S-shape harrow cutter bent arc forming machine

A forming machine and arc bending technology, which is applied in the field of arc bending machines, can solve problems such as poor accuracy, manpower consumption, and inability to achieve applicability, so as to solve the problems of one-time inspection and low pass rate, improve market competitiveness, and ensure precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and the embodiments thereof.

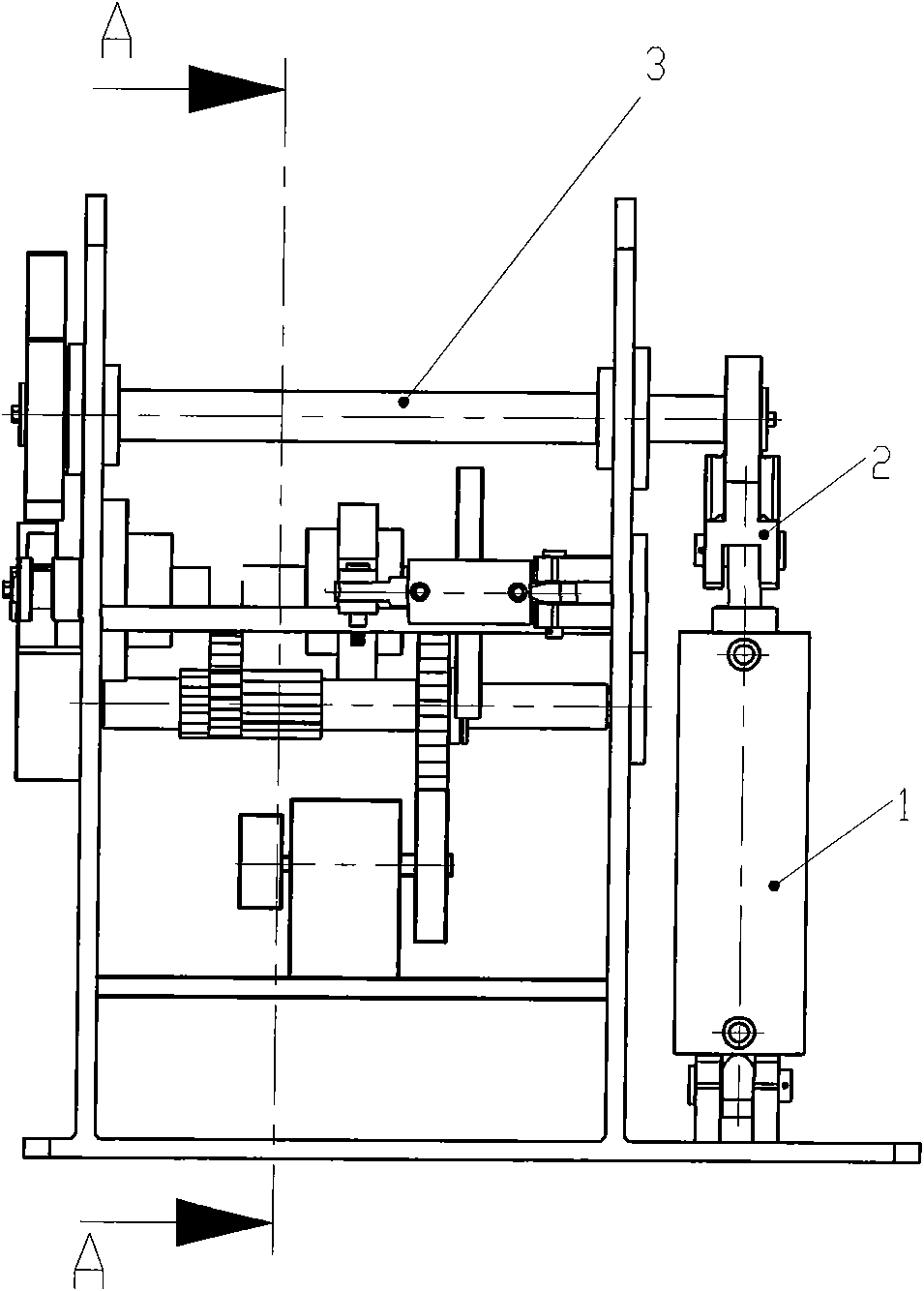

