Patents

Literature

57results about How to "Avoid demoulding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing gouge mark structure-containing columnar jointing sample for seepage test

ActiveCN106769753AAvoid demouldingAvoid problems such as secondary perfusionPreparing sample for investigationPermeability/surface area analysisColumnar jointingGeometric modeling

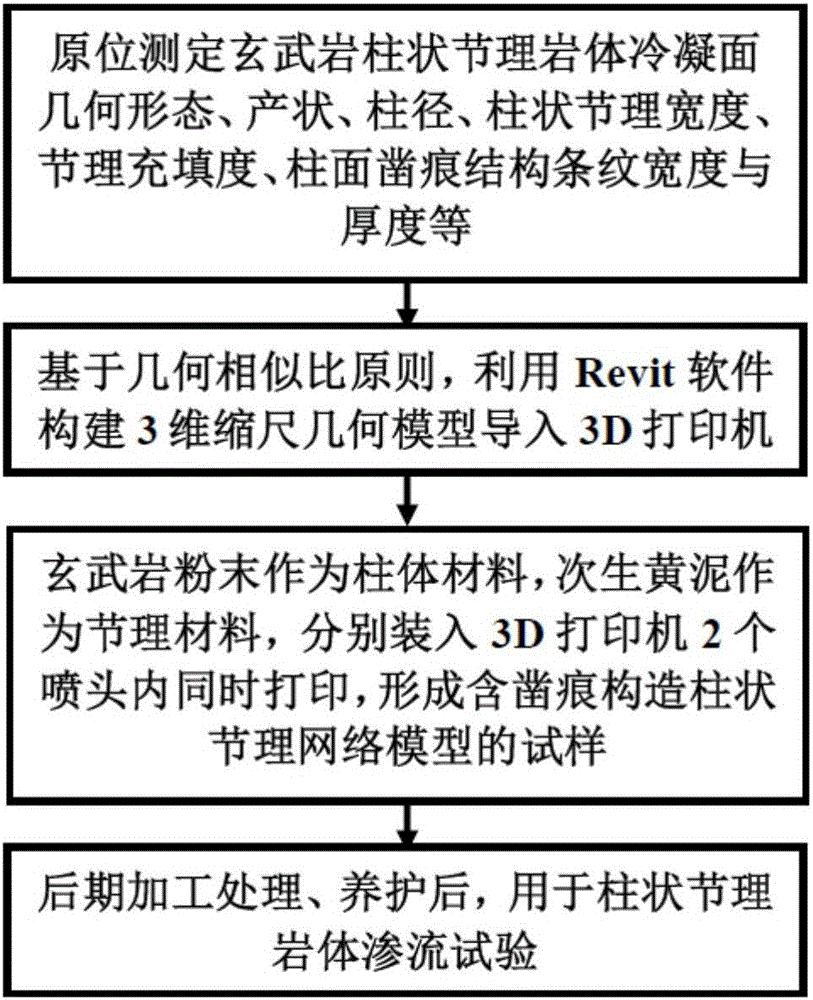

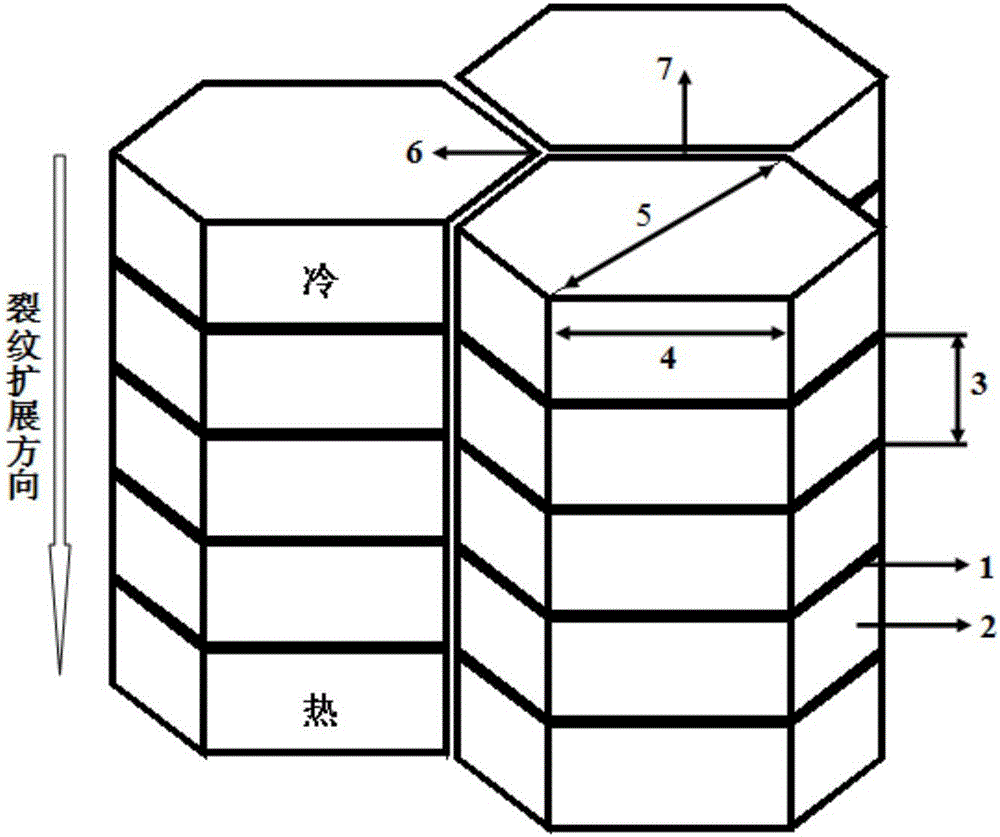

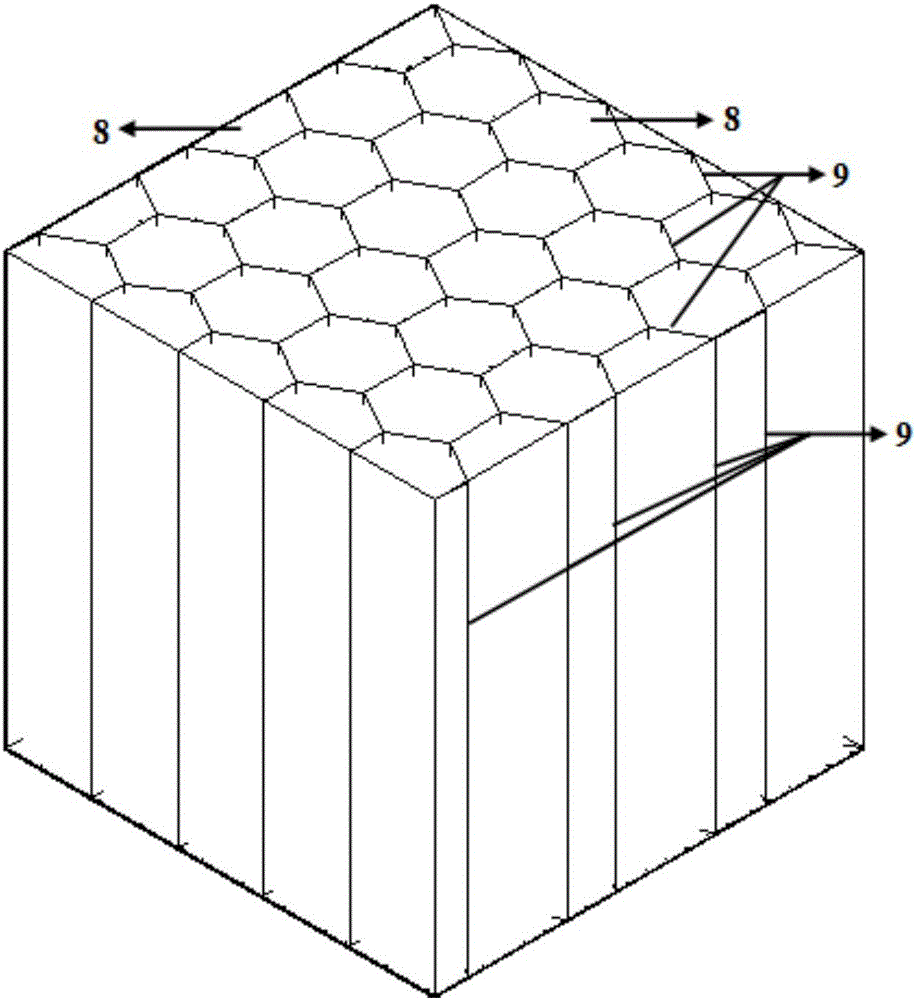

The invention discloses a method for preparing a gouge mark structure-containing columnar jointing sample for a seepage test. The method comprises measuring a geometrical shape, occurrence, a column diameter, columnar jointing width, a jointing filling degree, and cylindrical surface gouge mark structure stripe width and thickness of the condensing surface of a basalt columnar jointing rock in situ, according to a similarity ratio principle, building a 3D reduced scale geometric model through Revit software, introducing the 3D reduced scale geometric model into a 3D printer, respectively filling two nozzles of the 3D printer with basalt powder as a columnar material and secondary yellow mud as a jointing material, and carrying out synchronous printing to obtain a sample of a gouge mark structure-containing columnar jointing network model, wherein after later processing and curing, the model can be used for a columnar jointing rock seepage test. Through use of the jointing surface gouge mark structure, the sample can really reflect the structure and shape of the gouge mark structure-containing columnar jointing network model and can provide a novel research idea for anisotropic seepage of the columnar jointing.

