Patents

Literature

31results about How to "Control surface quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

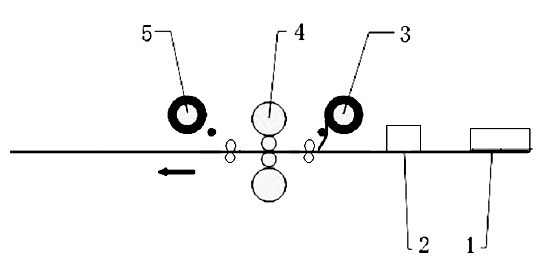

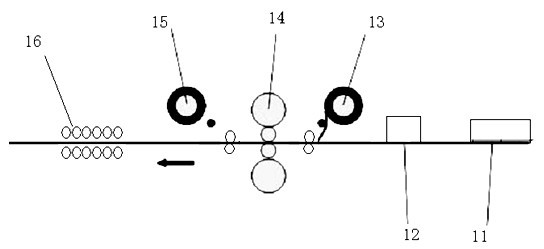

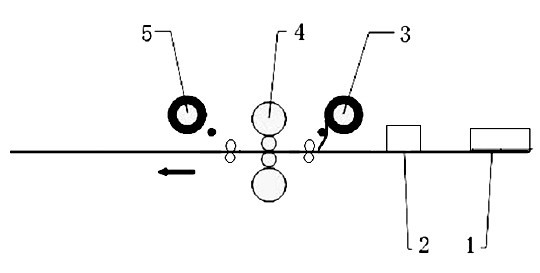

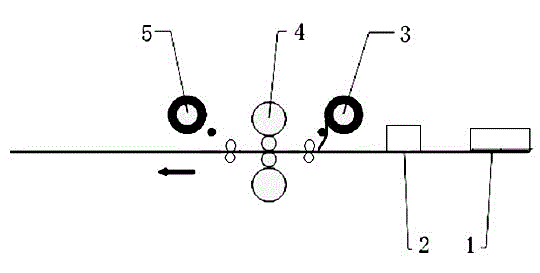

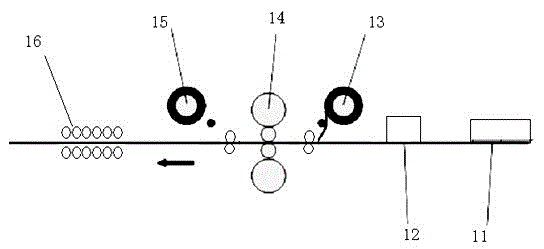

Method for rolling thin high-strength steel plate of single-frame steckel mill

ActiveCN102179406ASolve the problem of excessive rolling forceSolve quick stopRoll force/gap control deviceTemperature control deviceFurnace temperatureSheet steel

The invention discloses a method for rolling a thin high-strength steel plate of a single-frame steckel mill. The method comprises the following steps: producing the finished product of a high-strength steel plate with a thickness less than 10 millimeters by using a blank with the thickness of 150 millimeters and the length more than 10 meters; and then acquiring the thin high-strength steel plate with qualified property and plate shape by controlling a tapping temperature, a coiler furnace temperature, a reduction in last pass, a roller force, a final rolling speed and a high pressure water de-scaling system. When the rolling method is used for producing the thin steel plate, the thin high-strength steel plate is rolled by utilizing the heat preservation function of front and back mill coiler furnaces and controlling the tapping temperature of the blank, the reduction in the last rolling pass, the roller force and the final rolling speed, and the acquired plate shape and property of the steel plate are both qualified, thereby increasing the rolling mill capacity and achieving high plate yield and high property yield.

Owner:NANJING IRON & STEEL CO LTD

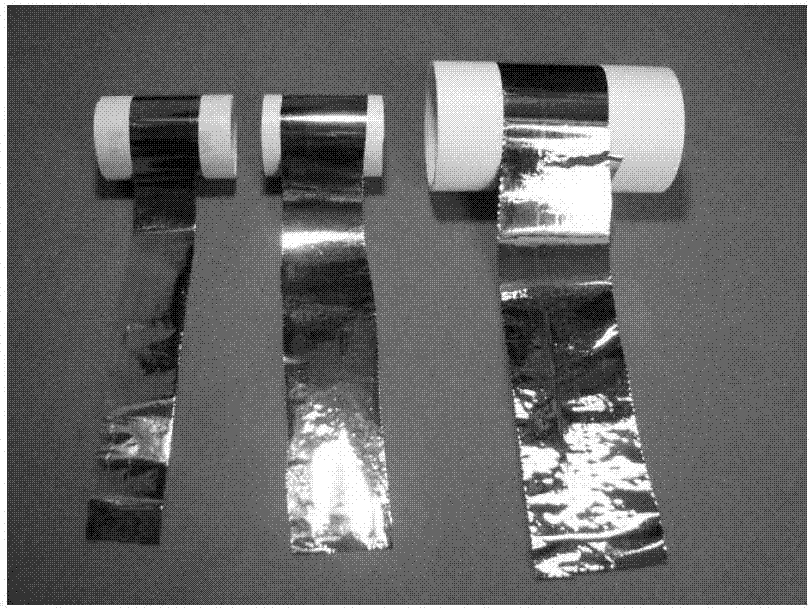

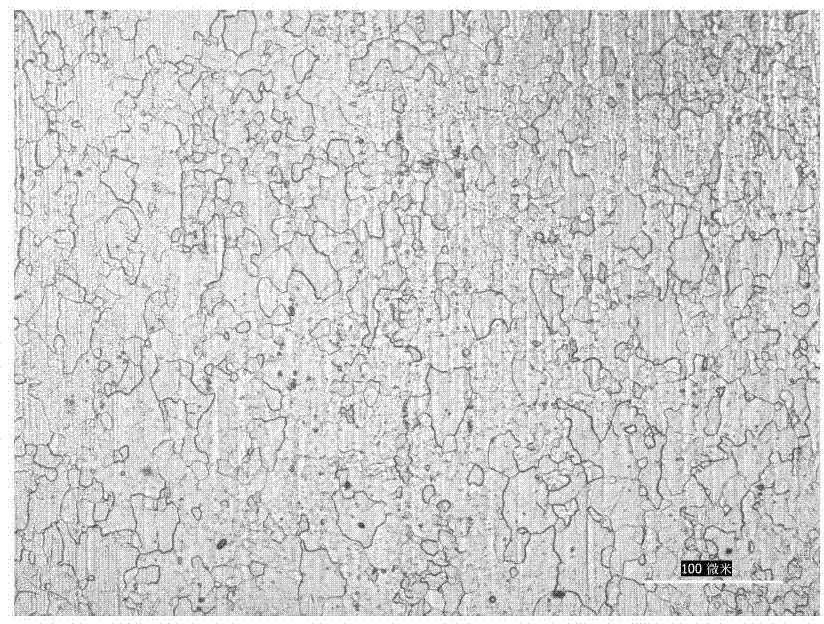

Preparation method of ultrathin Ta-W alloy foil

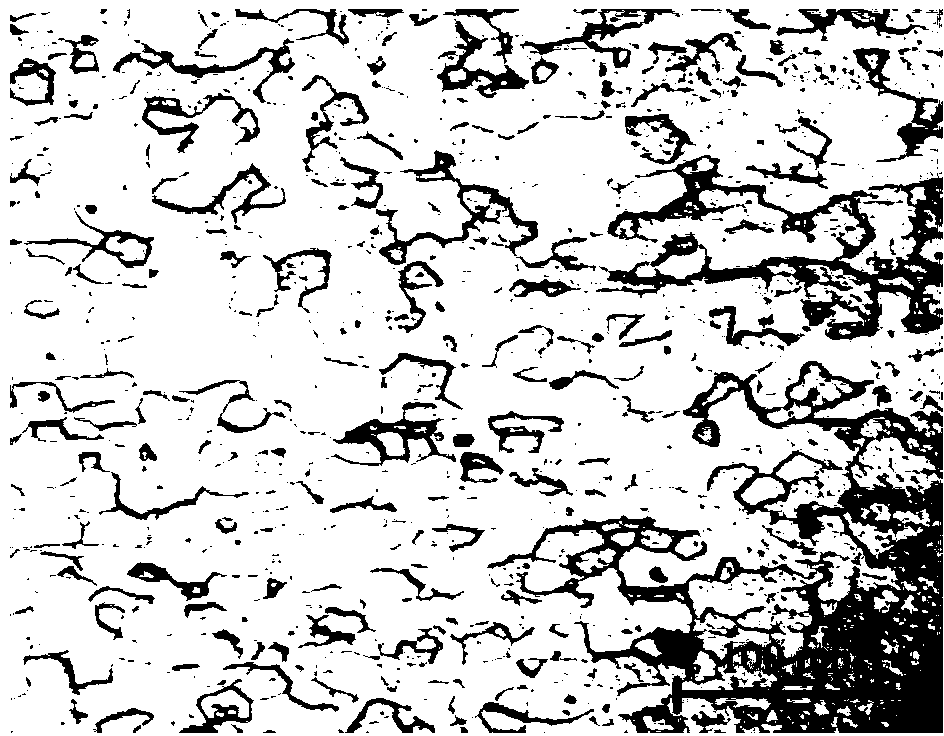

The invention provides a preparation method of ultrathin Ta-W alloy foil, and belongs to the technical field of Ta-W alloy machining. The preparation method includes the steps that cyclic operation of alloy billet prepared through a powder metallurgy method, cold rolling cogging, and cold rolling and vacuum annealing, 3-5 micrometer foil annealing, and the like. The thickness of the prepared foil can reach 3-5 micrometers. The preparation method is simple in process, the prepared foil is high in precision, and compared with pure Ta foil and other Ta-W alloy foil, the ultrathin Ta-W alloy foil has the advantages of being high in strength, good in surface quality, and the like. The prepared Ta-(5.0-7.5 wt%)W alloy foil with the thickness of 3-5 micrometers is suitable for high-power microwave tubes, traveling wave tubes, and other vacuum devices of electronic components, aerospace, and other industries. The preparation method has great significance on achieving high-power high-performance microwave tube localization, improving microwave tube using performance, prolonging service life, and the like.

Owner:CENT SOUTH UNIV

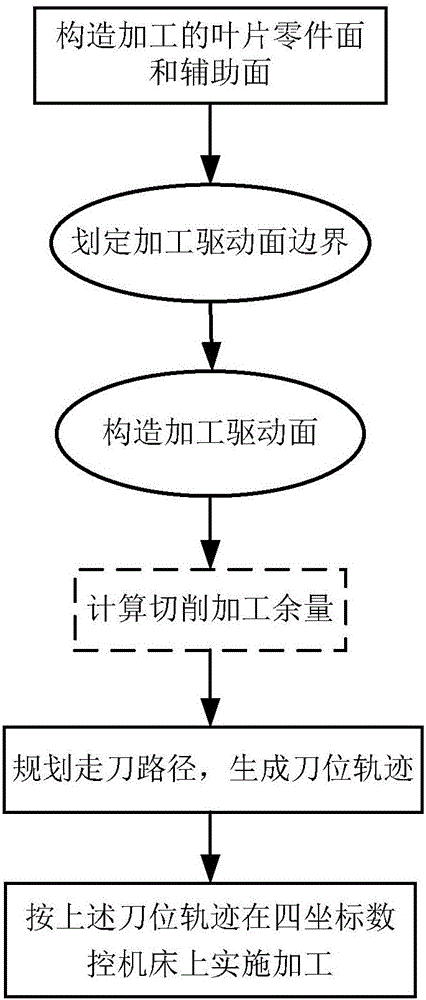

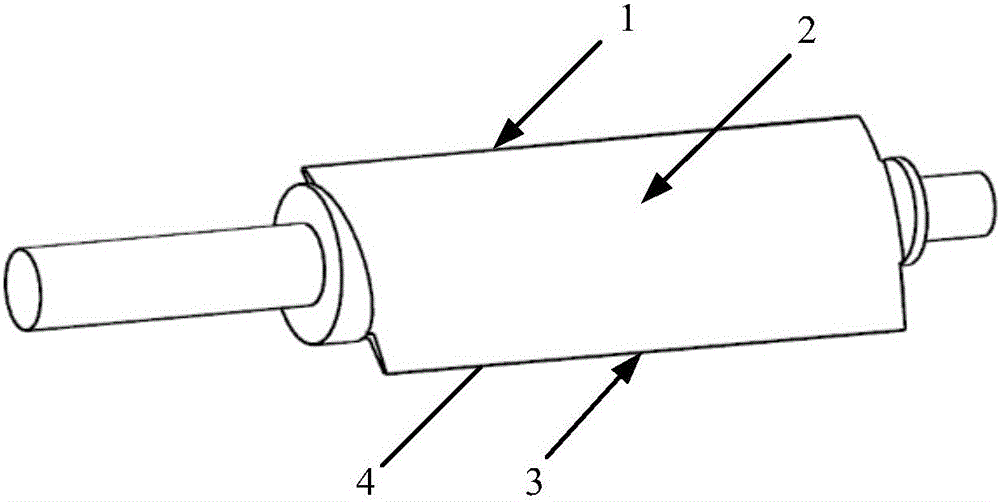

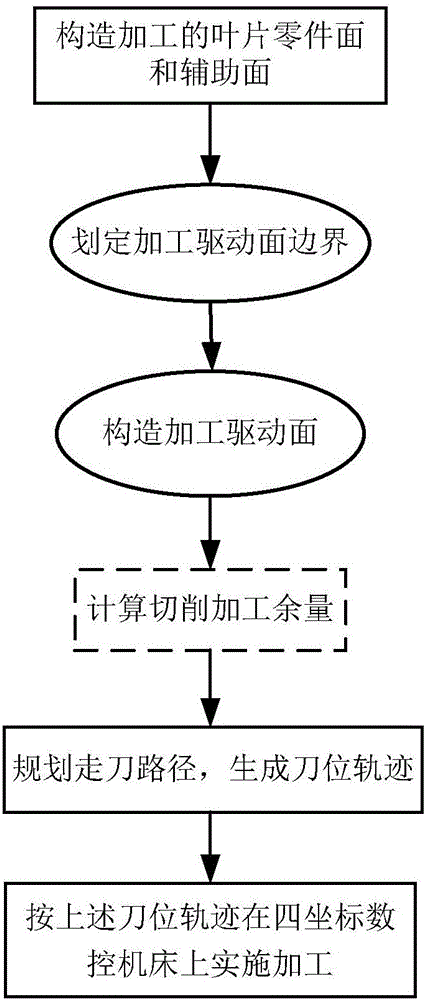

Thin-walled vane nine-point control variable-allowance milling method based on Newton interpolation

ActiveCN106001720AReduce bending deformationReduce torsional deformationWorkpiecesMilling equipment detailsPosition toleranceTorsional deformation

The invention provides a thin-walled vane nine-point control variable-allowance milling method based on Newton interpolation. Modeling is carried out by utilizing a three-dimensional modeling software, and an auxiliary surface and a boundary surface are formed, so that a driving surface is determined by utilizing a section line lofting process. Cutter machining paths are generated according to the driving surface, and the machining allowance of each cutter position point on each machining path is determined by adopting a Newton interpolation method. Finally, vanes are cyclically processed according to symmetrical milling rules. Compared with a traditional longitudinal fixed-allowance cutting and spiral milling method, the thin-walled vane nine-point control variable-allowance milling method has the advantages that technical problems, such as large torsional deformation, low contour precision, poor section position tolerance and difficult error control, in the machining process can be solved; and by adopting a Newton interpolation process allowance fine adjustment method, surface quality can be more comprehensively controlled, and problems, such as large bending deformation, poor section position tolerance and low surface contour precision, in the machining process can be effectively solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

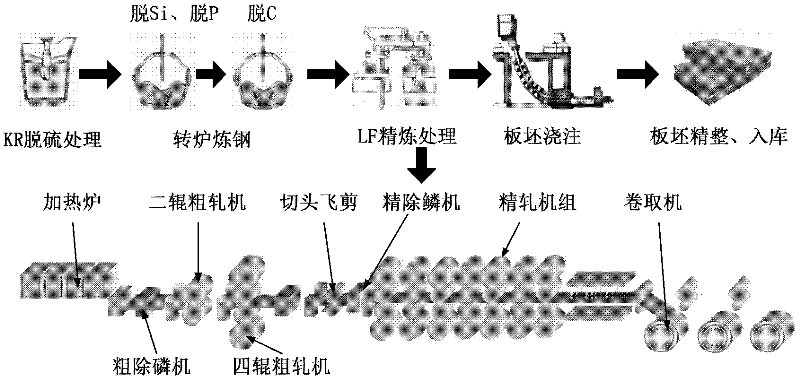

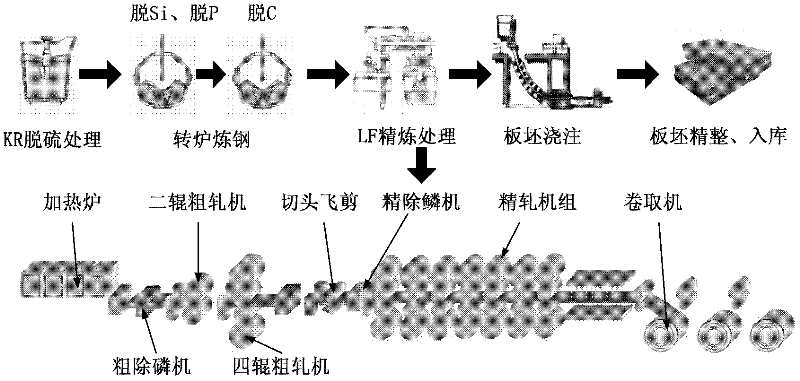

Steel for electric power tower and production method thereof

The invention discloses steel for an electric power tower, which comprises the following chemical components in percentage by weight: 0.04-0.10wt% of C, 0.01-0.10wt% of Si, 0.60-1.20wt% of Mn, less than 0.02wt% of P, less than 0.008wt% of S, 0.01-0.06wt% of V, 0.01-0.04wt% of Ti, more than 0.02wt% of Alt and the balance of Fe and inevitable impurity elements. The invention also discloses a method for producing the steel for the electric power tower. The invention has the characteristics that: on the basis of meeting the performance of the steel for the electric power tower, the surface quality of a hot-rolled steel coil is controlled through optimizing the chemical components, heating system, rolling process and the like of the steel for the electric power tower, thus the produced steel for the electric power tower has high strength, is easy to weld and is easy to coat, and the production cost can be lowered.

