A rotary stamping die ejection mechanism

A technology of stamping die and ejector mechanism, applied in the field of rotary stamping die ejector mechanism, can solve the problems of high wear rate, short life, high power consumption, etc., and achieve the effects of long life, low noise and power reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

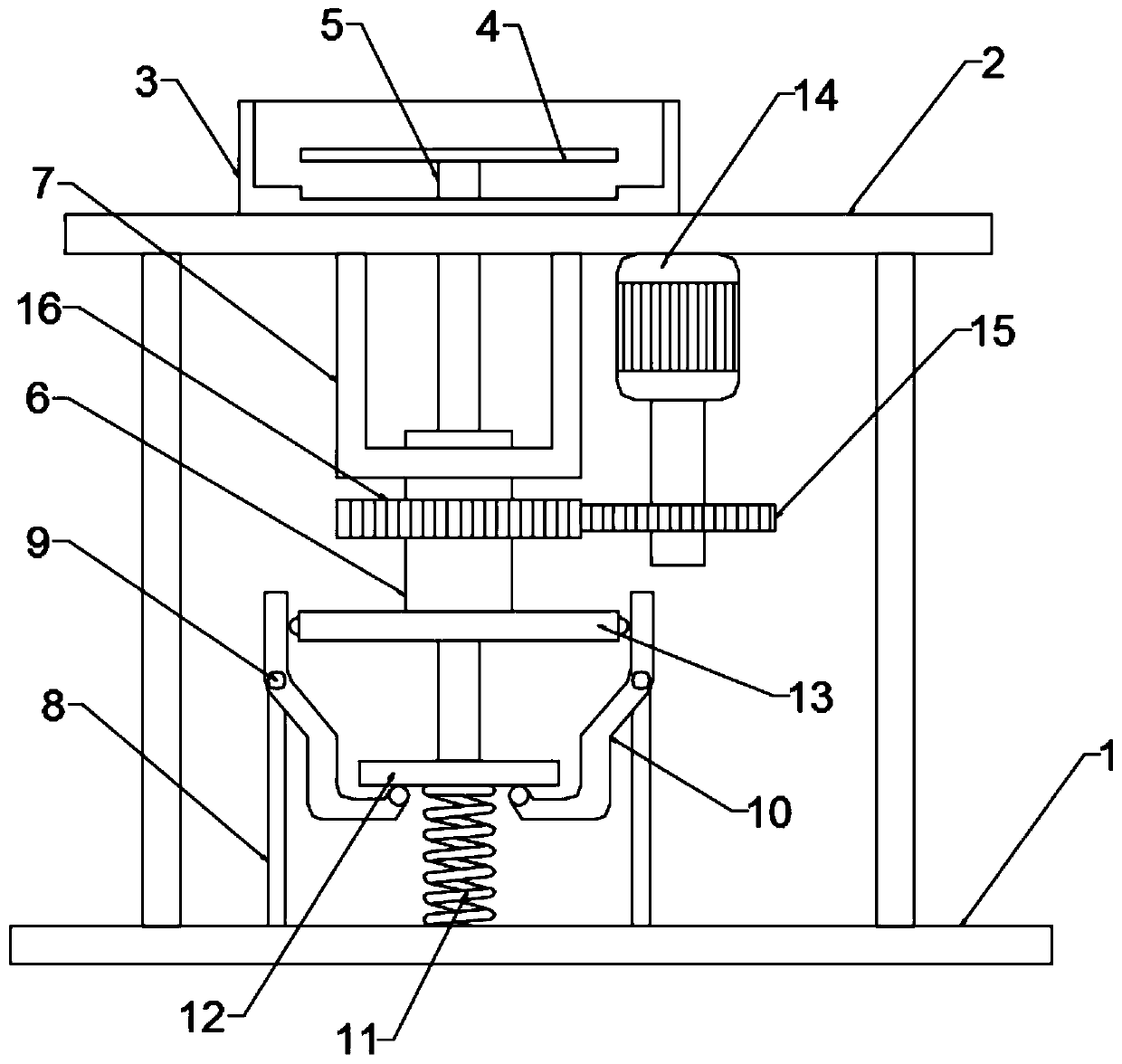

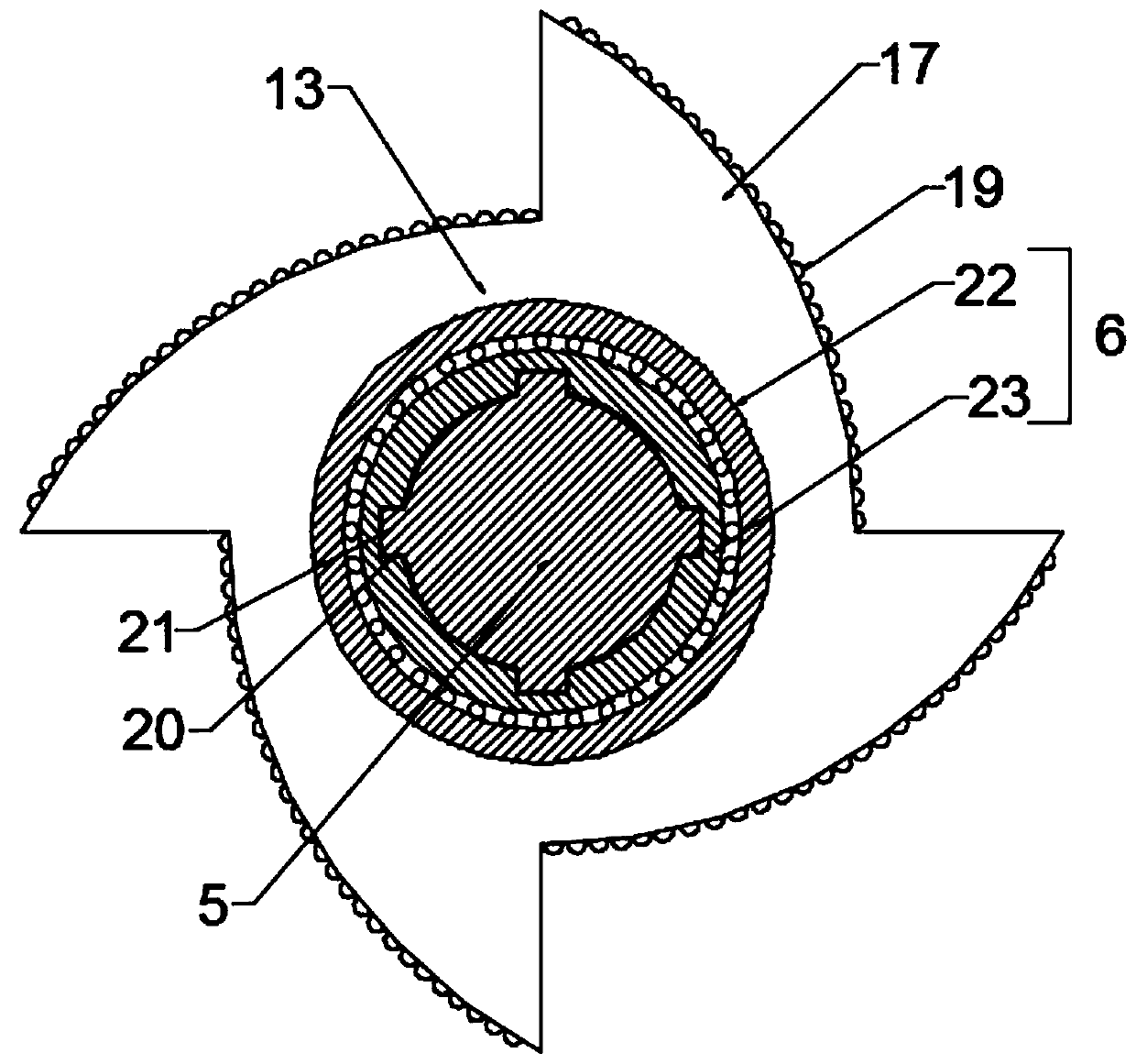

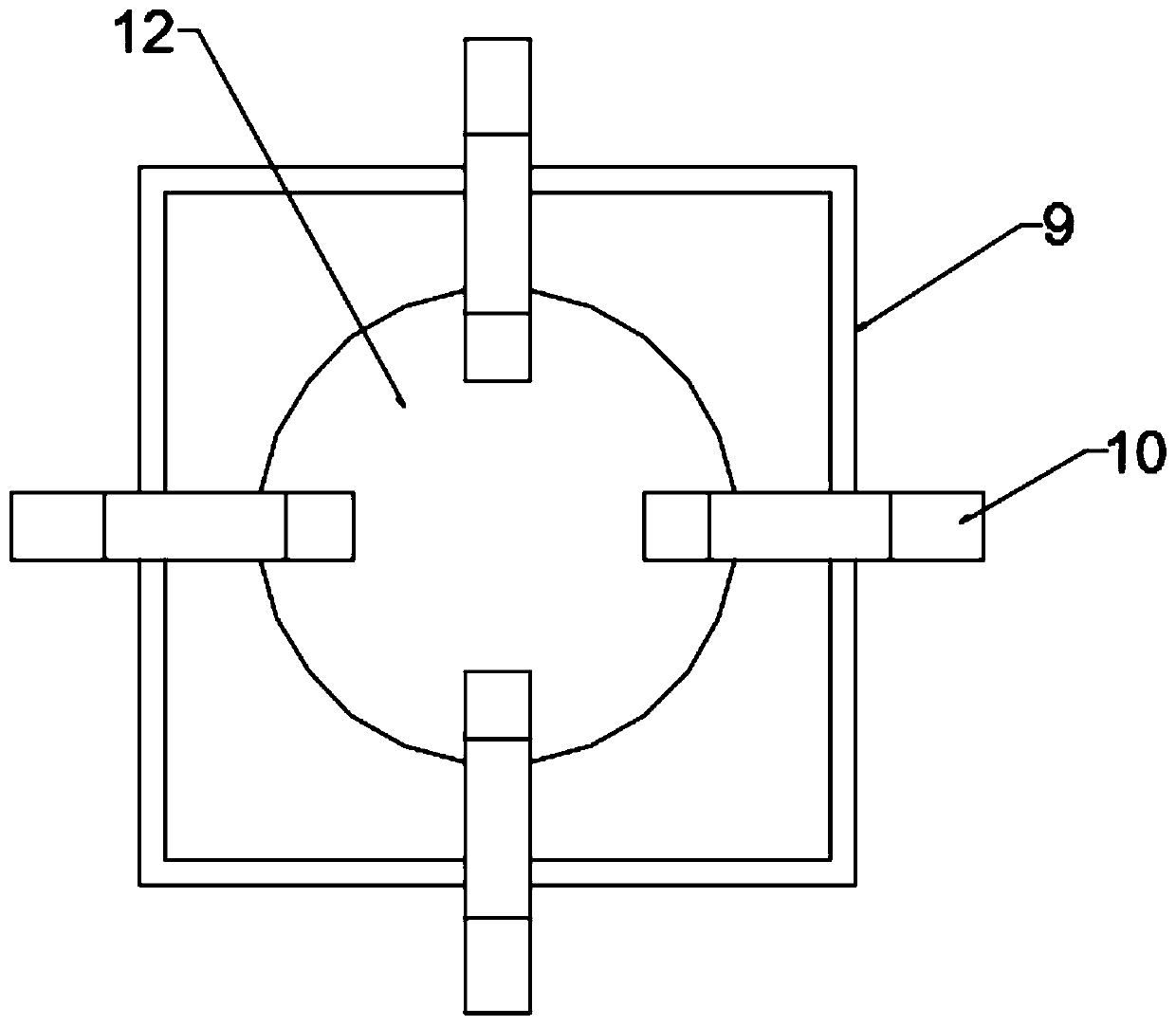

[0020] see Figure 1~3 , in an embodiment of the present invention, a rotary stamping die ejection mechanism includes a base substrate 1, a mold frame 2, a lower mold 3, and a push rod 5 for ejecting the mold, and the mold frame 2 is installed and fixed on the base substrate 1 The upper and lower molds 3 are installed on the upper side of the mold frame 2, and the upper end of the push rod 5 is inserted through the bottom into the inside of the lower mold 3, and the top of the push rod 5 is fixed with a demoulding push plate 4 located in the lower mold 3, and the mold frame 2 A power mechanism for pushing the ejector rod 5 to move vertically is installed on the inside of the inner side, and the power mechanism includes a rotating cylinder 6, a rotating push plate 13, a demoulding motor 14 and four rings arranged around the pushing rod 5 as the center. Toggle the push rod 10, the rotating cylinder 6 is sleeved on the outside of the push rod 5 and the outer wall of the rotating ...

Embodiment 2

[0023] The difference between the present embodiment and the first embodiment is that a plurality of anti-friction balls 19 are installed on the arc-shaped side wall of the arc-shaped pushing part 17 to reduce the friction with the upper end of the push rod 10 wear and tear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com