Owner:HOHAI UNIV

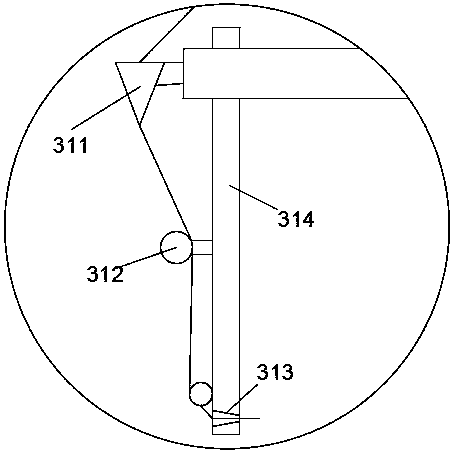

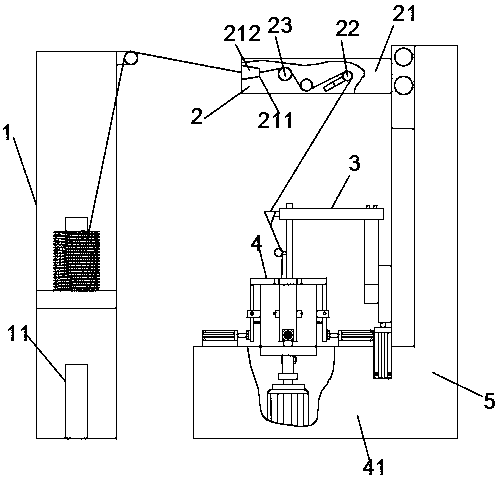

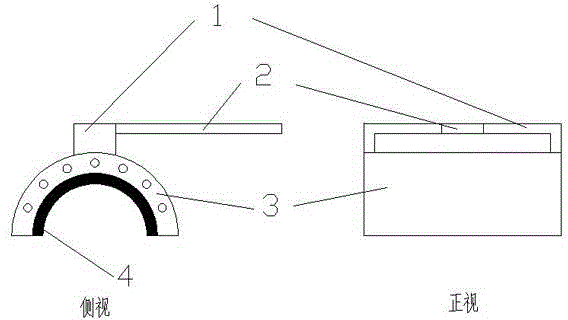

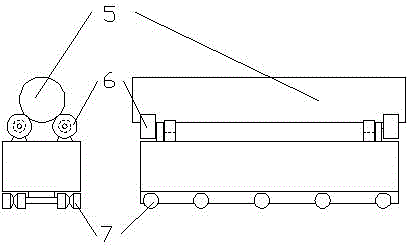

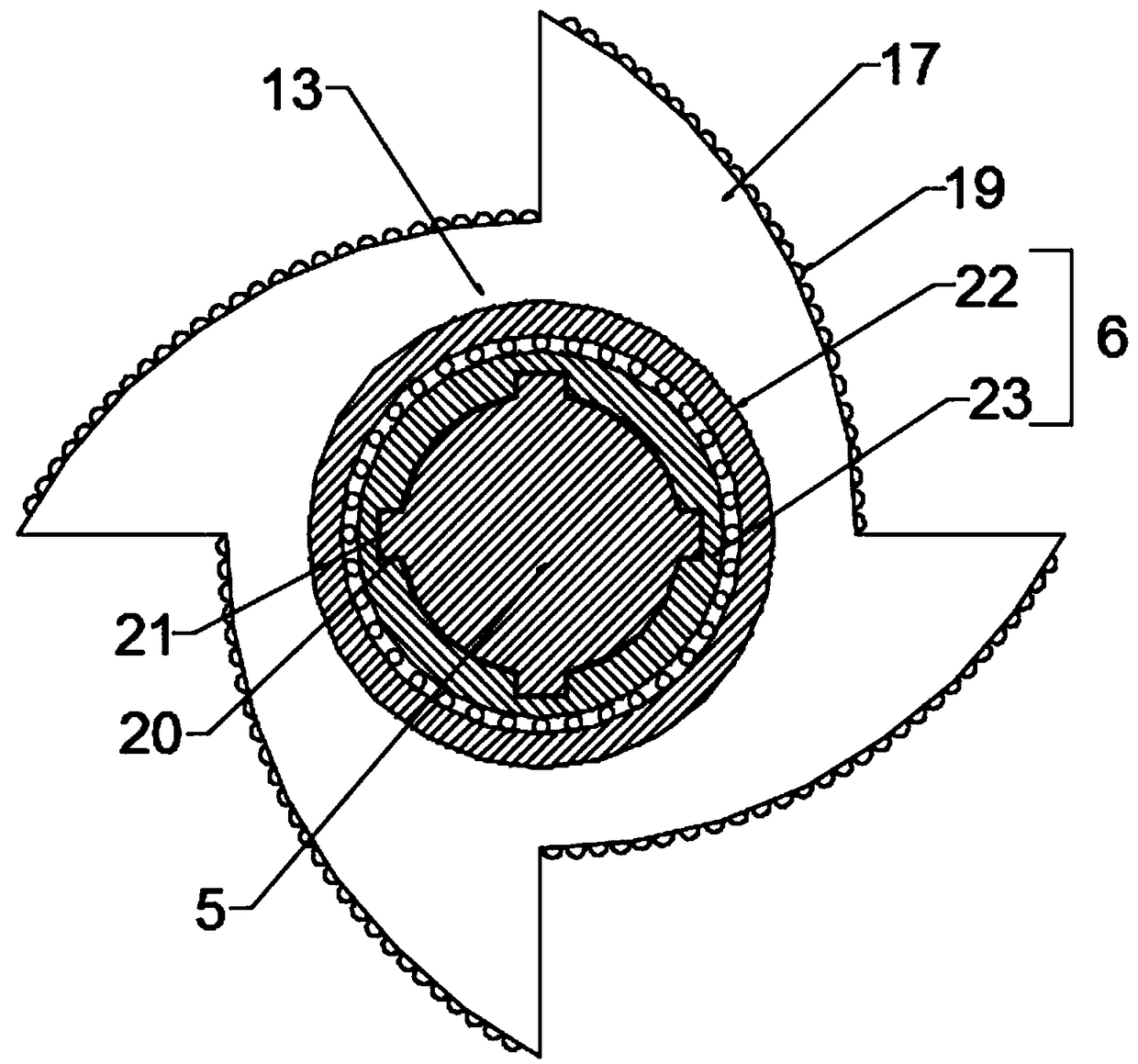

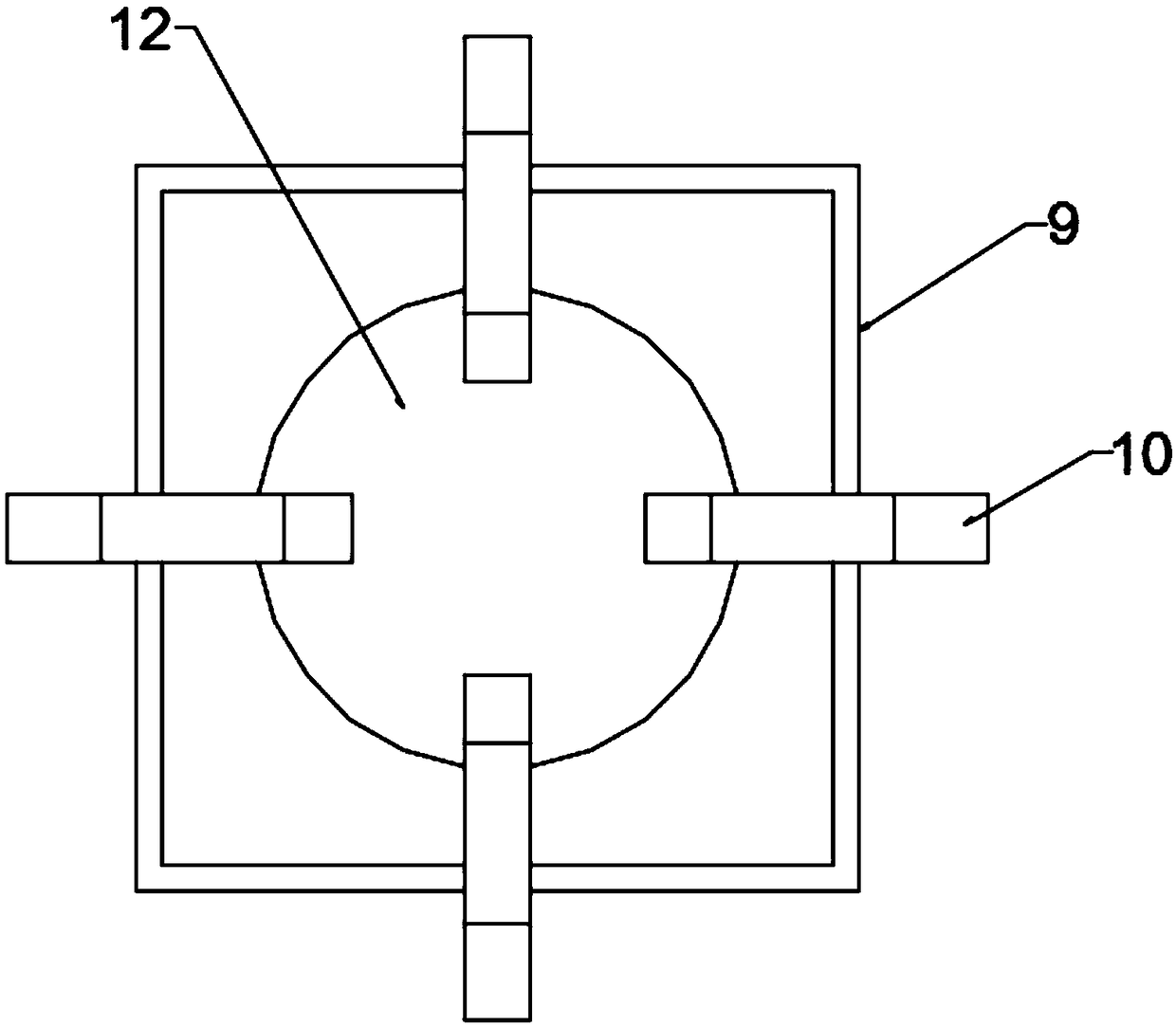

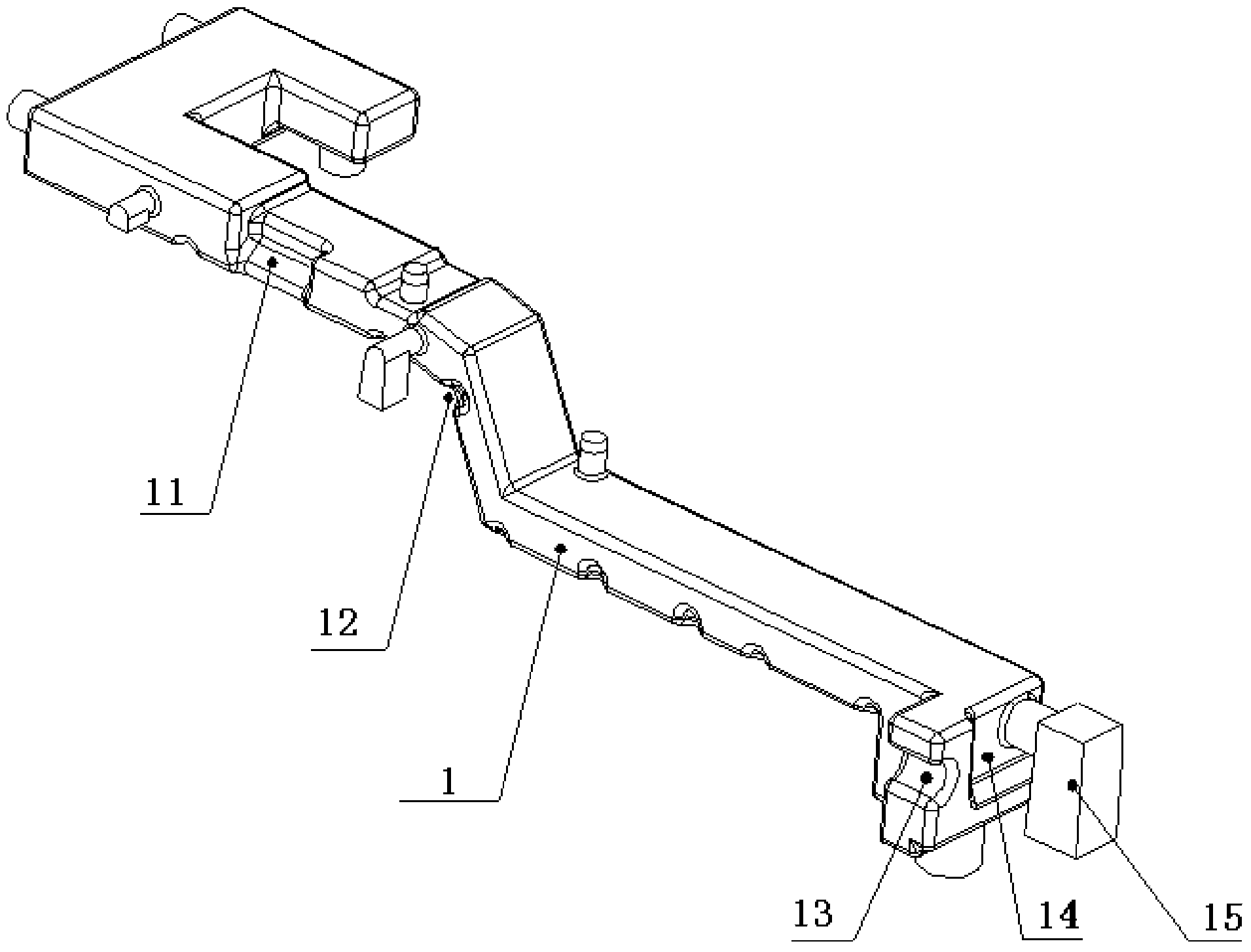

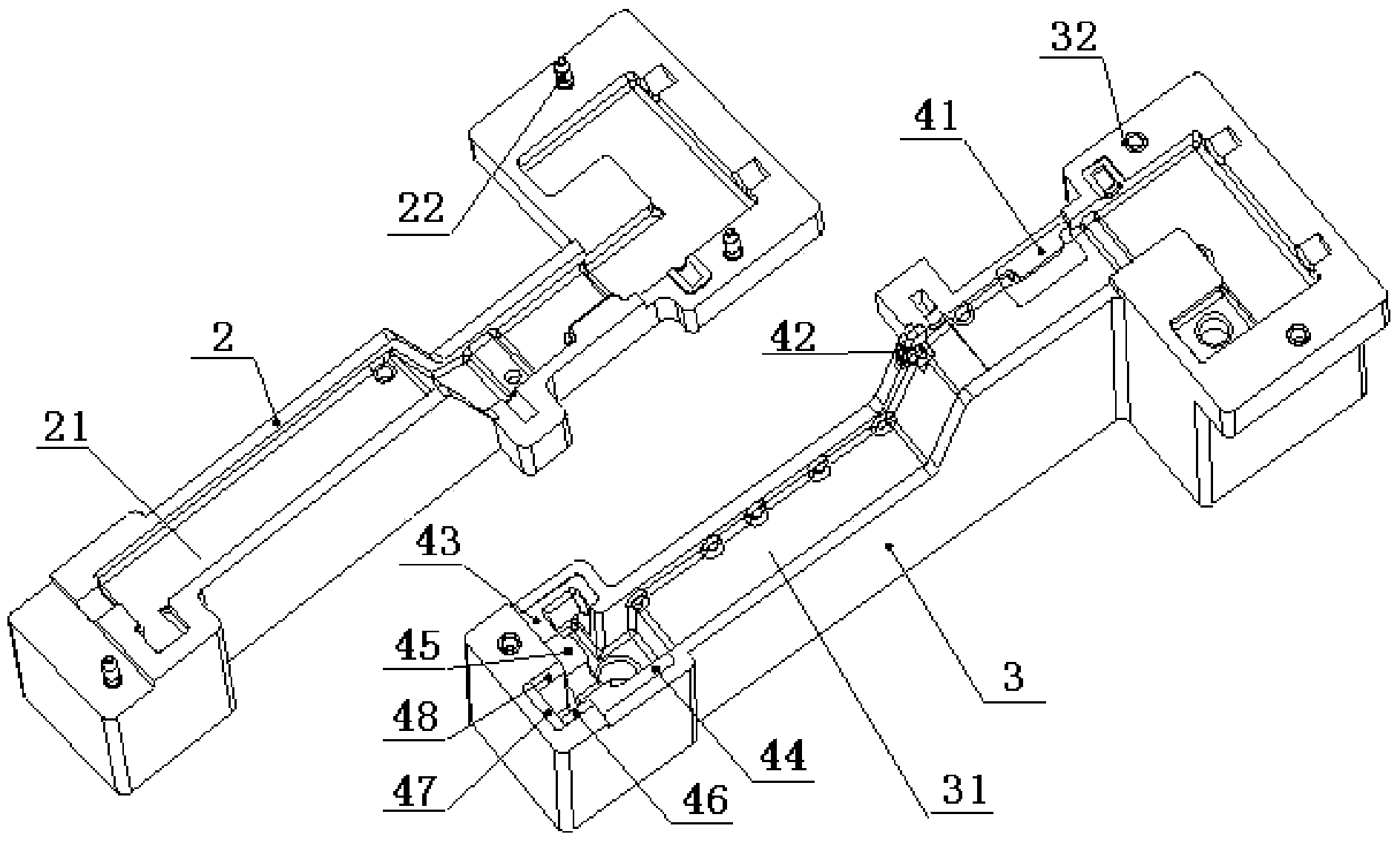

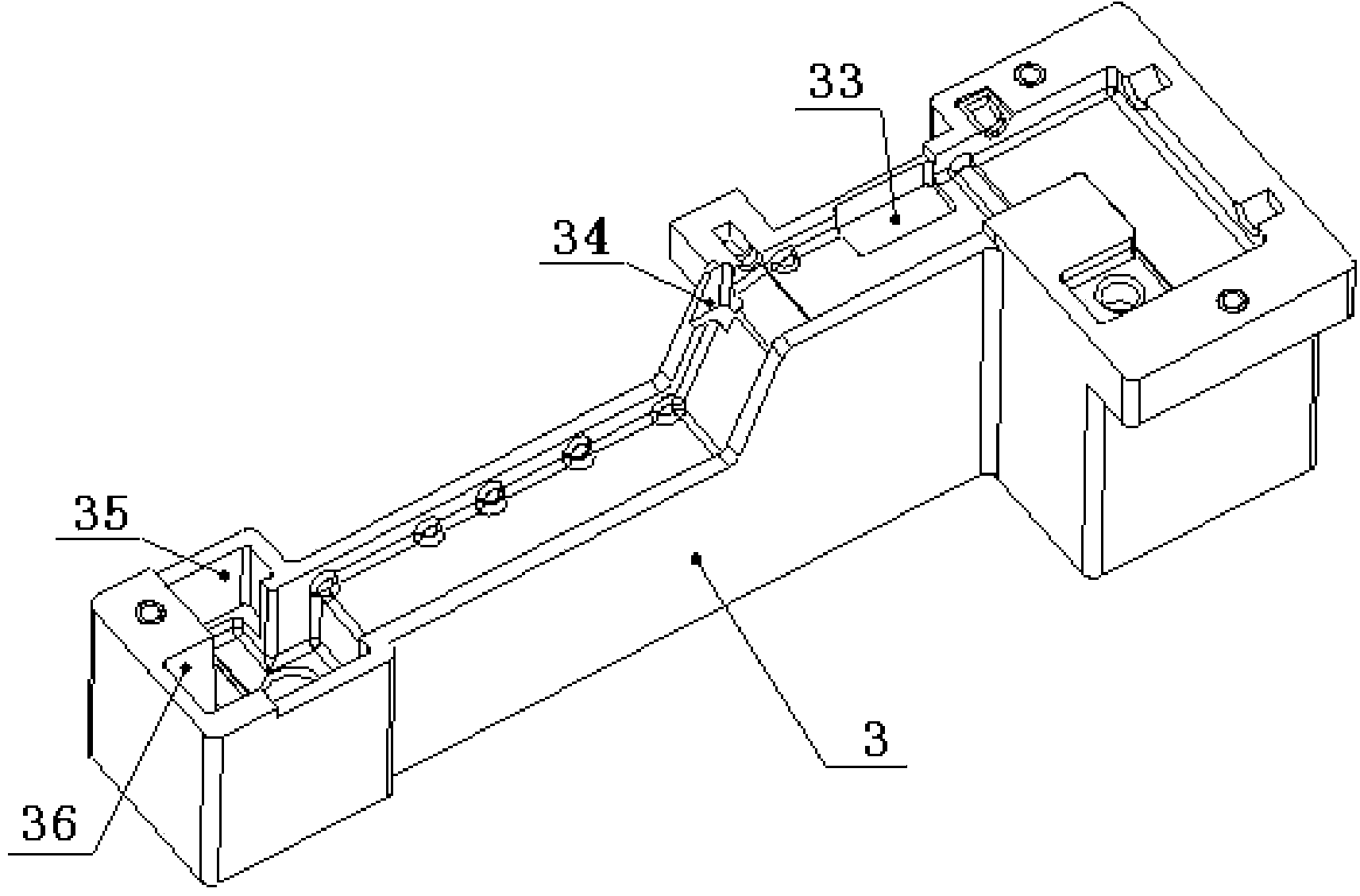

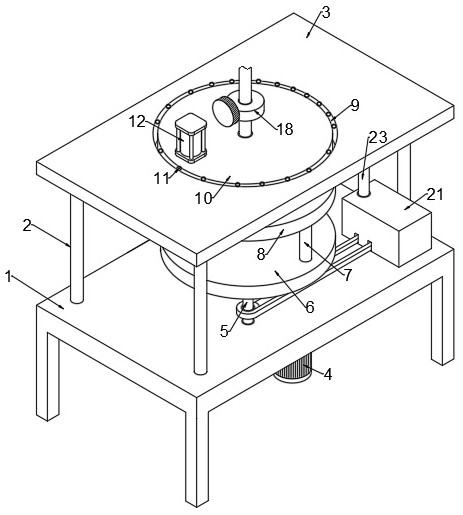

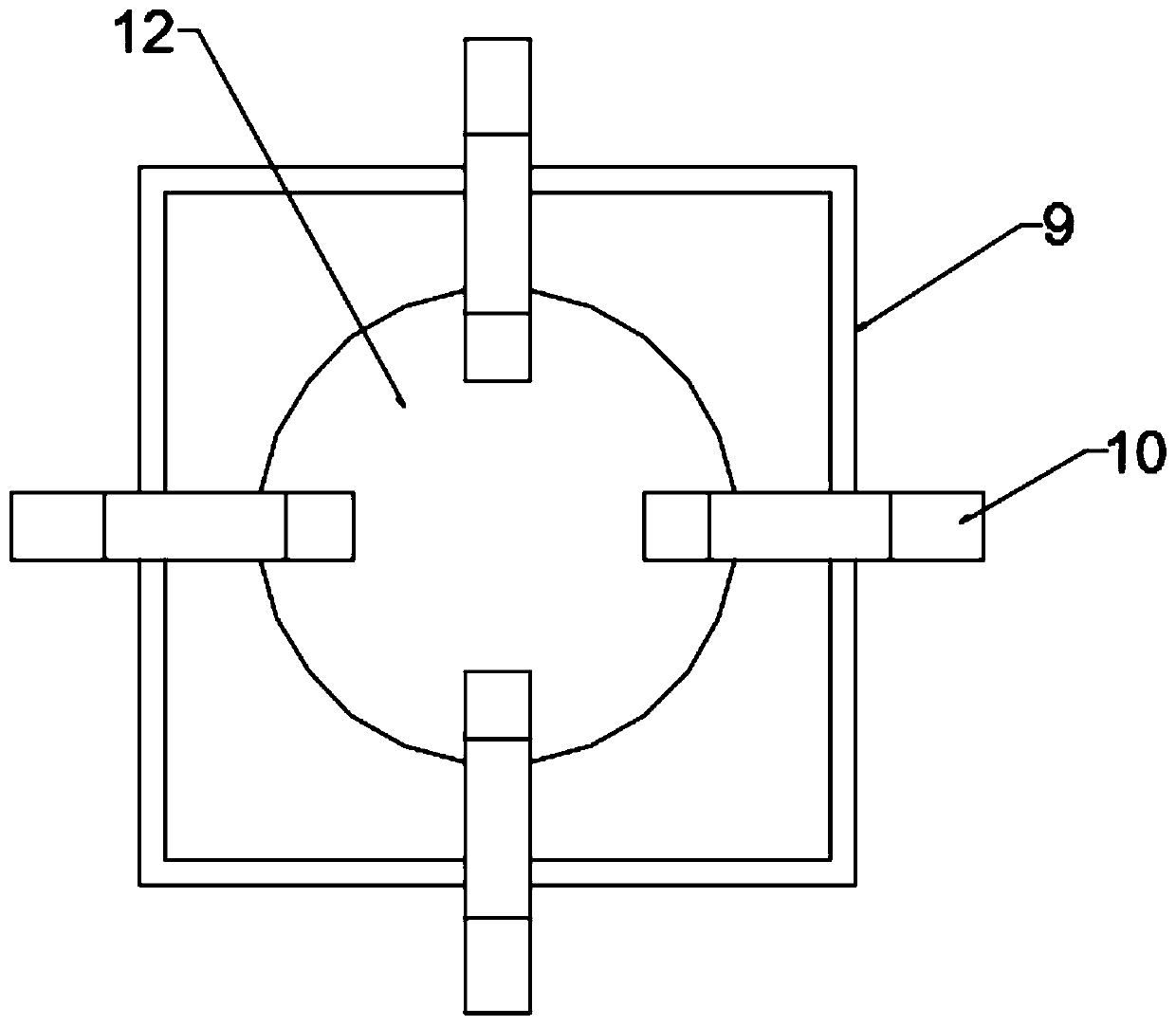

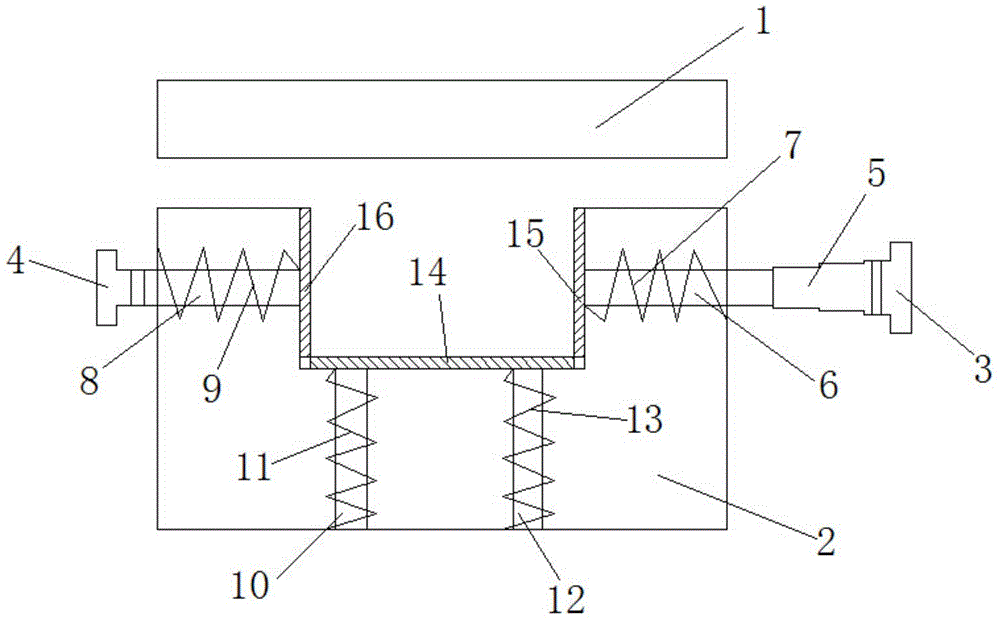

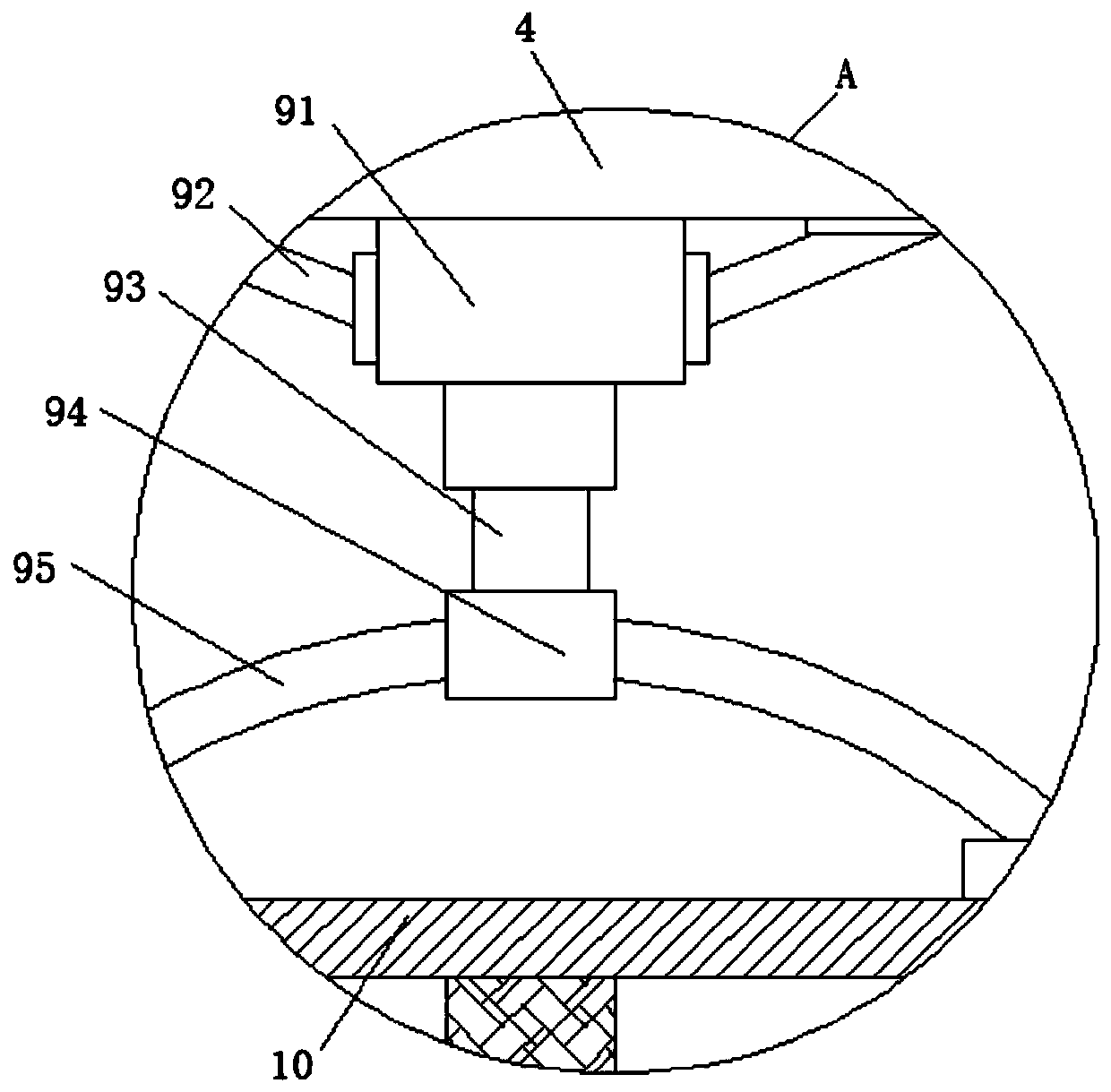

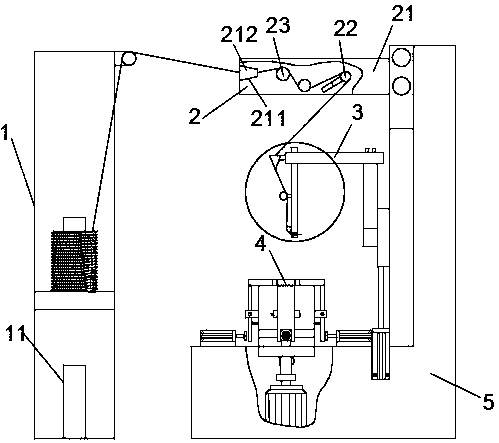

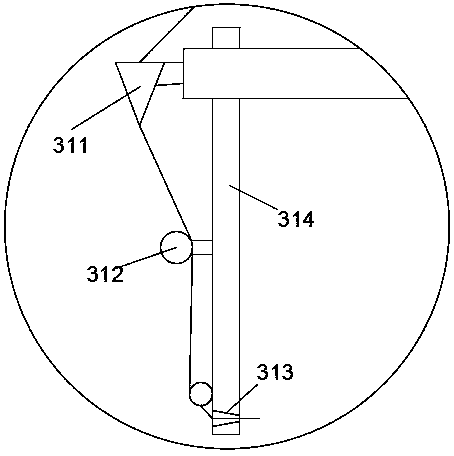

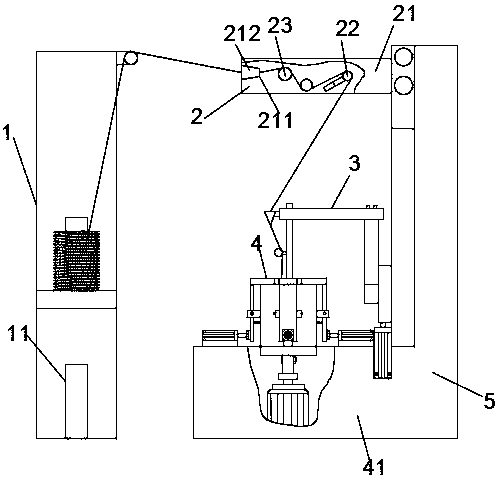

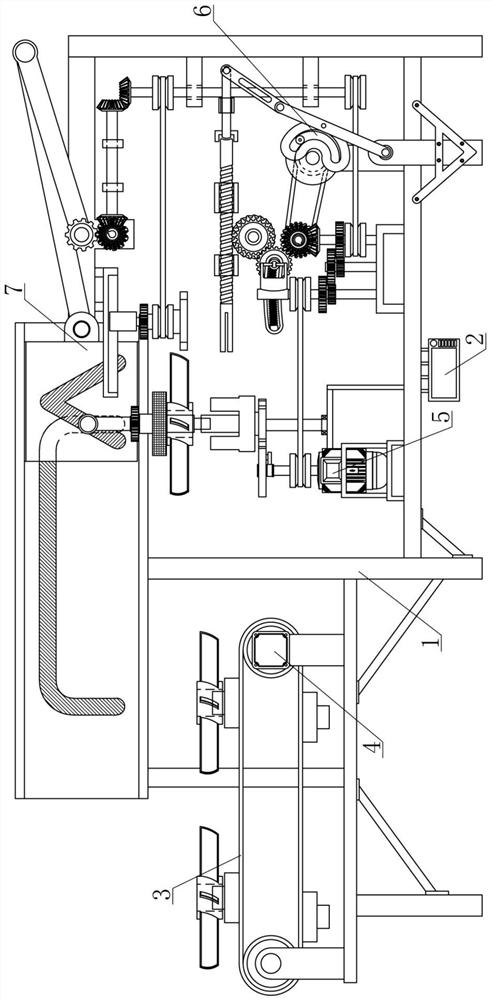

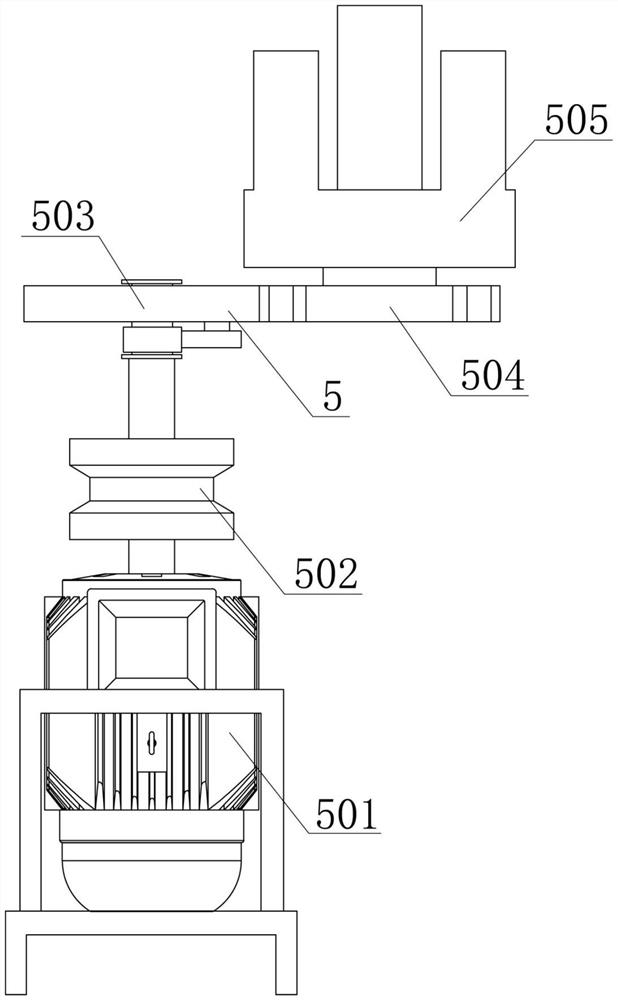

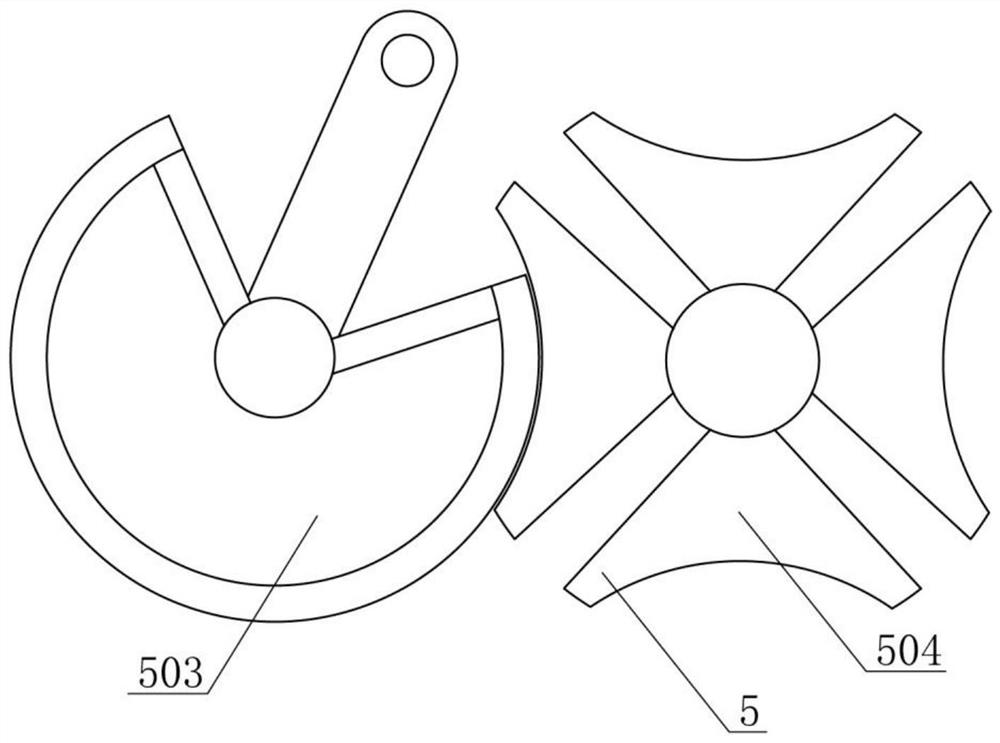

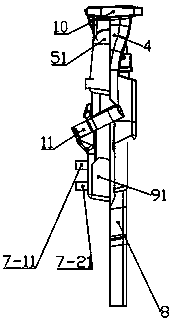

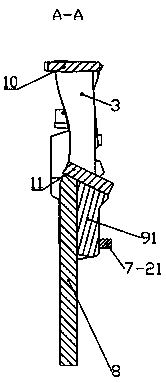

Automatic winding equipment and winding method for motor coil

ActiveCN109687660AFast windingPrecise windingManufacturing dynamo-electric machinesCopper wireLocking mechanism

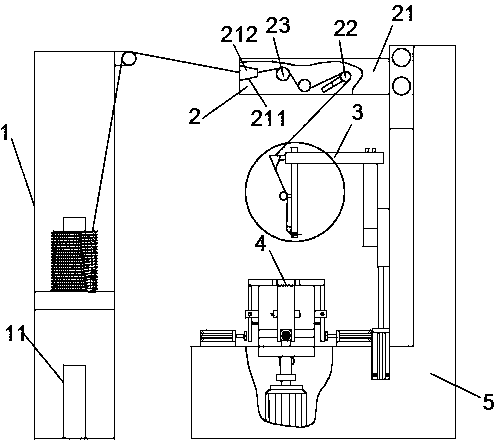

The invention relates to automatic winding equipment and a winding method for a motor coil, which are mainly used for winding the motor coil and aim to solve the problems of low winding efficiency andeasy error in the prior art. The invention provides a technical scheme that the automatic winding equipment and the winding method for the motor coil. The automatic winding equipment for the motor coil comprises a coil frame, a wire feeding mechanism, a frame, a clamping and breaking mechanism and a winding mechanism; the winding mechanism comprises a winding device for clamping and winding copper wires, and a winding die fixing device for clamping and rotating the winding die; the winding device comprises a winding mechanical arm, a rotating wheel, a lifting module and a translation module;the winding die fixing device comprises a rotating motor, a bearing, a second rotating connecting component, a coil sleeve and a locking mechanism. According to the automatic winding equipment and thewinding method for the motor coil, winding is carried out by utilizing the lifting of the winding mechanical arm in the winding device and the rotary reciprocating of the winding die fixing device, so that the winding step is simplified into two single reciprocating processes, and the production efficiency is effectively improved.

