Patents

Literature

72results about How to "Reduce crushing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

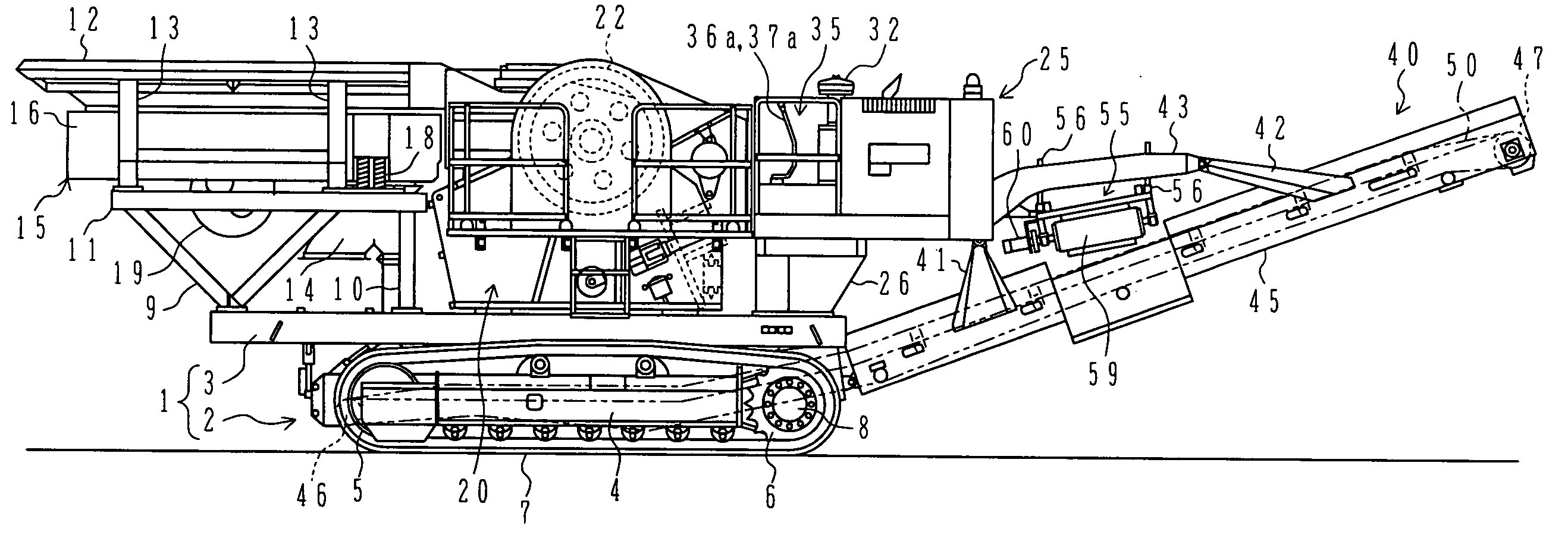

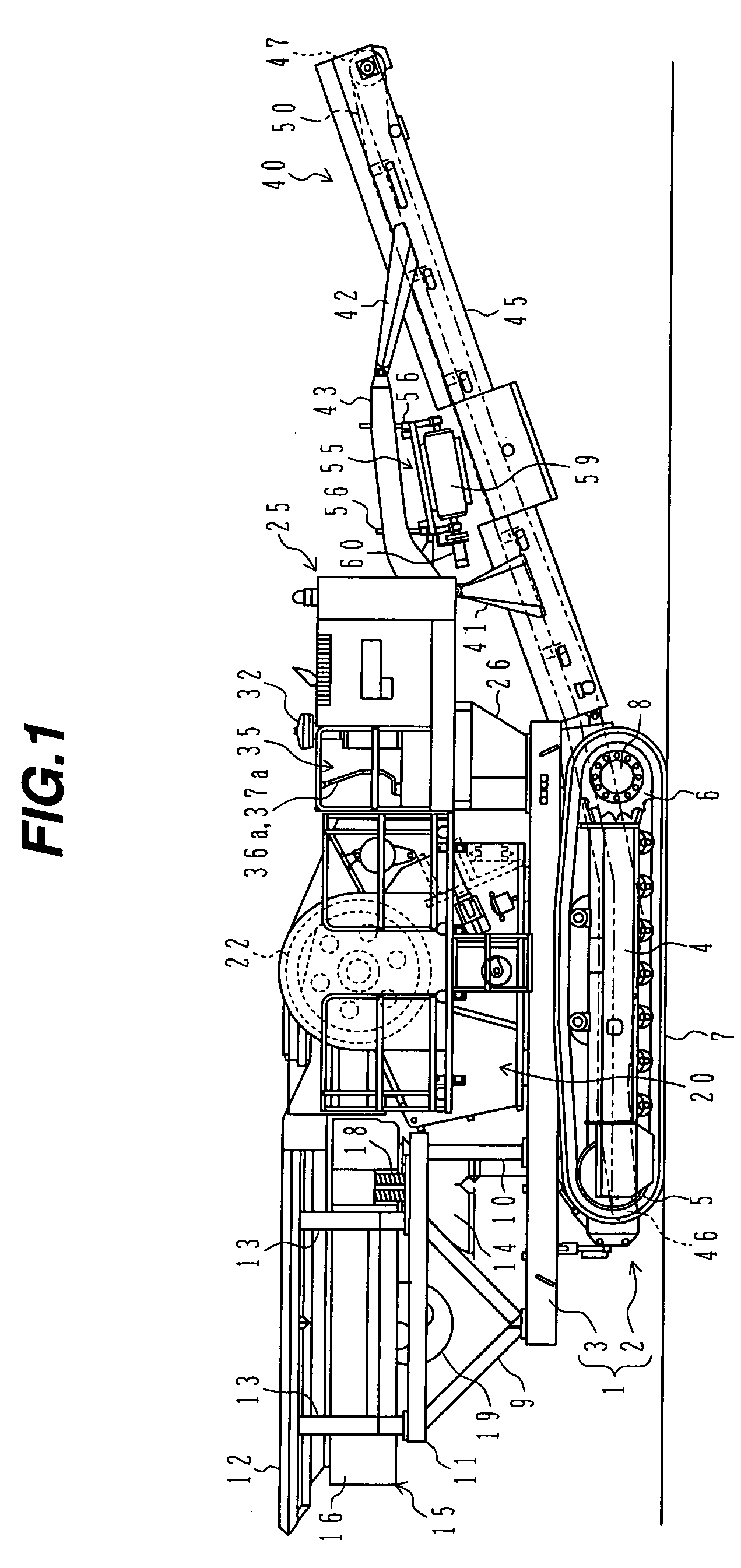

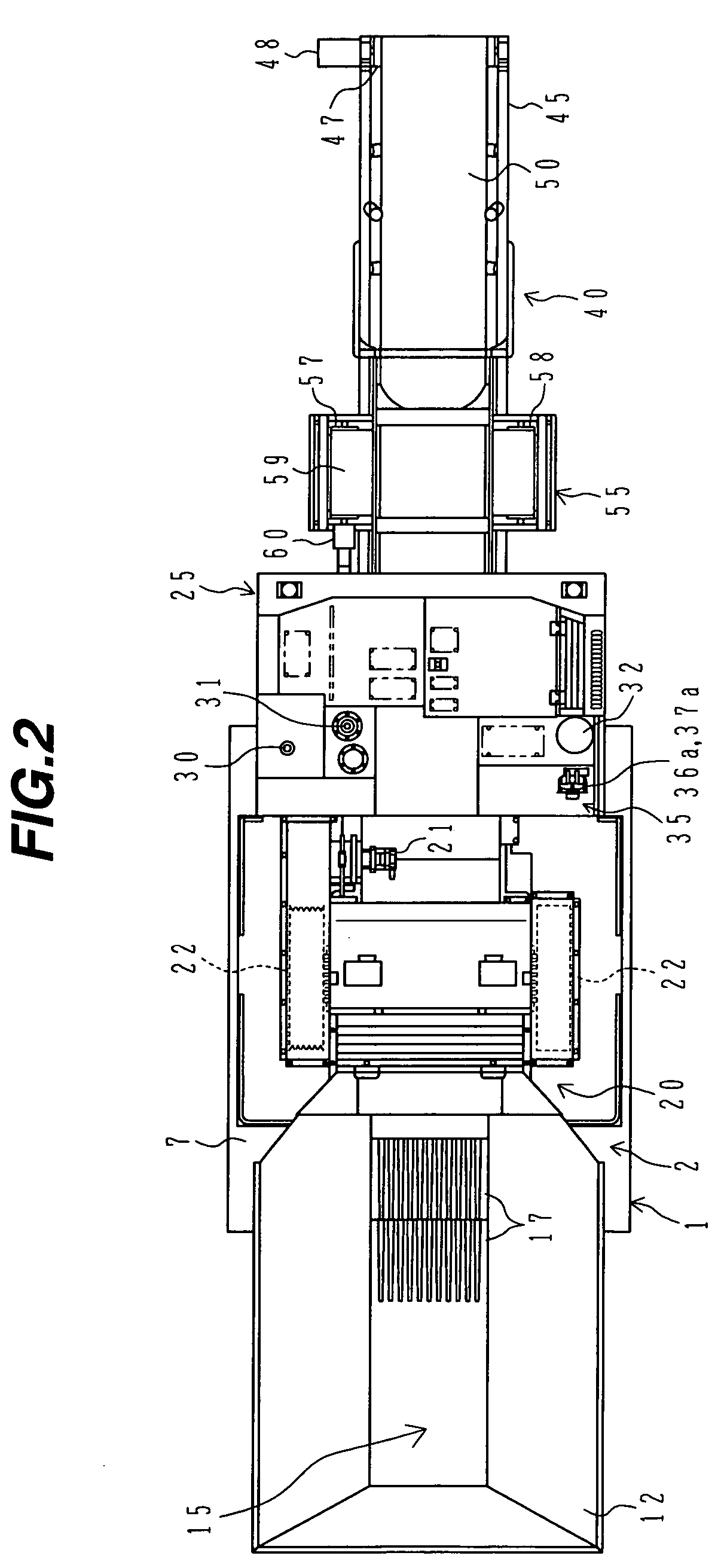

Self-propelling crusher

InactiveUS20050173570A1Reduce crushing efficiencyIncrease speedMowersMulti-purpose machinesEngineeringHydraulic pump

