Zinc solution iron removing method before production of external continuous hot galvanized plate for automobile and production method thereof

A technology of hot-dip galvanized sheet and production method, which is applied in the direction of hot-dip galvanizing process, coating, metal material coating process, etc., can solve the problems that do not have much practical significance and affect the glossiness of the product surface, and achieve control of the surface quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

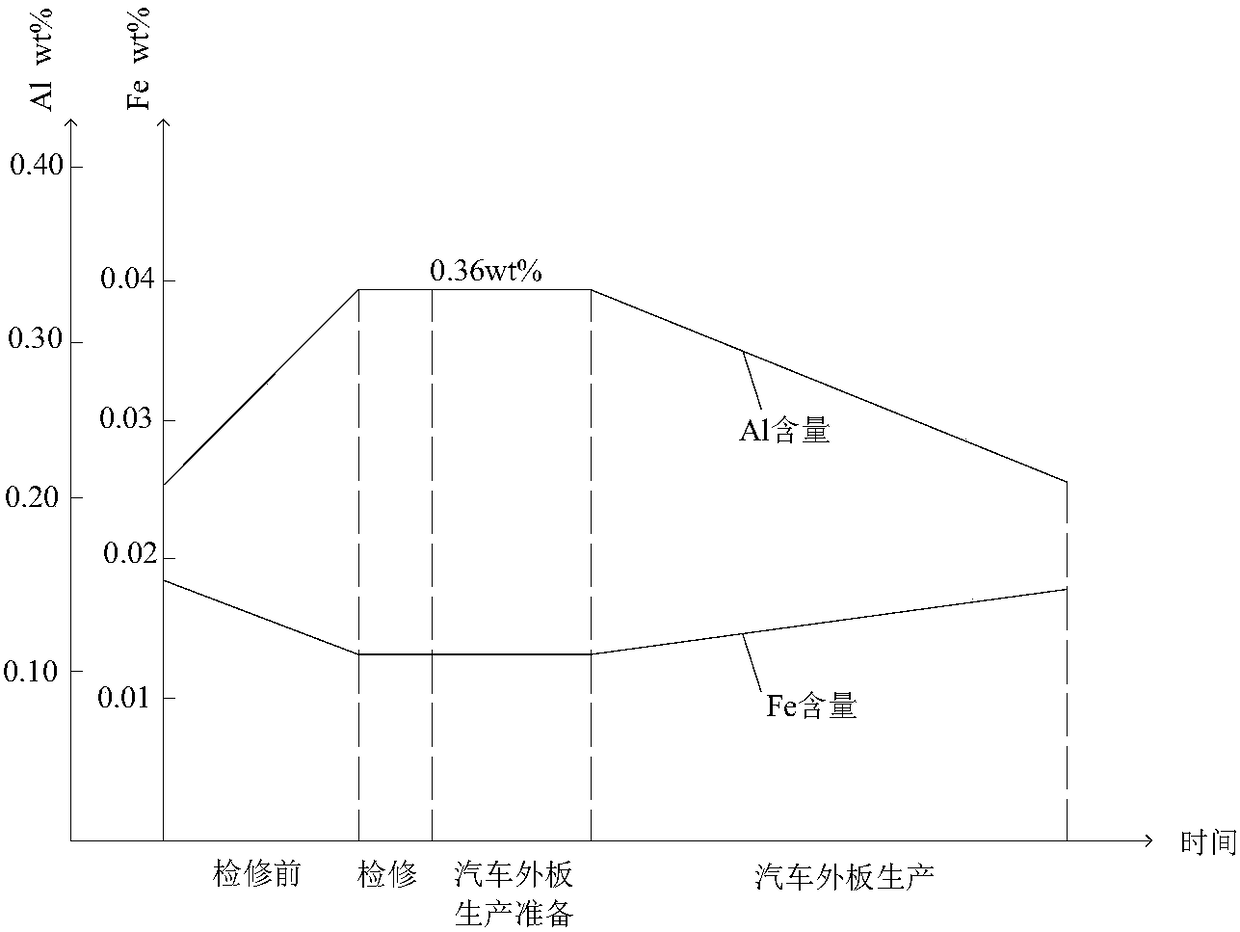

[0055] In this embodiment, the following operating process is adopted, and the temperature of the whole process zinc liquid and the theoretical curve of composition control are as follows: Figure 4 Shown:

[0056] 1) Before the production and maintenance of automobile outer panels, gradually reduce the zinc liquid level in the zinc pot; after the unit is shut down, add 2-3 pieces of zinc-aluminum composite ingots with an aluminum content of 5wt% to the zinc pot, and the aluminum content extracted from the zinc pot Higher zinc ingots (partial step 2 was taken out during production before to obtain zinc ingots cast from molten zinc) were allowed to melt naturally, and the aluminum contained in the molten zinc rose to 0.32wt%, while the temperature dropped to 440°C;