Owner:ZHEJIANG JEAMO MOTOR

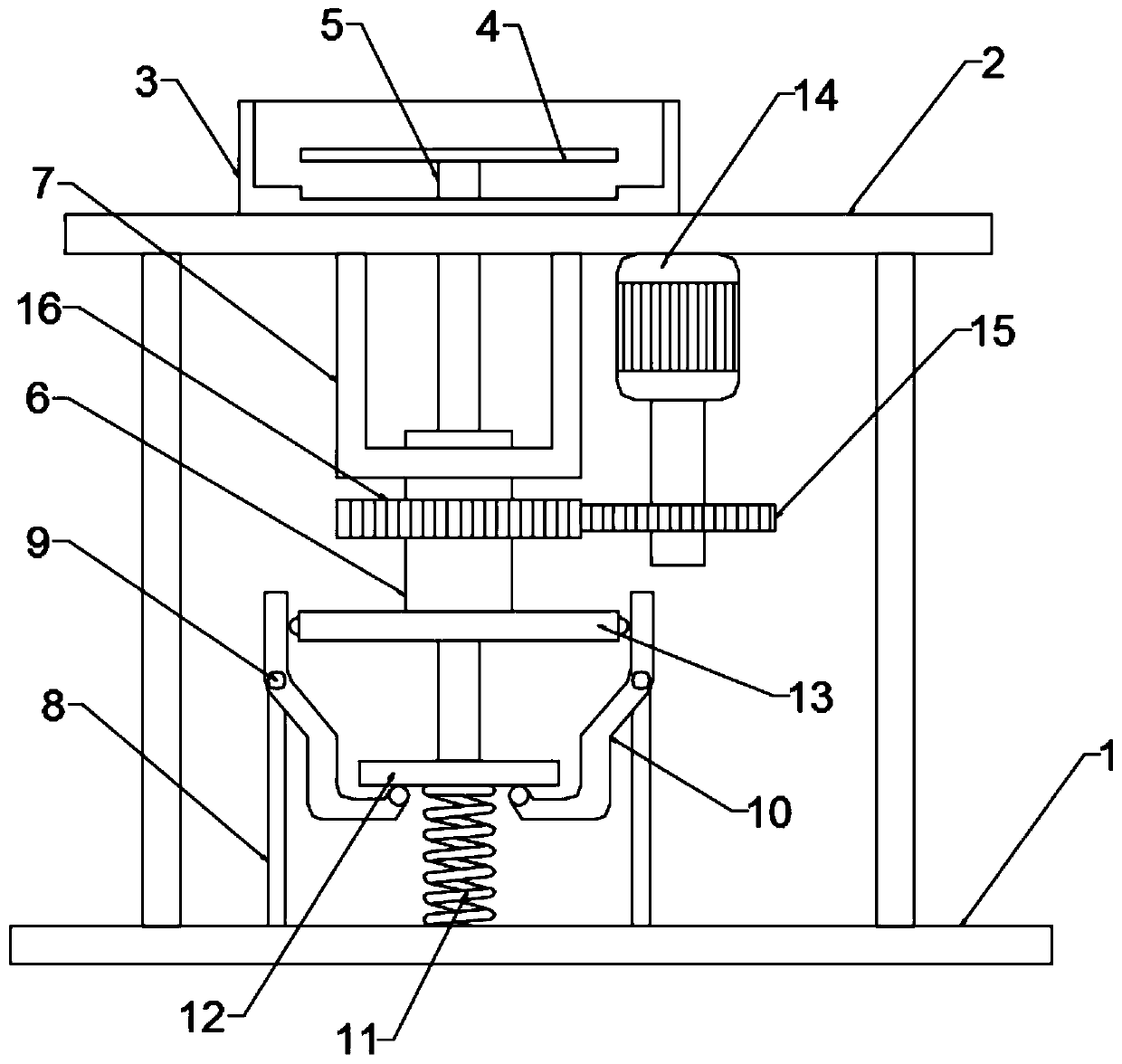

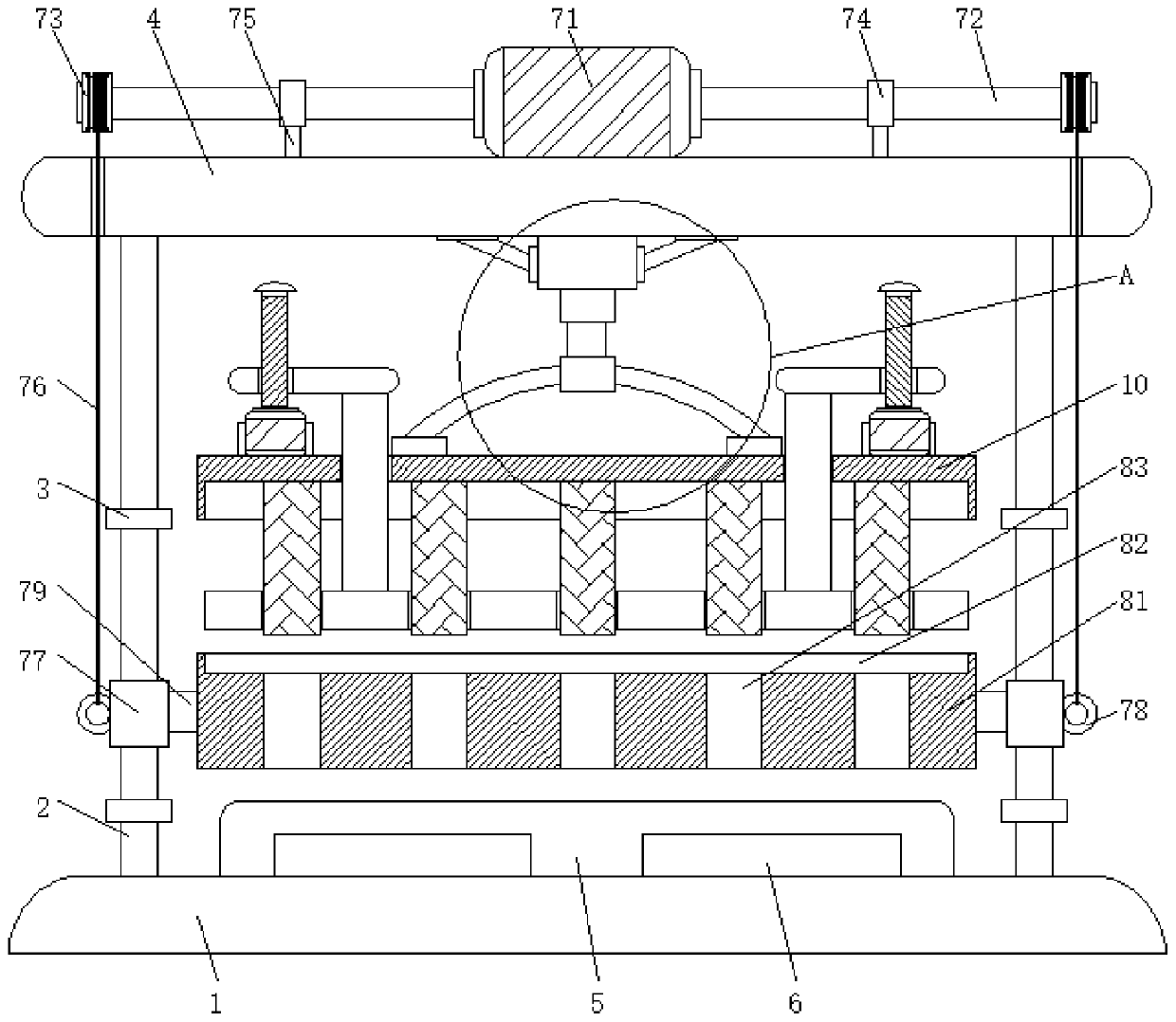

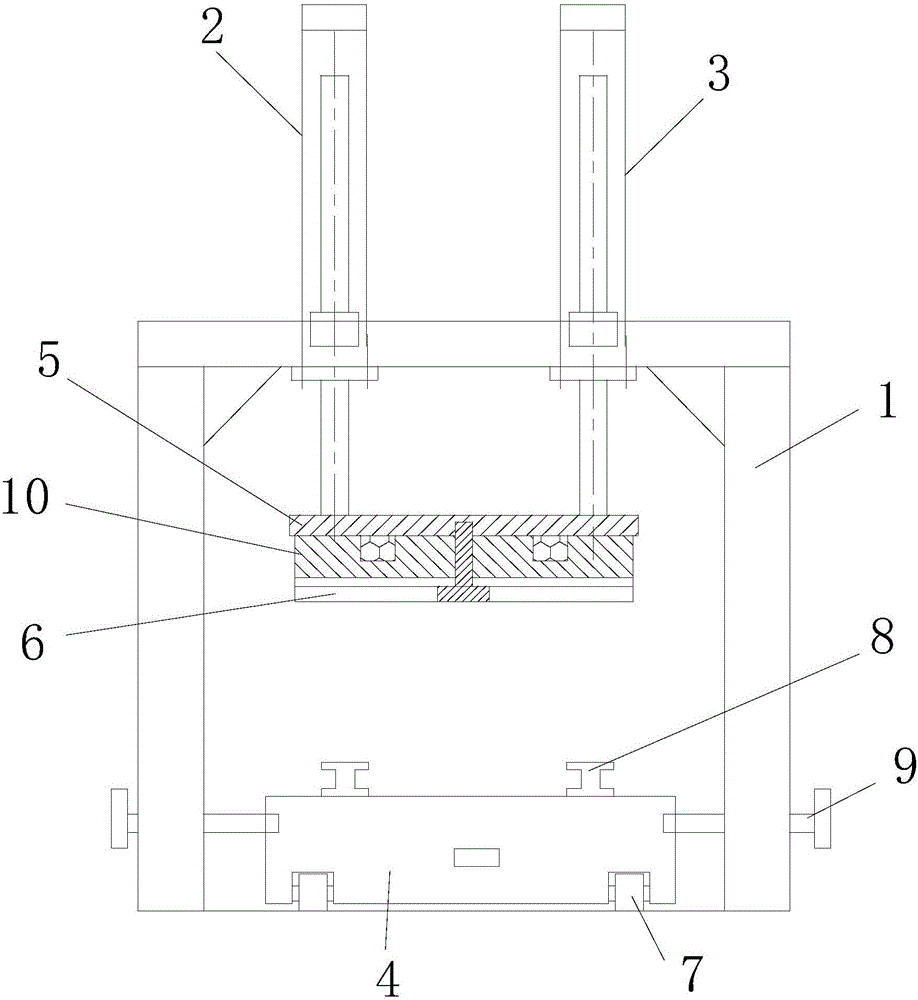

Cement brick manufacturing and demoulding device

ActiveCN109129837AAvoid demouldingQuality improvementDischarging arrangementMouldsDesign technologyEngineering

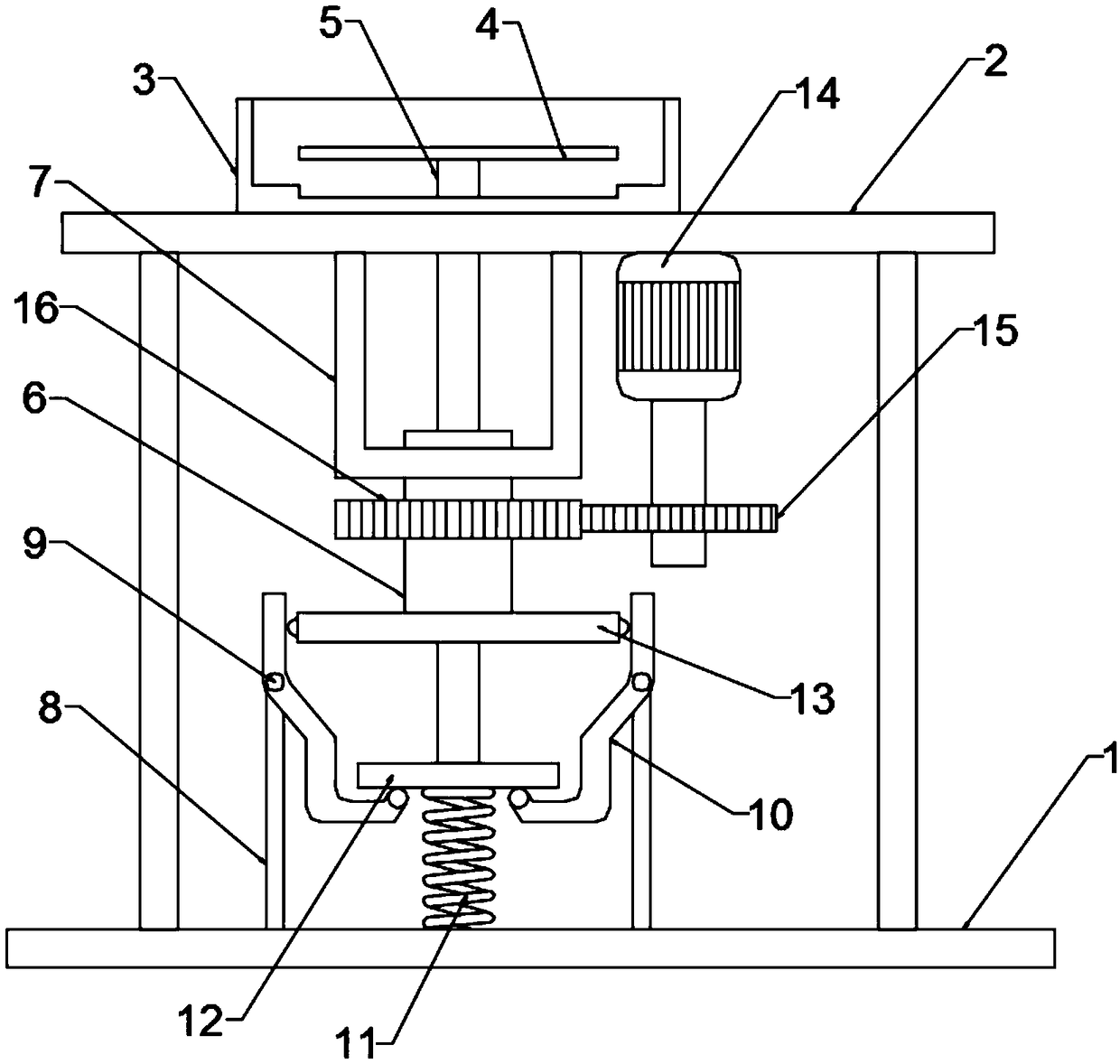

The invention relates to the technical field of industrial design, and discloses a cement brick manufacturing and demoulding device. The cement brick manufacturing and demoulding device comprises a bottom plate, wherein sliding rods are respectively welded to four corners of the top of the bottom plate, limiting rings are respectively welded to the upper and lower ends of the outer surfaces of thesliding rods, a top plate is welded to the tops of the four sliding rods, a placing plate is placed in the middle of the top of the bottom plate, strip-shaped grooves which penetrate through in a transverse direction are respectively formed in both sides of the bottom of the placing plate, a demoulding auxiliary mechanism is arranged on the top of the top plate, cement brick forming mechanisms are arranged between the four sliding rods, a power actuating mechanism is arranged at the bottom of the top plate, and a demoulding actuating mechanism is arranged at the bottom of the power actuatingmechanism. According to the cement brick manufacturing and demoulding device, prefabticated members of cement bricks in forming holes are extruded by pressing rods and fall on the top of the placing plate, and the demoulding is realized in an extruding mode, so that the demoulding efficiency is improved, the damage rate of the cement bricks is reduced, the damage to the cement bricks due to demoulding in a vibration mode is avoided, and the production cost is reduced.

Owner:NANTONG HENGDA MACHINERY MFG

Demolding mechanism of automobile hub mold

Owner:芜湖万联新能源汽车零部件有限公司

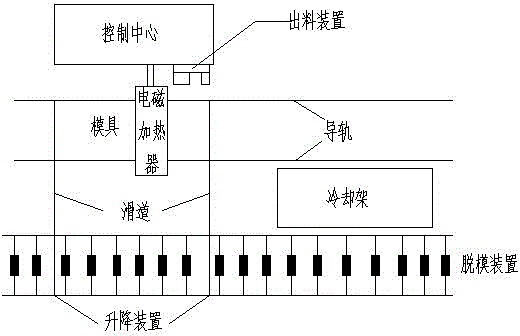

Automatic production line for heating and forming of novel krah pipe

InactiveCN104149326AIncrease productivityAvoid manual moldingTubular articlesElectromagnetic heatingIndustrial engineering

The invention provides an automatic production line for electromagnetic heating and forming of a novel krah pipe. The automation production line comprises a control center, a heating system, a discharging device, a mold bearing frame, a cooling frame and a demolding device. The automatic production line provided by the invention has the advantages that the traditional manual mode for mold loading, mold unloading and demolding is avoided; due to fully-automatic cooling operation, workers do not need to operate a high-temperature mold by hand, so that the potential danger is avoided; the heating system adopts an entirely-new electromagnetic heating mode, and compared with the traditional heating mode adopting gas, the energy is saved, simultaneously the waste gas generated by the traditional heating adopting coal gas can be reduced; and due to the advantage that the electromagnetic heating is fast, the production efficiency of the krah pipe can be greatly improved.

Owner:台州市健能工贸有限公司

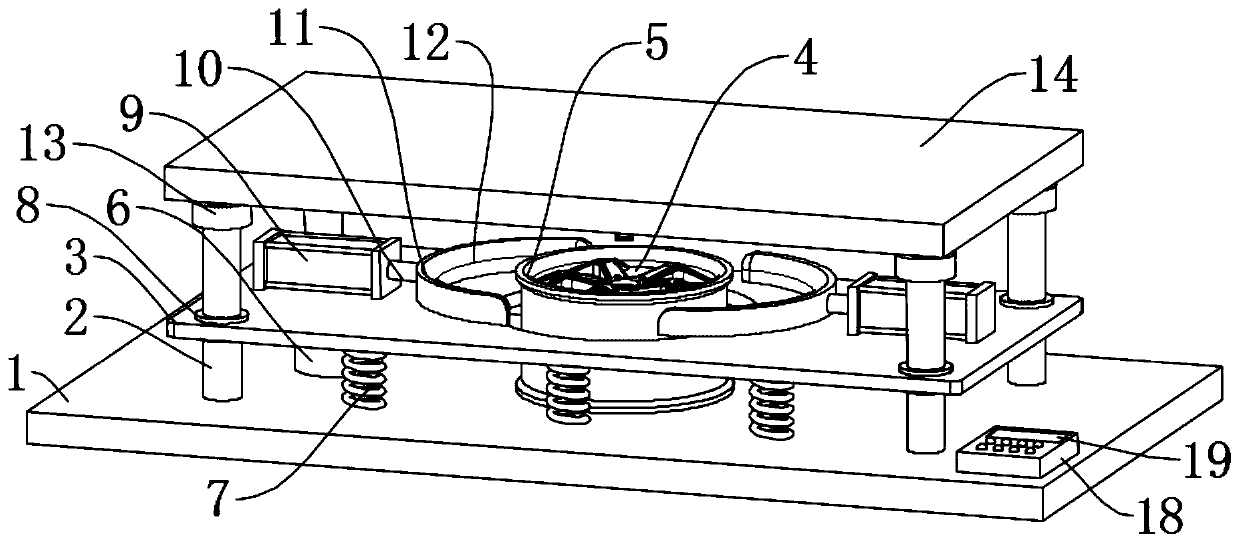

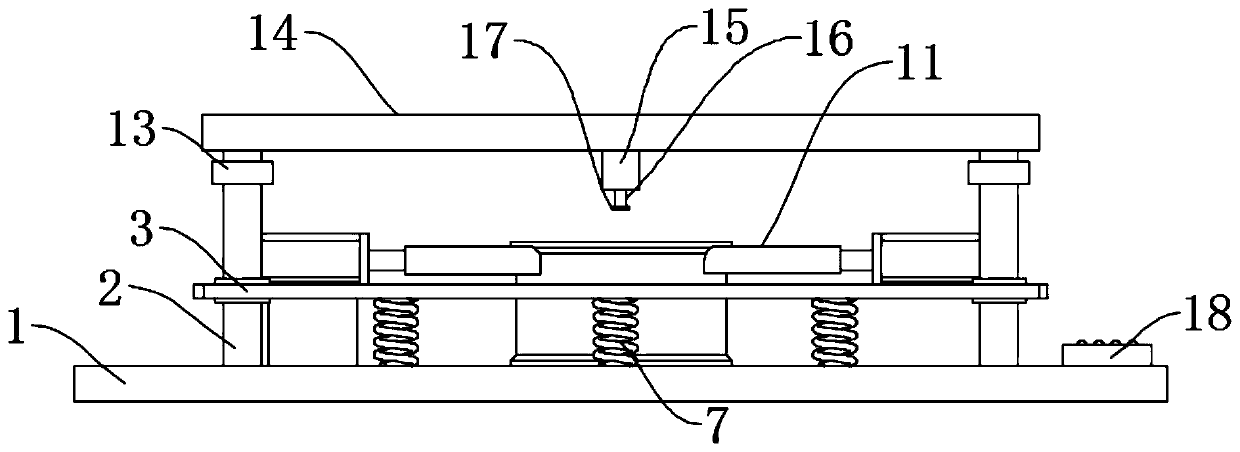

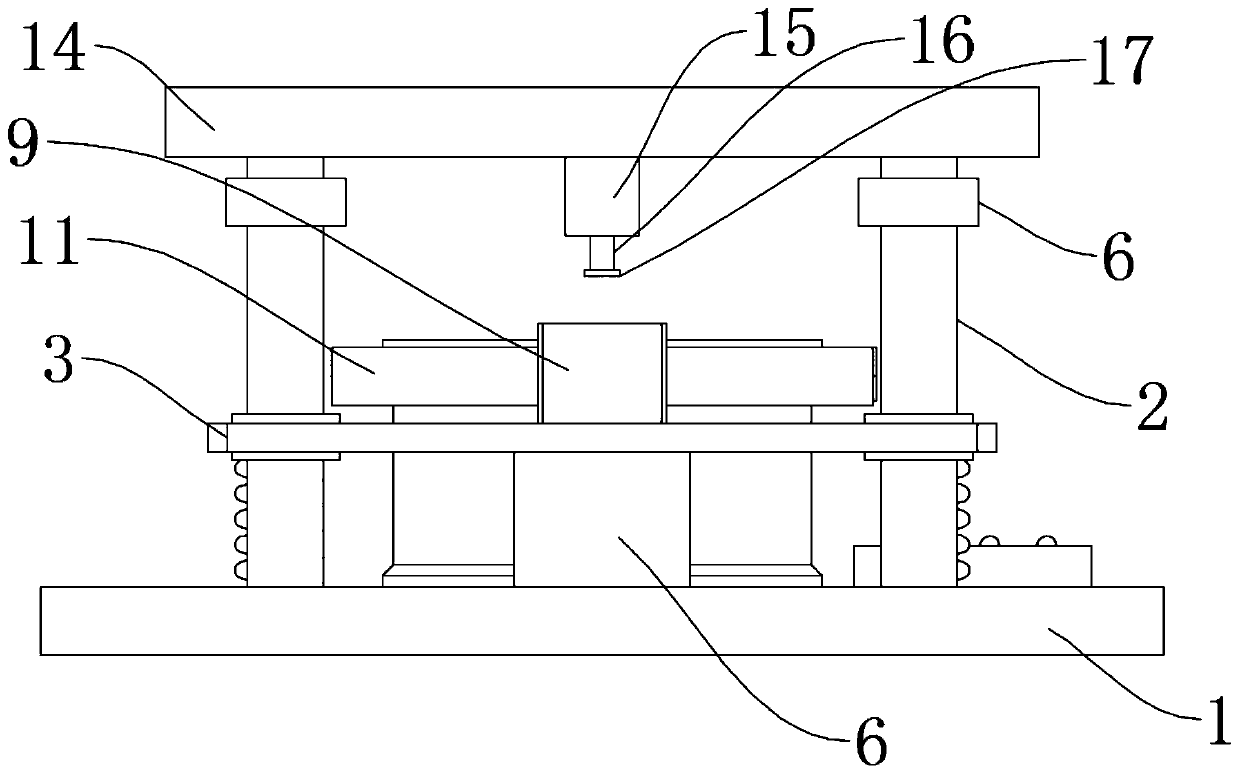

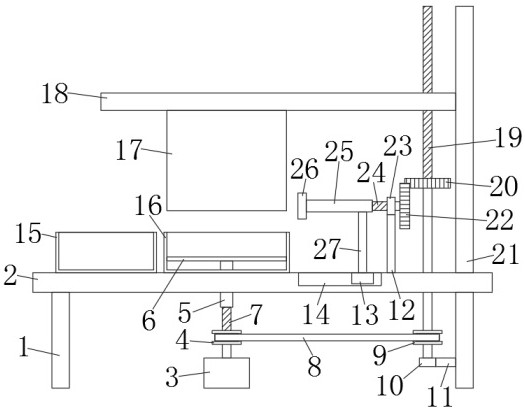

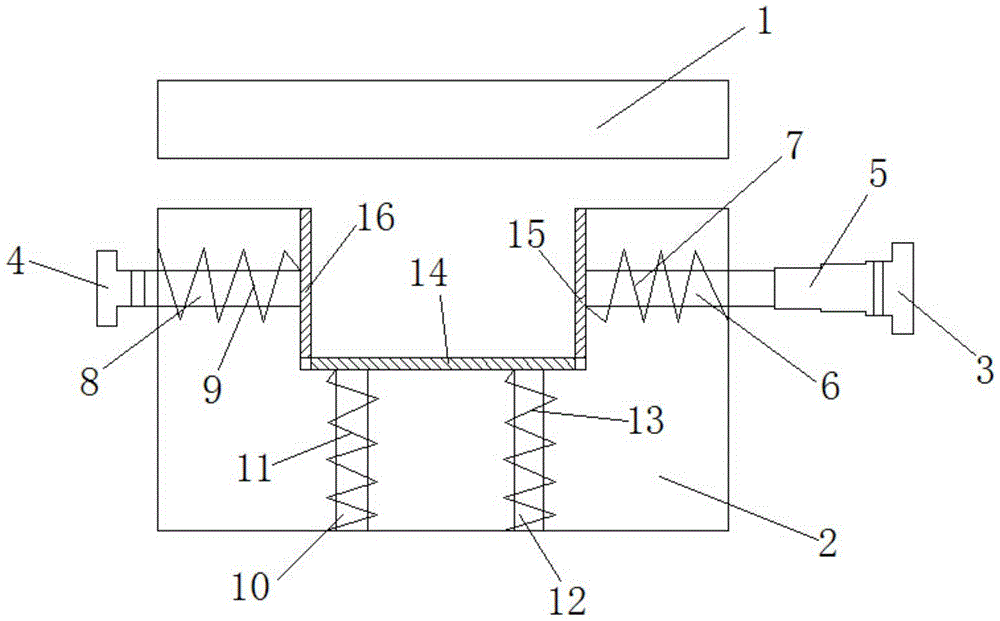

Stamping device for hardware stamping part

InactiveCN112355110AThe solution is not easy to demouldAvoid demouldingMetal-working feeding devicesPositioning devicesMechanical engineeringWork productivity

The invention discloses a stamping device for a hardware stamping part, and relates to the technical field of stamping devices. The stamping device aims at solving the problems that according to an existing stamping device, after stamping, an object is not prone to demolding, the stamped object needs to be collected manually, the whole process wastes time and labor, the labor intensity of workersis increased, and the working efficiency of the workers is reduced. According to the scheme, the stamping device comprises a placing plate, wherein supporting columns are fixedly connected to the twosides of the bottom of the placing plate, a stand column is fixedly connected to the right side of the top of the placing plate, a driving mechanism is arranged at the bottom of the placing plate, a stamping mechanism is arranged at the top of the placing plate, and an automatic material collecting mechanism is arranged at the top of the placing plate. The stamping device is novel in design, simple in structure and convenient to operate, the stamped object can be automatically demolded, the stamped object can be automatically collected, time and labor are saved in the whole process, the laborintensity of the workers is reduced, and the working efficiency of the workers is improved.

