Patents

Literature

35results about How to "Solving pass rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sand feeding method in manufacturing process of diamond roller

The invention provides a manual random sand feeding method in a process of processing a diamond roller by electroplating. The method comprises a gluing process and a sand feeding process. Through the method, the problems that the diamond rollers with different profile curves are difficult to process by a convection sand feeding method and the sand feeding efficiency is low and big diamond beyond 45 meshes cannot be processed when the diamond roller is processed by electroplating are solved, thus the diamond roller manufacturing range is widened.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

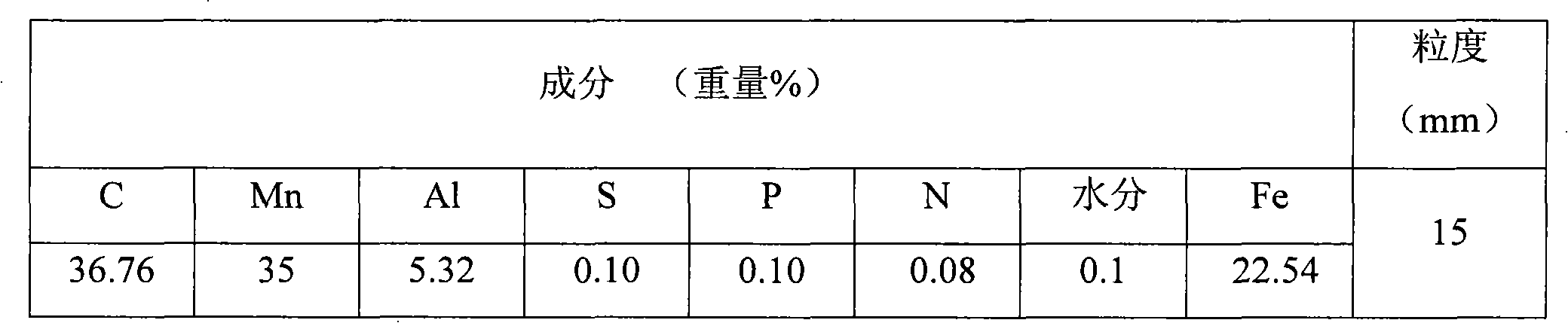

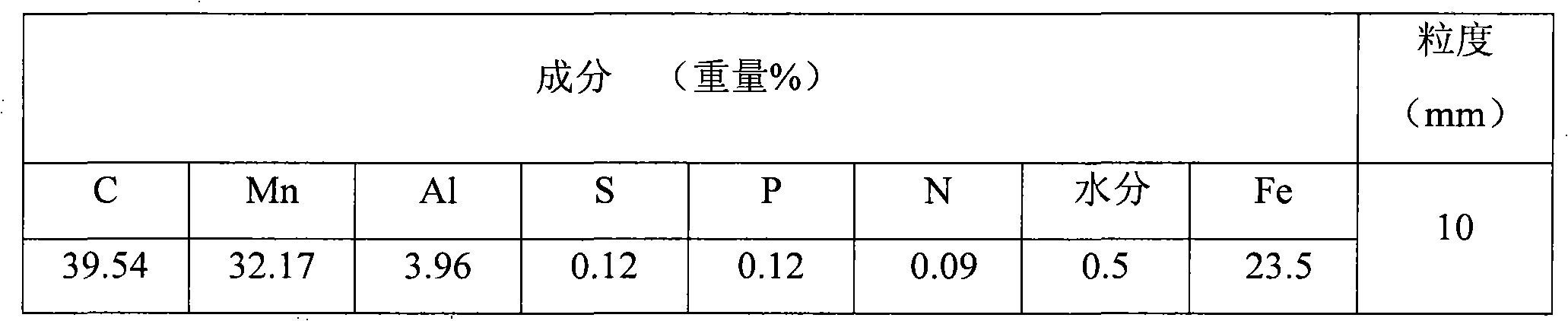

Carbon and manganese alloy material and preparation method thereof and steel making method applying material

The invention relates to a carbon and manganese alloy material and a preparation method thereof. The carbon and manganese alloy material comprises carbon (C), manganese (Mn), ferrum (Fe) and aluminum (Al), and moreover, by taking the total content of the carbon and manganese alloy material as a reference, the content of the C is 30-45 weight percent, the content of the Mn is 30-45 weight percent, the content of the Fe is 1-25 weight percent, the content of the Al is 3-10 weight percent, the content of phosphorus (P) is not greater than 0.15 weight percent, the content of sulfur (S) is not greater than 0.15 weight percent, the content of nitrogen (N) is not greater than 0.10 weight percent, and the content of moisture is not greater than 0.5 weight percent. The invention also provides a steel making method applying the carbon and manganese alloy material. By adopting the carbon and manganese alloy material prepared by the invention, molten steel can be stably recarburized or manganized, and the problems that the component of smelted steel is not stable, and the yield is low are solved. The recovery rate of carbon and the recovery rate of manganese are high and stable, and can be respectively and stably controlled to be between 90-96 percent, and moreover, the deoxidation rate of finished steel can also be simultaneously improved.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

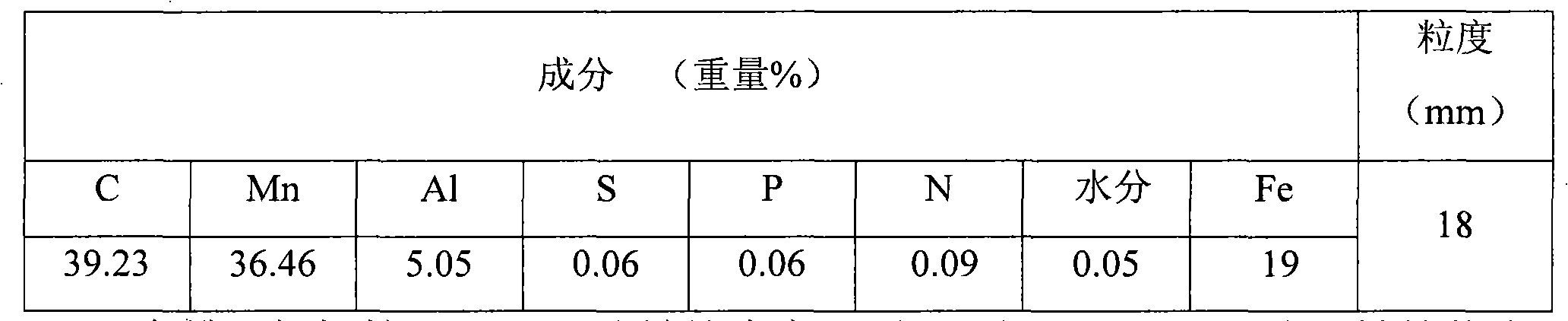

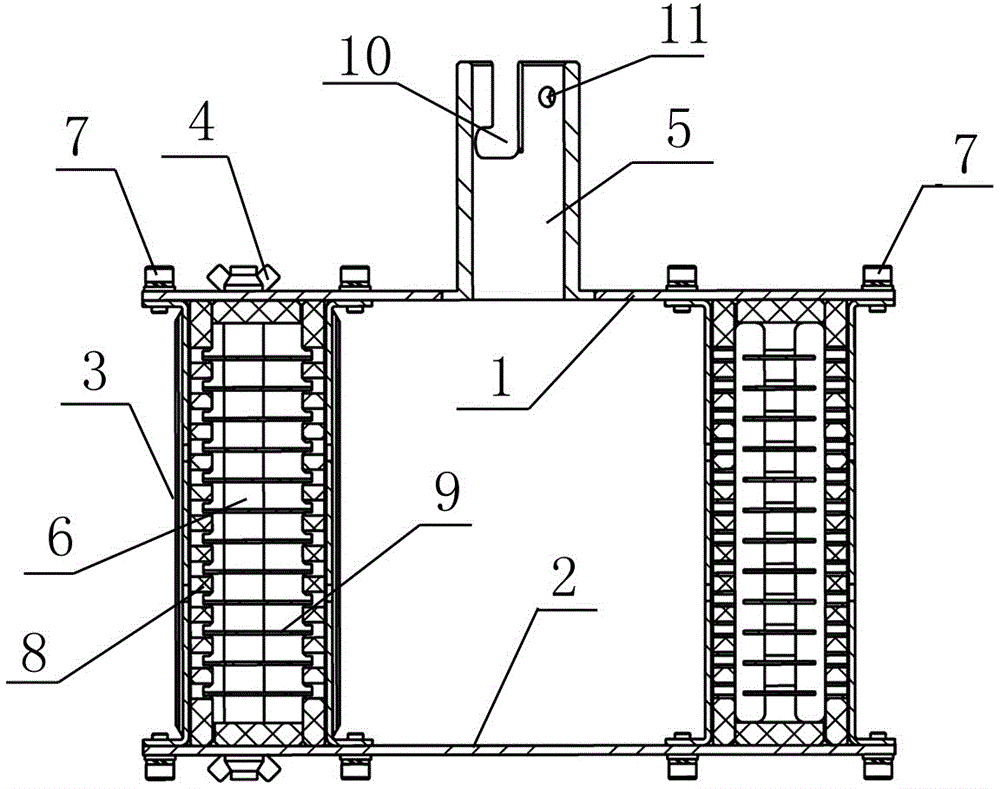

Multiple-parameter monitoring system used for electric welding machine

InactiveCN103157888AReasonable designLow input costArc welding apparatusComputer moduleMonitoring system

The invention discloses a multiple-parameter monitoring system used for an electric welding machine. The multiple-parameter monitoring system used for the electric welding machine comprises a lifting support, a lifting drive mechanism, a walking mechanism, a walking drive mechanism, an electromagnetic control switch, a welding speed calculating system based on welding depth estimating, a timing circuit for conducting statistics of weld time, a weld length calculating module, a temperature detecting unit, a first data storage unit, a deformation quantity calculating module, a first parameter input unit and a controller which controls walking speed of the walking mechanism, lifting height of the lifting support and on-off state of the electromagnetic control switch according to data detected by the welding speed calculating system, the deformation quantity calculating module and the weld length calculating module. The multiple-parameter monitoring system used for the electric welding machine has the advantages of being reasonable in design, easy and convenient to operate, good in use effect, capable of conducting motoring on parameters of welding depth, weld length, welding position deformation quantity of welding material and the like, and capable of solving problems existing in the existing welding process that welding quality is difficult to control, welding efficiency is low, product percent of pass is low and the like.

Owner:XIAN KUOLI MACHANICAL & ELECTRICAL TECH

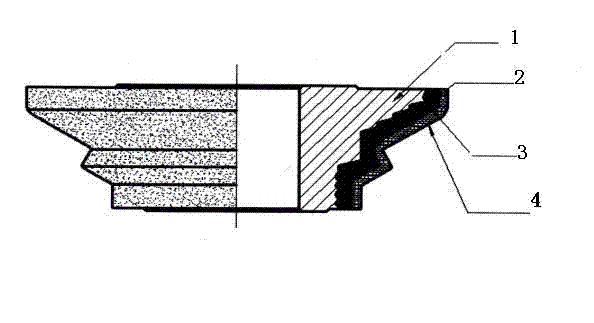

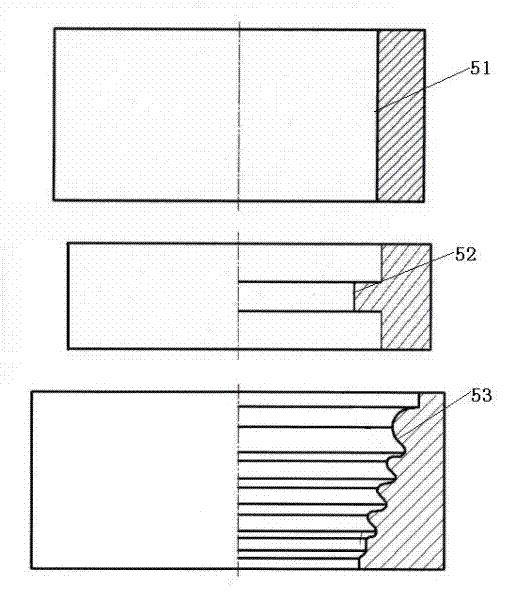

Clear dimension compression molding method for phenolic resin based complex profile product

InactiveCN101920562ADense inside the partImprove surface qualityCompression moldingMaterial consumption

The invention discloses a clear dimension compression molding method for a phenolic resin based complex profile product, which comprises the following steps of: firstly, preforming a plurality of equivalent flat plates, wherein each equivalent flat plate corresponds to one part of the phenolic resin based complex profile product; and then, superposing the equivalent flat plates, and matching the mold for molding to obtain the product. The method effectively improves the quality and the qualification rate of the product, reduces working procedures and material consumption, lowers cost and increases product efficiency.

Owner:国营江北机械厂

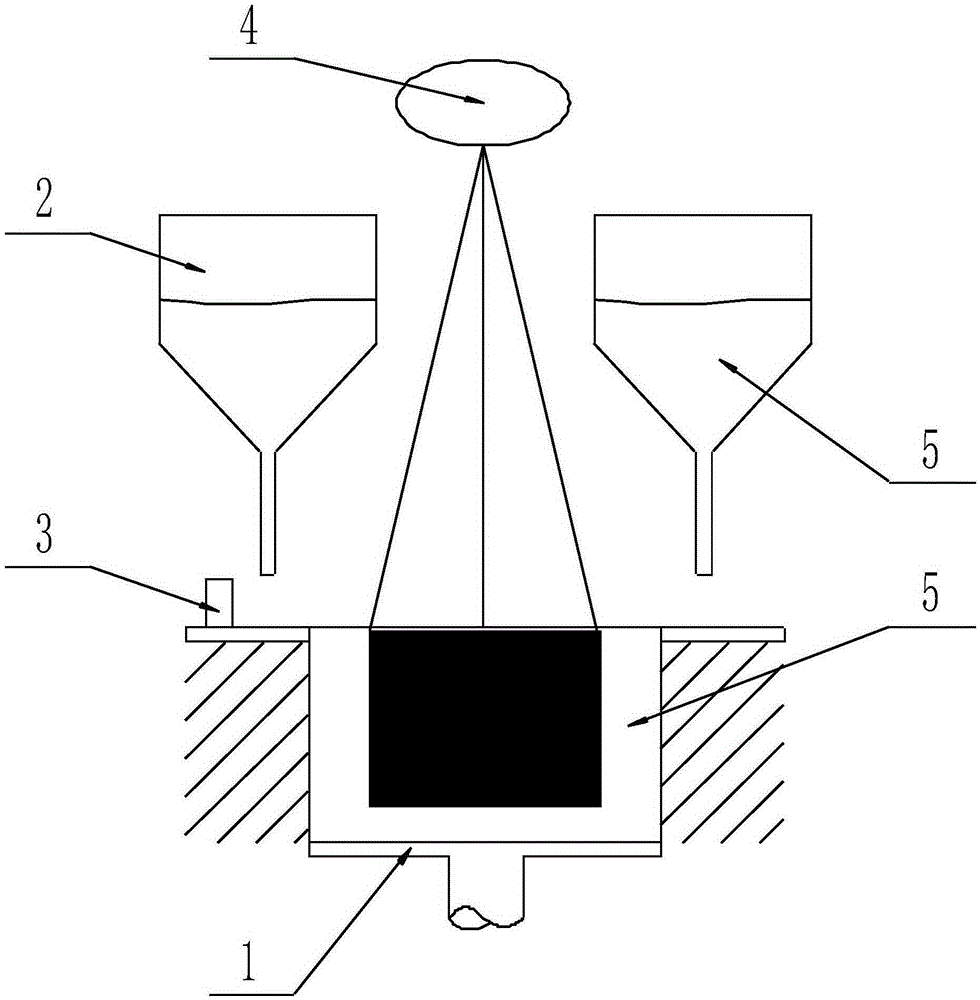

Method for growing complicated structures on surfaces of castings and forgings based on wire 3D printing

ActiveCN108339984AClosely connectedHigh material utilizationAdditive manufacturing apparatusIncreasing energy efficiencyStress concentrationEngineering

The invention relates to a method for growing complicated structures on the surfaces of castings and forgings based on wire 3D printing. The method comprises the following steps: (a) basal body structural parts are prepared; (b) three-dimensional scanning or three-coordinate machine modeling is performed on the basal body structural parts to prepare basal body structural part models; (c) structural design is performed on the surfaces of the basal body structural part models to obtain final part three-dimensional models; (d) two-dimensional slicing is performed on the three-dimensional models;obtained parameters are leaded into a 3D printer; and wires with the same materials with the basal body structural parts are leaded in to prepare printing; and (e) the basal body structural parts areplaced in the 3D printer; and added material manufacturing is performed on the surfaces of the basal body structural parts. The method generates the complicated structures on the surfaces of originalbasal body structural parts through the 3D printer; and meanwhile, the wires and the basal body structural parts are the same in material, so that printed complicated parts and the basal body structural parts are in tight metallurgical bonding and connection, and thick structures and centralized stress of the castings and low utilization rate of the forgings caused by machining are prevented.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD +1

Multi-station rotating stand device for washing and drying equipment and method for cleaning wafer

ActiveCN106024674ASolve efficiency problemsSolve the worse drying effectSemiconductor/solid-state device manufacturingCleaning processes and apparatusDynamic balanceEngineering

The invention relates to a multi-station rotating stand device for washing and drying equipment and a method for cleaning a wafer. The rotating stand device comprises a rotating stand base plate arranged horizontally, a rotating stand upper plate, and station structures; and the rotating stand upper plate arranged right above the rotating stand base plate is parallel to the rotating stand base plate and the station structures are arranged between the rotating stand base plate and the rotating stand upper plate vertically. At least two identical station structures are arranged on the rotating stand device and are distributed on the rotating stand device uniformly at intervals. Besides, a rotating stand small shaft arranged vertically is arranged at the center of the upper surface of the rotating stand upper plate. According to the invention, technical problems of low rotating standing working efficiency, poor drying effect, low dynamic balance value, poor cleaning effect, and reduced finished product yield of the traditional washing and drying equipment can be solved.

Owner:THE 45TH RES INST OF CETC

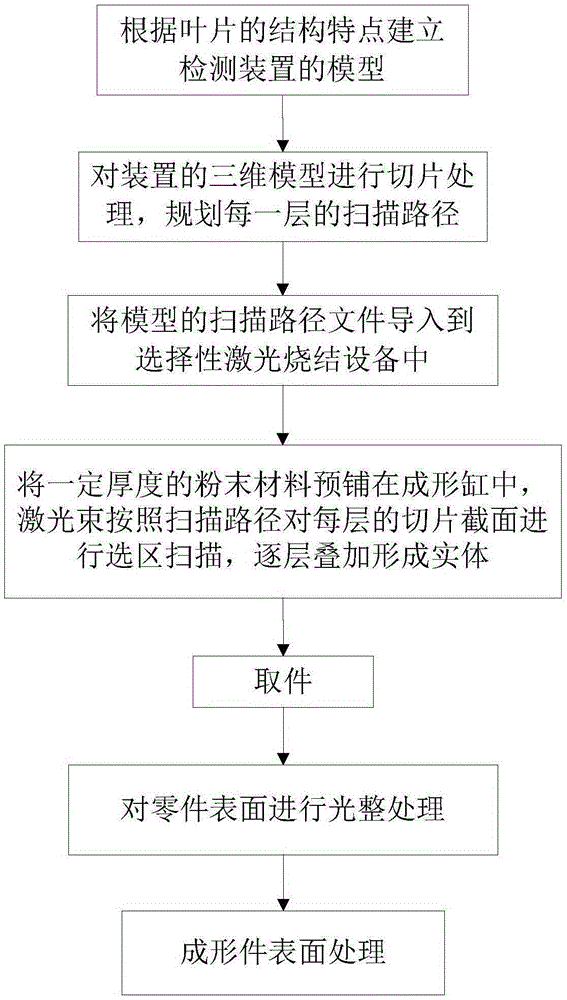

Rapid formation method of X-ray detecting device for blade of aviation engine

InactiveCN105269824ARapid Response ManufacturingImprove mechanical propertiesAdditive manufacturing apparatusAviationSelective laser sintering

The invention provides a rapid formation method of an X-ray detecting device for a blade of an aviation engine. The rapid formation method comprises the following steps: I, establishing a three-dimensional entity model of the X-ray detecting device according to the blade structure; II, slicing the model of the detecting device, and planning the laser scanning path of each layer; III, inputting the model on selective laser sintering equipment, setting the technological parameters of selective laser sintering, and adopting laser beams to scan powder material on each layer according to the planned scan path; IV, performing finishing treatment on the surface of a part after machining; V, enhancing the strength of a formed part; VI, after curing the part, removing the redundancy on the surface to obtain the X-ray detecting device. According to the rapid formation method, the technology is simple and easy to control, the operation is reliable, the production period is short, and the repeatability is high; the X-ray detecting device manufactured by adopting the rapid formation method is reliable in mechanical property, meets the operating requirements, and can realize rapid response manufacture according to different blade structures.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

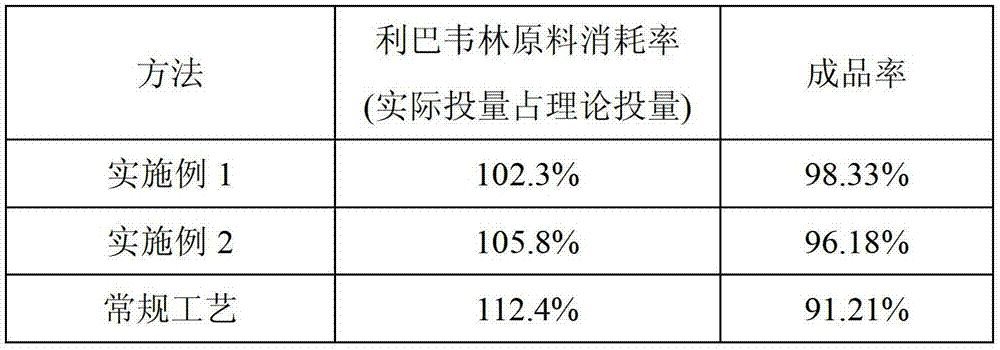

Ribavirin small-capacity injection preparation and preparation method thereof

InactiveCN103110949ASolve lossSolving pass rateOrganic active ingredientsPharmaceutical delivery mechanismHigh volume manufacturingFiltration

The invention discloses a ribavirin small-capacity injection preparation. The ribavirin small-capacity injection preparation comprises the following components in percentage by weight: 5%-15% of ribavirin, 1%-4% of anodyne, 0.01%-0.03% of active carbon, and water being supplemented to 100% by weight, wherein the pH value is regulated to 5.0-6.0 by a buffer solution. The invention further discloses a preparation method of the ribavirin small-capacity injection preparation. The ribavirin small-capacity injection preparation is detected and checked by regulating the dosage ratio of the anodyne, active carbon and the buffer solution in the prescription, and carrying out primary filtration, intermediate filtration and refined filtration by adopting a titanium rod filter, a 0.65-micron polypropylene filter core and a 0.22-micron polyether sulfone filter core in sequence, so that the defects of large primary medicine consumption and low percent of pass during the preparation process of the ribavirin small-capacity injection preparation are effectively solved. Besides, the prescription is simple, the yield is high, the clinical application is safe, the pain feeling is small, and the large-scale industrial production is convenient.