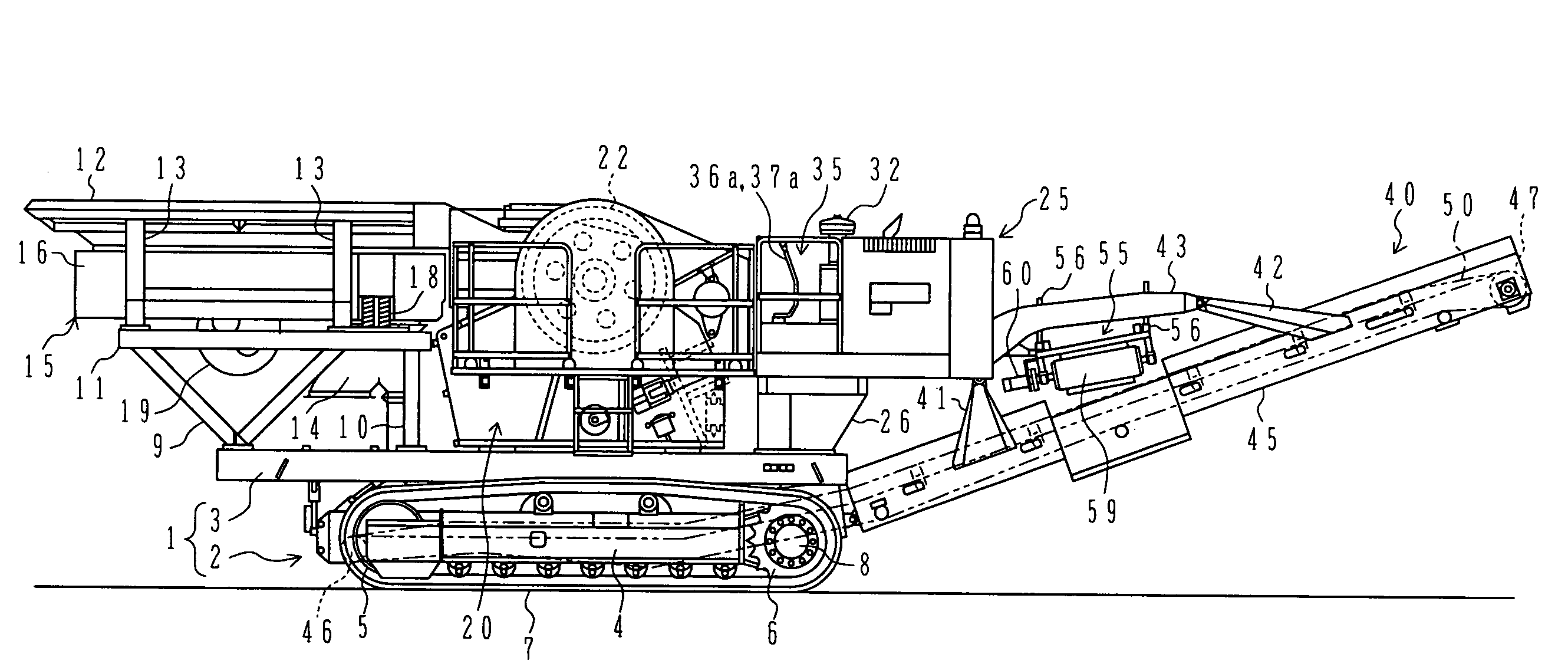

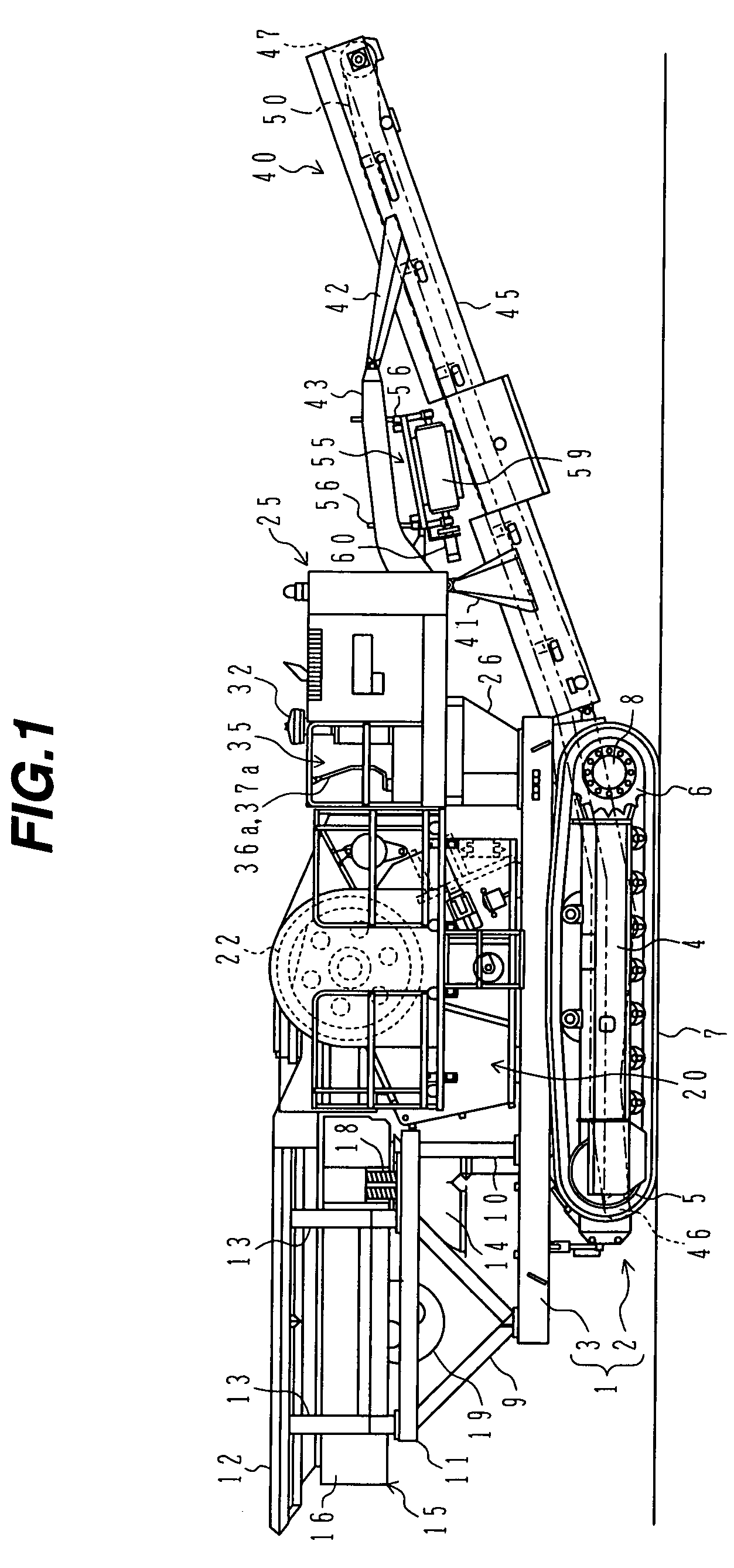

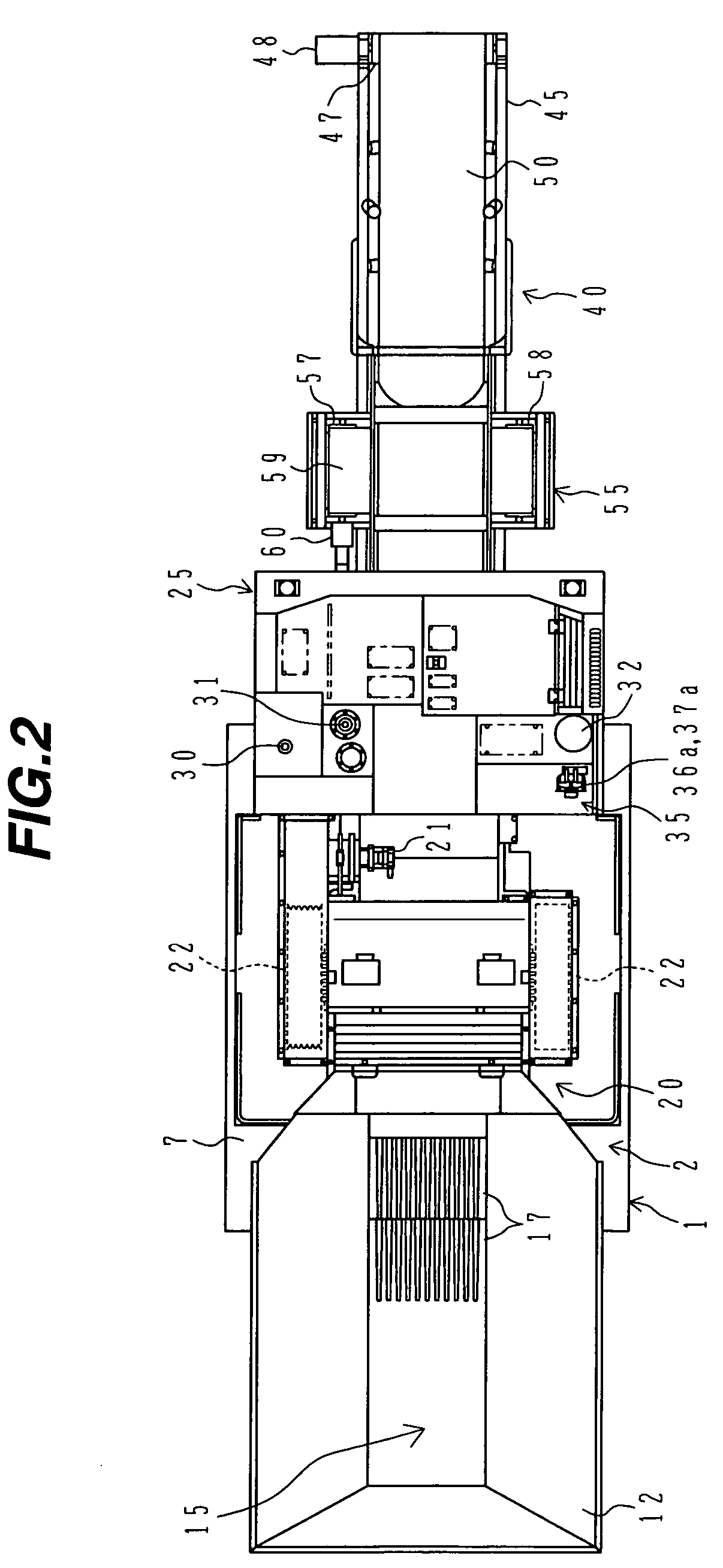

A self-propelled crushing machine comprises a crushing device 20; a hydraulic drive system including a crushing device hydraulic motor 21 for driving the crushing device 20, a first hydraulic pump 62 for driving the crushing device hydraulic motor 21, and an engine 61 for driving the first hydraulic pump 62; a pressure sensor 151 for detecting a load condition of the crushing device 20; and a controller 84″ for executing control to increase a revolution speed of the engine61 in accordance with a detected signal from the pressure sensor 151. Accordingly, even when a heavy load is imposed on the crushing device, a reduction of crushing efficiency can be prevented.