Owner:滁州市天鸿冲塑制品有限公司

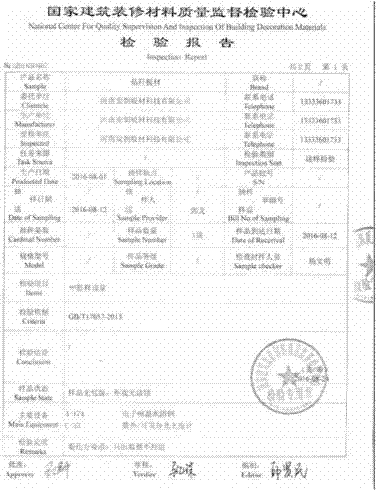

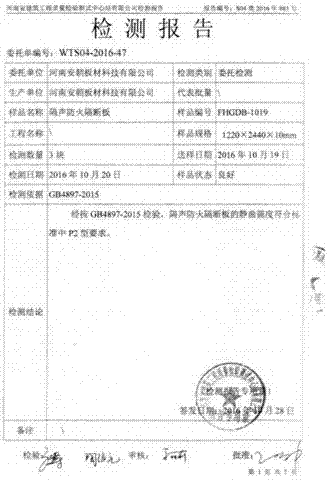

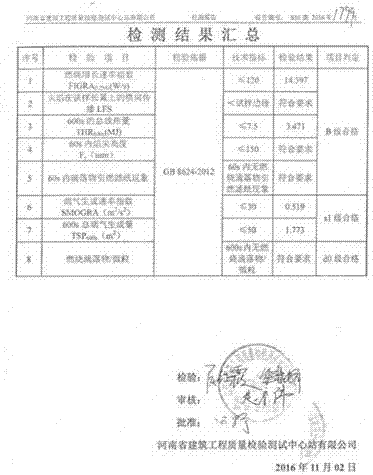

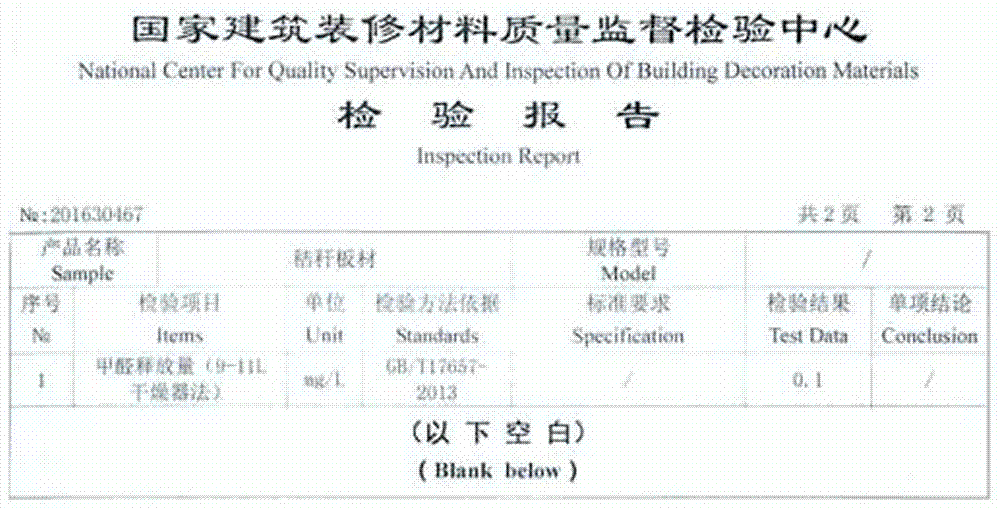

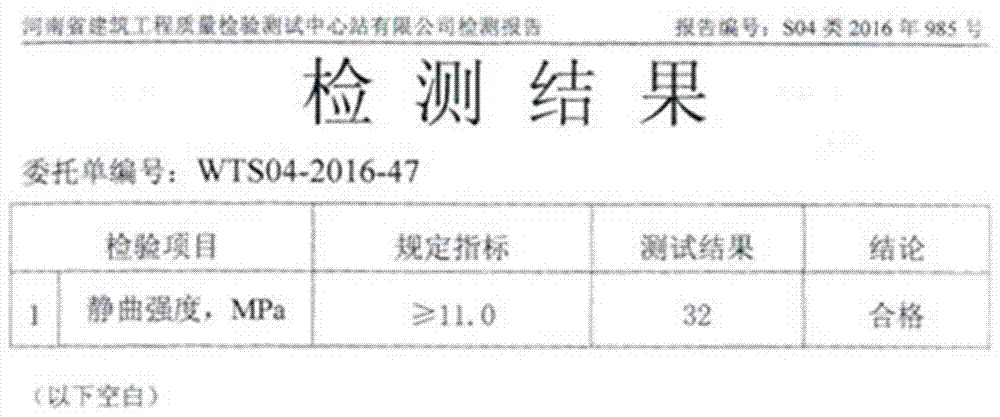

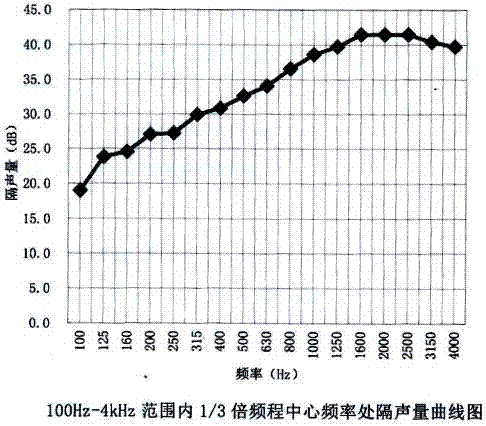

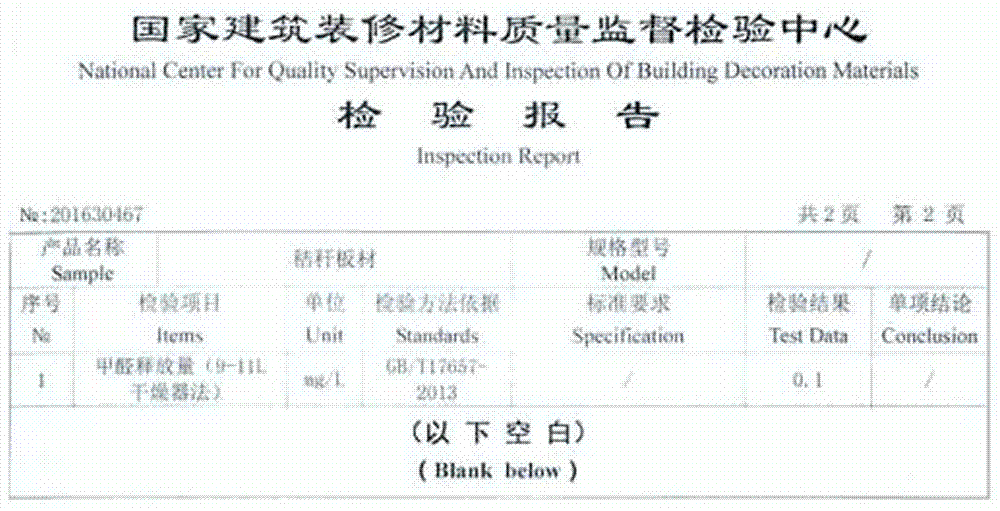

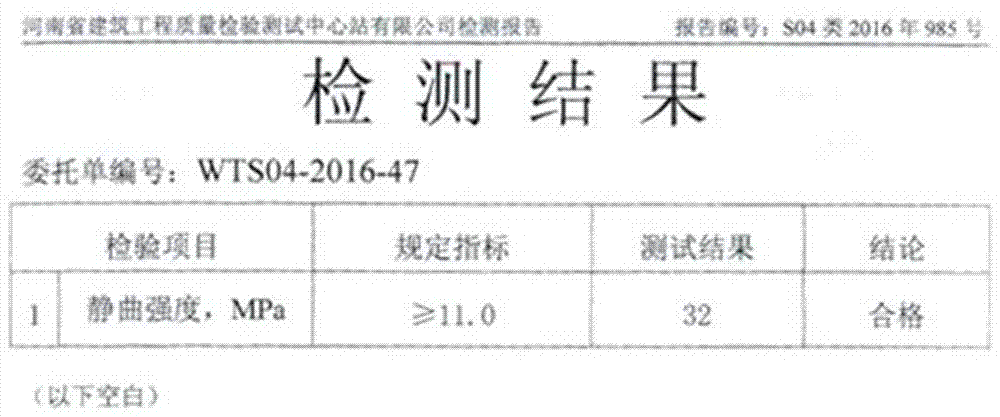

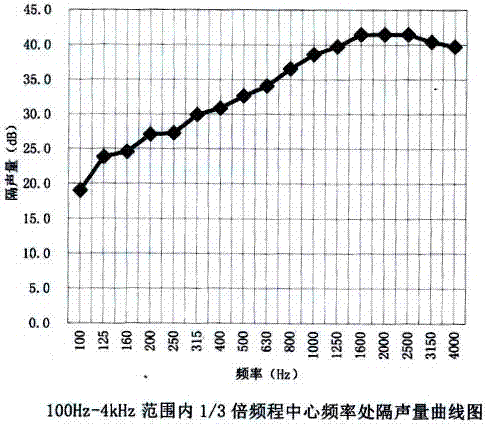

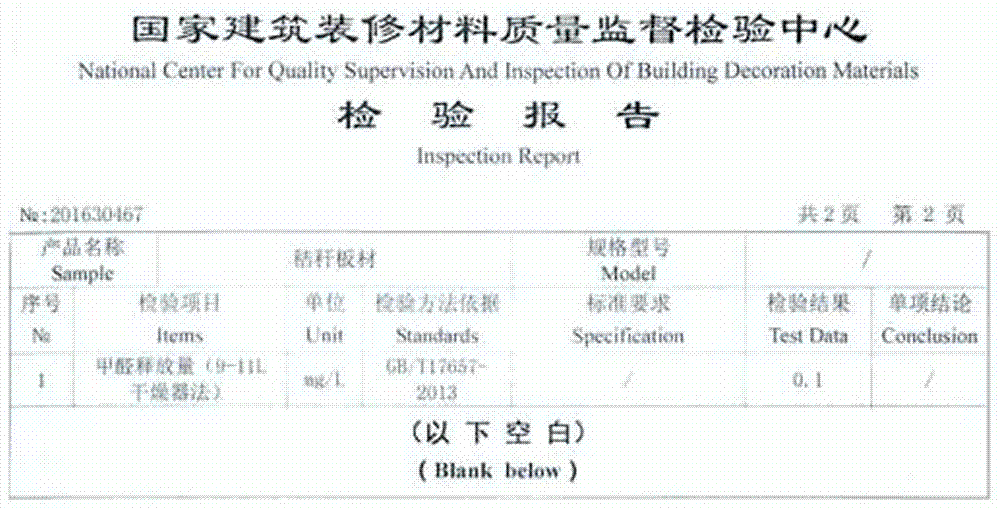

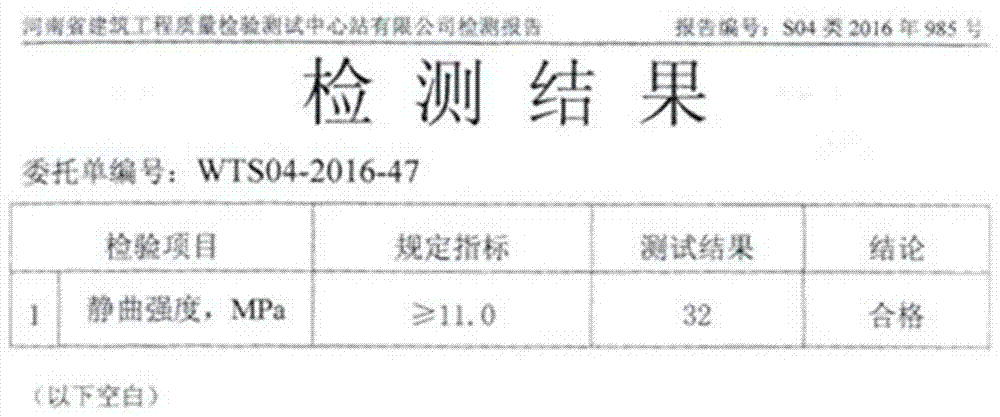

Environmental-protection straw light wall board production method

InactiveCN107498681AUniform bondingImprove waterproof performanceConstruction materialCeramic shaping apparatusAdhesiveSilicon oxygen

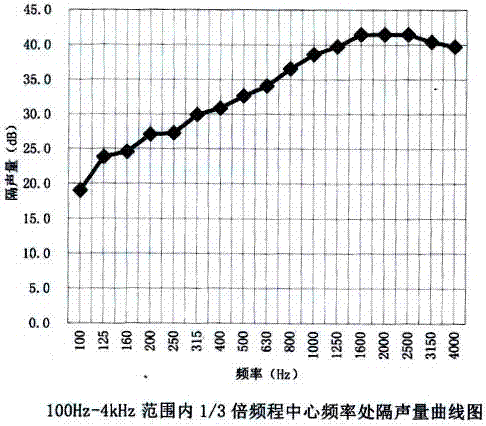

The invention discloses an environmental-protection straw light wall board production method. The production method comprises the preparation steps of: preparation of raw materials-surface treatment through physical and chemical combination methods-uniform glue mixing-pavement-hot pressing molding in a mold-fixed length cutting-accumulation protection curing-inspection-products; in preparation of the raw materials, the raw materials are divided into two types: one is surface layer raw materials, and the other one is middle layer raw materials; in the surface treatment step, wax on the surfaces of straws are treated by adopting physical and chemical combination methods; chemical raw materials containing silicon-oxygen chemical bond structures similar to wax structures on the surfaces of the straws and being 0.01-0.5 mass% of the straws are added; then, adhesives capable of forming hydrogen bonds or chemical bonds with polyhydroxyl structures are added; and in uniform glue mixing, strengthening materials are added in glue mixing of the middle layer raw materials. No harmful gas is discharged from boards prepared by the method; and the boards are smooth, unified and beautiful in textures and high in strength, flame retardance, sound insulation and damp prevention.

Owner:河南安朝板材科技有限公司

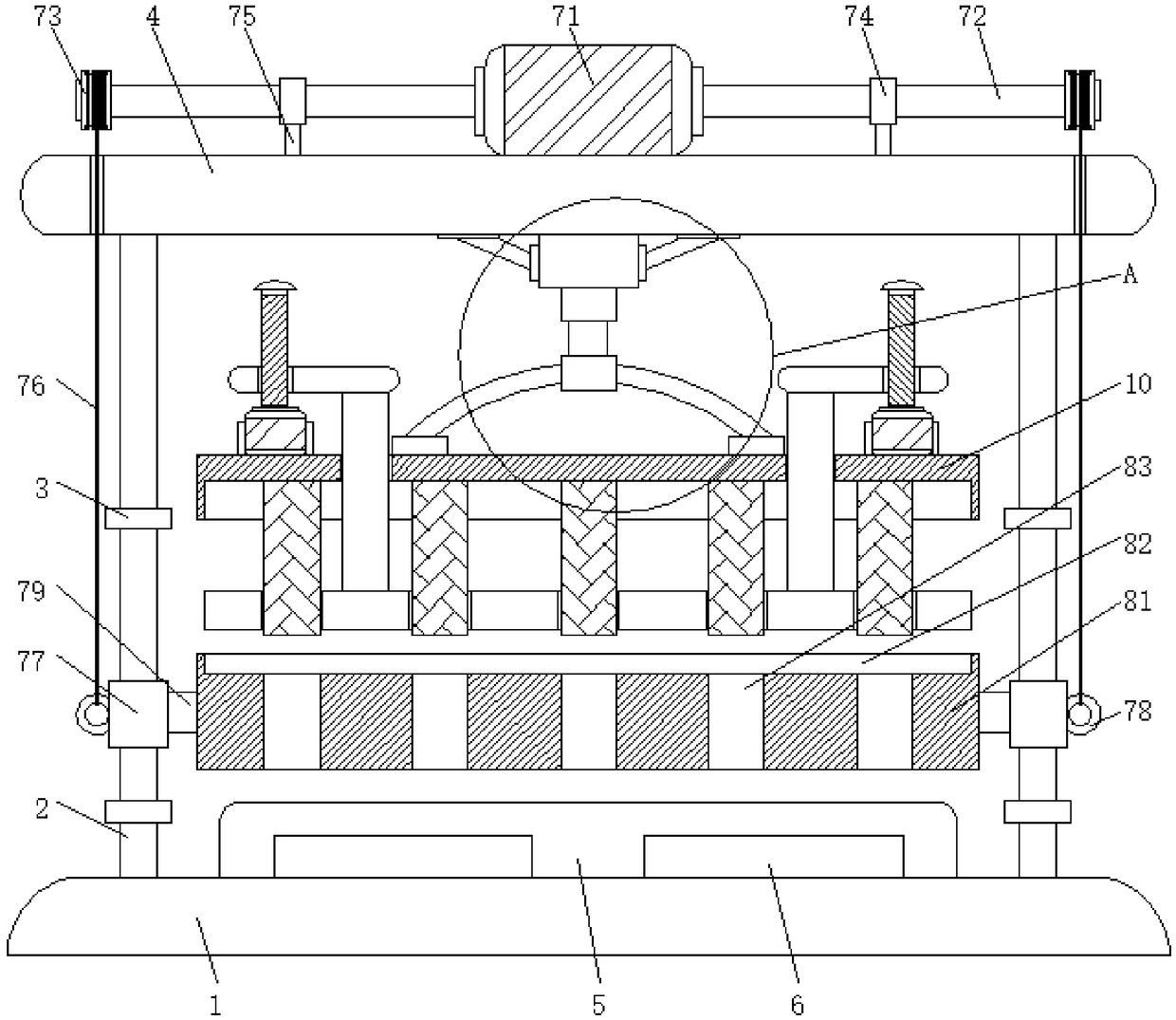

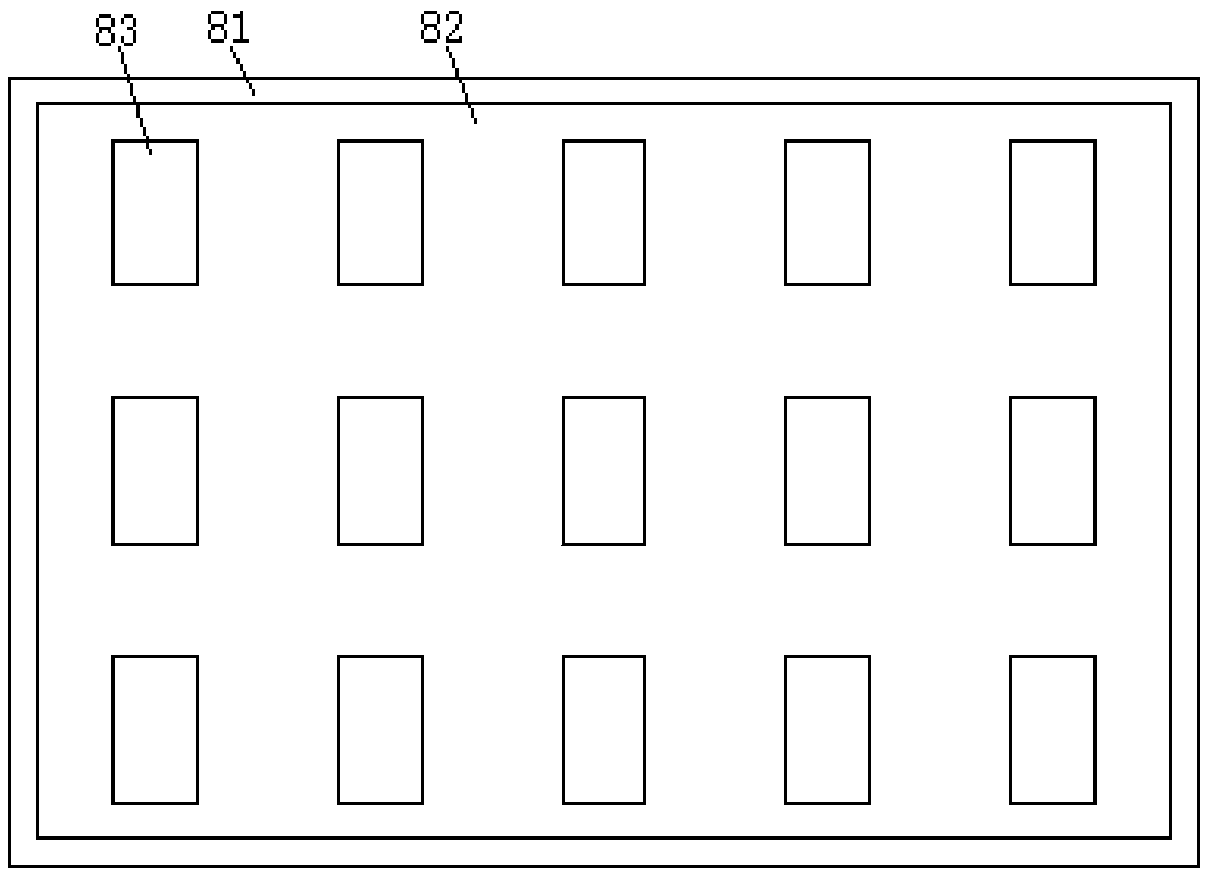

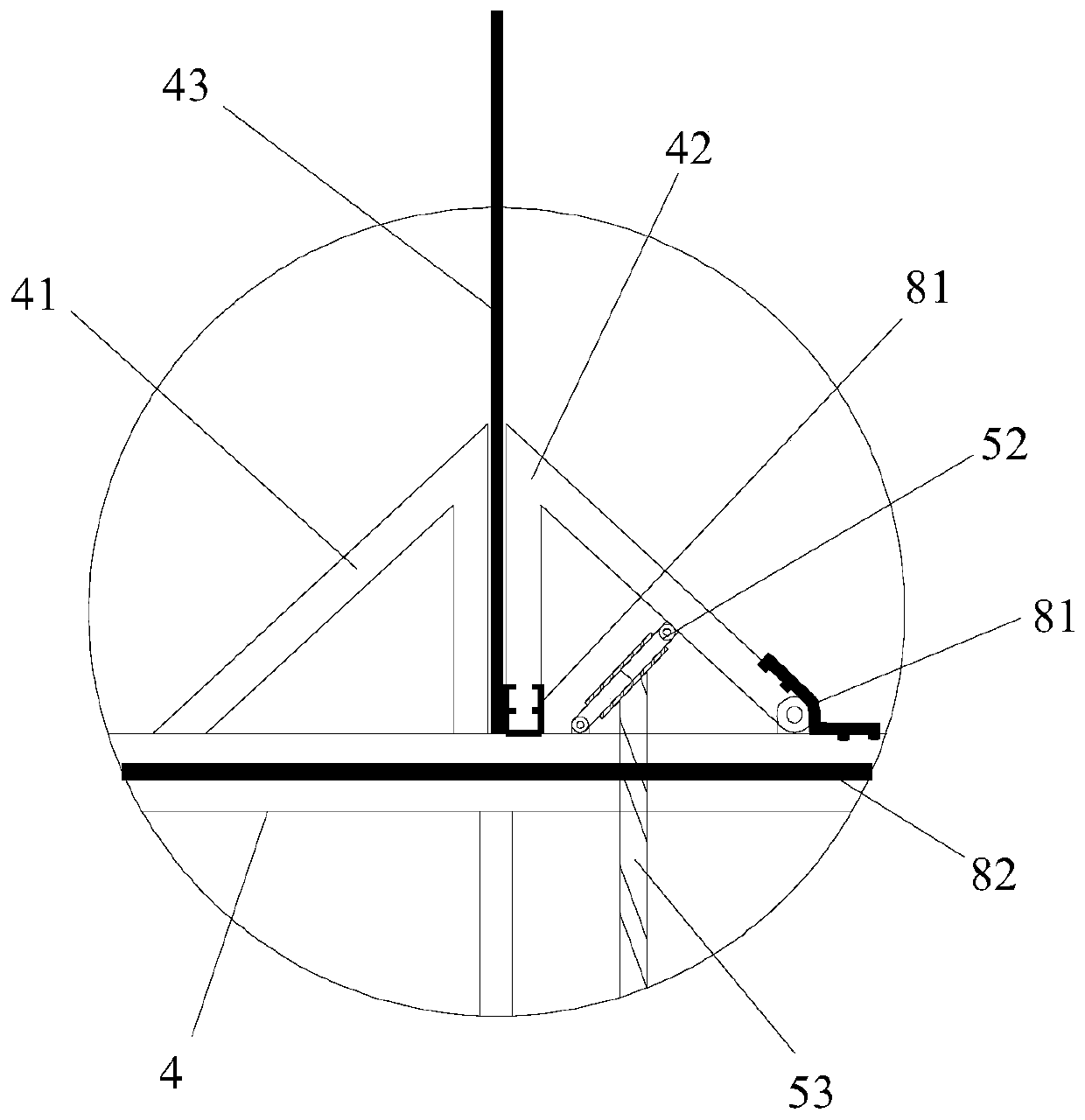

Mold for preparing test piece of geotechnical model and preparation method

ActiveCN110646273AEasy to vibrate and tampGuaranteed uniformityPreparing sample for investigationMold removalSupport plane

The invention discloses a mold for preparing a test piece of a geotechnical model and a preparation method, solves the problems in the prior art that the molds preparing test pieces are complicated instructure, and the uniformity and compactness of the test pieces cannot be guaranteed, and has the beneficial effects of effectively guaranteeing the compactness of the prepared test pieces and effectively facilitating the later demoulding. The solution is that the mold for preparing the test piece of the geotechnical model comprises a test piece cylinder for filling materials similar to the testpiece and mold support frames erected around the test piece cylinder, wherein a pressing plate is provided in the test piece cylinder and is connected to a pushing level running through one end surface of the test piece cylinder, and the other end surface of the test piece cylinder is opened; the test piece cylinder can realize movement along the inner side of the mold support frames under external force, and the mold support frames are detachably connected to the pushing level to realize adjustable height of the pushing level inserted into the test piece cylinder, so that the pushing level and the pressing plate perform vibration effect on one side of the material similar to the test piece in the test piece cylinder.