Owner:YANGZHOU ZHONGBAO PHARMA

Manufacturing method of precision ball bearing cage

InactiveCN106342090BSolve the noiseSolve the large change of synchronous currentBearing componentsTemperature controlBall bearing

The invention belongs to bearing manufacturing technology, and relates to a manufacturing method of a precision ball bearing of a flexible gyro motor of a reference platform. The technical steps of the cage of the present invention are as follows: selection of raw materials - raw material pretreatment - batching - charging - press molding - sintering - cold and heat cycle treatment - mechanical processing - cleaning and oil immersion. The invention can solve the problems such as high operating noise of gyro motor bearings under high and low temperature conditions, large synchronous current changes, low pass rate of bearing installed batches, and unstable movement of cages at low temperatures. Use under the condition of 100°C (+60°C~-40°C).

Owner:LUOYANG BEARING SCI & TECH CO LTD

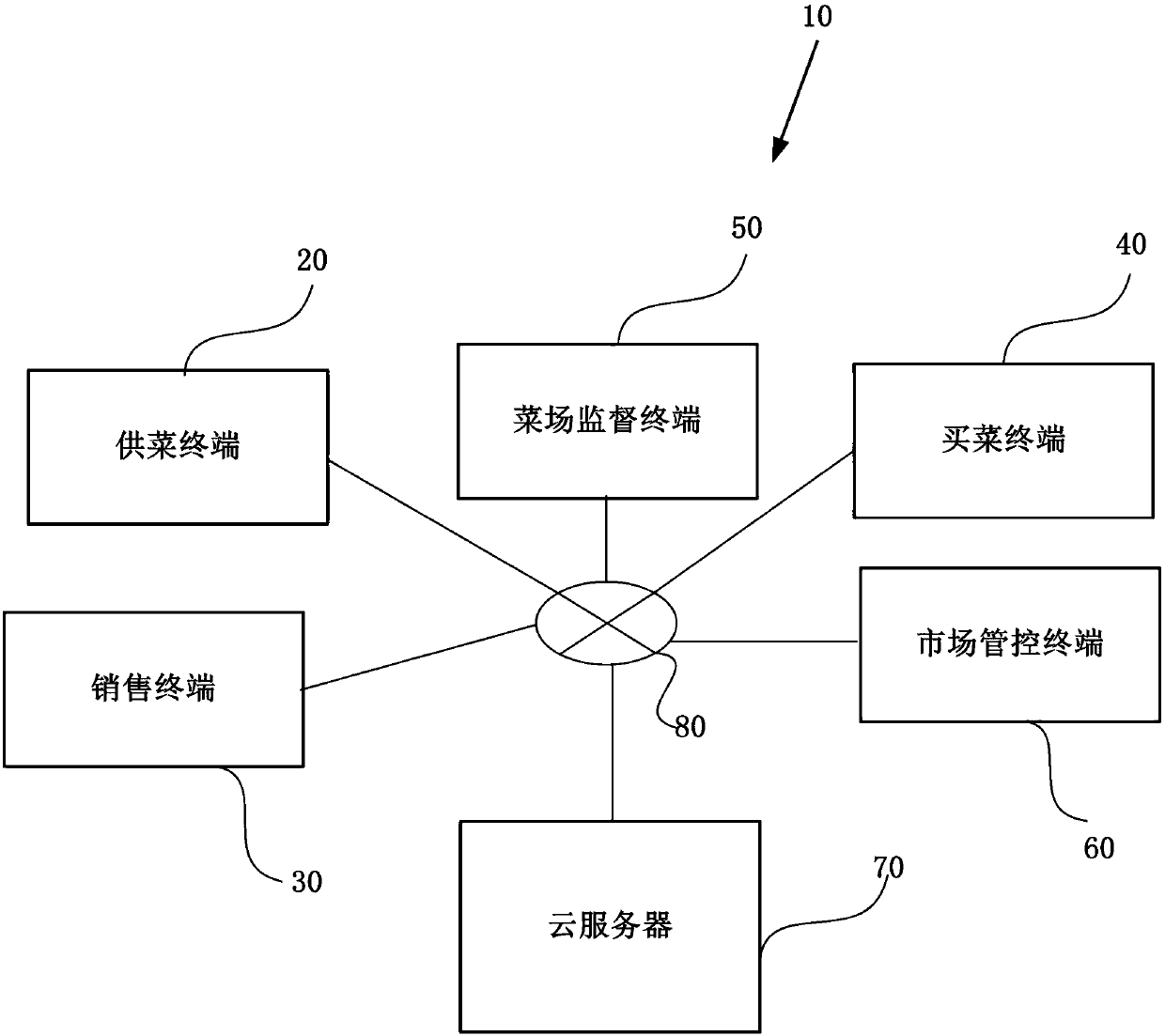

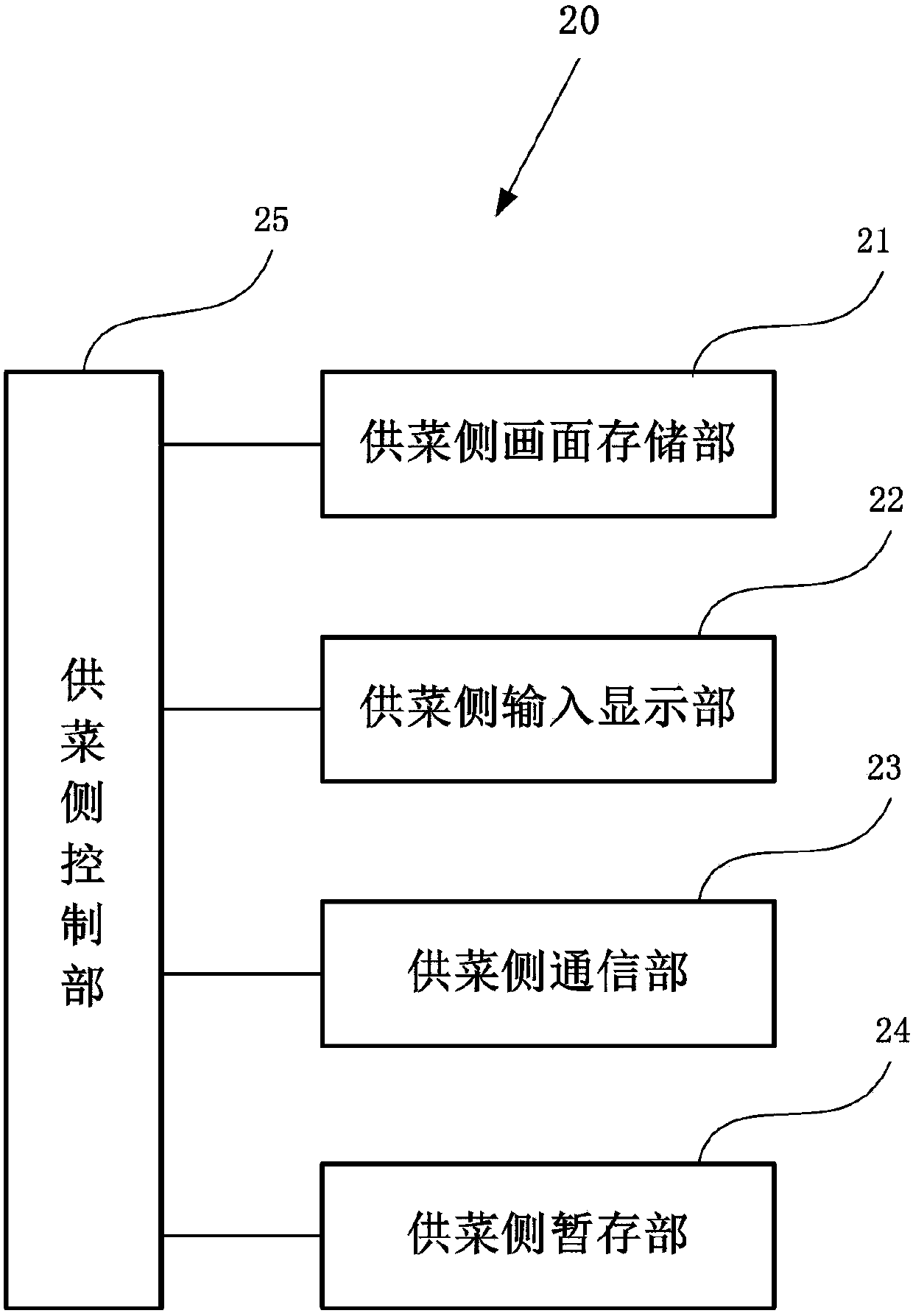

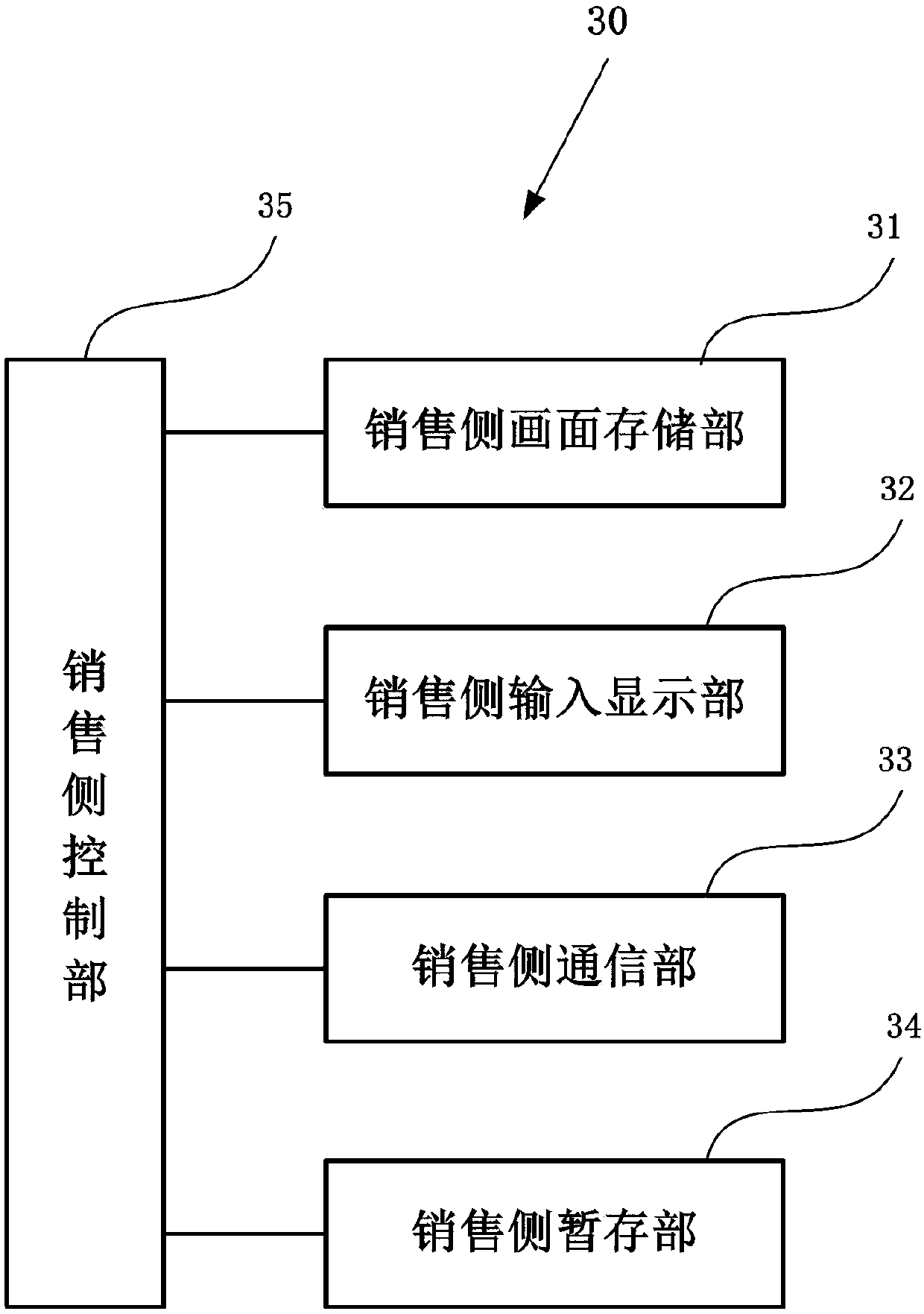

Agricultural and sideline product traceability supervision system

InactiveCN107944882ATimely processingHigh transparencyBuying/selling/leasing transactionsTransmissionProduct traceabilityEngineering

The invention provides an agricultural and sideline product traceability supervision system. The agricultural and sideline product traceability supervision system comprises a vegetable supply terminal, which is held by a vegetable supply person who provides agricultural and sideline products and has a unique vegetable supply identification code; a sales terminal, which is held by a merchant who sells the agricultural and sideline products and has a unique sales identification code; a vegetable buying terminal, which is held by a consumer which buys the agricultural and sideline products and has a unique vegetable buying identification code; a vegetable market supervision terminal, which is held by a supervisor who carries out vegetable market supervision on the agricultural and sideline products; a market management and control terminal, which is held by a government management and control department; and a cloud server, which is in communication connection with the vegetable supply terminal, the sales terminal, the vegetable buying terminal, the vegetable market supervision terminal and the market management and control terminal.

Owner:SHANGHAI FUBO AGRI TECH

Intelligent production compound formula and preparation method of novel multifunctional ecological health-maintenance diatom plate

The invention belongs to the field of building interior wall ornament and decoration materials, and particularly relates to an intelligent production compound formula and preparation method of a novelmultifunctional ecological health-maintenance diatom plate. The method comprises the steps that A, the diatom plate is formed by compounding a main material, an aggregate and an auxiliary material; B, the optimized compound formula of the main material, the aggregate and the auxiliary material is adopted; C, an intelligent automatic device is adopted for production, processing and profile preparation. According to the intelligent production compound formula and preparation method of the novel multifunctional ecological health-maintenance diatom plate, comprehensive innovation and transformation are conducted on the basis of multiple pilot scale tests, the defects of complication, high power consumption and high energy consumption are overcome, the principle of natural ecological health maintenance is utilized, the novel multifunctional high-efficiency ecological health-maintenance diatom plate is prepared physically, a new way is opened, production and manufacturing of the novel multifunctional ecological health-maintenance diatom plate are completed on a novel intelligent automatic production line starting from the modification of a raw material of diatomaceous earth and throughthe scientific mixing ratio formula, and the whole process of steps A, B and C is completed continuously.

Owner:辽宁美诚装饰建材有限公司

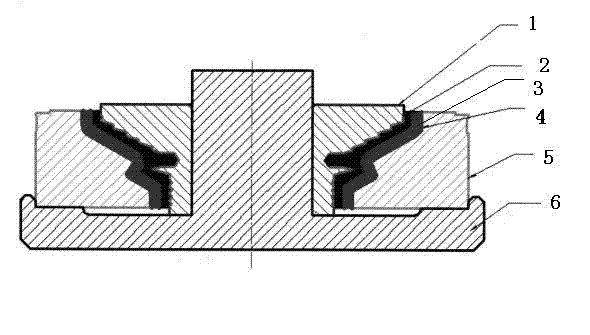

Small cylinder stretching device

The invention relates to the field of forming manufacture, and discloses a small cylinder stretching device comprising an stretching convex die rod, a concave die plate and a positioning guide plate, wherein the outer surface of the head of the stretching convex die rod is identical with the contour structure of the part to be stretched; a handle of the stretching convex die rod is a stress part and is used for bearing the pressure exerted by external force to the stretching convex die rod; the positioning guide plate is provided with a positioning guide port which has the diameter of larger than the outer diameter of the head of the stretching convex die rod; the concave die plate is provided with a cavity sleeved with the outer surface structure of the head of the stretching convex die rod; the concave die plate is arranged at the lower end of the guide plate; the cavity of the concave die plate is aligned with the positioning guide port of the guide plate; the head of the stretching convex die rod passes through the positioning guide port and applies force to the part to be stretched between the concave die plate and the positioning guide late. The stretching device is applicable to stretching forming manufacture of small cylinders of various materials, is characterized by being light, delicate and small, having low cost and convenient use and being capable of shortening the production cycle, and can be widely applied in manufacturing similar products of various types.

