Patents

Literature

48results about How to "Small amount of depression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for producing thin gauge pipeline steel by using double-stand medium and heavy plate mill

ActiveCN102671941AGuaranteed Dynamic RecrystallizationImprove lateral performanceTemperature control deviceWork treatment devicesMetallurgyLaminar cooling

The invention discloses a process for producing thin gauge pipeline steel by using a double-stand medium and heavy plate mill. A plate blank with the thickness of 180 mm is used for producing the thin gauge pipeline steel with the thickness less than 10 mm. On the basis that the performance of a rolled piece meets requirements, the thin gauge pipeline steel with a good plate shape can be obtained by controlling the tapping temperature of the plate blank, the rough rolling broadening pass pressing rate, the longitudinal rolling pass pressing rate after rough rolling broadening pass, the rough rolling finishing temperature, the thickness of a middle blank, the finish rolling ending pass pressing rate, the finish rolling finishing temperature, the roller gap inclination and sled function in the rolling process, a high pressure water descaling system, the water entry temperature, the re-reddening temperature, and the head and tail shielding and straightening process of a laminar cooling system. The deformation rate is reduced, and the economic benefit is increased.

Owner:NANJING IRON & STEEL CO LTD

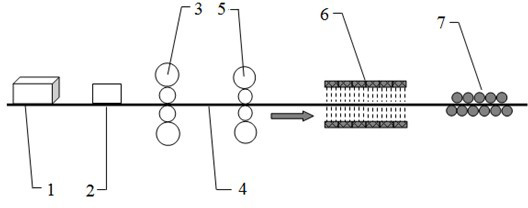

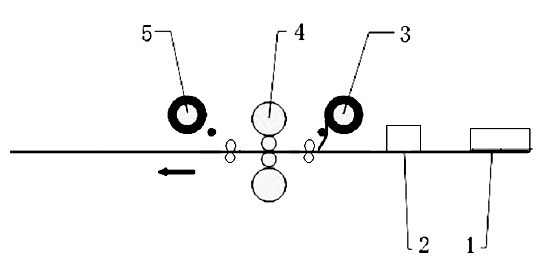

Method for rolling thin high-strength steel plate of single-frame steckel mill

ActiveCN102179406ASolve the problem of excessive rolling forceSolve quick stopRoll force/gap control deviceTemperature control deviceFurnace temperatureSheet steel

The invention discloses a method for rolling a thin high-strength steel plate of a single-frame steckel mill. The method comprises the following steps: producing the finished product of a high-strength steel plate with a thickness less than 10 millimeters by using a blank with the thickness of 150 millimeters and the length more than 10 meters; and then acquiring the thin high-strength steel plate with qualified property and plate shape by controlling a tapping temperature, a coiler furnace temperature, a reduction in last pass, a roller force, a final rolling speed and a high pressure water de-scaling system. When the rolling method is used for producing the thin steel plate, the thin high-strength steel plate is rolled by utilizing the heat preservation function of front and back mill coiler furnaces and controlling the tapping temperature of the blank, the reduction in the last rolling pass, the roller force and the final rolling speed, and the acquired plate shape and property of the steel plate are both qualified, thereby increasing the rolling mill capacity and achieving high plate yield and high property yield.

Owner:NANJING IRON & STEEL CO LTD

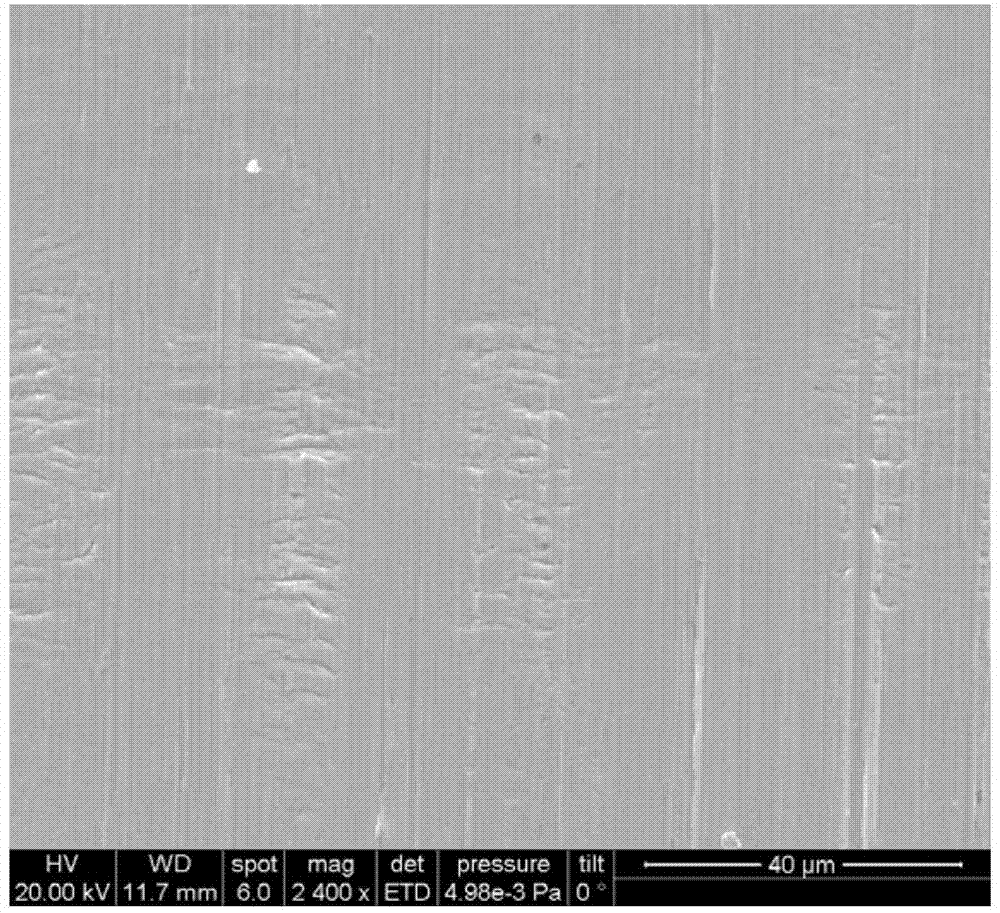

Super-hard austenitic stainless steel and preparation method thereof

The invention discloses a super-hard austenitic stainless steel and a preparation method thereof. The super-hard austenitic stainless steel comprises the following chemical components by weight percent: 0.08-0.13% of C, 0.3-1.0% of Si, less than 2.0% and greater than or equal to 0.5% of Mn, 16.5-17.5% of Cr, 6.5-7.5% of Ni, 0.03-0.08% of N, 0.5-0.8% of Mo, greater than or equal to 0.040% of P, greater than or equal to 0.01% of S, Fe and unavoidable impurities; the temperature of Md30 is 30-60 DEG C. By controlling the tempering and cold rolling reduction rate to 35-45%, controlling the rolling speed to less than or equal to 5m / s and the rolling temperature to less than or equal to 30 DEG C, the transformation from the austenite to the deformation martensite is created and the hardness of the material is greatly increased under the same deformation; when the tempering and cold-rolling reduction rate is 35%, the hardness HV is greater than 550 and the anisotropy of the super-hard state steel is reduced.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

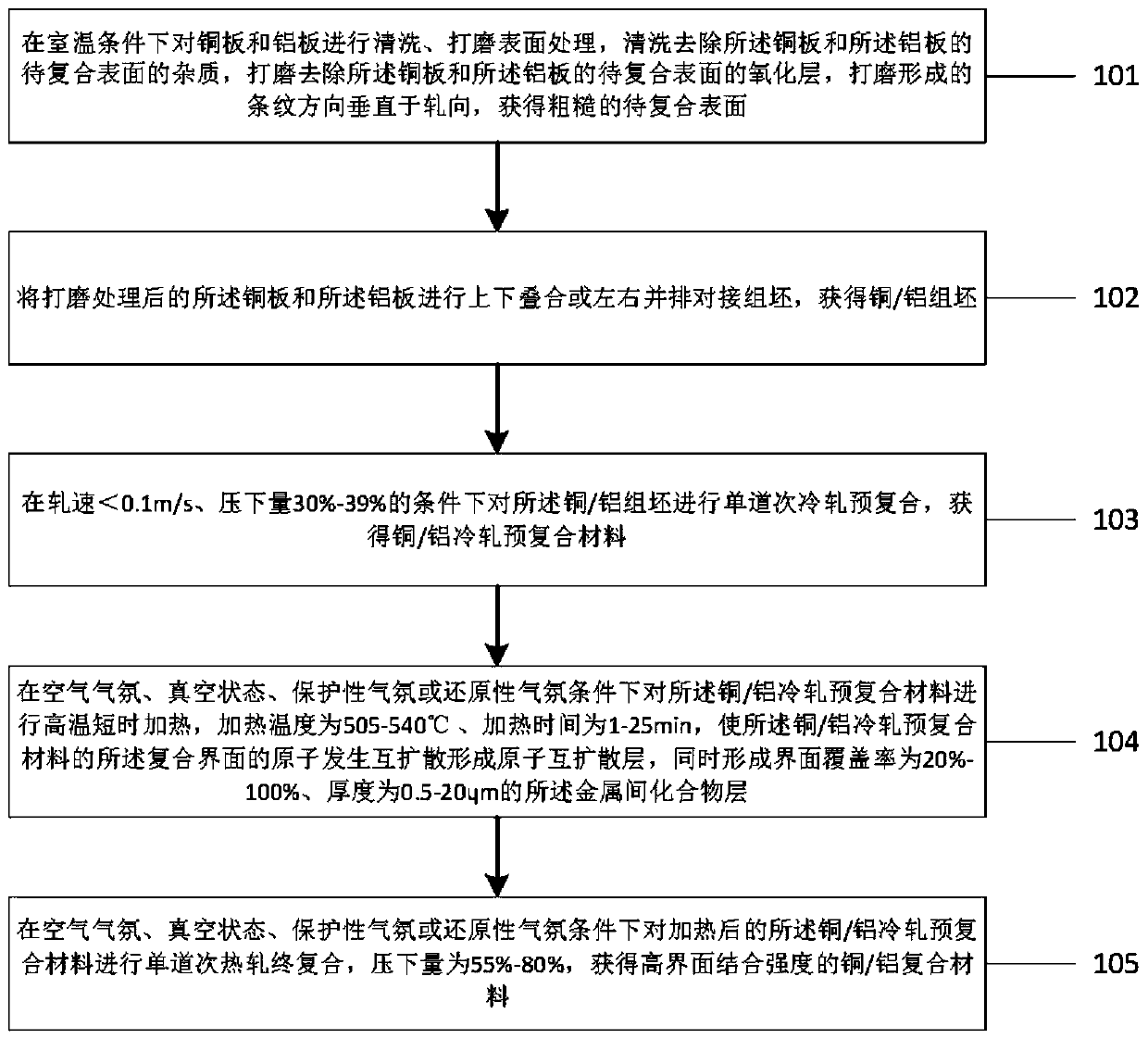

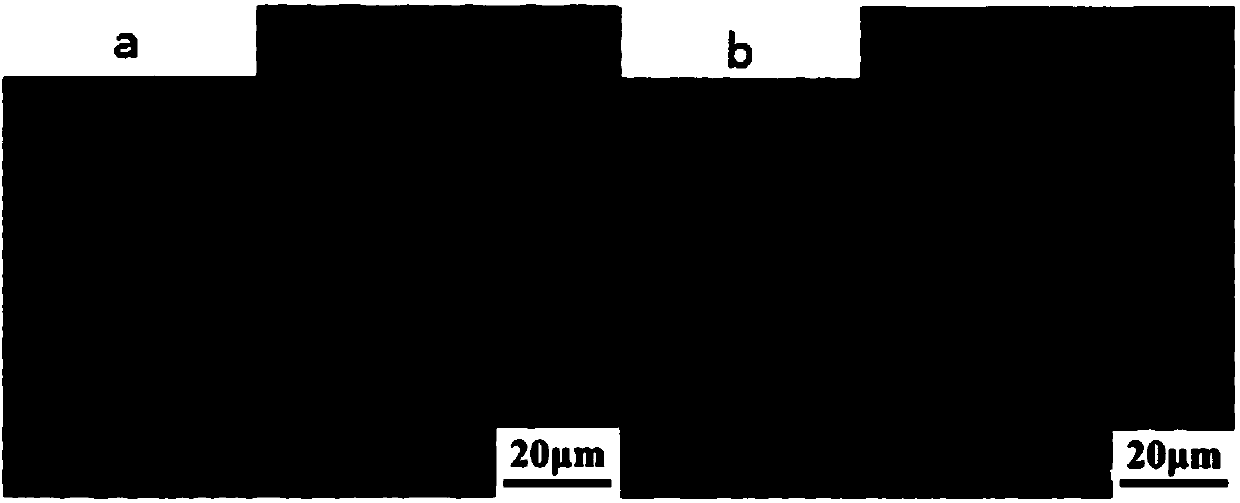

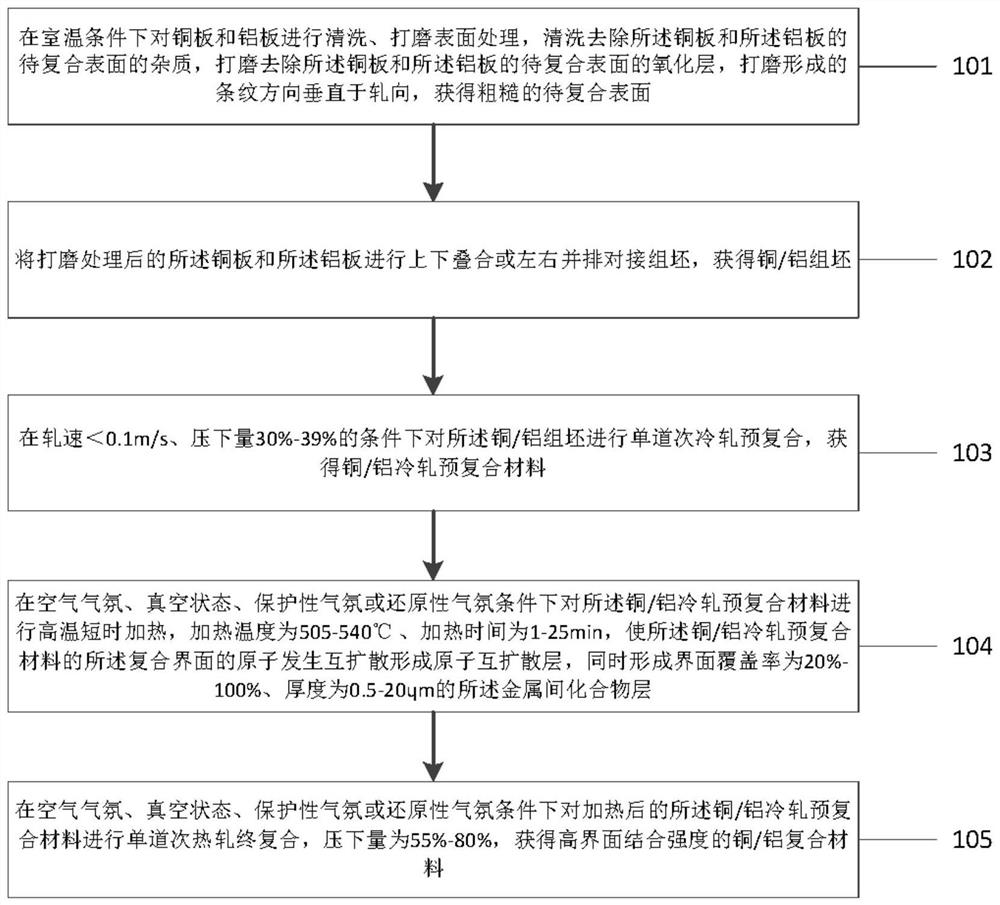

Forming method for high-interface-bonding-strength copper/aluminum composite material

ActiveCN110681694AImprove the bonding strength of the interfaceHigh interface frictionAuxillary arrangementsMetal rolling arrangementsAluminum compositesUltimate tensile strength