Owner:SHANDONG UNIV

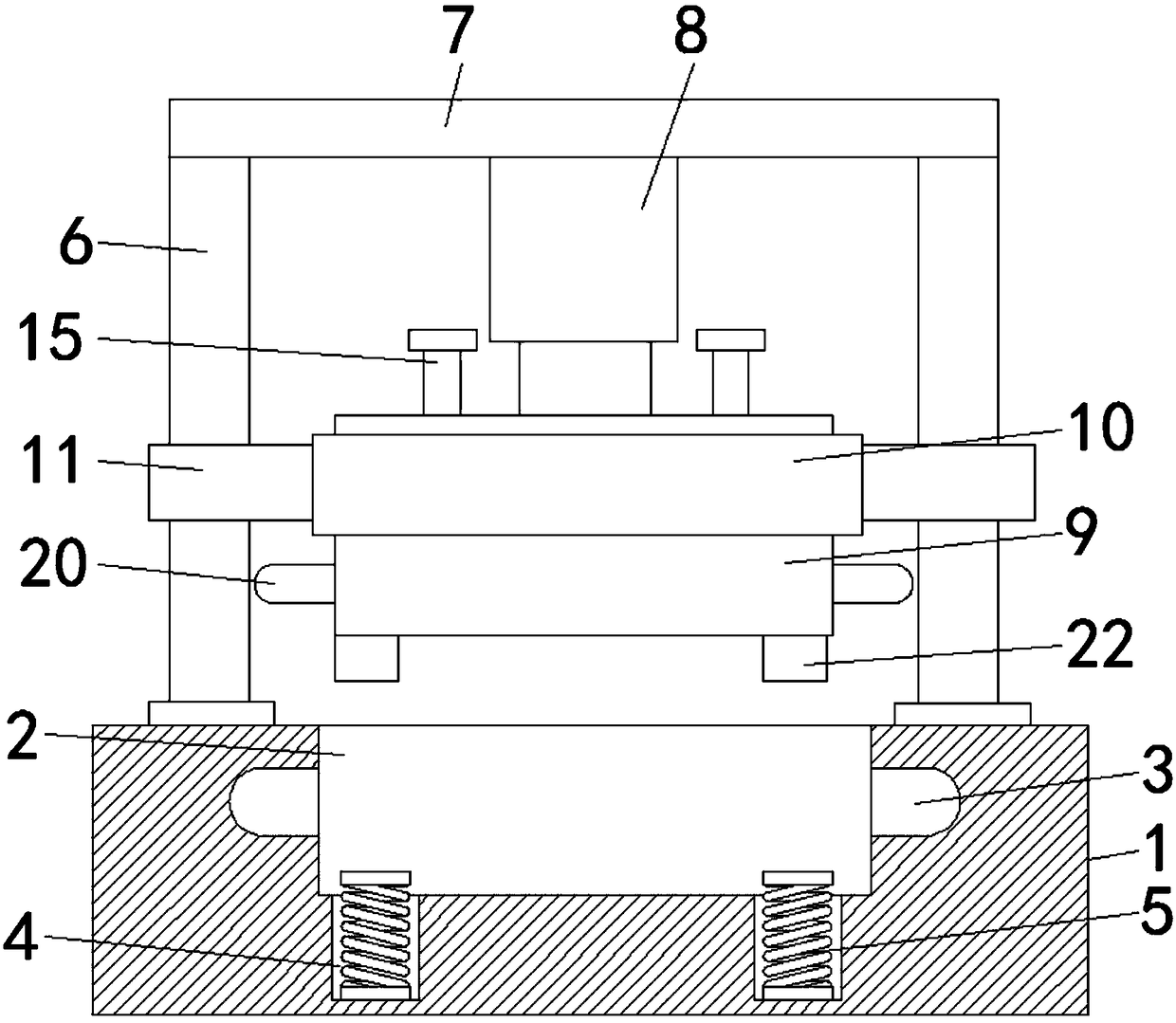

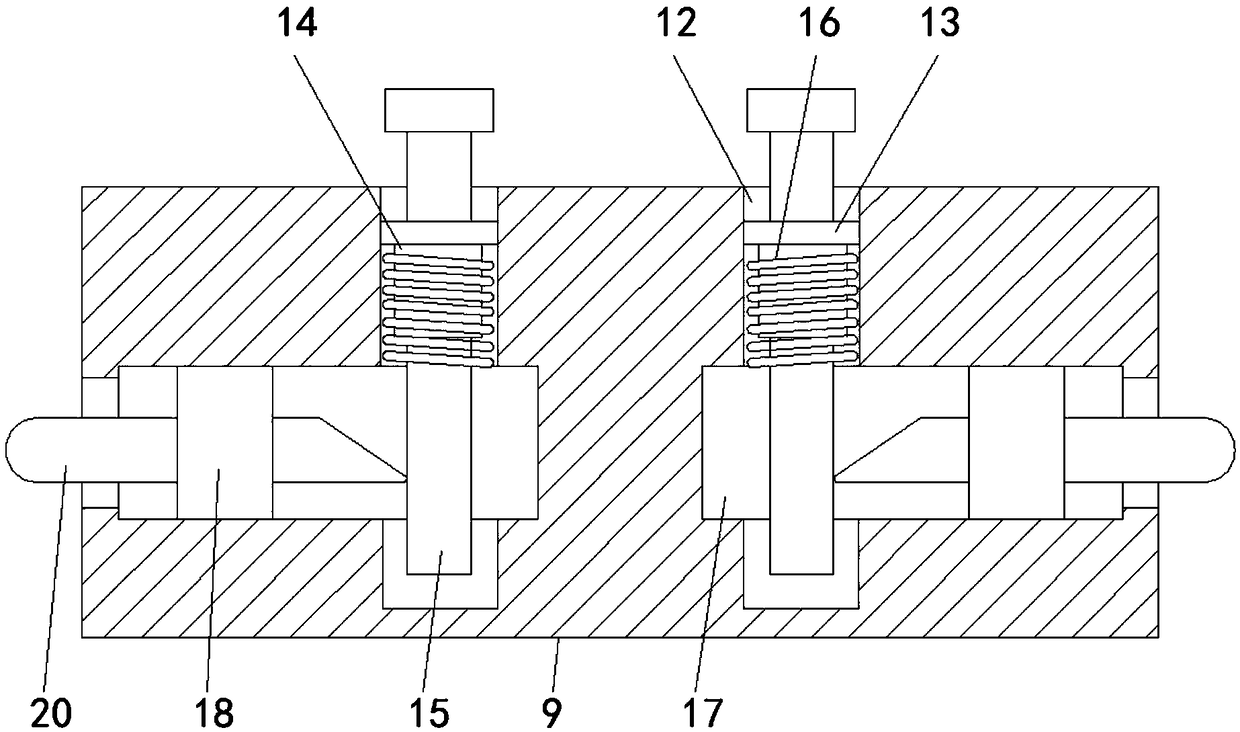

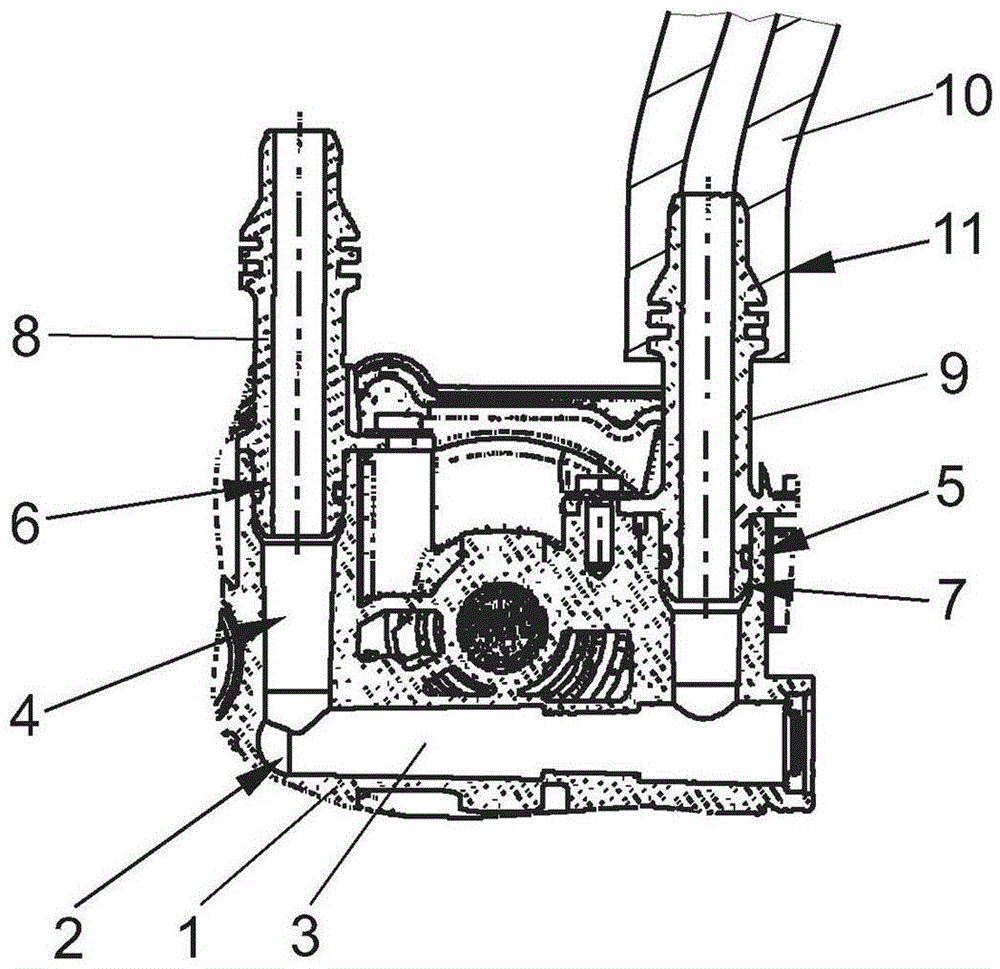

Flow-control valve for throttling hydraulic pressure medium

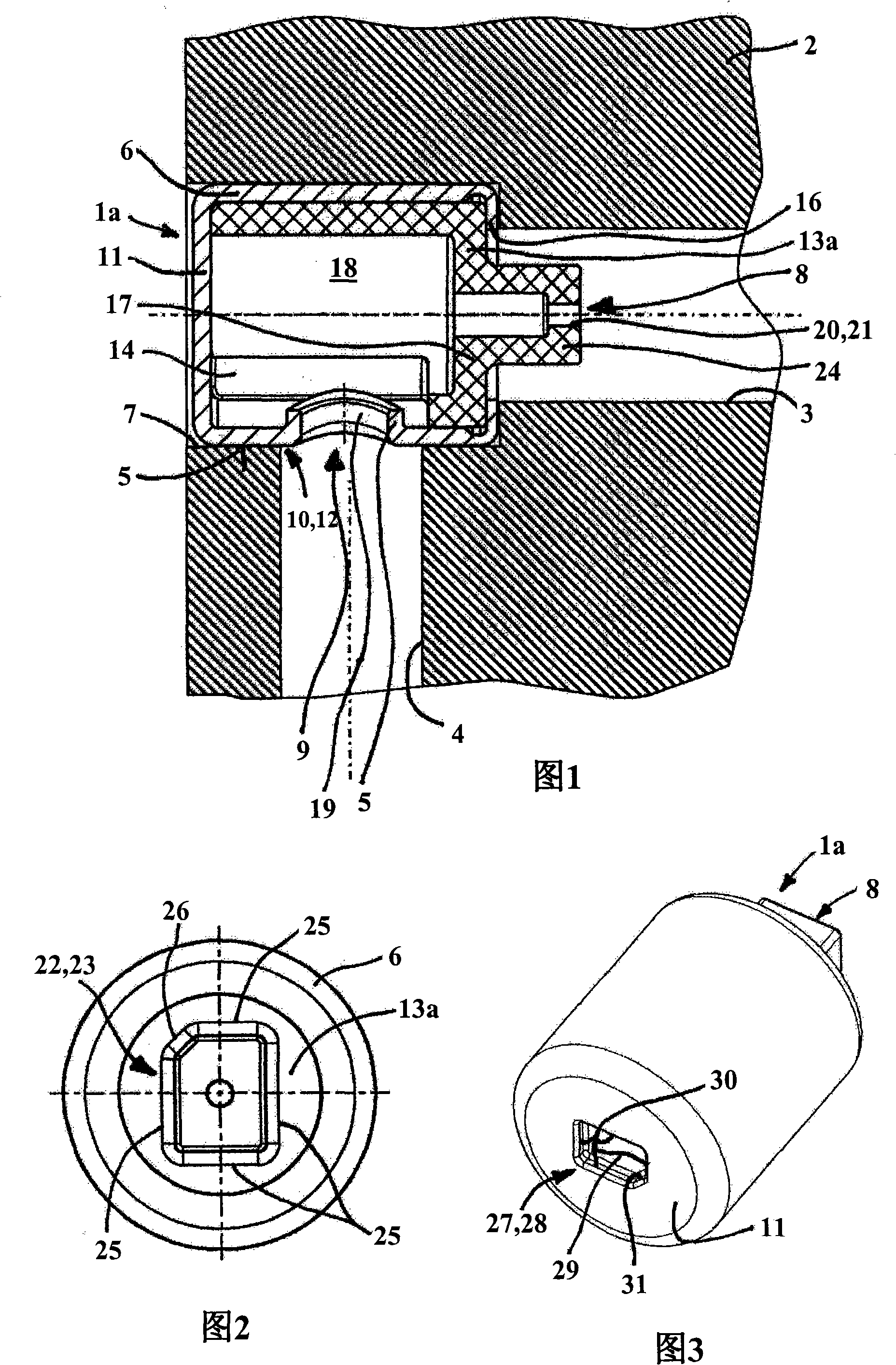

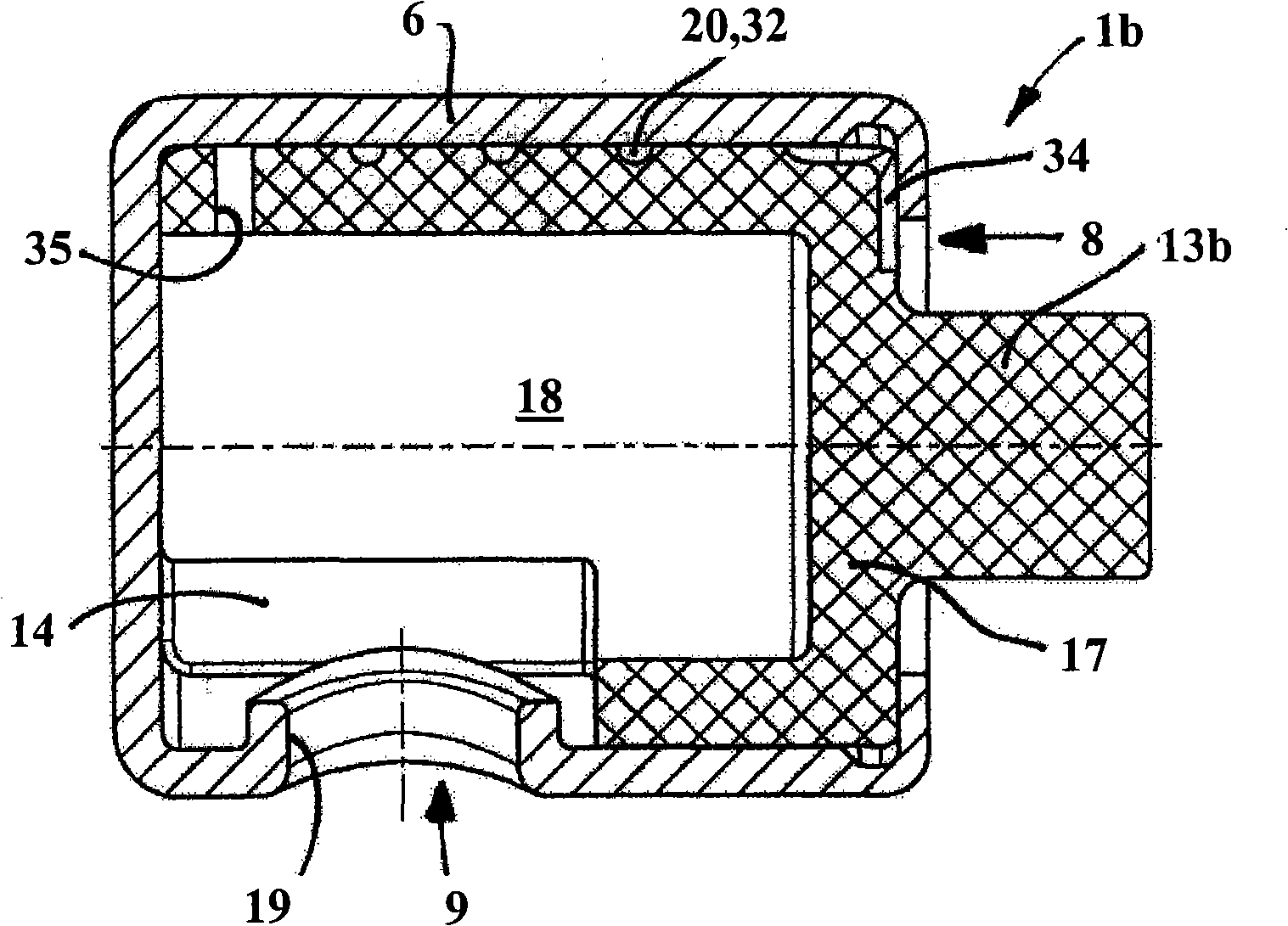

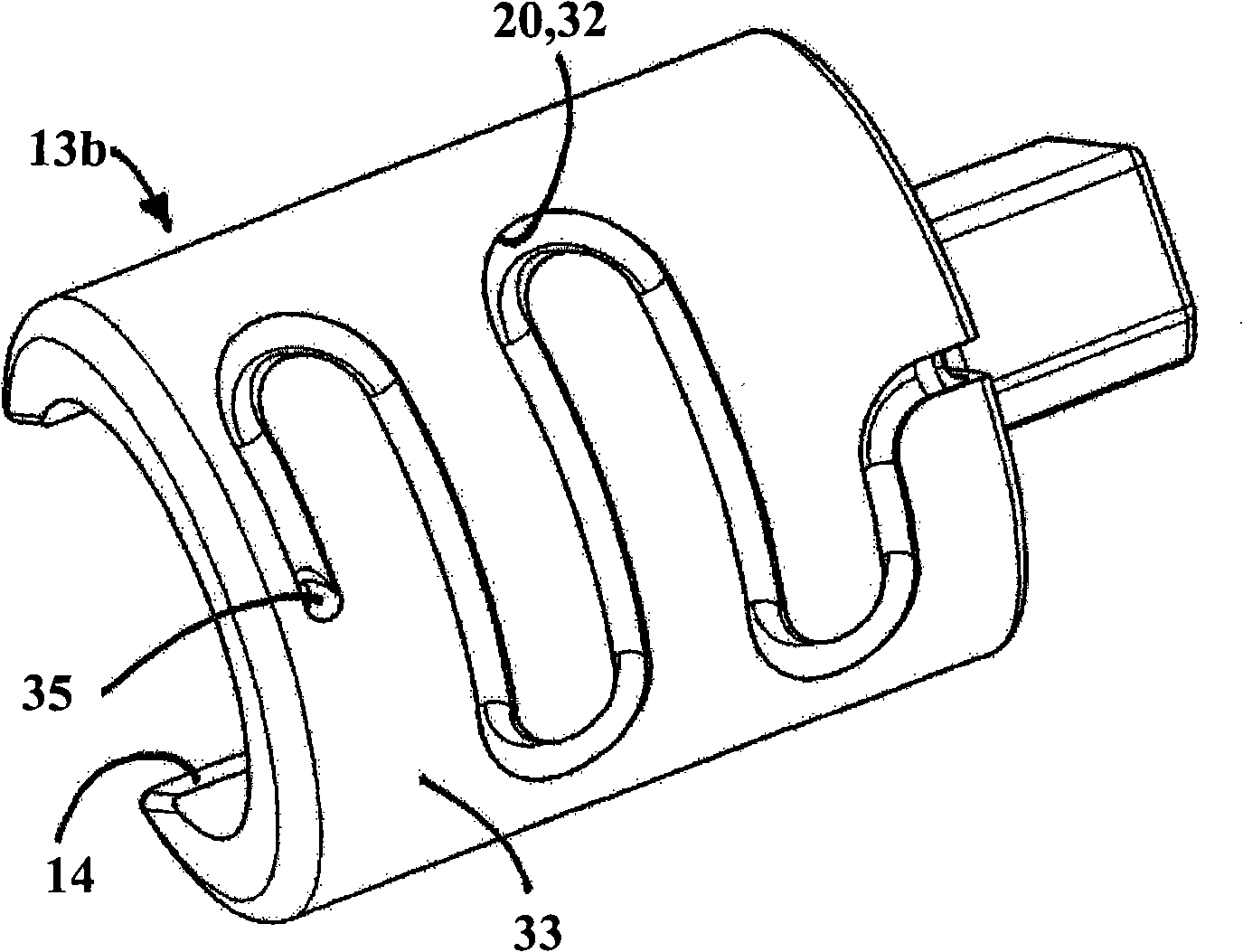

InactiveCN101273187AReliable workmanshipFully automatic radial alignmentPlug valvesProportioning devicesControl valvesHydraulic pressure

The invention relates to a flow-control valve (1 a, 1 b) for throttling a hydraulic pressure medium. Said flow-control valve (1 a, 1 b) is mounted with an outer envelope surface (5) of a valve housing (6) in a pressure medium channel (3) of a machine housing (2) comprising a plug (12) which is sealed from the pressure medium, on the mouth (7) of the pressure medium channel (3), close to the machine housing (2), and comprises a first pressure medium connection (8) on a side opposing the mouth (7). The plug (12) is formed by the flow-control valve (1 a, 1 b), a second pressure medium connection (9) extending radially through the outer envelope surface (5) and being connected to another pressure medium channel (4) which transversally merges into the original pressure medium channel (3).; An end section (10) of the valve housing (6), facing the mouth (7), comprises a closed housing bottom (11) and is inserted into the pressure medium channel (3) by means of a hydraulically sealing longitudinal press fit.