Owner:HUBEI SANJIANG AEROSPACE HONGFENG CONTROL

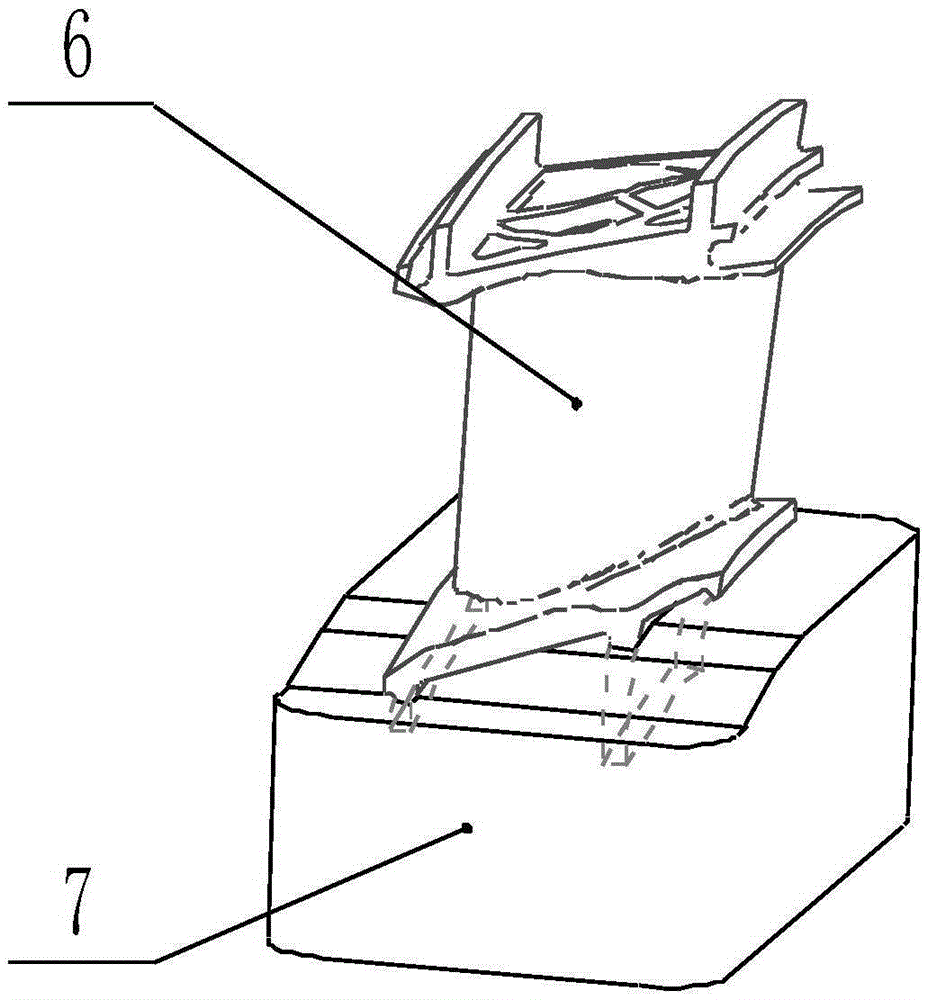

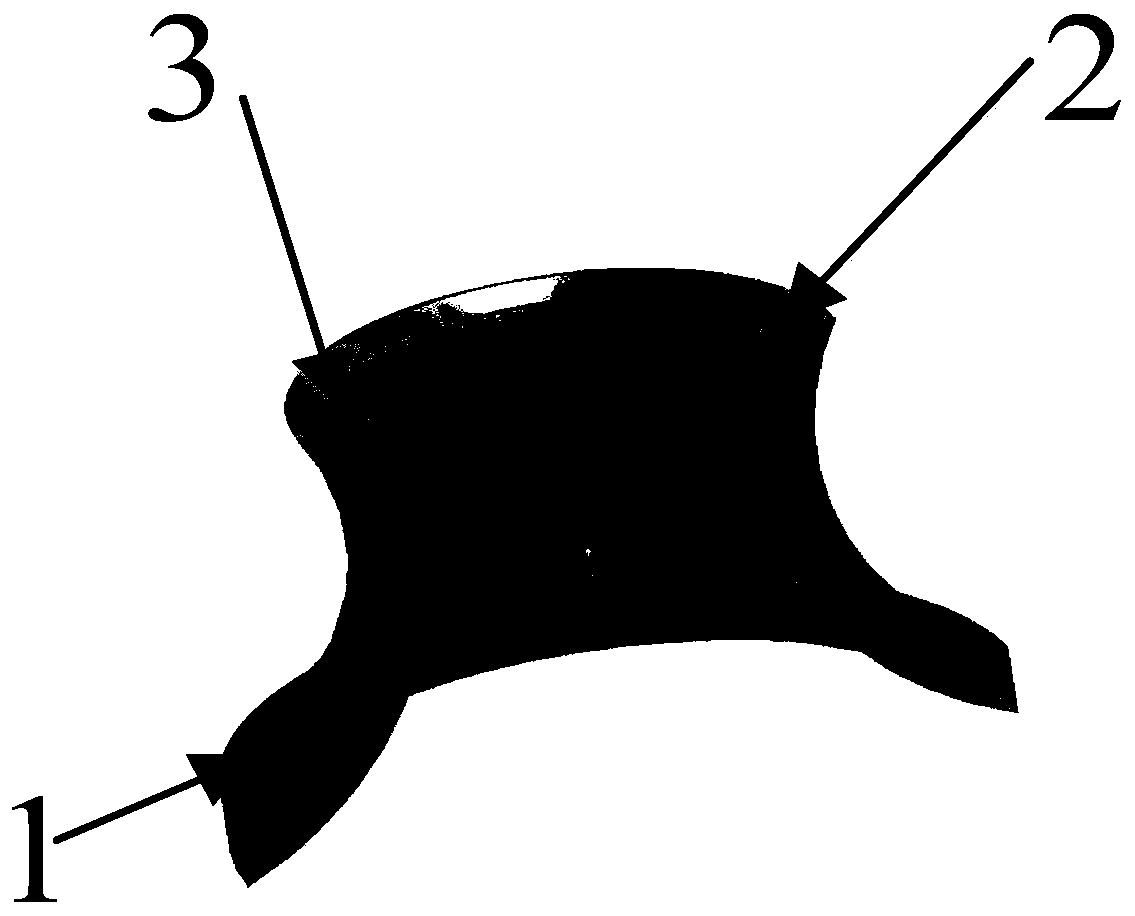

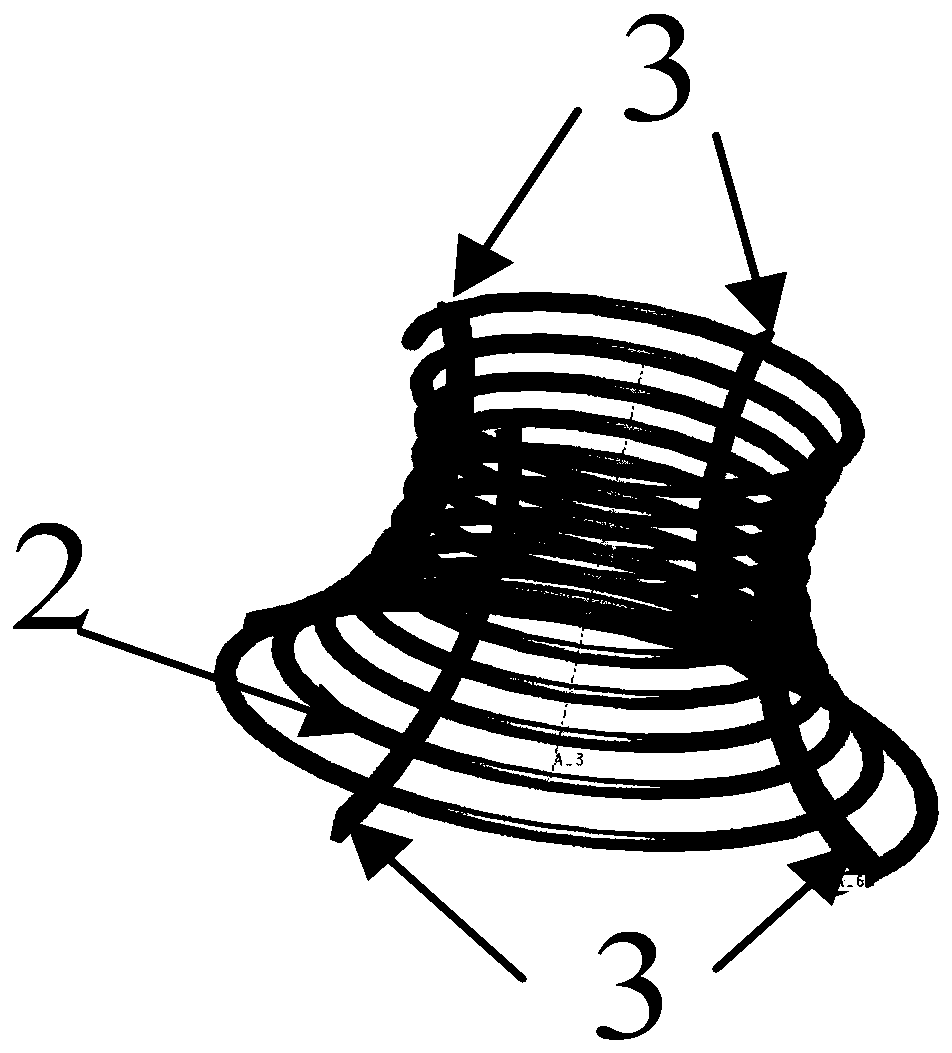

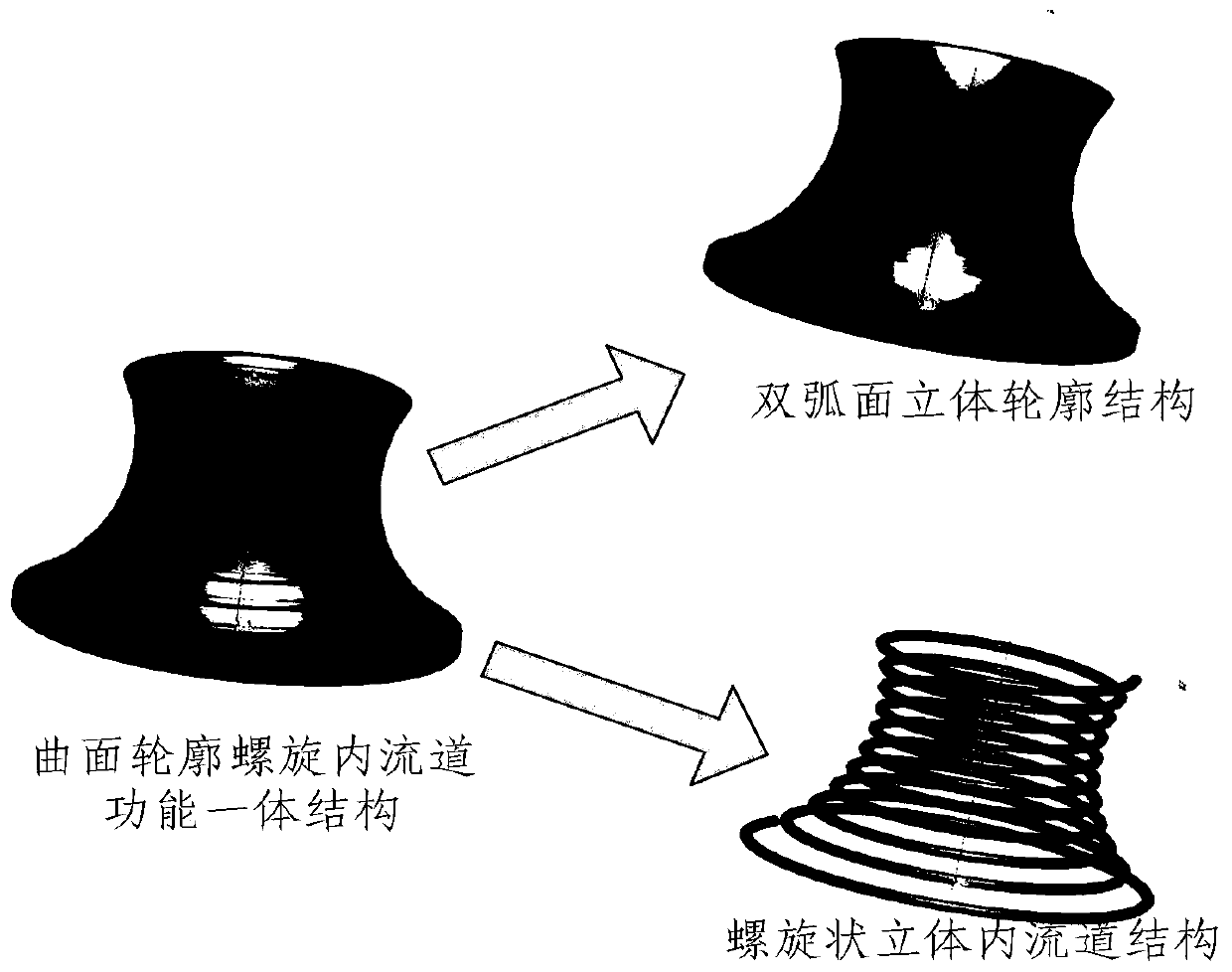

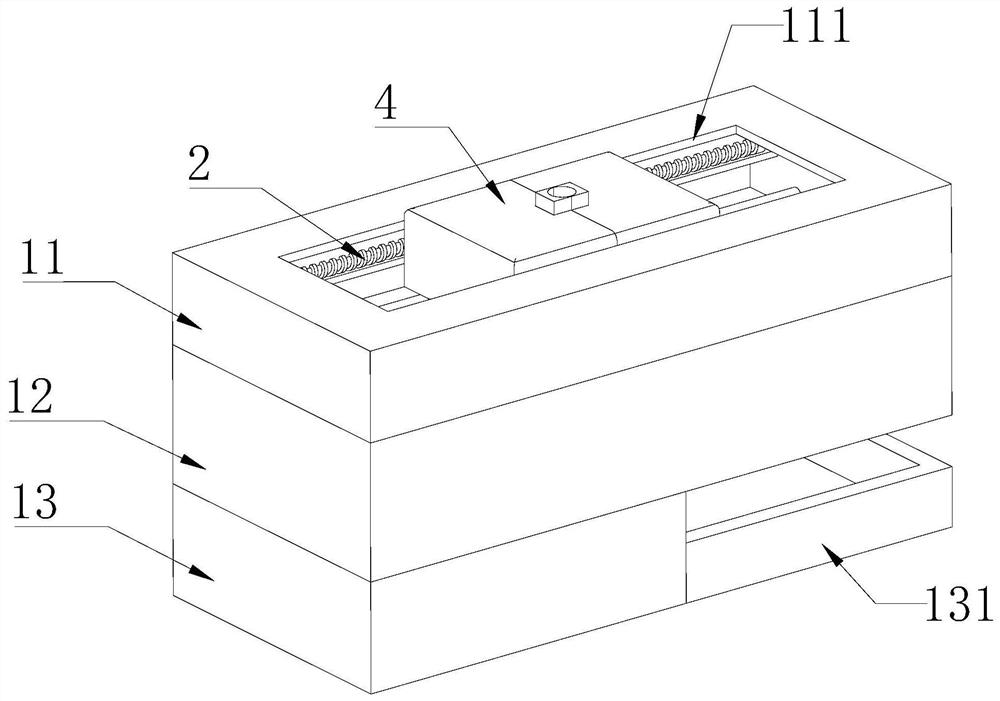

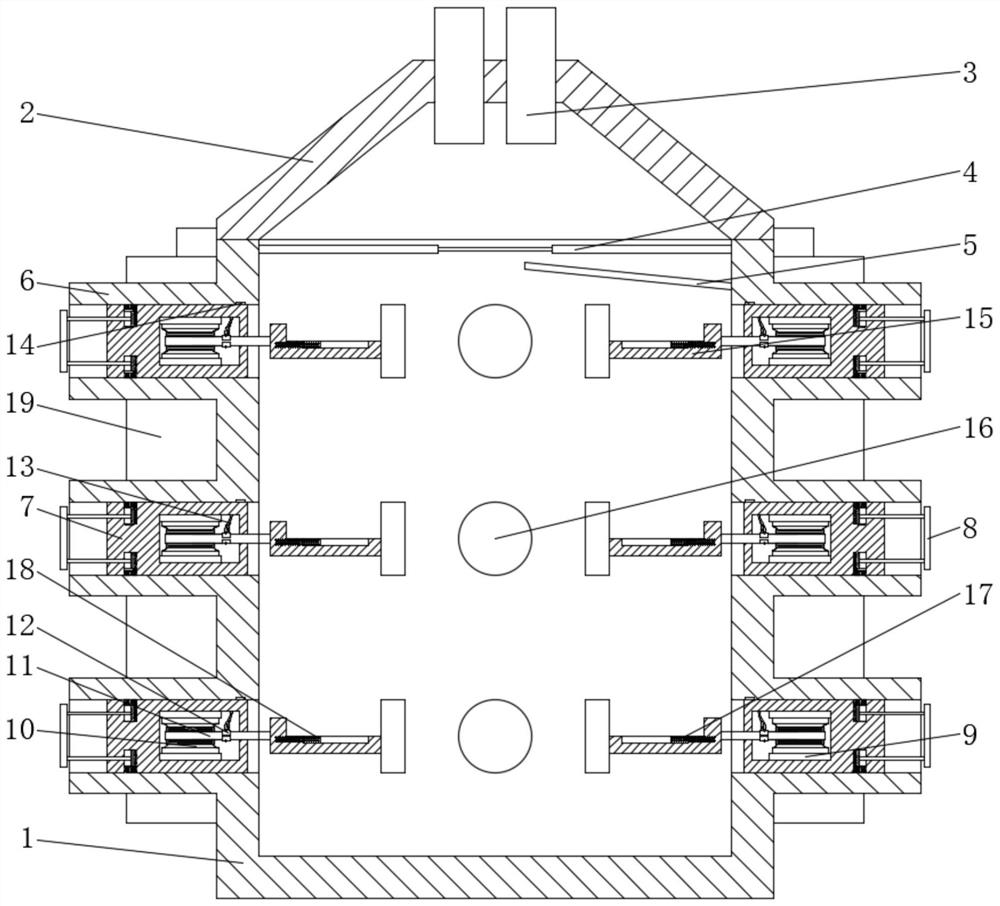

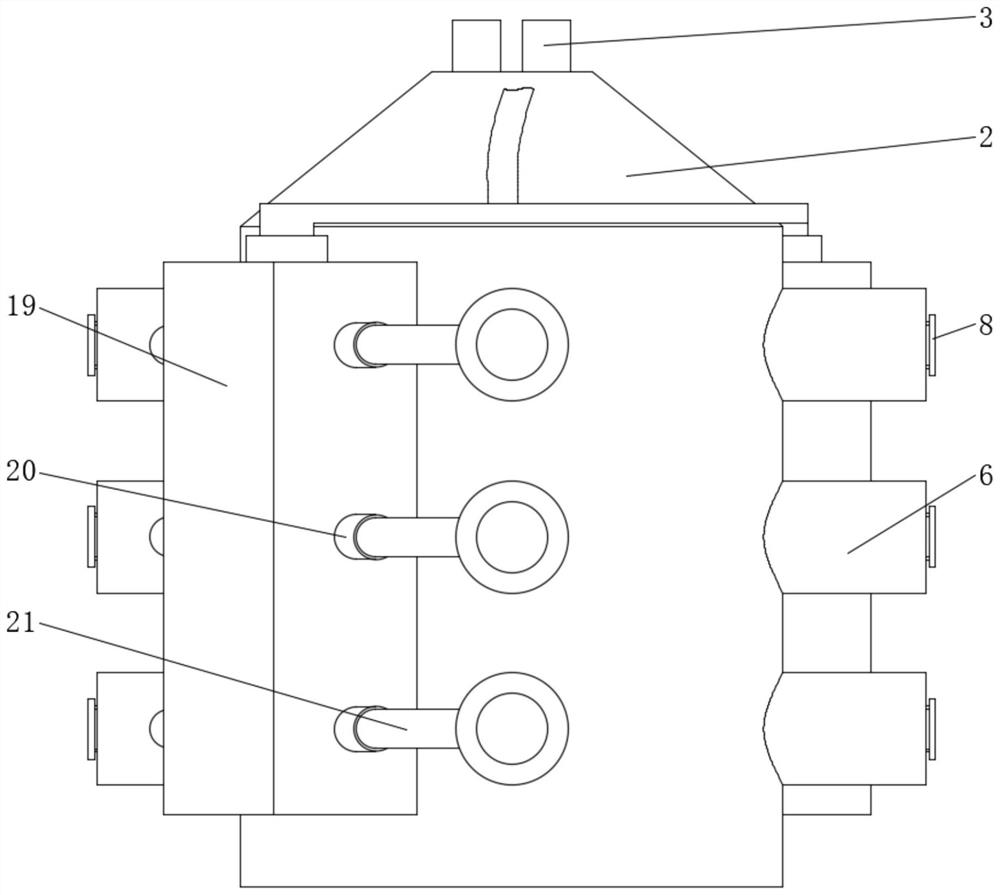

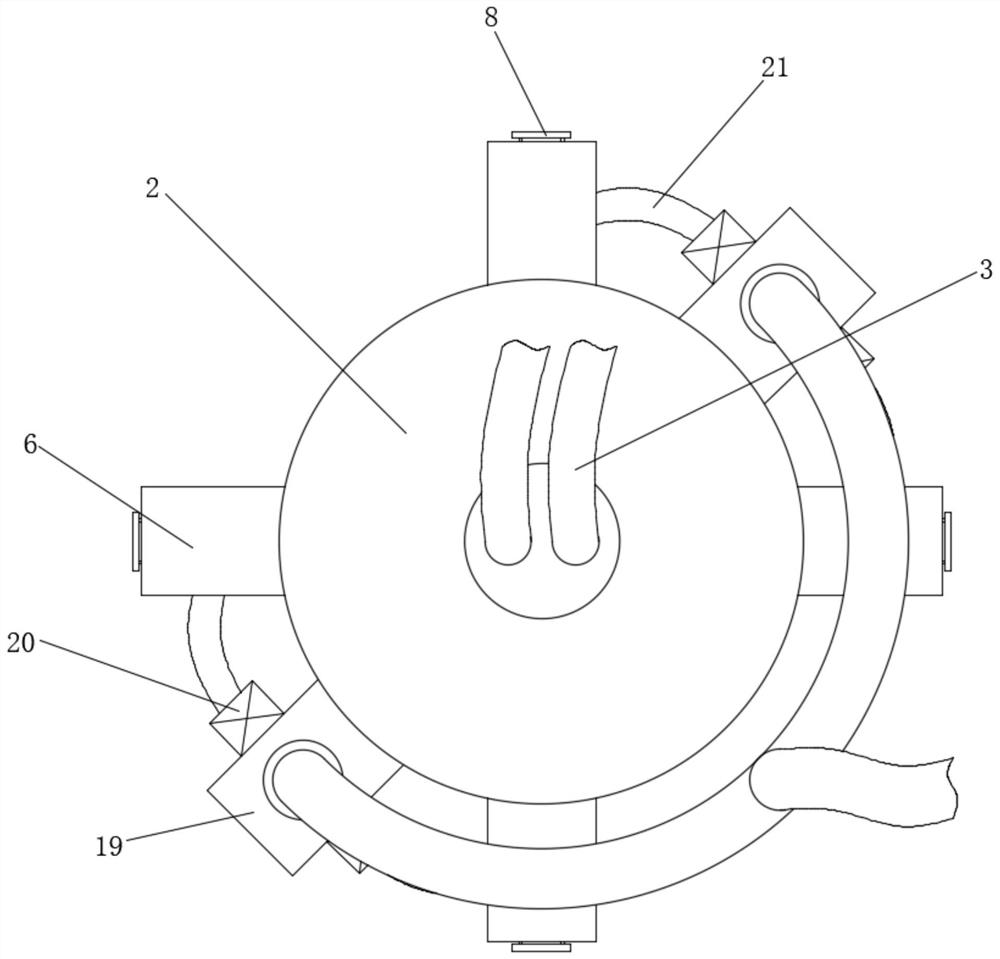

Precise molding method for complex internal flow passage structure

The invention discloses a precise molding method for a complex internal flow passage structure. By building a precise molding device for the complex internal flow passage structure and composed of a contour casting die (1), a prefabricated three-dimensional internal flow passage structure (2) and a fusible supporting frame (3), thin-wall metal pipes with high precision and smooth internal surfacesare adopted to be precisely wound into the three-dimensional internal flow passage structure, the high-precision fusible supporting frame is used for realizing precision positioning of a three-dimensional internal flow passage, and the structural position precision of the three-dimensional internal flow passage structure can be kept in the casting process. By utilizing differences between the three-dimensional internal flow passage structure and a three-dimensional outer contour structural material in melting points, erosion and deformation of the interior of the three-dimensional internal flow passage can be avoided. According to the precise molding method for the complex internal flow passage structure, the problems that in general manufacturing methods, the functionally integrated internal flow passage structure is difficult in a complex internal flow passage molding, low in percent of pass, poor in surface precision of the internal flow passage and the like are solved.

