Rain wiper control system and motor control method

A control system and motor control technology, used in vehicle cleaning, vehicle maintenance, transportation and packaging, etc., can solve the problems of ablated contacts, high failure rate of wiper combination switches, arcing, etc., to achieve isolation , to eliminate the combination switch contact ablation phenomenon, the effect of low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

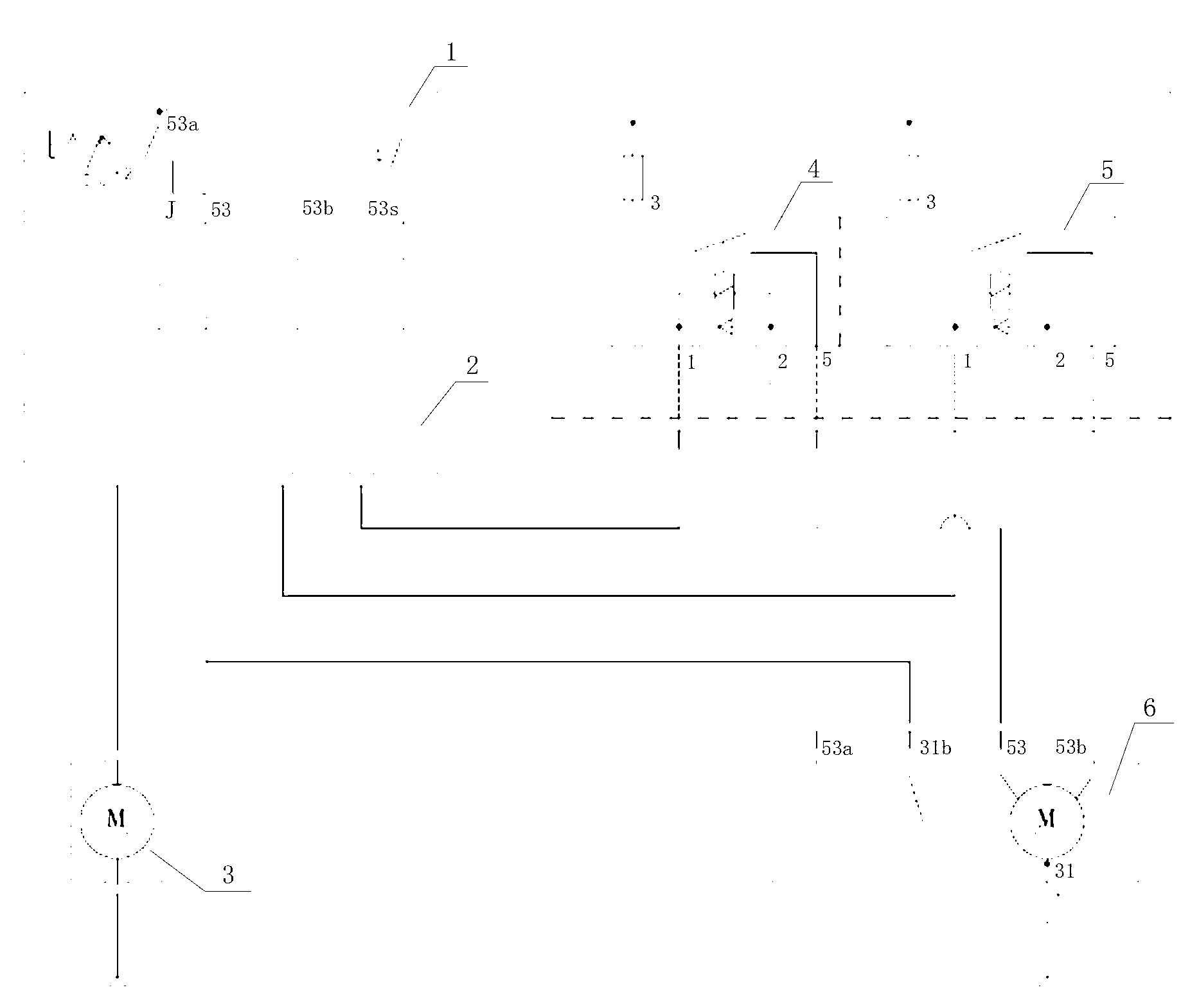

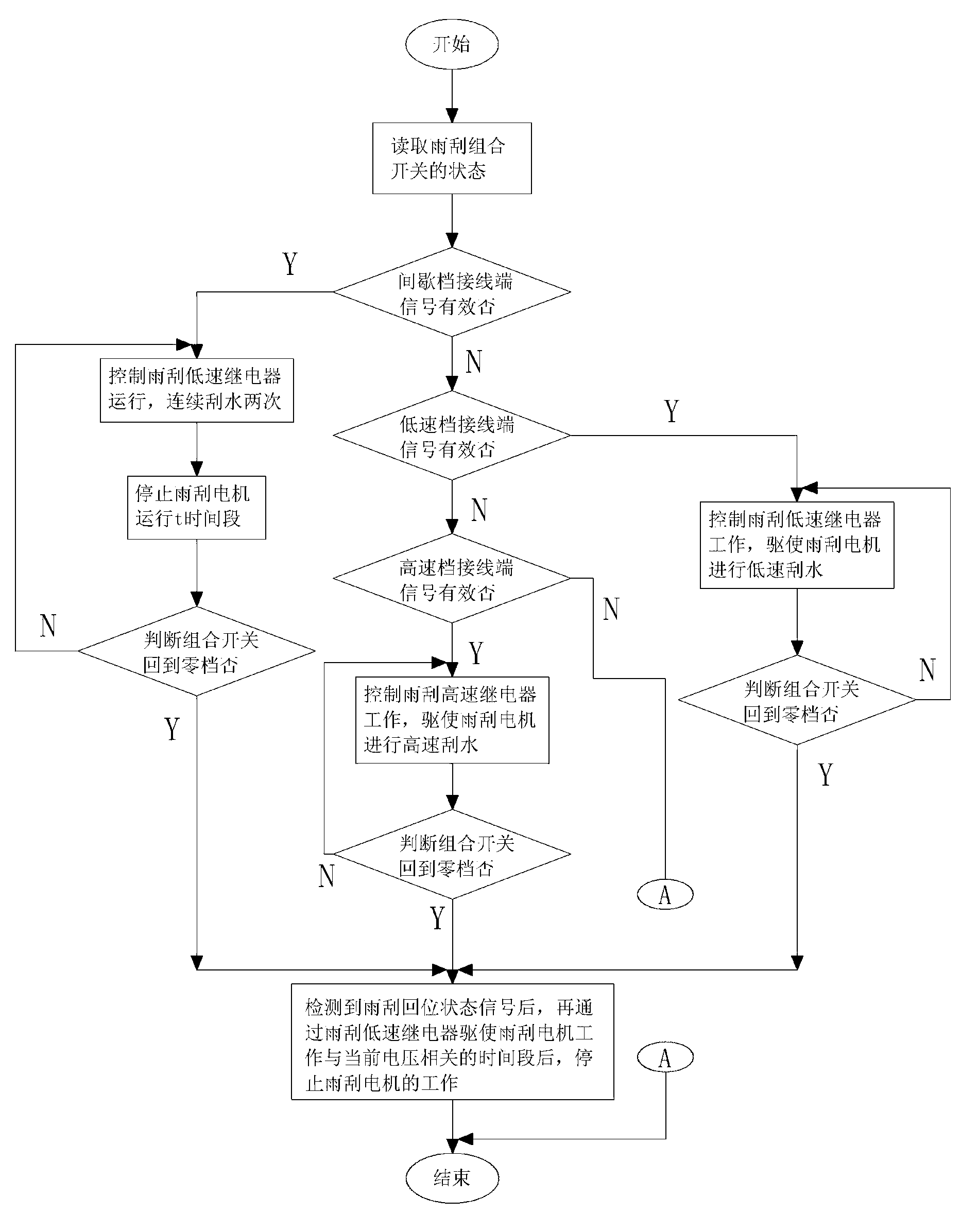

[0017] Such as figure 1 As shown, the circuit principle diagram of the wiper control system of the present invention is given, which includes a wiper combination switch 1, a vehicle body controller 2, a spray motor 3, a wiper low-speed relay 4, a wiper high-speed relay 5 and a wiper Motor 6; the shown wiper combination switch 1 is provided with intermittent gear, low speed gear, high speed gear and spray terminals, which are J, 53, 53b and 53s terminals respectively; the combination switch 1 is also equipped with zero gear . The intermittent gear, low gear, high gear and spray terminals of the combined wiper switch 1 are all connected to the input terminal of the body controller 2, and the microcontroller has the functions of collection, calculation and processing, and it can adopt a PLC microcontroller.

[0018] The wiper motor 6 is used to drive the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com