Owner:HITACHI CONSTR MASCH CO LTD

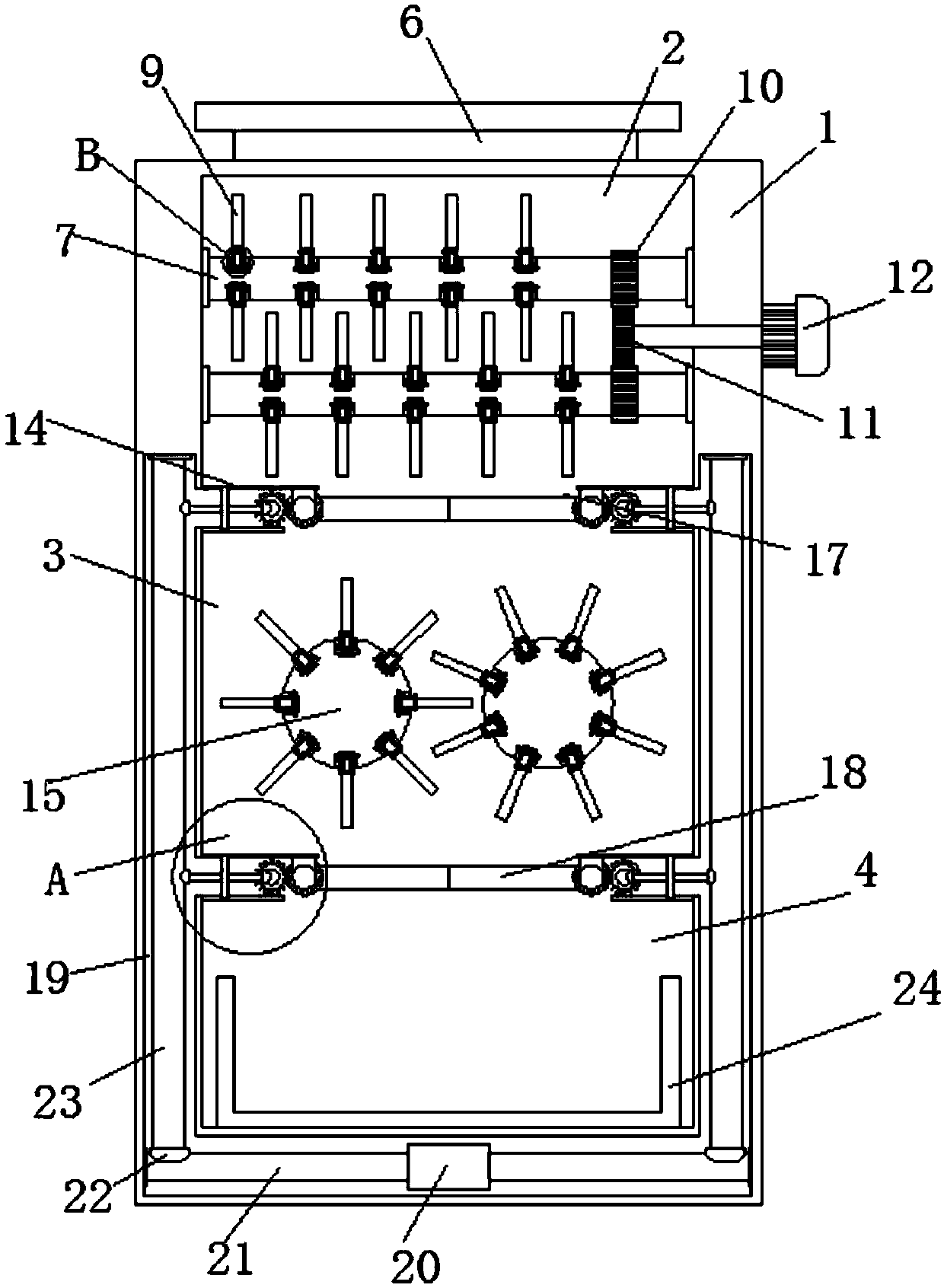

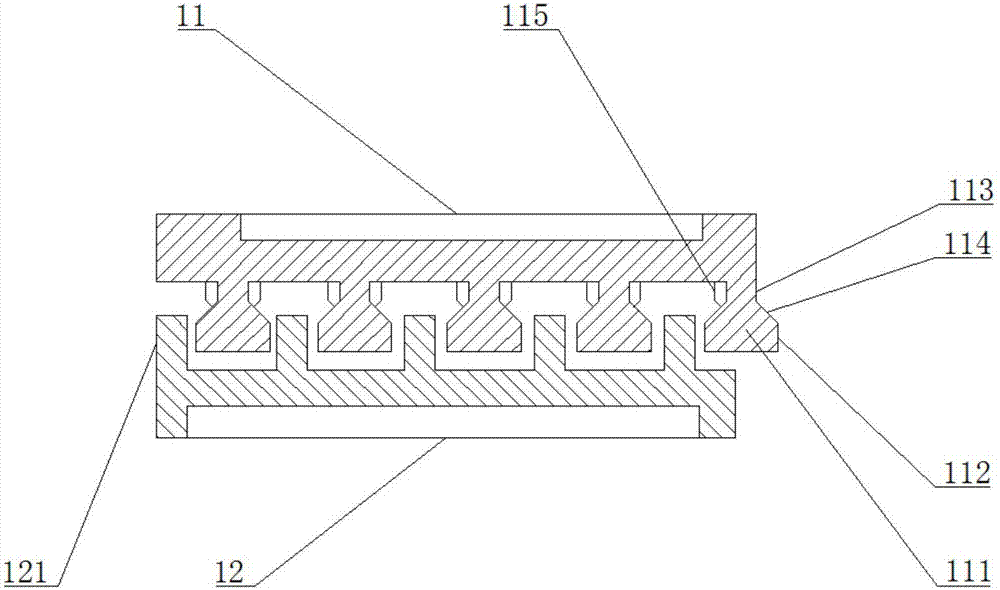

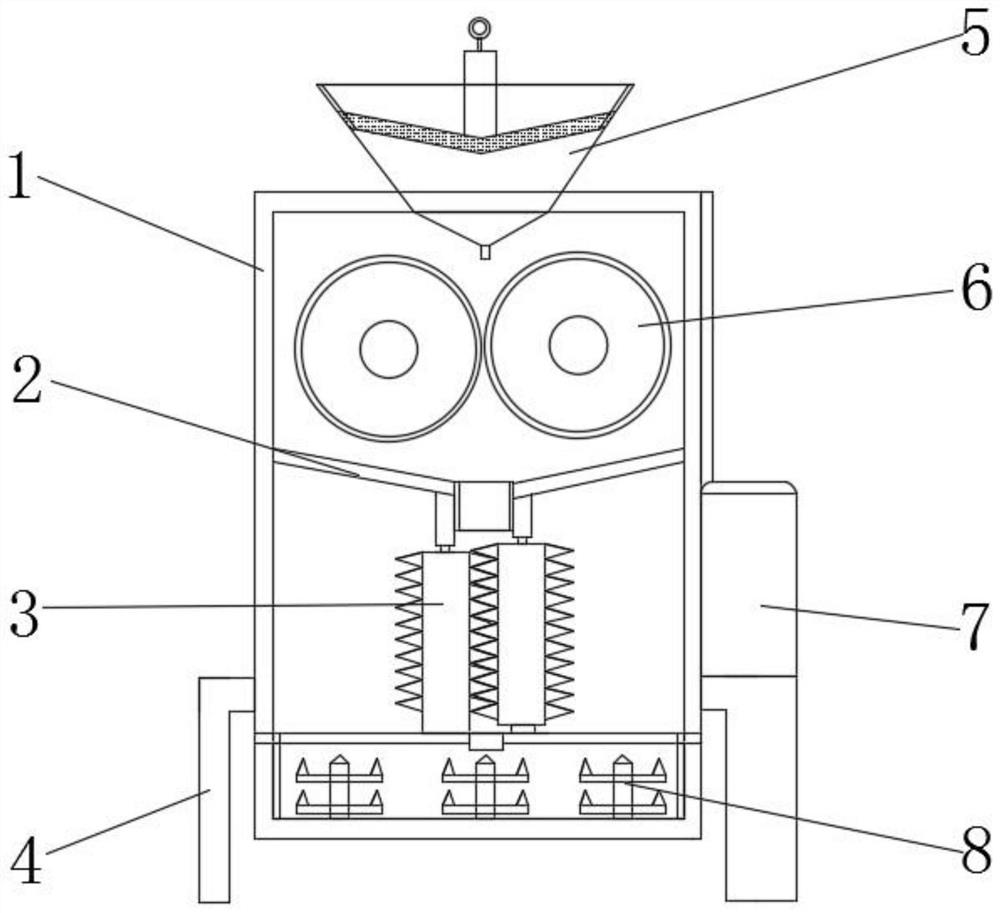

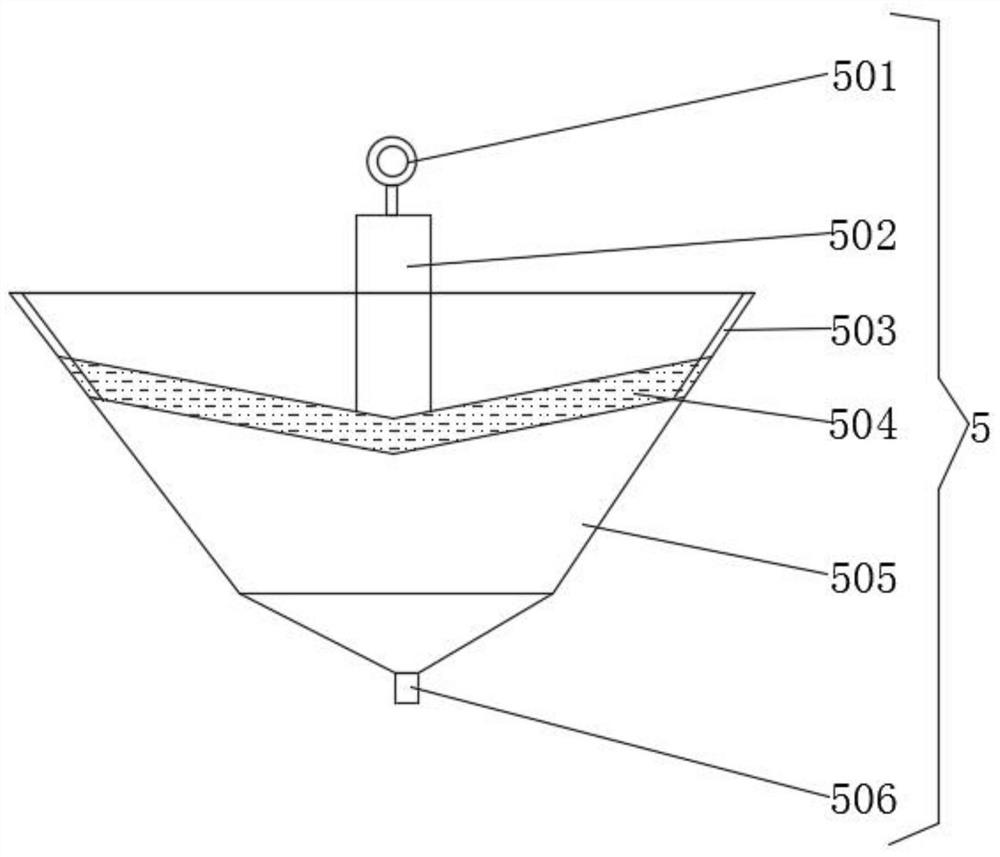

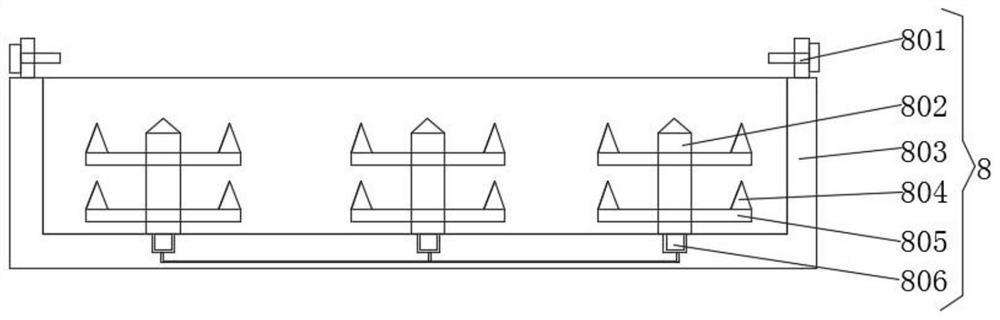

Plastic product recycling machine

InactiveCN108015927ACompletely brokenReduce recycling efficiencyPlastic recyclingGrain treatmentsEngineeringPlastic recycling