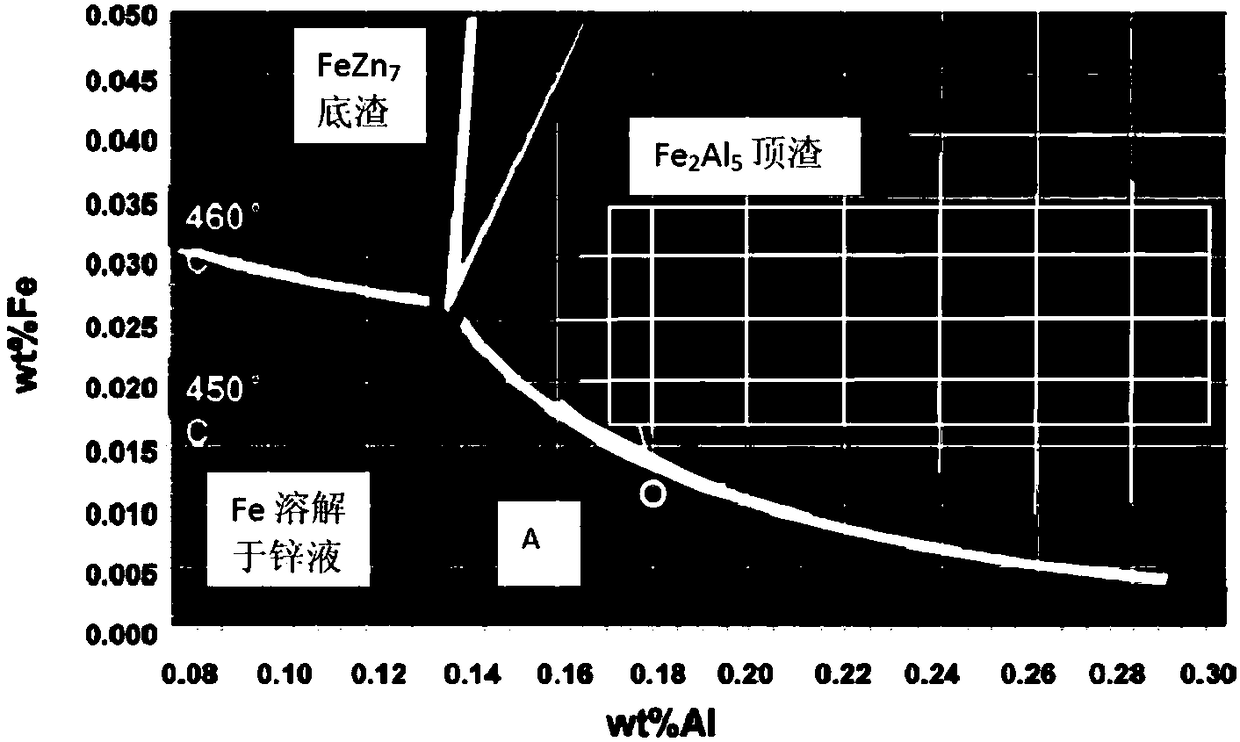

[0057] 2) Carry out iron removal treatment, insert a high-pressure nitrogen pipe into the zinc pot, pass high-pressure nitrogen to fully stir the zinc liquid, so that iron and aluminum can fully react, and Fe 2 Al...

Embodiment 2

[0063] In this embodiment, the following operation process is adopted:

[0064] 1) Before the production and maintenance of automobile outer panels, gradually reduce the zinc liquid level in the zinc pot; after the unit is shut down, add 2-3 pieces of zinc-aluminum composite ingots with an aluminum content of 5wt% to the zinc pot, and the aluminum content extracted from the zinc pot Higher zinc ingots (partial step 2 was taken out during production before to obtain zinc ingots cast from molten zinc) were allowed to melt naturally, and the aluminum contained in the molten zinc rose to 0.35wt%, while the temperature dropped to 450°C;

[0065] 2) Carry out iron removal treatment, insert a high-pressure nitrogen pipe into the zinc pot, pass high-pressure nitrogen to fully stir the zinc liquid, so that iron and aluminum can fully react, and Fe 2 Al 5 Precipitation of solid particles; standing for 24 hours to allow the small solid zinc slag particles in the zinc pot to fully collid...

Embodiment 3

[0071] In this embodiment, the following operation process is adopted:

[0072] 1) Before the production and maintenance of automobile outer panels, gradually reduce the zinc liquid level in the zinc pot; after the unit is shut down, add 2-3 pieces of zinc-aluminum composite ingots with an aluminum content of 5wt% to the zinc pot, and the aluminum content extracted from the zinc pot Higher zinc ingots (the zinc liquid obtained from part of step 2) was extracted during production before, and cast into zinc ingots), and allowed to melt naturally, the aluminum contained in the zinc liquid rose to 0.28wt%, and the temperature dropped to 430°C;

[0073] 2) Carry out iron removal treatment, insert a high-pressure nitrogen pipe into the zinc pot, pass high-pressure nitrogen to fully stir the zinc liquid, so that iron and aluminum can fully react, and Fe 2 Al 5 Precipitation of solid particles; standing for 24 hours to allow the small solid zinc slag particles in the zinc pot to full...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com