Control method for head warpage of plate blank

A control method and slab technology, which is applied in the field of steel rolling, can solve problems such as bumping equipment damage and stacking steel accidents, and achieve the effects of reducing accident time, head warping accidents, and unplanned downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

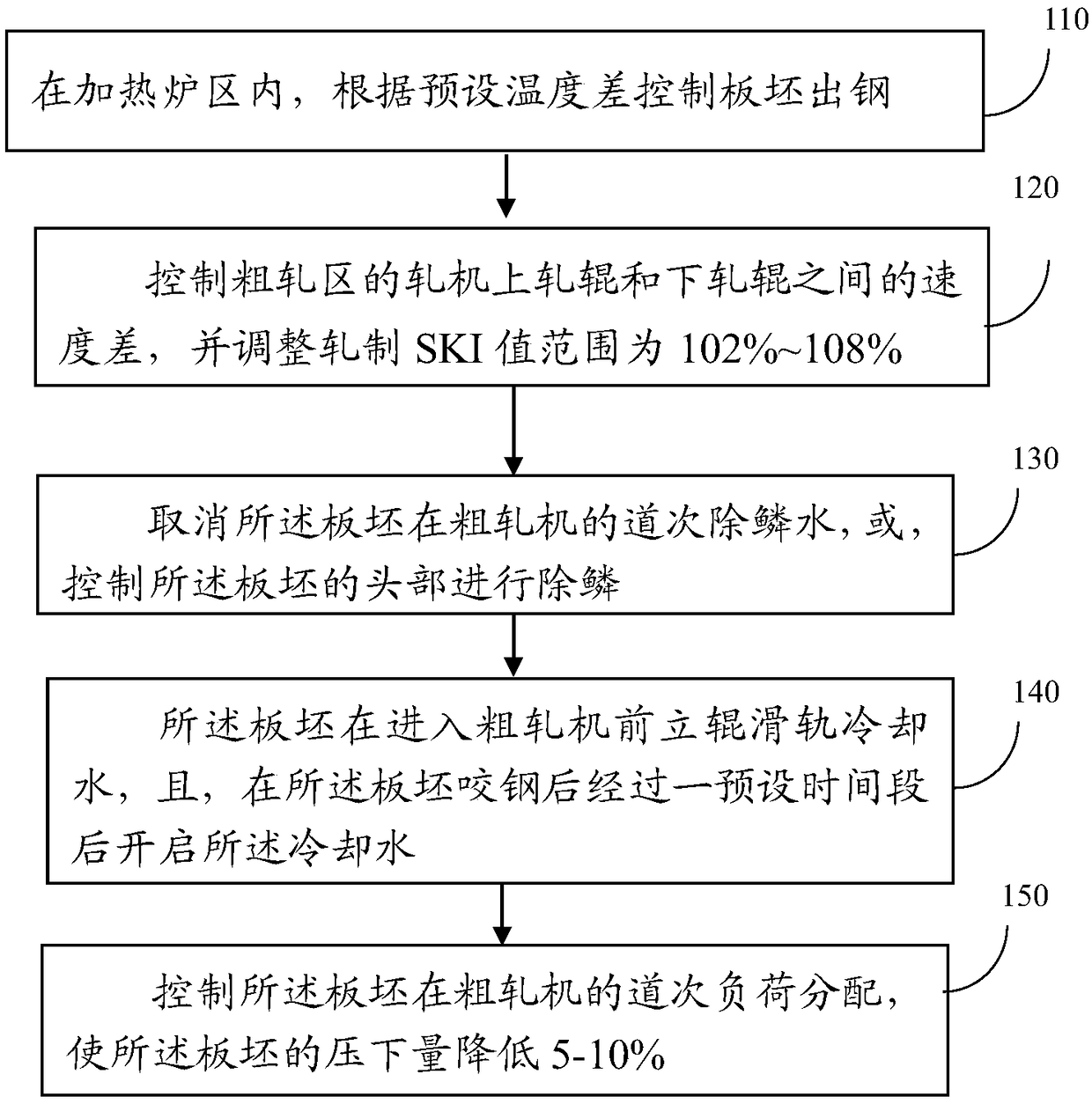

[0021] figure 1 It is a schematic flow chart of a method for controlling warping of a slab in an embodiment of the present invention. Such as figure 1 As shown, the method includes:

[0022] Step 110: In the heating furnace area, control the tapping of the slab according to the preset temperature difference;

[0023] Further, the method further includes: the preset temperature difference ranges from -20°C to 0°C.

[0024] Further, the temperature of the lower surface of the slab is lower than the temperature of the upper surface of the slab, and, during the rolling process, the elongation of the upper surface of the slab is greater than the elongation of the lower surface of the slab.

[0025] Specifically, firstly, the temperature difference between the upper and lower surfaces of the slab in the heating furnace area is controlled. Specifically, the operator controls the tapping according to the temperature difference between -20°C and 0°C, thereby ensuring that the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com