Owner:BEIJING INST OF REMOTE SENSING EQUIP

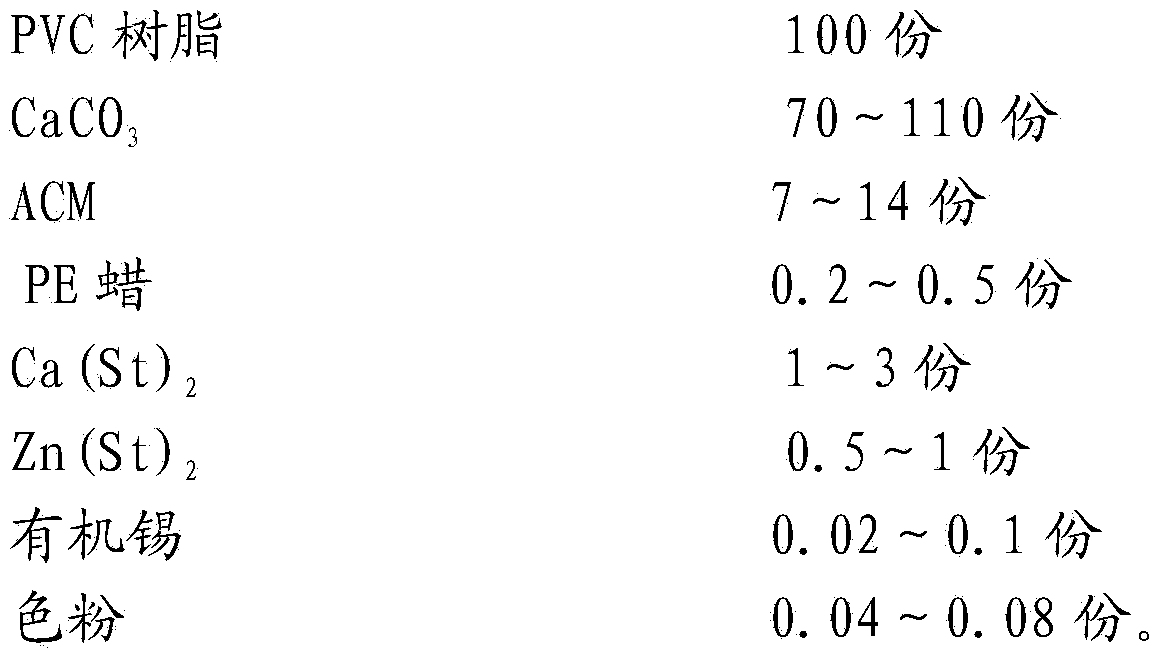

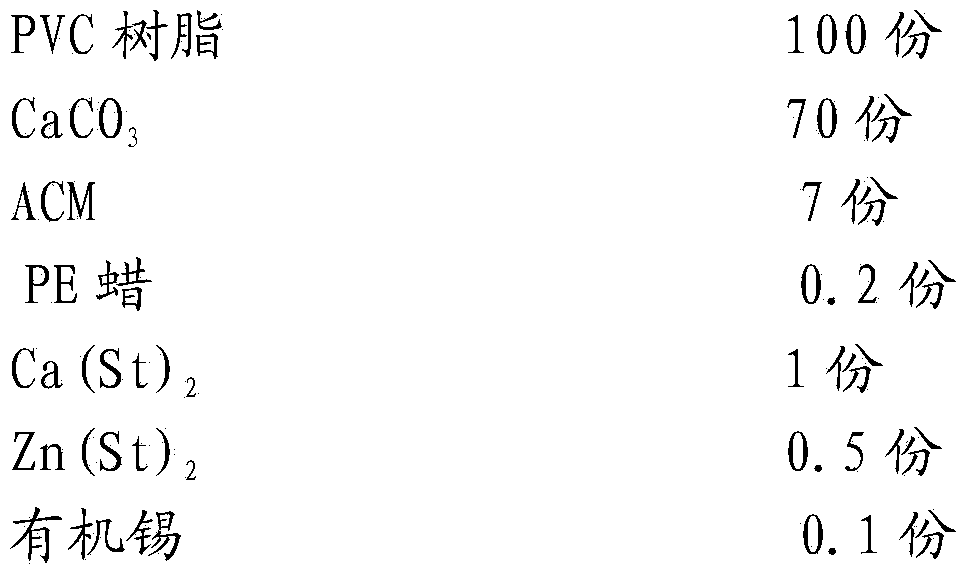

PVC extrusion column and molding technology thereof

The invention provides a PVC extrusion column and a molding technology thereof. The PVC extrusion column comprises the following raw materials in parts by mass: 100 parts of polyvinyl chloride (PVC) resin, 70-110 parts of calcium carbonate (CaCO3), 7-14 parts of a PVC anti-impact processing modifier (ACM), 0.2-0.5 part of polyethylene (PE) wax, 1-3 parts of calcium stearate (Ca(Sa)2), 0.5-1 part of zinc stearate (Zn(St)2), 0.02-0.1 part of organic tin and 0.04-0.08 part of a toner. According to the provided PVC extrusion column and the molding technology thereof, the column extruding molding technology relatively well solves the problems that a sprayed column is server in environment pollution, low in finished-product qualified rate, complex in preparation technology and the like. Additionally, Ca(St)2, Zn(St)2 and organic tin are taken as PVC heat stabilizers, low-price PVC resin and CaCO3 are taken as the main raw materials, and the column extruding molding technology is employed, so that the PVC extrusion column profiles are prepared.

Owner:CHUZHOU UNIV

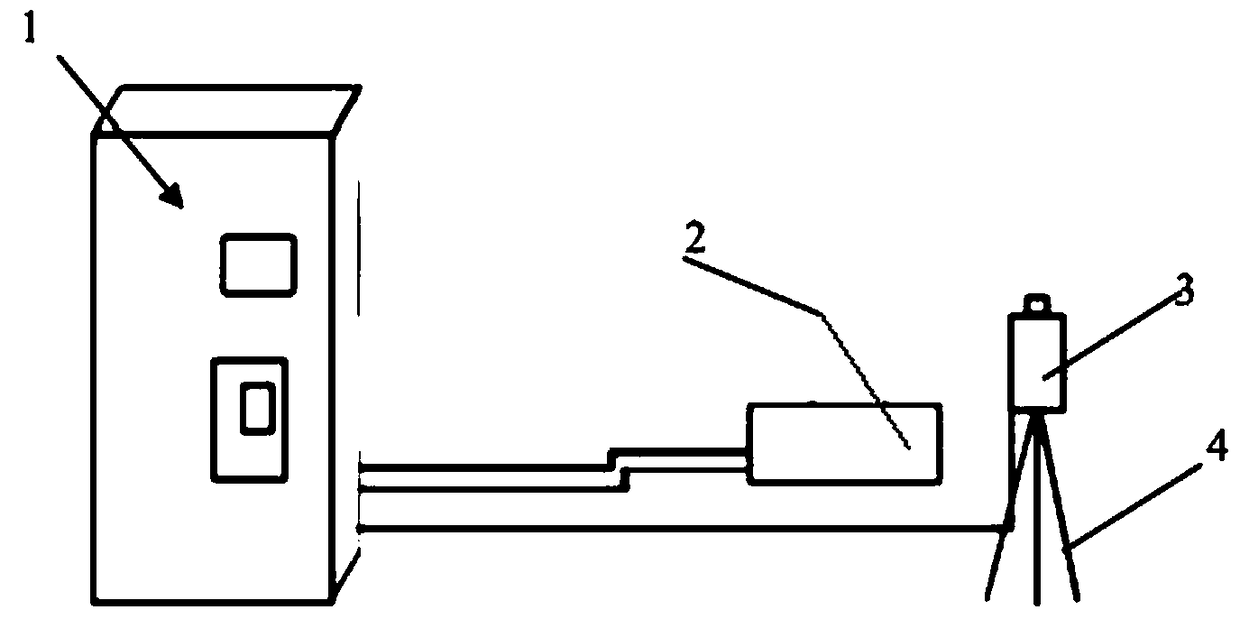

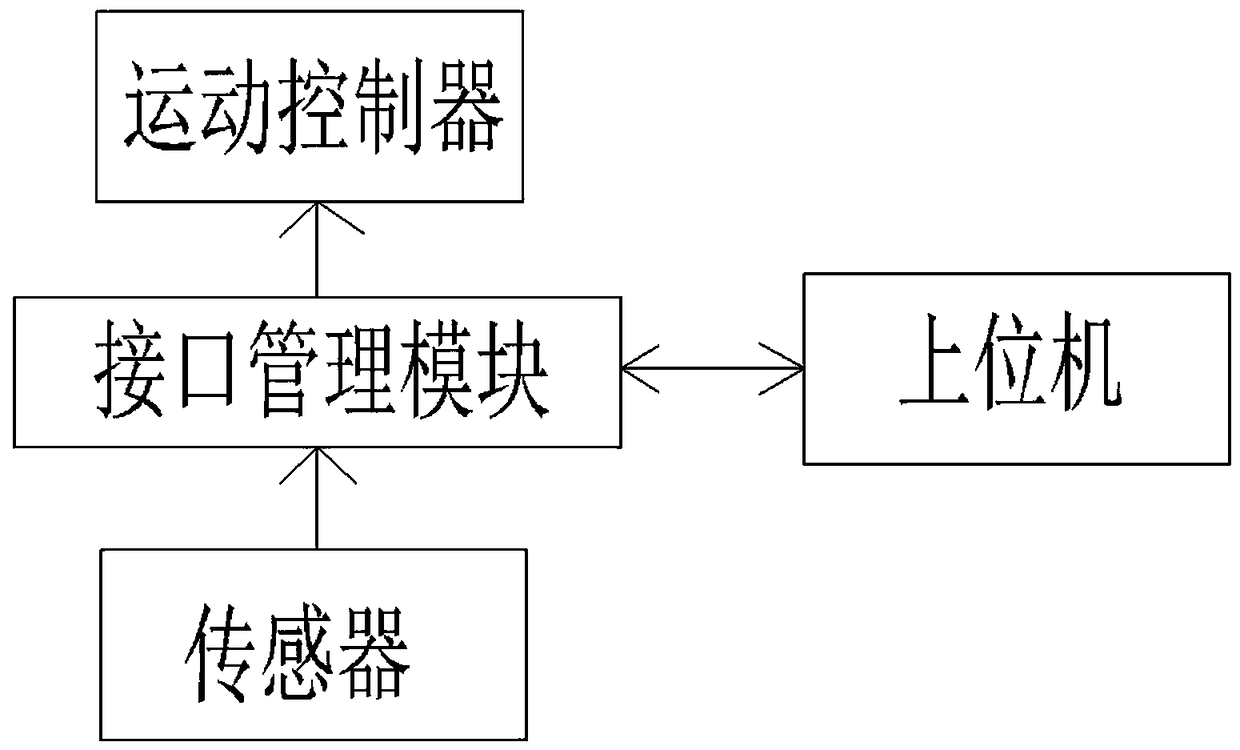

Control system of robot

InactiveCN108098764ASolve replacementSolving pass rateProgramme-controlled manipulatorElectricityControl system

Provided is a control system of a robot, pertaining to the technical field of robot control. The invention especially relates to the control system of the robot. With the control system, the real-timecapability and reliability are improved. The rapid locating function is fulfilled. The control system comprises a controller, the robot and a visual system. The robot and the controller are in the relationship of control interaction. The visual system is arranged on one side of the robot and is in communication connection with the controller. The visual system comprises a camera fixed by a support and the controller. The controller is kept in communication connection with the robot and the camera. The controller is an upper computer and multiple peripheral serial devices. The peripheral serial devices are in communication with the upper computer by being connected with an interface management module electrically connected with the upper computer. The interface management module is equipped with multiple serial ports in data transmission with all the peripheral serial devices, a control chip used for packing, transferring and processing data of all serial ports, and a power supply assembly used for supply electricity to the control chip.

Owner:沈阳元生鑫达科技有限公司

Glow-ion nitriding treatment method for gear made of 05Cr17Ni4Cu4Nb material

The invention discloses a glow-ion nitriding treatment method for a gear made of a 05Cr17Ni4Cu4Nb material. The method comprises the processes of material preparing, rough turning, solution treating, finish turning, gear hobbing, precipitation hardening, gear grinding, abrasive blasting, nitriding, inspecting and warehousing. According to the method, the glow-ion nitriding treatment process is added after the precipitation hardening treatment process. By means of all the processes adopted in the method, energy can be saved, stability of hardness and a diffusion layer of the gear which is made of the 05Cr17Ni4Cu4Nb material and subjected to glow-ion nitriding treatment, and the technical problems that current products are low in yield and insufficient in fatigue property are well solved. Abrasive resistance of parts is obviously improved, the service life of the parts is prolonged, operation reliability of the parts is improved, and the defects in the prior art are overcome.

Owner:GUIZHOU QUNJIAN PRECISION MACHINERY

Light environment-friendly aluminum alloy and preparation technology thereof

The invention discloses light environment-friendly aluminum alloy and a preparation technology thereof, and relates to the technical field of aluminum alloy casting. The light environment-friendly aluminum alloy comprises, by weight, 4.0%-6.0% of silicon, 0.2%-0.3% of ferrum, 2.5%-4.0% of copper, 0.2%-0.4% of manganese, 0.3%-0.5% of magnesium, 0.05%-1.0% of titanium, 0-0.5% of nickel, tin and lead, 0-0.2% of zinc, 0-0.05% of cadmium, mercury and chromium, the balance aluminum, 0-0.5% of other elements (the highest weight of each element accounts for 0.05%) and inevitable impurities. Accordingto the light environment-friendly aluminum alloy and the preparation technology thereof, the formula and the aluminum alloy preparation technology are reasonably designed, and the problems that an existing aluminum alloy production percent of pass is low, alloy product performance is poor, the technology is complex and manufacturing cost is high are solved.