Owner:SHOUGANG CORPORATION

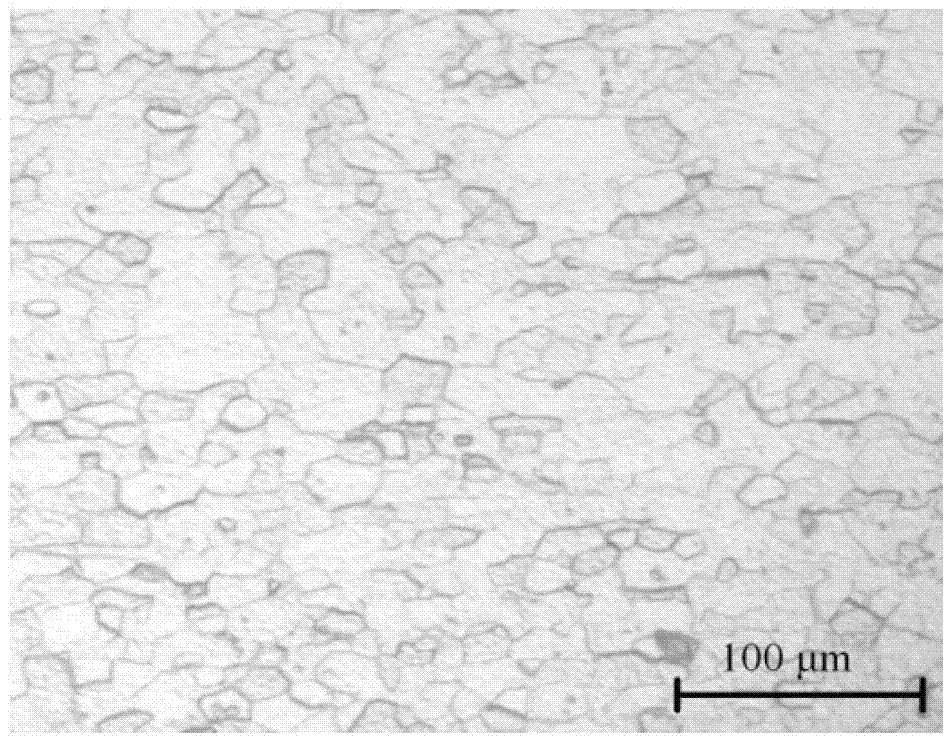

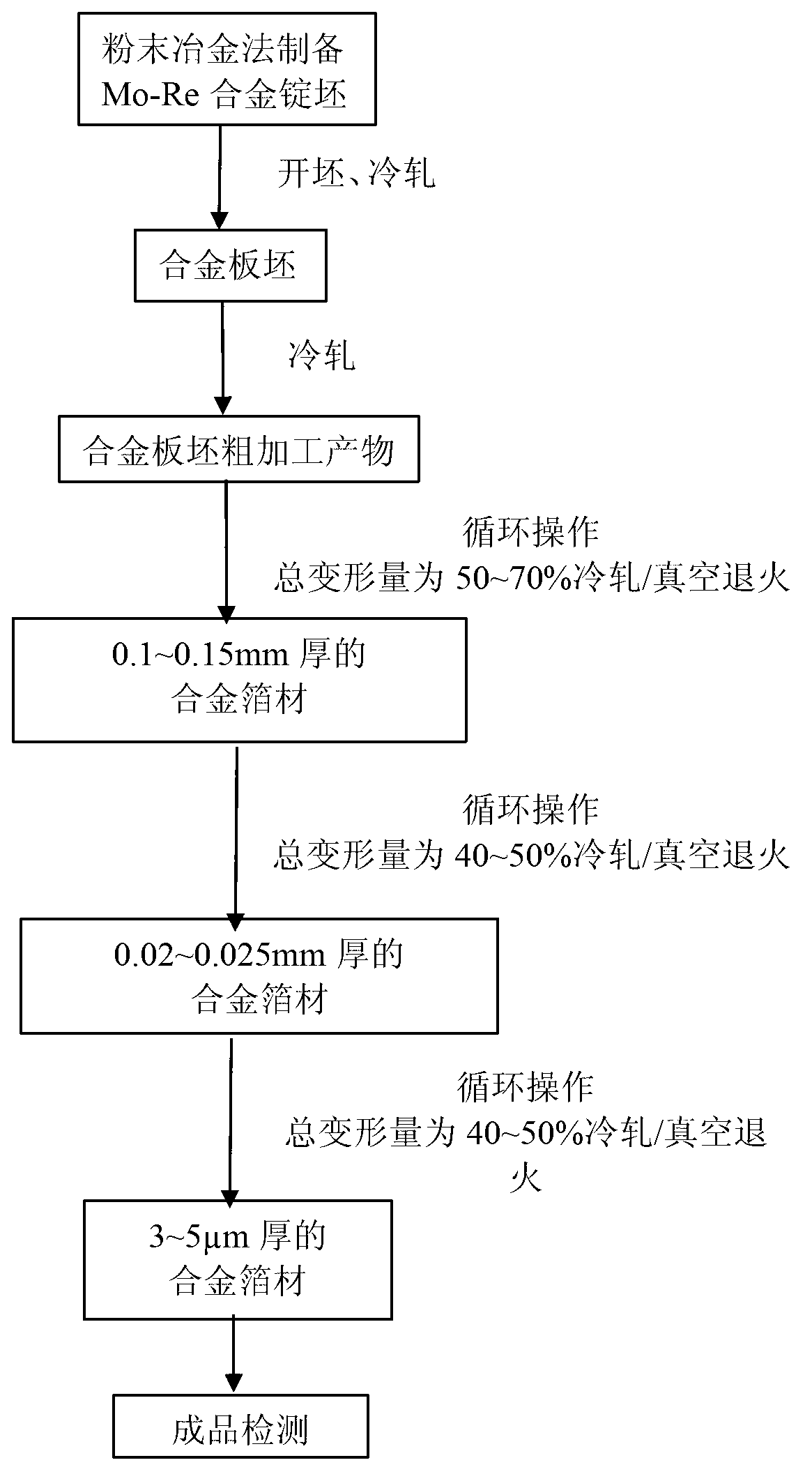

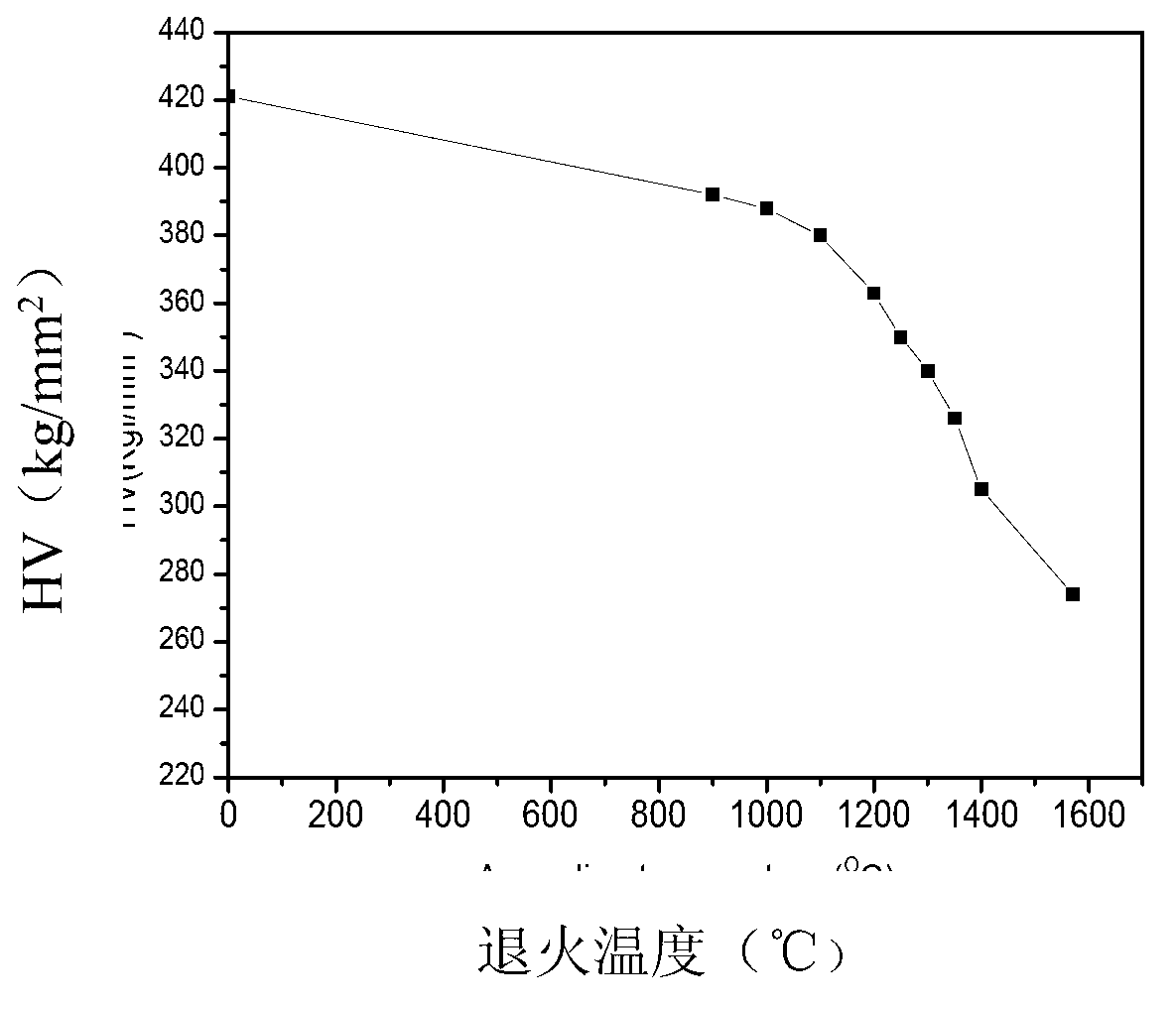

Preparation method of ultrathin Mo-Re alloy foil

InactiveCN103100563ASimple preparation processLow costMetal rolling arrangementsPowder metallurgyMicrometer

The invention provides a preparation method of an ultrathin Mo-Re alloy foil, and belongs to the technical field of Mo-Re alloy machining. The preparation method solves the problems that a Mo-Re alloy foil which is with the thickness smaller than 10 micrometers and good in surface quality is hard to prepare, and can be used for preparing the Mo-Re alloy foil which is with the thickness of 3-5 micrometers and good in surface quality. The preparation method comprises circulating operations of preparing an alloy billet with a powder metallurgy, cold rolling cogging, and cold rolling / vacuum annealing, and the method further comprises a step of annealing of a foil of 3-5 micrometers and other steps. The component range of a prepared alloy foil is, by weight, Re of 43.5-47.5%, and the balance is Mo. The thickness of the prepared alloy foil is 3-5 micrometers. The preparation method is simple in technology, the elastic coefficient of the prepared foil is 340-350 GPa, the tensile strength at 1200 DEG C is 220-260 Mpa, microhardness is 420-450 HV, the surface roughness (Rmax) is 0.02-0.05 micrometer, and the foil is suitable for platinotrons and travelling wave tubes and other vacuum components in aerospace equipment.

Owner:CENT SOUTH UNIV

Production technology of mirror surface copper belt for button fabric product

The invention discloses a production technology of a mirror surface copper belt for a button fabric product, and belongs to the technical field of copper belt production technologies. The production technology comprises the steps of (1) smelting and ingot casting; (2) saw cutting; (3) hot rolling; (4) surface milling; (5) rough rolling, wherein the specified thickness of a belt coil subjected to rough rolling is 2.5 mm; (6) primary annealing; (7) primary cleaning; (8) intermediate rolling; (9) secondary annealing; (10) secondary cleaning; (11) intermediate finish rolling; (12) tertiary annealing; (13) finish rolling; (14) fourth annealing; (15) inspection and delivery. Through the technical scheme, the surface quality and performance of the copper belt can be effectively improved, production requirements of the button fabric product are met, workshop cost is reduced, and productive profit is increased.

