Combined type intake manifold aluminum alloy lower manifold casting blank and special mold thereof

A technology of intake manifold and casting blank, which is applied in the field of combined intake manifold aluminum alloy lower manifold casting blank and its special mold, which can solve problems such as unbalanced ejection and product end sticking, and increase friction force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

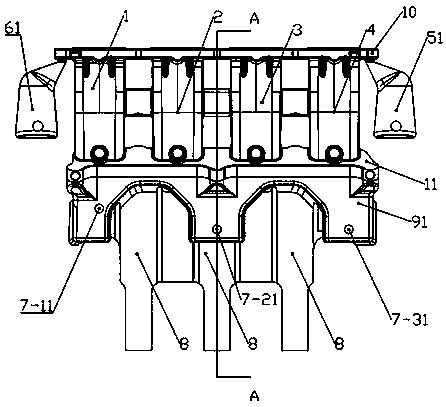

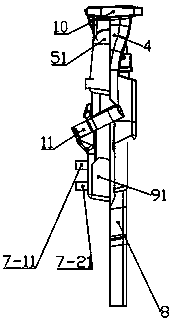

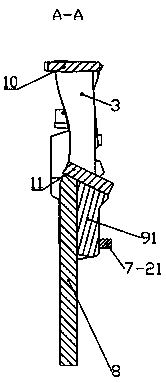

[0046] Such as figure 1 figure 2 and image 3 As shown, the technical scheme adopted by the aluminum alloy lower manifold casting blank of the combined intake manifold of the present invention includes a cylinder head connecting flange 11, and three blank casting runners are arranged under the cylinder head connecting flange 11 8. In front of the three blank casting runners 8 below the cylinder head connecting flange 11, there is an inverted mountain-shaped blank casting riser 91, and a first inverted mountain-shaped blank casting riser 91 is respectively provided. The riser holding column 7-11, the second riser holding column 7-21 and the third riser holding column 7-31 are provided on the cylinder head connecting flange 11 to connect with the cylinder head connecting flange 11. The first airway 1, the second airway 2, the third airway 3 and the fourth airway 4, in the first airway 1, the second airway 2, the third airway 3 and the fourth airway 4 A butt flange 10 for con...

specific Embodiment approach 2

[0050] Such as Figure 4 , Figure 5 , Figure 6 and Figure 8 As shown, the aluminum alloy lower manifold casting blank special mold for the combined intake manifold of the present invention includes a lower mold fixing plate 18, and a lower mold ejection mechanism 19 is installed on the lower mold fixing plate 18, so that The lower mold ejector mechanism 19 includes a lower ejector plate 19-1, on which several lower ejector pins 19-2 are installed, and a lower mold ejector mechanism connecting plate is installed in the middle of the lower ejector plate 19-1 19-3, the lower die 17 is installed on the upper surface of the lower die fixing plate 18, and the right blank riser of the lower die is provided on the lower die 17 corresponding to the right blank riser 51 and the left blank riser 61 The die cavity 53 and the blank riser die cavity 63 on the left side of the lower die are provided with a sprue cup 16 below the corresponding upper die sprue 15 on the lower die 17 .

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com