Owner:SCHAEFFLER TECH AG & CO KG

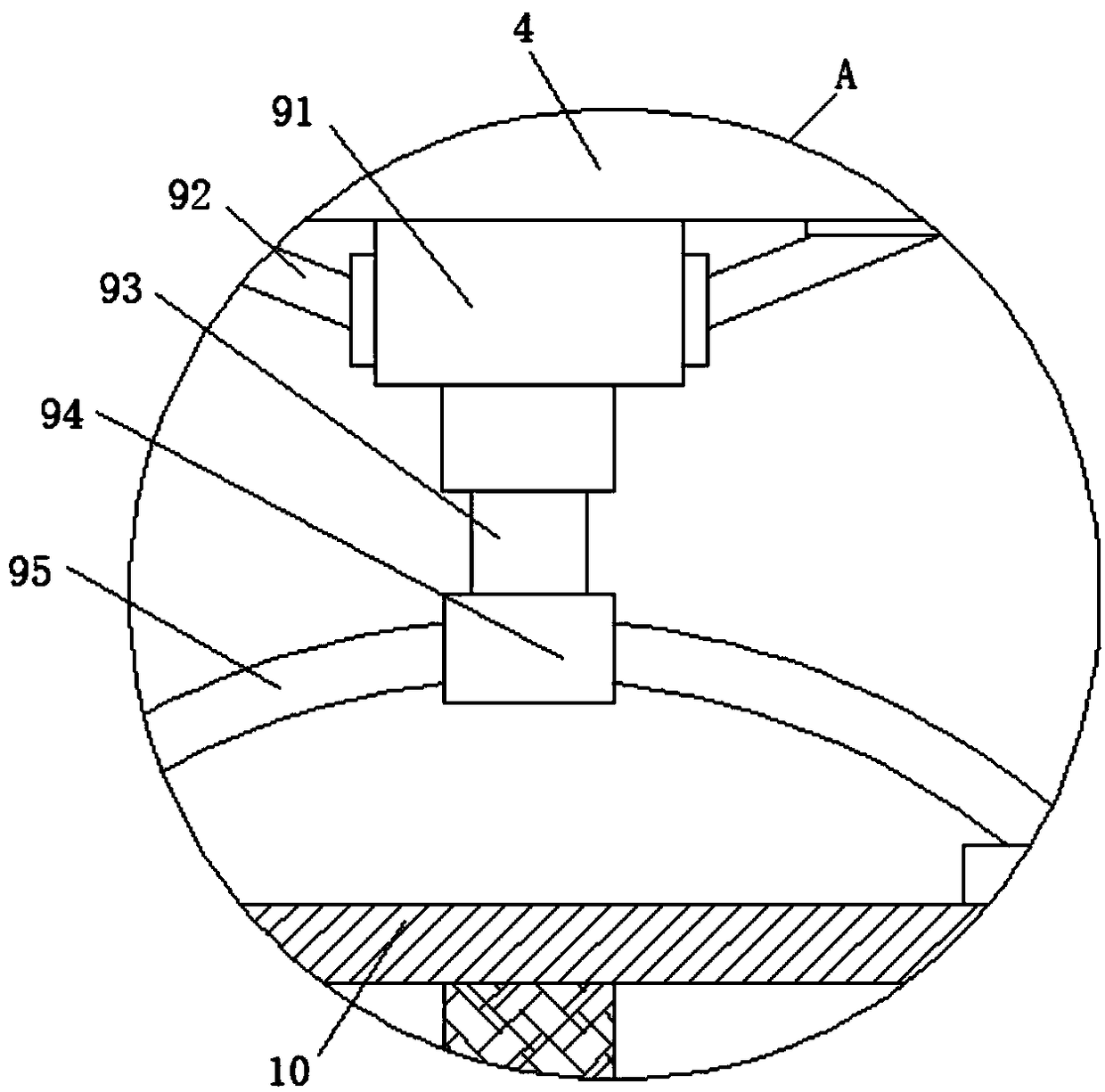

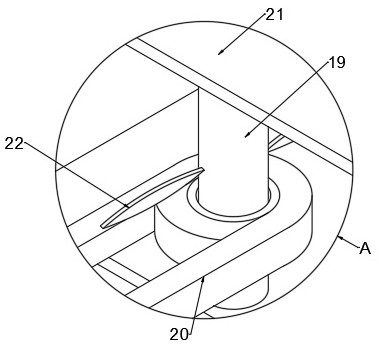

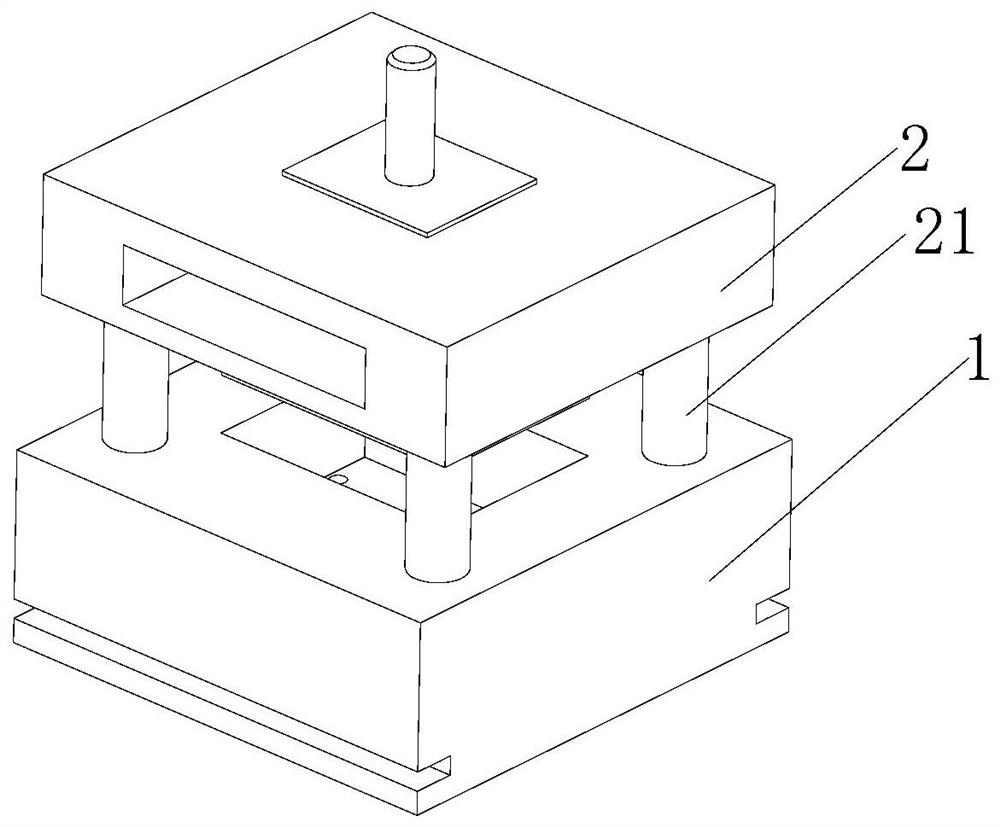

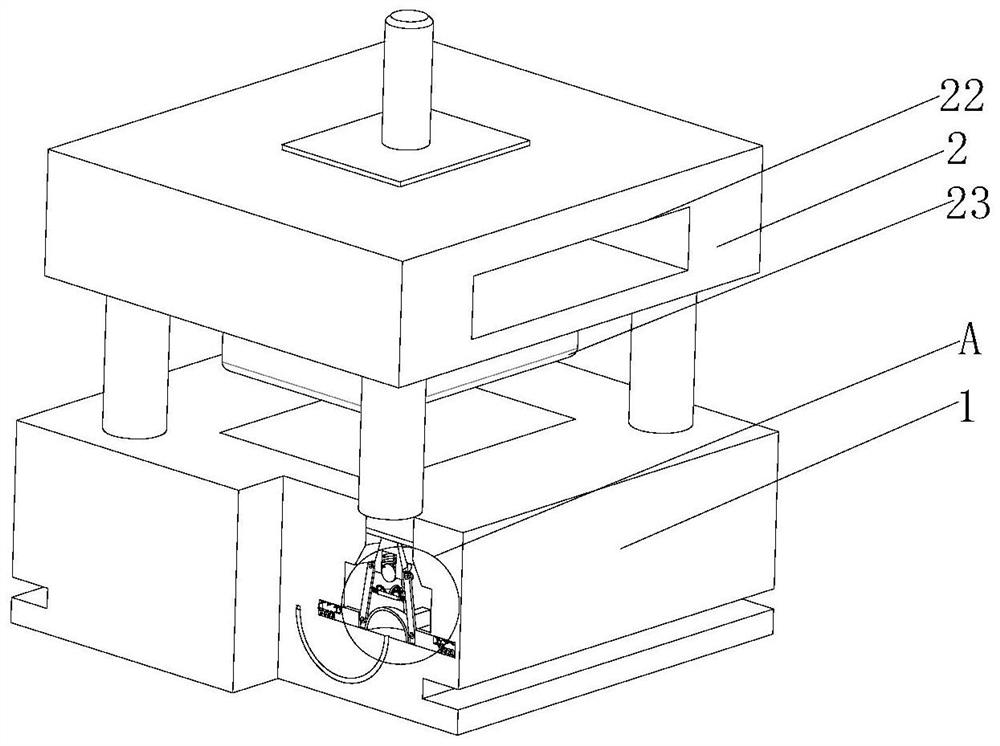

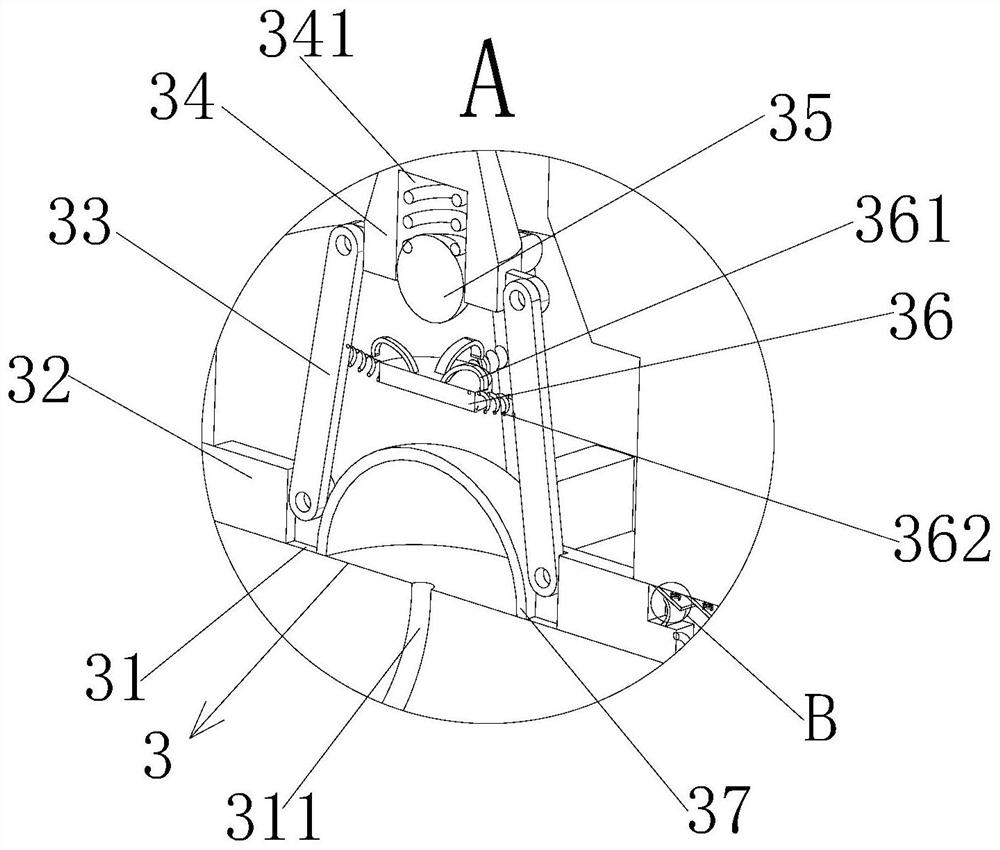

Rotary type stamping die push-out mechanism

The invention discloses a rotary type stamping die push-out mechanism which comprises a base substrate, a die support, a lower die and a pushing ejection rod used for die stripping. A die stripping push plate located in the lower die is fixed to the top end of the pushing ejection rod, a power mechanism used for pushing the pushing ejection rod to move vertically is installed on the inner side ofthe die support, the power mechanism comprises a rotary barrel, a rotary push plate, a die stripping motor and four stirring push rods circularly arranged with the pushing ejection rod as the center,the rotary barrel is arranged on the outer side of the push ejection rod in a sleeving manner, fixed pin shafts hinged to the four stirring push rods are inserted into the middle portions of the fourstirring push rods in a penetrating manner, four annularly-arranged arc pushing parts are arranged on the outer side of the rotary push plate, and the lower end face of a lower push plate is further connected with the upper end face of the base substrate through a reset spring. By means of the rotary type stamping die push-out mechanism avoids the condition that a traditional lead screw overcomesspiral friction force to push the pushing ejection rod to achieve die stripping, power is reduced, energy consumption is reduced, noise is reduced, the service life is long, and the practicability ishigh.

Owner:广东日信高精密科技股份有限公司

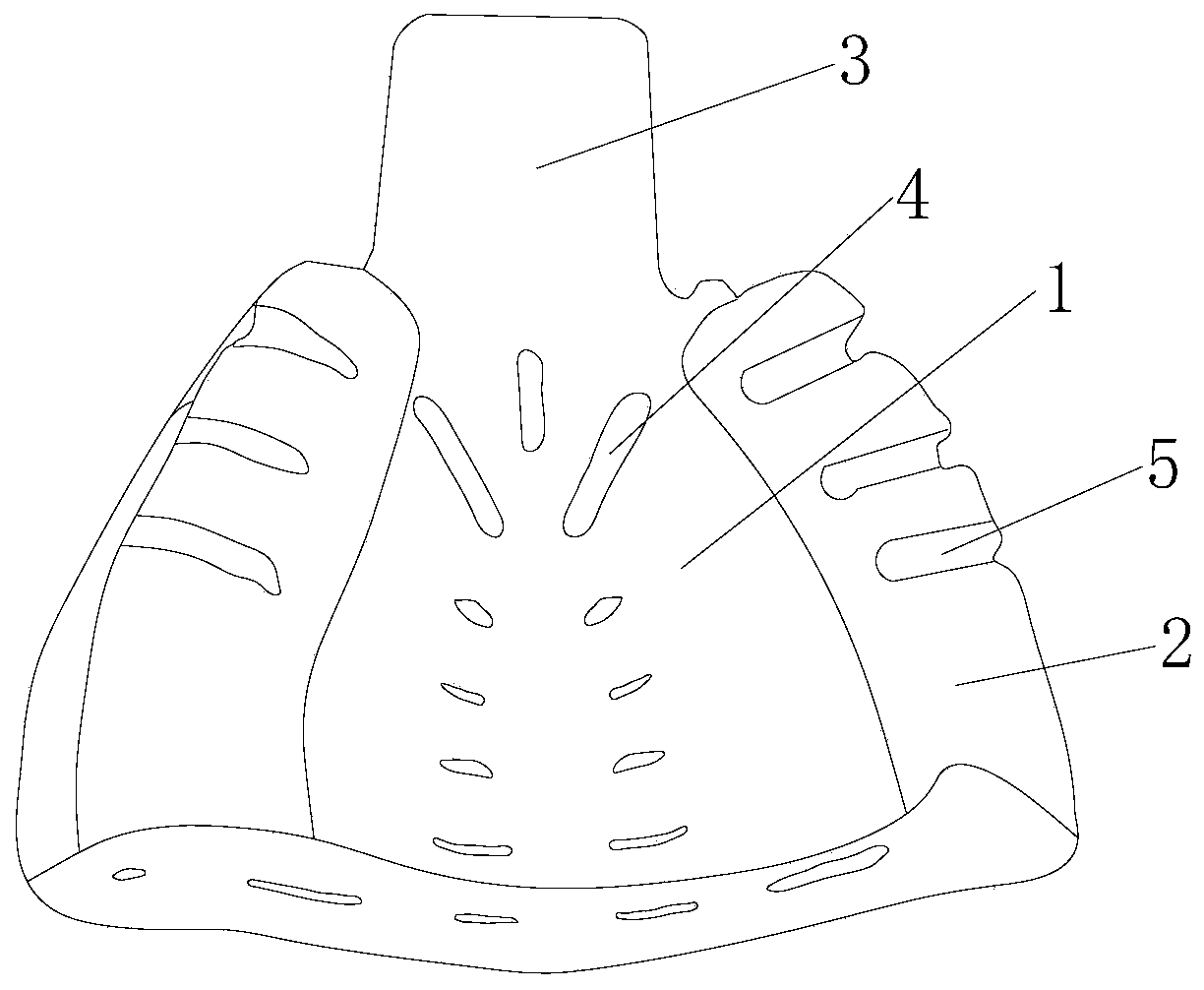

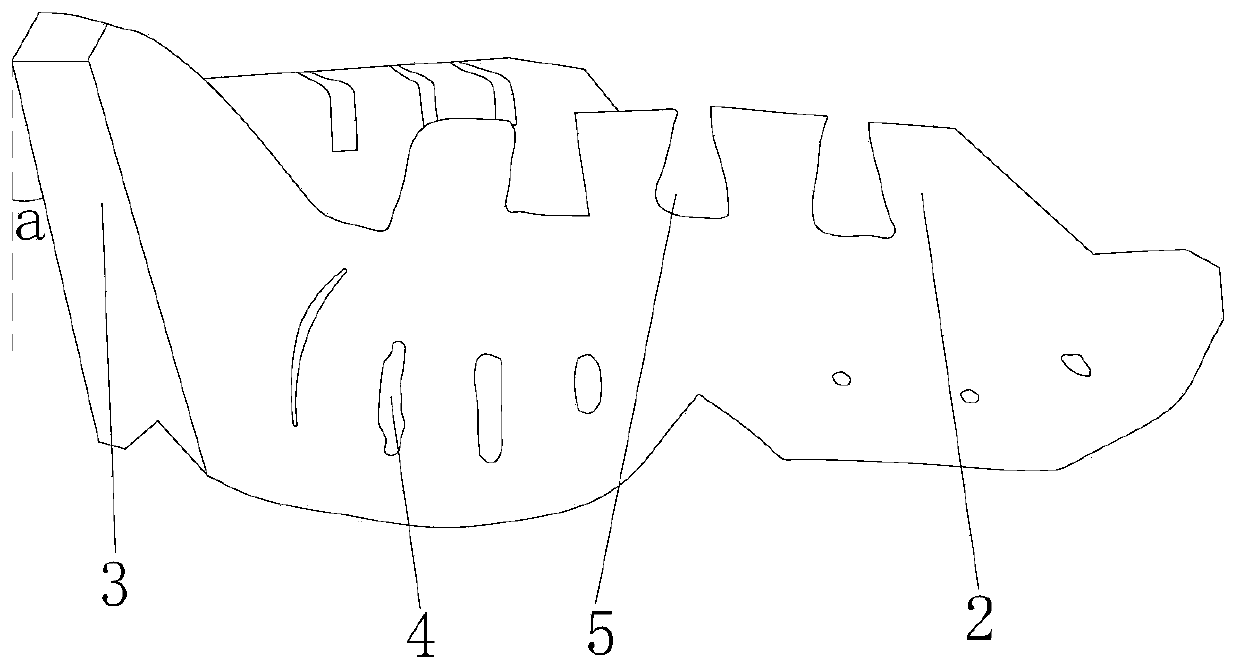

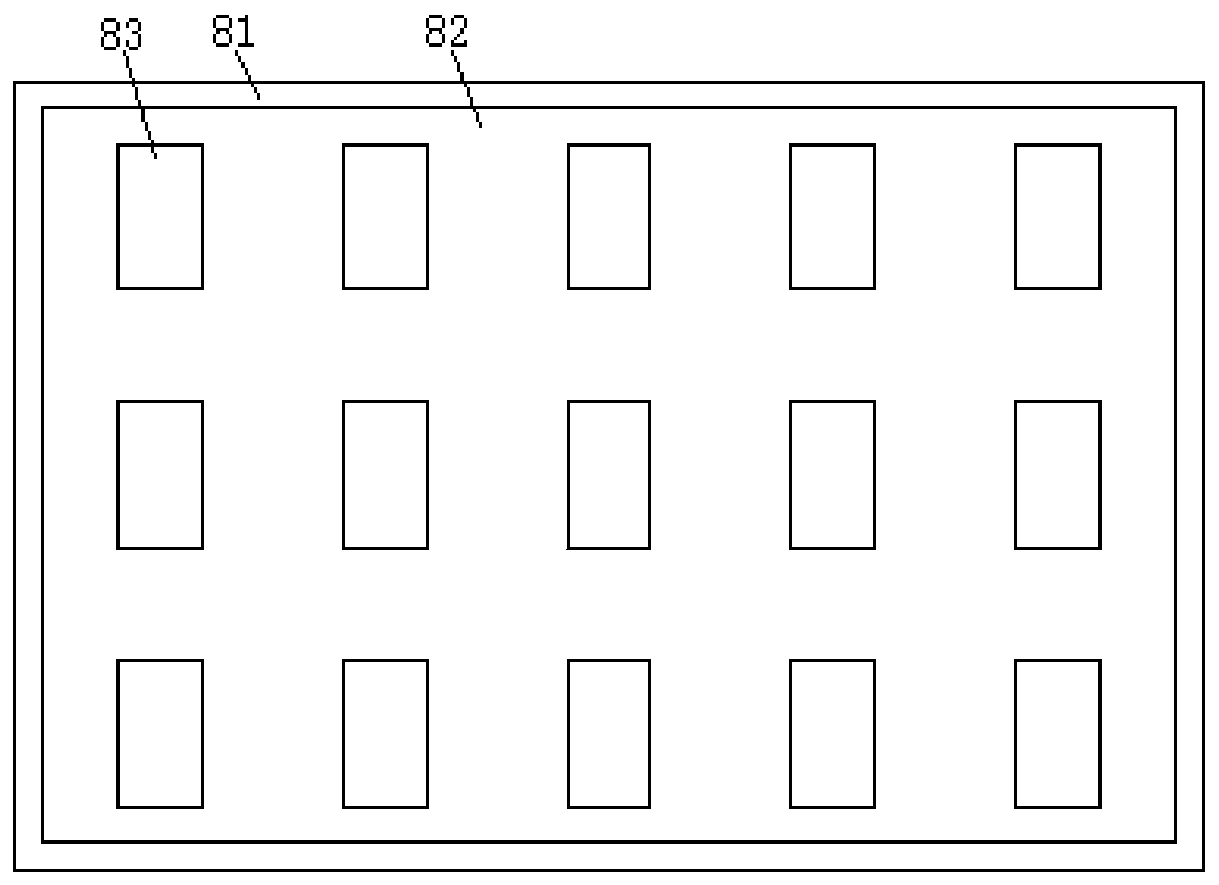

Improved complete denture maxillary blank mold tray

The invention belongs to the technical field of dental molding apparatuses, and discloses an improved complete denture maxillary blank mold tray. The blank mold tray comprises a tray base located in the middle and a tray body composed of occlusion banks on the two sides. The positions of the occlusion banks correspond to alveolar ridge crests between the first premolar tooth and the second premolar tooth on the two sides of human teeth respectively. A tray handle connected with the tray base is arranged at one end of the tray body. A plurality of overflow discharge holes are evenly formed in the tray base. The width of the occlusion banks is gradually increased from one end close to the tray handle to the other end. Three fixing grooves are formed in the occlusion banks at intervals. Whenan impression is prepared from the maxillary blank mold tray, the primary occlusion position relation can be prepared; the length and the position of the tray handle cannot interfere with the motionsof an upper lip, operability is high, a patient can hardly be interfered with, a doctor can more easily observe whether the mandible of the patient stretches forwards or not, and the patient is more easy to control.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Mould of air cooler sand core in large diesel engine

ActiveCN103736919ASimple structureSolve the problem of smooth demouldingFoundry mouldsFoundry coresEngineeringUltimate tensile strength

The invention discloses a sand core mould of an air cooler sand core in a large diesel engine. The sand core mould comprises an upper core box, a lower core box and a plurality of side surface loose pieces, wherein the upper core box is provided with an upper cavity of the air cooler sand core; a lower cavity of the air cooler sand core, which is matched with the upper cavity of the upper core box and is provided with a plurality of yielding loose piece-shaped surfaces, is formed in the lower core box; the side surface loose pieces are arranged in the yielding loose piece-shaped surfaces of the lower core box. According to the mould, the structure is simple and reasonable, each core box is made of a cast iron material, the shape of the periphery of the core box is designed to be matched with the sand core, and the total weight of the mould can be reduced and the manufacturing cost can be saved while the strength of the core box is guaranteed and the deformation is prevented; the local part of the core box adopts a loose piece structure, so that the problem that the sand core cannot be smoothly demoulded is effectively solved, the operation is convenient and flexible, and the core-making efficiency is high; moreover, the made sand core is small in deformation and good in sizing precision.

Owner:GUANGXI YUCHAI MASCH CO LTD

Production method for green and environment-friendly rice husk plate

InactiveCN107498680AReduced breakage stepsHigh energy consumptionFlat articlesDomestic articlesEnvironmental resistanceToxic material

The invention discloses a production method for a green and environment-friendly rice husk plate. The production method comprises the following preparation steps: preparing pure rice husk; carrying out surface treatment in a manner of combining a physical method with a chemical method; uniformly mixing glue; paving; pre-pressing; carrying out hot-pressing forming; carrying out fixed-length edge cutting; curing; drying; carrying out trimming and surface treatment; and obtaining the product, wherein in the step of surface treatment, a small amount of nanometer material capable of pitting a waxy surface under the temperature condition of greater than 120 DEG C is added at first, then chemical raw materials occupying 0.01%-0.5% of wheat straw, having structures similar to the waxy structure of the surface of the rice husk, containing silicon-oxygen chemical bonds and having similar or approximate structures are added, and finally an adhesive capable of forming hydrogen bonds or chemical bonds with a polyhydroxyl structure is added, and the dosage of the adhesive is 0.1%-5%. The plate prepared by the method is free from harmful gas emission, smooth, uniform and beautiful in texture, light-weight and environment-friendly, free from toxic substance release, high in strength, flame-retardant, sound-isolation and moistureproof, and is a wood plate substitute which is low in price and excellent in performance.

Owner:河南安朝板材科技有限公司

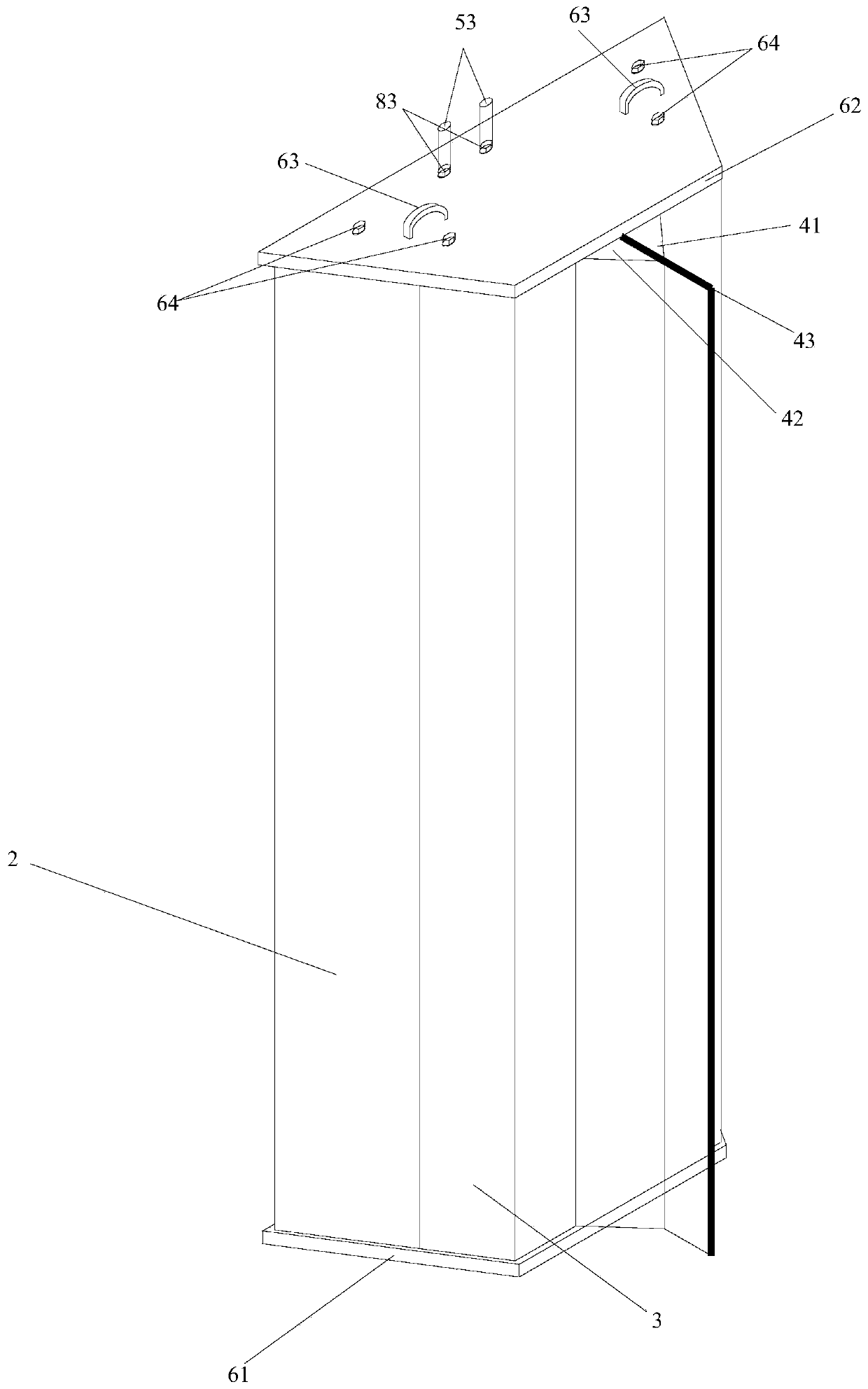

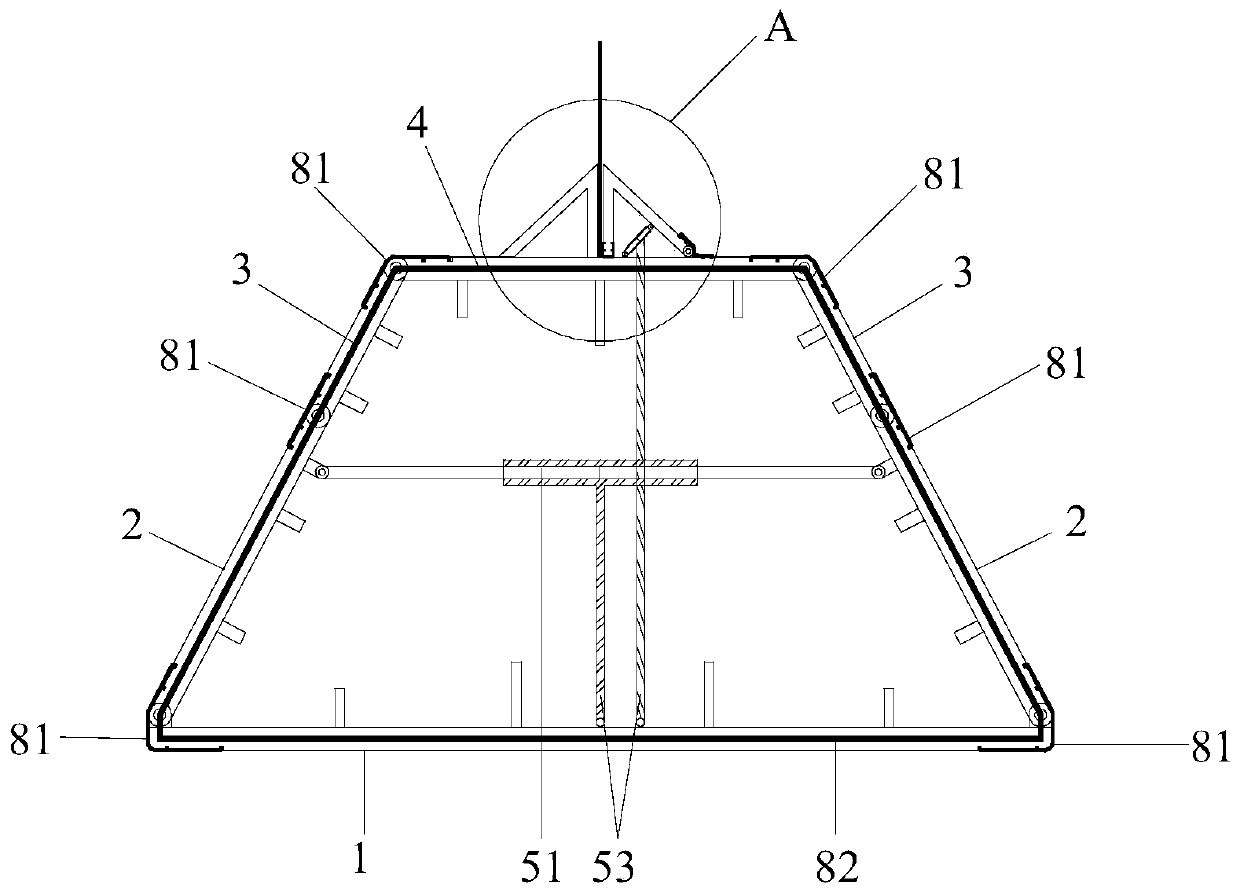

Construction method for installing rubber waterstop on automatic folding type joint box of underground continuous wall

ActiveCN110387876AGuaranteed installation axis positionImprove waterproof and anti-seepage performanceArtificial islandsProtective foundationSocial benefitsSlurry wall

The invention relates to a construction method for installing a rubber waterstop on an automatic folding type joint box of an underground continuous wall. The method comprises the steps of guide wallconstruction, trench excavation, reinforcement cage binding and lowering, joint box assembling and installation, concrete pouring, joint box contraction and lifting out and the like. A back plate, rear side plates, front side plates and a front plate of the joint box are hinged to each other and are sealed by strip-shaped waterstop, a plurality of folding hydraulic arms are arranged between the rear side plates, a plurality of rubber waterstop clamping devices and clamping hydraulic arms are arranged on the front plate, the folding hydraulic arms and the clamping hydraulic arms are connected with a hydraulic pump through independent hydraulic pipes, and the joint box is connected into a whole through fastening pull rods; after the concrete of the underground continuous wall reaches a certain strength, the folding hydraulic arms are contracted, and the clamping hydraulic arm are stretched synchronously, so that the joint box integrally contracts and folds, the clamping device releases the rubber waterstop, and the joint box is lifted out. The water stop and seepage prevention performance of the joint of the concrete underground continuous wall can be improved, construction is convenient and fast, and economic and social benefits are good.