Owner:ANHUI CHUJIANG TECHCAL NEW MATERIAL CO LTD

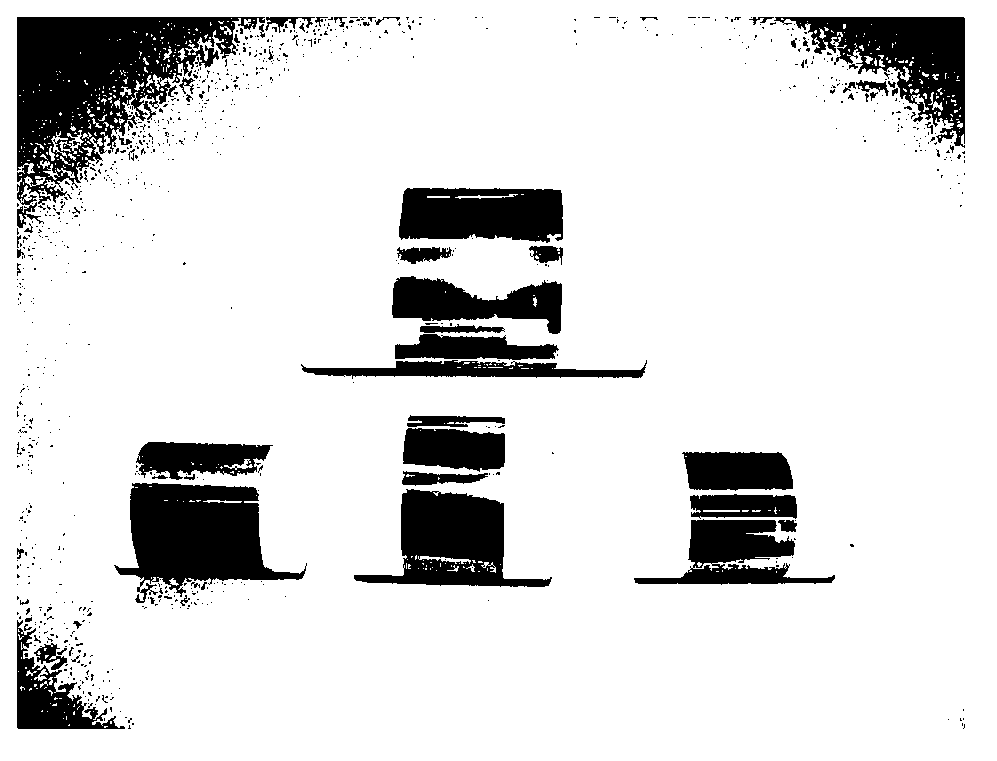

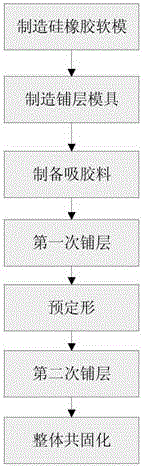

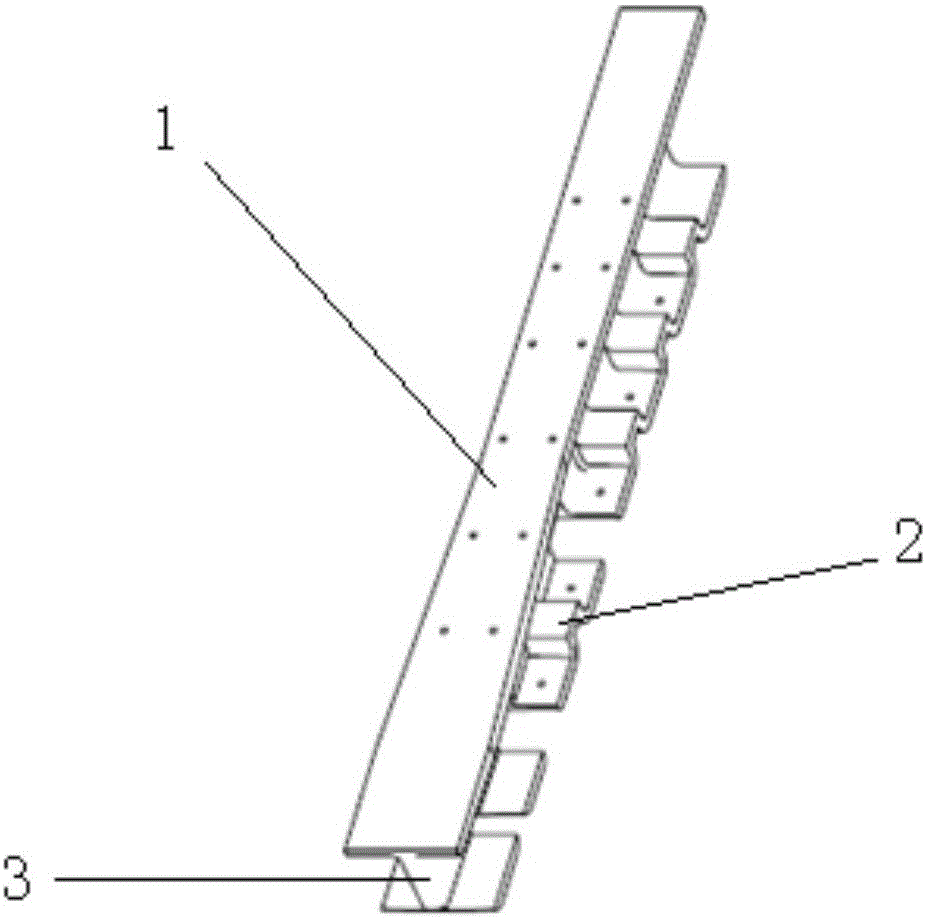

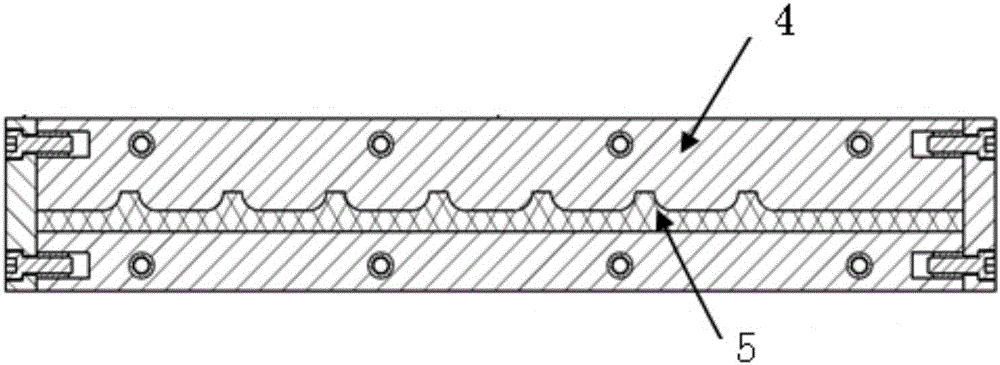

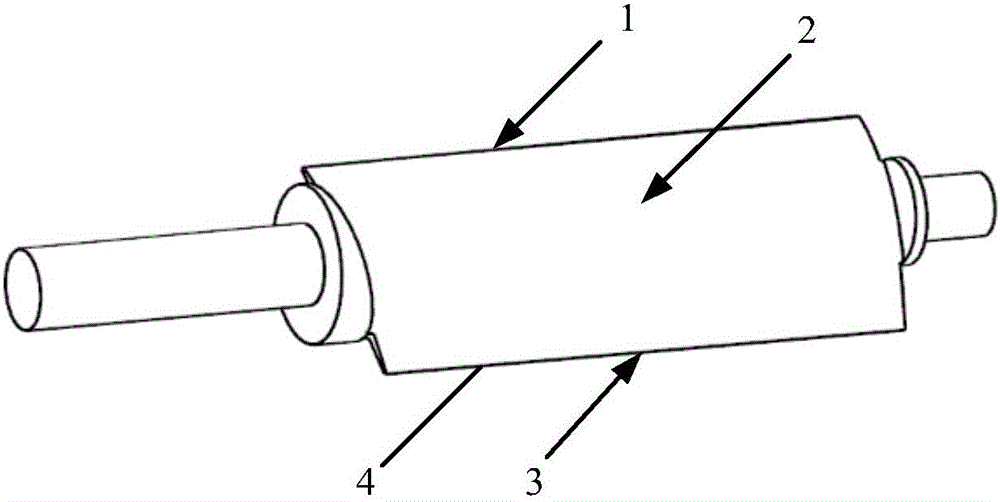

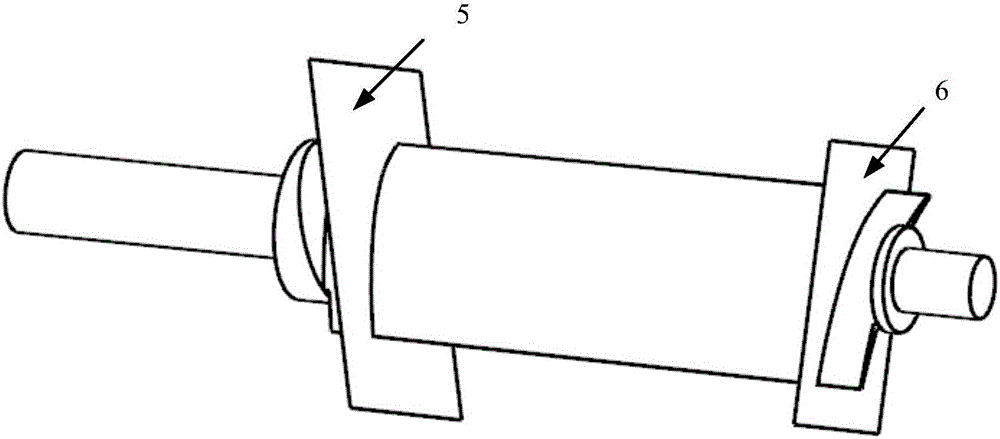

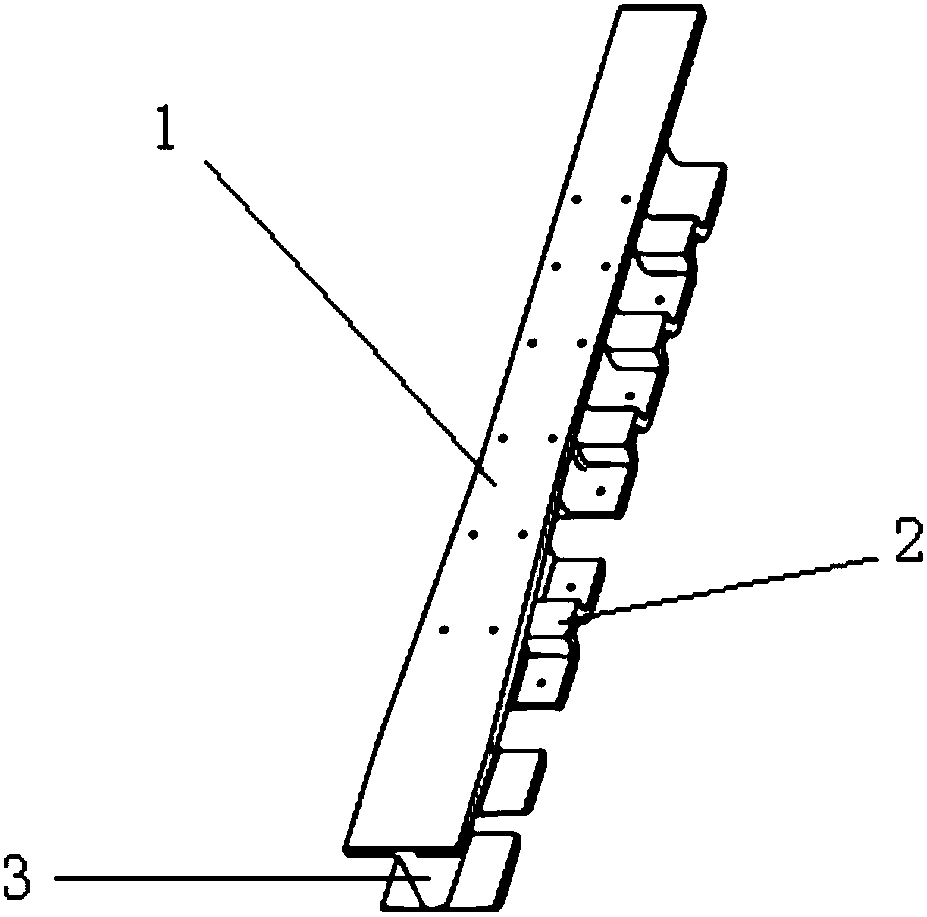

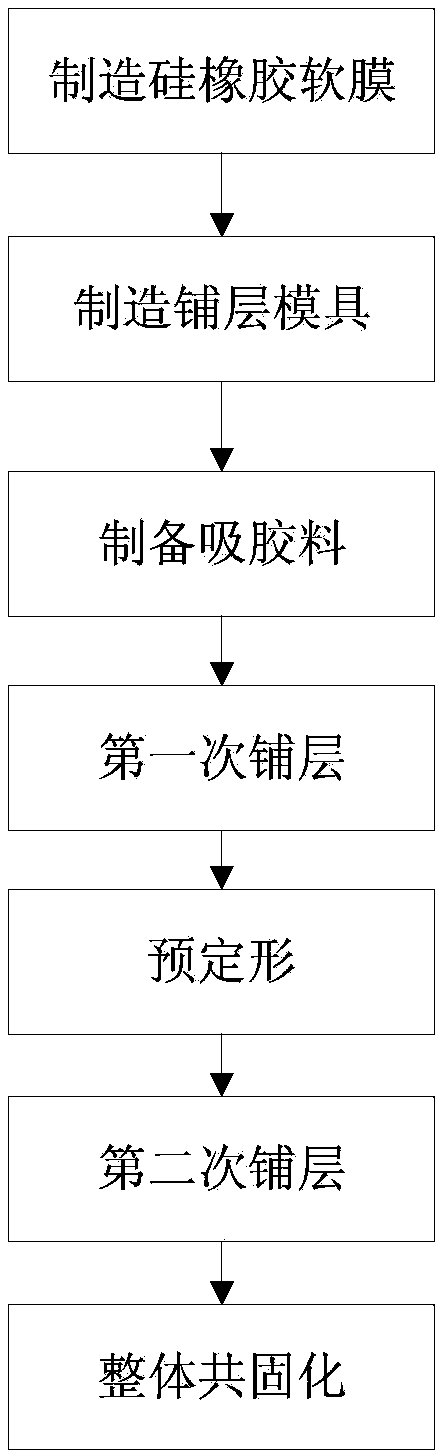

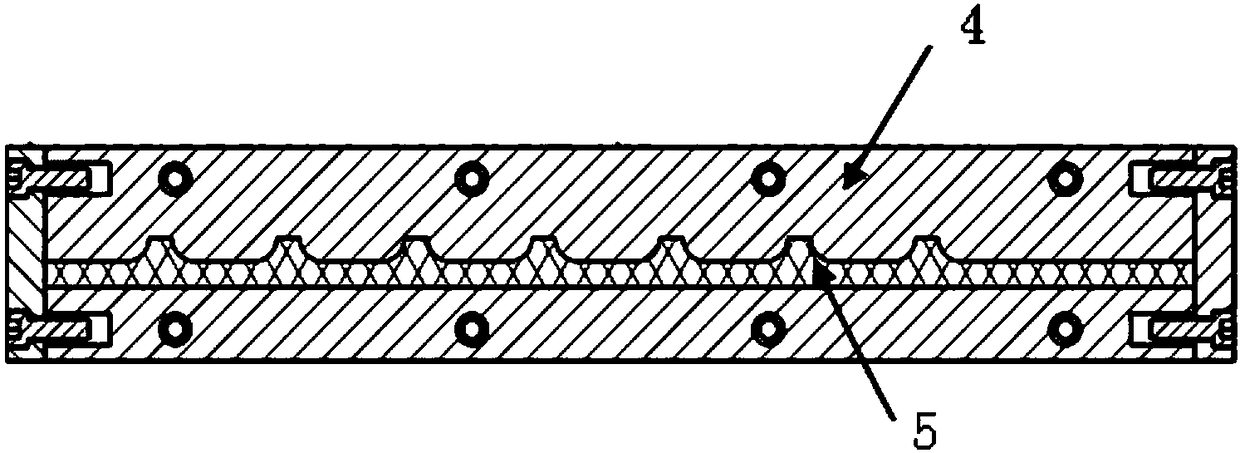

Soft mold auxiliary forming method for variable section I-beam containing corrugated flange plate

ActiveCN106113522AControllable under pressureTo achieve curing moldingDomestic articlesInternal pressureEngineering

The invention discloses a soft mold auxiliary forming method for a variable section I-beam containing a corrugated flange plate. According to the soft mold auxiliary forming method for the variable section I-beam containing the corrugated flange plate, the non-closed form that a metal mold and a silicon rubber mold are combined is adopted; the silicon rubber soft mold is wrapped inside the metal mold; corrugated flange plate side pressurizing (internal pressure) is conducted through heat expansion of the silicon rubber soft mold, the hot pressing tank (external pressure) forming process is combined, and internal and external two-way pressurizing is conducted, so that the pressure applied to a complex section is uniform and controllable, integral curing forming of the composite variable section I-beam containing the corrugated flange plate is well achieved, and the problem that a corrugated structure is not easy to pressurize is solved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

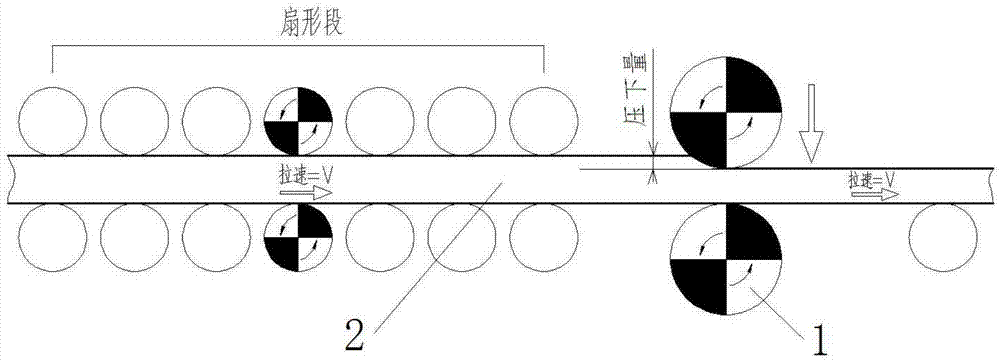

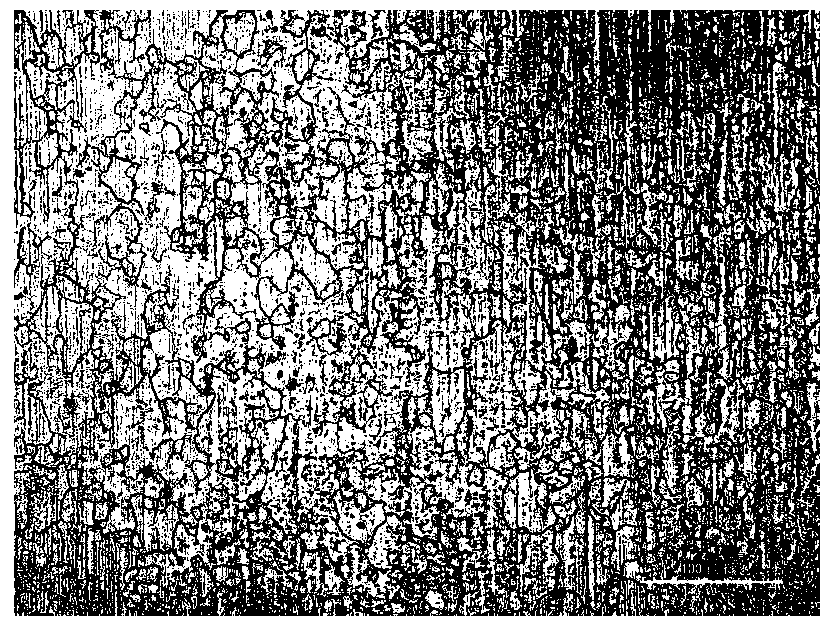

Method for eliminating central looseness of casting blank and improving density of casting blank

The invention discloses a method for eliminating central looseness of a casting blank and improving density of the casting blank. The method includes arranging a plurality of sets of hold-down rollers in the rear of the exit of a fan-shaped section of a continuous casting machine and allowing the linear speed of the hold-down rollers to be synchronous with the casting speed of the continuous casting machine. The hold-down rollers are arranged in the rear of the fan-shaped section of the continuous casting machine, so that deformation on the middle portion of the casting blank is larger than that of the surface by changing set positions of the hold-down rollers, central gaps of the casting blank are eliminated, the problem about central looseness of the casting blank is solved, and the central density of the casting blank is improved; the forming process of the casting blank and the matching relation between the hold-down rollers and hold-down quantities are controlled, so that surface cracks of the casting blank can be effectively prevented, densification in central tissue can be improved, quality of the interior of the casting blank can be improved, and control over the quality of the surface of the casting blank can be realized.