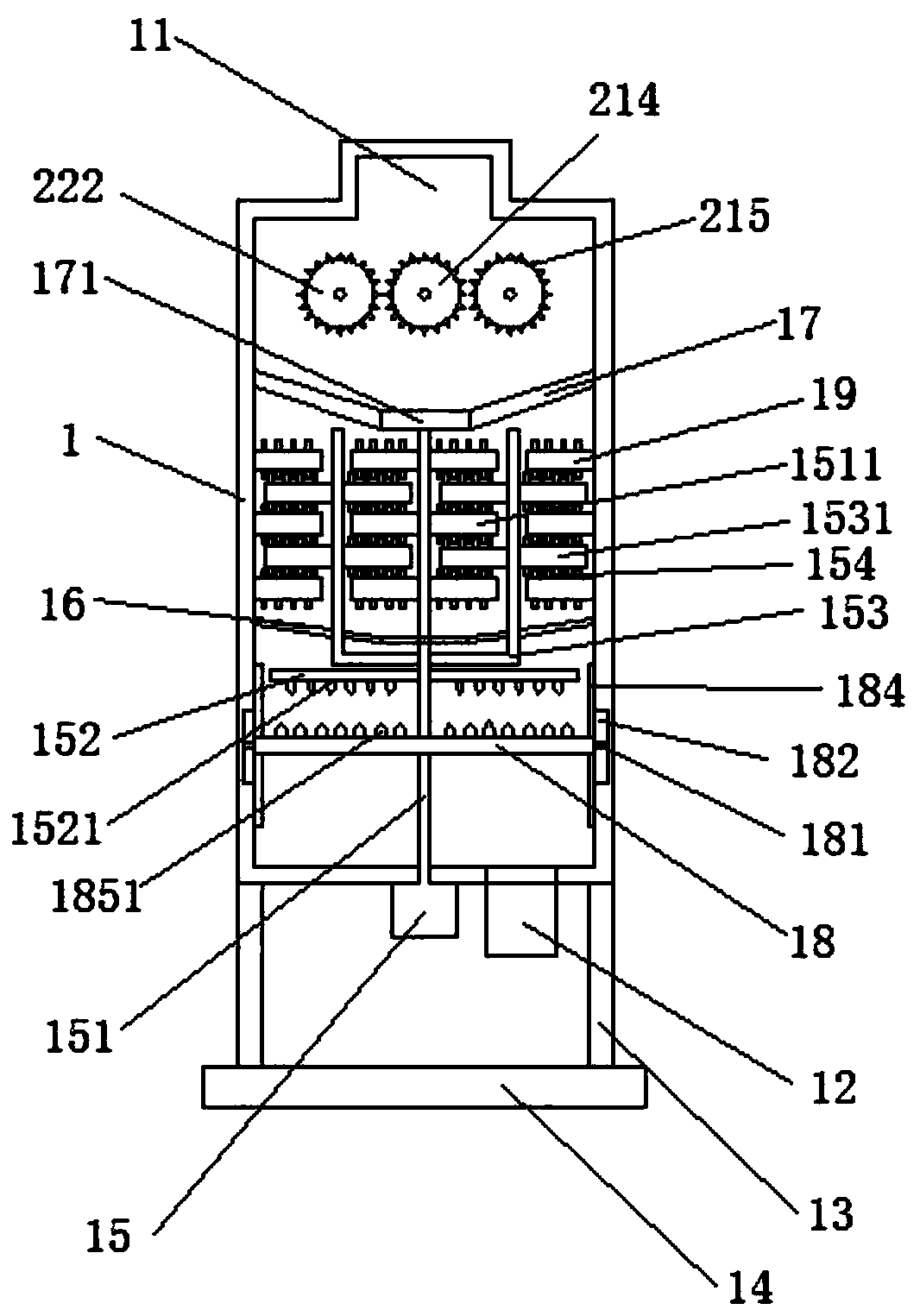

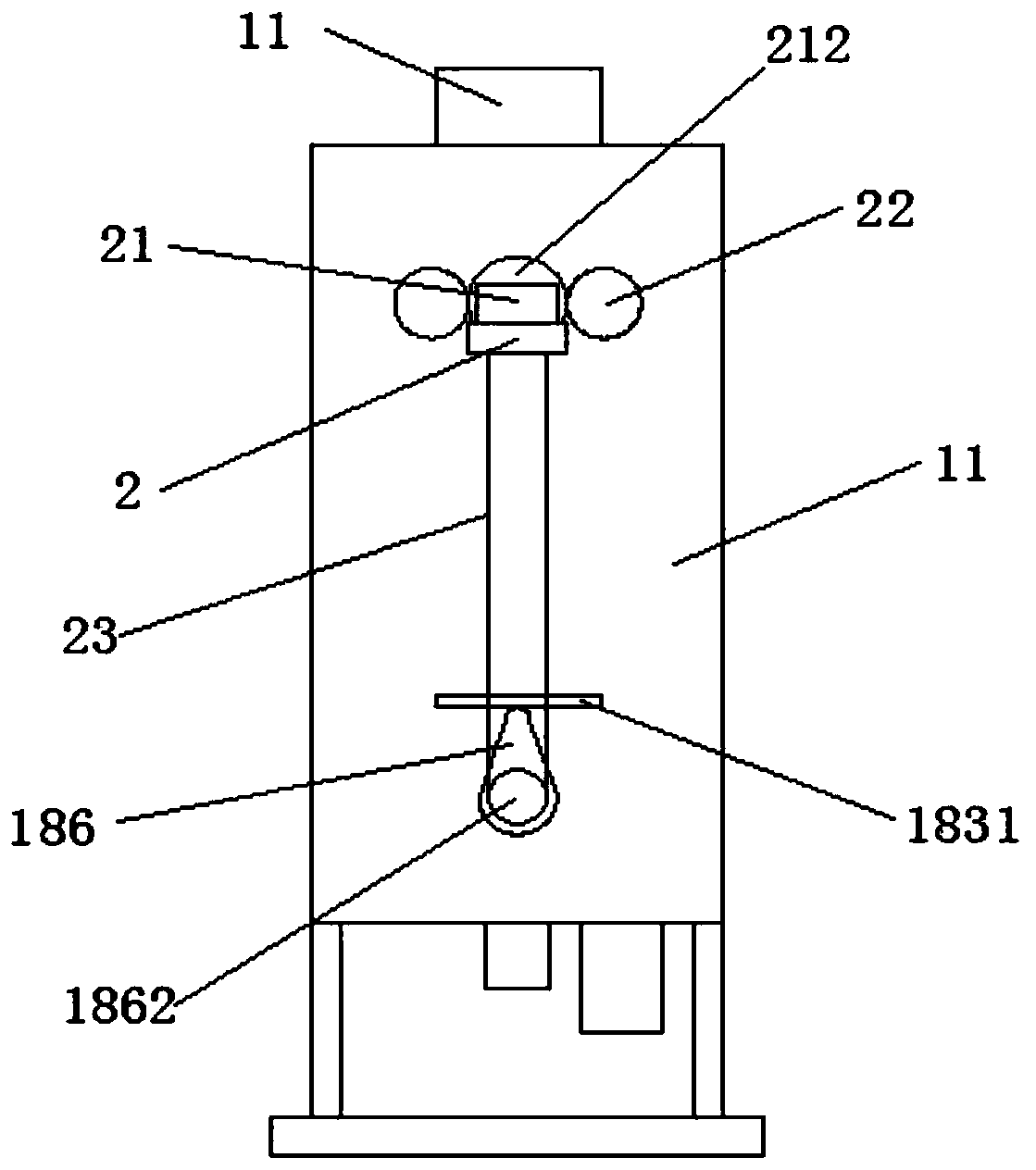

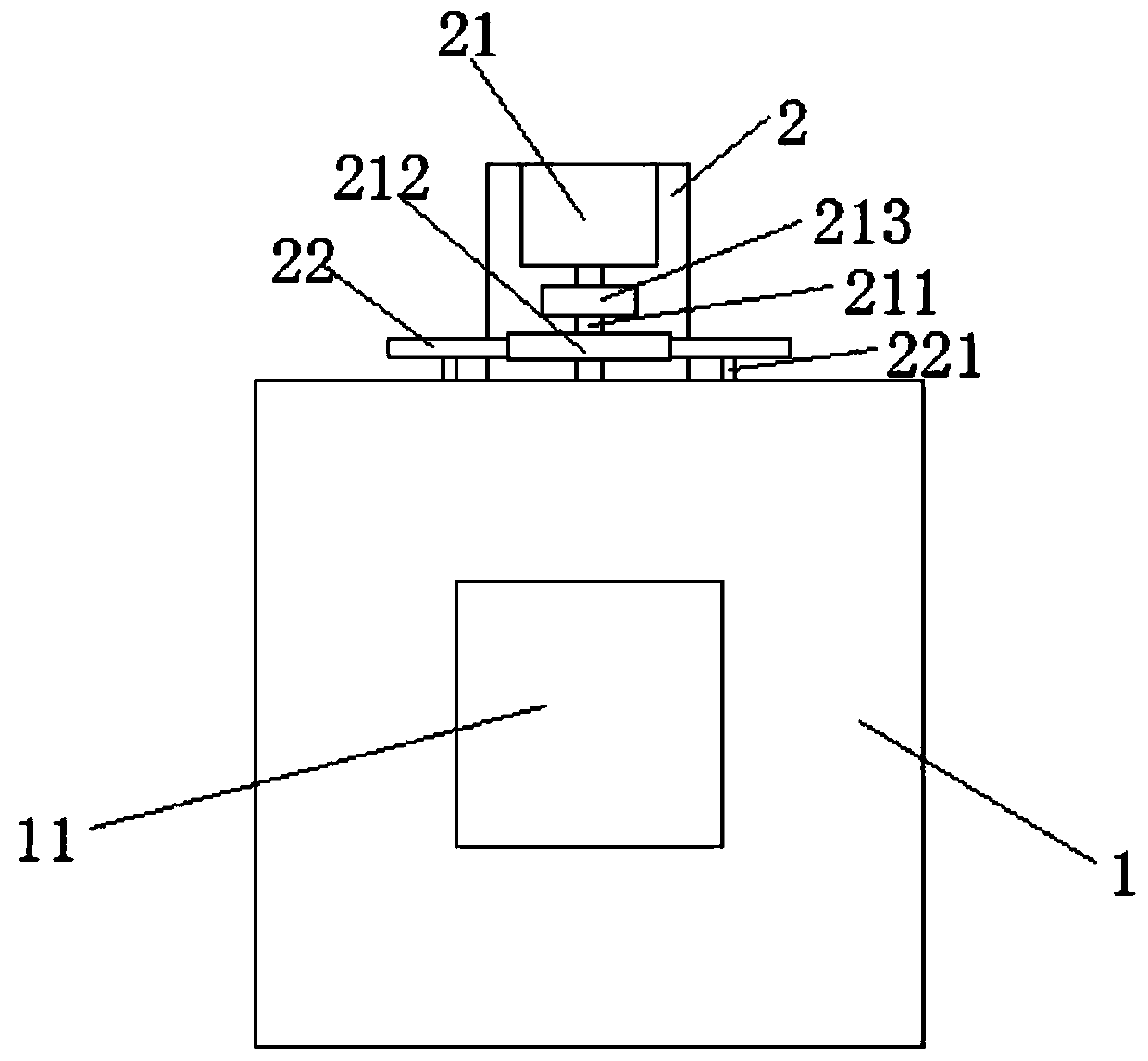

The invention discloses a plastic product recycling machine. The plastic product recycling machine comprises a shell, wherein the shell is of a hollow structure; the interior of the shell is divided into a first crushing cavity, a second crushing cavity and a collecting cavity through two partition plates which are arranged in parallel; discharge ports are formed in the partition plates; the firstcrushing cavity, the second crushing cavity and the collecting cavity communicate with one another through the discharge ports; two first rotating rollers which are arranged in parallel are connectedin the first crushing cavity in a rotating mode; and a plurality of cutting blades are arranged on the two first rotating rollers and are arranged in a staggered mode. According to the plastic product recycling machine, waste plastic can be fully crushed so that the plastic can be crushed more thoroughly, the space, occupied by the plastic, of a collecting box can be decreased, and the phenomenonthat the collecting box is frequently replaced can be avoided; and meanwhile, the cutting blades on the rotating rollers can be conveniently replaced, and the phenomenon that the plastic recycling efficiency is reduced due to the fact that the crushing efficiency is influenced by blade passivation can be avoided.