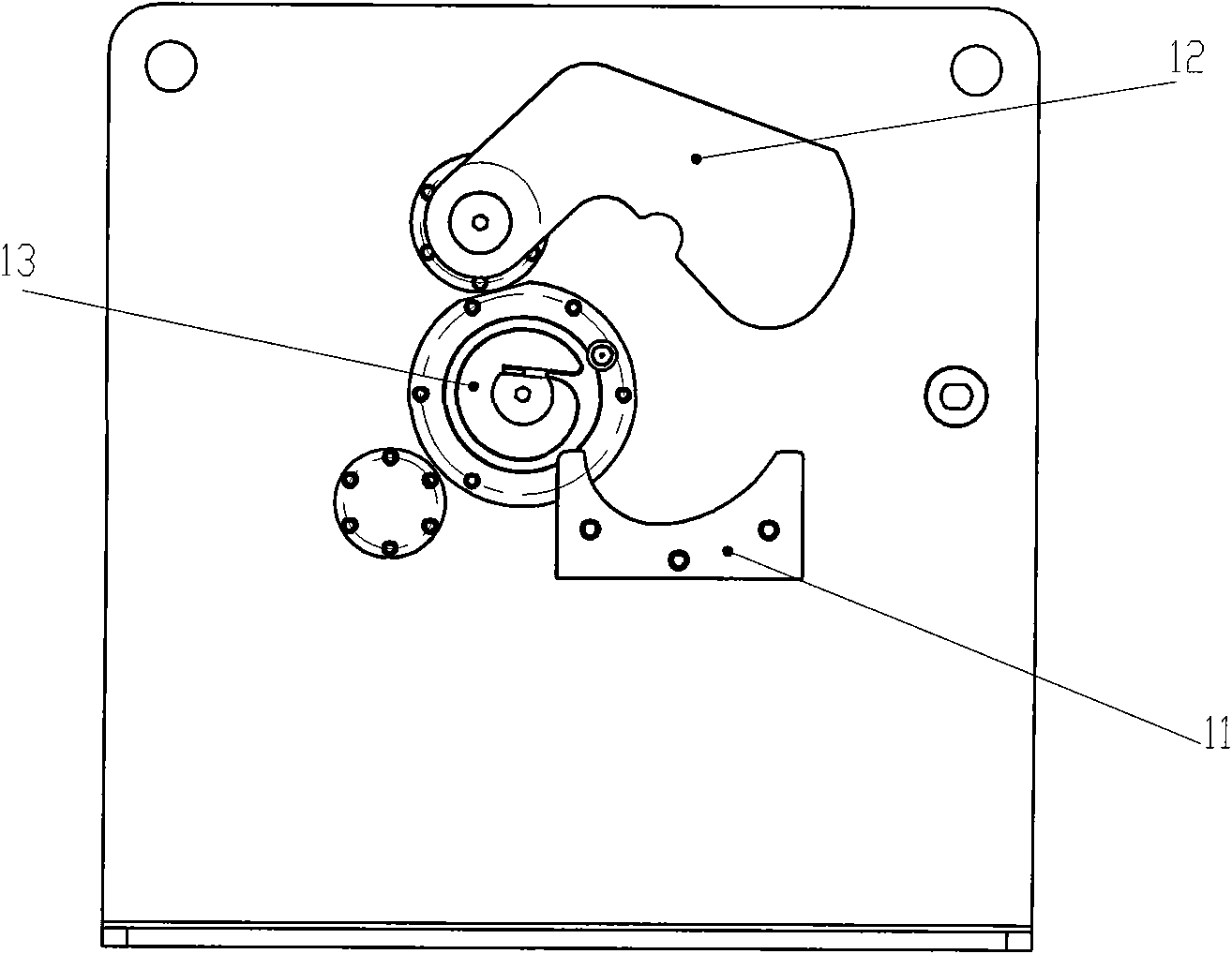

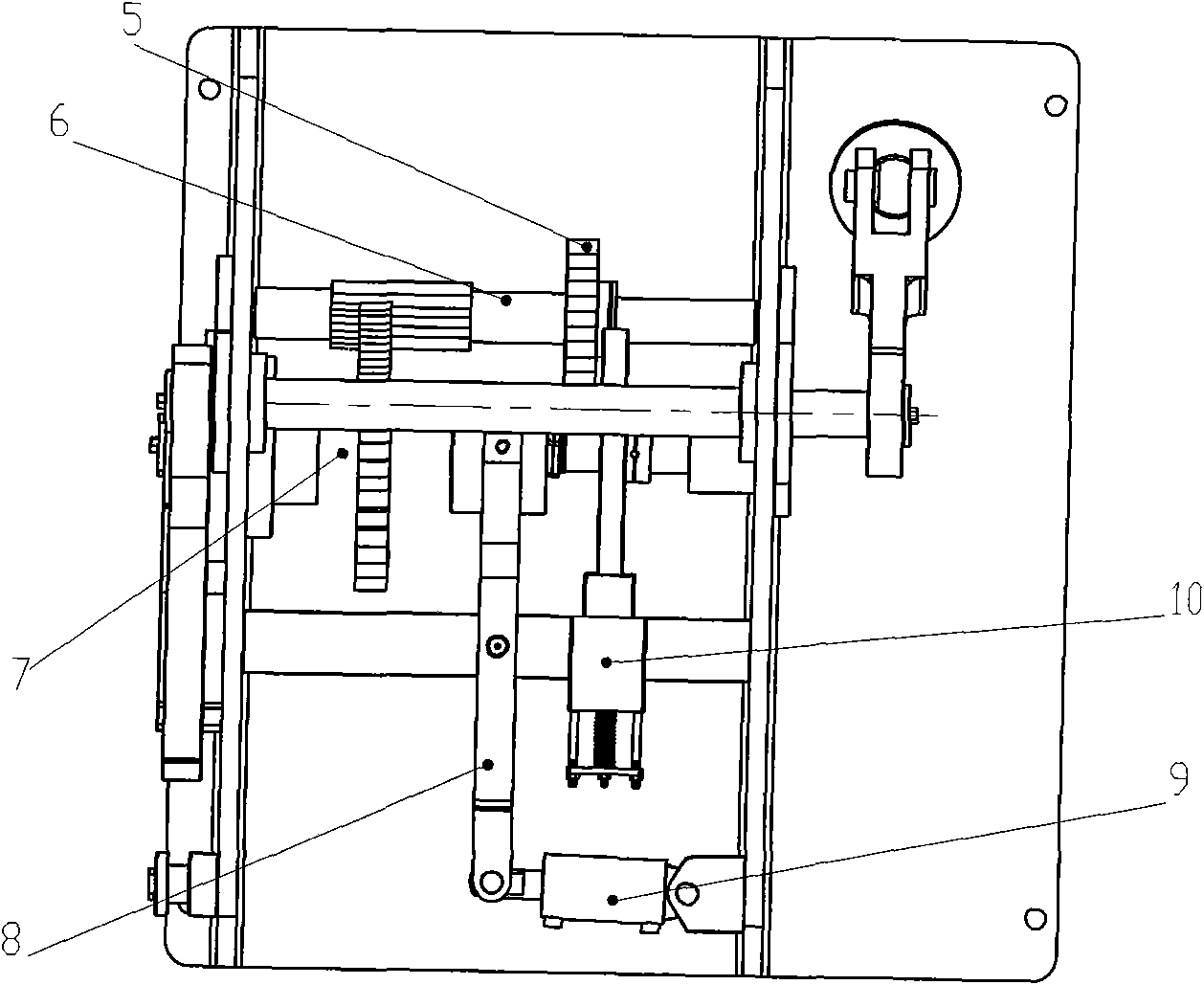

[0015] like figure 1 , figure 2 , image 3 and Figure 4 As shown, put the workpiece into the machine and drive the crimping die to rotate 270 degrees and then stop. The rocker cylinder advances to drive the upper die to rotate and hold the pressure for 2 seconds. The rocker cylinder retreats, the pressing upper mold is released and returns to its position, the fork cylinder advances and the rolling mold is moved back, so that the workpiece is separated from the rolling mold and the workpiece is taken out. The crimping die rotates 90 degrees and returns to its position, the fork oil cylinder retreats, the crimping die protrudes, and then the second workpiece is processed.

[0016] The motor 14 drives the gearbox 16 to rotate the gear shaft 6 through the gear set 5, and the gear shaft 6 drives the curling shaft 7 to rotate thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com