Owner:CISDI ENG CO LTD

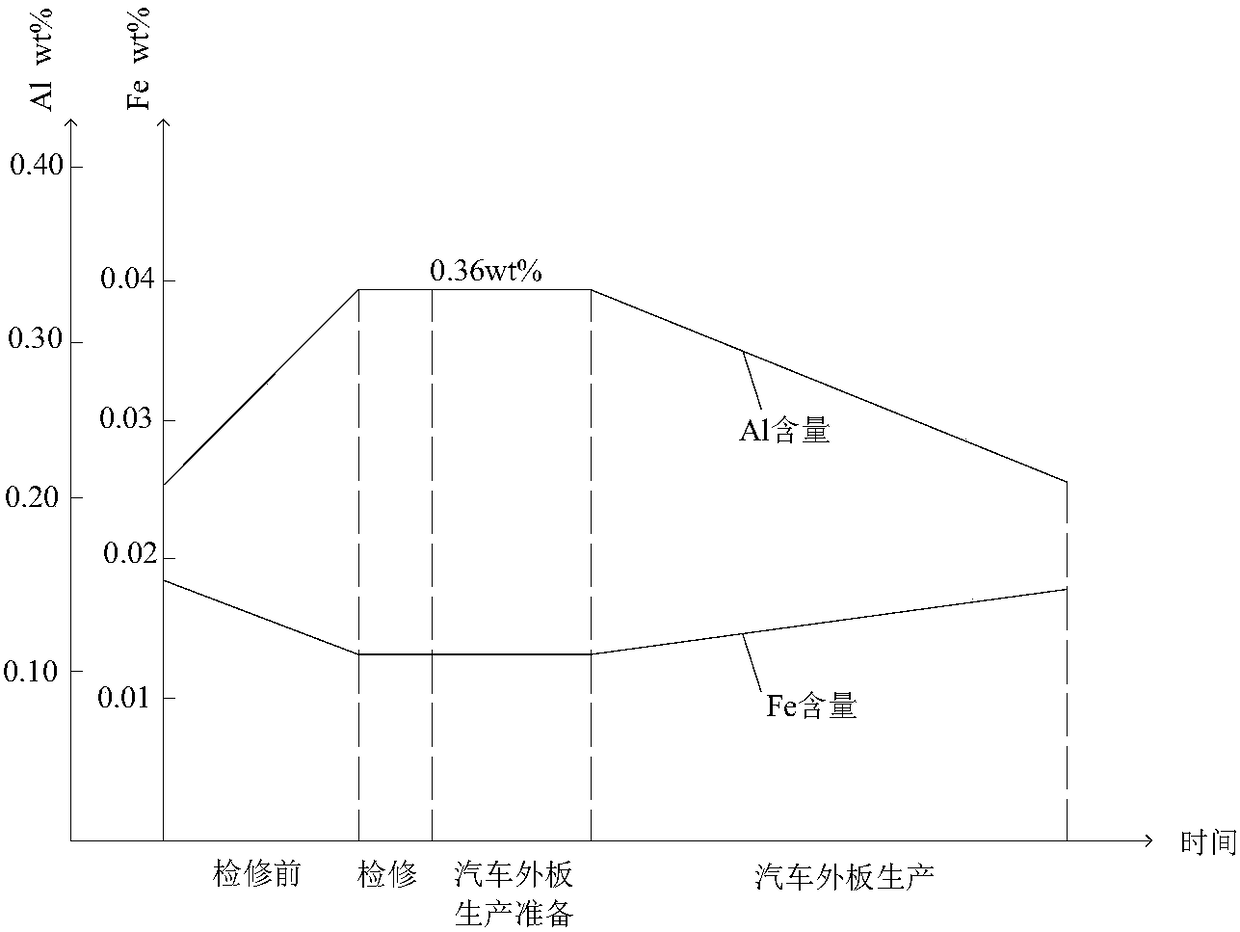

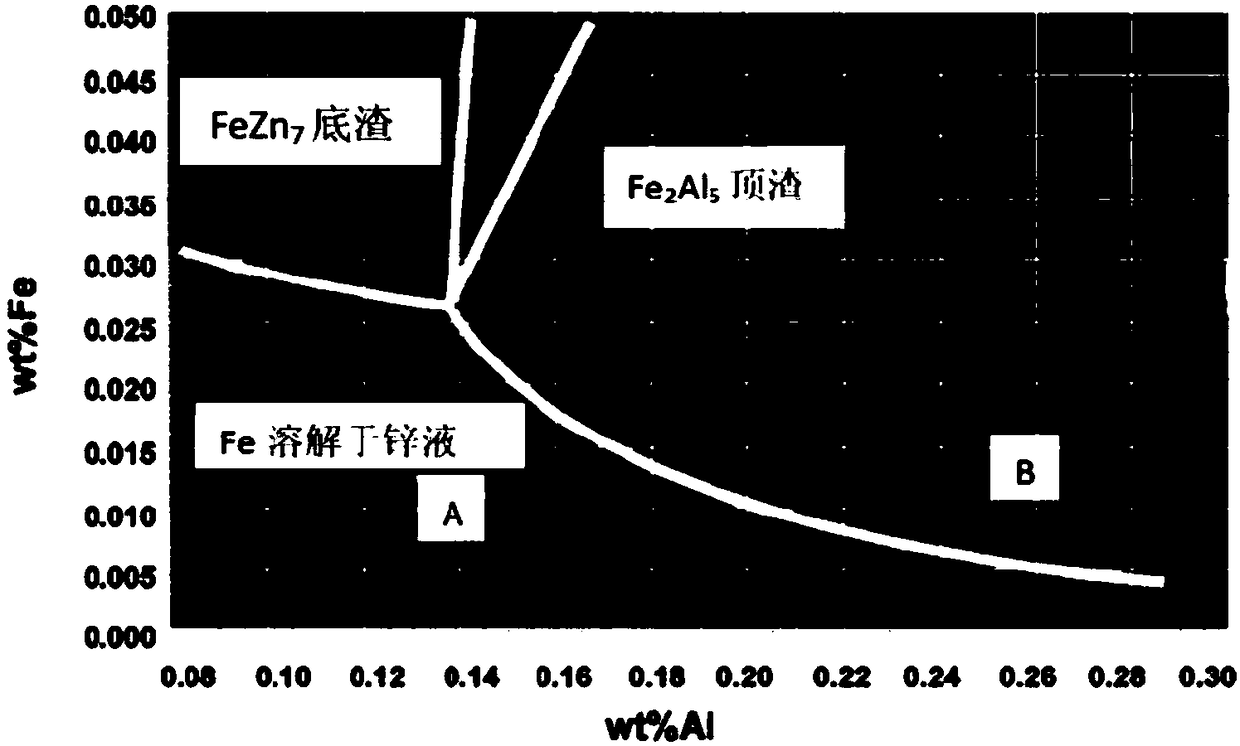

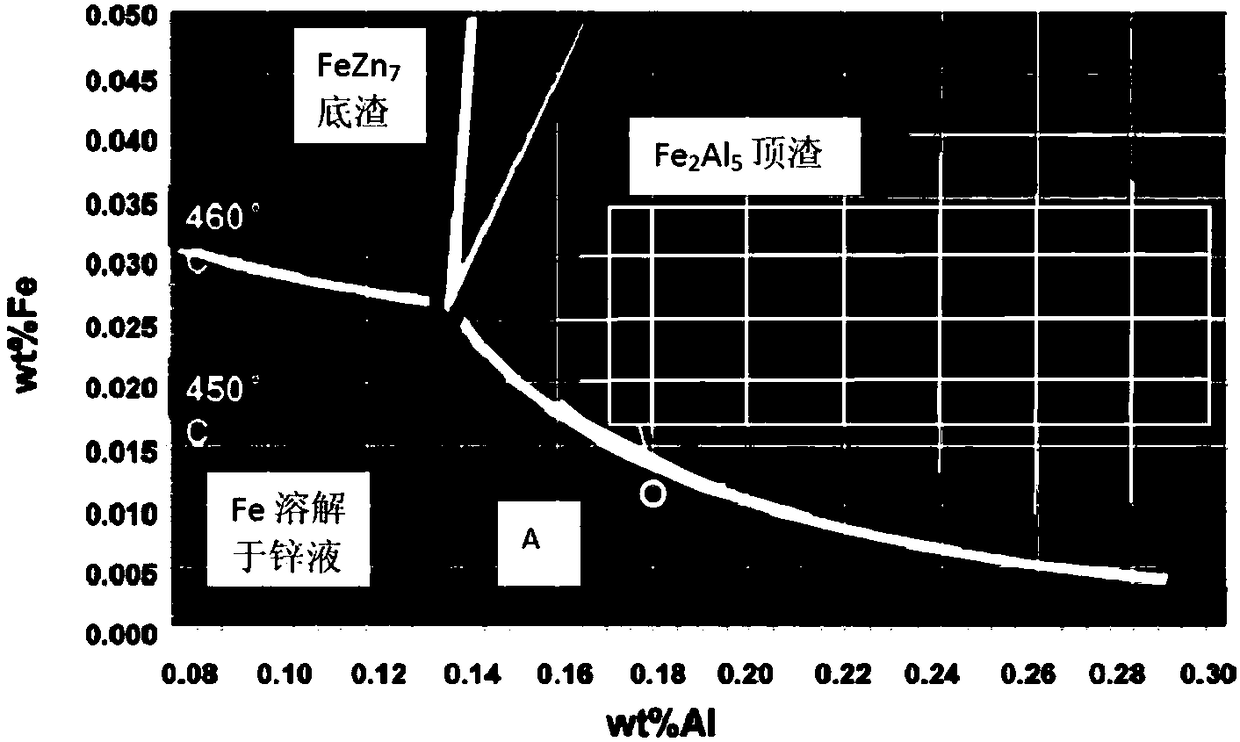

Zinc solution iron removing method before production of external continuous hot galvanized plate for automobile and production method thereof

The invention provides a Zinc solution iron removing method before the production of an external continuous hot galvanized plate for an automobile and a production method thereof, wherein the iron removing method comprises the following steps: 1) adjusting the aluminum content in the Zinc solution to be between 0.28-0.3wt%, and adjusting the temperature to 430-450 DEG C; 2) introducing inert gas into the zinc solution obtained in the step 1) and stirring, reacting the iron with aluminum, precipitating with Fe2Al5 solid particles, standing, and removing the slag. According to the method, the unreasonable part in the prior art is eliminated, the solubility of Fe in Zinc solution is controlled through the method of reducing the aluminum and the temperature, the slag-free process window for producing the outer plate of the automobile is created, the surface quality is excellently controlled, and the ideal effect is achieved.

Owner:CISDI ENG CO LTD

Method for improving surface quality of LED copper belt

InactiveCN105478471AControl surface qualityAvoid uniformityRevolution surface grinding machinesWork cleaning devicesNumerical controlThin membrane

The invention discloses a method for improving the surface quality of an LED copper belt and belongs to the field of control over the surface quality of the LED copper belt. The method includes the steps of rough rolling of a blank copper belt, primary annealing, primary cleaning, primary rolling, secondary annealing, secondary cleaning, secondary rolling, tertiary cleaning and the like. The surfaces of all rollers of a rolling mill are accurately ground through a high-precision numerical control roll grinder for primary rolling and secondary rolling, the surfaces of the rollers directly make contact with the copper belt, and the surface of the copper belt is ground. No brush roller grinding is adopted for secondary cleaning and tertiary cleaning, so that grinding non-uniformity and brush marks are avoided. When the blank copper belt is conveyed among all the procedures, a PET thin film is flatly laid on the surface of the blank copper belt, and therefore scrapes caused by direct contact of layers and the scrape problem which cannot be solved on equipment are avoided. By the adoption of the technical scheme, the scrapes in the production process can be greatly reduced, and the surface quality of the product can be improved.

Owner:ANHUI CHUJIANG TECHCAL NEW MATERIAL CO LTD

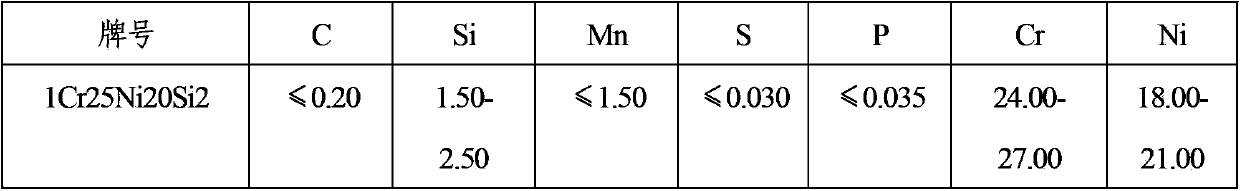

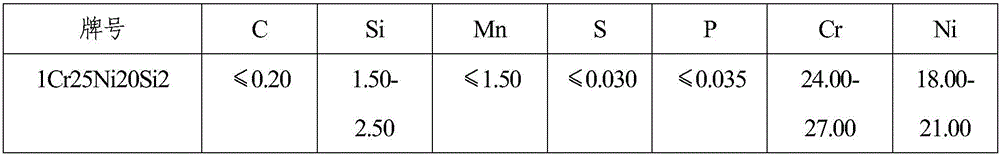

Manufacturing method for silicon-containing stainless steel seamless tube

ActiveCN103962410AShort holding timeIncrease heat treatment temperatureForward backwardHot Temperature

The invention discloses a manufacturing method for a silicon-containing stainless steel seamless tube. The method comprises the following procedures: heating of a tube blank; perforating; cold rolling; heat treatment; straightening; and pickling. In the procedure of heat treatment, a short-time high-temperature heat treatment process is employed, heat treatment temperature is 1090 to 1110 DEG C, a heat preservation coefficient is 0.8 to 1.5 min / mm, and heat preservation time is determined according to steel tube thickness and is calculated by multiplying the heat preservation coefficient with the steel tube thickness; and in the procedure of straightening, a forward-backward bidirectional straightening method is employed, backward straightening is carried out after original unidirectional straightening, so the effect of integral fragmentation of a surface oxide skin is realized. According to the invention, the short-time high-temperature heat treatment process is employed, so the surface oxide skin becomes thinner and loose after heat treatment, which facilitates easy removal of the oxide skin during pickling; the forward-backward bidirectional straightening method is employed for integral fragmentation of the surface oxide skin, so the oxide skin left in pickling is eliminated, a better fragmentation effect is exerted on the loose oxide skin, and product surface quality after pickling is further guaranteed.

Owner:宝武特种冶金有限公司

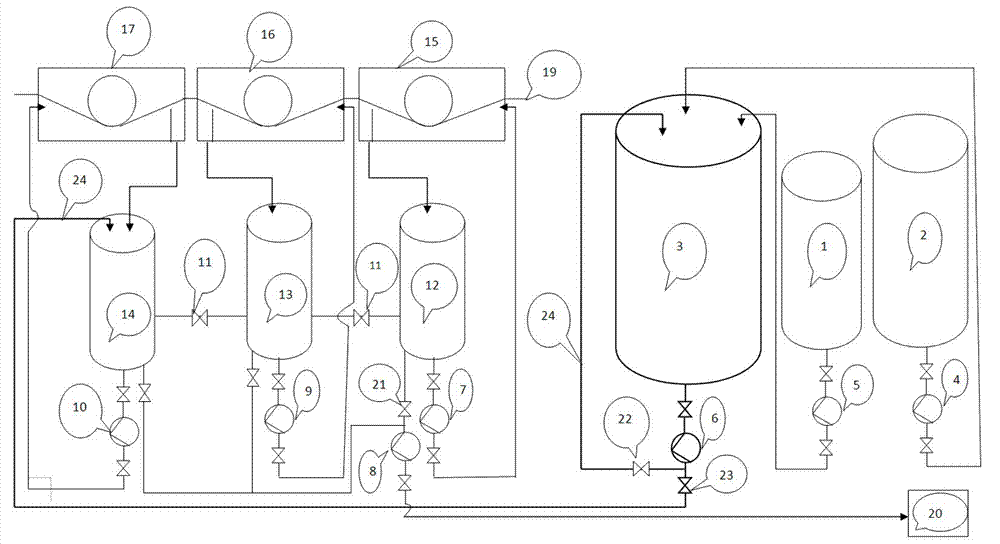

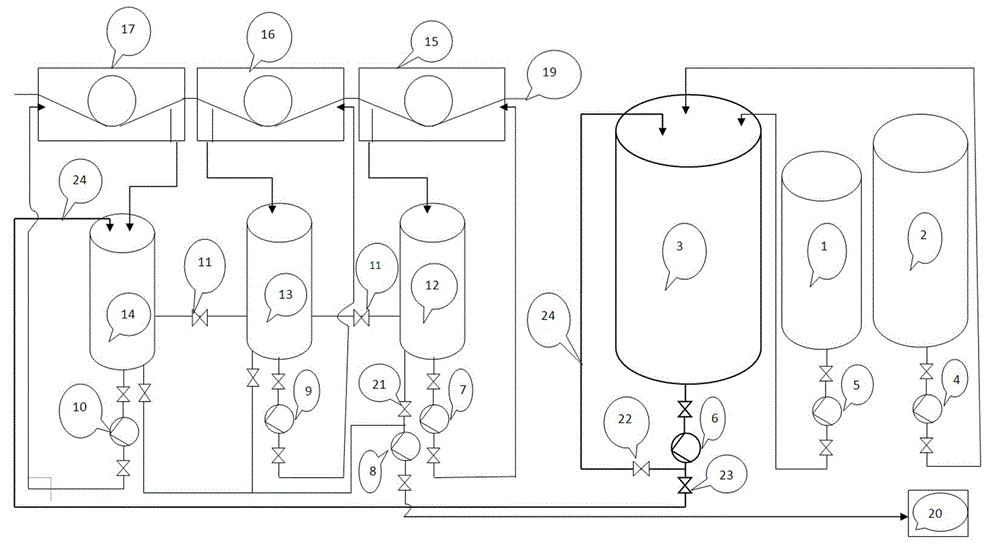

Method for controlling acid washing quality of titanium tape rolls

ActiveCN103046065AControl surface qualityStable pickling concentrationAcid washingProcess engineering

The invention discloses a method for controlling the acid washing quality of titanium tape rolls. An acid supply and drainage system for acid washing of the titanium tape rolls (19) comprises an acid preparation system and an acid washing process section. The method has the characteristics and effects that acid is supplied continuously and stably in the acid washing process section, and proper process rate and reaction temperature are matched, so that the stability of the acid washing concentration of the process section is ensured, the surface quality of the acid washed titanium tape rolls can be stably controlled, and excessive acid washing and under acid washing are prevented; the acid washing yield of the titanium rolls can be improved; the utilization rate of acid can be improved, the consumption of the acid can be reduced, the treatment quantity of waste acid is reduced, and environmental protection is facilitated; and the method is simple, easy to operate and strong in practicability.