Owner:YINGSHANG LONGYUYANG IND & TRADE

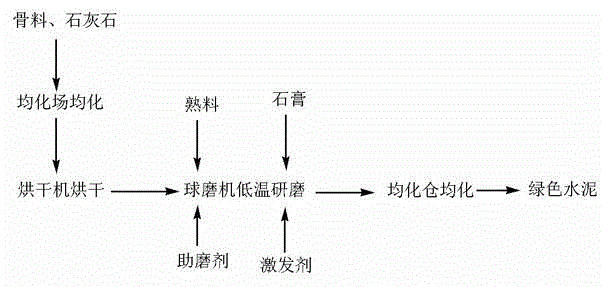

Environment-friendly high-performance cement and production method thereof

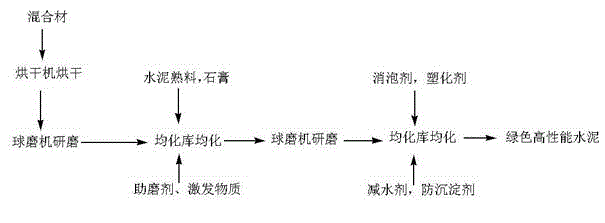

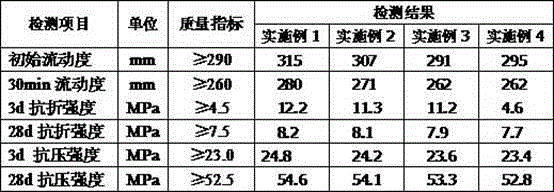

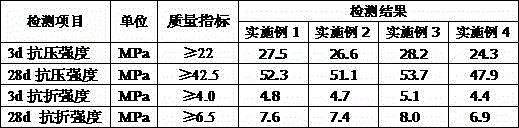

ActiveCN103601381AReduce crushing efficiencyImprove liquidityCement productionPlasticizerCement slurry

The invention provides environment-friendly high-performance cement which is characterized by consisting of the following raw materials in parts by weight: 50-60 parts of admixture, 32-40 parts of cement clinker, 6-8 parts of gypsum, 0.03-0.05 part of grinding aid, 3-5 parts of excitation substance, 0.05-0.1 part of antifoaming agent, 0.05-0.1 part of plasticizer, 0.03-0.05 part of anti-precipitating agent and 0.2-0.4 part of water reducing agent. In the environment-friendly high-performance cement provided by the invention, a large mixing amount of cement slurry can be realized by adopting a mechanical-chemical excitation production process, a great quantity of industrial waste residues can be consumed, the yield is increased, and the production cost is lowered; moreover, by adding a functional additive, the performance of the product is improved, and the needs of civil engineering are met.

