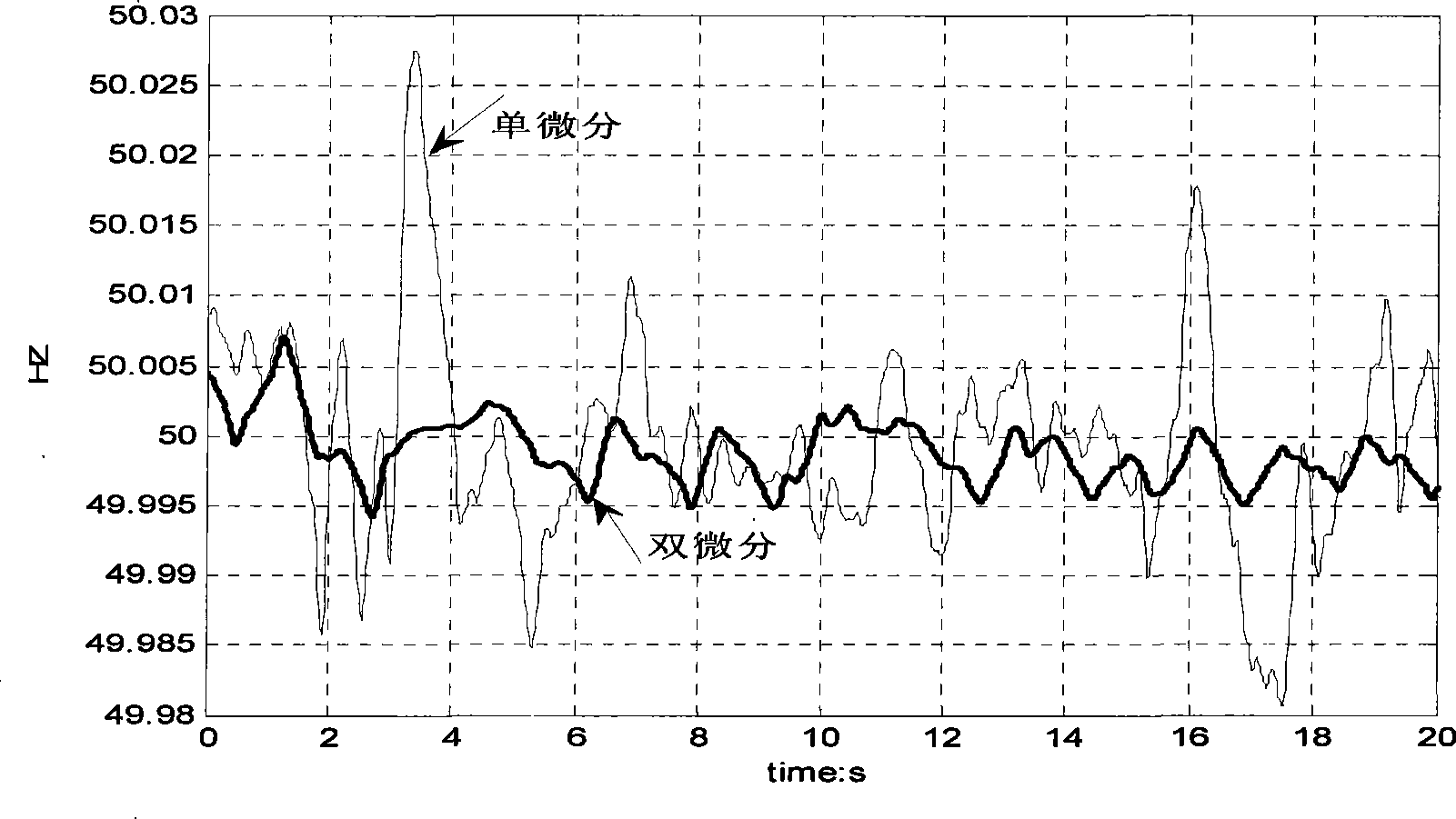

Double-differentiation channel PID control algorithm for pumping energy storage machine unit speed regulating device