Owner:YUNNAN TITANIUM IND

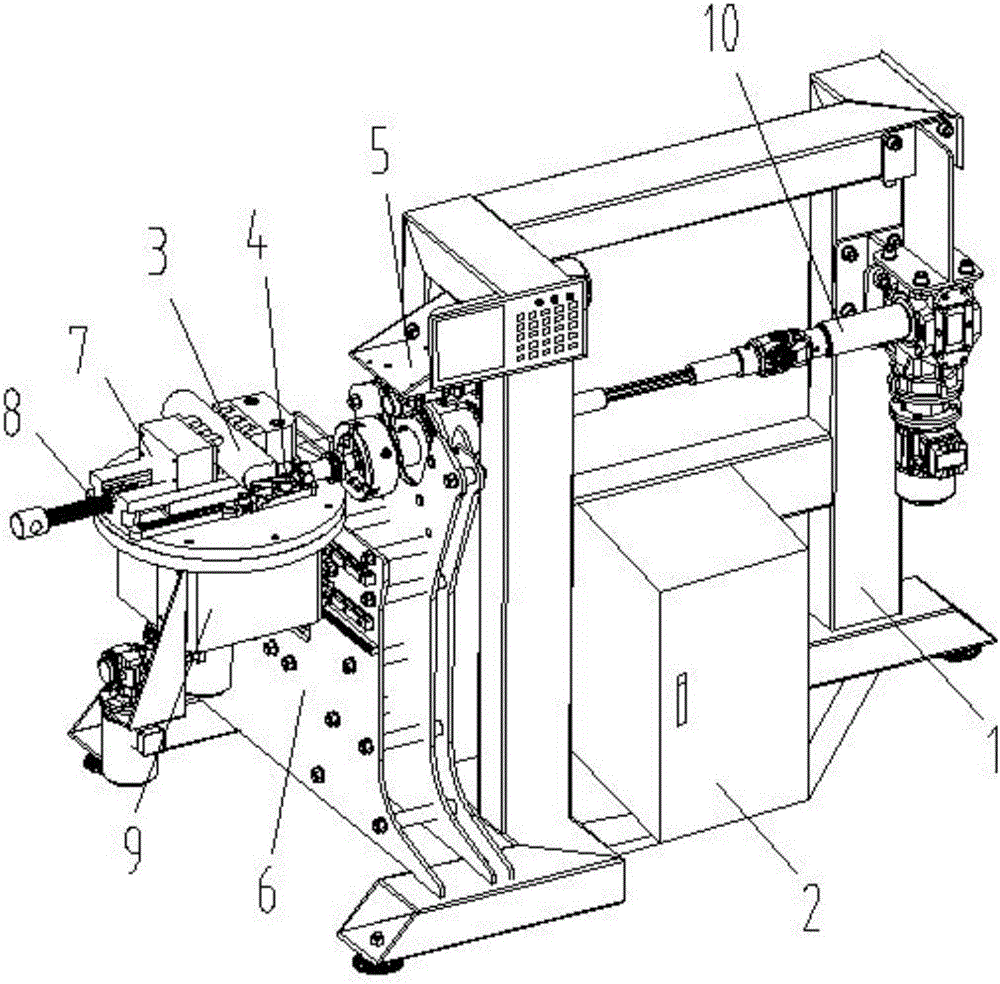

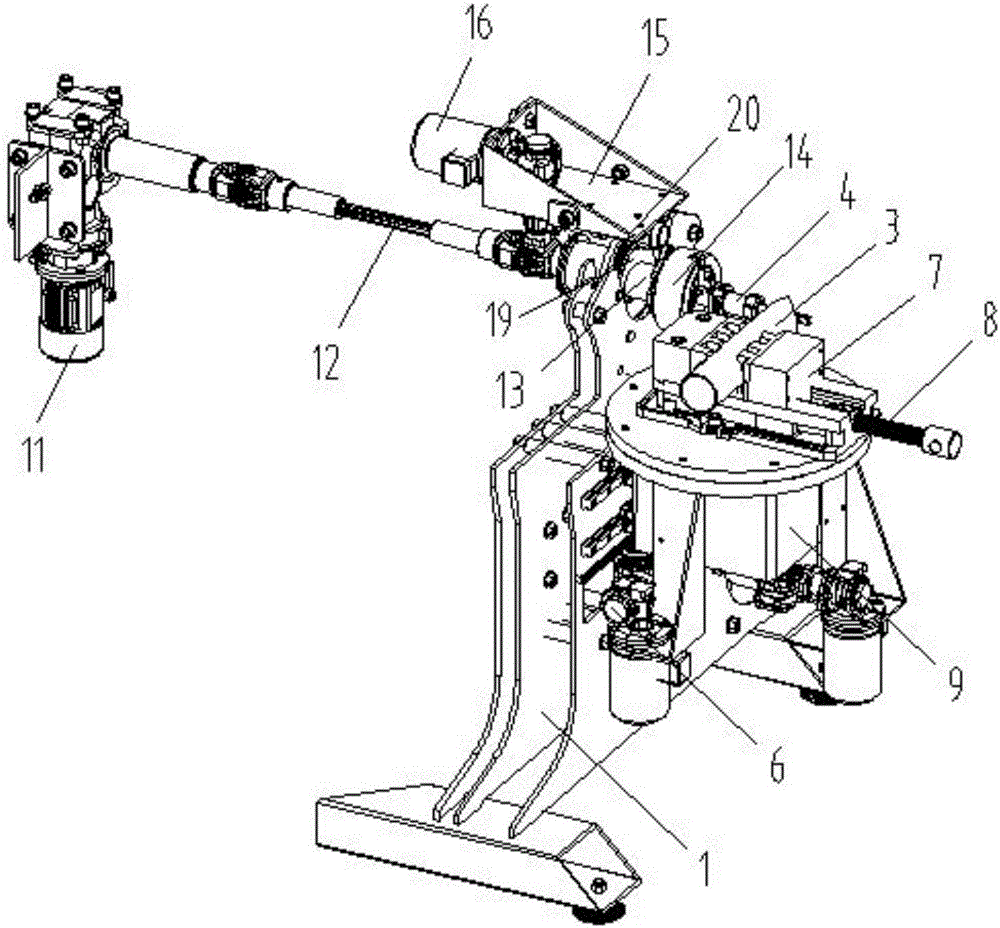

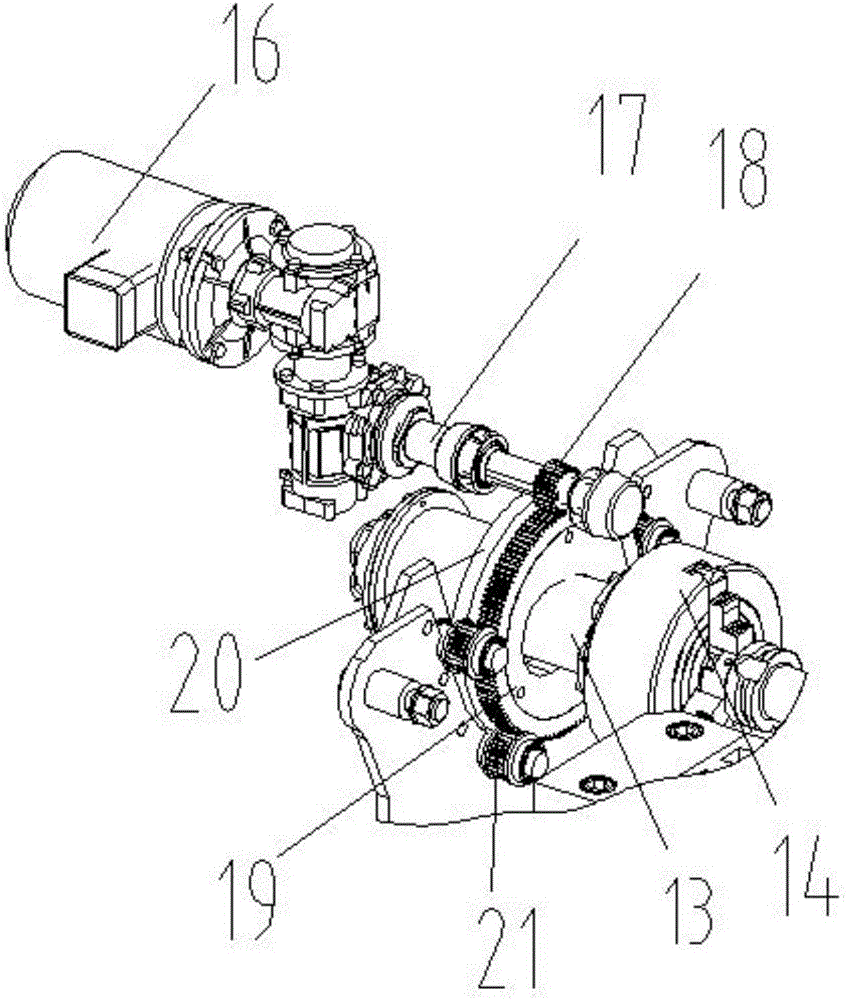

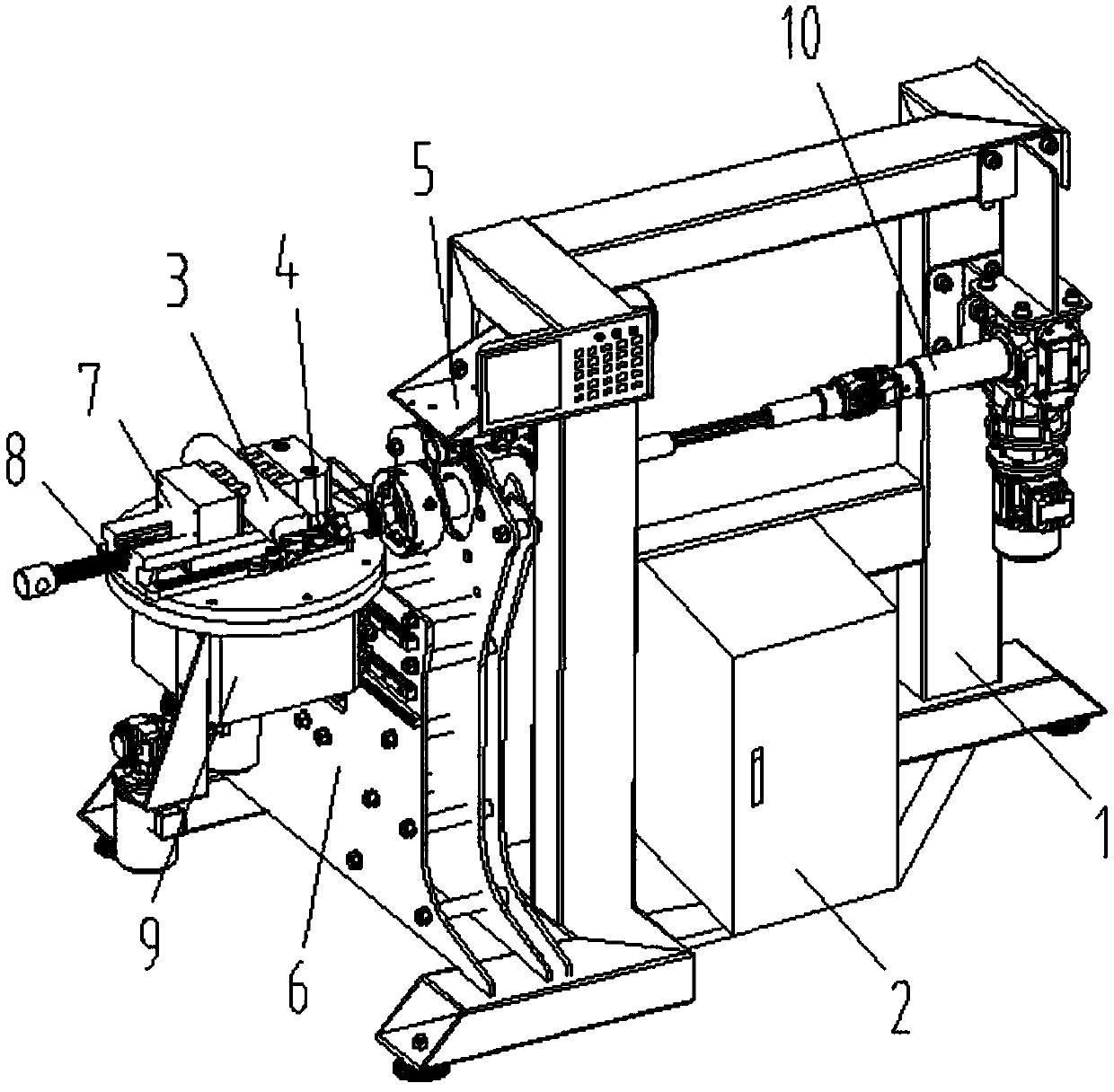

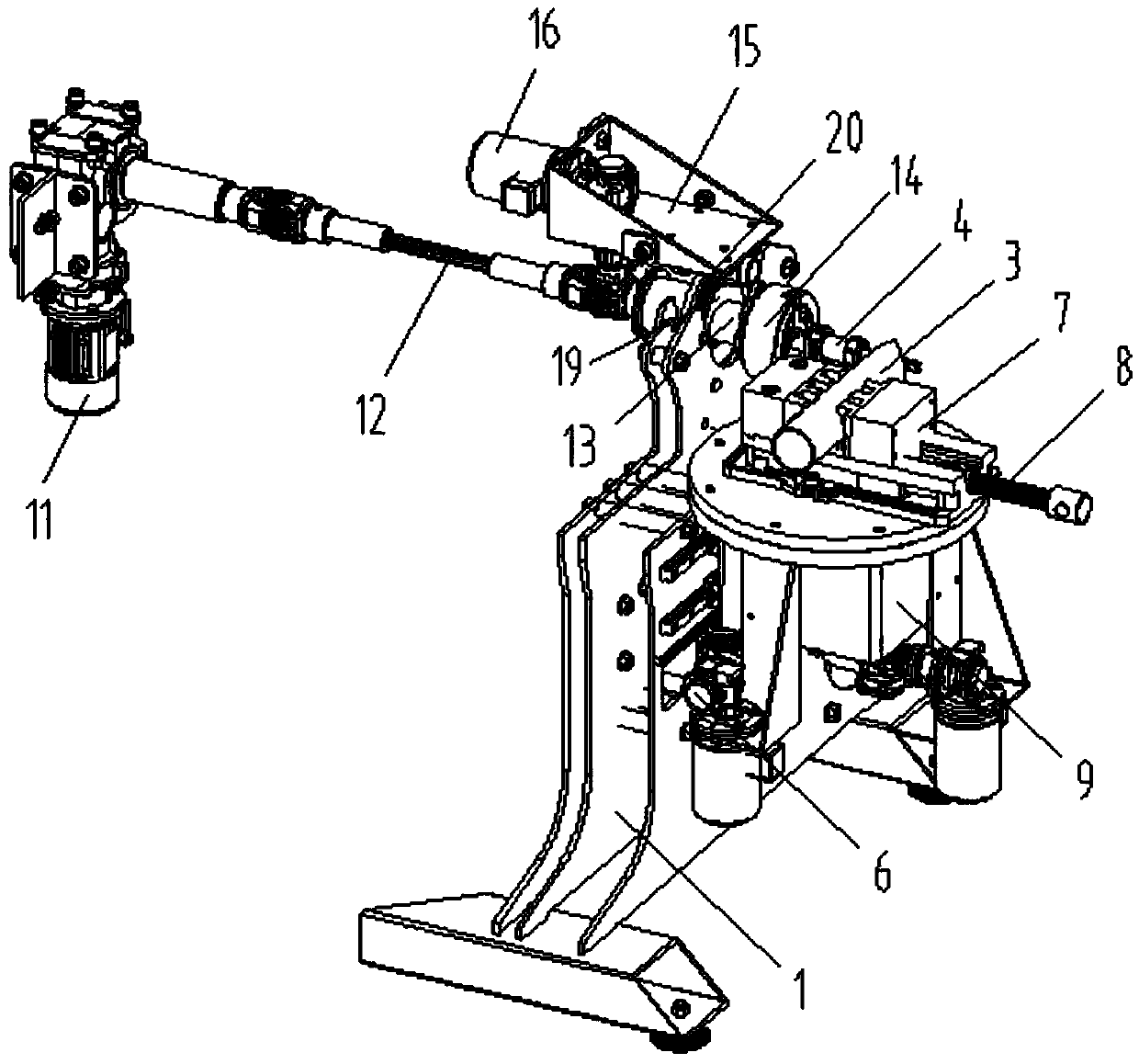

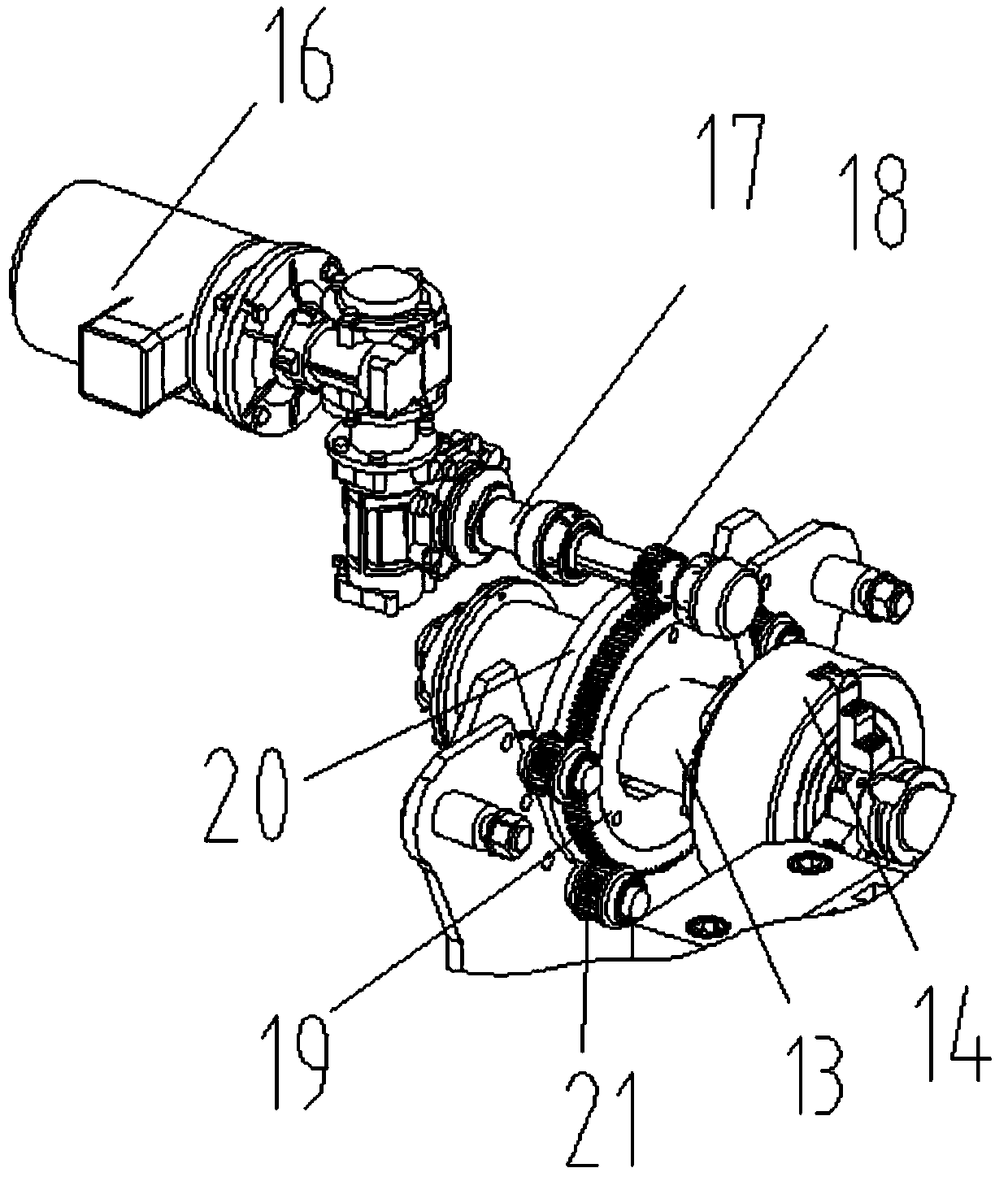

Multifunctional lathe with tool rotation function

ActiveCN106694907ASimple structureEasy to operateDriving apparatusTurning machinesRotation functionPrism

The invention relates to a multifunctional lathe with tool rotation function, comprising a frame and a power distribution box; the frame is provided with a tool rotating shaft and a tool feeding device, a tool rotator is fitted to the tool rotating shaft, an end of the tool rotating shaft is provided with a grip disc type tool mounting disc, a tool is mounted in the tool mounting disc, a product carrier is fitted to the tool, the product carrier is disposed on a carrier feeding device on the frame, the carrier and the tool have perpendicular feeding directions, and the tool feeding device, the tool rotator and the carrier feeding device are connected to the power distribution box; the tool mounting disc is mounted on the tool rotating shaft and connected to the tool rotator, the tool feeding device is fitted to the carrier that can provide forward and backward feeding, processing a product in various shapes via various techniques can be achieved through changing the tool, tool feeding can be fitted to carrier feeding, a sidewall can be turned into a polygonal prism shape, and the surface quality of a workpiece can be controlled well.