Owner:广西云燕特种水泥建材有限公司

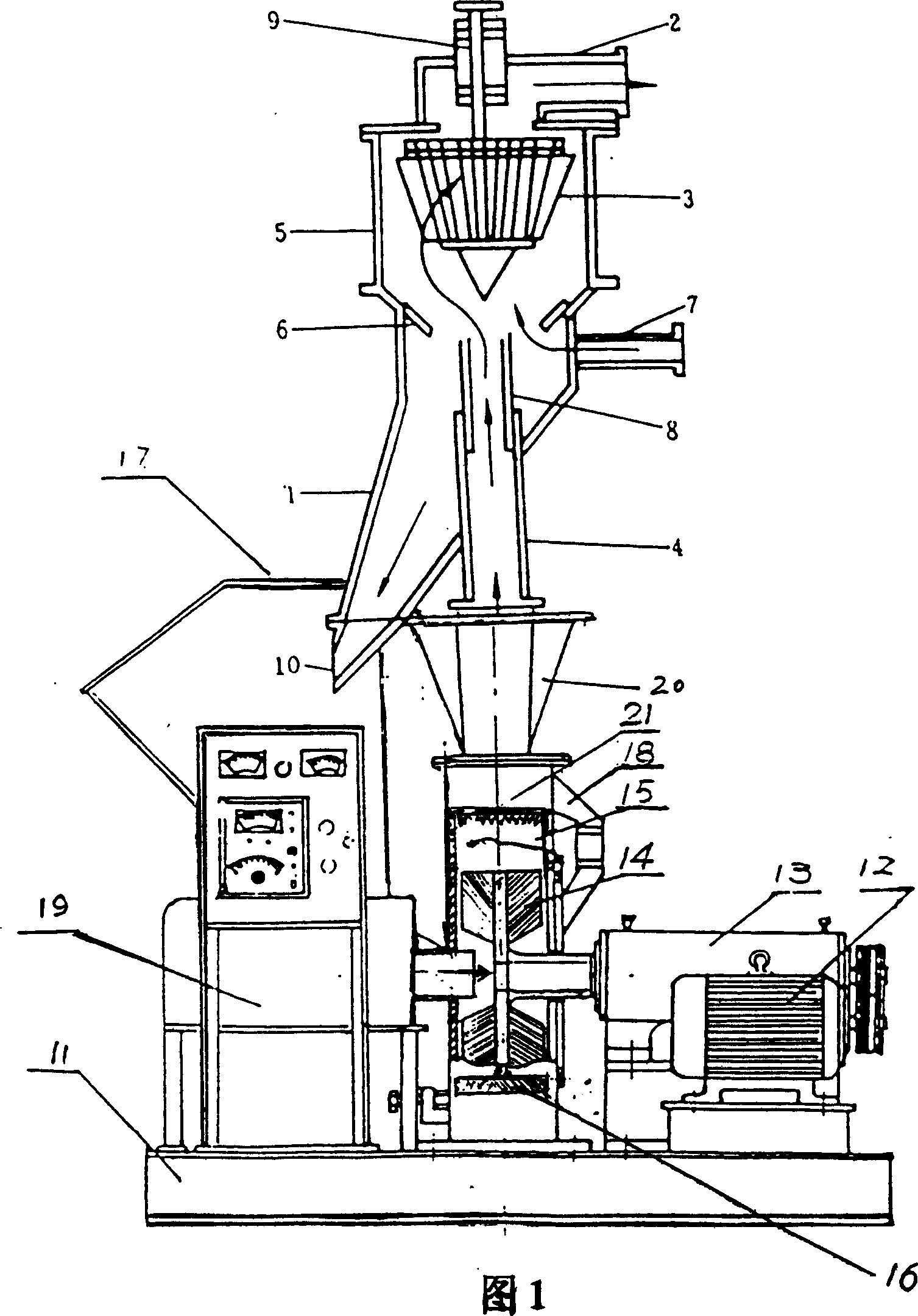

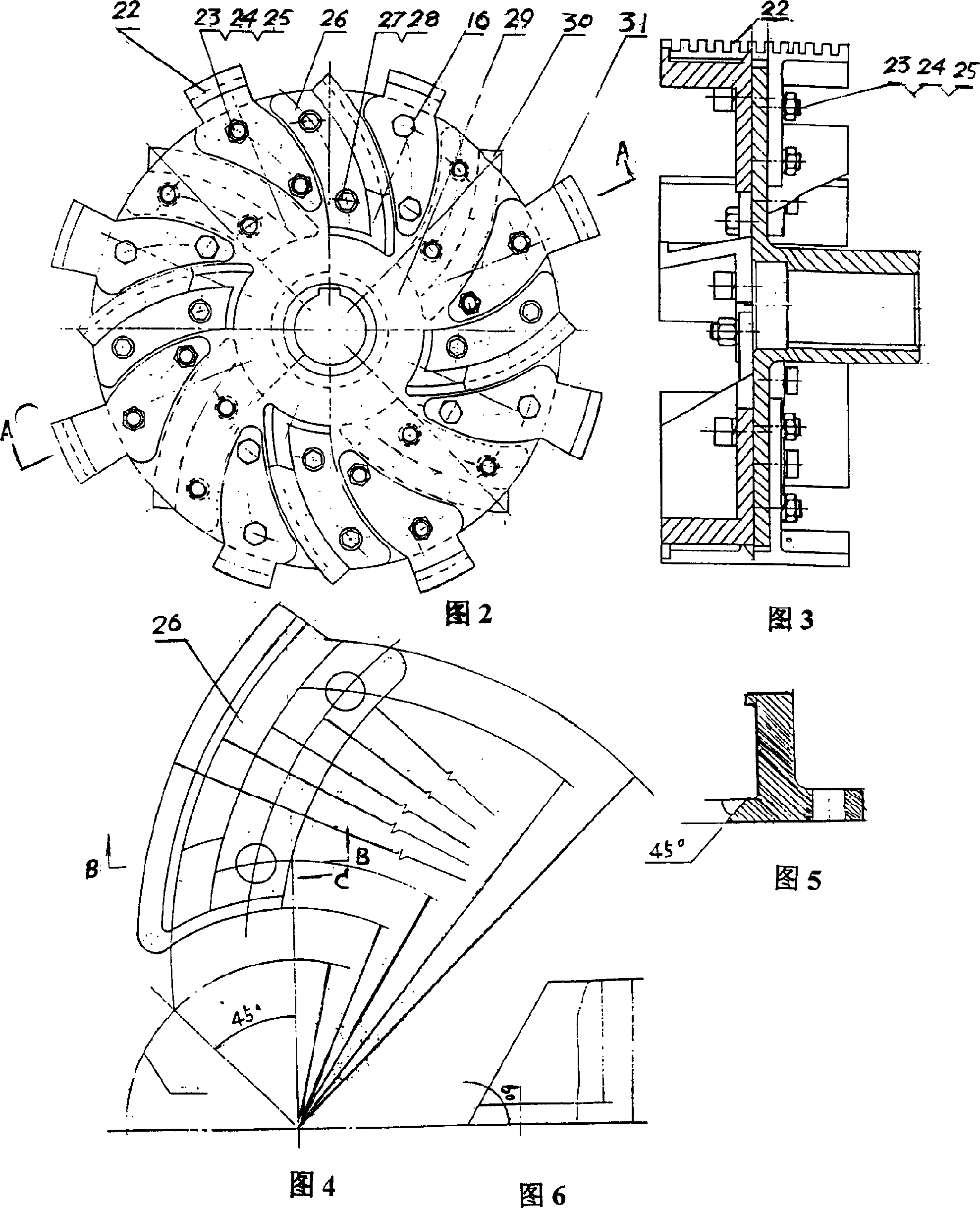

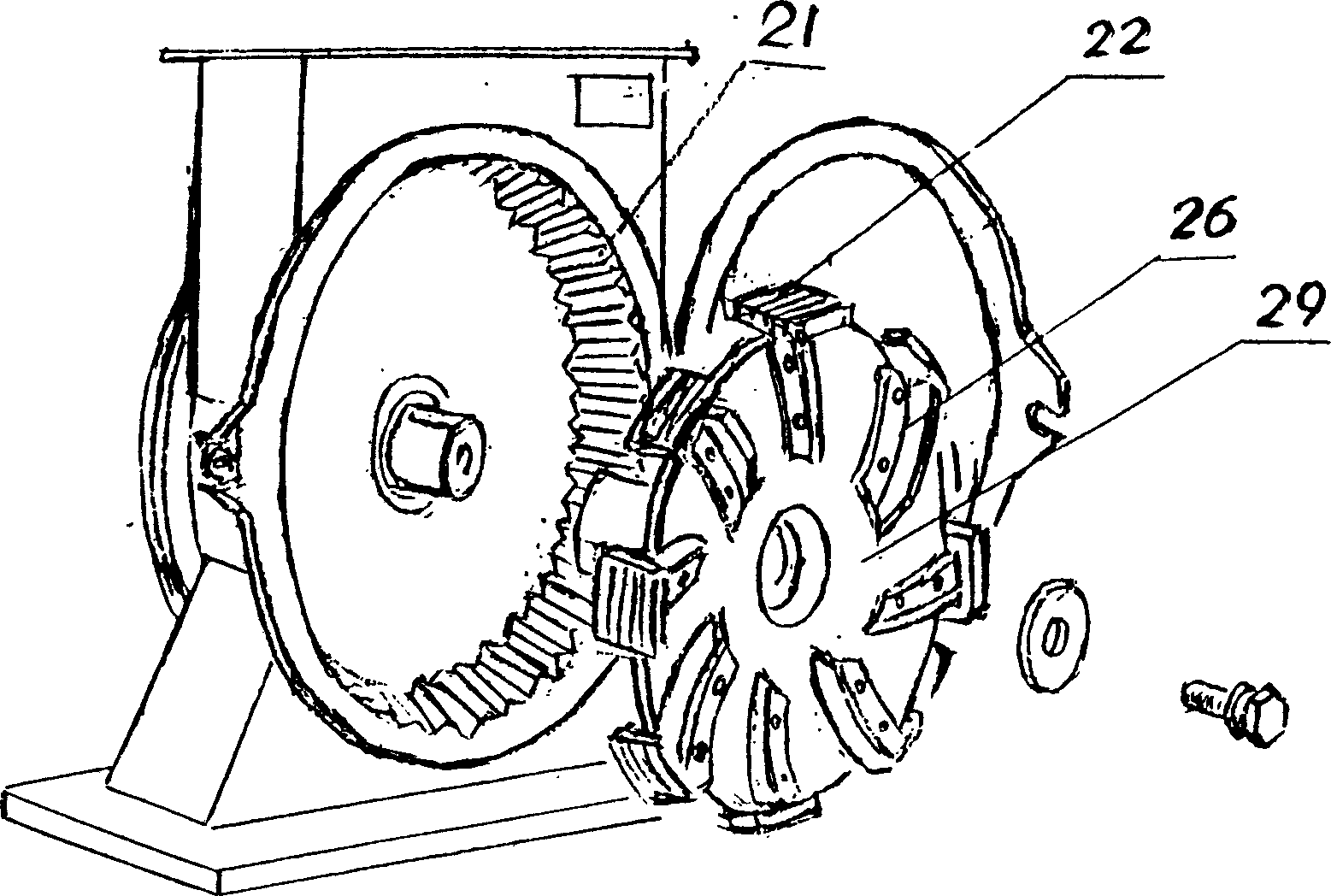

Mechanical turbulence milling tools

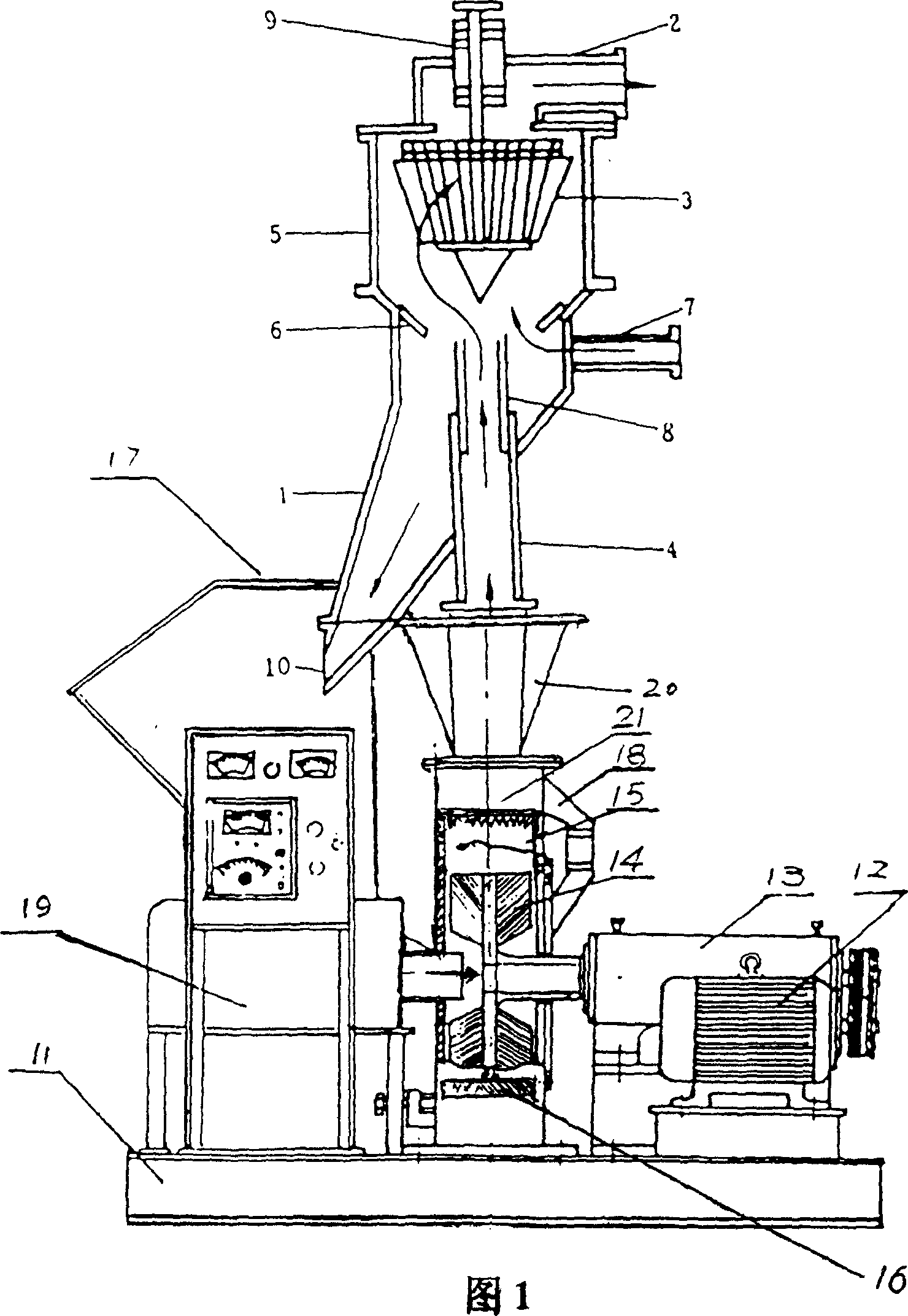

InactiveCN1562489AImprove energy savingDelightful environmental protection effectGrain treatmentsDrive shaftMechanical equipment

A mechanical turbulent grinder for preparing superfine powder is composed of a grinder with dual negative-pressure blade wheels to generate turbulence in cavity and spiral convayer, a separator, a classifier with inlet connected to outlet of separator, and the cyclone collector and cloth-bag collector communicated with the discharge outlet of classifier.

Owner:杨富茂

Method for manufacturing soft-magnetic alloy powder

The production method of soft magnetic alloy powder includes the following steps: smelting soft magnetic mother alloy, making molten metal be quickly coagulated into crystalline sheet alloy, breaking the sheet alloy to obtain alloy powder, and making the alloy powder undergo the processes of activation, annealing treatment and passivation treatment. Said soft magnetic alloy powder is low in oxygen content, stable in property and good in magnetic powder core performance.

Owner:CENT IRON & STEEL RES INST

Environment-friendly cement and production method thereof

ActiveCN103601382AReduce crushing efficiencyImprove liquidityCement productionMethods of productionToxic industrial waste

The invention discloses environment-friendly cement. The raw materials include various industrial waste residues, limestone, cement clinker, gypsum, a grinding aid and an excitation substance. The environment-friendly cement is characterized in that the weight parts of the raw materials are as follows: 50-60 parts of admixture, 32-40 parts of cement clinker, 4-8 parts of gypsum, 0.03-0.05 part of grinding aid and 3-5 parts of excitation substance. Since the production process of the environment-friendly cement adopts a low-temperature mechanical-chemical co-excitation technology, the mixing amount of the admixture is large, multiple industrial waste residues can be used as raw materials, the raw materials are widely available, the cost is low, a great quantity of industrial waste residues can be consumed, the waste is turned into wealth, and the performance of the obtained product is remarkably improved from the quality index.

Owner:广西云燕特种水泥建材有限公司

Honeycomb essence buccal tablet and preparation process thereof

InactiveCN103230012AFully absorbedEasy to GrindAnthropod material medical ingredientsPharmaceutical non-active ingredientsHoneycombUltra fine