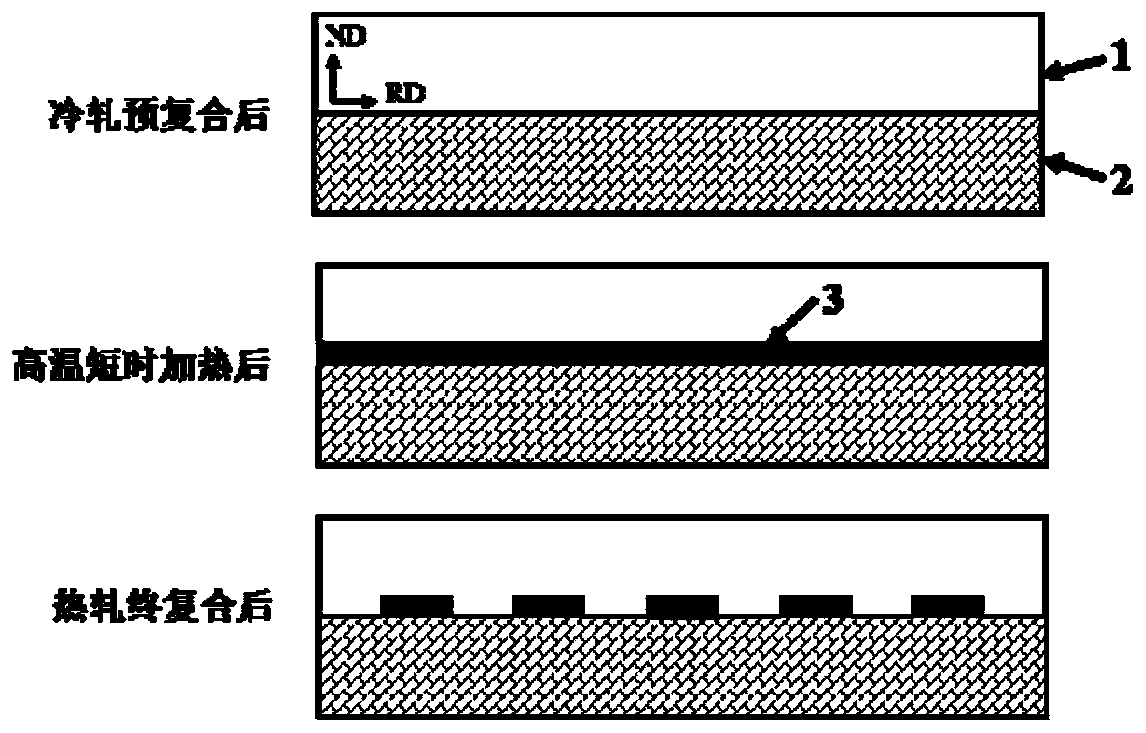

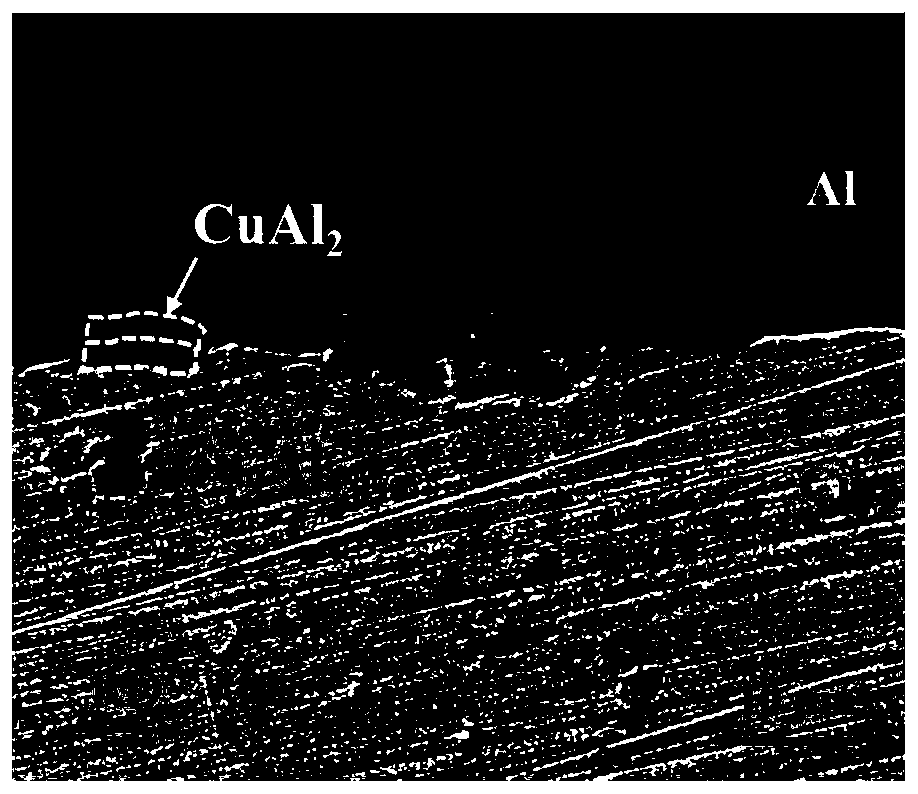

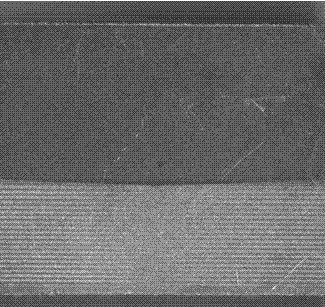

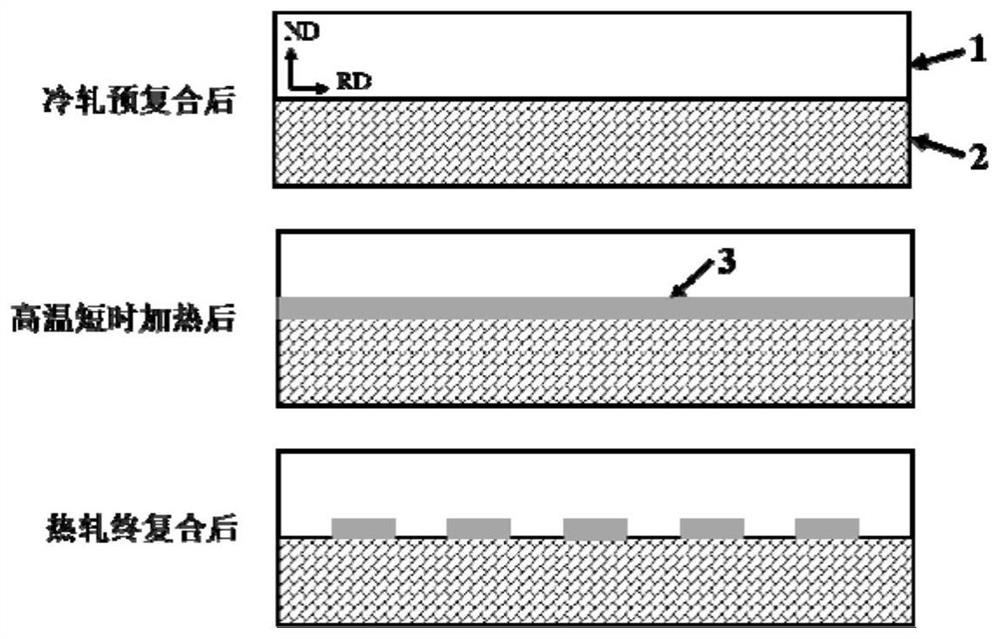

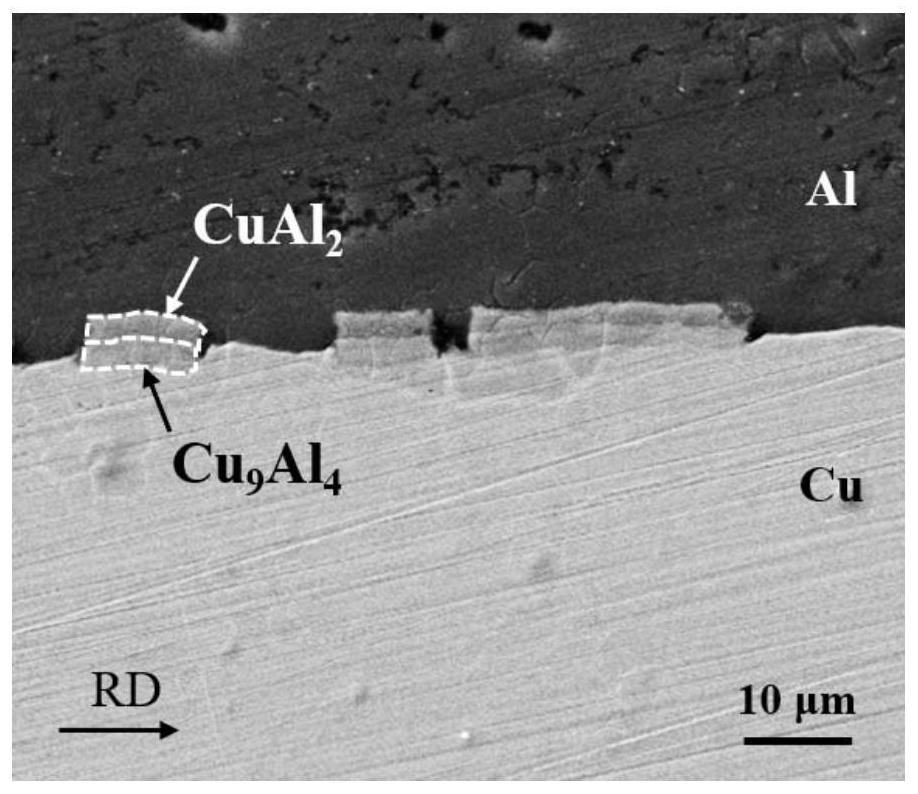

The invention discloses a forming method for a high-interface-bonding-strength copper / aluminum composite material, and belongs to the technical field of metal laminar composite material preparing. According to the forming method, to-be-combined surfaces of a copper plate and an aluminum plate are machined, macroscopic rugged to-be-combined surfaces are obtained, a louvre blade is adopted for conducting grinding treatment on the to-be-combined surfaces, the direction of stripes formed through grinding is perpendicular to the rolling direction, then, the copper plate and the aluminum plate are overlapped up and down or arranged left and right side by side to be in butt joint, and a copper / aluminum assembly is obtained; then, single-pass low-rolling-reduction cold rolling pre-composition is conducted, high-temperature short-time heating is conducted, finally, single-pass hot rolling final composition is conducted, and the high-interface-bonding-strength copper / aluminum composite materialis obtained. The forming method has the advantages that the capability requirement for a rolling machine needed for producing the copper / aluminum composite material is low, the technology is simple, the production cost is low, a macroscopic composite interface of a non-flat artificial structure and a microcosmic composite interface of a particle pinning structure can be obtained, the interface bonding strength is larger than or equal to 90 MPa, the applicable copper / aluminum composite material range is wide, and industrial popularization is easy.

Owner:UNIV OF SCI & TECH BEIJING

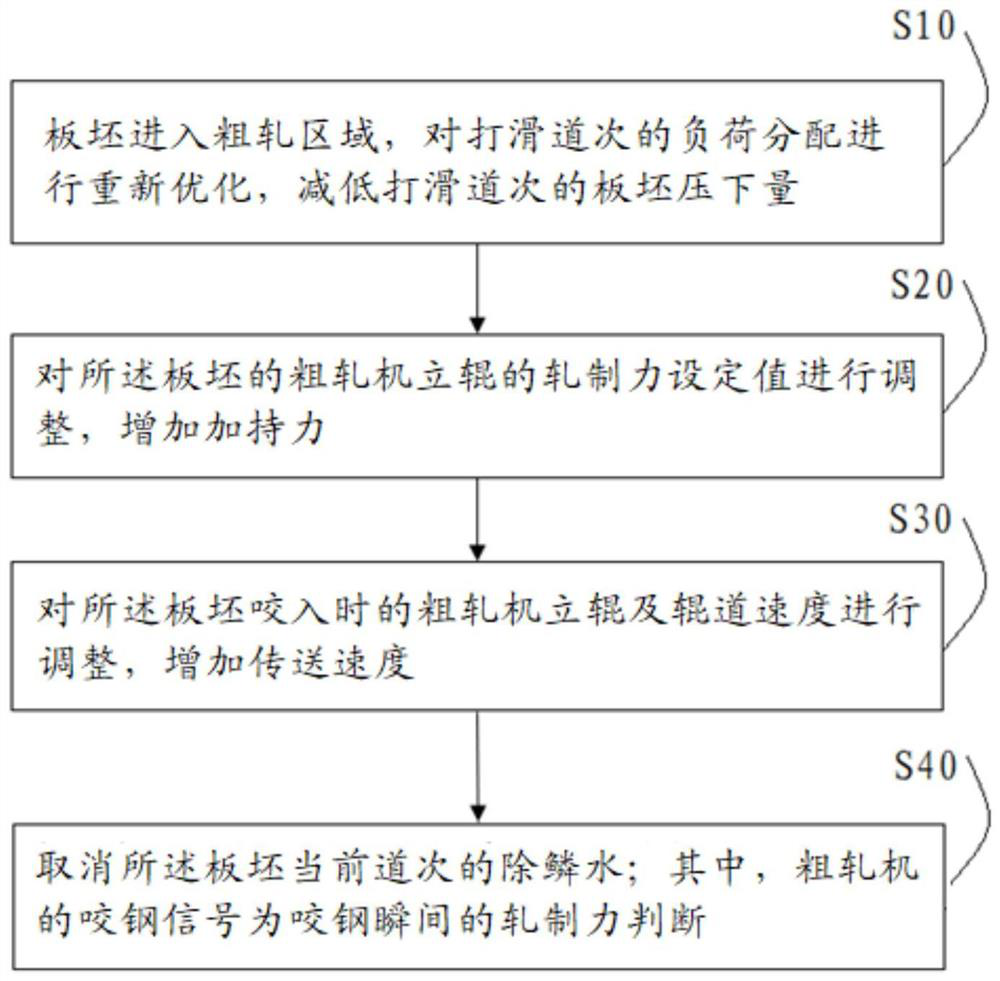

Control method for head warpage of plate blank

InactiveCN108838216ASmall amount of depressionAlleviate the problem of warped headRare end control deviceProduction lineTemperature difference