Owner:南京市溧水同发机械刀模具制造有限公司

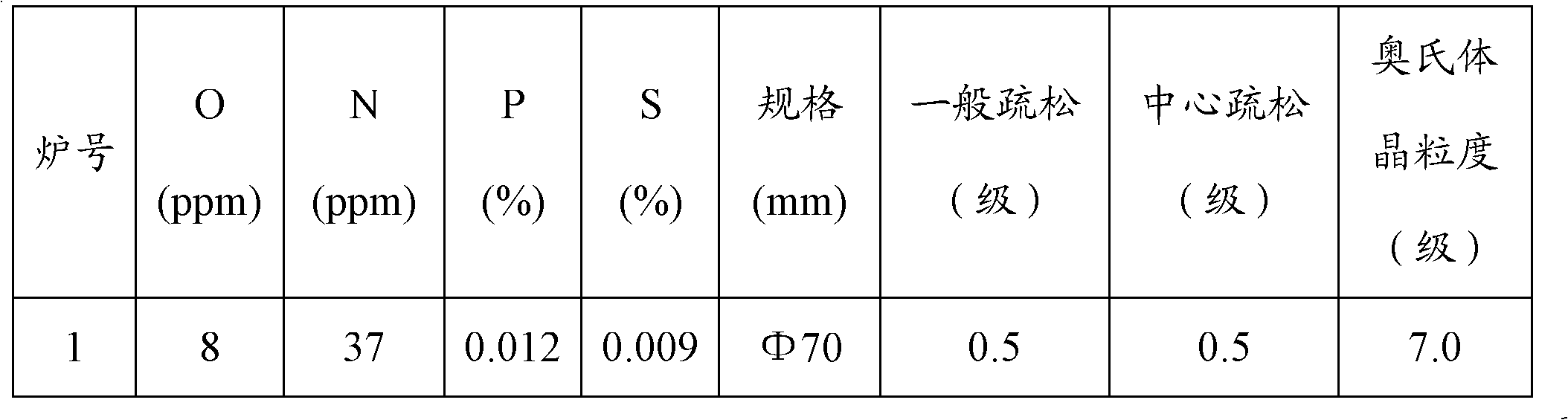

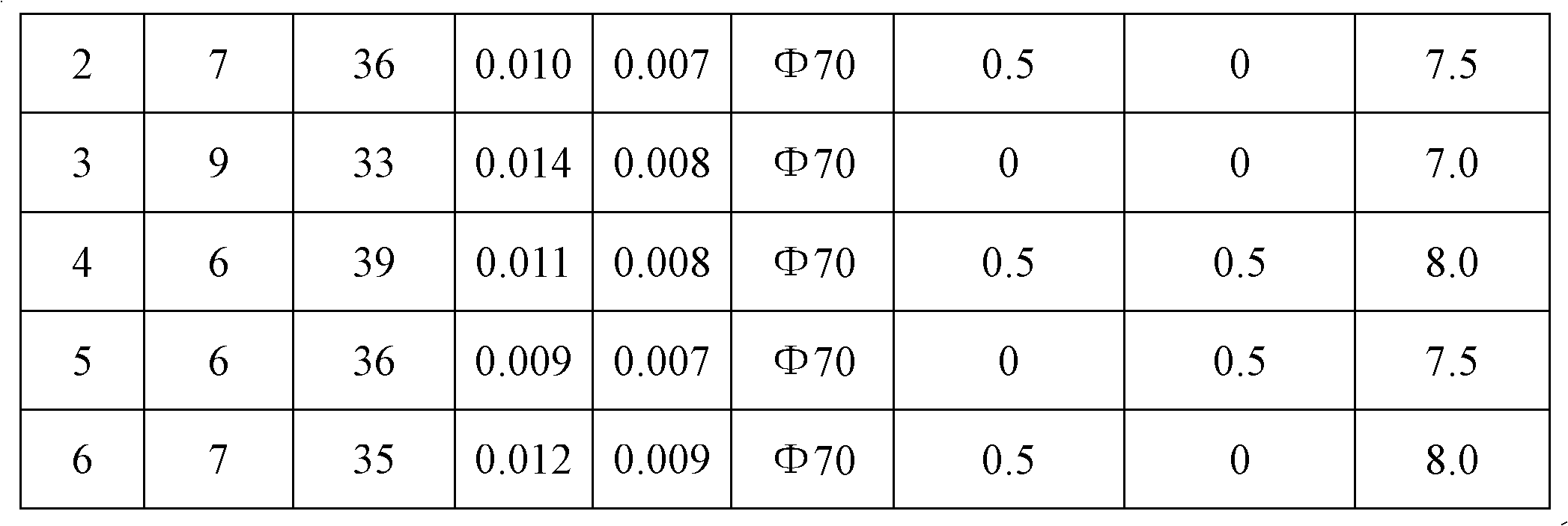

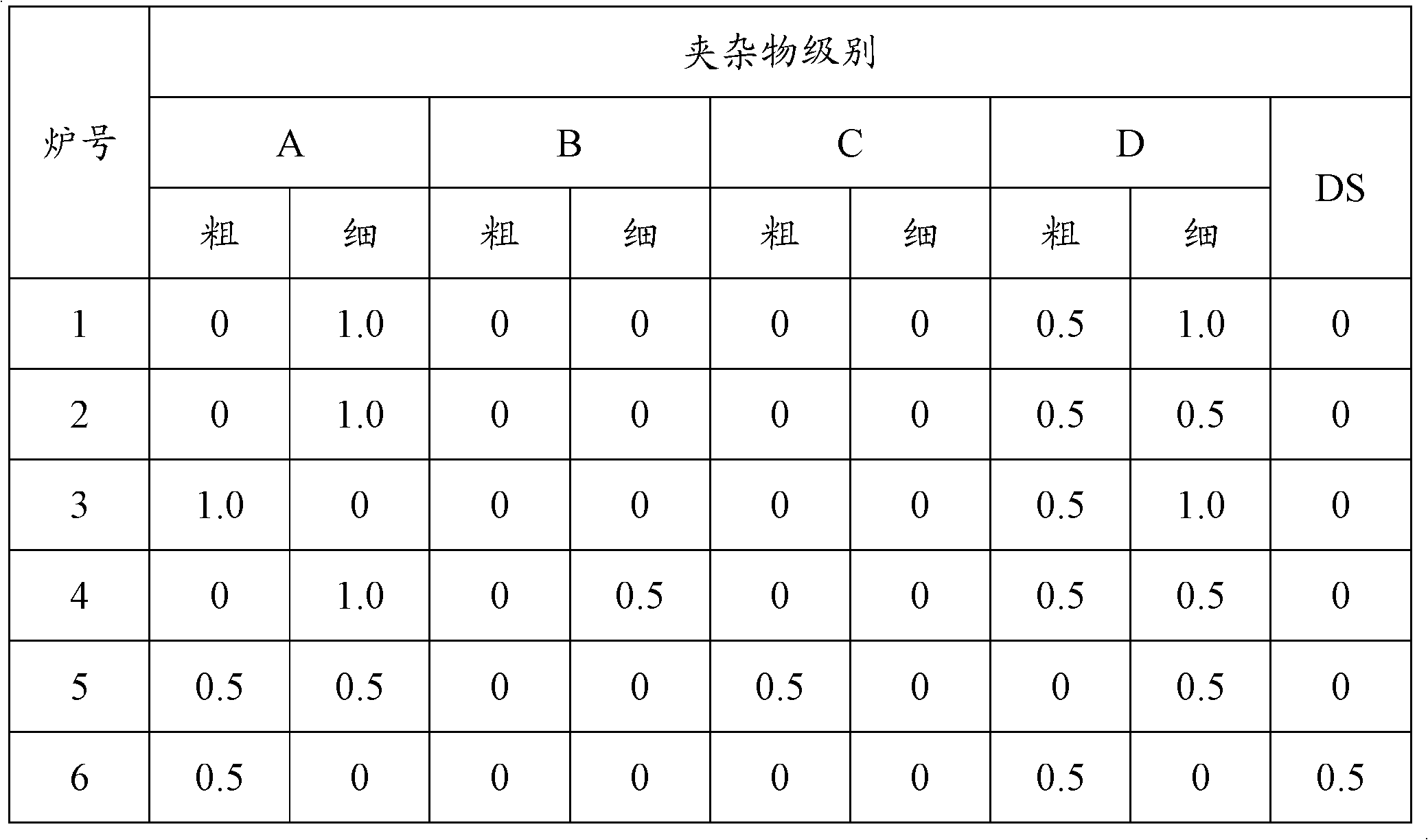

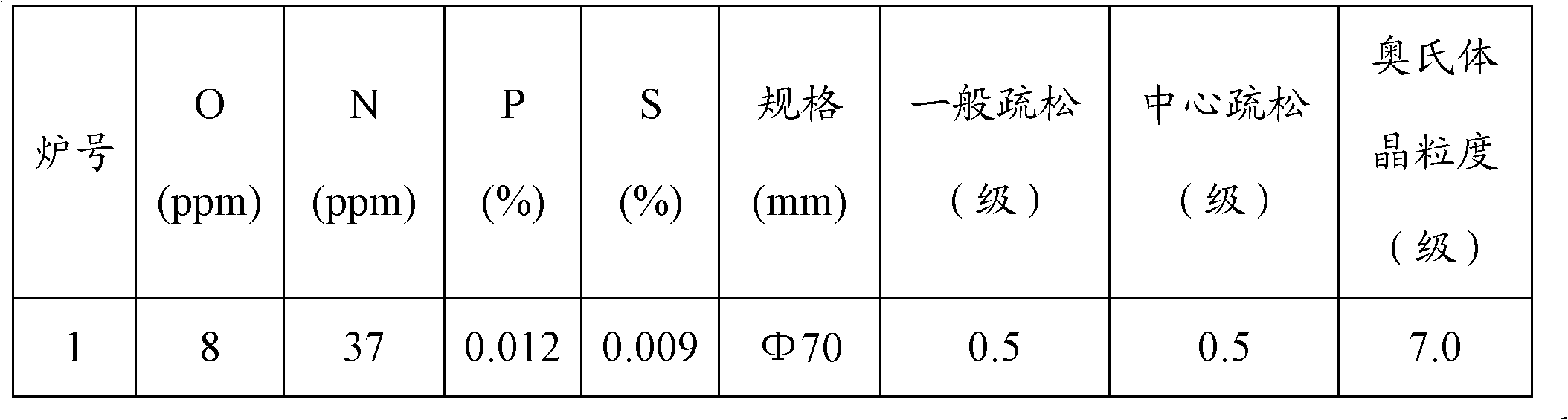

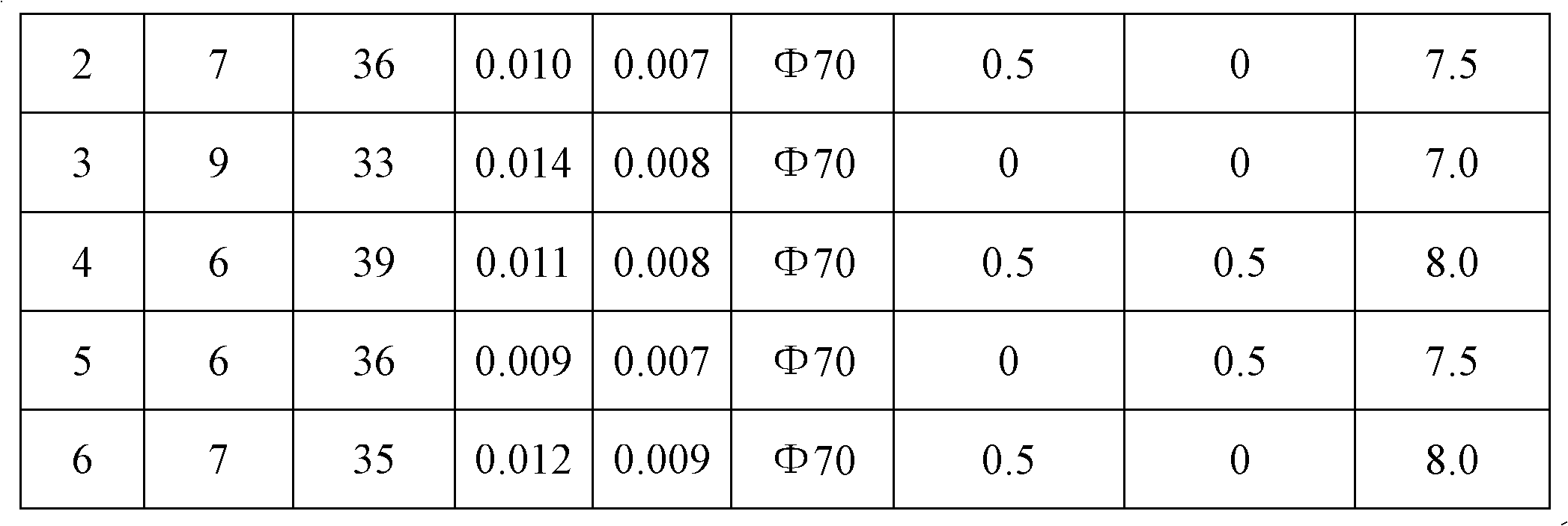

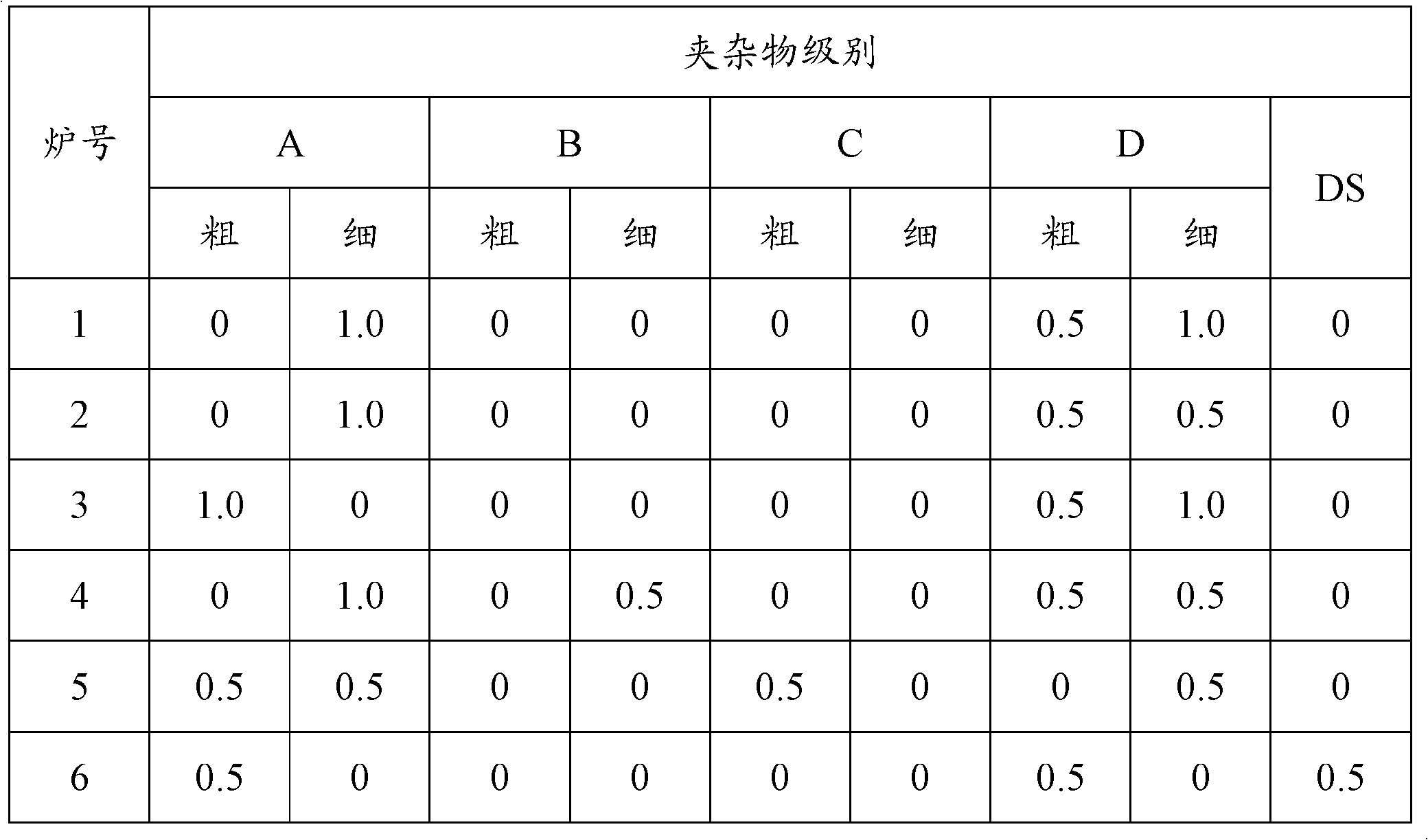

37Mn5 steel and production technology thereof

InactiveCN102382929AIncrease oxygen contentReduce oxygen contentManufacturing convertersRigid pipesPorosityGranularity

The invention relates to 37Mn5 steel. The 37Mn5 steel is characterized by containing less than or equal to 15ppm of O, less than or equal to 0.015 percent of P and less than or equal to 0.010 percent of S; the center porosity is less than or equal to level 1.0; the steel has no visual shrinkage cavities, bubbles, cracks, inclusions, skull patches or white spots; and the sum of nonmetallic inclusion levels is less than or equal to level 3, the banded structure is less than or equal to level 2, and the granularity is level 6 to 8. A production technology of the 37Mn5 steel comprises the following processes of: (1) converter treatment, (2) refining, (3) continuous casting, (4) steel rolling and (5) finishing. The 37Mn5 steel can be used for producing thin-wall pipes.