ActiveCN101436035AImprove stabilityReduce the impactPump controlControllers with particular characteristicsPid control algorithmUnit speed

The invention relates to a PID control algorithm for double differential passages for a speed regulator of a water pumping and energy storing unit. The PID control algorithm comprises two differential passages with same structures. The sampling period of a first differential passage is comparatively short, while the sampling period of a second differential passage is comparatively long. The algorithm treats a quick change part and a slow change part of frequency separately, namely, adopting the first differential passage at the quick change part and adopting the second differential passage at the slow change part, so that a differential link functions within a wider regulating range all the time, and the rotating speed of the unit can have less fluctuation nearby a network frequency value. The PID control algorithm for the double differential passages effectively solves the problem that the prior PID control algorithm has larger differential dead area after discretization and the problem of effectively regulating narrow bandwidth, improves stability of the water pumping and energy storing unit during idle running at low water head, reduces influence of S-shaped characteristics to stable running of the water pumping and energy storing unit, and improves high-frequency interference inhibiting capability of the speed regulator of the water pumping and energy storing unit at the same time.

Owner:STATE GRID XINYUAN +2

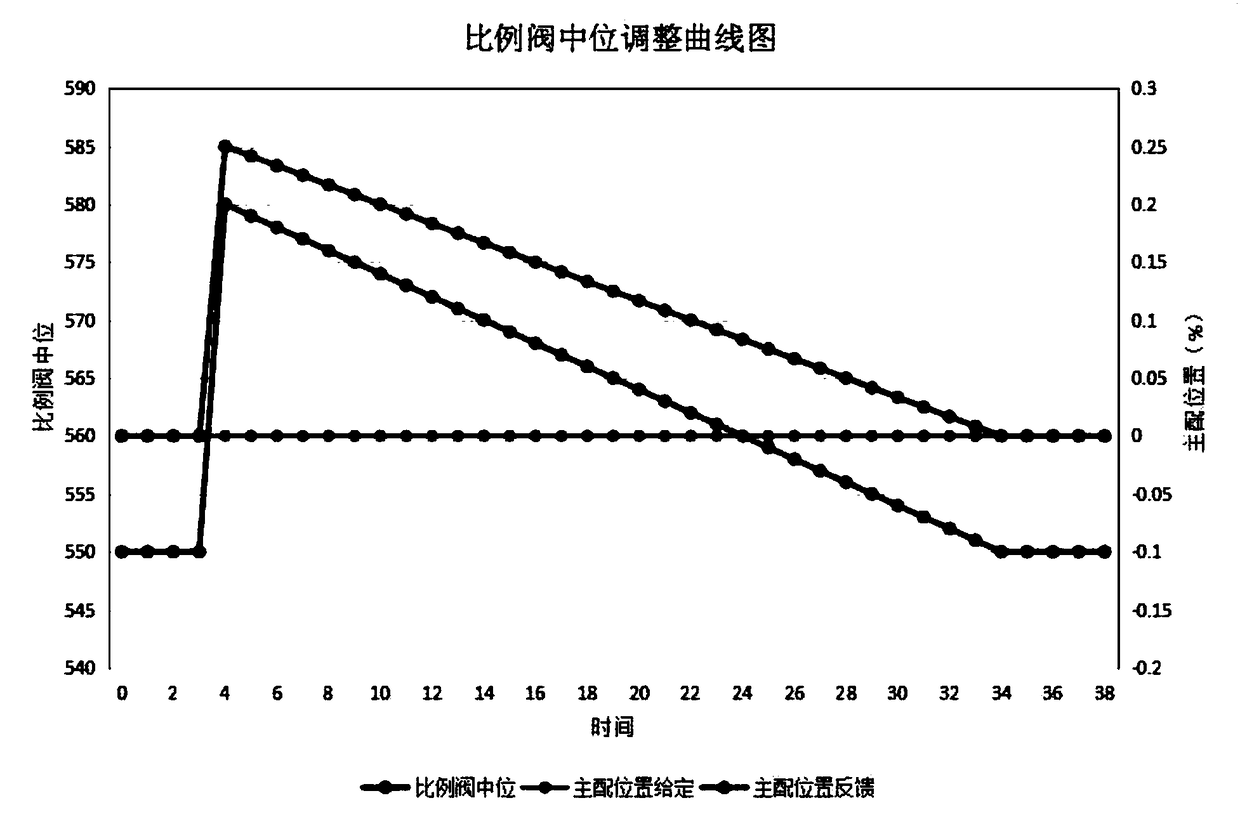

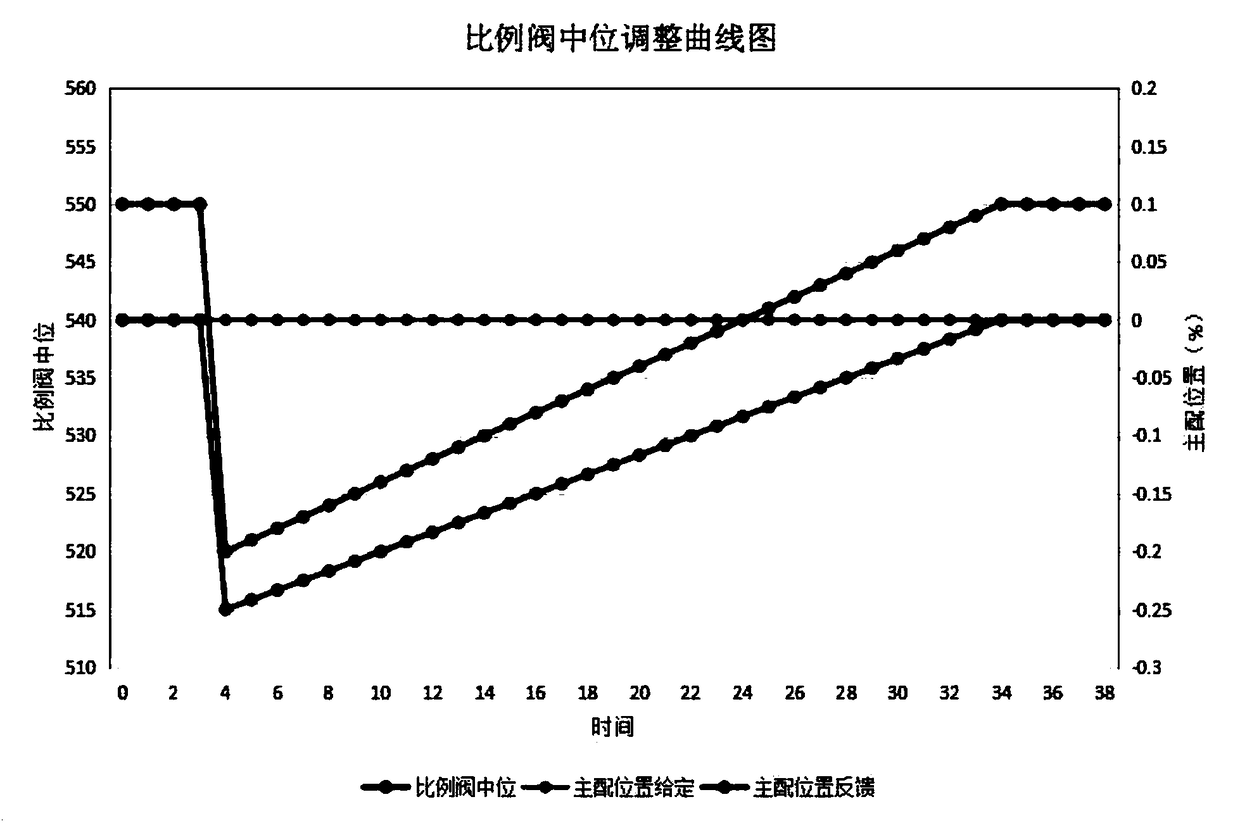

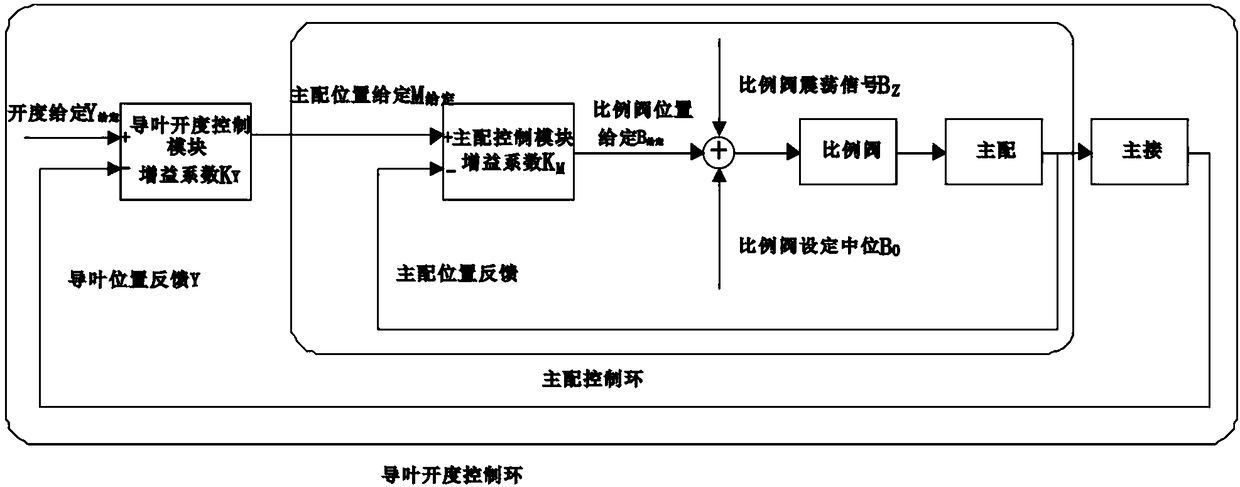

Speed controller proportional valve median adjusting method based on hydraulic slave system static balance

ActiveCN108468616APerfect and reliable theoretical basis guidanceSimple methodHydro energy generationPassive/reactive controlElectricityPower mode

Provided is a speed controller proportional valve median adjusting method based on hydraulic slave system static balance. The method comprises: step 1, keeping given power of a unit speed controller in a grid connected power mode constant, or switching a speed controller to an electric manual state, to make a speed controller hydraulic slave system in static balance; step 2, a speed controller electrical control system acquiring main distribution position feedback M, main distribution position set Mset data; determining whether the main distribution position feedback M is equal to the main distribution position set Mset; if M<Mset, using the highest unit precision i of a proportional valve median set value as step length, gradually increasing the proportional valve median set value B0, returning to the step 2; if M>Mset, using i as the step length, gradually reducing the proportional valve median set value B0, returning to the step 2; if the main distribution position feedback M is equal to the main distribution position set Mset, the B0 value being a proportional valve actual median value B0actual, an adjusting process ending. The method can accurately determine the speed controller proportional valve median, and solves a problem of adjusting quality of a speed controller hydraulic slave system caused by inaccurate setting of the speed controller proportional valve median.