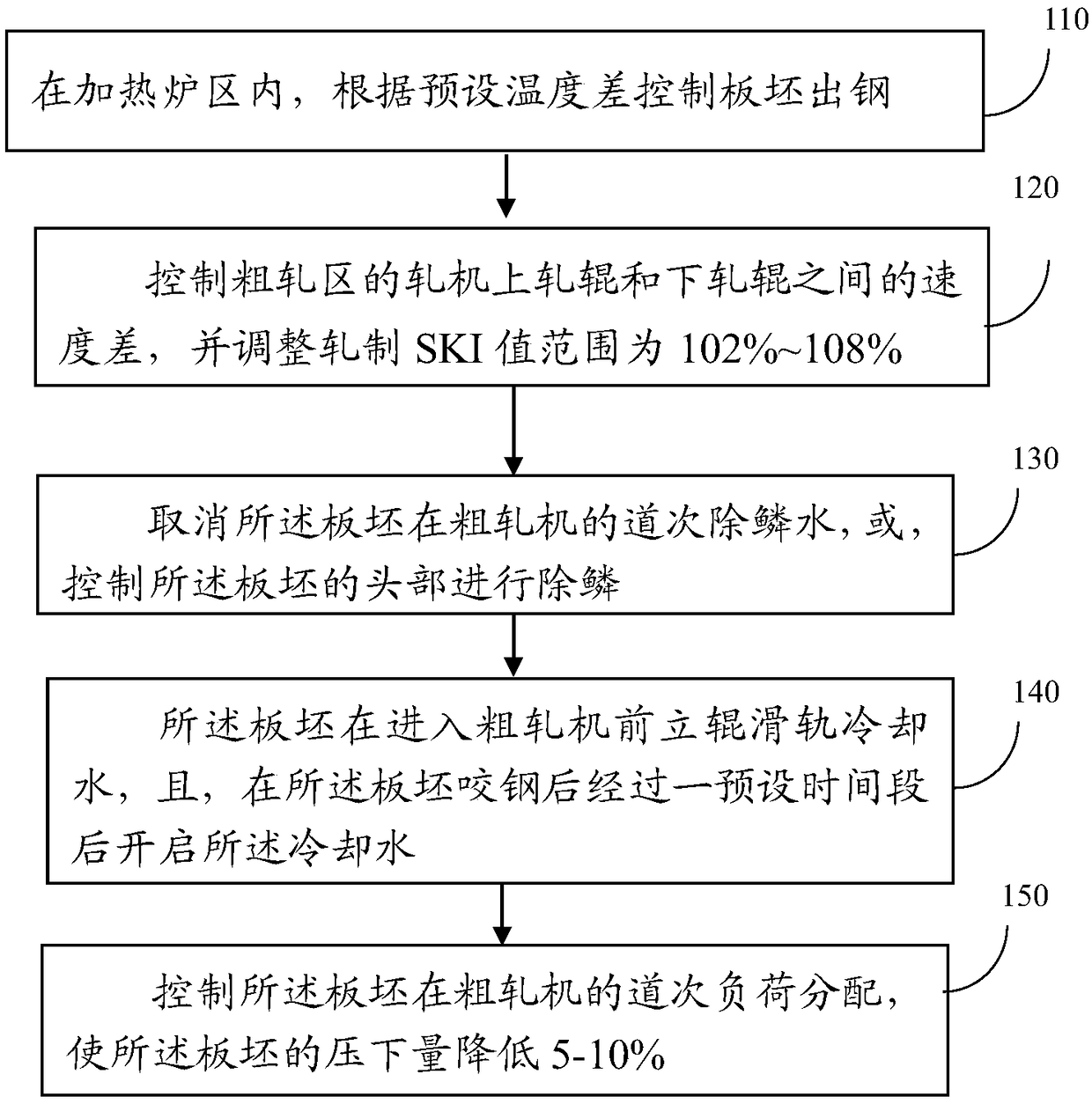

The invention discloses a control method for head warpage of a plate blank, and belongs to the technical field of steel rolling. The method comprises the following steps of controlling outlet steel ofthe plate blank according to a preset temperature difference in a heating furnace area; controlling the speed difference between an upper roller and a lower roller of a rolling machine in a rough rolling area, and regulating the SKI value range of rolling to be 102 to 108 percent; removing pass descaling water of the plate blank in a rough rolling machine, or, controlling the head of the plate blank to perform descaling; turning off cooling water of a vertical roller sliding rail before the plate blank enters the rough rolling machine, and, turning on the cooling water after a preset time after the steel of the plate blank is bitten; and controlling pass load distribution of the plate blank in the rough rolling machine so that the rolling reduction of the plate blank is reduced by 5 to 10percent. Through the method, the technical problem that a head warpage phenomenon can often be caused in the rough rolling area of a production line in the prior art is solved; and the technical effects of shortening accident time and non-scheduled shutdown time, relieving the head warpage problem of the plate blank, greatly reducing head warpage accidents, and improving the operation rate of a production line are achieved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Preparation method for copper-steel composite

InactiveCN102671942AImprove bindingEffective combinationHot-dipping/immersion processesMetal rolling arrangementsThermal insulationZinc alloys

The invention relates to a bimetal composite, in particular to a composition method for copper or copper alloys on the surface of steel. Steel and copper can be both compounded with zinc or zinc alloys with a low melting point effectively, a layer of zinc is plated on the surface of each of a copper plate and a steel plate by a hot-dip method, the zinc is heated to a temperature higher than the melting point of zinc under protection of gases, the copper plate and the steel plate are pressed together under pressure, liquid thin zinc layers on the surfaces of the plates are compounded and diffused mutually by thermal insulation, and accordingly composition of steel and copper is achieved.

Owner:JIANGSU UNIV

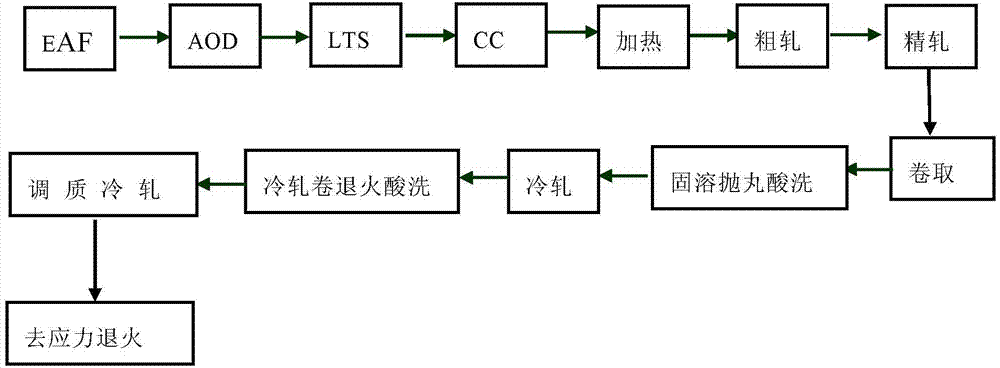

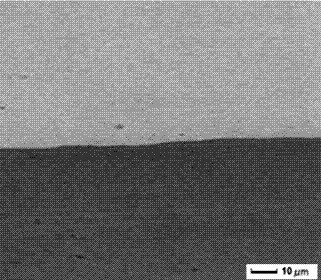

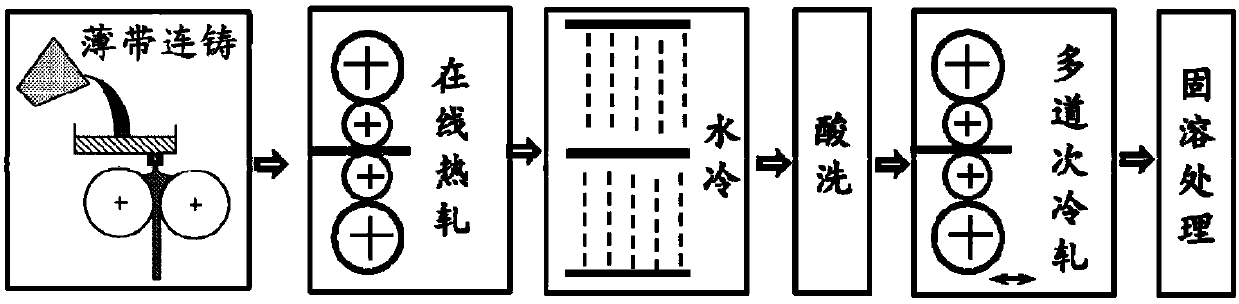

Near-net shaping preparation method of super double-phased stainless steel thin strip

The invention discloses a near-net shaping preparation method of a super double-phased stainless steel thin strip. The super double-phased stainless steel thin strip is composed of, by mass, 0-0.03% of C, 24-32% of Cr, 0.5-2.5% of Mn, 0.3-0.5% of N, 2-6% of Mo, 4-8% of Ni, and the balance Fe and other inevitable impurities. The preparation method comprises the following steps that (1) a thin stripbillet is obtained through smelting and thin strip continuous casting, and the smelting temperature is 1530-1570 DEG C; (2) online hot rolling is conducted, and the hot rolling rate is 20-30%; (3) acid pickling is conducted; (4) cold rolling is conducted and the cold rolling overall reduction is 60-85%; and (5) solution treatment is conducted. The obtained thin strip has the good mechanical performance and excellent corrosion resistance, and compared with a conventional process, the yield is greatly improved, and energy consumption is greatly reduced.

Owner:NORTHEASTERN UNIV

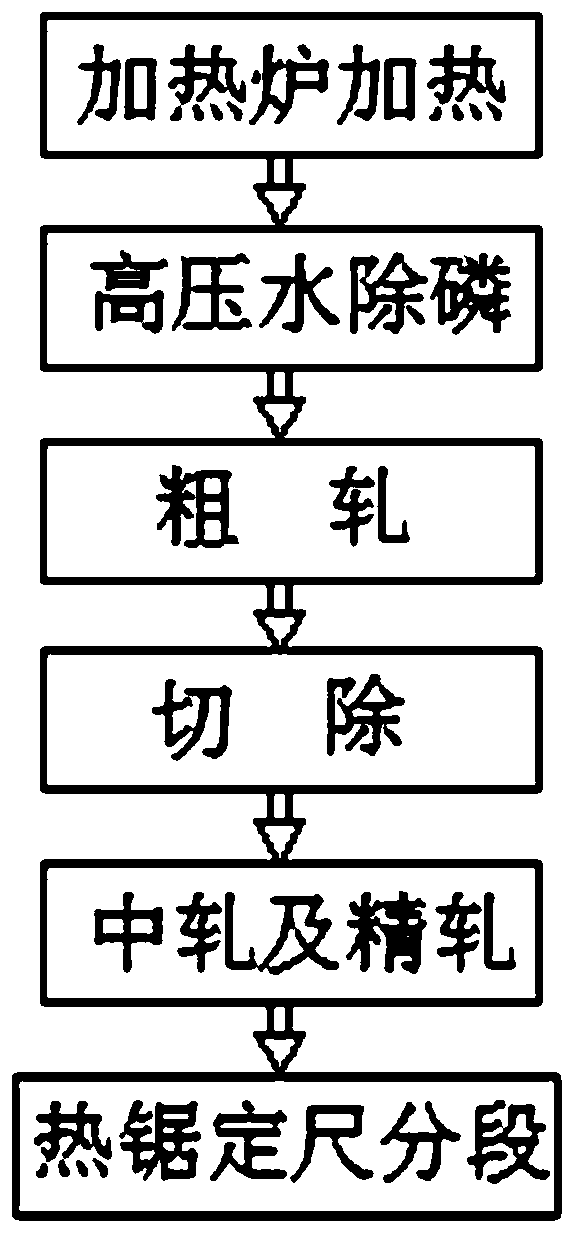

High-sulfur steel rolling process

InactiveCN110681696ASolve the problem of biting and slippingReduce meltingMetal rolling stand detailsOther manufacturing equipments/toolsHeating furnaceGrinding wheel

The invention relates to a high-sulfur steel rolling process. The process comprises the following steps that a heating furnace is used for heating, a continuous casting billet is fed into the heatingfurnace to be heated according to a heating standard, and is discharged after meeting the process requirements; then scale on the surface of a steel billet is removed by using high-pressure water, rough rolling is conducted by adopting a two-roll reversing mill, and rough rolling is conducted by adopting a soft reduction rolling process to obtain a rolled billet; defects of the end part of the rolled billet are cut off, and then intermediate rolling and finish rolling are conducted by adopting a continuous rolling machine; and the finish rolled billet is cut to specific length by using a sheargauge, then segmenting is conducted by using an abrasive-disk cutter, so that round steel is obtained, the received round steel is subjected to finish machining such as chamfering, heat treatment andflaw detection. The problems that high-sulfur steel slips during rolling and end cracking is produced can be well solved, the process is simple and feasible, the requirements of stable production ofhigh-sulfur steel are further met, the production cost is effectively lowered, and the production efficiency is improved.

Owner:BAOSTEEL SPECIAL STEEL SHAOGUAN CO LTD

Non-oriented silicon steel and production method thereof

The invention discloses a non-oriented silicon steel and a production method thereof. Molten steel is smelted by adopting a vacuum induction furnace. Molten steel is directly cast into a cast belt with the thickness between 1mm and 3mm through a pair of crystallization rollers rotating in opposite directions. The casting temperature of the molten steel is between 1500 DEG C and 1700 DEG C. The cast belt is subjected to one pass or multiple passes hot rolling and rolled into hot-rolled strip steel with thickness being 0.7mm and 2.5 mm. The hot rolling temperature is between 800 DEG C and 1150 DEG C, and the hot-rolled strip steel is coiled into a roll at the temperature between 500 DEG C and 800 DEG C. Normalizing annealing is conducted on the hot-rolled steel roll after the hot-rolled steel roll is subjected to a levelling or tension levelling working procedure with the elongation rate being 1.0% and 5.0%, and the normalizing annealing temperature is between 700 DEG C and 1000 DEG C. After the steel roll after normalizing annealing is subjected to cold rolling and the final annealing and coating working procedures, low-iron loss and high magnetic induction non-oriented silicon steel products are acquired. The non-oriented silicon steel products manufactured with the production method has high-proportion magnetic induction-favorable <100> and <110> structures, and the product magnetic induction is above 1.80 T.