Owner:铜陵市腾发铝制品加工有限责任公司

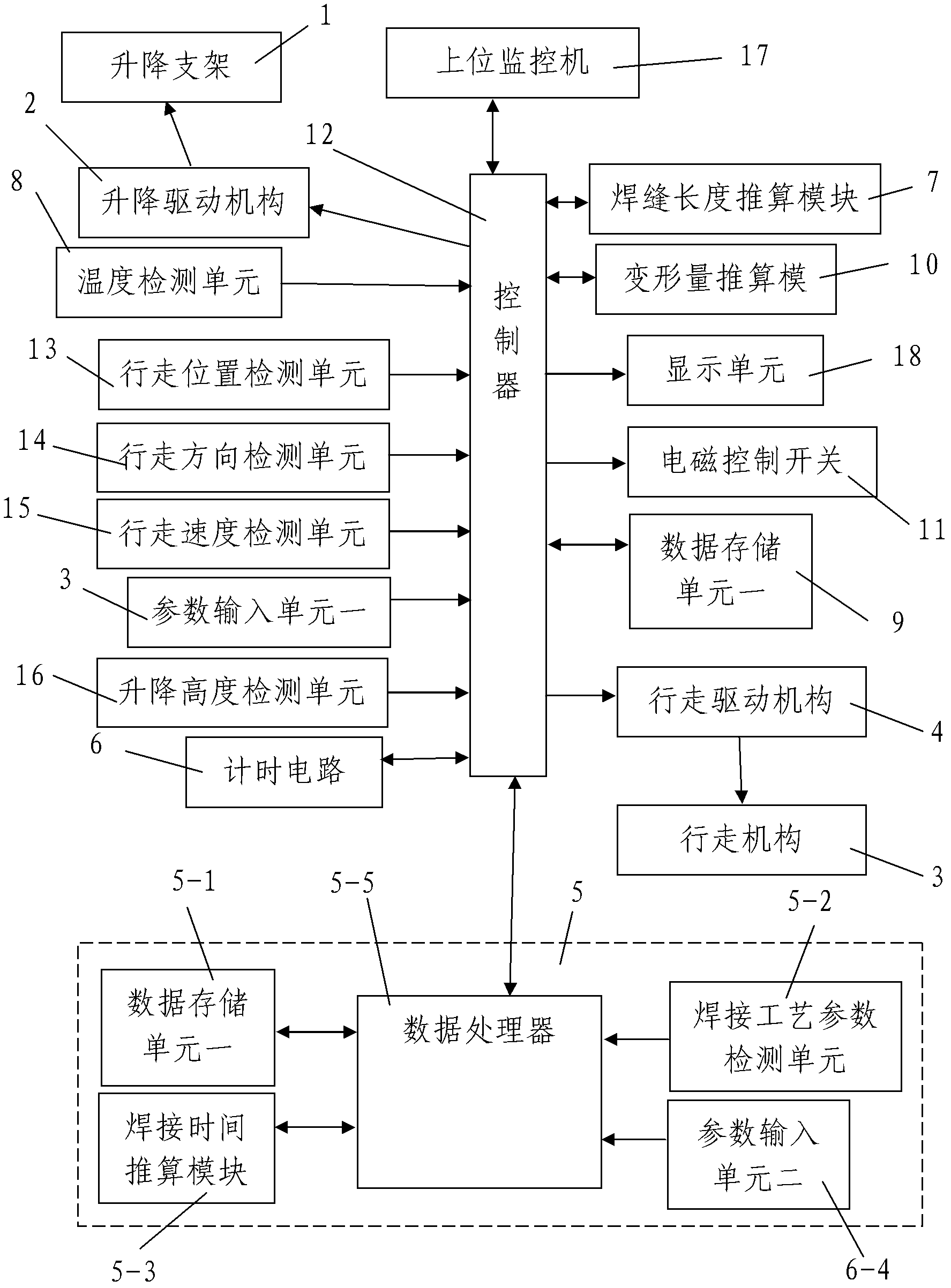

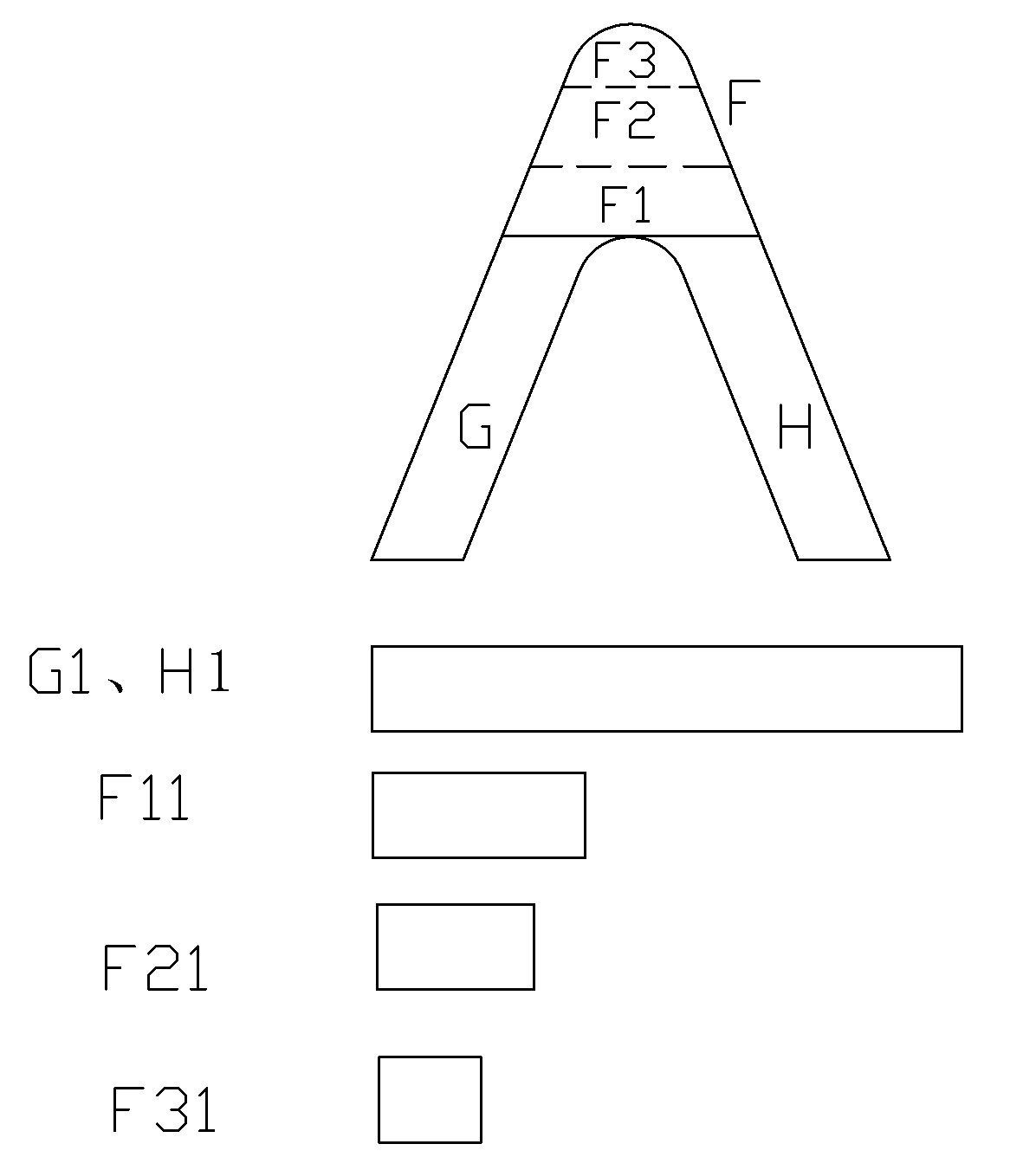

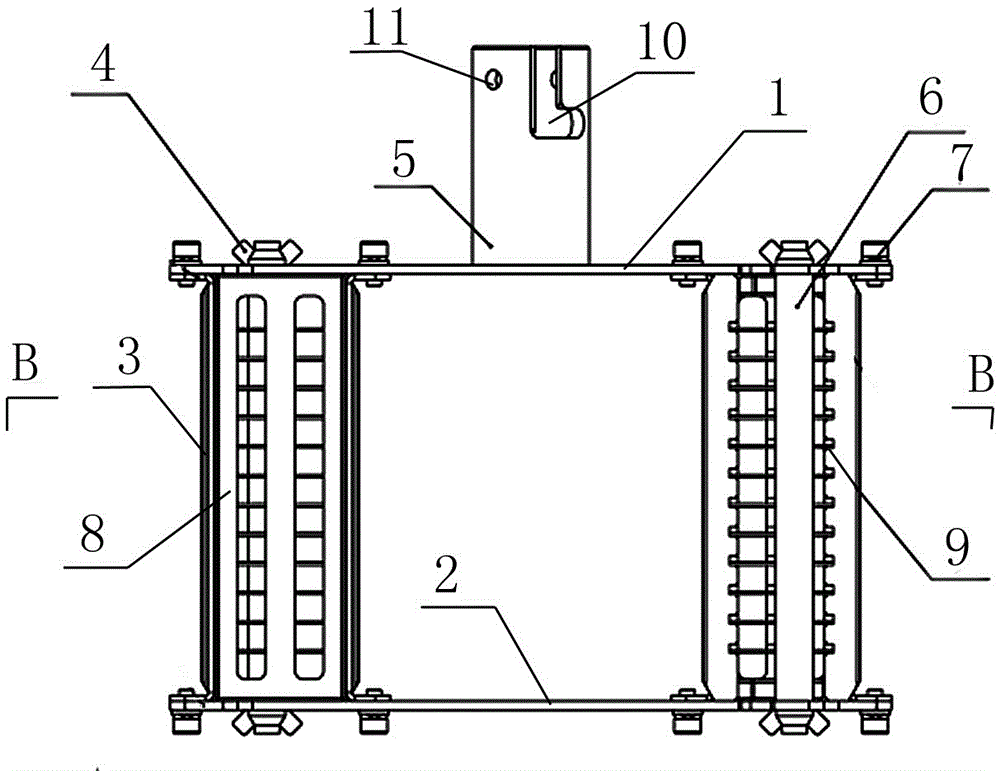

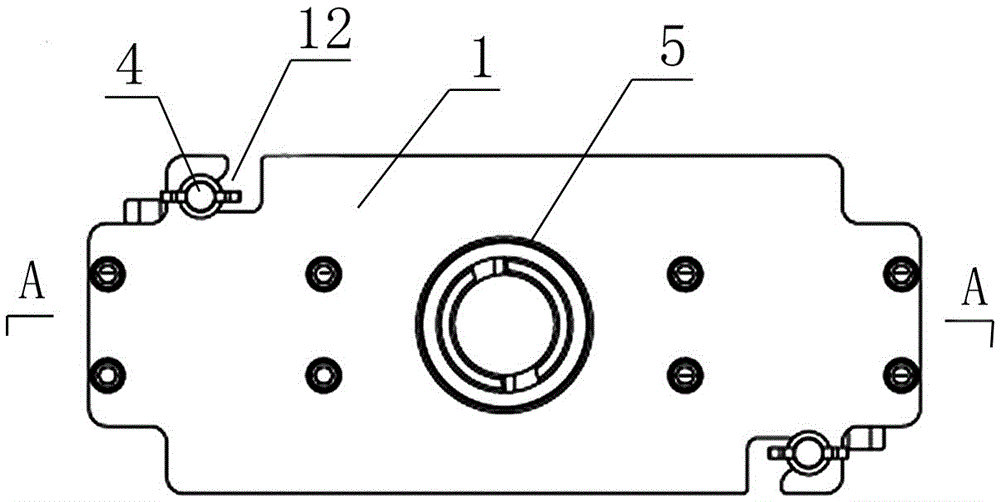

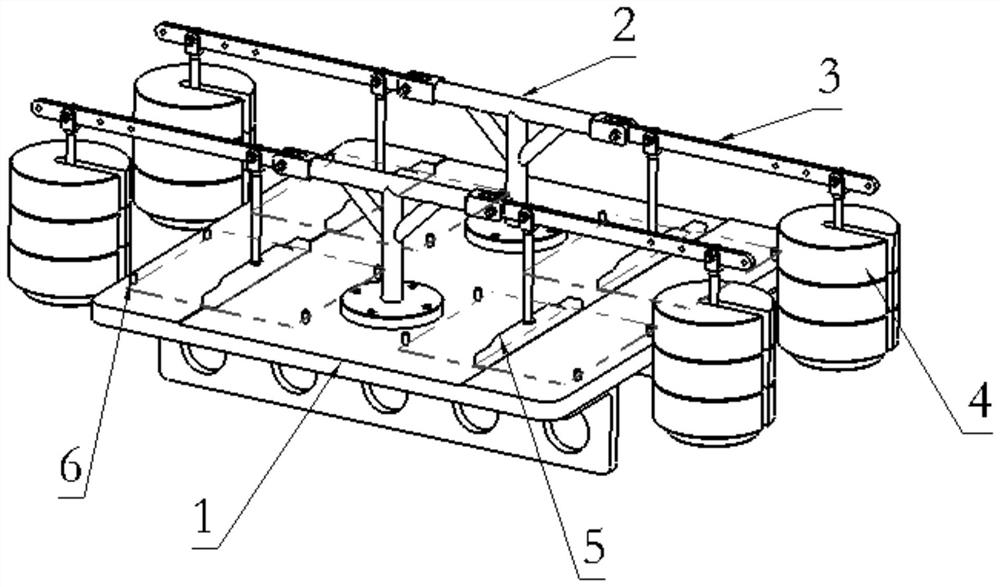

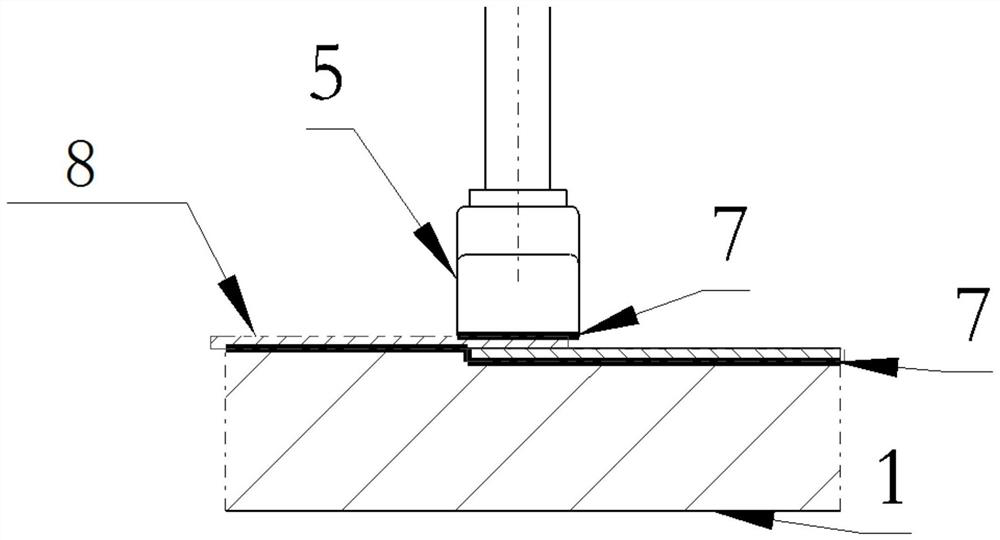

Accurate pressurizing gluing clamp

PendingCN112525637AEasy to demouldSolving pass rateMaterial gluingPreparing sample for investigationHanging positionAluminium alloy

The invention provides an accurate pressurizing gluing clamp. The clamp is based on a lever principle, is provided with a connecting rod mechanism, realizes the adjustment of gluing pressure by adjusting the weight of a balancing weight and the hanging position of the balancing weight, can simultaneously glue a plurality of groups of test pieces 8 by reasonably arranging the structure of a pressurizing mechanism, enables the structure to be bilaterally symmetrical, balances the whole gravity center and avoids overturning. The part in contact with the test pieces 8 is made of an aluminum alloymaterial and is coated with demolding cloth, so that the test pieces 8 are conveniently demolded. According to the invention, the problems that the test pieces 8 are low in qualification rate in the test stage and the quality cannot be ensured are solved, the most suitable curing parameters and pressure are obtained through a comparison test in a short time, and the gluing quality, the productionefficiency and the product stability of the test pieces 8 are ensured.

Owner:CHANGHE AIRCRAFT INDUSTRIES CORPORATION

Hardware casting demolding device and demolding process thereof

PendingCN113732274ASolve efficiency problemsSolving pass rateFoundry mouldsFoundry coresEngineeringMachining

The invention discloses a hardware casting demolding device and a demolding process thereof, and relates to the technical field of hardware casting machining. The hardware casting demolding device comprises a bearing mechanism, a moving mechanism, a discharging mechanism and a mold, the moving mechanism and the discharging mechanism are both arranged in the bearing mechanism, the mold is arranged above the bearing mechanism, the mold is connected with the moving mechanism, a feeding hole, a placing groove and a forming groove are formed in the mold, the feeding hole is located above the mold, the forming groove is located in the mold and located below the feeding hole, the placing groove is located below the forming groove, the discharging mechanism is located under the mold, and the working end of the discharging mechanism is located in the placing groove of the mold. The problems that in the prior art, a hardware casting is possibly damaged in the demolding process, so that a product needs to be reworked or directly scrapped, and the overall efficiency and the yield are reduced are solved.

Owner:惠州市靖睿自动化机械有限公司

A kind of decorative glaze for medium-temperature daily-use ceramics and its application method

The invention discloses a fancy glaze for decorating medium-temperature daily ceramic, and a use method thereof. The base formula of the fancy glaze comprises 10-14 wt% of kaolin, 20-40 wt% of quartz, 2-6 wt% of albite, 2-6% of feldspar, 7-14 wt% of calcite, 7-12 wt% of wollastonite, 2-6 wt% of zinc oxide, 2-6 wt% of titanium dioxide, 2-6 wt% of bone ash, 2-6 wt% of calcium phosphate, 3-6 wt% of ammonium molybdate, 1-3 wt% of cerium oxide, 1-3 wt% of yttrium oxide, and 2-5 wt% of an external coloring oxide. The use method comprises the following steps: carrying out mixing, ball milling and sieving on the above raw materials, applying the obtained raw materials to a medium-temperature daily ceramic briquette, and carrying out medium-temperature one-time sintering to obtain the product. Medium-temperature daily ceramic decorated with the fancy glaze has the advantages of simple process, high adaptability and unique effect, so the fancy glaze has broad market prospect.

Owner:HUNAN KARPERY INDAL

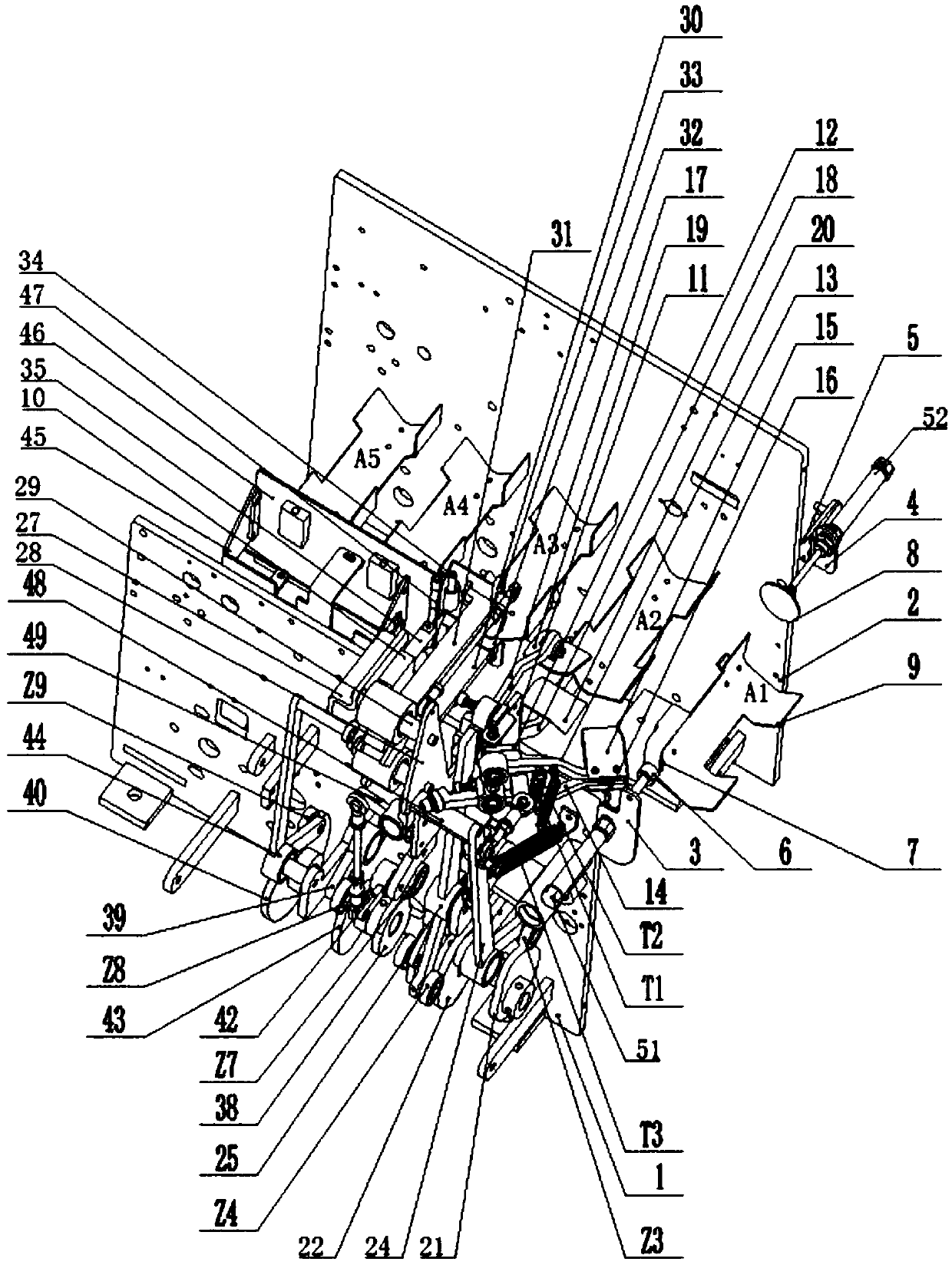

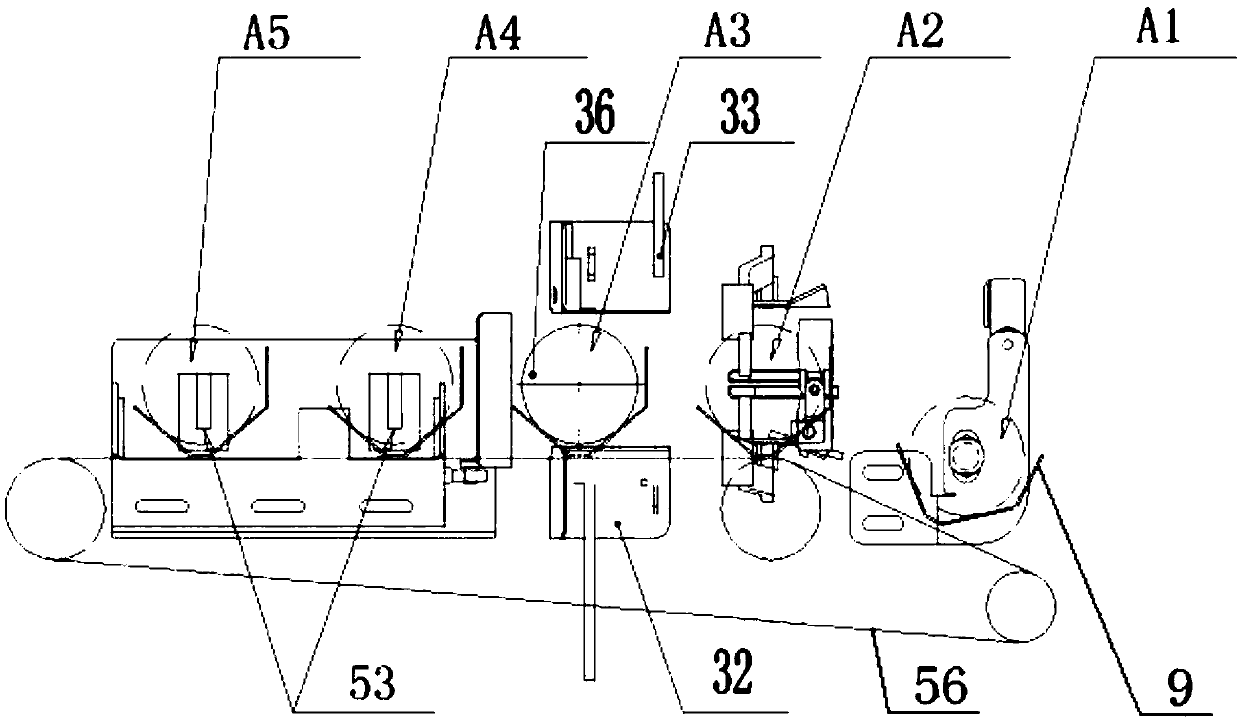

New tail sealing device for liner paper packaging machine

ActiveCN110356645AEfficient sealingSecurely sealedBio-packagingWrapper twisting/gatheringPaper sheetWall plate

The invention relates to a new tail sealing device for a liner paper packaging machine. The new tail sealing device is characterized by comprising a station I, a station II, a station III, a station IV and a station V arranged between a left wallboard and a right wallboard in sequence from front to back, wherein the station I is used for stopping the seam of a cylindrical liner in a proper position so as to enter the station II for paper folding; the station II is used for folding the right side paper of the tail of the cylindrical liner and carrying out indentation setting for the upper sidepaper and the lower side paper; the station III is used for folding the upper side paper and the lower side paper which are subjected to indentation setting, and then carrying out indentation settingthe left side paper and gluing; and the station IV is used for folding the left side paper which is subjected to indentation setting to complete tail sealing action and heating glue and drying the glue. The new tail sealing device has the advantages of simplifying the structure and realizing efficient, firm and beautiful tail sealing of the cylindrical liner. The device has a simple structure, less stations and convenience in debugging and achieves a higher automation technology leap and a good solution to the industry problem that the qualified rate of the firm and aesthetic degree of tail sealing of the cylindrical liner is low.

