New tail sealing device for liner paper packaging machine

A kind of veneer, paper bag technology, applied in packaging sealing/fastening, packaging, transportation packaging and other directions, can solve the problems of unsightly sealing effect, short heating time, weak sealing, etc. The effect of less bits and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

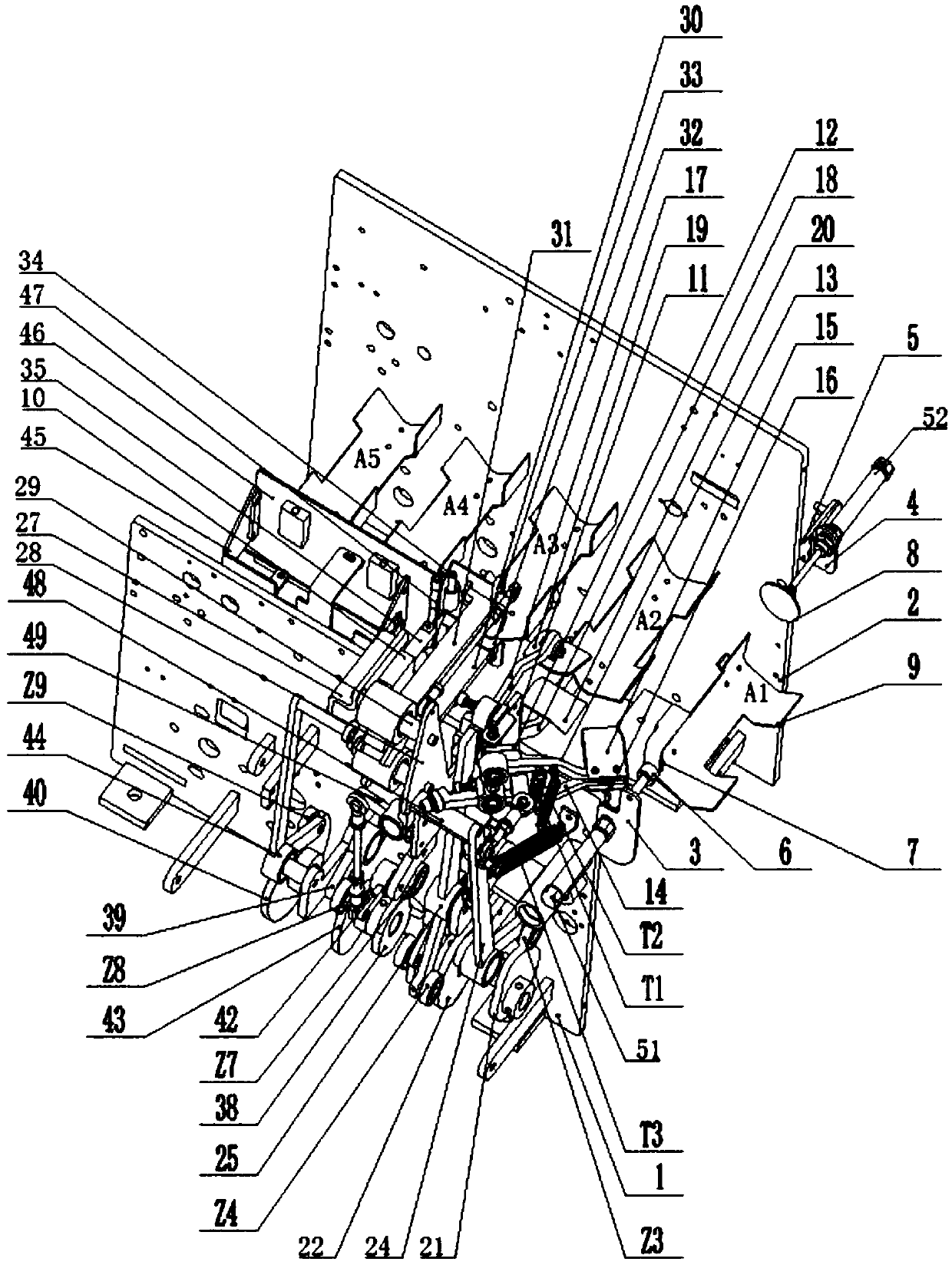

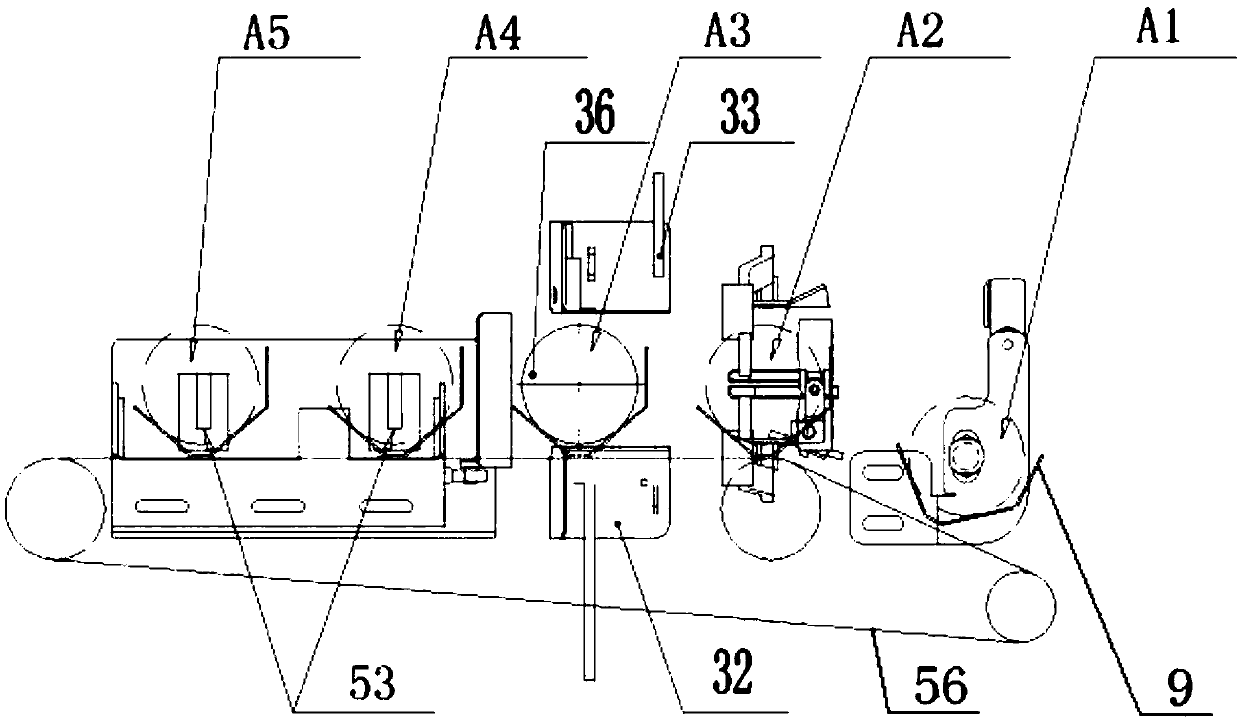

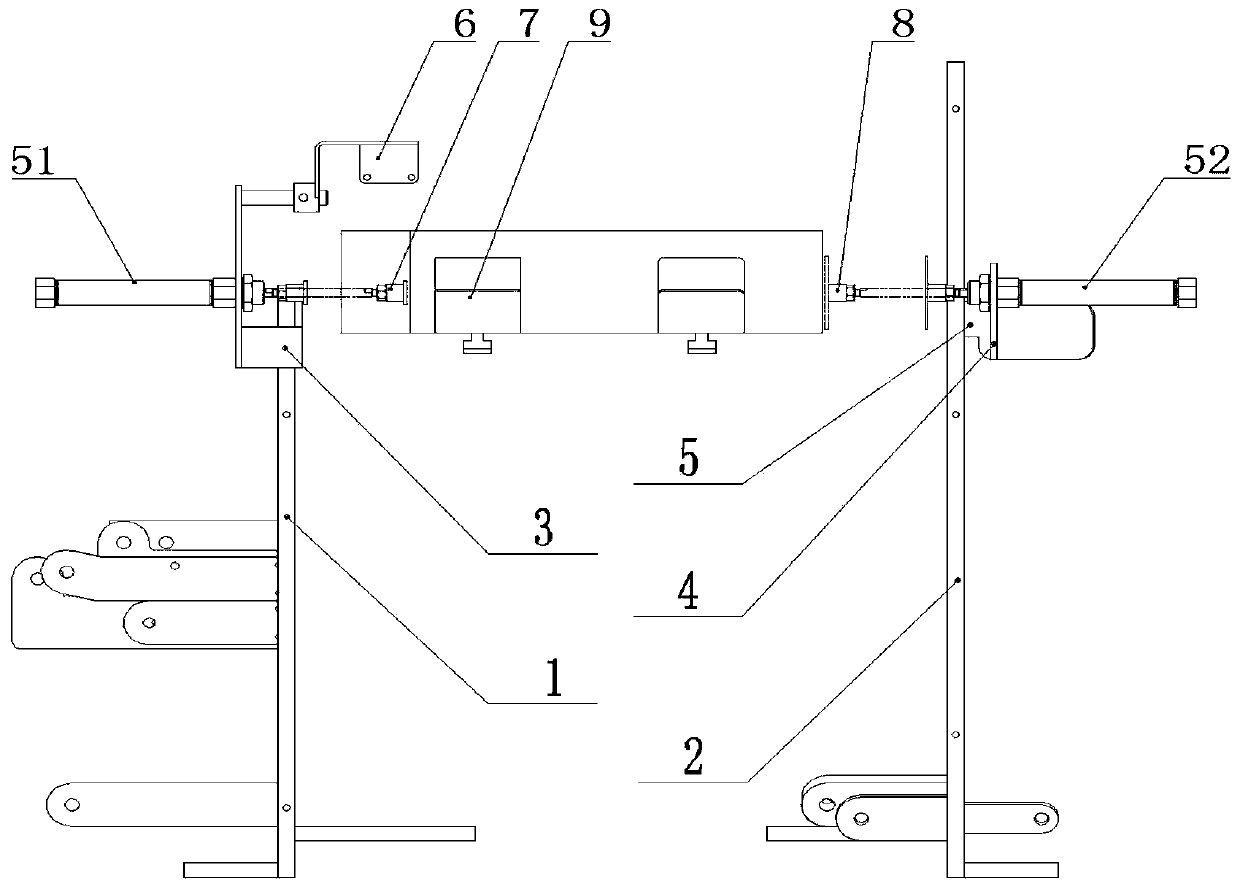

[0021] see figure 1 and figure 2 , the new sealing device of a noodle packaging machine according to the present invention is characterized in that it includes station one A1-station five A5 installed between the left wallboard 1 and the right wallboard 2 in sequence from front to back, Station 1 A1 is used to stop the seam of the cylindrical vermicelli at a suitable position, so as to enter station 2 A2 for folding; this station 2 A2 is used to fold in the paper on the right side of the tail of the cylindrical vermicelli, and The upper and lower side papers are indented and shaped; the station three A3 is used to fold in the upper and lower side papers that have been indented and shaped, and then the left paper is indented and glued; the station four A4 is used for Fold the creased and shaped left paper into it to complete the sealing action and heat and dry the glue.

[0022] A station 5 A5 with the same structure can also be provided behind the station 4 A4, which is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com