Owner:SHAGANG GROUP +2

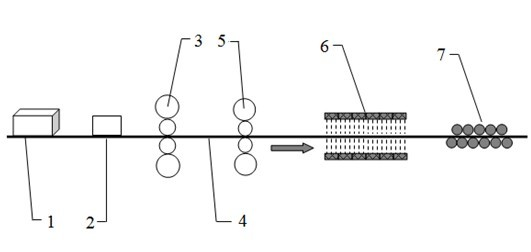

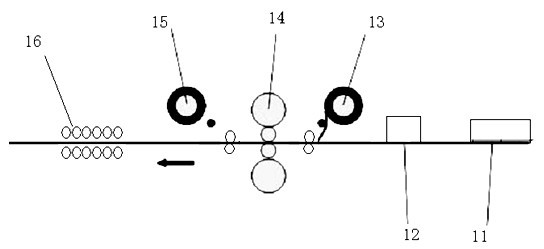

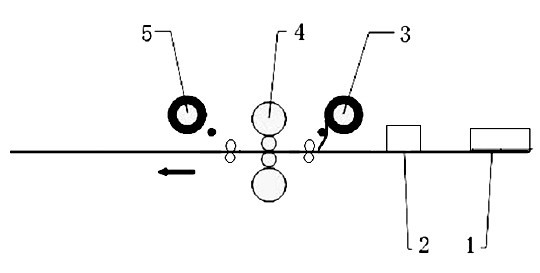

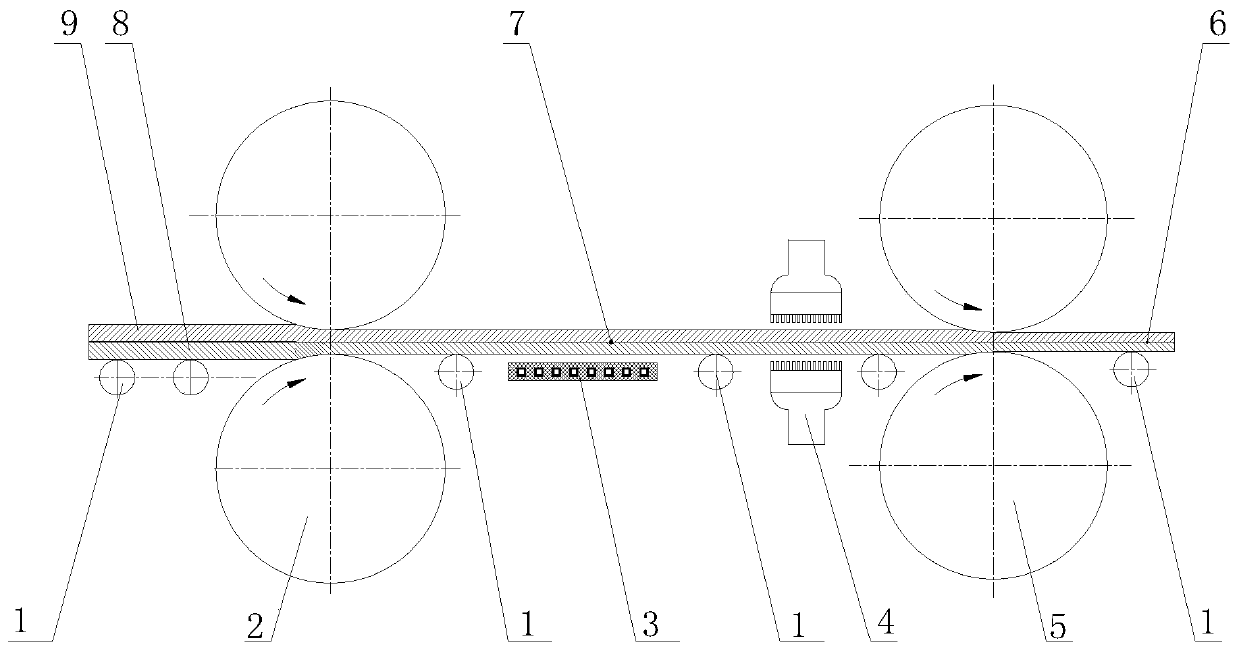

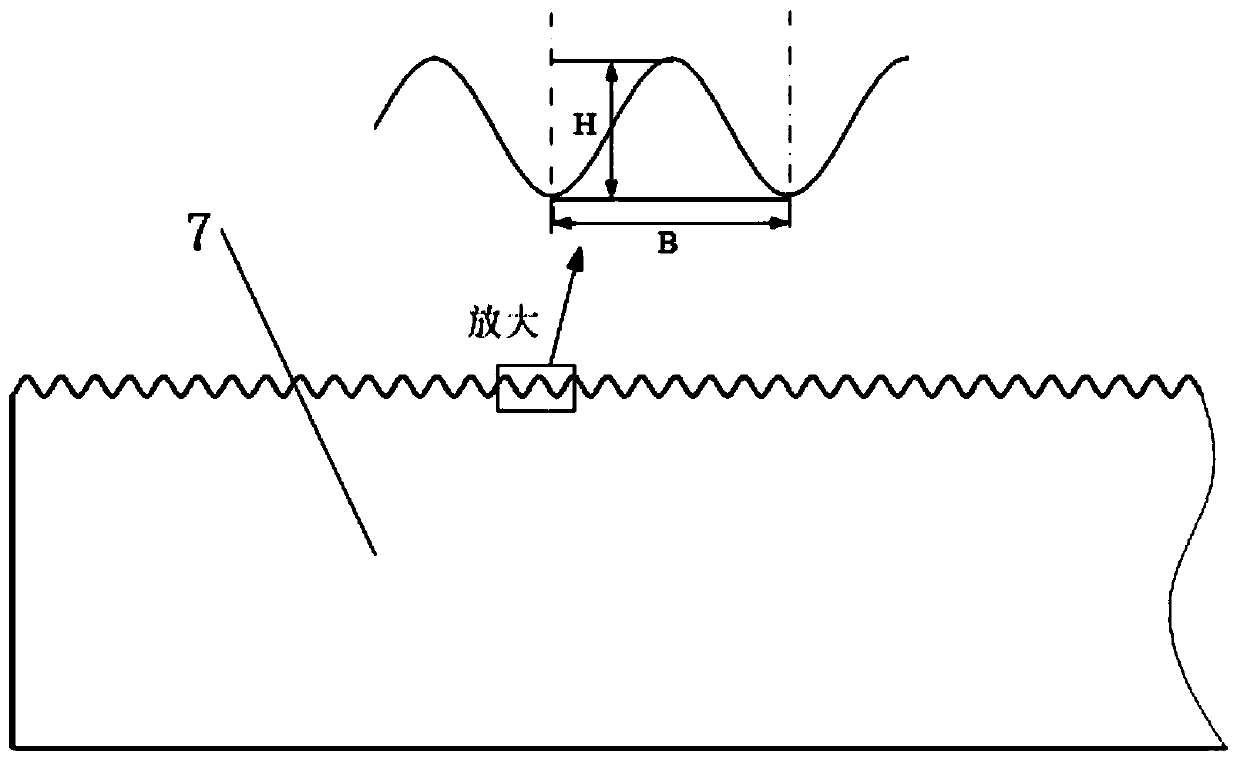

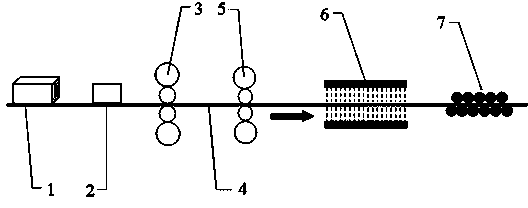

Method and device for preparing steel/aluminum laminated composite plate by hot continuous rolling with small rolling reduction

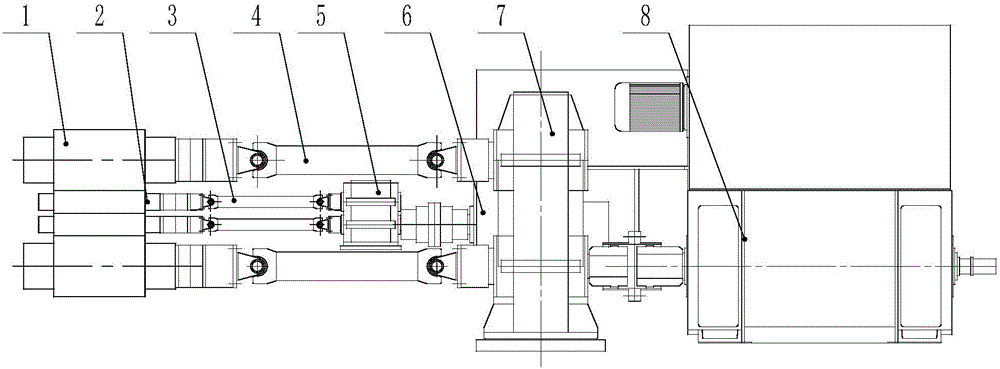

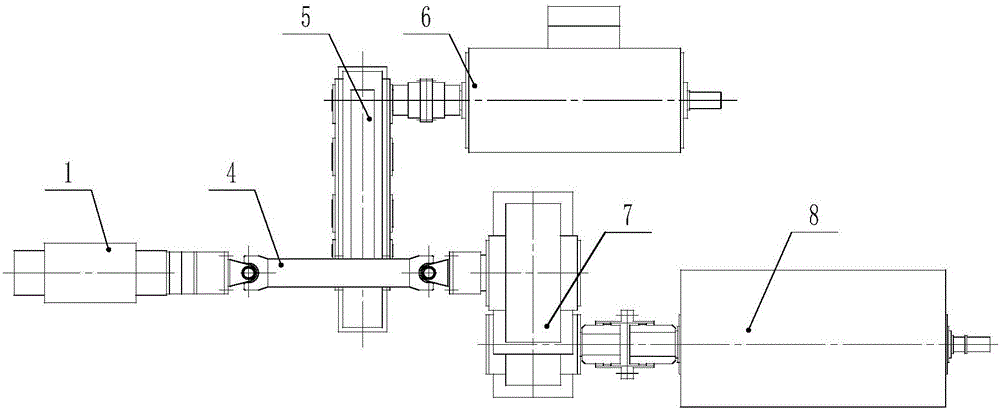

ActiveCN111014294AAchieving Microscale MeltingReduce the difficulty of combinationWork cooling devicesWork heating devicesComposite plateContinuous rolling

The invention belongs to the technical field of preparation of metal laminated composite plates, and particularly relates to a method and device for preparing a steel / aluminum laminated composite plate by hot continuous rolling with small rolling reduction. The device for preparing the steel / aluminum laminated composite plate by hot continuous rolling with small rolling reduction comprises a roller way, a cold rolling mill, a flat plate type induction heating device, a cooling device and a hot rolling mill, wherein the cold rolling mill, the flat plate type induction heating device, the cooling device and the hot rolling mill are sequentially arranged in the roller way from left to right to form a rolling production line. Corrugation is processed on the surface to be compounded of the steel plate to be compounded, cold rolling is carried out, and the steel side of the meshed steel / aluminum laminated composite plate formed by cold rolling is rapidly heated, so that the micro-scale solid-liquid phase phenomenon occurs on the bonding surface of the meshed steel / aluminum laminated composite plate, rapid cooling and hot rolling are carried out, and the steel / aluminum laminated compositeplate is prepared by hot continuous rolling with small rolling reduction, the interfacial space metallurgical bonding thick-specification steel / aluminum laminated composite plate can be prepared, theproduct performance is stable, and the bonding strength is high.

Owner:TAIYUAN UNIV OF TECH

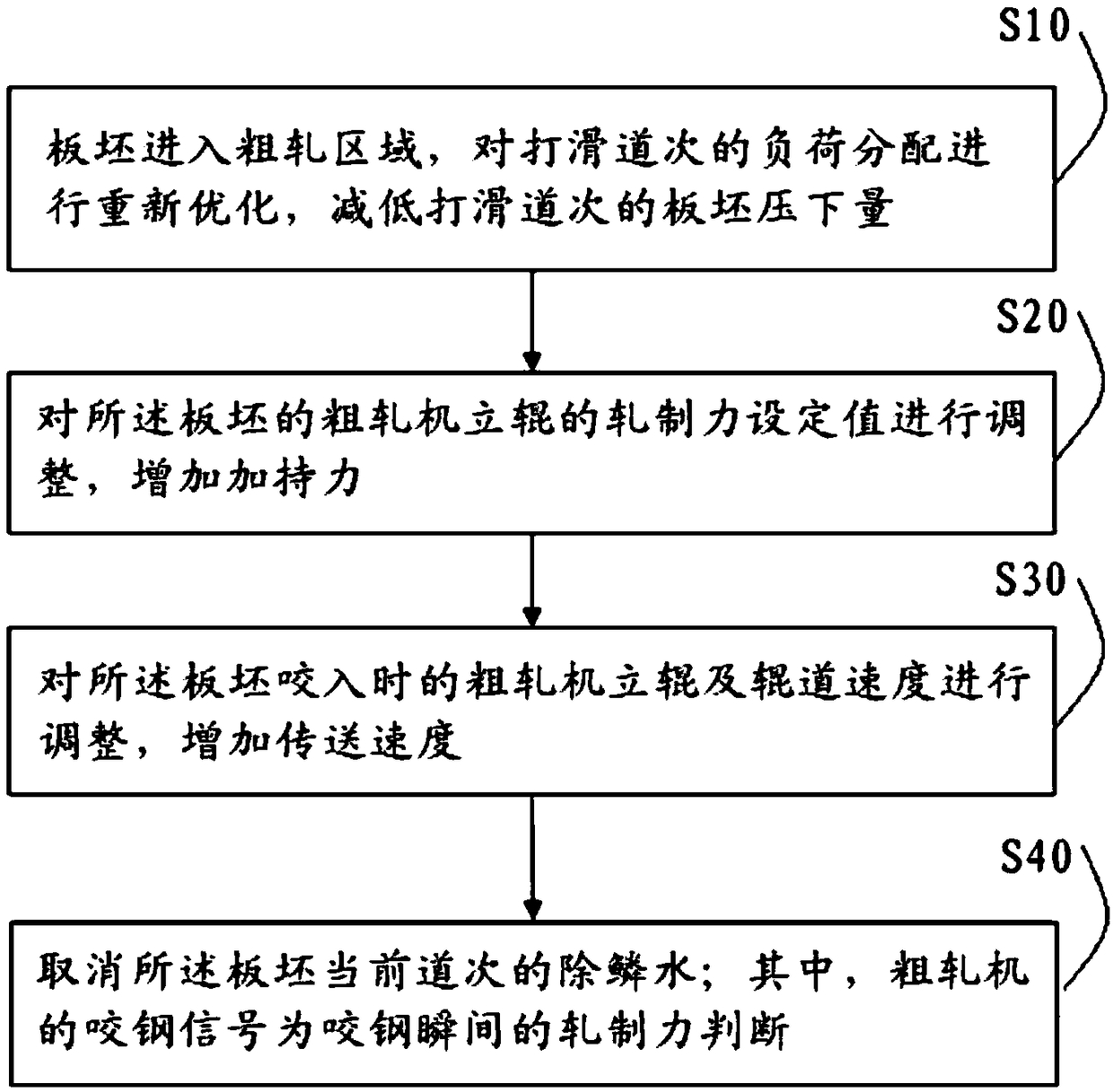

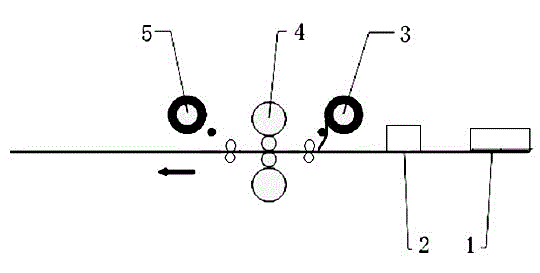

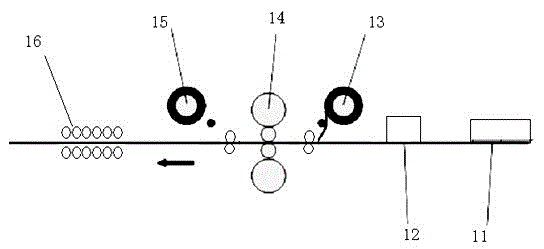

Control method of hot rolling roughing mill

ActiveCN108838212ASmall amount of depressionAdjustable speedRoll mill control devicesMetal rolling arrangementsStrip millEngineering

The invention discloses a control method of a hot rolling roughing mill. The method comprises the steps that a board blank enters a rough rolling area, load distribution of a slip pass is optimized again, and the board blank rolling reduction of the slip pass is reduced; the set value of rolling force of a roughing mill vertical roll of the board blank is adjusted, and the holding force is increased; the speed of the roughing mill vertical roll and a roller way when the board blank is gripped is adjusted, and the conveying speed is increased; and descaling water of the current pass of the board blank is eliminated, wherein the steel gripping signal of the roughing mill is judgment of rolling force at the moment of steel gripping. The technical problem that due to the slip phenomenon of a board blank in a roughing mill in the prior art, the board blank cannot be normally gripped, and accordingly normal production rhythm is affected is solved. The technical effect that rapid response isachieved when the board blank slides while being gripped in the roughing mill, the production accidents of board blank abandoning and rollback are avoided, and the production efficiency is improved are achieved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

