Automatic production line for heating and forming of novel krah pipe

An automatic assembly line and heating forming technology, which is applied to tubular objects, other household appliances, household appliances, etc., can solve the problems of production inefficiency, large gas consumption, and waste gas generation, and achieve the goals of improving production efficiency, reducing waste gas, and saving energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further described now in conjunction with accompanying drawing:

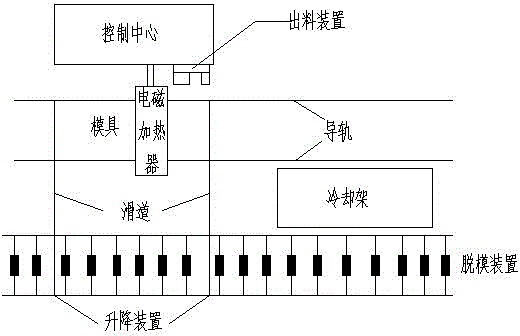

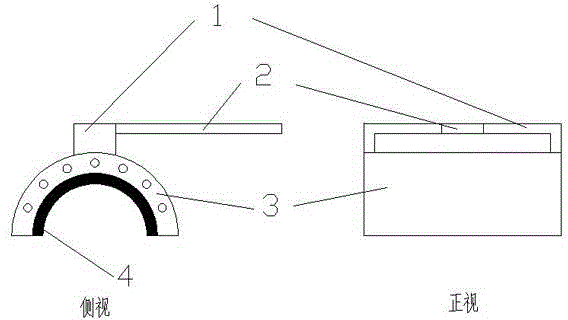

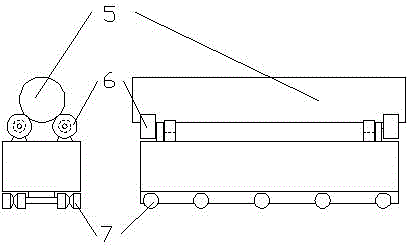

[0022] A new type of automatic assembly line for carat tube electromagnetic heating molding, including a control center, a heating system, a discharge device, a mold support frame 12, a cooling frame and a demoulding device 10, and the length of the mold support frame 12 is twice as long as the mold. 2.5 times the guide rail, the main body structure of the mold support frame is a box structure, and two rollers 6 with centers of circles located on the same horizontal plane are arranged at both ends of the support frame body, and the rollers are driven by the motor under the mold support frame 12 through a conveyor belt. The lower end of the support frame is provided with a pulley 7 that can slide along the guide rail. The entire mold supporting frame 12 will move to the right along the guide rail at a constant speed during the processing. Both ends of the mold supporting fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com