A kind of ultra-wide aluminum alloy plate and preparation method thereof

A technology for aluminum alloy sheet and aluminum alloy ingot, applied in the field of aluminum alloy, can solve the problems of two-rib wave thickness, increased temperature gradient, large quenching stress, etc., and achieves low cost, improved strength and elongation performance, and refined surface. organizational effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 17050

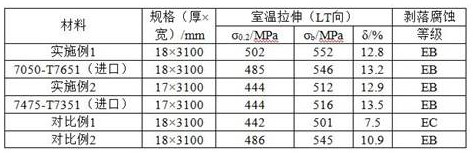

[0044] Example 1 Preparation of 7050 aluminum alloy ultra-wide plate

[0045] (1) The chemical composition of 7050 alloy is: Zn 6.2 wt%, Mg 2.2 wt%, Cu 2.3 wt%, Zr 0.1 wt%, Mn≤0.1 wt%, Ti≤0.06, Cr≤0.04 wt%, Fe≤0.15 wt% , Si≤0.12 wt%, the balance is Al and other unavoidable impurities.

[0046] (2) After batching, smelting, slag removal, degassing, and filtration according to the alloy composition, the alloy liquid is cast into an aluminum alloy square ingot by a low-speed semi-continuous casting process; the melting temperature is 720°C.

[0047] (3) The aluminum alloy ingot is placed in a heating furnace for homogenization treatment, and then the head and tail are cut off for surface milling. The homogenization treatment temperature is 450°C and the treatment time is 6.5h.

[0048] (4) The homogenized aluminum alloy ingot is subjected to 3 passes of hot rolling, and ultrasonic treatment is carried out at the same time to obtain a slab; the starting rolling temperature is 410...

Embodiment 27475

[0053] Example 2 Preparation of 7475 aluminum alloy ultra-wide plate

[0054] (1) The chemical composition of 7475 alloy is: Zn 5.8 wt%, Mg 2.4 wt%, Cu 1.6 wt%, Cr 0.22 wt%, Mn≤0.06 wt%, Ti≤0.06 wt%, Fe≤0.12 wt%, Si≤0.10 wt%, the balance is Al and other unavoidable impurities.

[0055] (2) After batching, smelting, slag removal, degassing, and filtration according to the alloy composition, the alloy liquid is cast into an aluminum alloy square ingot by a low-speed semi-continuous casting process; the melting temperature is 710°C.

[0056] (3) The aluminum alloy ingot was placed in a heating furnace for homogenization treatment, and then the head and tail were cut off for surface milling. The homogenization treatment temperature was 480° C., and the treatment time was 7 hours.

[0057] (4) The homogenized aluminum alloy ingot is subjected to 3 passes of hot rolling, and ultrasonic treatment is carried out at the same time to obtain a slab; the starting rolling temperature is 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com