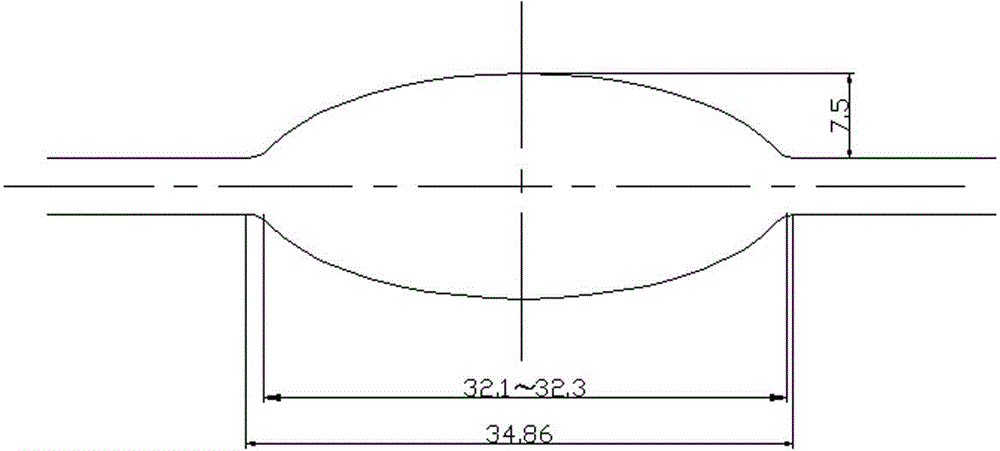

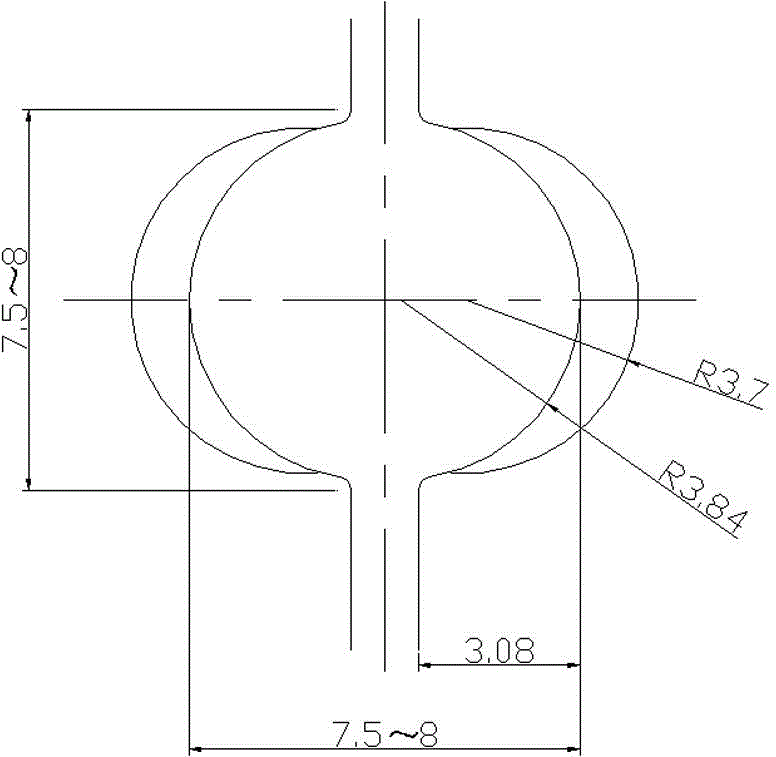

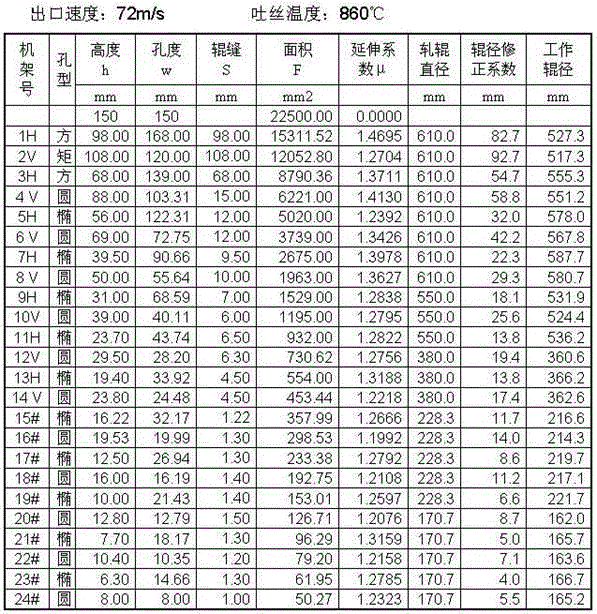

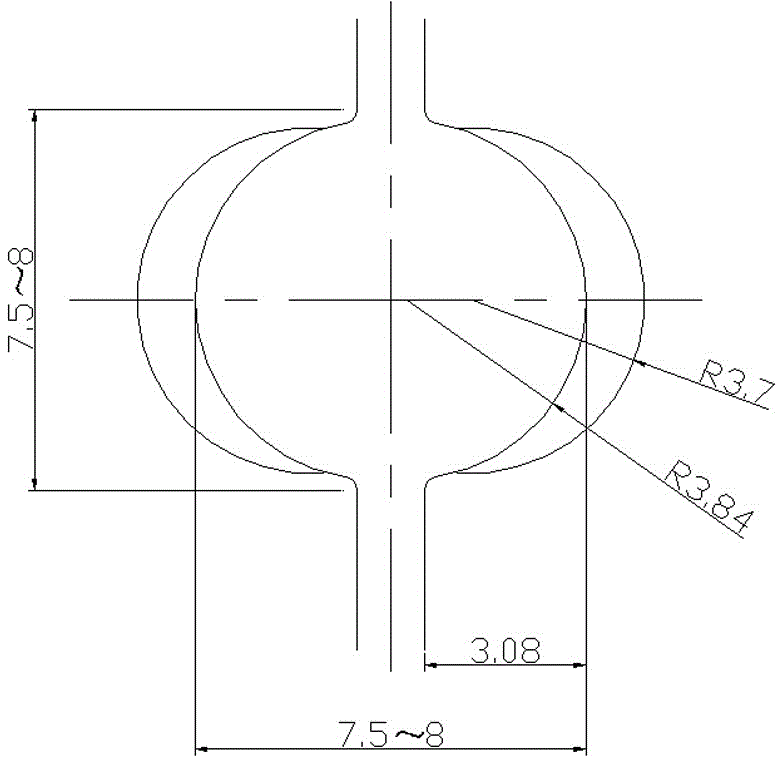

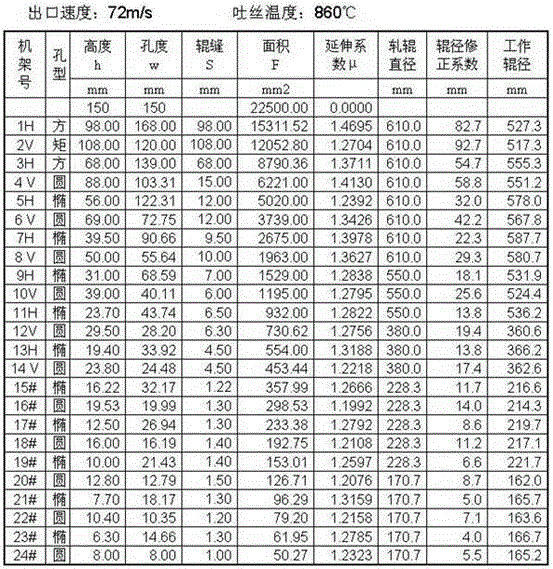

Production method with low energy consumption, 24 passes and high efficiency for hot rolling of phi-8 coiled reinforced bar

Owner:红河钢铁有限公司

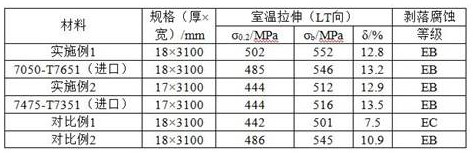

Ultra-wide aluminum alloy plate and preparation method thereof

ActiveCN113564502AReduce residual internal stressHigh strengthSolution treatmentUltrasonic vibration

The invention belongs to the technical field of aluminum alloys, and particularly relates to an ultra-wide aluminum alloy plate and a preparation method thereof. According to the preparation method, ultrasonic treatment is carried out in the hot rolling process, vacancies are continuously injected into materials through ultrasonic vibration, a large number of fine and dispersed nanometer precipitated phases are dynamically precipitated from the materials, and a pre-stretching procedure is added before solution treatment, so that the residual internal stress of the aluminum alloy plate is reduced, the strength and the extension performance of the aluminum alloy plate are improved, the produced aluminum alloy plate is stable in performance, high in surface flatness, low in residual internal stress and not prone to deformation during machining.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

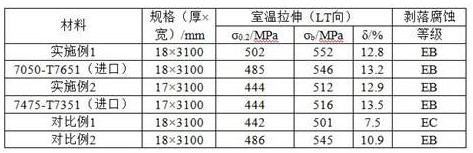

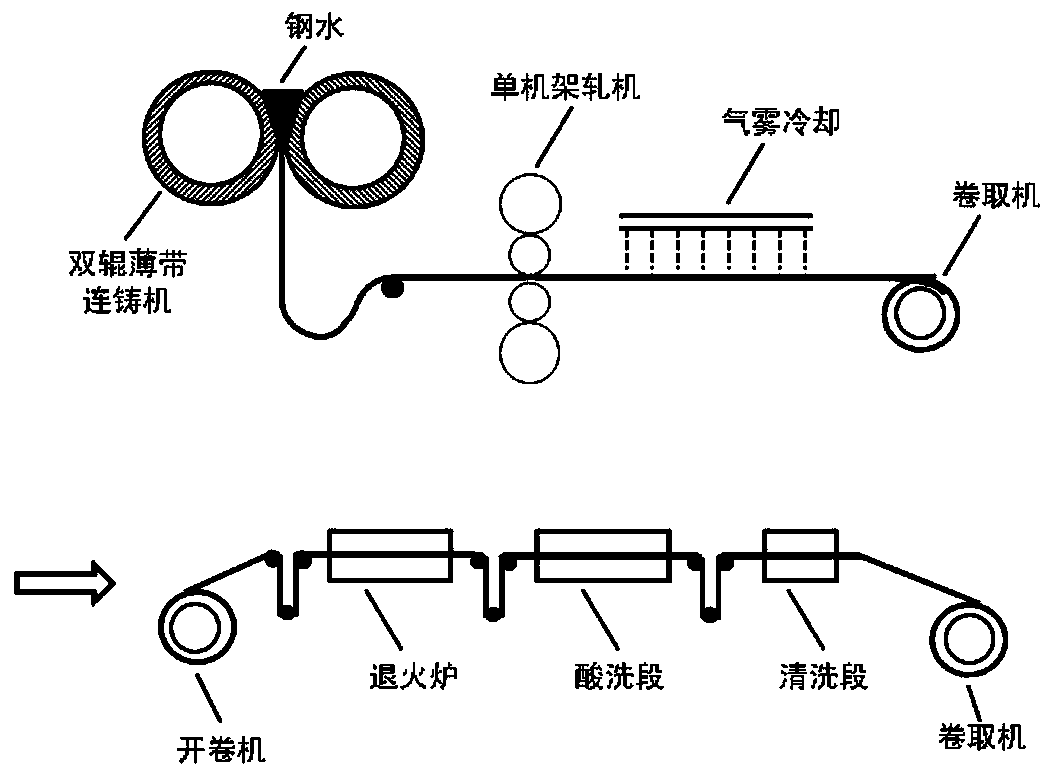

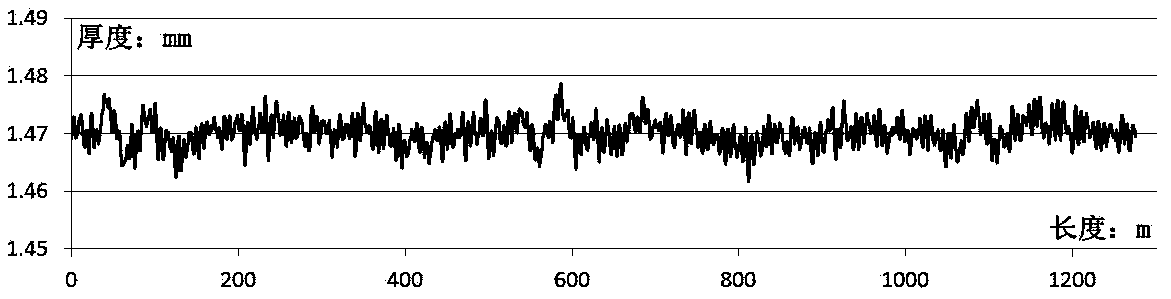

High-strength steel for seat slide rails and method for producing the same based on thin strip casting-rolling

InactiveCN111218607AReduce production processLess emissionsFurnace typesProcess efficiency improvementAerosol MistContinuous annealing

The invention belongs to the technical field of steel production, and particularly relates to high-strength steel for seat slide rails and a method for producing the same based on thin strip casting-rolling. Molten steel is subjected to thin strip continuous casting to obtain a cast strip, the cast strip is subjected to single-pass hot rolling and aerosol cooling and coiled to obtain a hot-rolledcoil, then the hot-rolled coil is opened on a continuous annealing-pickling line, and after an annealing stage and a pickling stage, cleaning, oiling and coiling are performed to obtain a high-strength pickled coil. According to the method, a thin strip casting-rolling and continuous annealing-pickling technology is adopted to produce the high-strength steel for the seat slide rails, the problem that a thin, high-strength and high-dimensional-accuracy product cannot be easily produced through a traditional hot rolling technology is solved, and the problem that a hot rolling, pickling, cold rolling and annealing technology has a long process, high energy consumption and poor product isotropy is also solved. In the product, low-temperature coiling is adopted to obtain a high-yield-ratio rodlike bainite phase, Nb, V and the like are sufficiently separated out by the subsequent annealing technology, phase transformation stress is released, the plasticity is further improved while high strength and the high yield ratio are achieved, and the steel is more suitable for manufacturing the seat slide rails.

Owner:SHAGANG GROUP +2

Production method of high-carbon martensitic stainless steel steckel mill

ActiveCN113172089AControl heating rateReduce decarbonizationTemperature control deviceProcess efficiency improvementMartensitic stainless steelHeating furnace

The invention discloses a production method of a high-carbon martensitic stainless steel steckel mill, and relates to high-carbon steel produced by the steckel mill and a production process of the high-carbon steel. The process technology focuses on overcoming the defects of decarburization, peeling, edge cracking, layering and the like of high-carbon martensitic stainless steel, the defects of decarburization, peeling, edge cracking, layering and the like of the high-carbon martensitic stainless steel caused by long rolling time of the steckel mill are effectively overcome by controlling the tapping temperature, heating furnace residual oxygen, pass reduction, vertical roll rolling force, a descaling system and other processes, and the surface quality and the yield are improved.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