Owner:QINGDAO HAIKEJIA ELECTRONCE EQUIP MFG

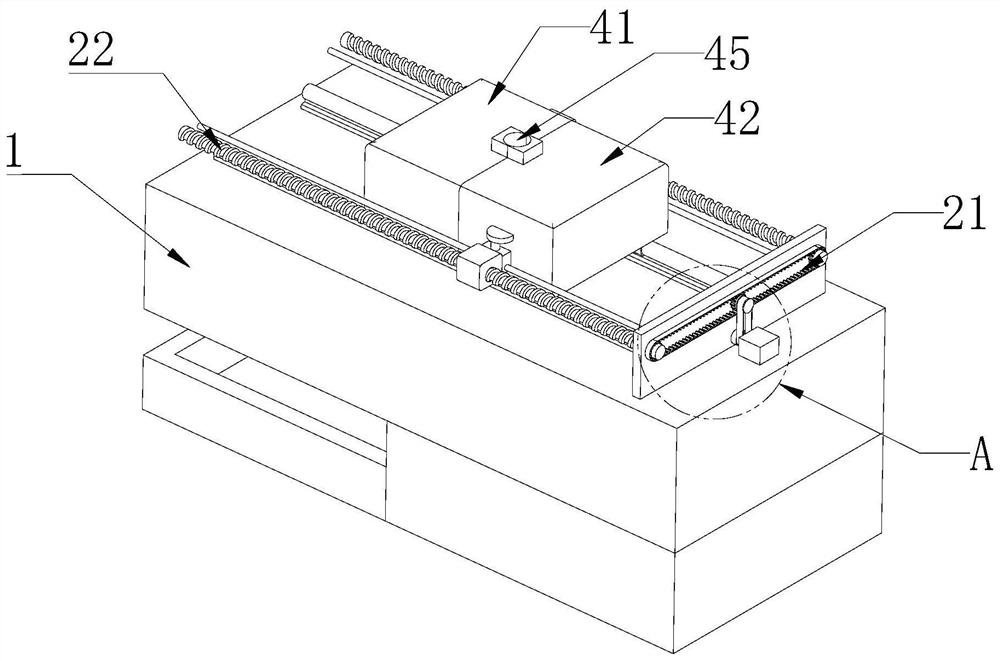

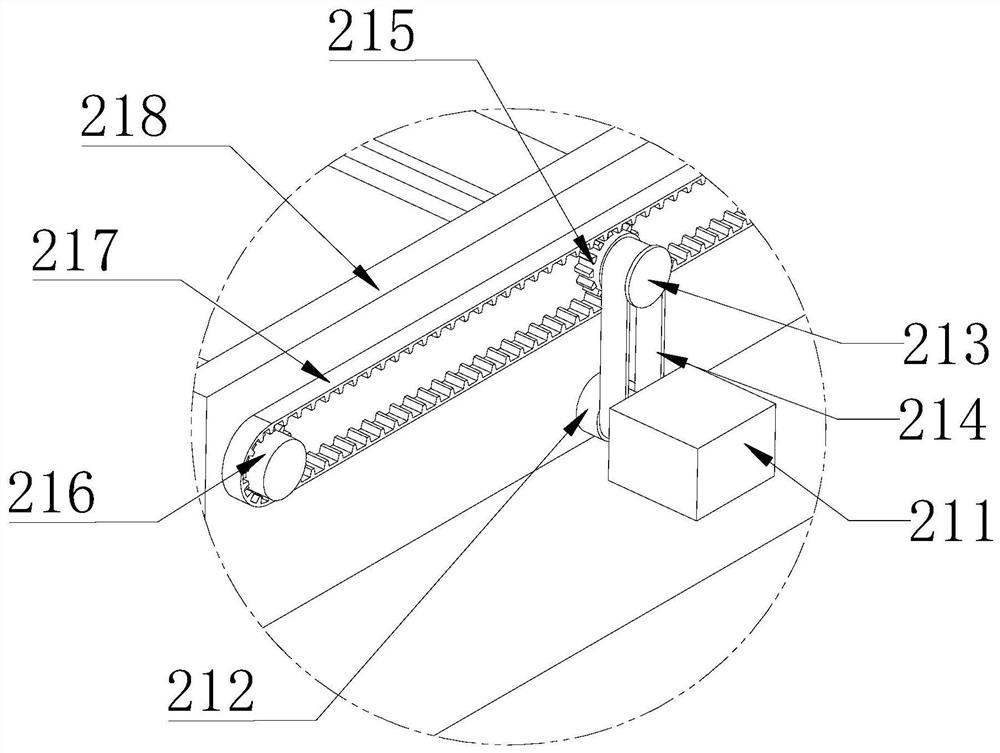

Laminating equipment

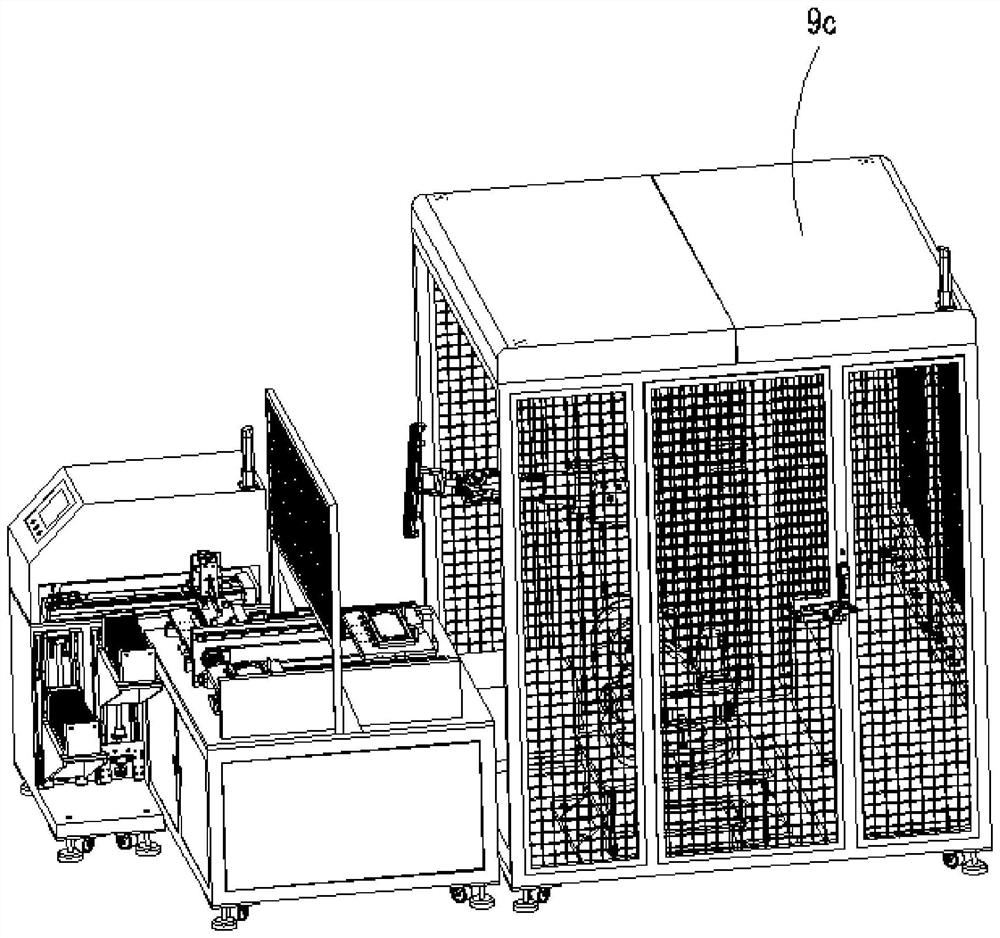

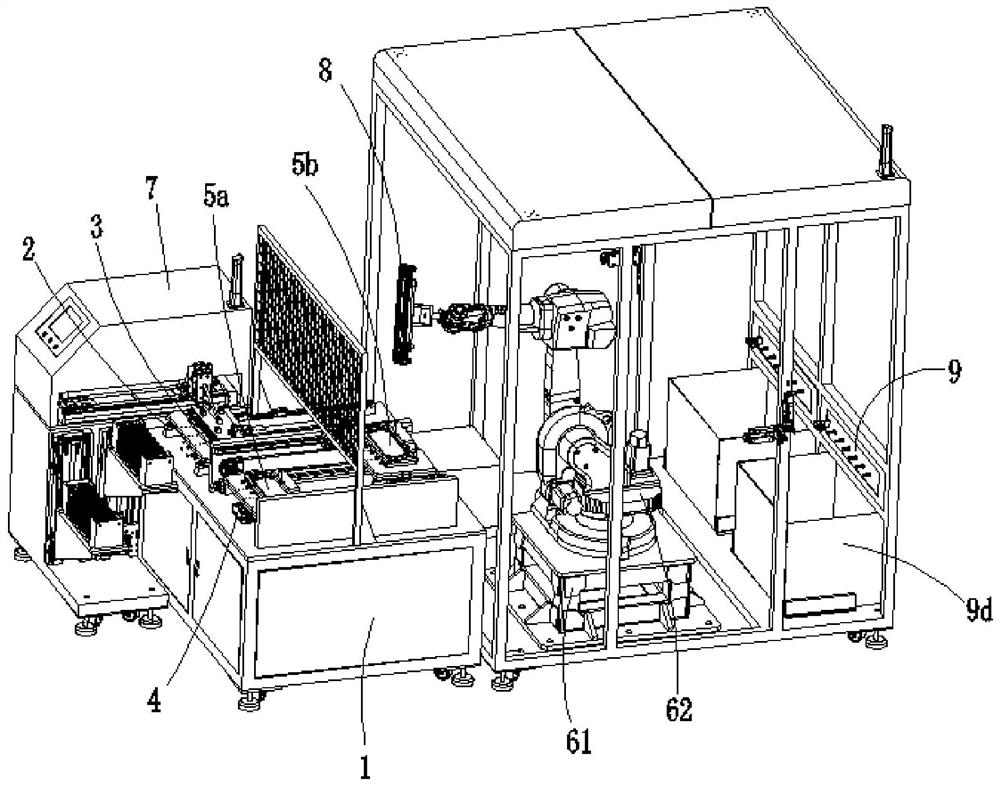

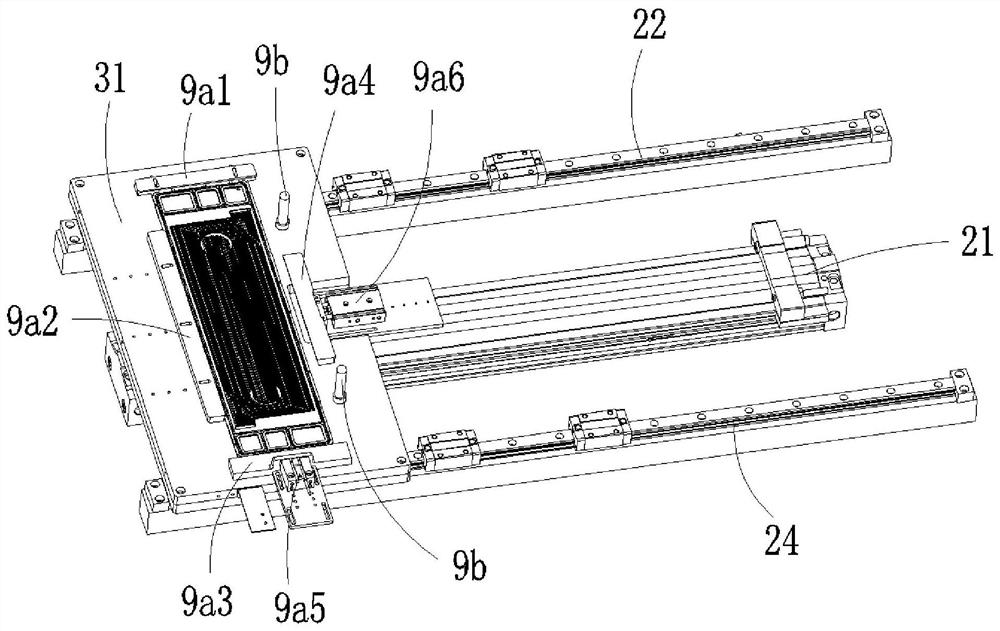

ActiveCN112478772ASolve efficiency problemsSolving pass rateMaterial gluingConveyor partsMechanical engineeringManual handling

The invention relates to the technical field of bipolar plate assembly, in particular to laminating equipment. A joint robot drives a first adsorption device to adsorb a sealing ring, then moves the sealing ring to a film tearing mechanism to tear off a protective film, then moves the sealing ring to an attaching station, installs the sealing ring into a sealing groove of a bipolar plate and attaches the sealing ring to the bipolar plate through gum, and the problems that most bipolar plates and sealing rings are attached through manual operation, the production efficiency is low and the percent of pass is low are solved.

Owner:深圳市昆龙卓盈机电有限公司

Magnetron sputtering vacuum coating machine

InactiveCN112126904AGood coating effectEasy to slideVacuum evaporation coatingSputtering coatingSuction forcePumping vacuum

The invention relates to the technical field of coating equipment, and discloses a magnetron sputtering vacuum coating machine. The machine comprises a box body, wherein a box cover is fixedly mountedon the upper surface of the box body, and the top of the box cover is fixedly sleeved with a vacuumizing pipe. According to the magnetron sputtering vacuum coating machine, through cooperation of airsuction pipes and convex pipes, under the control effect of valves, air suction control can be conducted on the corresponding convex pipes, waste of air suction power consumption is effectively prevented, when a workpiece is replaced and which material frame needs to be pulled out, only the corresponding valve needs to be opened, suction force can correspond to the interiors of the convex pipes,the whole equipment does not need to be covered for air suction, it is guaranteed that the power consumption of air exhaust kinetic energy is minimum, the construction cost is reduced, carried air canbe exhausted in the workpiece pushing process after the workpiece is replaced, the situation that the workpiece cannot meet the qualified standard after coating due to influence on workpiece coatingcaused by the fact that dust carried in the air enters the box body is prevented, and the qualified rate of the workpiece is guaranteed.