Owner:CHINA YANGTZE POWER

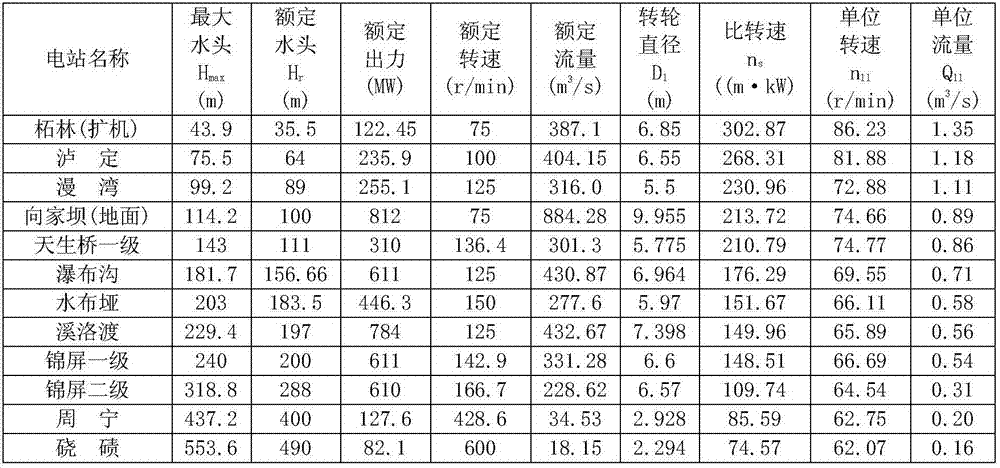

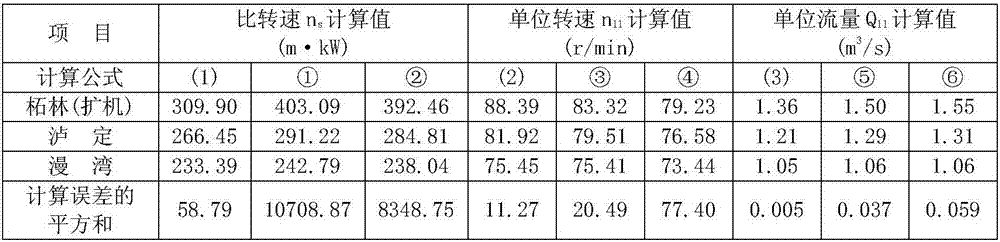

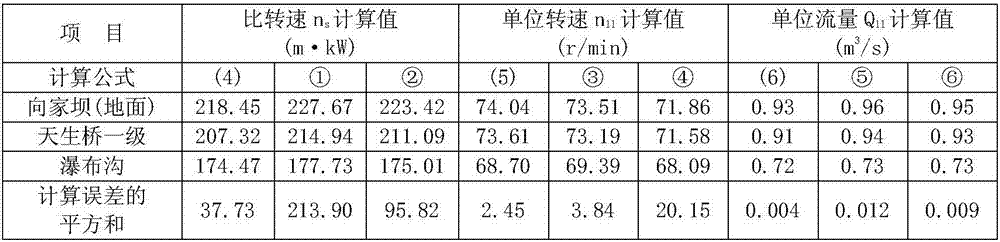

Method for estimating basic parameters of mixed-flow type water turbine

ActiveCN107153753AMeet the requirements of hydropower engineeringGeometric CADComplex mathematical operationsMixed flowWater turbine

The invention relates to a water turbine, provides a method for estimating basic parameters of a mixed-flow type water turbine, and aims to estimate the basic parameters of the mixed-flow type water turbine. The basic parameters to be estimated of the water turbine comprise a specific speed ns, a unit speed n11 and unit flow Q11. The method comprises the following steps: determining the specific speed of the mixed-flow type water turbine to be estimated, and recording the specific speed as ns; determining the maximum application water head of the mixed-flow type water turbine to be estimated, recording the maximum application water head as Hmax, and judging a range where the Hmax falls; estimating the basic parameters according to estimation formulas of the corresponding ranges of Hmax, wherein the formulas are as follows: when Hmax is less than or equal to 100 m, ns=374.05e<-0.0053Hr>, n11=45.395e<0.0022ns> and Q11=5.9 x 10<-3> x ns<0.9516>; when Hmax is greater than 100 m and less than or equal to 200 m, ns=2191.5Hr<-0.5007>, n11=48.289e<0.002ns> and Q11=1.0642Ln(ns)-4.7812; when Hmax is greater than 200 m and less than or equal to 300 m, ns=343.12e<-0.0042Hr>, n11=1.2874ns<0.7878> and Q11=0.7821Ln(ns)-3.3718; when Hmax is greater than 300 m, ns=3609.2Hr<-0.6189>,n11=37.207ns<0.1186> and Q11=0.3652Ln(ns)-1.4009. The method is applicable to the mixed-flow type water turbine and can better meet new hydropower engineering requirements.

Owner:POWERCHINA CHENGDU ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com