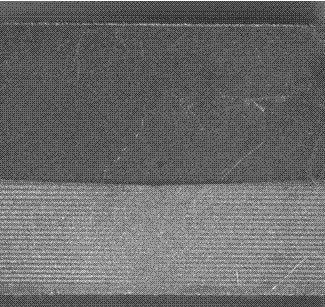

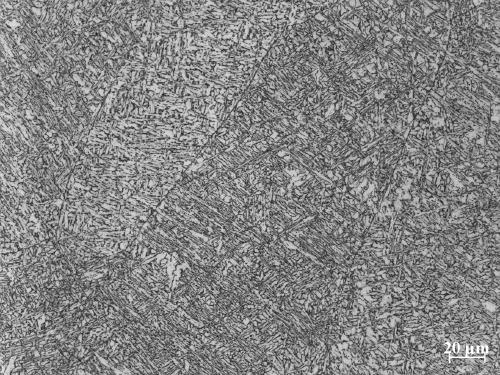

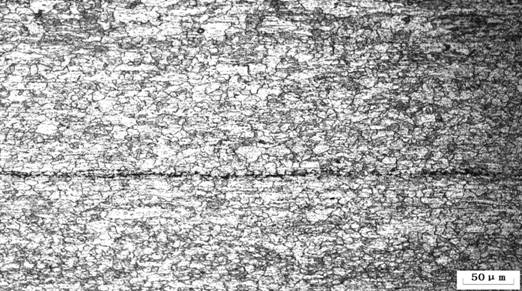

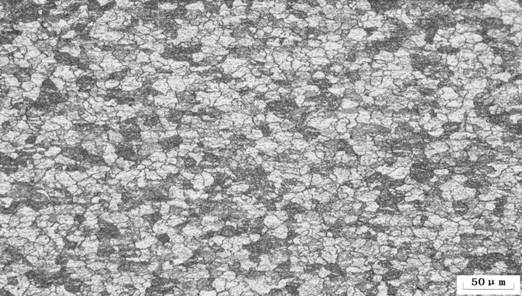

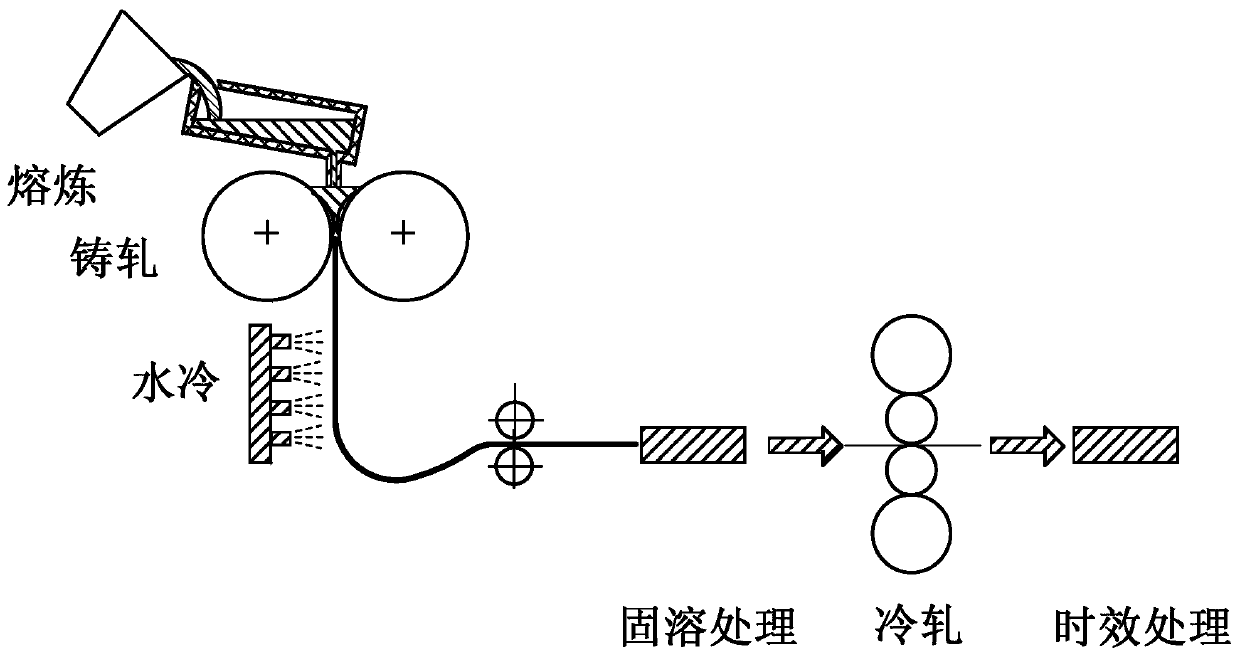

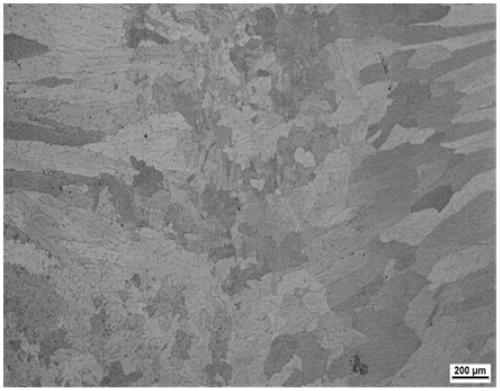

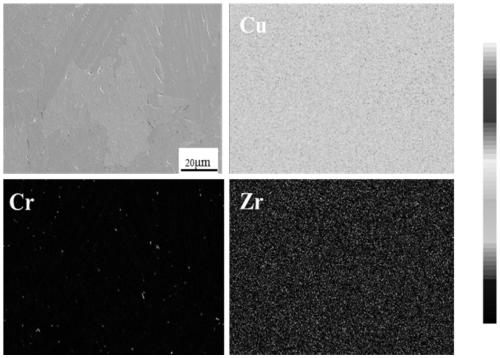

A Preparation Method of Cu-Cr-Zr Alloy Ribbon Based on Subrapid Solidification

A preparation method based on sub-rapid solidification Cu‑Cr‑Zr alloy thin strip, including the following steps: (1) Smelting Cu‑Cr‑Zr alloy melt according to the designed composition, the composition contains Cr 0.5~1.5%, Zr 0.1~ 0.2%, the rest is Cu; (2) Pour into the tundish, control the superheat to 50-100°C, then pour into the double-roller thin strip casting and rolling mill, and water-cool after the rolls are out; (3) Perform multi-pass cold rolling, and the total The reduction rate is 85-95%; (4) Aging treatment is performed at 350-500°C. Since the molten metal can directly form a near-net shape thin strip, the method of the present invention can eliminate the need for processes such as homogenization annealing and hot rolling. Sub-rapid solidification improves the solid solubility of Cr in Cu and effectively suppresses the formation of Cr and Zr. Segregation improves the yield and significantly reduces the cost. After aging, the tensile strength is ≥567MPa and the electrical conductivity is ≥80% IACS. While saving energy and reducing emissions, simplifying the process and reducing production, a thin strip with excellent comprehensive properties is finally obtained.

Owner:NORTHEASTERN UNIV LIAONING

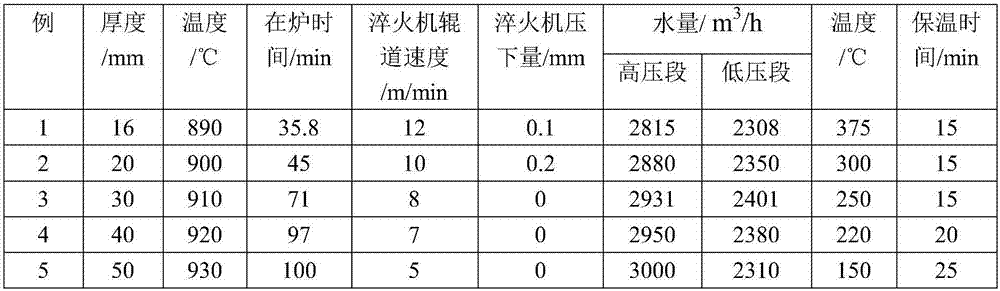

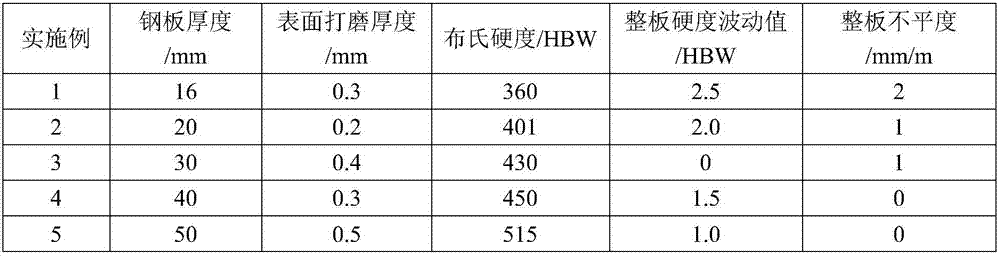

Heat treatment method for improving hardness uniformity of wear-resistant steel surface

InactiveCN107164612ASmall amount of depressionReduce roller speedFurnace typesHeat treatment furnacesQuenchingSteel plates

The invention relates to the technical field of wear-resistant steel, in particular to a heat treatment method for improving the uniformity of surface hardness of wear-resistant steel. The heat treatment method for improving the uniformity of surface hardness of wear-resistant steel of the present invention comprises the following steps: 1) carrying out shot blasting treatment on the wear-resistant steel plate in a hot-rolled state; 2) entering the steel plate after shot blasting treatment into a roller hearth type continuous heat treatment furnace Heating; 3) using high-pressure water in the spiral roller gap type pressure quenching machine to perform quenching treatment; wherein, the water volume of the high-pressure section of the quenching machine is 2800~3000m3 / h, and the water volume of the low-pressure section of the quenching machine is 2300~2500m3 / h; 4 ) Tempering the quenched steel plate. The wear-resistant steel plate produced by the production method of the invention has good hardness uniformity, excellent plate shape and good surface quality, the unevenness of the steel plate reaches 0-3 mm / m, and a tempered martensite structure is obtained. The preparation method is simple and practical.

Owner:SHANDONG IRON & STEEL CO LTD

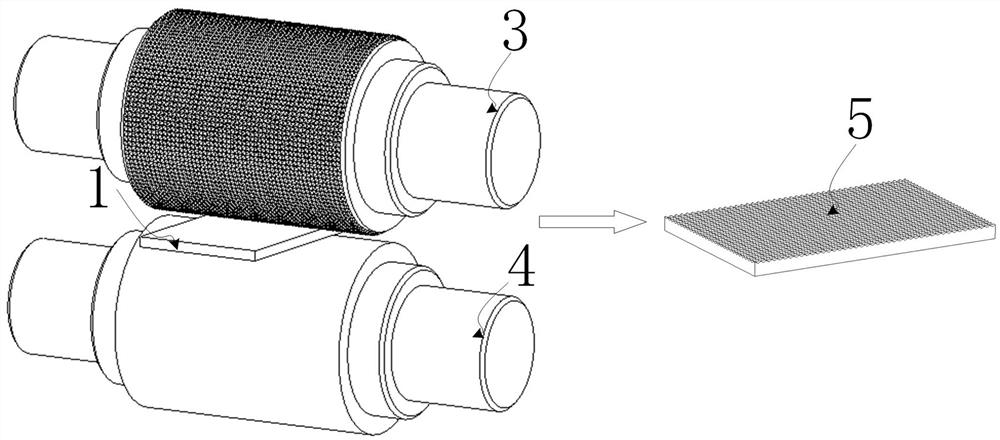

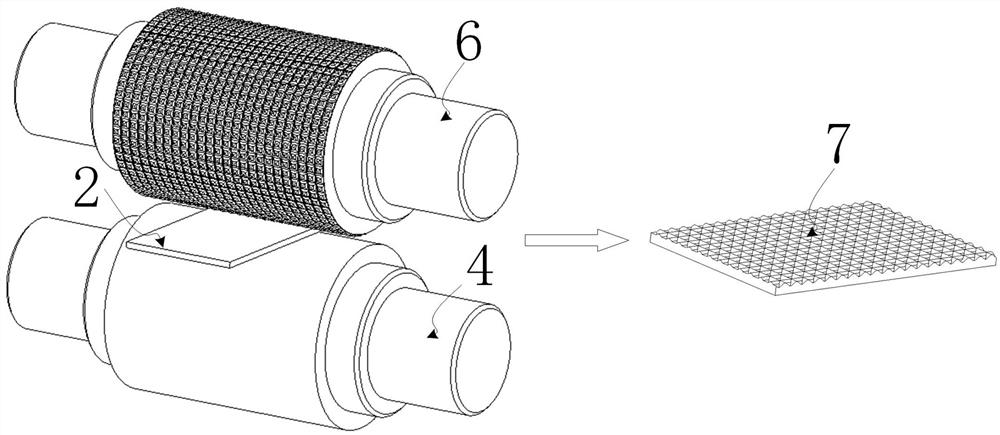

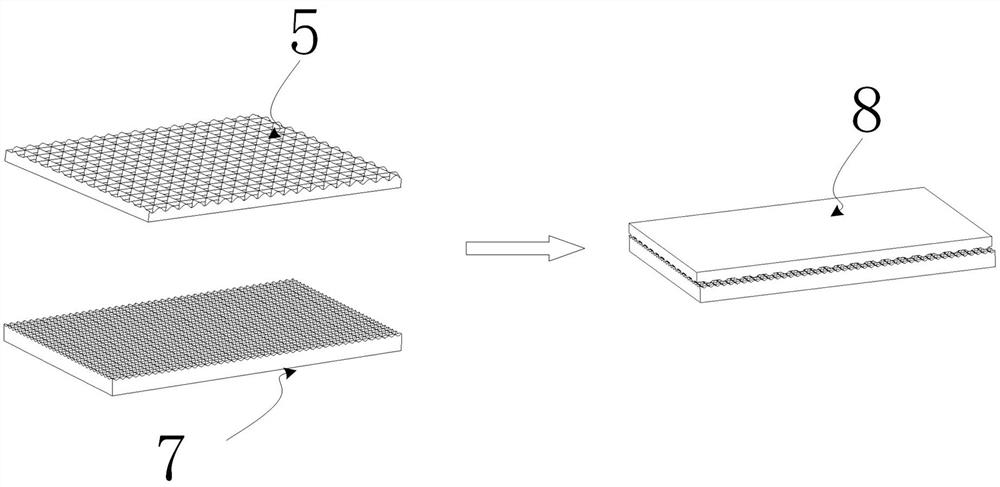

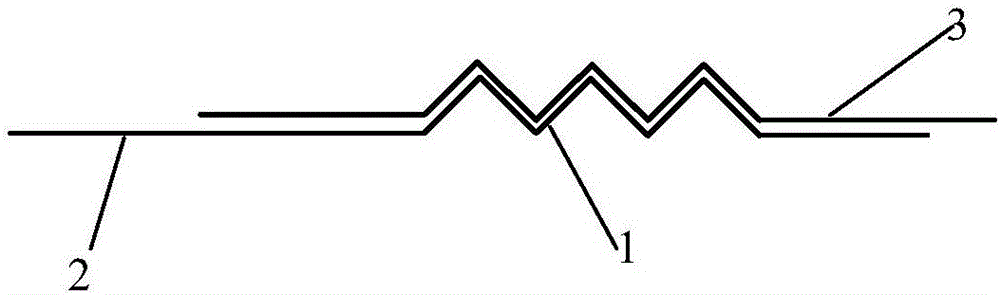

Rolling method for metal composite plate with prefabricated crossed corrugated interface

ActiveCN113020262ASolve warpingIncrease the areaWork heating devicesAuxillary arrangementsComposite plateUltimate tensile strength

The invention relates to the technical field of metal composite plate preparation, in particular to a rolling method for a metal composite plate with a prefabricated crossed corrugated interface, and aims to solve the technical problems that a metal composite plate manufactured by adopting an existing rolling method is low in interface bonding strength, serious in warping and edge cracking and the like. According to the technical scheme, a crossed corrugated roller with a triangular waveform is used for prefabricating corrugations on the to-be-compounded surface of a base plate, the ratio of the amplitude of the corrugated roller to the thickness of the base plate is 1 / 20-1 / 10, the reduction rate is 5%-10%, a crossed corrugated roller with a sine curve waveform is used for prefabricating corrugations on the to-be-compounded surface of a compound plate, the ratio of the wave amplitude to the thickness of the compound plate is between 1 / 10 and 1 / 2, the reduction rate of the working procedure is between 10% and 50%, and then a base plate blank and a compound plate blank are stacked and are flatly rolled under the condition that the reduction rate is lower than 50%. Compared with a traditional rolling method, the bonding strength can be improved, the residual stress can be reduced, plate warping can be controlled, and the high-quality metal composite plate can be prepared.

Owner:TAIYUAN UNIV OF TECH

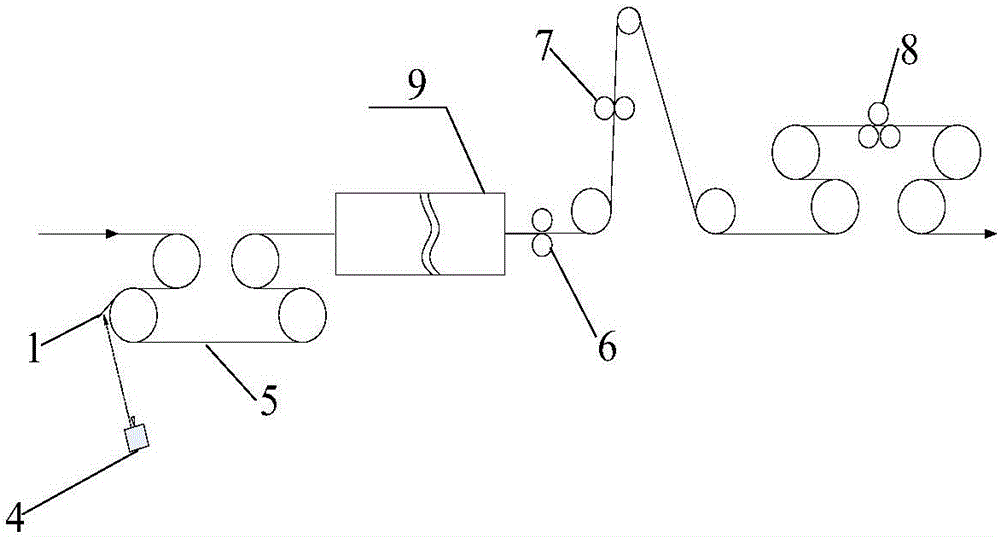

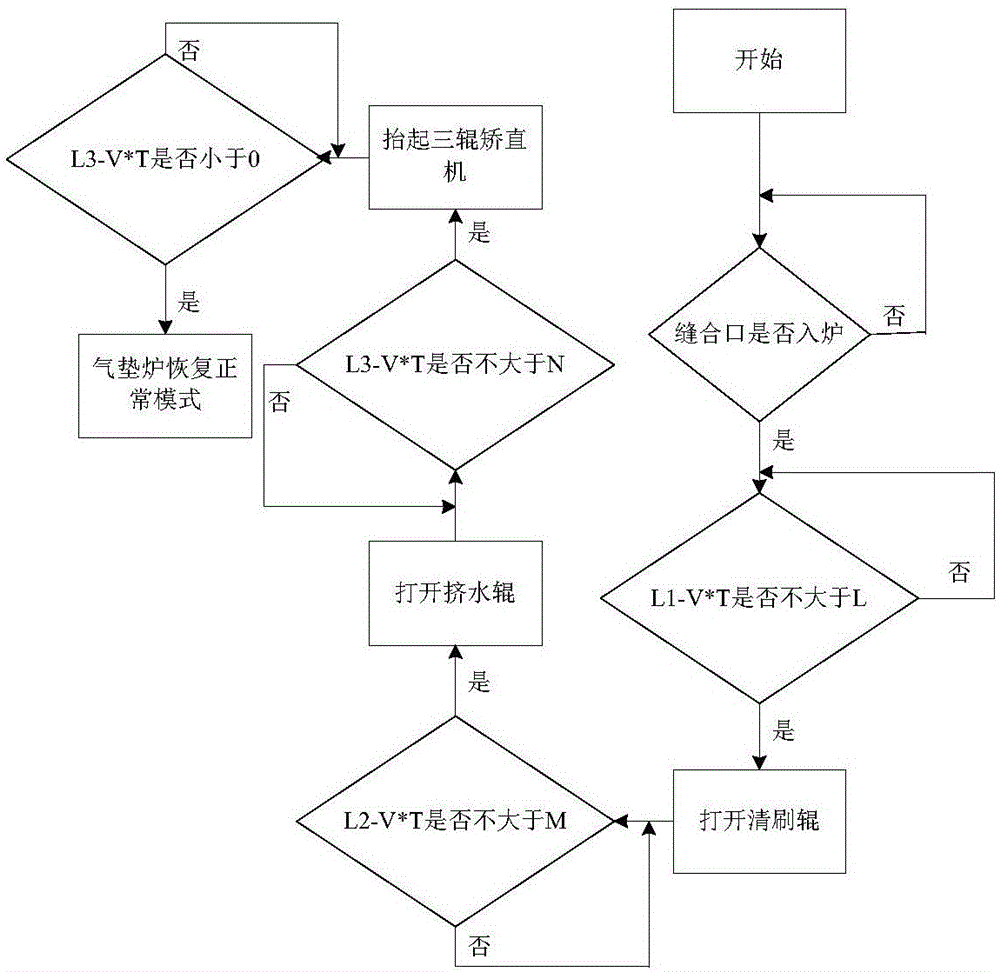

Method for feeding strip provided with seam into furnace and air cushion furnace

InactiveCN106755936AReduce tensionSmall amount of depressionFurnace typesHeat treatment process controlEngineeringContinuous production