Owner:黎方建

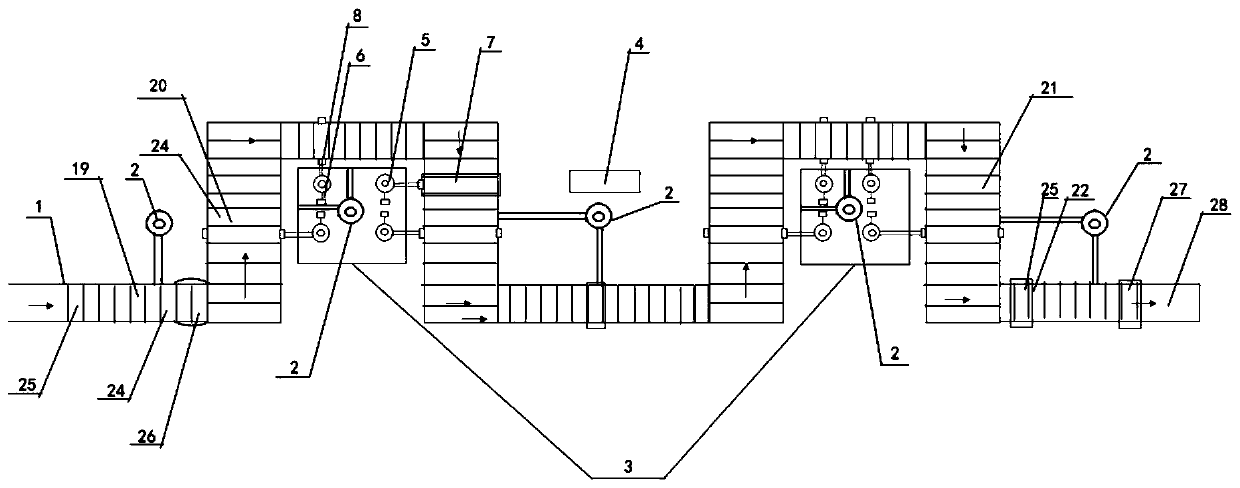

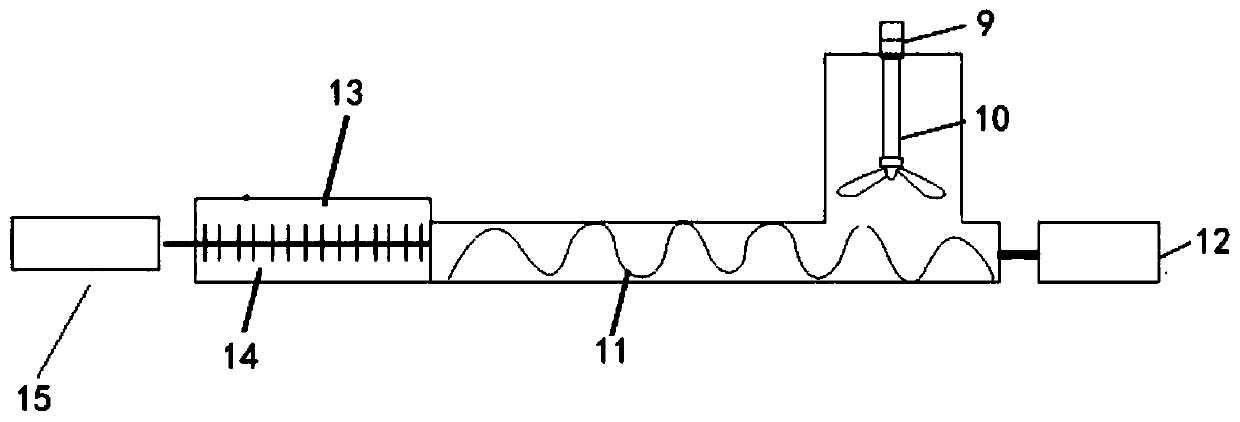

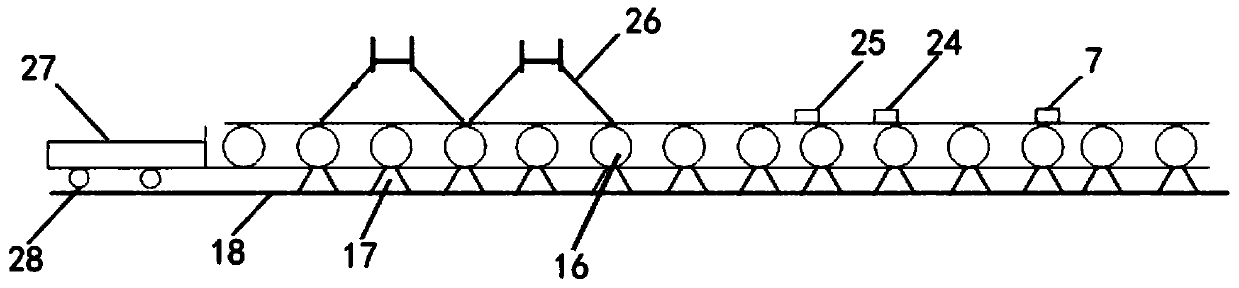

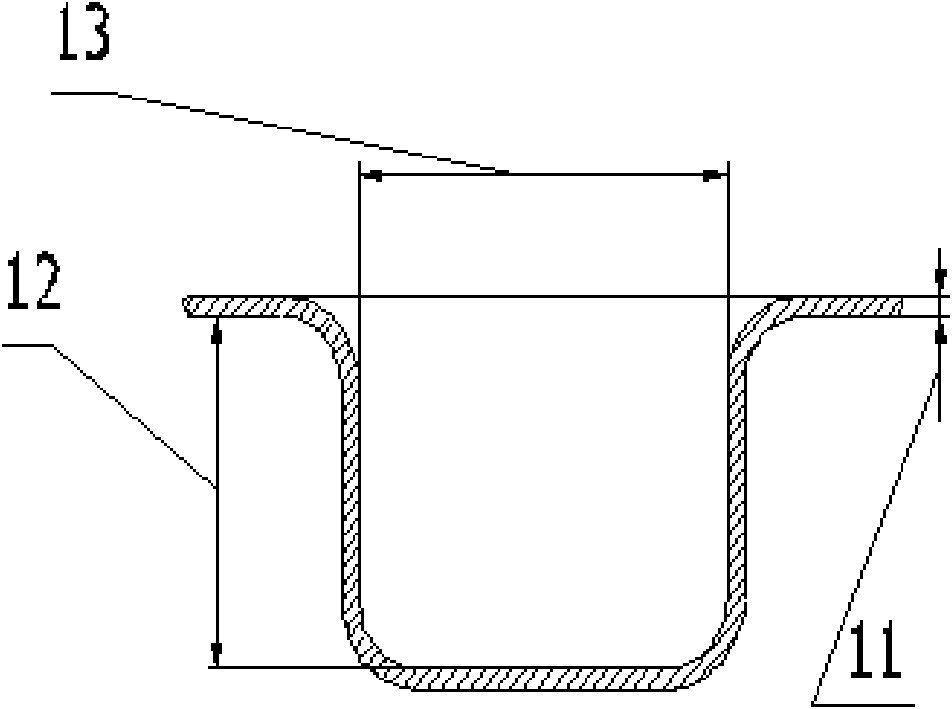

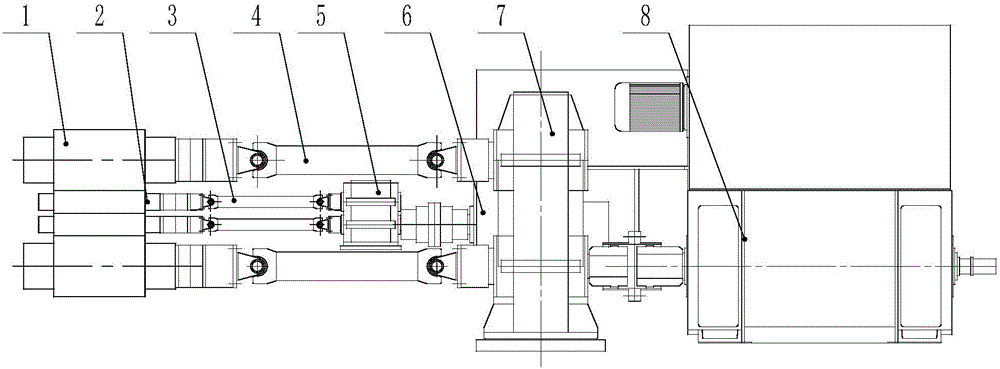

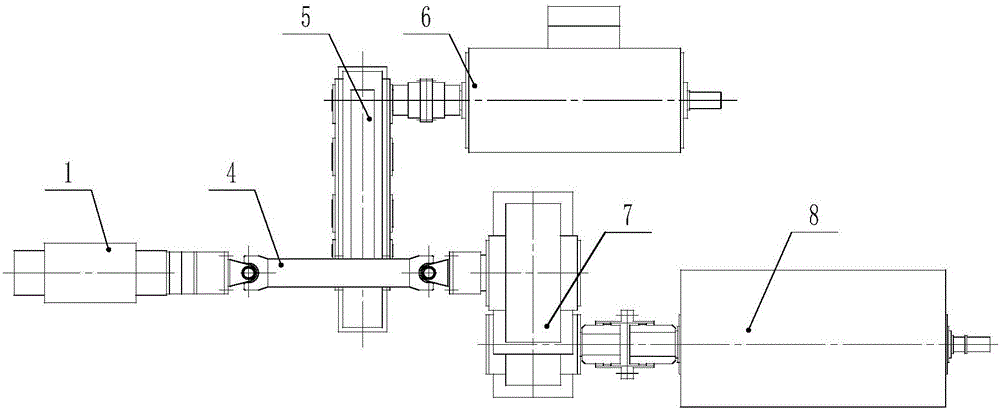

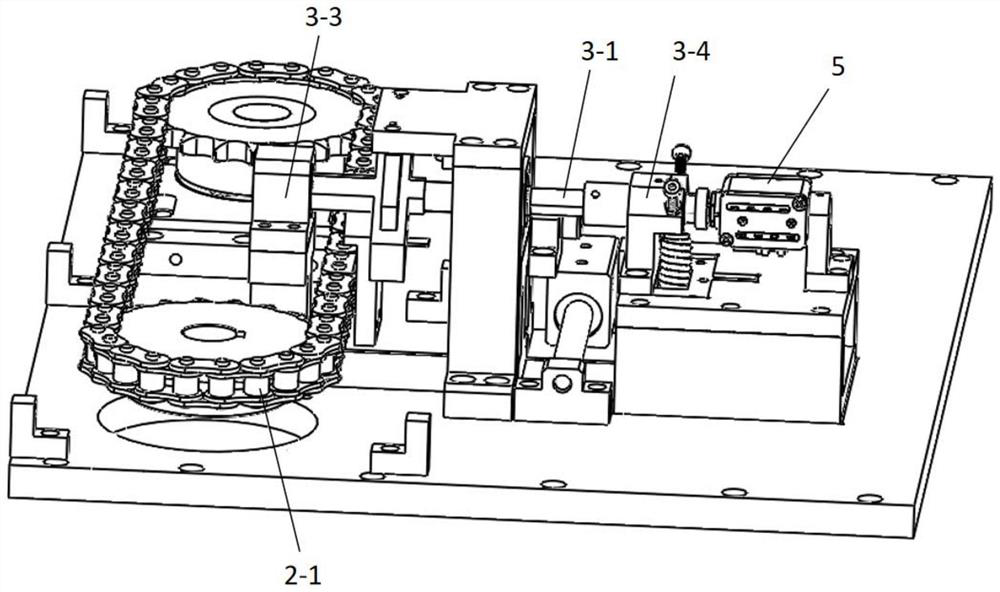

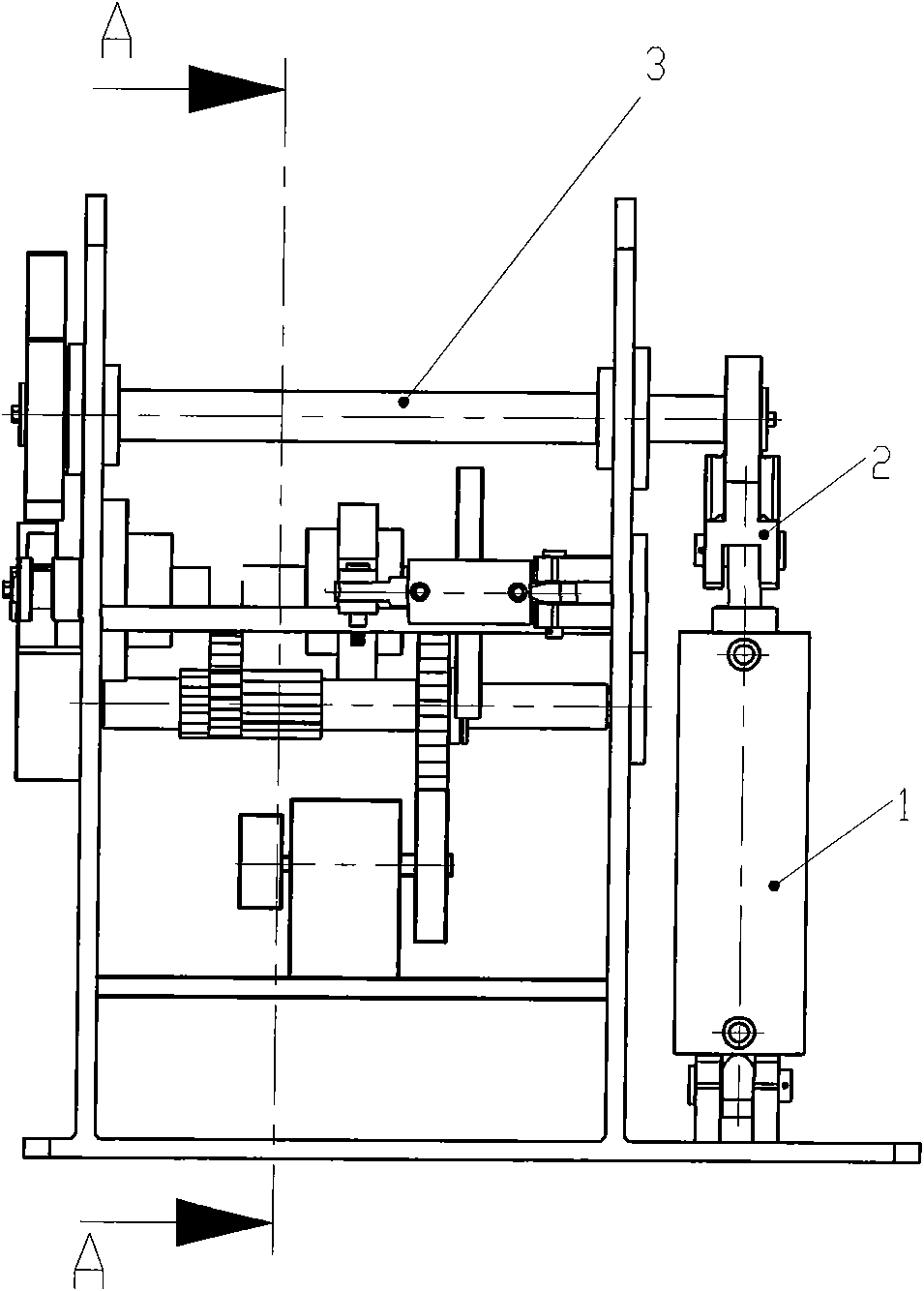

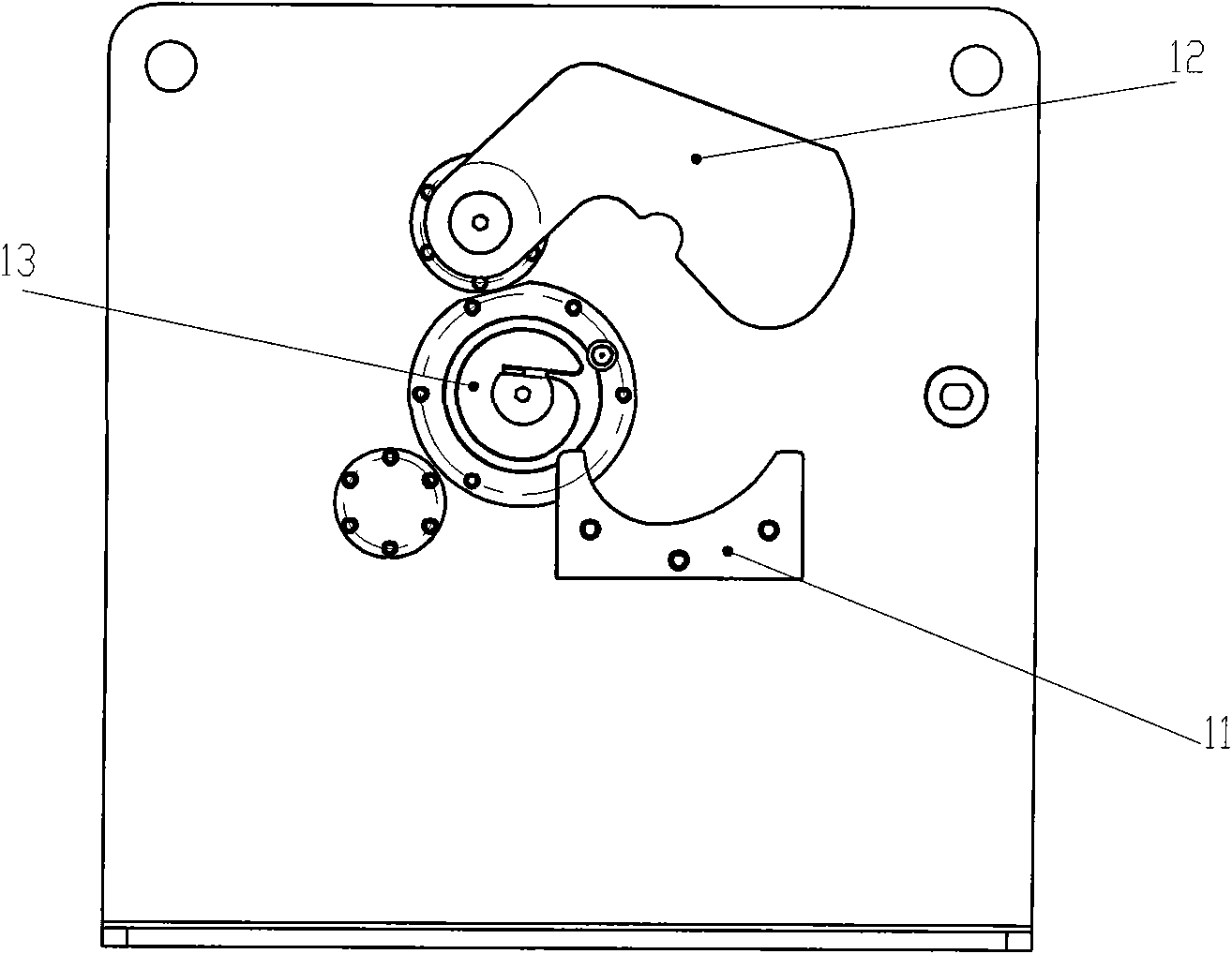

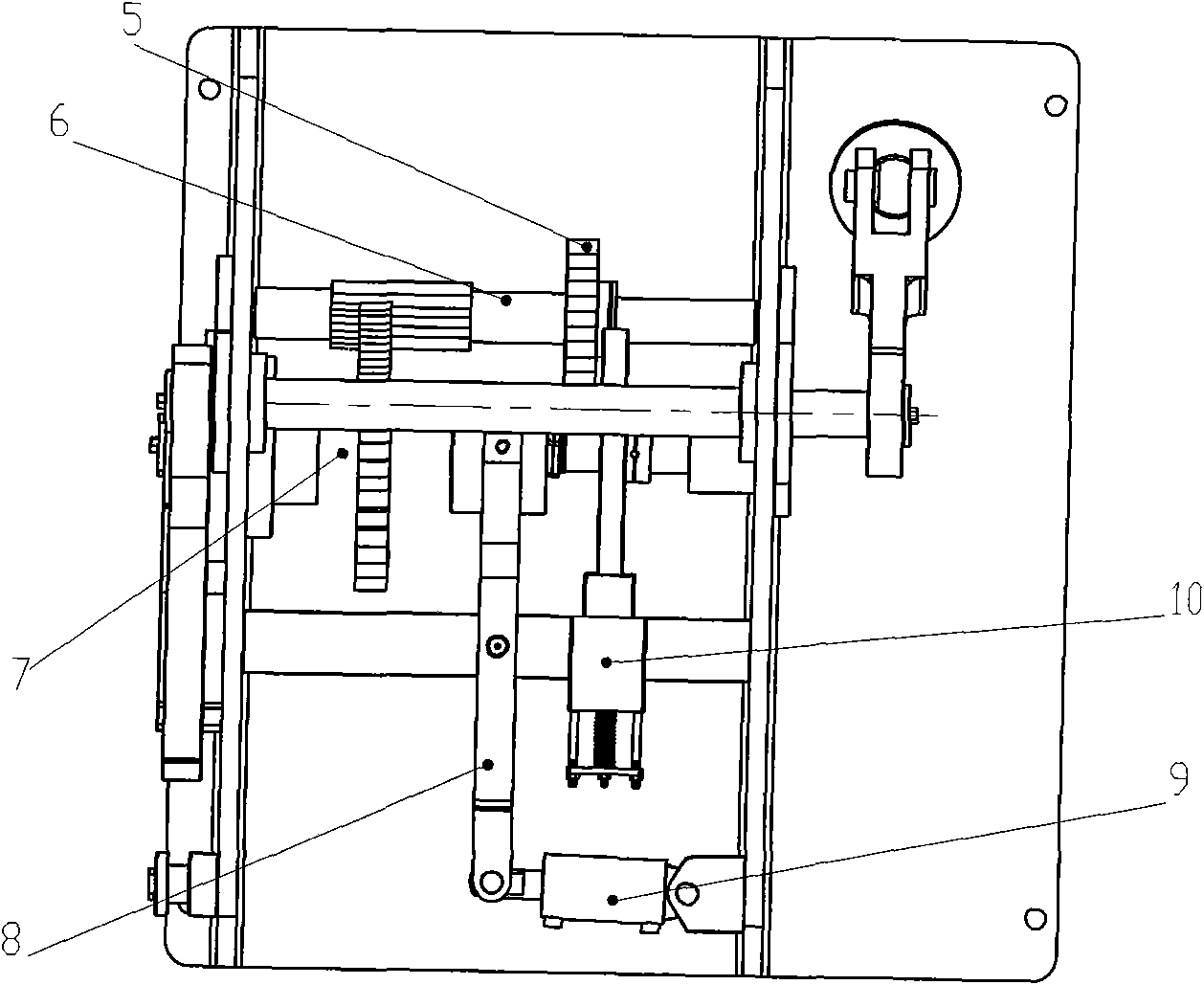

Multiple-transmission device for rolling mill

InactiveCN105710134ASolve the slipping phenomenonSolving pass rateRolling mill drivesAuxillary arrangementsWork rollMaterials science

The invention relates to a multiple-transmission device for a rolling mill and belongs to a multiple-transmission device for a rolling mill in metallurgy industry. The multiple-transmission device is used for solving the technical problems of high possibility of slipping, low quality passing percent of products and small rolling range of a working roll in an existing four-roll or multi-roll rolling mill. In order to solve the technical problems, the technical scheme adopted by the invention is as follows: the multiple-transmission device for the rolling mill comprises two rolling transmission devices, wherein one rolling transmission device is a support roll transmission device; the support roll transmission device is connected with a support roll and used for realizing large-torque rolling; the other rolling transmission device is a working roll transmission device; and the working roll transmission device is connected with the working roll and used for realizing high-speed small-torque milling. The multiple-transmission device has the advantages of multiple transmission devices, good product surface quality of rolled pieces, independent transmission and simultaneous transmission.

Owner:SHANXI CHUANGQI IND

In-situ microfiber reinforced MC nylon composite material preparation method

InactiveCN109054029AHigh grafting rateRealize online automatic controlMaterials preparationAutomatic control

The invention discloses an in-situ microfiber reinforced MC nylon composite material preparation method. According to the preparation method disclosed, isocyanate is utilized as a compatibilizer to solve the problem that polypropylene and nylon 6 are incompatible; by means of using the compatibilizer, in-site polymerization and in-situ fiber formation in a blend system can be synchronously finished, a technological process is shortened, the grafting percent of the compatibilizer is improved, and a copolymerization degree of the polypropylene and the nylon 6 system is improved. A and B tanks and a one-step multi-kettle serial continuous production technology are utilized to prepare an in-situ microfiber reinforced composite material, online automatic control on technological parameters is achieved, the production efficiency of the nylon composite material is improved, and raw material loss is reduced.

Owner:江苏利德尔新材料科技有限公司 +1

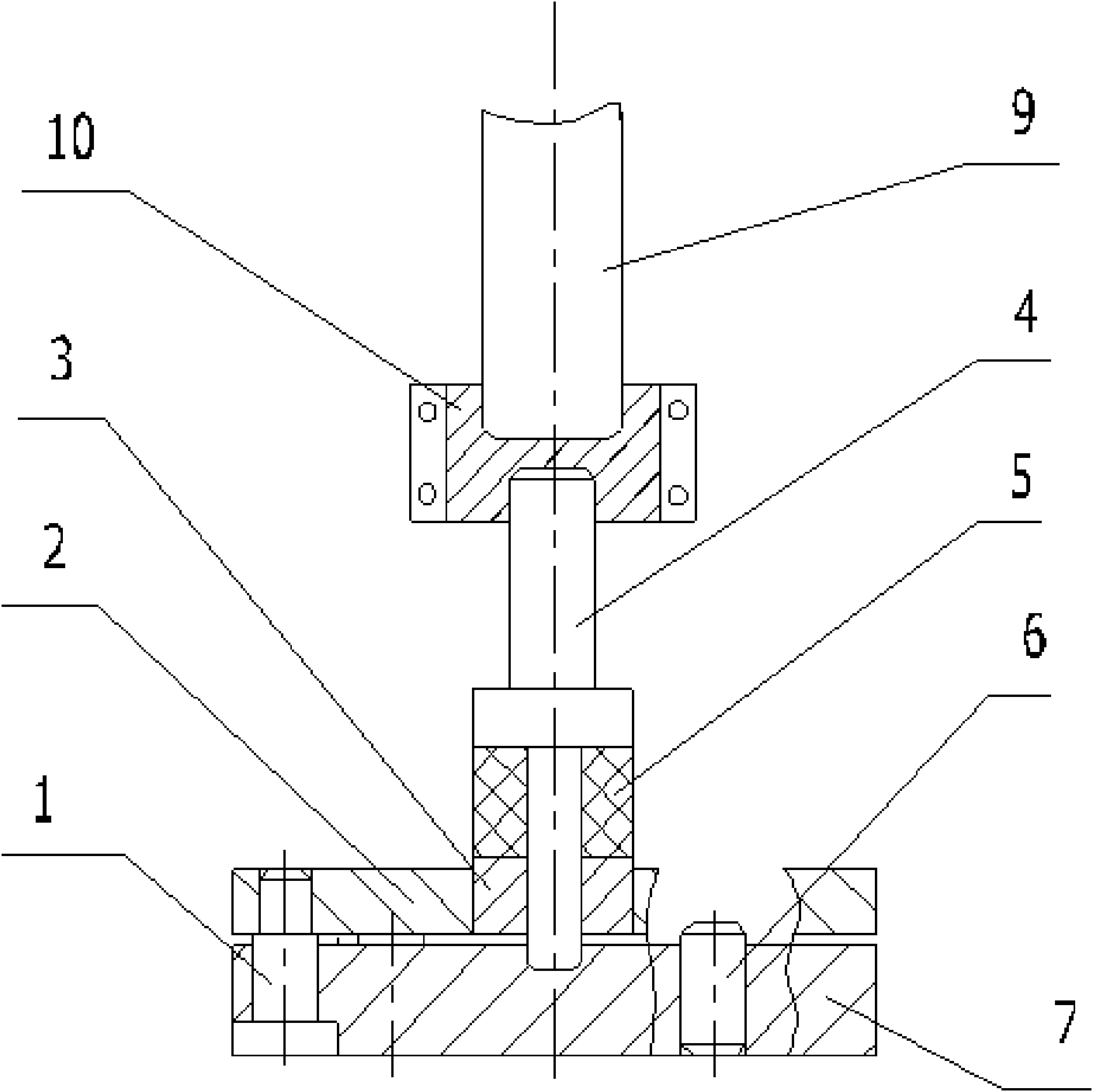

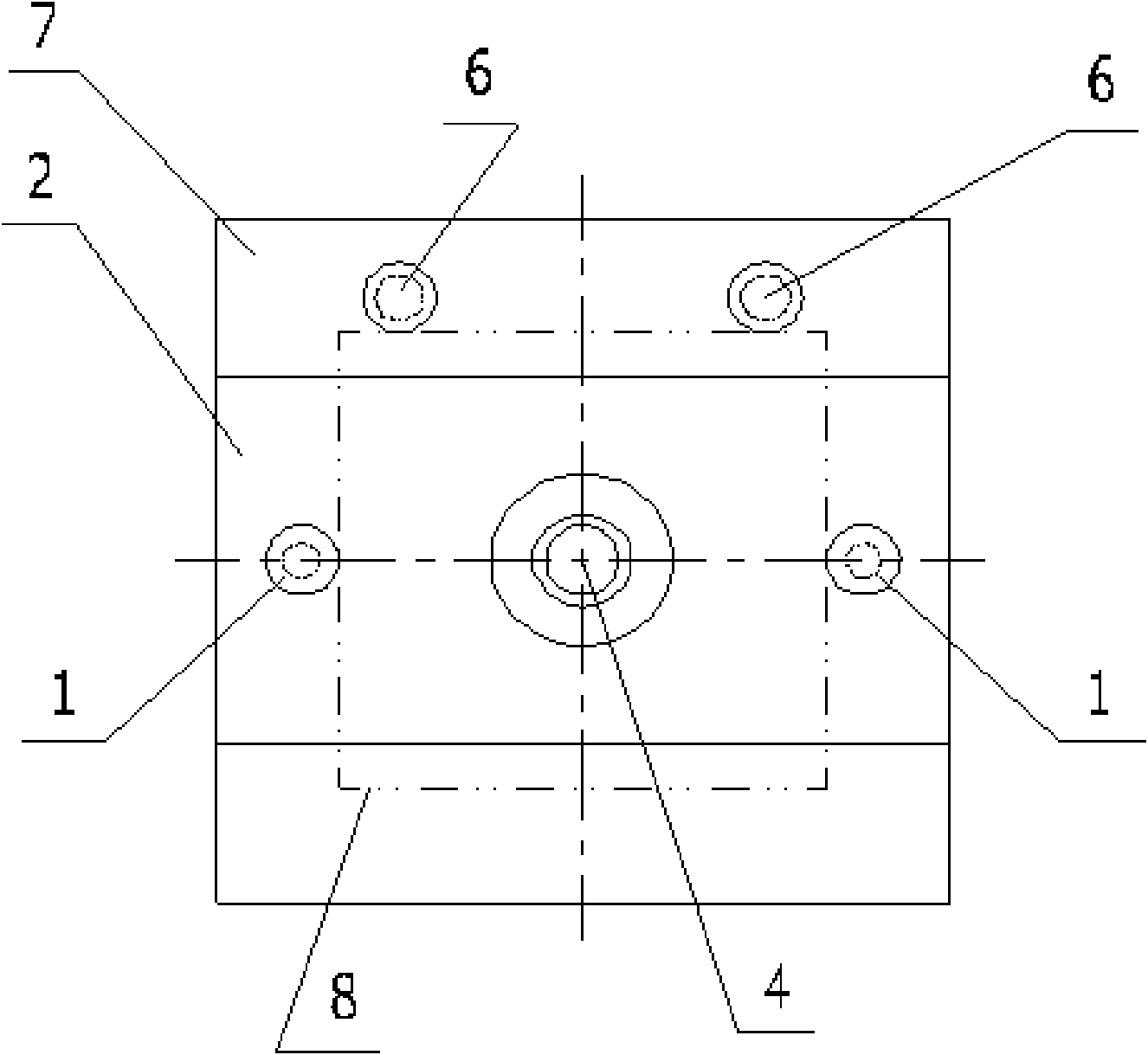

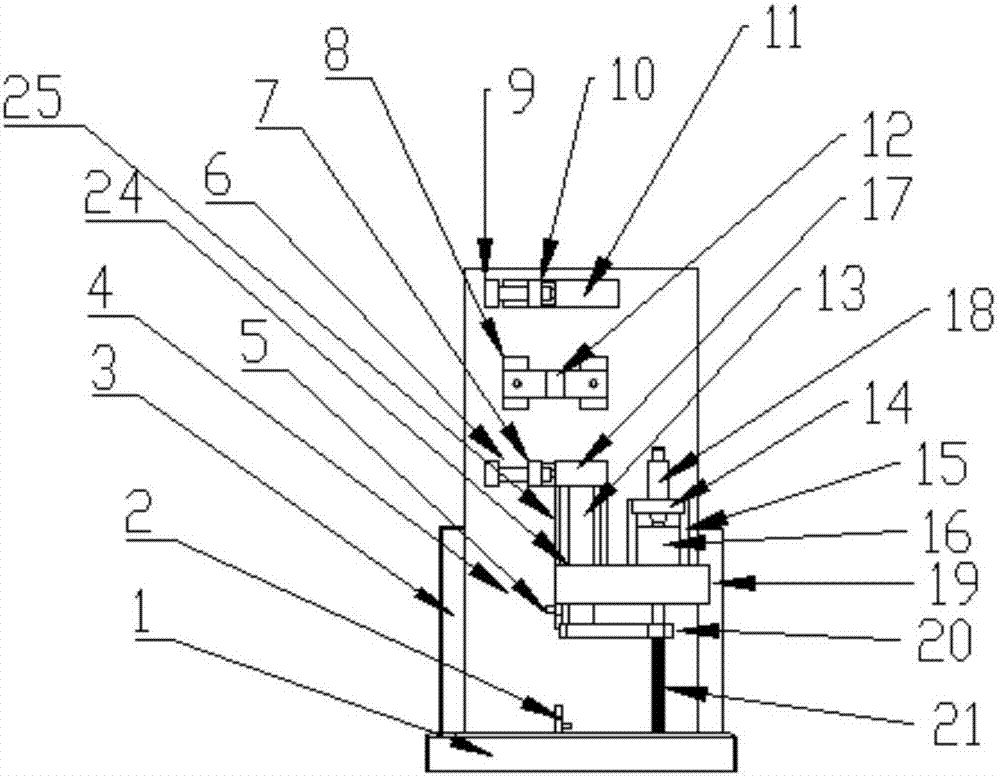

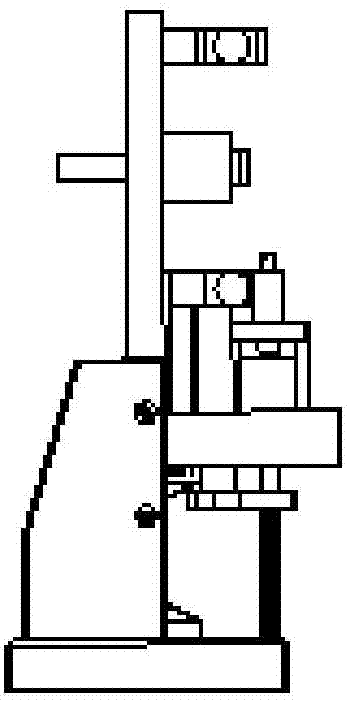

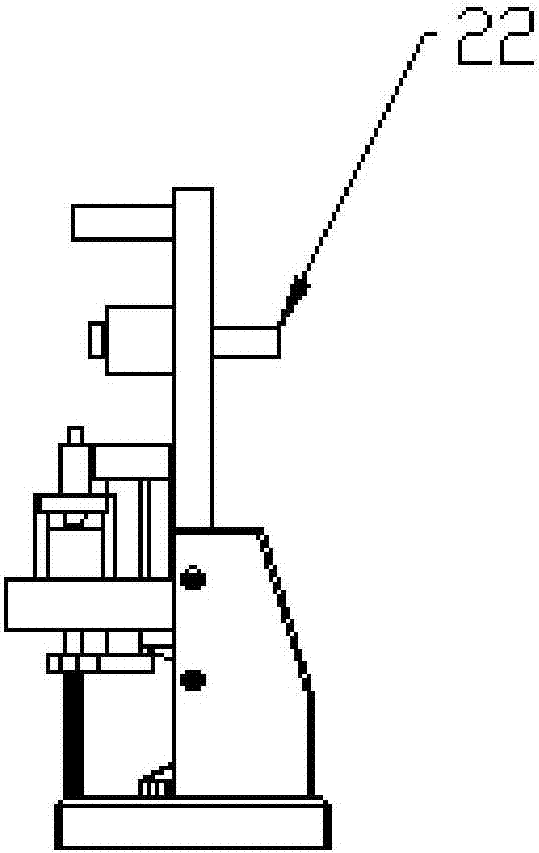

Micro-nano nozzle drawing-forging device and method integrating drawing and forging

ActiveCN106865962AImprove reliabilityImprove accuracyGlass reforming apparatusGlass productionShape changeEngineering

The invention discloses a micro-nano nozzle drawing-forging device and a method integrating drawing and forging. The device comprises a base and a backing plate, wherein a microneedle clamping mechanism, a heating wire clamping mechanism and a drawing-forging needle moving mechanism are arranged on the backing plate; the microneedle clamping mechanism is arranged on the upper part of the backing plate and is used for clamping one end of a glass tube; the heating wire clamping mechanism is arranged in the middle part of the backing plate and is used for heating the glass tube; the drawing-forging needle moving mechanism is arranged on the lower part of the backing plate, and is used for clamping the other end of the glass tube and driving the glass tube to move so as to realize a drawing process. Compared with the prior art, the device has the characteristics of integration of drawing and forging, simple structure, convenience in installation, easiness in use, and the like; the reliability and the accuracy in a micro-nano nozzle drawing-forging process are improved; the problems that the micro-nano nozzle caliber is not easy to control, the shape change is non-uniform, the time and the labor are wasted, the product qualification rate is low and the like during a traditional drawing process are solved; the device and the method are suitable for manufacturing mass glass micro-nano nozzles in a lab and a factory.