Owner:CHENGDE JIANLONG SPECIAL STEEL

Efficient pollution-free wax mould cleaning agent and preparing method thereof

InactiveCN106010816AConvenient sourceEasily biodegradableInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsCleansing AgentsFatty acid

The invention discloses an efficient pollution-free wax mould cleaning agent. The efficient pollution-free wax mould cleaning agent is prepared from, by weight, 20-25 parts of octylphenol polyoxyethylene ether, 12-15 parts of salicylic acid, 8-16 parts of acetamide, 10-16 parts of 2-hydroxyphosphonoacetic acid, 9-12 parts of propylene glycol monomethyl ether, 6-10 parts of butanone, 10-15 parts of cyclohexane, 5-12 parts of nonylphenol polyoxyethylene ether, 18-25 parts of fatty acid polyoxyethylene ether sulfate, 10-15 parts of alkyl benzene sulfonic acid, 6-15 parts of triethanolamine, 14-20 parts of fatty alcohol polyvinyl ether, 6-8 parts of sodium silicate, 9-14 parts of sodium gluconate, 16-18 parts of ethyl alcohol, 12-16 parts of isopropanol, 5-9 parts of trichloro ethylene and 120-150 parts of deionized water. The preparing method is simple, the process is reasonable and is conducted at normal temperature and normal pressure, operation is convenient, and control is easy; meanwhile, raw materials are widely available, investment is low, cost is low, and market potential is great; the number of residues left after a wax mould is cleaned is small, and the surface quality of a casting is easy to control; the cleaning agent is free of corrosion or toxicity to skin, an adopted surfactant can be biodegraded easily, and environment pollution and air pollution are avoided.

Owner:安徽宜安精密机械零部件有限公司

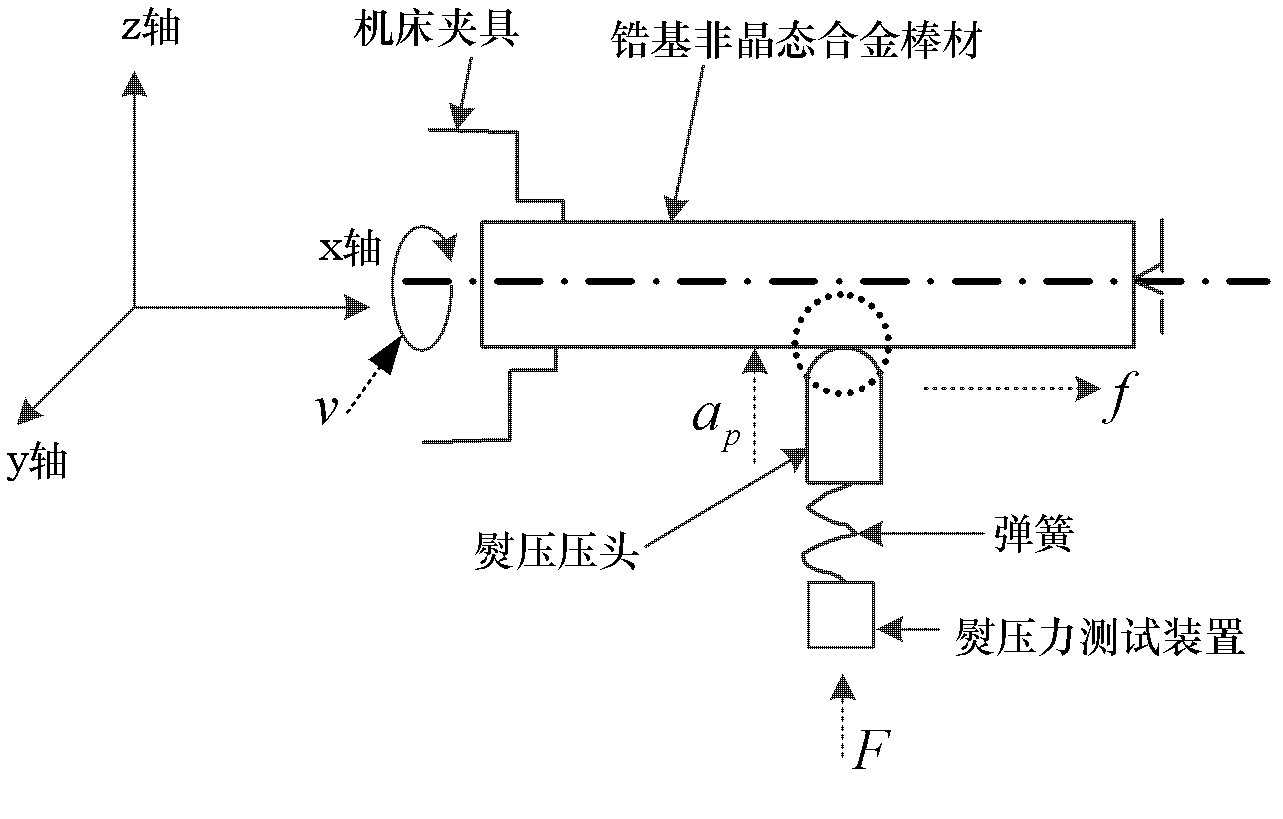

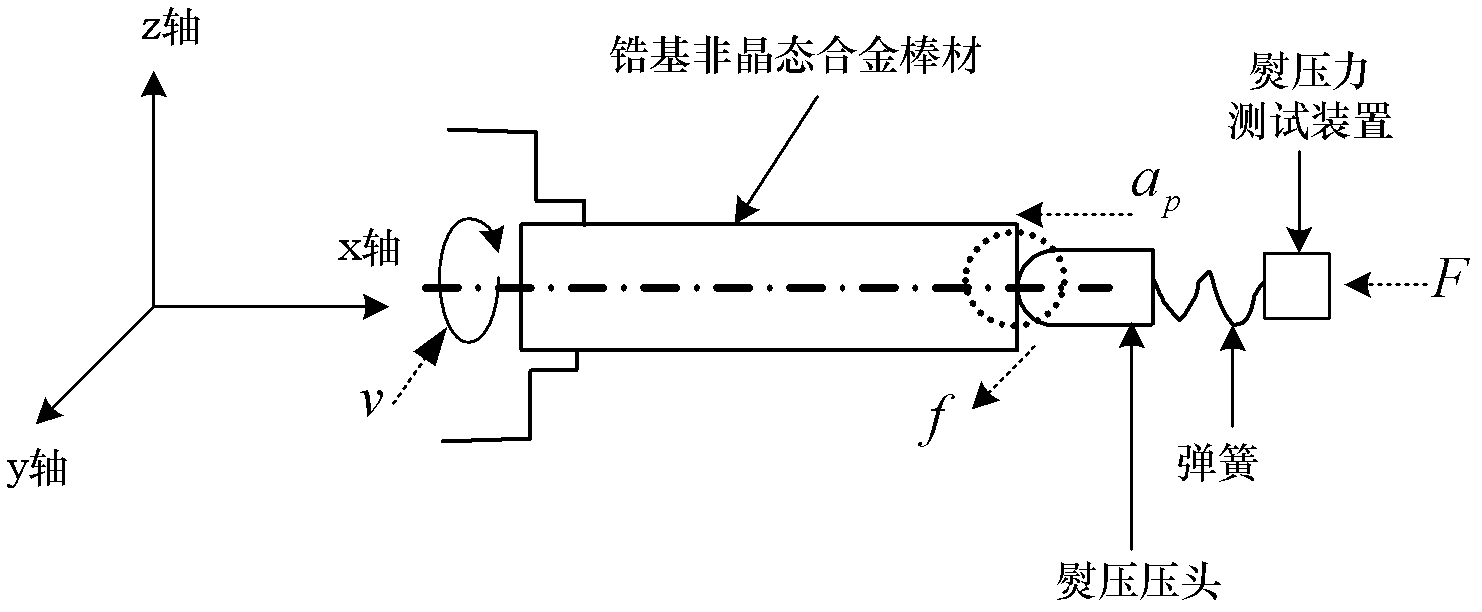

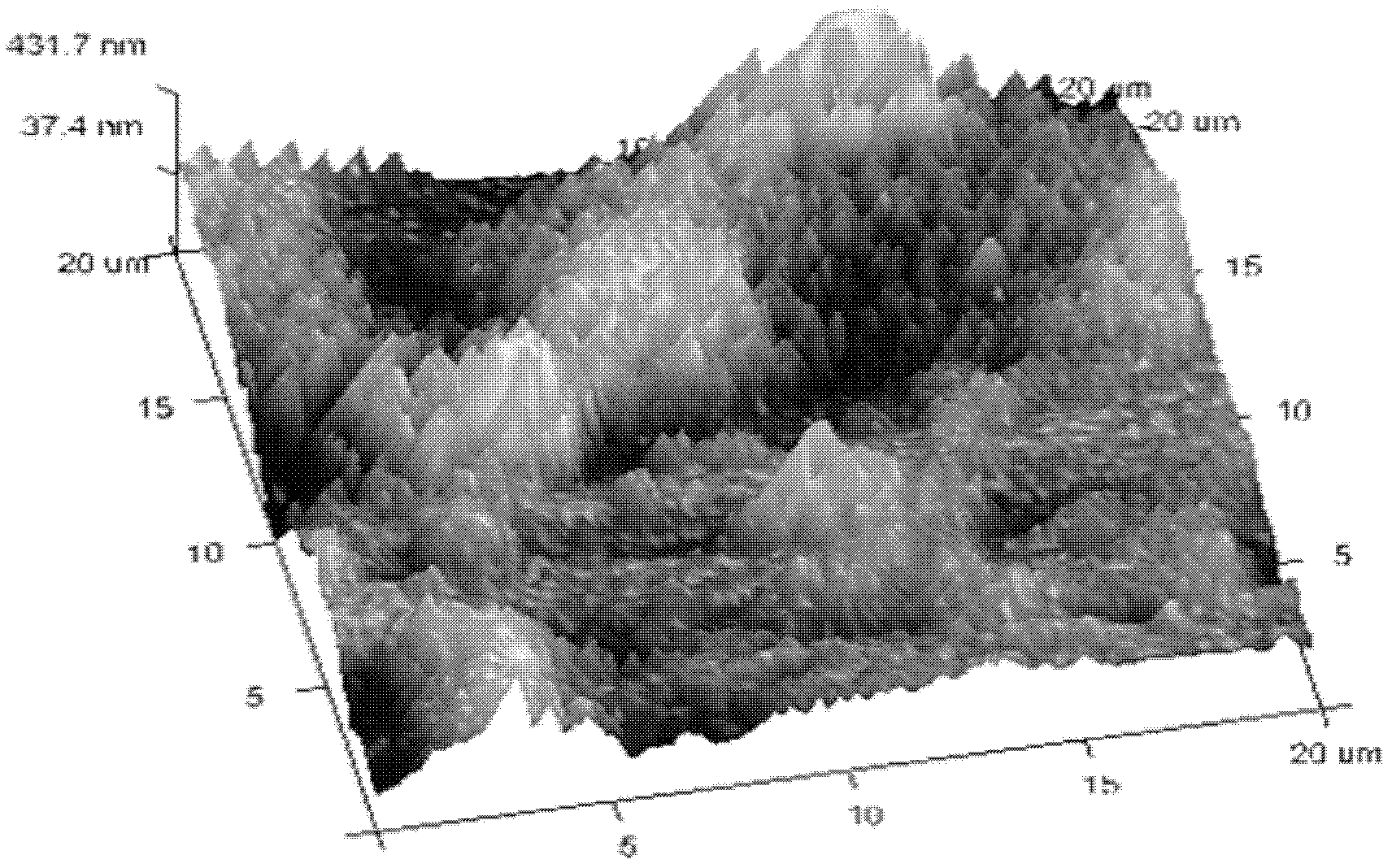

Copper mould casting and ironing combined method for preparing corrosion-resistant Zr-based amorphous alloy

The invention discloses a copper mould casting and ironing combined method for preparing corrosion-resistant Zr-based amorphous alloy. The method comprises the following steps: preparing a Zr-based amorphous alloy rod through a copper mould casting process; and carrying out surface treatment on the Zr-based amorphous alloy rod through an ironing process, so as to reduce roughness and obtain the corrosion-resistant Zr-based amorphous alloy.

Owner:BEIHANG UNIV

Method for controlling pin positioning accuracy by seamless tube extrusion locking pin process

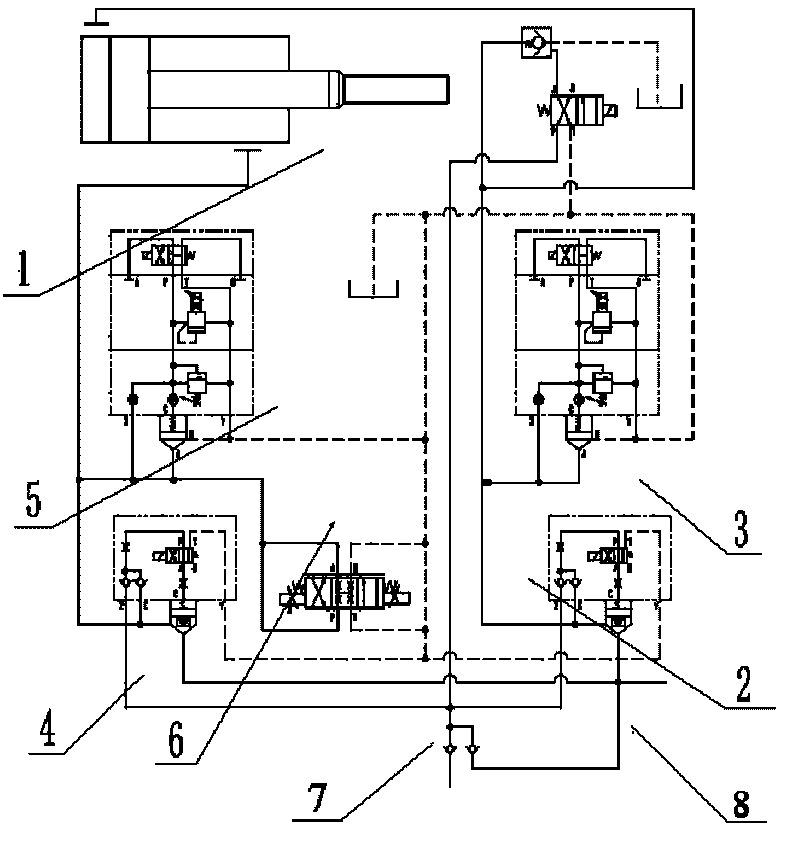

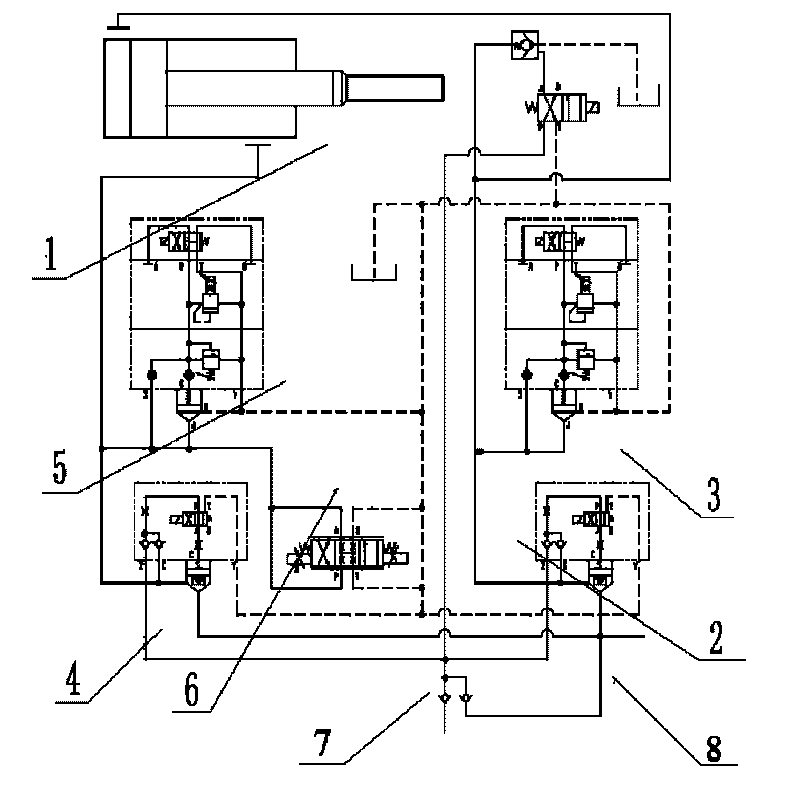

InactiveCN101733301ARapid control forwardQuick control backExtrusion control devicesEngineeringMechanical engineering

The invention belongs to the field of metallurgic equipment, relates to a method for controlling pin positioning accuracy for pecker locking in an extruder, in particular to a method for controlling the pin positioning accuracy by a seamless tube extruding locking pin process. The method is characterized by comprising a perforation cylinder, a filling valve of a piston cavity, a drain valve of the piston cavity, a filling valve of a piston rod cavity and a drain valve of the piston rod cavity, wherein an oil path of the piston cavity of the perforation cylinder is connected with the filling valve of the piston cavity and the drain valve of the piston valve; an oil path of the piston rod cavity of the perforation cylinder is provided with the filling valve of the piston rod cavity and the drain valve of the piston rod cavity; and the filling valve of the piston cavity of the perforation cylinder, the drain valve of the piston cavity, the filling valve of the piston rod cavity and the drain valve of the piston rod cavity control the perforation cylinder to move forwards and backwards. The invention provides the method for controlling the pin positioning accuracy by the seamless tube extruding locking pin process capable of improving the response speed of the perforation cylinder and the pin positioning accuracy for pecker locking and the inner surface quality of tubes.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Production technology of 37Mn5 steel

InactiveCN102382929BIncrease oxygen contentReduce oxygen contentManufacturing convertersRigid pipesPorosityGranularity

The invention relates to 37Mn5 steel. The 37Mn5 steel is characterized by containing less than or equal to 15ppm of O, less than or equal to 0.015 percent of P and less than or equal to 0.010 percent of S; the center porosity is less than or equal to level 1.0; the steel has no visual shrinkage cavities, bubbles, cracks, inclusions, skull patches or white spots; and the sum of nonmetallic inclusion levels is less than or equal to level 3, the banded structure is less than or equal to level 2, and the granularity is level 6 to 8. A production technology of the 37Mn5 steel comprises the following processes of: (1) converter treatment, (2) refining, (3) continuous casting, (4) steel rolling and (5) finishing. The 37Mn5 steel can be used for producing thin-wall pipes.