The invention discloses a method for feeding a strip provided with a seam into a furnace. The method for feeding the strip provided with the seam into the furnace comprises the steps that the position of the seam is detected, when it is detected that the position of the seam is located at an inlet of the air cushion furnace, the tension in the air cushion furnace is reduced to be within the safe tension value range, and when the seam enters the air cushion furnace, the phenomenon that the strip is broken because of bearing excessively large tension in the furnace, so that continuous production cannot be conducted is avoided; before the seam reaches scrubbing rollers, the scrubbing rollers are controlled to be open, before the seam reaches squeeze rollers, the squeeze rollers are controlled to be open, and the phenomenon that when the seam passes through the scrubbing rollers and the squeeze rollers, because the seam is ragged and collides with the scrubbing rollers and the squeeze rollers, the scrubbing rollers or the squeezing rollers are damaged is avoided; and before the seam reaches a three-roller straightening machine, the rolling reduction of the three-roller straightening machine is reduced, the drawing and straightening tension of the three-roller straightening machine is reduced, and the phenomenon that the strip is broken is avoided. Therefore, the production efficiency is effectively improved.

Owner:SOUTHWEST ALUMINUM GRP

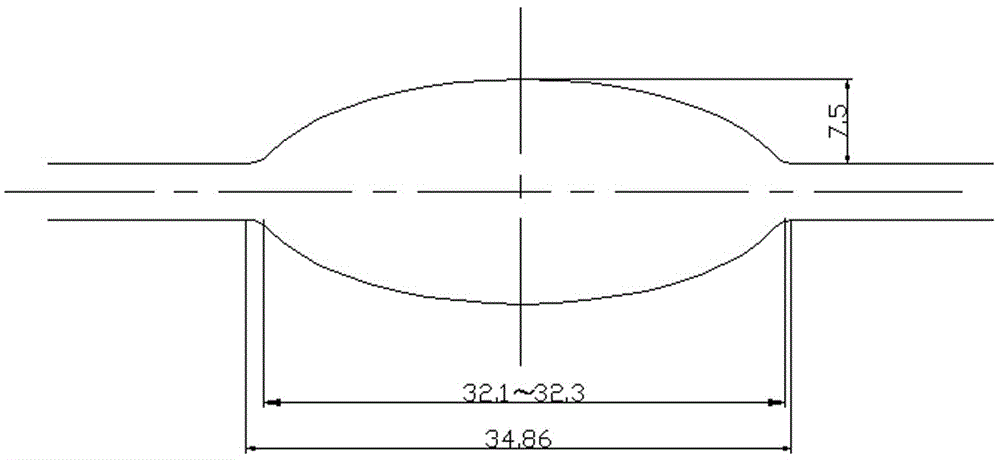

A production method of 24-pass high-efficiency hot-rolled φ8 coiled snails with low energy consumption

The invention discloses a production method with low energy consumption, 24 passes and high efficiency for hot rolling of a phi-8 coiled reinforced bar. The production method comprises four rolling mills for rough milling, six rolling mills for intermediate rolling, four rolling mills for finish rolling of bars and ten rolling mills for finish rolling of wires, wherein 1H to 3H racks roll by adopting a slotless form; 4V to 14V racks and No.15 to No. 24 racks roll by adopting a round / elliptical pass form; the 14V rack produces rolled pieces which are round bars of 24+ / -0.5mm; the pass width of the No.15 rack is 32.1-32.3mm, and the pass height is 16.15-16.30mm. According to the production method disclosed by the invention, by meticulously designing pass parameters of all the passes prior to the wire finish rolling mills for the hot rolling of the phi-8 coiled reinforced bar, and controlling the size and the precision of incoming bars for wire finish rolling, the safety of a motor of the wire finish rolling mill is guaranteed; the elongation percentage is reasonably distributed by the wire finish rolling racks, so that the phi-8 hot-rolled coiled reinforced bars are rolled on the 24 racks. Compared with a mode of rolling by 26 racks in the prior art, the mode disclosed by the invention has the advantages that the consumption of spare parts and the production energy consumption can be greatly reduced, and the production efficiency is improved.

Owner:红河钢铁有限公司

Process for producing thin gauge pipeline steel by using double-stand medium and heavy plate mill

ActiveCN102671941BGuaranteed Dynamic RecrystallizationImprove lateral performanceTemperature control deviceWork treatment devicesMetallurgyLaminar cooling

The invention discloses a process for producing thin gauge pipeline steel by using a double-stand medium and heavy plate mill. A plate blank with the thickness of 180 mm is used for producing the thin gauge pipeline steel with the thickness less than 10 mm. On the basis that the performance of a rolled piece meets requirements, the thin gauge pipeline steel with a good plate shape can be obtained by controlling the tapping temperature of the plate blank, the rough rolling broadening pass pressing rate, the longitudinal rolling pass pressing rate after rough rolling broadening pass, the rough rolling finishing temperature, the thickness of a middle blank, the finish rolling ending pass pressing rate, the finish rolling finishing temperature, the roller gap inclination and sled function in the rolling process, a high pressure water descaling system, the water entry temperature, the re-reddening temperature, and the head and tail shielding and straightening process of a laminar cooling system. The deformation rate is reduced, and the economic benefit is increased.

Owner:NANJING IRON & STEEL CO LTD

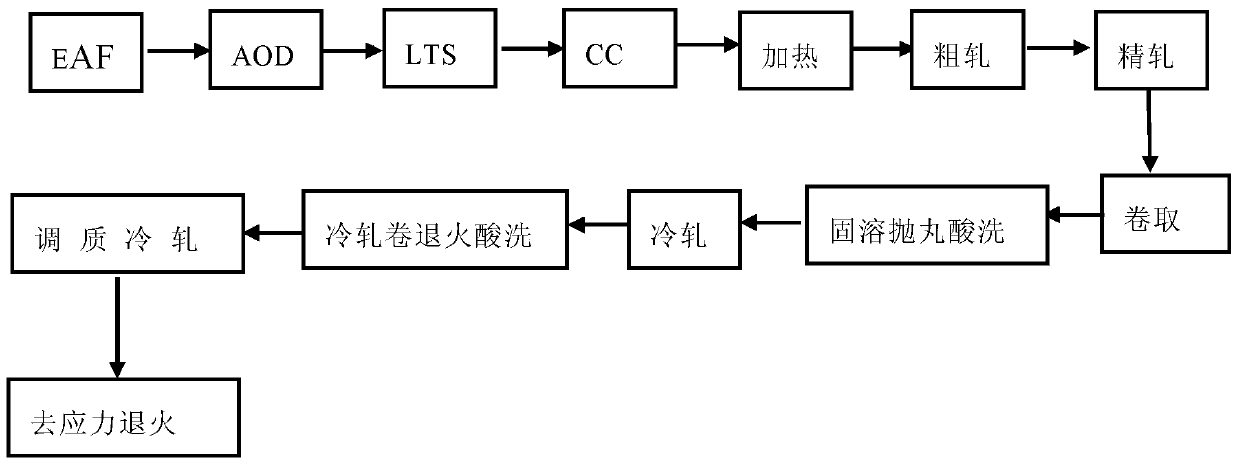

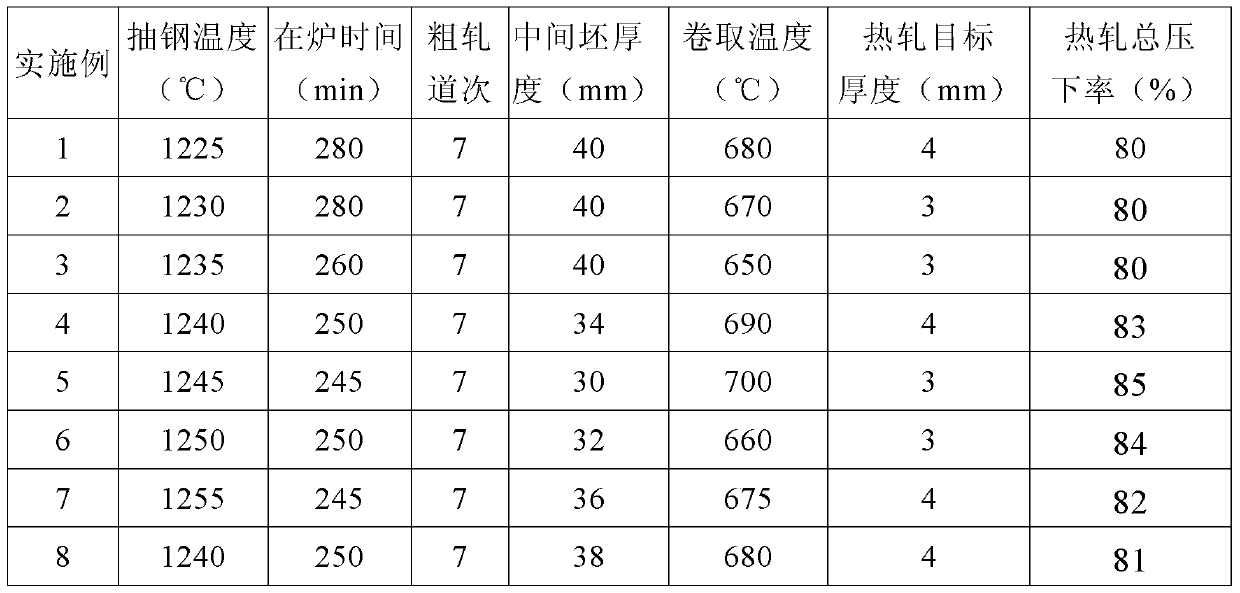

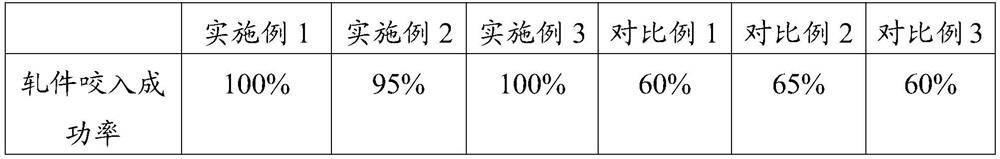

A kind of superhard austenitic stainless steel and its manufacturing method

The invention discloses a super-hard austenitic stainless steel and a preparation method thereof. The super-hard austenitic stainless steel comprises the following chemical components by weight percent: 0.08-0.13% of C, 0.3-1.0% of Si, less than 2.0% and greater than or equal to 0.5% of Mn, 16.5-17.5% of Cr, 6.5-7.5% of Ni, 0.03-0.08% of N, 0.5-0.8% of Mo, greater than or equal to 0.040% of P, greater than or equal to 0.01% of S, Fe and unavoidable impurities; the temperature of Md30 is 30-60 DEG C. By controlling the tempering and cold rolling reduction rate to 35-45%, controlling the rolling speed to less than or equal to 5m / s and the rolling temperature to less than or equal to 30 DEG C, the transformation from the austenite to the deformation martensite is created and the hardness of the material is greatly increased under the same deformation; when the tempering and cold-rolling reduction rate is 35%, the hardness HV is greater than 550 and the anisotropy of the super-hard state steel is reduced.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