Owner:GUIZHOU UNIV

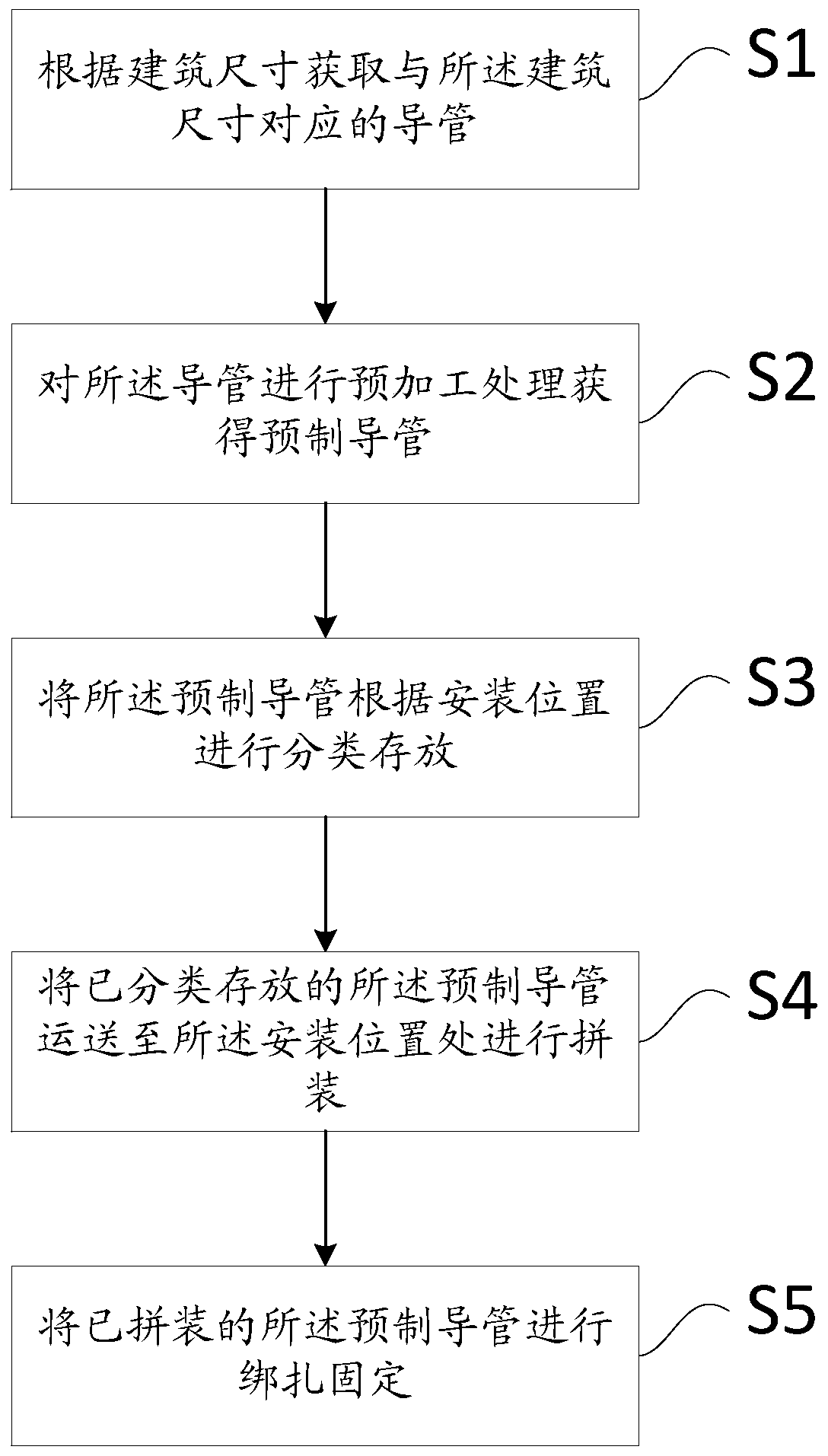

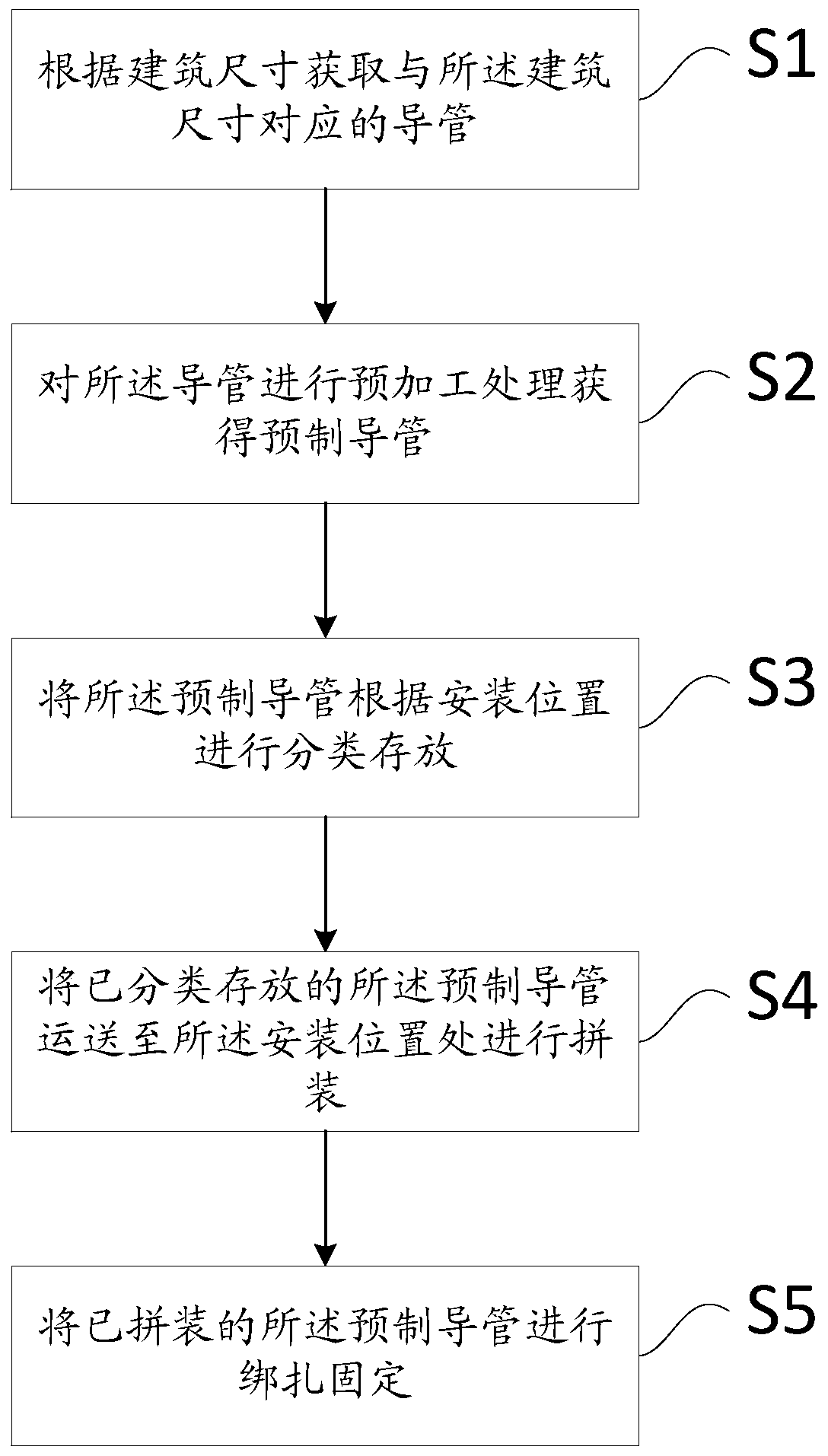

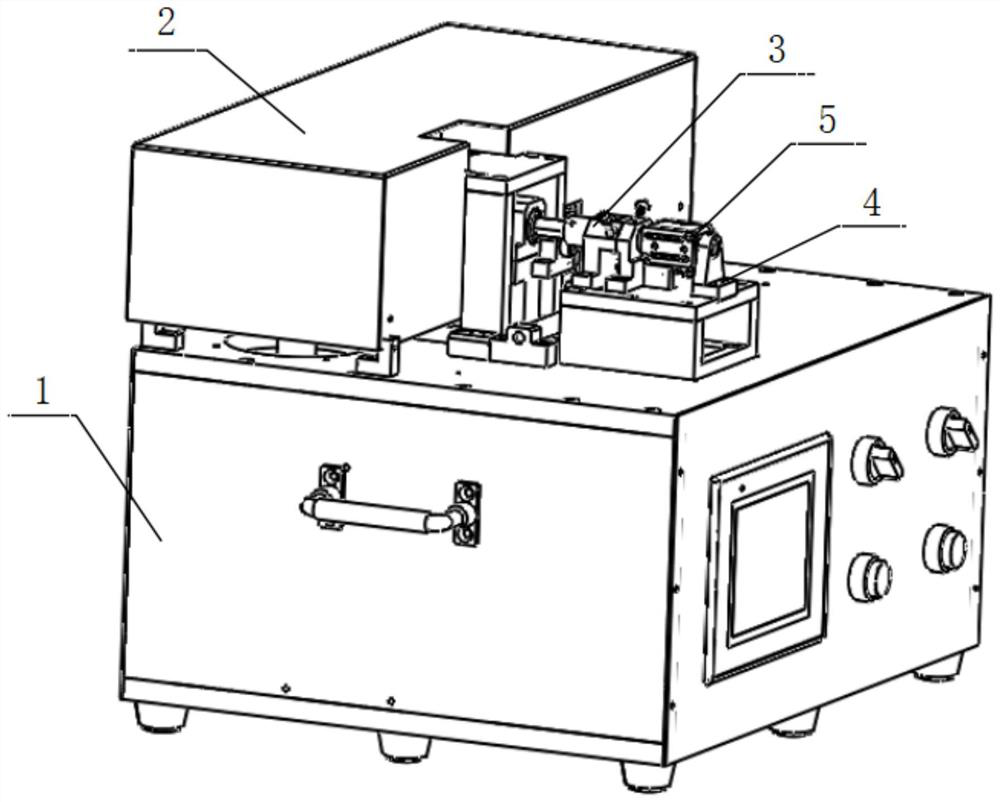

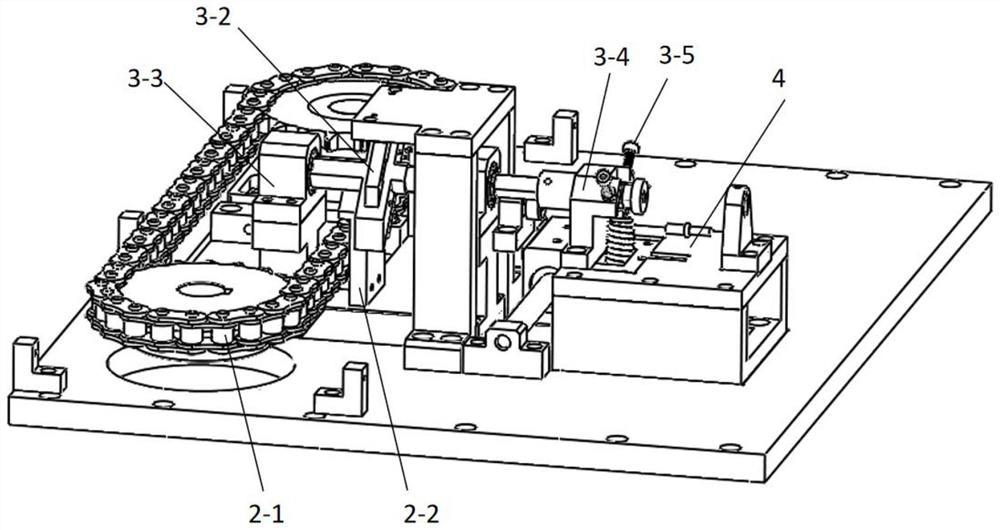

Assembled electrical prefabrication conduit construction method

InactiveCN111151976AExtended service lifeResolution timeCable installation apparatusArchitectural engineeringElectrical conduit

The invention discloses an assembled electrical prefabrication conduit construction method. The assembled electrical prefabrication conduit construction method comprises the steps that conduits corresponding to a building size are obtained according to the building size; pre-machining treatment is conducted on the conduits to obtain prefabrication conduits; the prefabrication conduits are stored in a classified mode according to mounting positions; the prefabrication conduits stored in the classified mode are conveyed to the mounting positions for assembly; and the assembled prefabrication conduits are fixed in a bound mode. According to the provided assembled electrical prefabrication conduit construction method, before the electrical conduits are pre-buried, the conduits are subjected toprocedures such as in-advance bending, cutting, deburring, and assembly connection, the problems of long machining time on an operation layer, congestion of multi-work machining spaces, low machiningquality pass rate and the like in the site construction process are solved, meanwhile, after being fixed in the bound mode, the conduits are further inspected and protected, and the service life of the conduits is prolonged.

Owner:SHANGHAI BAOYE GRP CORP

Low-gas-content electrolytic cobalt preparation method

ActiveCN108950598AReduce gas contentImprove densification performancePhotography auxillary processesOxygenPulse power supply

The invention belongs to the technical field of electrolytic refining, and particularly relates to a low-gas-content electrolytic cobalt preparation method. The method comprises the following steps that 1, a cobalt ammonia system is built, specifically, ammonia water of which the mass fraction is 10-15% is added into a cobalt chloride solution for complex reaction, and a cobalt ammonia solution isobtained; 2, solution circulation is conducted, specifically, the solution obtained in the step 1 is poured into a diaphragm electrolytic cell, and the flow speed in each cathode diaphragm zone is 3-4L / h; and 3, electrolysis is conducted, specifically, cobalt electrolytic deposition is carried out through a pulse power supply, the duty ratio is controlled to be 40:1, the gas element oxygen in anelectrolytic deposition cobalt pole plate is controlled to be lower than 10ppm, and carbon is controlled to be lower than 5ppm. According to the low-gas-content electrolytic cobalt preparation method,the unqualified problems that in the electrolytic deposition process, due to the fact that the cathode gas content is increased, the surface of the pole plate is loosened, pores are increased, and the electrolytic cobalt physical quality is reduced can be effectively solved, the electrolytic cobalt yield is greatly increased, in addition, technology operation is easy, and broadened scale production is facilitated.

Owner:山东有研国晶辉新材料有限公司 +1

Program control box circuit switch synchronism testing device

PendingCN114089185AEnsure consistencySmooth and controllable lifting speedMeasurement instrument housingCircuit interrupters testingRotational axisProduct testing

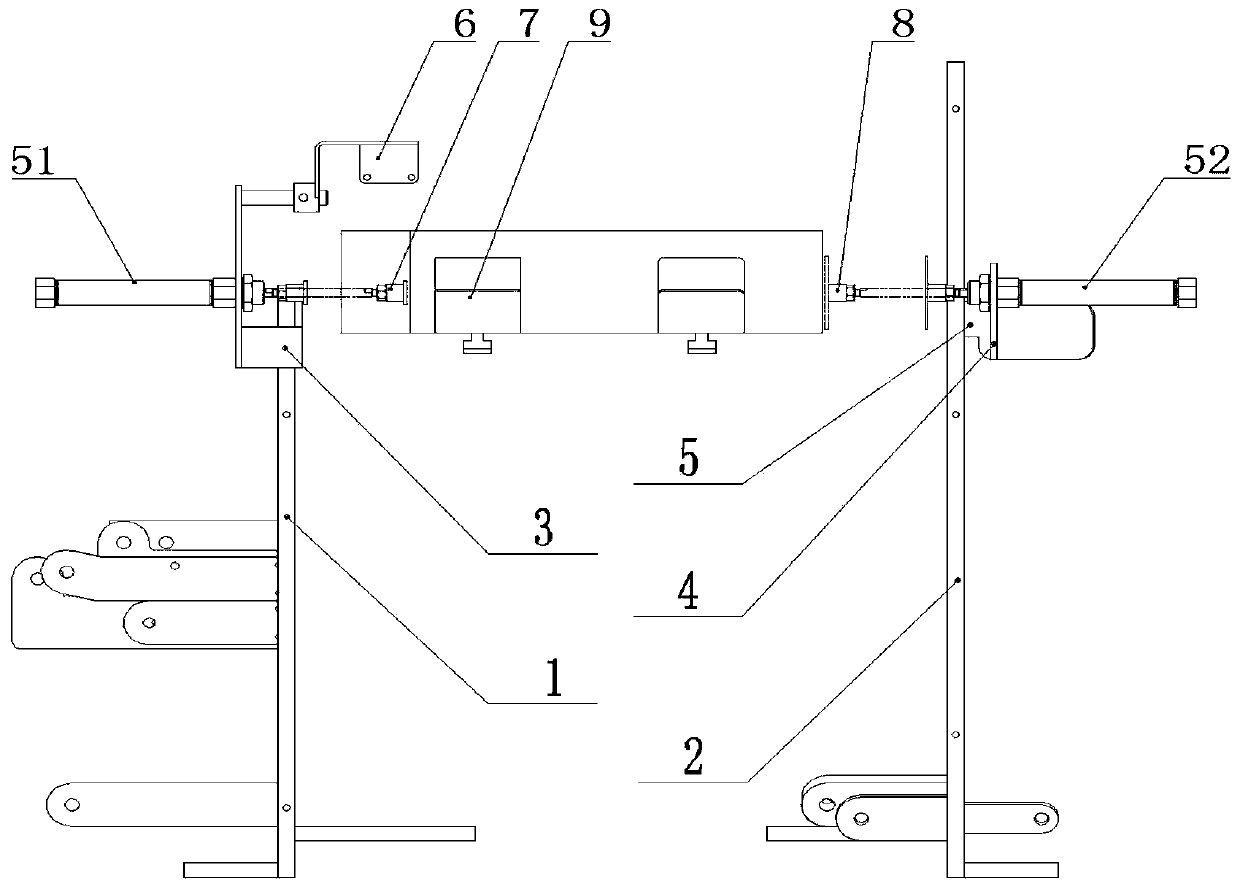

The invention provides a program control box circuit switch synchronism testing device, and belongs to the technical field of program control boxes. The device specifically comprises: an equipment support which is used for providing support; a driving assembly which is used for providing power; a rotating shaft assembly which is connected with the driving assembly and rotates through the power provided by the driving assembly; a mounting clamp, wherein a program control box is arranged in the mounting clamp, the program control box is connected with the rotating shaft assembly, and a switch of a circuit of the program control box is controlled through rotation of the rotating shaft assembly. The driving assembly, the rotating shaft assembly and the product mounting clamp are sequentially arranged on the equipment support. According to the processing scheme, the lifting speed is stable and controllable, the consistency of multiple test results of the same product can be ensured, the problems of unsatisfactory results and low product percent of pass caused by uncontrollable manual test speed are solved, and the product test stability and the test result reliability are improved.

Owner:沈阳兴华航空电器有限责任公司

S-shape harrow cutter bent arc forming machine

The invention discloses an S-shape harrow cutter bent arc forming machine, comprising a motor and a transmission mechanism. The S-shape harrow cutter bent arc forming machine is characterized by further comprising a curling die, a profiling upper die and a profiling lower die, wherein the curling die rotates for 270 degrees to enable one end of a workpiece to form a spiral shape of specified size, and the profiling upper die rotates to close with the profiling lower die to shape the other end of the workpiece. Via organic combination of hydraulic transmission and mechanical transmission, the workpiece is shaped at a time in multiple steps, the problem of low qualification ratio under first acceptance check of the processed products in multiple steps is thoroughly solved, and the international market competitiveness of products is improved. By using a ratchet wheel and a pawl automatic stop device, accuracy of position of the curling die under the outer force is ensured.

Owner:青岛东陆科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com