Precise molding method for complex internal flow passage structure

A kind of internal runner, complex technology, applied in the direction of casting molding equipment, casting mold, core, etc., can solve the problems of low pass rate, poor surface precision of inner runner, difficult forming of inner runner, etc., and achieve the goal of avoiding ablation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

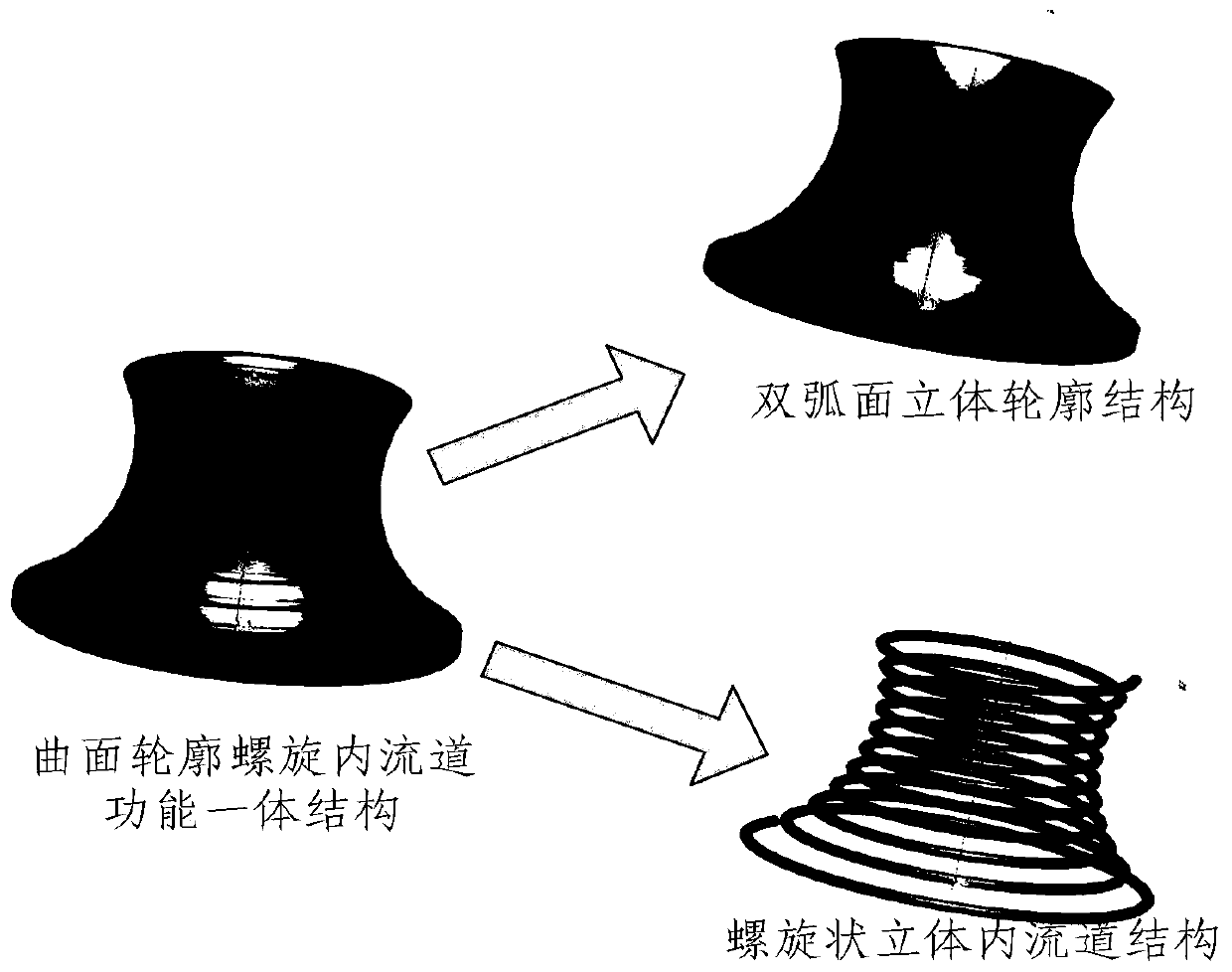

[0021] Taking the manufacture of a double-arc contour spiral inner runner function integrated structure with aluminum alloy as the base material as an example, a precise forming method for a complex inner runner structure is described. The specific steps are as follows:

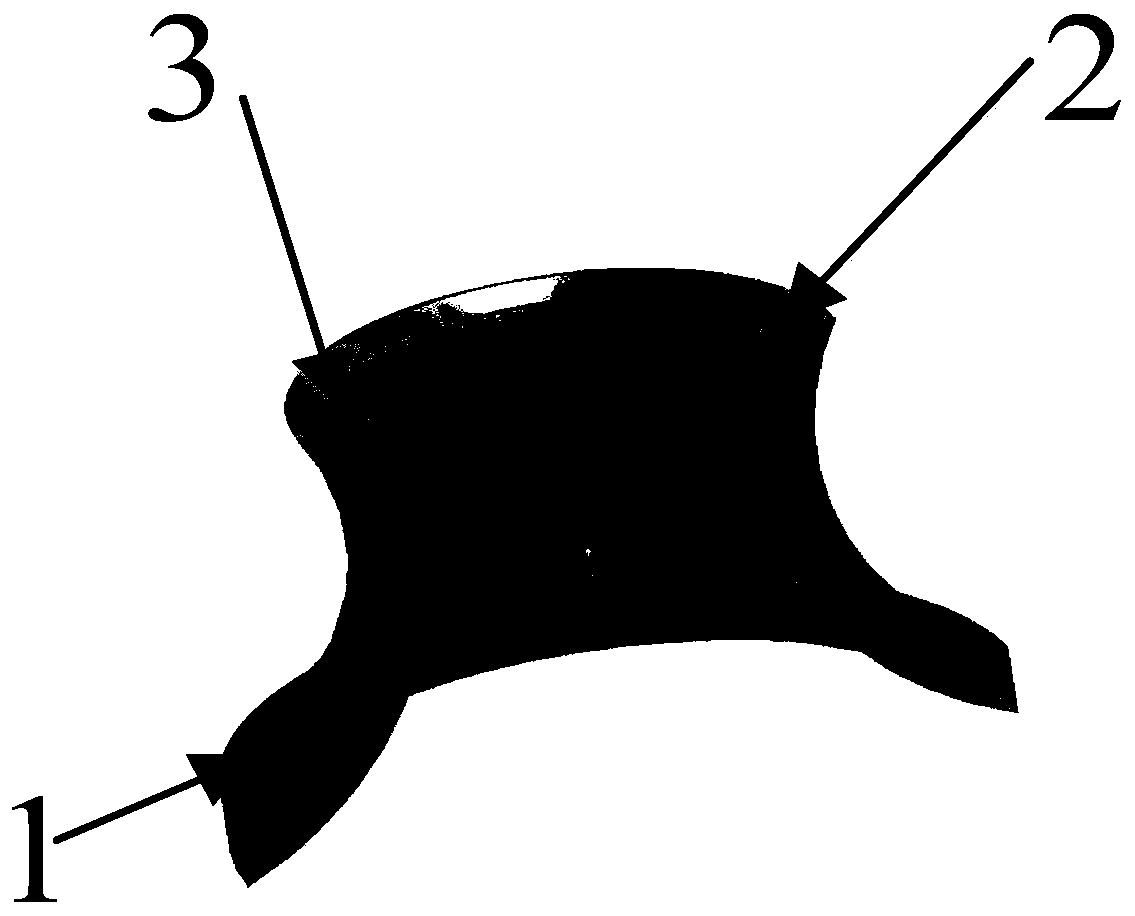

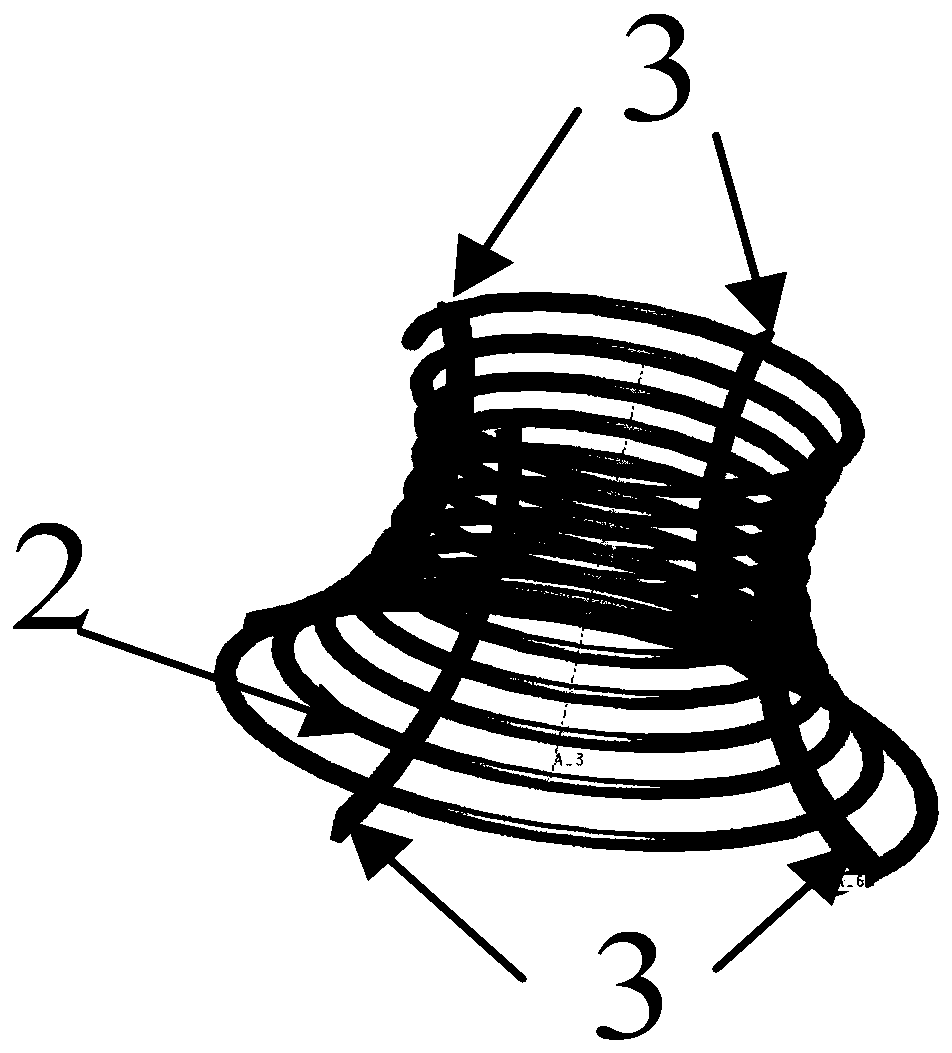

[0022] The first step is to decompose the structure into two parts: the three-dimensional outer contour configuration and the three-dimensional inner runner configuration

[0023] The function-integrated structure of the double-arc contour spiral inner flow channel is decomposed into a double-arc three-dimensional contour structure and a helical three-dimensional inner flow channel structure.

[0024] The second step material selection

[0025] The base material is aluminum alloy, and the aluminum alloy is selected as the double-arc three-dimensional outer contour structure material. According to the requirement that the melting point is increased by more than 100 degrees Celsius, the spiral three-dimensional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com