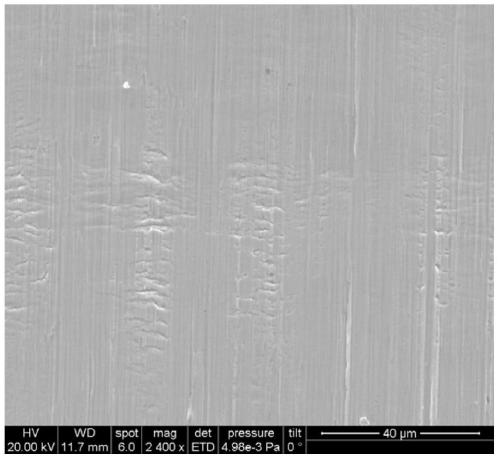

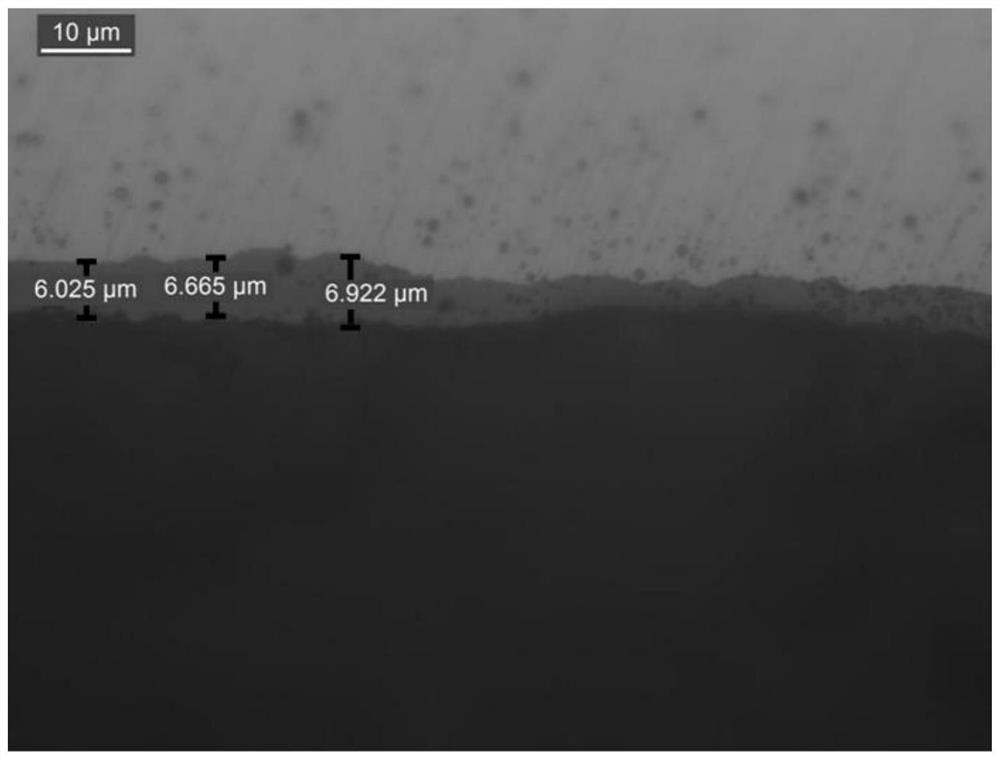

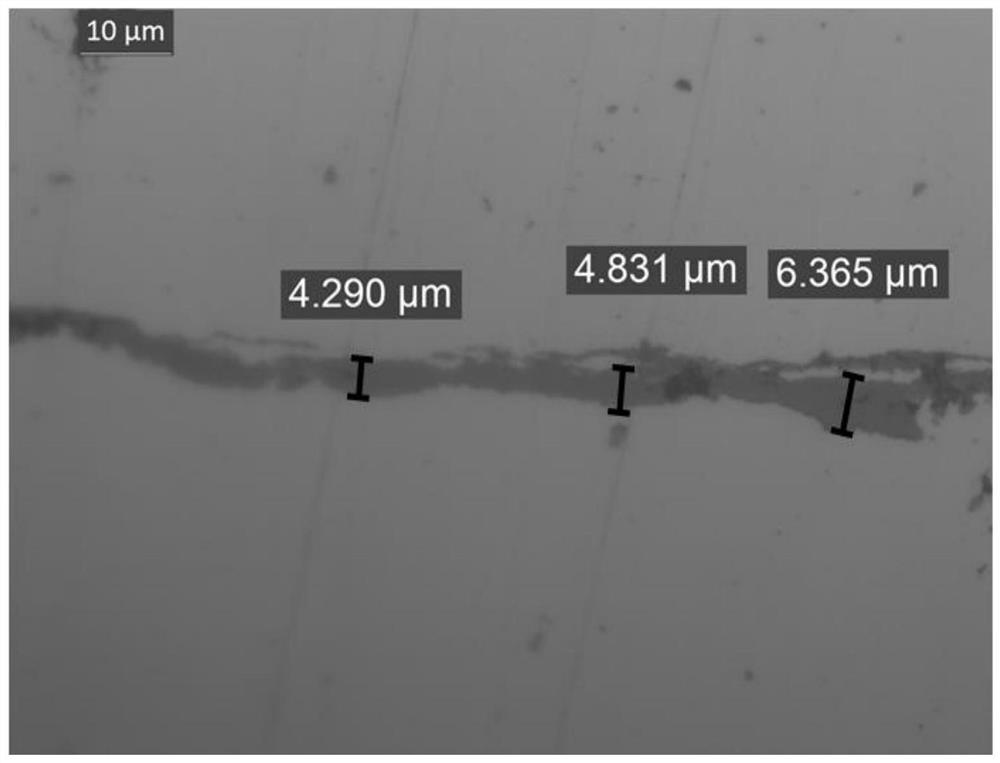

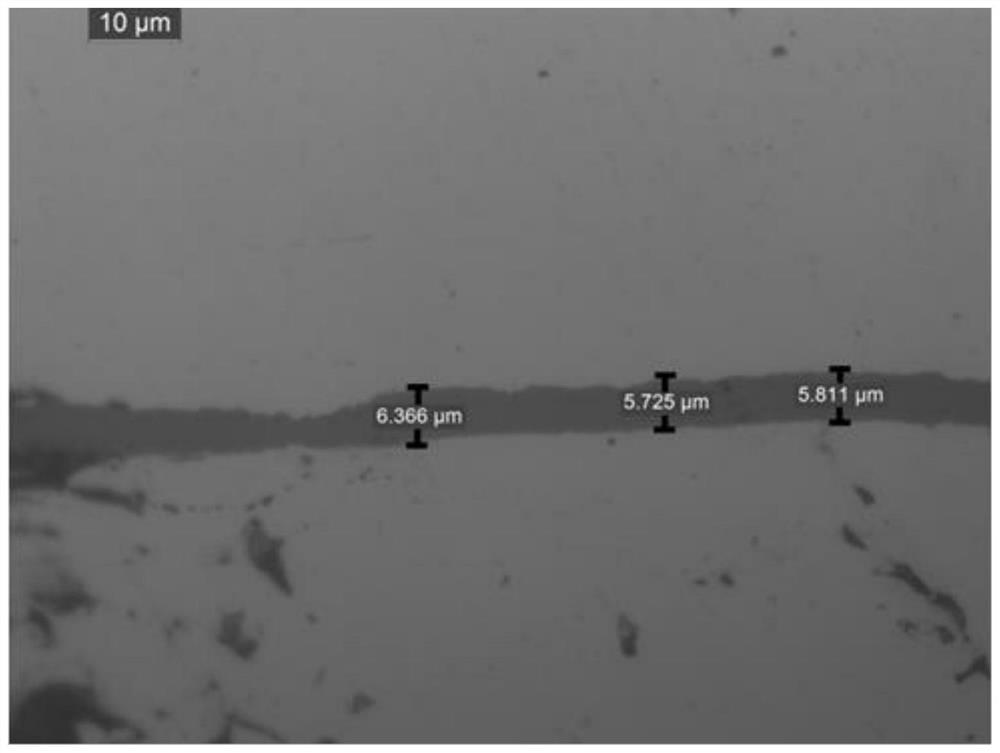

A kind of hot-rolled narrow strip steel for fan blade and its preparation method

The invention provides hot-rolled narrow strip steel for fan blades, and belongs to the field of special steel. According to the hot-rolled narrow strip steel and the preparation method, the heating temperature of a uniform heating section is controlled in a narrow range, the heating time of the uniform heating section is prolonged, the temperature uniformity of a casting blank is improved, the temperature difference in and outside the blank body is reduced, and the phenomena of bending and twisting of rolled pieces in the rolling process are avoided; the bouncing value of a rolling mill is reduced, the stability of the rolling process is improved, the finish rolling roller diameter difference is strictly controlled and the roller diameter of the finish rolling working roller is standardized, the roller diameter is arranged from large to small, the contact arc length of the small-diameter working roller and the rolled material is short, the rolling force, the friction force and the torque can be greatly reduced, and the rolling precision is improved. The data of the embodiment show that the product prepared by the method is high in dimensional precision, the AB difference is less than or equal to 0.01 mm, the three-point difference is less than or equal to 0.03 mm, the strip difference is less than or equal to 0.04 mm, the production requirements of fan blades can be met, the cost is not increased compared with the conventional production process, meanwhile, the implementation difficulty is low, and the method has extremely high generalization performance.

Owner:QIANAN CITY JIUJIANG WIRE

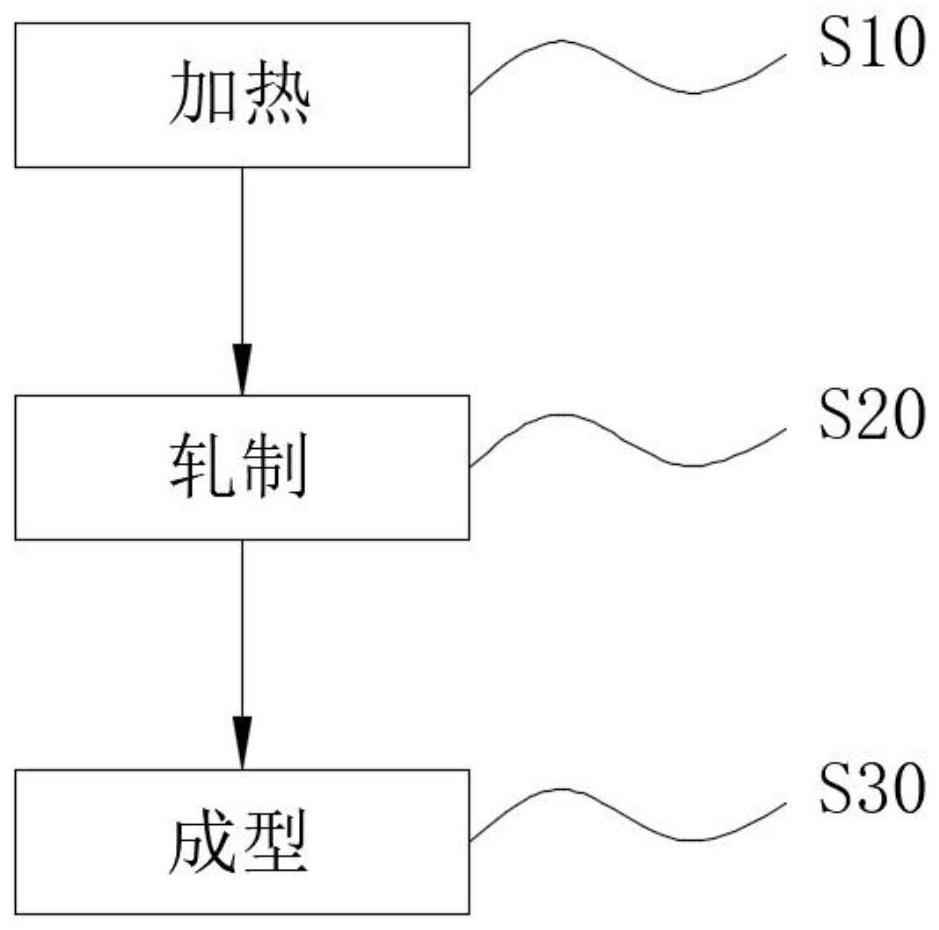

Method for improving H13 steel rolling, and H13 round steel

PendingCN112170480AImprove organizational center porosityAffect production efficiencyRollsMetal rolling arrangementsContinuous rollingRolling mill

The invention discloses a method for improving H13 steel rolling, and H13 round steel. The method comprises the steps of heating: specifically, heating an H13 steel billet in a continuous furnace; rolling: specifically, performing multi-pass rolling for the heated H13 steel billet in a cogging mill, wherein a low pressing process is adopted in the first-pass rolling; stopping roller cooling waterfor rolling, and obtaining an H13 intermediate billet; and forming: specifically rolling and forming the H13 intermediate billet rolled by the cogging mill in a continuous rolling mill. According to the method, through improvement of a first pass, a second pass and a third pass, in the first rolling pass, the low pressing process is adopted for rolling, and the pressing amount is reduced, so thatthe press-in angle of a rolled piece in the rolling process is small, thereby facilitating press-in; meanwhile, in the second rolling pass and the third rolling pass, a high pressing process is adopted for rolling, not only are the advantages of the high pressing process reserved, and the structure center porosity of a finished product is improved, but also reduction or remelting of rolled wastesis reduced; and the production efficiency and the production cost are ensured.

Owner:BAOSTEEL SPECIAL STEEL SHAOGUAN CO LTD

Method for rolling thin high-strength steel plate of single-frame steckel mill

ActiveCN102179406BGrain refinementEliminate temperature differenceRoll force/gap control deviceTemperature control deviceFurnace temperatureSheet steel

The invention discloses a method for rolling a thin high-strength steel plate of a single-frame steckel mill. The method comprises the following steps: producing the finished product of a high-strength steel plate with a thickness less than 10 millimeters by using a blank with the thickness of 150 millimeters and the length more than 10 meters; and then acquiring the thin high-strength steel plate with qualified property and plate shape by controlling a tapping temperature, a coiler furnace temperature, a reduction in last pass, a roller force, a final rolling speed and a high pressure water de-scaling system. When the rolling method is used for producing the thin steel plate, the thin high-strength steel plate is rolled by utilizing the heat preservation function of front and back mill coiler furnaces and controlling the tapping temperature of the blank, the reduction in the last rolling pass, the roller force and the final rolling speed, and the acquired plate shape and property of the steel plate are both qualified, thereby increasing the rolling mill capacity and achieving high plate yield and high property yield.

Owner:NANJING IRON & STEEL CO LTD

A control method for a hot rolling roughing mill

ActiveCN108838212BSmall amount of depressionAdjustable speedRoll mill control devicesMetal rolling arrangementsLoad distributionRapid response

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

A forming method of copper/aluminum composite material with high interfacial bonding strength

ActiveCN110681694BHigh interface frictionEasy extrusion weldingAuxillary arrangementsMetal rolling arrangementsAluminum compositesUltimate tensile strength

The invention discloses a forming method of a copper / aluminum composite material with high interface bonding strength, belonging to the technical field of metal layered composite material preparation. This forming method processes the surface to be compounded of the copper plate and the aluminum plate to obtain a macroscopic uneven surface to be compounded, and uses a louver to polish the compounded surface. The direction of the stripes formed by grinding is perpendicular to the rolling direction, and then the copper plate and the Aluminum plates are stacked up and down or side by side to obtain copper / aluminum billets, followed by single-pass low-pressure cold rolling pre-compounding, then high-temperature short-term heating, and finally single-pass hot rolling final compounding to obtain high interface bonding Strong copper / aluminum composite. The invention has the advantages of low requirement on the capacity of the rolling mill required to produce the copper / aluminum composite material, simple process, and low production cost, and can obtain a macroscopic composite interface of a non-straight artificial structure and a microscopic composite interface of a particle pinning structure, and the interface is combined The strength is greater than or equal to 90MPa, and the range of applicable copper / aluminum composite materials is wide, which is easy for industrial promotion.

Owner:UNIV OF SCI & TECH BEIJING

Multiple-transmission device for rolling mill

InactiveCN105710134ASolve the slipping phenomenonSolving pass rateRolling mill drivesAuxillary arrangementsWork rollMaterials science

The invention relates to a multiple-transmission device for a rolling mill and belongs to a multiple-transmission device for a rolling mill in metallurgy industry. The multiple-transmission device is used for solving the technical problems of high possibility of slipping, low quality passing percent of products and small rolling range of a working roll in an existing four-roll or multi-roll rolling mill. In order to solve the technical problems, the technical scheme adopted by the invention is as follows: the multiple-transmission device for the rolling mill comprises two rolling transmission devices, wherein one rolling transmission device is a support roll transmission device; the support roll transmission device is connected with a support roll and used for realizing large-torque rolling; the other rolling transmission device is a working roll transmission device; and the working roll transmission device is connected with the working roll and used for realizing high-speed small-torque milling. The multiple-transmission device has the advantages of multiple transmission devices, good product surface quality of rolled pieces, independent transmission and simultaneous transmission.

Owner:SHANXI CHUANGQI IND

A kind of hot-rolled narrow strip steel for stamping parts and its preparation method and application

ActiveCN109332379BReduce rolling loadHigh dimensional accuracyTemperature control deviceWork treatment devicesStrip steelUltimate tensile strength

The invention provides a hot rolled narrow strip used for a stamping part, a preparation method and an application and belongs to the technical field of metallurgy. The prep ration method comprises the following steps: successively conducting heating, a first dephosphorization, roughing, a second dephosphorization, finish rolling and winding a casting blank so as to obtain a hot rolled narrow strip used for a stamping part. For the hot rolled narrow strip provided by the invention, the AB difference is less than or equal to 0.01mm; the difference of three points is less than or equal to 0.03mm; the difference of a cleaning rod is less than or equal to 0.04mm; the thickness of a sinter is less than or equal to 7 microns; the yield strength is 258-285MPa; the tensile strength is 364-385MPa;the percentage elongation after fracture is 44.0-46.0%, so the hot rolled narrow strip can meet the production demand of the stamping part; compared with a conventional production process, the cost isnot increased; meanwhile, with small implementation difficulty, the invention has high generalizability.

Owner:QIANAN CITY JIUJIANG WIRE

A kind of ultra-wide aluminum alloy plate and preparation method thereof

ActiveCN113564502BReduce residual internal stressHigh strengthSolution treatmentUltrasonic vibration

The invention belongs to the technical field of aluminum alloys, in particular to an ultra-wide aluminum alloy plate and a preparation method thereof. The invention carries out ultrasonic treatment in the hot rolling process, continuously injects vacancies into the material through ultrasonic vibration, so that the material dynamically precipitates a large number of fine and dispersed nano-precipitated phases, and adds a pre-stretching process before solution treatment to reduce the aluminum alloy The residual internal stress of the plate improves the strength and elongation of the aluminum alloy plate, and the produced aluminum alloy plate has stable performance, high surface smoothness, low residual internal stress of the plate, and the plate is not easily deformed during machining.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com