Owner:CHENGDE JIANLONG SPECIAL STEEL

A small size led copper strip production process

ActiveCN108155281BGuaranteed roughnessEliminate work hardeningSemiconductor devicesIngot castingIndustrial engineering

The invention discloses a small-size LED copper strip production process, and belongs to the technical field of the copper strip production process. The production process includes the following stepsof (1) smelting and ingot casting, (2) hot rolling, (3) milling, (4) rough rolling, (5) first annealing, (6) one-step cleaning, (7) intermediate rolling, (8) secondary annealing, (9) secondary cleaning, (10) intermediate finish rolling, (11) third annealing, (12) third cleaning, (13) finish rolling, (14) unwinding, (15) fourth annealing, (16) fourth cleaning, (17) refine rolling, (18) fifth cleaning, (19) flattening and (20) cutting and delivery. According to the technical scheme, the quality of small-size LED copper strips can be improved, the workshop cost is reduced, and the production profits are increased.

Owner:ANHUI CHUJIANG TECHCAL NEW MATERIAL CO LTD

A kind of manufacturing method of silicon-containing stainless steel seamless pipe

The invention discloses a manufacturing method for a silicon-containing stainless steel seamless tube. The method comprises the following procedures: heating of a tube blank; perforating; cold rolling; heat treatment; straightening; and pickling. In the procedure of heat treatment, a short-time high-temperature heat treatment process is employed, heat treatment temperature is 1090 to 1110 DEG C, a heat preservation coefficient is 0.8 to 1.5 min / mm, and heat preservation time is determined according to steel tube thickness and is calculated by multiplying the heat preservation coefficient with the steel tube thickness; and in the procedure of straightening, a forward-backward bidirectional straightening method is employed, backward straightening is carried out after original unidirectional straightening, so the effect of integral fragmentation of a surface oxide skin is realized. According to the invention, the short-time high-temperature heat treatment process is employed, so the surface oxide skin becomes thinner and loose after heat treatment, which facilitates easy removal of the oxide skin during pickling; the forward-backward bidirectional straightening method is employed for integral fragmentation of the surface oxide skin, so the oxide skin left in pickling is eliminated, a better fragmentation effect is exerted on the loose oxide skin, and product surface quality after pickling is further guaranteed.

Owner:宝武特种冶金有限公司

Method for rolling thin high-strength steel plate of single-frame steckel mill

ActiveCN102179406BGrain refinementEliminate temperature differenceRoll force/gap control deviceTemperature control deviceFurnace temperatureSheet steel

The invention discloses a method for rolling a thin high-strength steel plate of a single-frame steckel mill. The method comprises the following steps: producing the finished product of a high-strength steel plate with a thickness less than 10 millimeters by using a blank with the thickness of 150 millimeters and the length more than 10 meters; and then acquiring the thin high-strength steel plate with qualified property and plate shape by controlling a tapping temperature, a coiler furnace temperature, a reduction in last pass, a roller force, a final rolling speed and a high pressure water de-scaling system. When the rolling method is used for producing the thin steel plate, the thin high-strength steel plate is rolled by utilizing the heat preservation function of front and back mill coiler furnaces and controlling the tapping temperature of the blank, the reduction in the last rolling pass, the roller force and the final rolling speed, and the acquired plate shape and property of the steel plate are both qualified, thereby increasing the rolling mill capacity and achieving high plate yield and high property yield.

Owner:NANJING IRON & STEEL CO LTD

Adhesion method for optical glass with film-coating marked surface

The invention discloses an adhesion method for optical glass with a film-coating marked surface. The method includes: selecting a proper glass cushion and wiping the glass cushion; determining that the to-be-processed optical glass with the film-coating marked surface is free of damage; keeping optical protective glue and beeswax for adhesion clean, and selecting a hairbrush which must be made ofwool, which is not liable to fall off, length of the wool being larger than that of the to-be-processed glass. The method can effectively control the surface quality of the components after processing, and prevent the film-coating surfaces of the components from fouling and scratch, and can avoid edge breakage during shape processing and punching for forming bottoms of pores.

Owner:SHANGHAI MODERN ADVANCED ULTRA PRECISION MFG CENT

Technology improving scratches on surface of copper material used for LED lamp supports

InactiveCN105344711AControl surface qualityAvoid uniformityRollsWork cleaning devicesNumerical controlCopper

The invention discloses a technology improving scratches on the surface of a copper material used for an LED lamp support and belongs to the field of quality control over the surface of the copper material used for the LED lamp support. The technology includes rough rolling, primary annealing, primary cleaning, primary rolling, secondary annealing, secondary cleaning, secondary rolling, third-time cleaning and other steps. During primary rolling and secondary rolling, the surfaces of rollers of a rolling mill are fine ground through a high-precision numerical control roll grinder; the surfaces of the rollers directly make contact with the copper material; and the surface of the copper material is ground. During secondary cleaning and third-time cleaning, no brush rollers are adopted for grinding, and uneven grinding and brush marks are avoided. When the blank copper material is conveyed between the procedures, a layer of cigarette paper is flatly laid on the surface of the blank copper material, and friction scratches caused by direct contact between layers and the friction scratch problem which cannot be solved on equipment are avoided. By means of the technical scheme, the friction scratches generated in the production process can be substantially reduced, and the surface quality of products is improved.

Owner:ANHUI CHUJIANG TECHCAL NEW MATERIAL CO LTD

A Method for Steadily Controlling the Pickling Quality of Titanium Coils

ActiveCN103046065BControl surface qualityStable pickling concentrationAcid washingProcess engineering

The invention discloses a method for controlling the acid washing quality of titanium tape rolls. An acid supply and drainage system for acid washing of the titanium tape rolls (19) comprises an acid preparation system and an acid washing process section. The method has the characteristics and effects that acid is supplied continuously and stably in the acid washing process section, and proper process rate and reaction temperature are matched, so that the stability of the acid washing concentration of the process section is ensured, the surface quality of the acid washed titanium tape rolls can be stably controlled, and excessive acid washing and under acid washing are prevented; the acid washing yield of the titanium rolls can be improved; the utilization rate of acid can be improved, the consumption of the acid can be reduced, the treatment quantity of waste acid is reduced, and environmental protection is facilitated; and the method is simple, easy to operate and strong in practicability.

Owner:YUNNAN TITANIUM IND

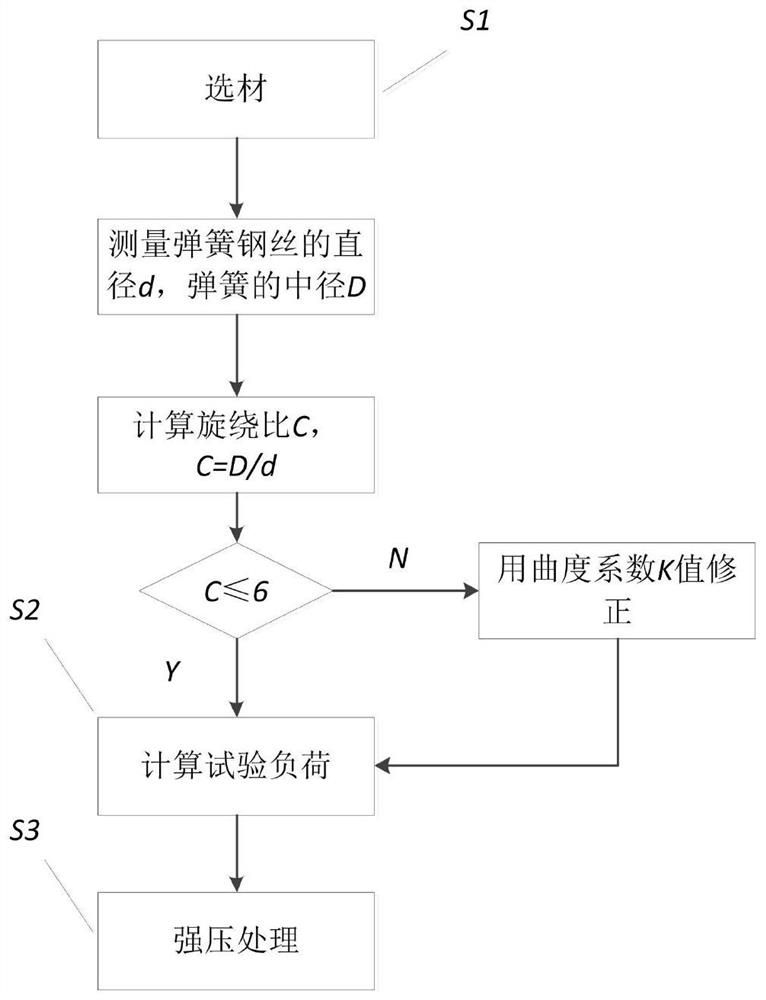

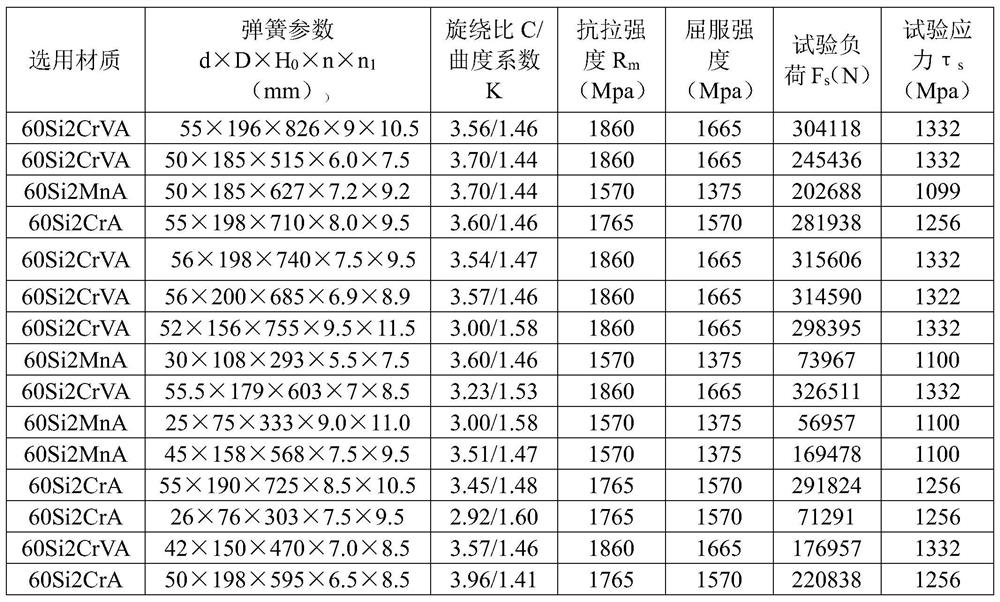

Selection method for determining test stress corresponding to test load during spring prestressing treatment

PendingCN111931308AFulfil requirementsMeet the drawing requirementsGeometric CADDesign optimisation/simulationSpring steelUltimate tensile strength

The invention relates to a selection method for determining test stress corresponding to a test load during spring prestressing treatment. The selection method comprises the following steps: S1, selecting materials including selecting spring steel made of three materials, namely 60Si2MnA, 60Si2CrA and 60Si2CrVA; S2, calculating a test load including setting a test load as Fs and spring steel teststresses of different materials as tau s, and calculating according to a calculation formula (1) or a calculation formula (2), wherein the calculation formula (1) is calculated and determined according to 70% of the lower limit value of the tensile strength required by the design: tau s = 0.7 sigma b (1), or the calculation formula (2) is as follows: tau s is equal to 0.8 sigma s (2) according to80% of the yield strength required by the spring steel design; taking a larger value of results obtained in the calculation formula (1) and the calculation formula (2); calculating the test load according to a calculation formula (3); S3, carrying out prestressing treatment under the condition that the test stresses corresponding to the three materials of 60Si2MnA, 60Si2CrA and 60Si2CrVA are addedwith 5% of test load or the deformation of 3mm of the spring. Product reliability is improved.

Owner:无锡金峰园弹簧制造有限公司

Nine-point control variable margin milling method for thin-walled blades based on newton interpolation

ActiveCN106001720BImprove positionImprove surface profileWorkpiecesMilling equipment detailsPosition toleranceTorsional deformation

The invention provides a thin-walled vane nine-point control variable-allowance milling method based on Newton interpolation. Modeling is carried out by utilizing a three-dimensional modeling software, and an auxiliary surface and a boundary surface are formed, so that a driving surface is determined by utilizing a section line lofting process. Cutter machining paths are generated according to the driving surface, and the machining allowance of each cutter position point on each machining path is determined by adopting a Newton interpolation method. Finally, vanes are cyclically processed according to symmetrical milling rules. Compared with a traditional longitudinal fixed-allowance cutting and spiral milling method, the thin-walled vane nine-point control variable-allowance milling method has the advantages that technical problems, such as large torsional deformation, low contour precision, poor section position tolerance and difficult error control, in the machining process can be solved; and by adopting a Newton interpolation process allowance fine adjustment method, surface quality can be more comprehensively controlled, and problems, such as large bending deformation, poor section position tolerance and low surface contour precision, in the machining process can be effectively solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A Soft Membrane Assisted Forming Method for I-beams with Variable Sections Containing Corrugated Edge Plates

ActiveCN106113522BControllable under pressureTo achieve curing moldingDomestic articlesInternal pressureEngineering

The invention discloses a soft mold auxiliary forming method for a variable section I-beam containing a corrugated flange plate. According to the soft mold auxiliary forming method for the variable section I-beam containing the corrugated flange plate, the non-closed form that a metal mold and a silicon rubber mold are combined is adopted; the silicon rubber soft mold is wrapped inside the metal mold; corrugated flange plate side pressurizing (internal pressure) is conducted through heat expansion of the silicon rubber soft mold, the hot pressing tank (external pressure) forming process is combined, and internal and external two-way pressurizing is conducted, so that the pressure applied to a complex section is uniform and controllable, integral curing forming of the composite variable section I-beam containing the corrugated flange plate is well achieved, and the problem that a corrugated structure is not easy to pressurize is solved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

A multifunctional lathe with tool rotation

ActiveCN106694907BControl surface qualitySimple structureDriving apparatusTurning machinesRotation functionEngineering

The invention relates to a multifunctional lathe with tool rotation function, comprising a frame and a power distribution box; the frame is provided with a tool rotating shaft and a tool feeding device, a tool rotator is fitted to the tool rotating shaft, an end of the tool rotating shaft is provided with a grip disc type tool mounting disc, a tool is mounted in the tool mounting disc, a product carrier is fitted to the tool, the product carrier is disposed on a carrier feeding device on the frame, the carrier and the tool have perpendicular feeding directions, and the tool feeding device, the tool rotator and the carrier feeding device are connected to the power distribution box; the tool mounting disc is mounted on the tool rotating shaft and connected to the tool rotator, the tool feeding device is fitted to the carrier that can provide forward and backward feeding, processing a product in various shapes via various techniques can be achieved through changing the tool, tool feeding can be fitted to carrier feeding, a sidewall can be turned into a polygonal prism shape, and the surface quality of a workpiece can be controlled well.

Owner:南京市溧水同发机械刀模具制造有限公司

Preparation method of ultrathin Ta-W alloy foil

Owner:CENT SOUTH UNIV

A kind of preparation method of high-performance shock-absorbing spring steel belt for automobile

The invention discloses a preparing method of a high-performance shock absorbing spring steel band for an automobile and belongs to the technical field of spring steel band preparation. The preparing method comprises the following steps: preparing raw materials, carrying out acid pickling, carrying out continuous rolling, adopting a bell type furnace to carry out first annealing, carrying out rolling and splitting, adopting the bell type furnace to carry out second annealing, examining finished products, carrying out oiled packaging and carrying out warehousing. The fluctuation of the thickness tolerance and the width tolerance of the spring steel band prepared by adopting the technical scheme is small, so that the spring steel band has stable performance. Besides, the strength, hardness and ductility of the spring steel band are effectively improved, so that the requirement of the automobile on a shock absorbing effect can be met. At the same time, the defects of a preparing technology of the spring steel band in the prior art are overcome.

Owner:ANHUI CHUJIANG SPECIAL STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com