Owner:杭州悦为科技有限公司

An injection mold that is easy to release

Owner:滁州用朴合金工具有限公司

Ejection device of injection mold

The invention discloses an ejection device of an injection mold. The ejection device of the injection mold comprises a workbench, wherein supporting legs are fixedly connected to the four opposite angles of the workbench, the tops of the four supporting legs are fixedly connected with the same top plate, a driving motor is fixedly connected to the bottom of the workbench, the output end of the driving motor is fixedly connected with a driving shaft, and the driving shaft penetrates through the workbench and is fixedly connected with a bottom plate. Through cooperative use of the driving motor, the driving shaft, a floor, supporting rods, a bottom mold, a mounting opening, a rotating plate, an air cylinder, a telescopic rod, a fixing plate, an ejector pin, an ejector opening and a connecting plate, injection molding materials can be evenly fed, and then materials can be evenly stored in the bottom mold; and meanwhile through cooperative use of the air cylinder, the telescopic rod, the connecting plate and the fixing plate, rapid and automatic ejection of the injection mold is achieved, the problem that in a traditional device, demolding of an injection mold is achieved in a manual ejection mode is solved, and labor is saved.

Owner:高春鹏

Injection mold with piston buffer structures at four corners

The invention discloses an injection mold with piston buffer structures at the four corners. The injection mold comprises a lower mold plate, a plurality of guide rods are movably inserted into the surface of the lower mold plate, auxiliary buffer mechanisms are arranged at the bottoms of the guide rods, a cavity is formed in the lower mold plate, a pair of clamping grooves are formed in the side wall of the lower mold plate, an upper mold plate is fixedly welded to the guide rods, a connecting shaft is fixedly connected to the upper mold plate, a driving groove is formed in the side wall of the upper mold plate, a mold core is fixedly connected to the bottom of the upper mold plate, a cooling groove is formed inside the mold core and communicates with the driving groove, and a cooling mechanism is fixedly connected to the bottom of the driving groove. Compared with the prior art, when the guide rods are stressed to move, ejector blocks can be pushed to move downwards, hinge rods can move, buffer rods are pushed to move in straight grooves, a buffer effect can be achieved through reset springs and extrusion springs, the situation that bubbles are generated in an injection molding part due to the fact that the guide rods move too fast is avoided, and the defective product rate of the injection molding part can be reduced.

Owner:长兴优浩科技有限公司

Environmental-protection rice husk and straw board production method

InactiveCN107498683AReduce crushing efficiencyReduce surface tensionWood working apparatusDomestic articlesAdhesiveSilicon oxygen

The invention discloses an environmental-protection rice husk and straw board production method. The production method comprises the preparation steps of: mixing of straw fragments and rice husks-surface treatment-treatment through physical and chemical combination methods-uniform glue mixing-pavement-prepressing-hot pressing molding-fixed length edge cutting-curing-drying-trimming and surface treatment-products; in raw materials, the mass percentage ratio of the use levels of the straws and the rice husks is (1-3): 1; in the surface treatment step, chemical raw materials containing silicon-oxygen chemical bond structures similar to wax structures on the surfaces of the straws are added; few nanomaterials pitting the wax surfaces under the temperature condition of above 90 DEG C are added; adhesives capable of forming hydrogen bonds or chemical bonds with polyhydroxyl structures are added; and finally, the uniform mixing is performed by a physical method for surface treatment. A board prepared by the method is high in strength; no harmful gas is discharged; the board is excellent in crush resistance, water resistance and environmental protection property; and the strength and the yield of the board are improved.

Owner:河南安朝板材科技有限公司

A rotary stamping die ejection mechanism

The invention discloses a rotary type stamping die push-out mechanism which comprises a base substrate, a die support, a lower die and a pushing ejection rod used for die stripping. A die stripping push plate located in the lower die is fixed to the top end of the pushing ejection rod, a power mechanism used for pushing the pushing ejection rod to move vertically is installed on the inner side ofthe die support, the power mechanism comprises a rotary barrel, a rotary push plate, a die stripping motor and four stirring push rods circularly arranged with the pushing ejection rod as the center,the rotary barrel is arranged on the outer side of the push ejection rod in a sleeving manner, fixed pin shafts hinged to the four stirring push rods are inserted into the middle portions of the fourstirring push rods in a penetrating manner, four annularly-arranged arc pushing parts are arranged on the outer side of the rotary push plate, and the lower end face of a lower push plate is further connected with the upper end face of the base substrate through a reset spring. By means of the rotary type stamping die push-out mechanism avoids the condition that a traditional lead screw overcomesspiral friction force to push the pushing ejection rod to achieve die stripping, power is reduced, energy consumption is reduced, noise is reduced, the service life is long, and the practicability ishigh.

Owner:广东日信高精密科技股份有限公司

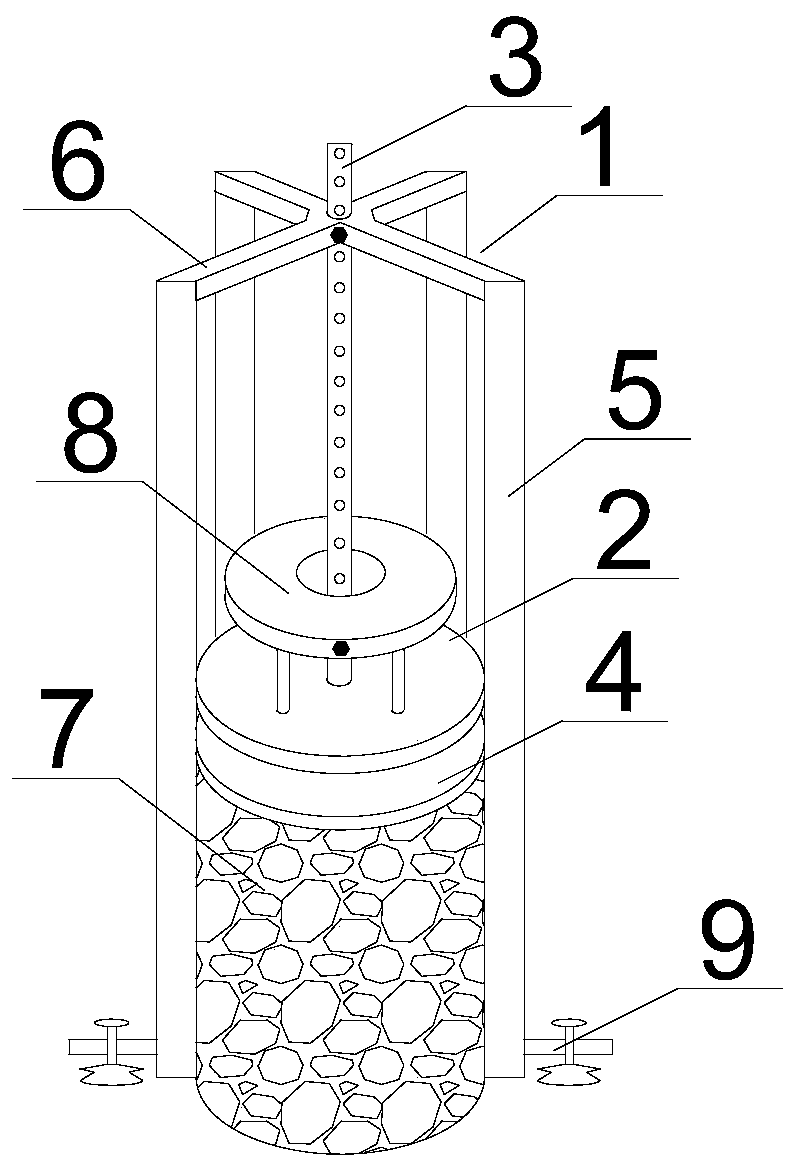

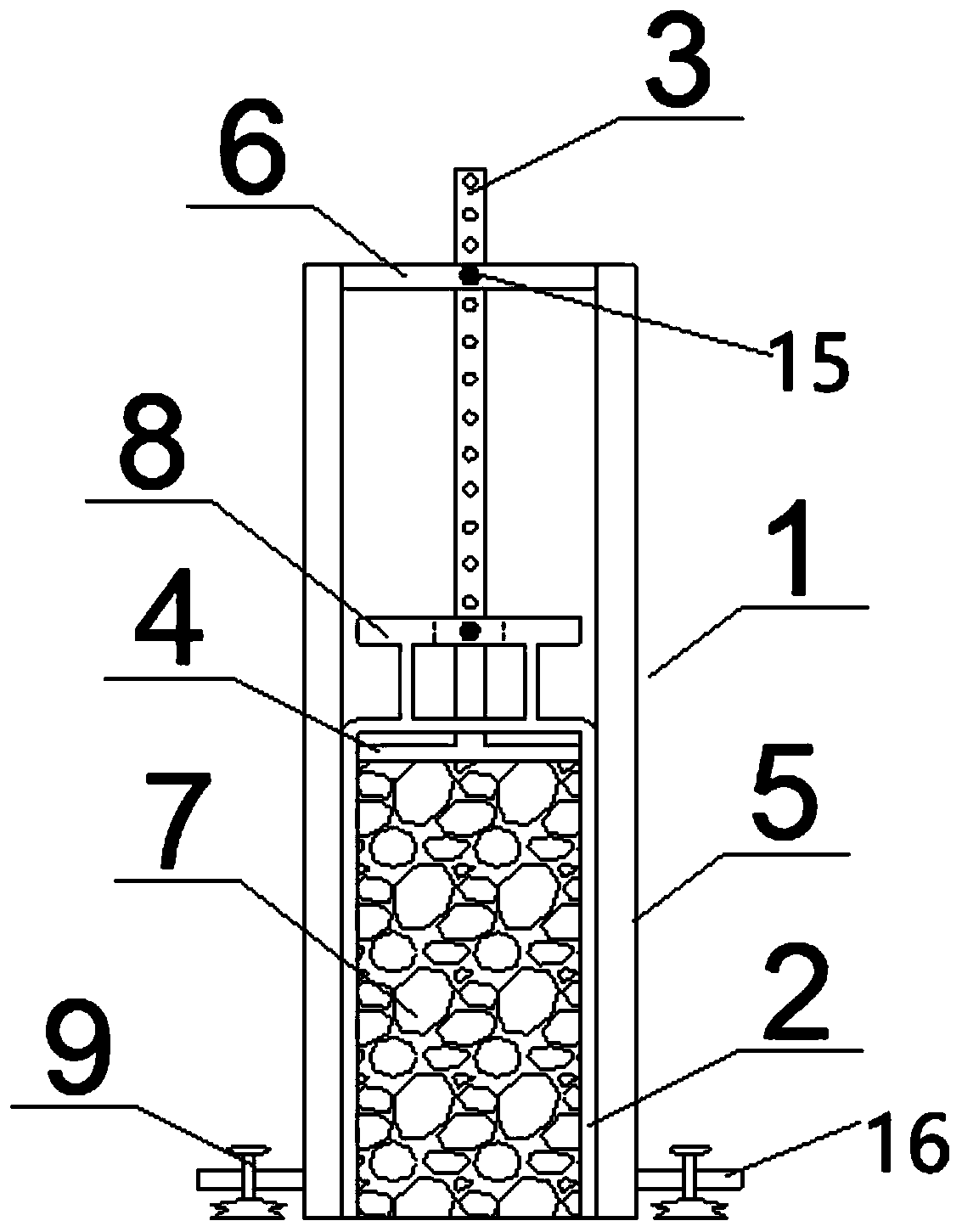

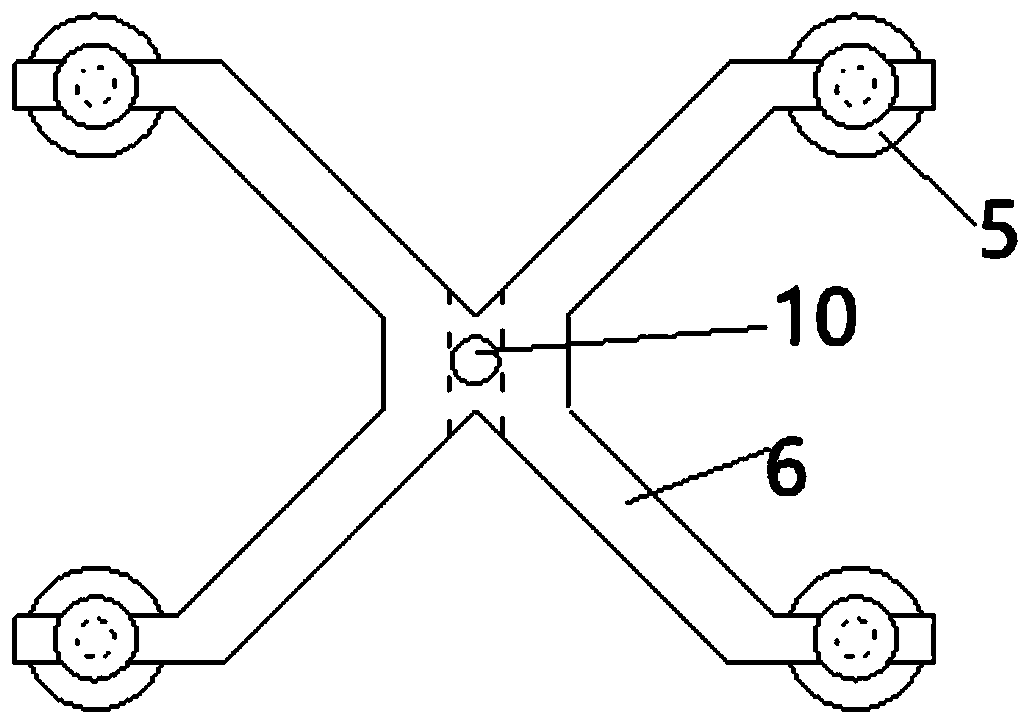

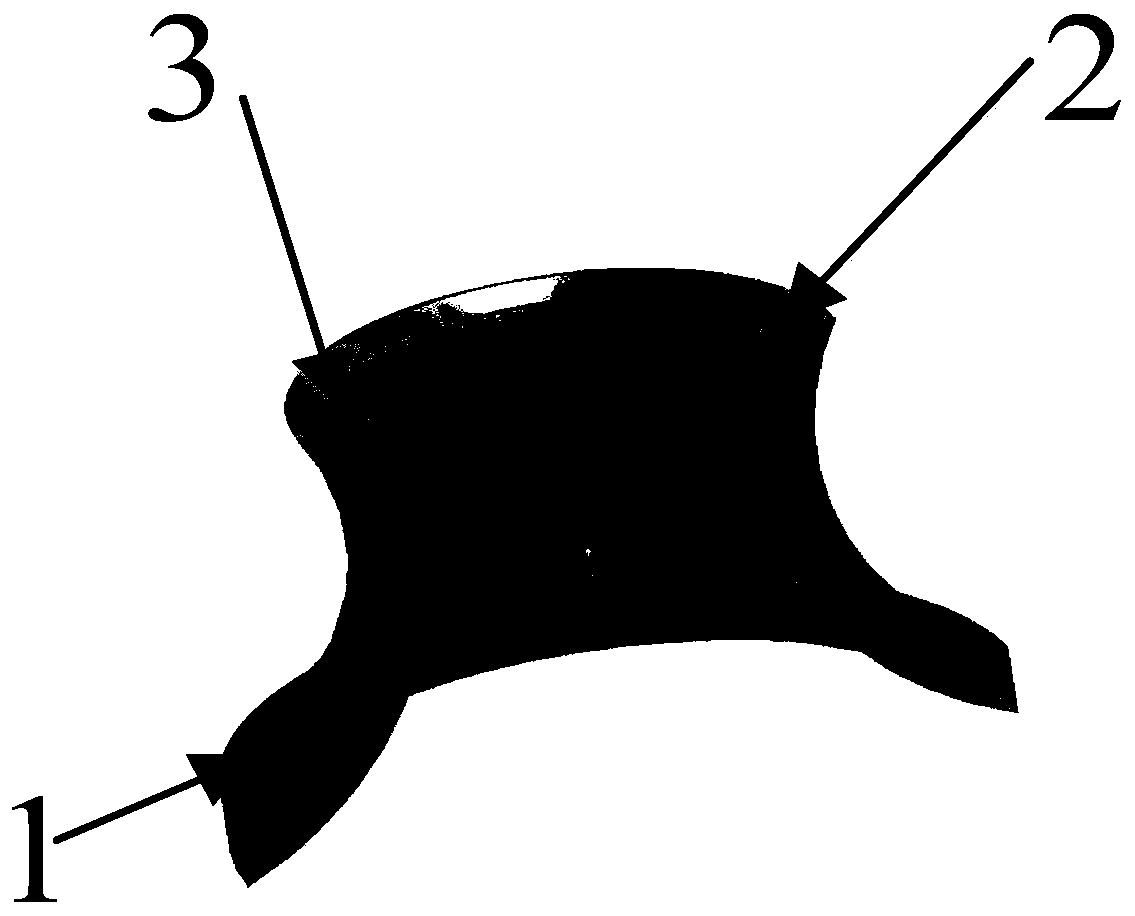

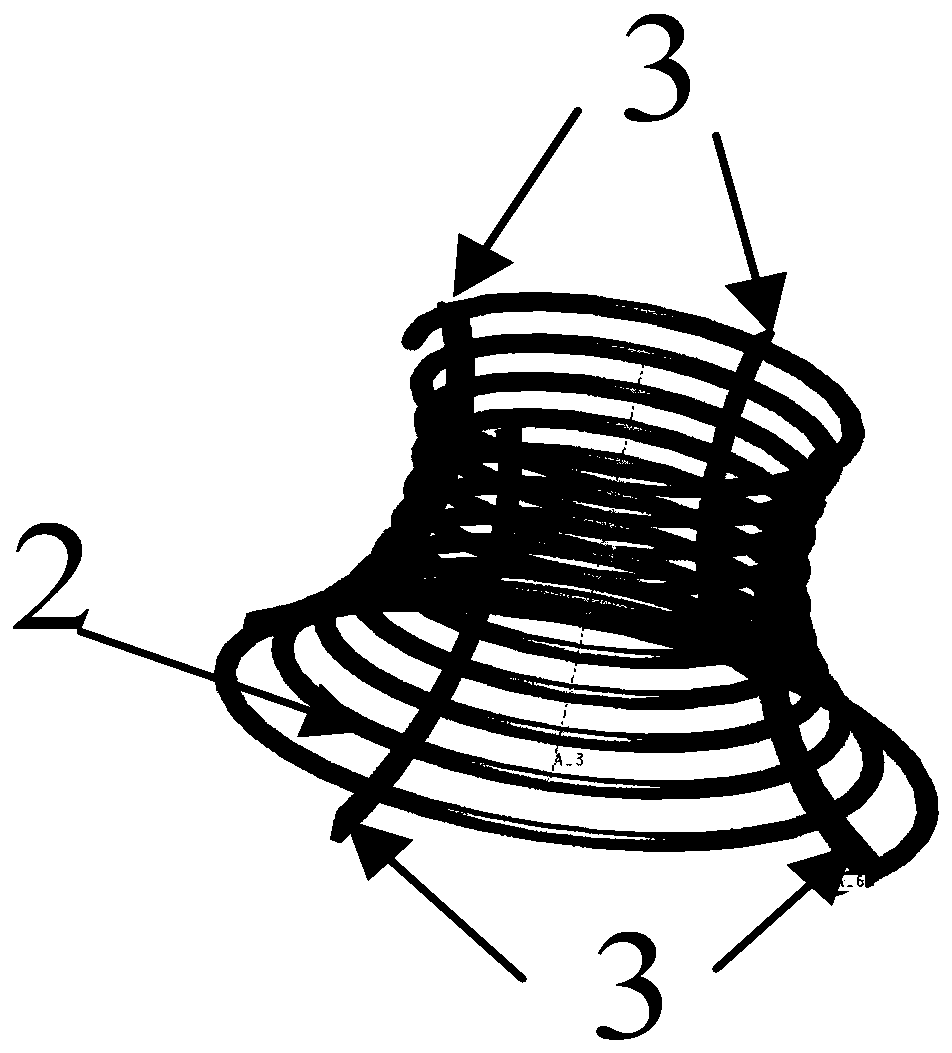

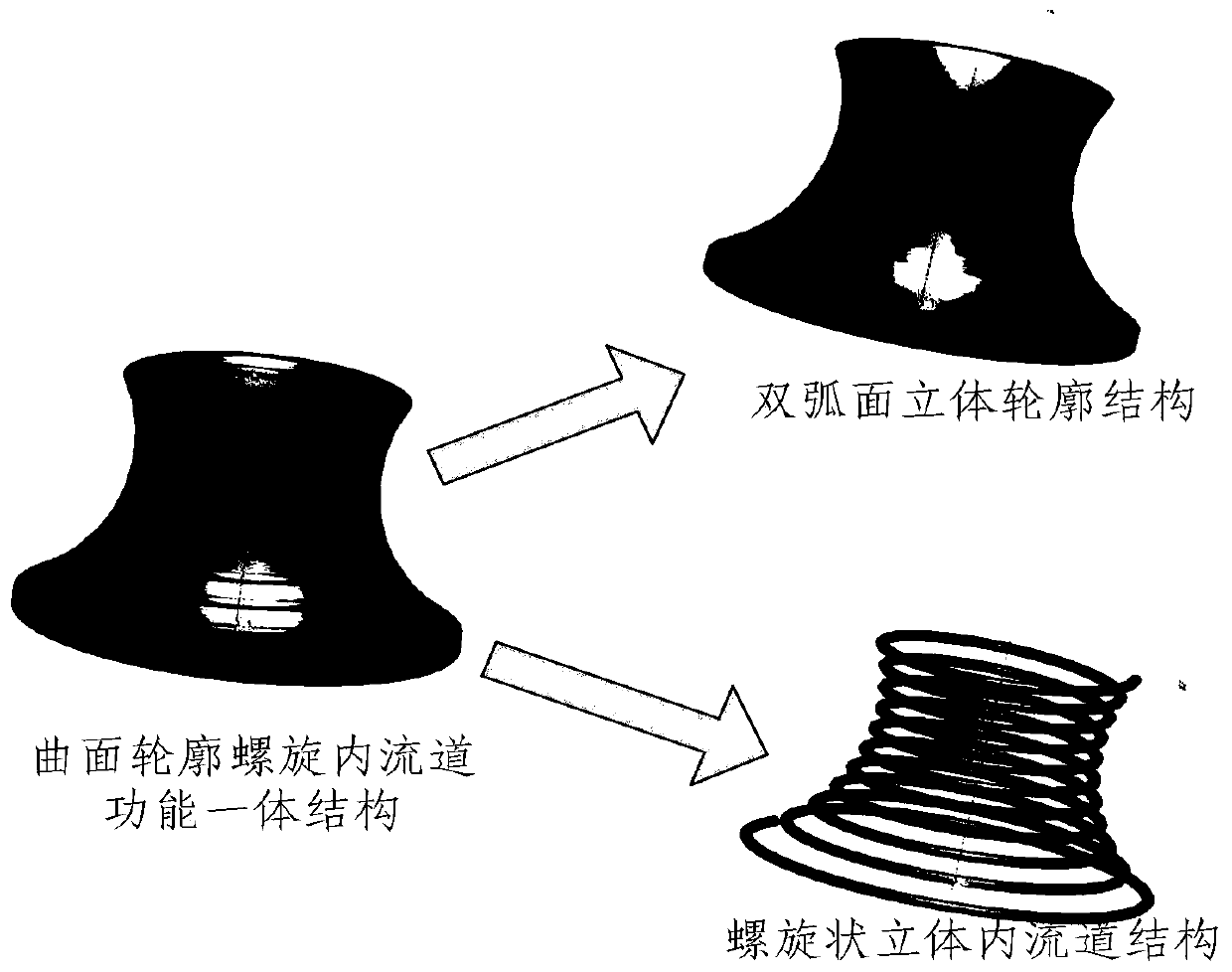

Precise molding method for complex internal flow passage structure

The invention discloses a precise molding method for a complex internal flow passage structure. By building a precise molding device for the complex internal flow passage structure and composed of a contour casting die (1), a prefabricated three-dimensional internal flow passage structure (2) and a fusible supporting frame (3), thin-wall metal pipes with high precision and smooth internal surfacesare adopted to be precisely wound into the three-dimensional internal flow passage structure, the high-precision fusible supporting frame is used for realizing precision positioning of a three-dimensional internal flow passage, and the structural position precision of the three-dimensional internal flow passage structure can be kept in the casting process. By utilizing differences between the three-dimensional internal flow passage structure and a three-dimensional outer contour structural material in melting points, erosion and deformation of the interior of the three-dimensional internal flow passage can be avoided. According to the precise molding method for the complex internal flow passage structure, the problems that in general manufacturing methods, the functionally integrated internal flow passage structure is difficult in a complex internal flow passage molding, low in percent of pass, poor in surface precision of the internal flow passage and the like are solved.

