Heating/cooling device for a housing particularly for a throttle valve nozzle

A technology for cooling devices and throttle valves, applied in valve heating/cooling devices, fuel heat treatment devices, valve devices, etc., can solve the problems of heavy hose weight and high production cost, and achieve simplified installation and improved sealing reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

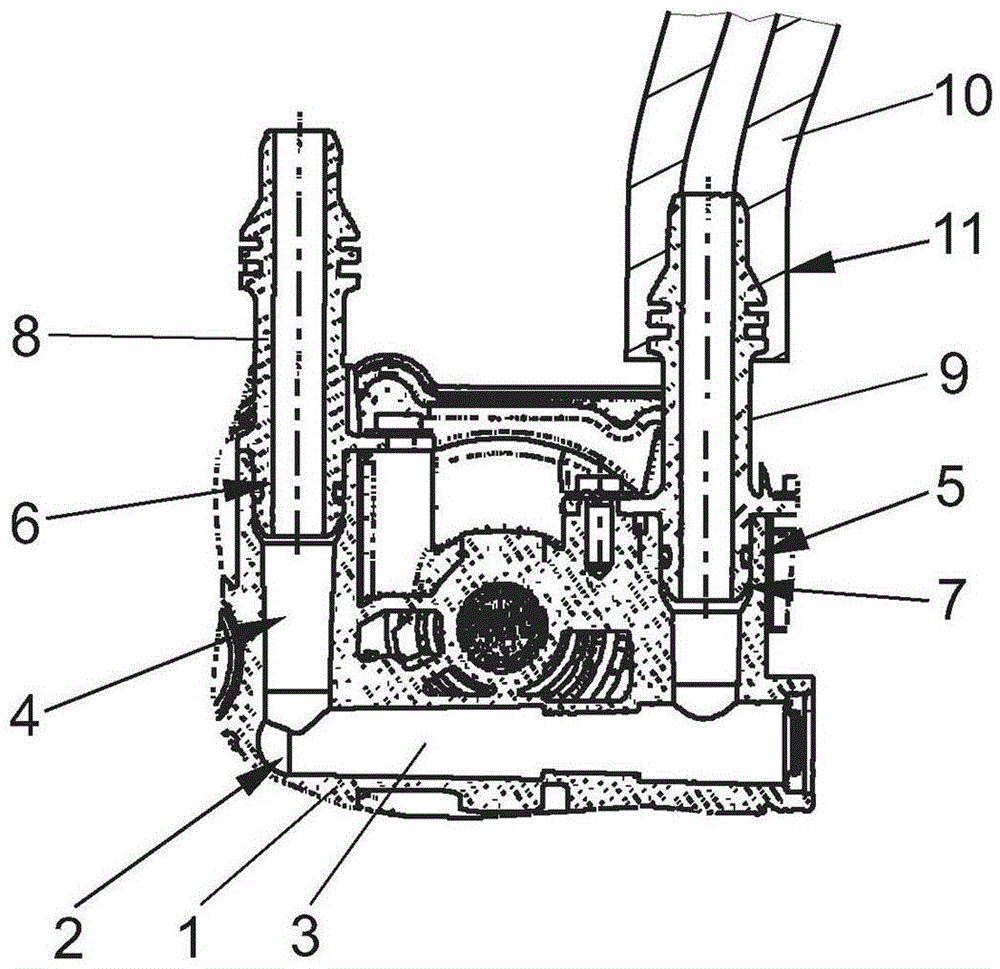

[0018] figure 1 The housing 1 of a throttle bushing of a motor vehicle internal combustion engine is shown. The housing 1 is designed as a sensor housing of a generally known drive of a throttle valve (not shown in detail) and has a heating / cooling device 2 with a channel 3 . The channel 3 is situated between the two connections 4 , 5 and serves for the passage of a heating or cooling medium for heating or cooling the housing 1 . The housing 1 has a receptacle 6 , 7 for each tube 8 , 9 . On one of the pipes 9 , for example a medium-carrying hose 10 is connected by means of a quick coupling 11 .

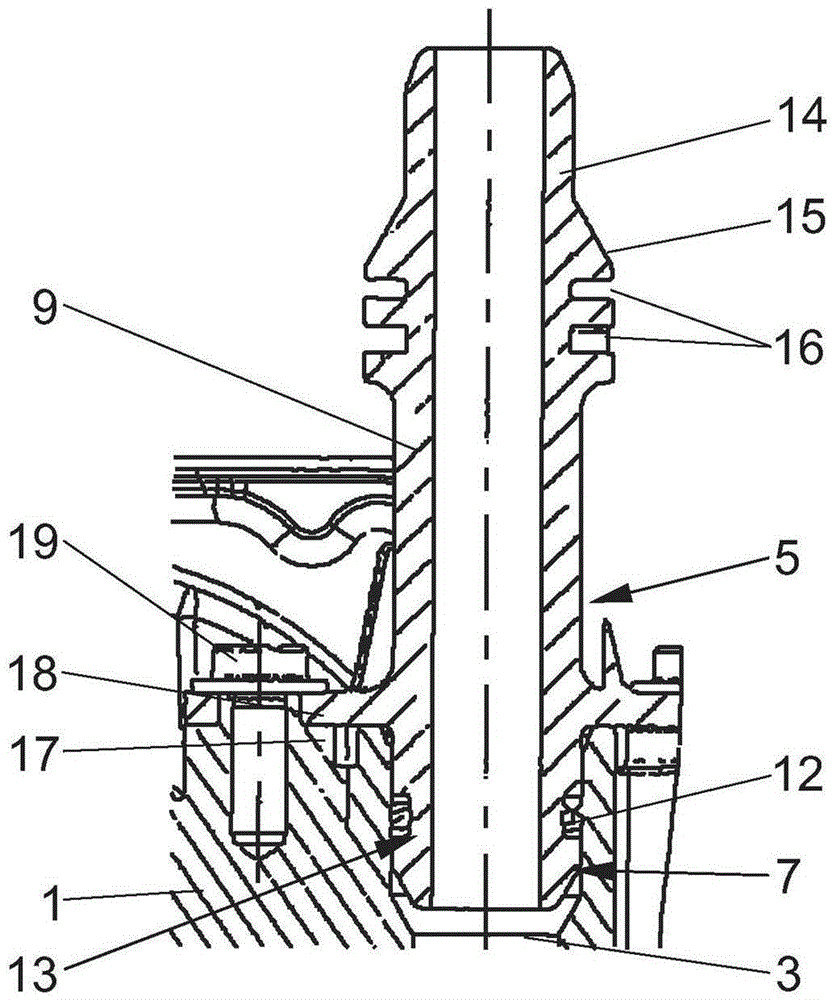

[0019] figure 2 greatly magnified showing the figure 1 Interface 5 in . It should be noted here that the tube 9 in the receptacle 7 is sealed by means of the sealing element 12 . The sealing element 12 is designed as a radially sealing O-ring and is arranged in a circumferential groove 13 of the tube 9 . The part of the tube 9 which protrudes beyond the housing 1 has a connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com