Owner:BEIJING INST OF REMOTE SENSING EQUIP

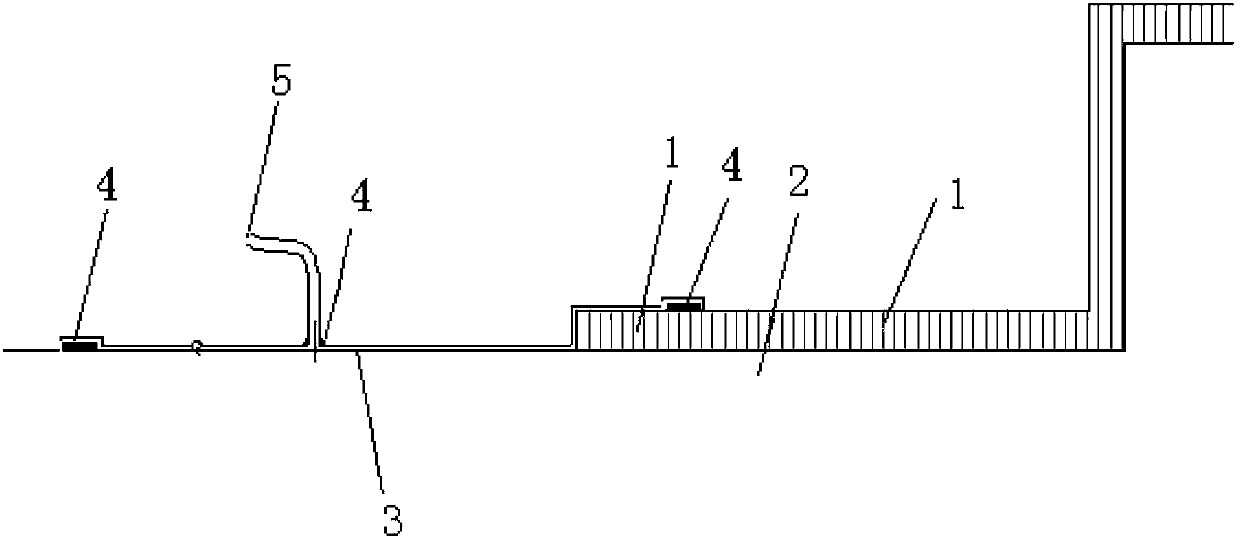

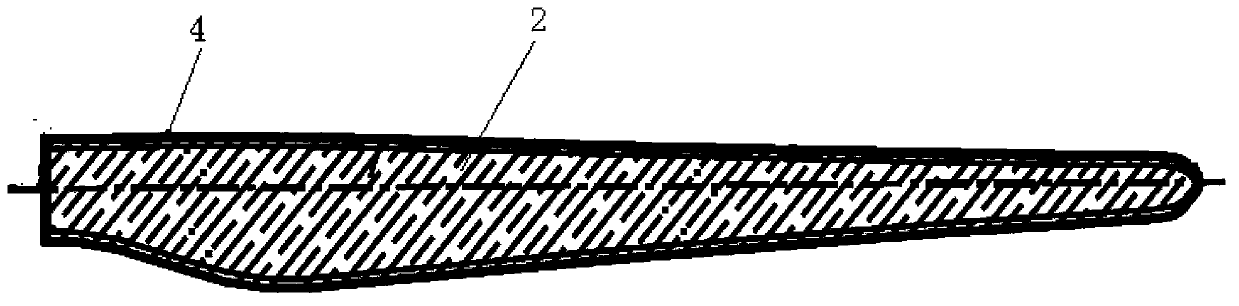

Method for preventing product demolding in megawatt blade die locking process

InactiveCN103358570ARealize anti-release filmSolve the demoulding problemDomestic articlesEngineeringFlange

The invention relates to a method for preventing product demolding in a megawatt blade die locking process. The method is characterized in that the method comprises the following steps: 1, placing a blade product in a die for connecting one side of a flange edge which is the edge of the die with the blade product, arranging a sealing strip between the flange edge and the blade product, and arranging a sealing strip between the other side of the flange edge and the die to form sealed environment between the die and the blade product and guarantee no leakage of the die or the blade product; and 2, arranging a suction pipeline on the flange edge, evacuating to the degree of vacuum reaching -0.6 - -0.8atm through the suction pipeline, and dwelling for 10-20min under a constant degree of vacuum to realize the demolding prevention of the blade product. In the invention, the die demolding can be prevented according to the shape of the die and the different characteristics of the blade product, the possibility of a product in the die in the overturning process of a large die when the large die moves is solved, and the blade product can be smoothly demolded only through releasing the pressure in the die.

Owner:无锡乘风新能源工程科技有限公司

Injection mold easy to strip

Owner:滁州用朴合金工具有限公司

Green and environment-friendly straw stalk plate production method

InactiveCN107498685AReduce crushing efficiencyHigh energy consumptionFlat articlesDomestic articlesWaxSilicon oxygen

The invention discloses a green and environment-friendly straw stalk plate production method. The method comprises the preparation methods of straw stalk crushing, surface treatment of a physical and chemical phase combination method, uniform glue mixing, paving, pre-pressing, hot press forming, sizing side cutting, maintenance, drying, trimming and surface treatment and product forming. In the step of surface treatment, a silicon-oxygen chemical bond structure containing similar chemical raw material similar to the straw surface wax structure is added, then a small quantity of nano-material capable of achieving pitting on the wax surface under the condition with the temperature being 90 DEG C or above is added, then an adhesive capable of forming a hydrogen bond or a chemical bond with a polyhydroxy structure is added, finally, uniform mixing is carried out through a physical method, and surface treatment is carried out. A plate prepared through the method is light, environment-friendly and free of harmful substance release, achieves high strength, fire resisting, sound insulation and dampproofness, is level and unified and attractive in texture and is a wood plate substitute article low in price and excellent in performance.

Owner:河南安朝板材科技有限公司

A cement brick production and demoulding device

ActiveCN109129837BAvoid demouldingQuality improvementDischarging arrangementMouldsBrickIndustrial design

The invention relates to the technical field of industrial design, and discloses a cement brick manufacturing and demoulding device. The cement brick manufacturing and demoulding device comprises a bottom plate, wherein sliding rods are respectively welded to four corners of the top of the bottom plate, limiting rings are respectively welded to the upper and lower ends of the outer surfaces of thesliding rods, a top plate is welded to the tops of the four sliding rods, a placing plate is placed in the middle of the top of the bottom plate, strip-shaped grooves which penetrate through in a transverse direction are respectively formed in both sides of the bottom of the placing plate, a demoulding auxiliary mechanism is arranged on the top of the top plate, cement brick forming mechanisms are arranged between the four sliding rods, a power actuating mechanism is arranged at the bottom of the top plate, and a demoulding actuating mechanism is arranged at the bottom of the power actuatingmechanism. According to the cement brick manufacturing and demoulding device, prefabticated members of cement bricks in forming holes are extruded by pressing rods and fall on the top of the placing plate, and the demoulding is realized in an extruding mode, so that the demoulding efficiency is improved, the damage rate of the cement bricks is reduced, the damage to the cement bricks due to demoulding in a vibration mode is avoided, and the production cost is reduced.

Owner:NANTONG HENGDA MACHINERY MFG

Automatic winding device and winding method for motor coil

ActiveCN109687660BAdjustable tightnessAvoid demouldingManufacturing dynamo-electric machinesWinding machineElectric machine

The invention relates to automatic winding equipment and a winding method for a motor coil, which are mainly used for winding the motor coil and aim to solve the problems of low winding efficiency andeasy error in the prior art. The invention provides a technical scheme that the automatic winding equipment and the winding method for the motor coil. The automatic winding equipment for the motor coil comprises a coil frame, a wire feeding mechanism, a frame, a clamping and breaking mechanism and a winding mechanism; the winding mechanism comprises a winding device for clamping and winding copper wires, and a winding die fixing device for clamping and rotating the winding die; the winding device comprises a winding mechanical arm, a rotating wheel, a lifting module and a translation module;the winding die fixing device comprises a rotating motor, a bearing, a second rotating connecting component, a coil sleeve and a locking mechanism. According to the automatic winding equipment and thewinding method for the motor coil, winding is carried out by utilizing the lifting of the winding mechanical arm in the winding device and the rotary reciprocating of the winding die fixing device, so that the winding step is simplified into two single reciprocating processes, and the production efficiency is effectively improved.

Owner:ZHEJIANG JEAMO MOTOR

Mould with high stable performance for producing mobile phone shell

The invention relates to the technical field of processing of mobile phone shells, and discloses a mould with high stable performance for producing a mobile phone shell. The mould with the high stableperformance for producing the mobile phone shell comprises a bottom plate, a placement groove is formed in the bottom plate, and clamping grooves are formed in the two sides of the placement groove.Two supporting rods are fixedly installed on the upper surface of the bottom plate, the top ends of the two supporting rods are fixedly connected with the lower surface of a top plate, and a hydrauliccylinder is fixedly installed on the lower surface of the top plate. According to the mould with the high stable performance for producing the mobile phone shell, by arranging a moving rod, a reset spring, a clamping rod and a clamping groove, the moving rod is pulled, so that the clamping rod moves inside the clamping groove, the clamping rod can extend outside a processing mould body or be stored inside the processing mould body, so that the clamping rod is extended into the clamping groove, the fixation of the processing mould body is completed, the phenomenon of demoulding of the processing mould body is avoided, thus the advantage of the high stability is achieved, and the problem of poor processing quality due to the fact that a material is prone to demoulding is solved.

Owner:苏州优熠精密机械有限公司

Demolding device for large-scale valve bush

The invention relates to the technical field of valve manufacturing, in particular to a demolding device for a large-scale valve bush. The demolding device for the large-scale valve bush comprises a machine frame, a first hydraulic oil cylinder, a second hydraulic oil cylinder and a mold supporting seat. The first hydraulic oil cylinder and the second hydraulic oil cylinder are fixed to the upper portion of the machine frame. A piston rod of the first hydraulic oil cylinder and a piston rod of the second hydraulic oil cylinder are connected with a connecting plate. A pressing plate is connected to the lower portion of the connecting plate. The mold supporting seat is arranged below the pressing plate. Rolling wheels are arranged on the lower portion of the mold supporting seat. Mold supporting blocks are arranged on the upper portion of the mold supporting seat. Compared with the prior art, the demolding device for the large-scale valve bush lifts a mold on the mold supporting seat in the manner that the two hydraulic oil cylinders drive the pressing plate to move and moves the mold to the position below the hydraulic oil cylinders through the rolling wheels, the hydraulic oil cylinders drive the pressing plate to move downwards to press the edge of the mold after the hydraulic oil cylinders are started, the mold can be separated from a rubber bush when the pressing plate continues to press the mold downwards, the situation that workers hit the mold to achieve demolding is avoided, and therefore the demolding device for the large-scale valve bush improves work efficiency.

Owner:TIANJIN HONGRUI RUBBER

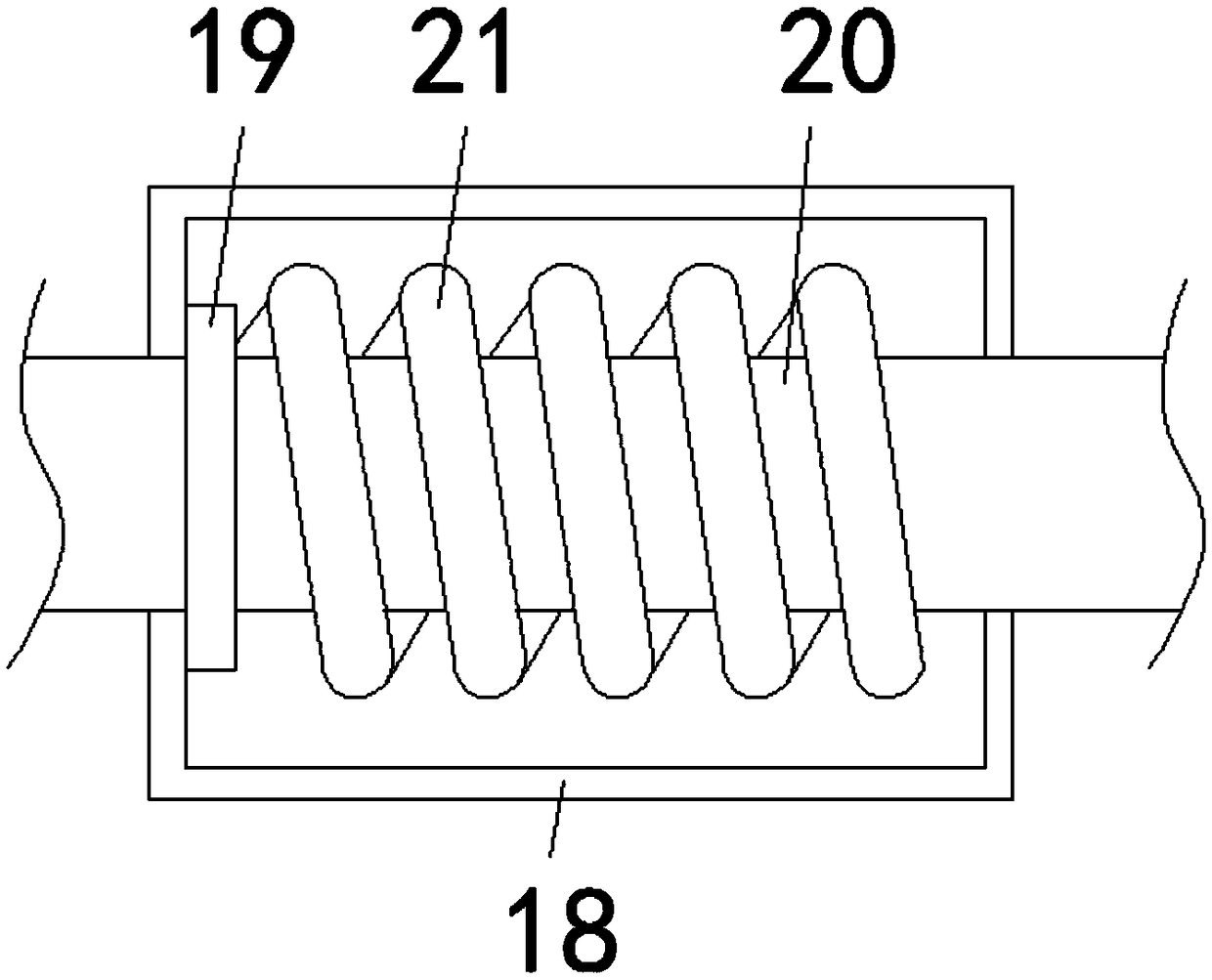

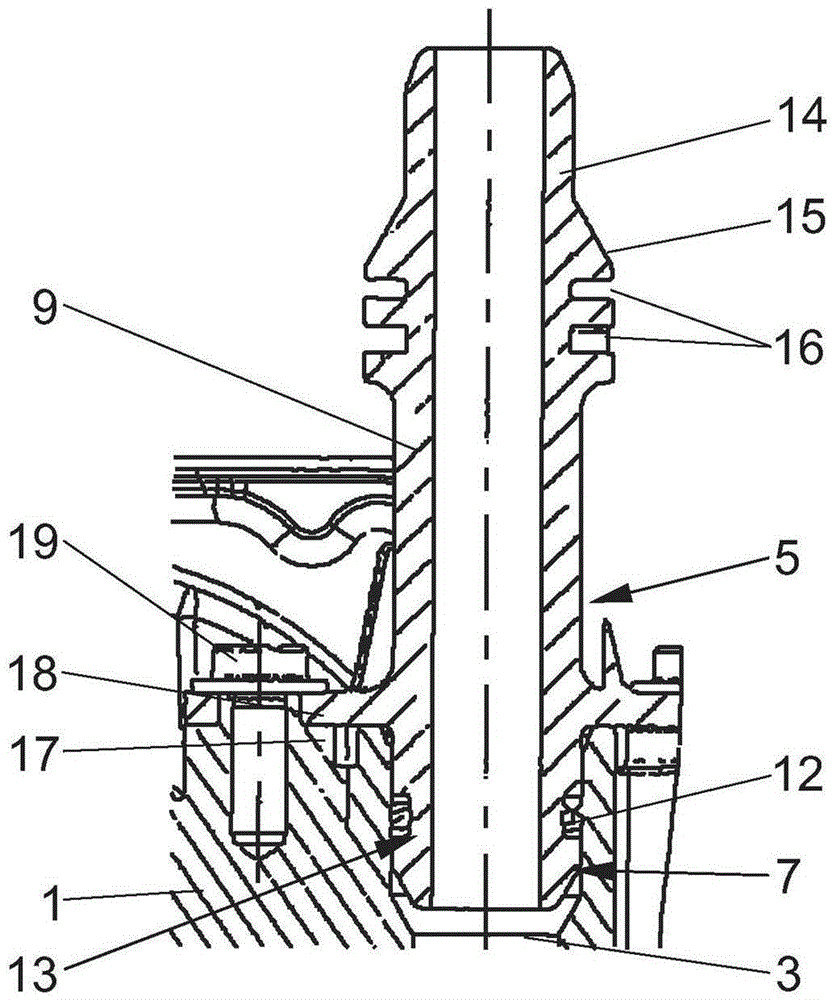

Heating/cooling device for a housing particularly for a throttle valve nozzle

InactiveCN104564309AImprove sealingEasy to installInternal combustion piston enginesValve members for heating/coolingCouplingPlastic materials

A heating / cooling device (2) for a sensor housing (1) a throttle valve housing of an internal combustion engine has a pipe (9) connected with the passage (3) of a leading medium, manufactured from a plastics material, and detachably fixed in the housing (1). The tube (9) axially prestress against the housing (1) and is sealed radially with respect to this. Further, the tube (9) has a part of a quick coupling device (11) connected with a leading medium line (10).

Owner:CONTINENTAL AUTOMOTIVE GMBH

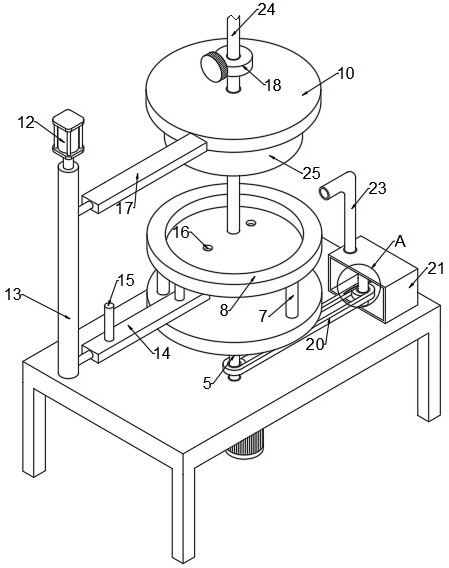

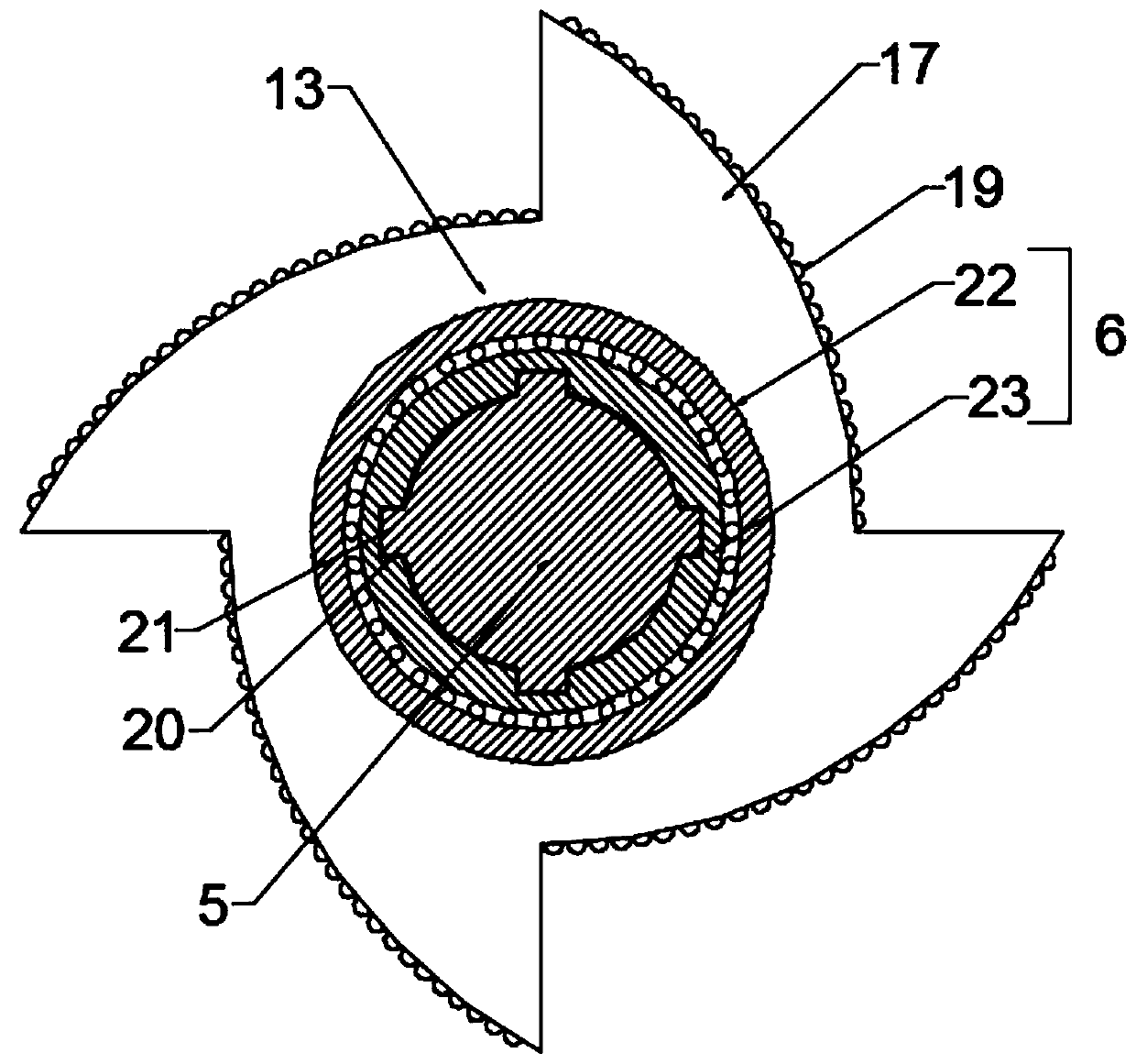

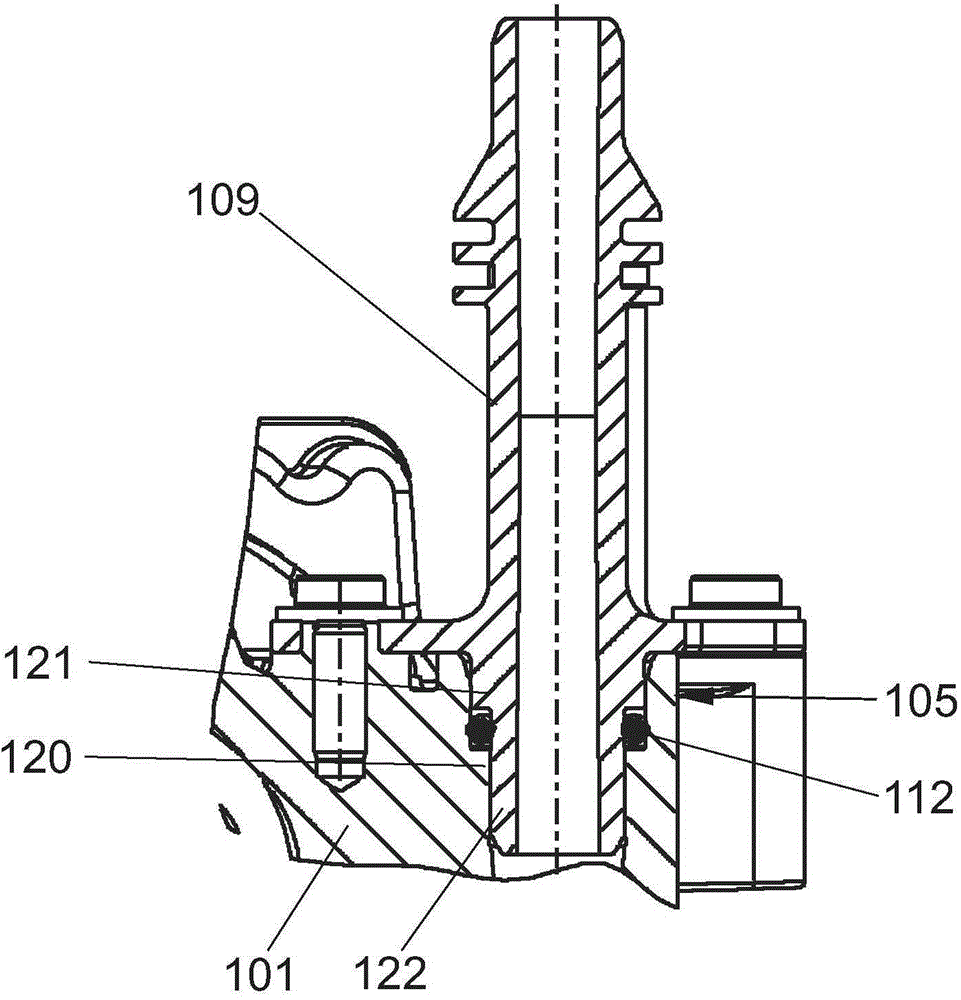

An aluminum alloy propeller cold forging device

ActiveCN110883291BIncrease push volumeLimit positionForging press drivesEngine componentsAir volumeTransmission belt

The invention relates to an aluminum alloy cold forging device, in particular to an aluminum alloy propeller cold forging device. The technical problem to be solved by the present invention is to provide an aluminum alloy propeller cold forging device. An aluminum alloy propeller cold forging device, including a mounting frame, a controller, a transmission belt mechanism, a micro motor, a step-stop mechanism, a blade bending mechanism and an electromagnetic pick-and-place mechanism; Welding; the left part of the bottom end of the installation frame is welded with the transmission belt mechanism. The invention achieves the bending of a single blade of a straight-blade aluminum alloy propeller, so that the blade undergoes a curve change, so that the curve of the blade conforms to a fluid structure, and at the same time increases the air intake of the blade and the propulsion of the propeller. At the same time, the position of the straight-blade aluminum alloy propeller is limited so that it is not easy to shift during twisting, preventing the straight-blade aluminum alloy propeller from being lost during the transfer process and causing injury to the operator.

Owner:西安拓力士航空技术有限公司

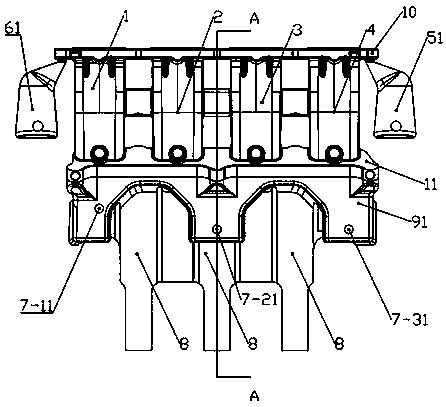

Combined type intake manifold aluminum alloy lower manifold casting blank and special mold thereof

PendingCN110899632AIncrease frictionAvoid the phenomenon that the riser cavity is cast out of the upper mold blankFoundry mouldsFoundry coresEngineeringMechanical engineering

The invention discloses a combined type intake manifold aluminum alloy lower manifold casting blank and a special mold thereof, and belongs to the technical field of automobile engines. The problem that the weight of a casting riser end of the aluminum alloy intake lower manifold casting blank in the prior art is greater than the weight of a product end, which causes the riser end to first separate from an upper mold blank casting riser cavity, so that the product end is stuck in the mold, the ejection is unbalanced, the demolding is difficult, the product end is injured, the production efficiency is low and the rejection rate is high is overcome. The combined type intake manifold aluminum alloy lower manifold casting blank is characterized in that a first riser holding column, a second riser holding column and a third riser holding column are arranged on the blank casting riser, and a first riser holding column cavity, a second riser holding column cavity and a third riser holding column cavity are arranged on an upper mold. The combined type intake manifold aluminum alloy lower manifold casting blank has the beneficial effects that the three riser holding columns penetrate into the riser holding column cavities of the upper mold, the friction forces between the casting blank risers and the mold cavities are increased, the phenomenon that the riser end first separates from thecasting riser cavities is overcome, and the purpose of ejecting balance of the aluminum alloy lower manifold casting blank is achieved.

Owner:沈阳航天新光汽车零部件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com