The invention discloses a honeycomb essence buccal tablet and a preparation process thereof, belonging to the technical field of honeycomb preparation. The honeycomb essence buccal tablet disclosed by the invention is prepared from ultra-fine powder of a honeycomb essence composition, a filling agent, a sweetening agent, an acidulant, edible essence and a lubricating agent. The invention further provides the preparation process of the honeycomb essence buccal tablet. The honeycomb essence buccal tablet disclosed by the invention has the characteristics of being easy for taking, good in mouth feel and rapid in absorption and is capable of overcoming the disadvantages of being insufficient in honeycomb mouth feel and lower in absorption utilization rate, and obviously increasing the absorption utilization rates of effective components in the honeycomb essence; and the honeycomb essence buccal tablet has important value and contribution for clinical treatment, health care and prevention of nasopharyngitis.

Owner:FUJIAN XINZHIYUAN BIOLOGICAL PROD

Self-propelling crusher

InactiveUS7318463B2Reduce crushing efficiencyIncrease speedMowersMulti-purpose machinesHydraulic pumpEngineering

A self-propelled crushing machine comprises a crushing device 20; a hydraulic drive system including a crushing device hydraulic motor 21 for driving the crushing device 20, a first hydraulic pump 62 for driving the crushing device hydraulic motor 21, and an engine 61 for driving the first hydraulic pump 62; a pressure sensor 151 for detecting a load condition of the crushing device 20; and a controller 84″ for executing control to increase a revolution speed of the engine 61 in accordance with a detected signal from the pressure sensor 151. Accordingly, even when a heavy load is imposed on the crushing device, a reduction of crushing efficiency can be prevented.

Owner:NIHON KENKI CO LTD

Wear-resistant corrosion-resistant powder paint for aluminum alloy template and preparation process thereof

PendingCN111471358AReduce performanceImprove light resistanceSievingOrganic chemistryStearic acidSilicon dioxide

The invention discloses wear-resistant corrosion-resistant powder paint for an aluminum alloy template and a preparation process thereof. The powder paint is prepared from the following raw materialsin parts by weight: 20-25 parts of polyvinylidene chloride, 1.5-4 parts of titanium dioxide powder, 1.5-4 parts of silicon dioxide powder, 3-5 parts of stearic acid, 4-8 parts of a reinforcing agent,1.6-2 parts of silicone oil and 2-4.5 parts of polyethylene wax. The powder paint contains the stearic acid. When the powder paint is smeared on the aluminum alloy template, a layer of hydrophobic film is formed on the surface of the aluminum alloy template, and water is prevented from penetrating through the coating film to be in contact with the aluminum alloy template, so that the corrosion resistance of the aluminum alloy template is improved. The reinforcing agent is prepared on the preparation process of the powder paint and contains a benzoquinone structure, the benzoquinone structure has good light shielding property, and the reinforcing agent contains a hindered phenol structure, so that light resistance of the powder paint is improved.

Owner:丁彪

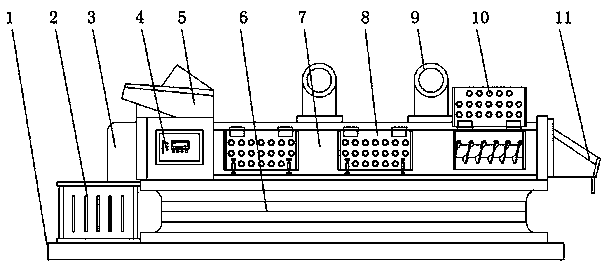

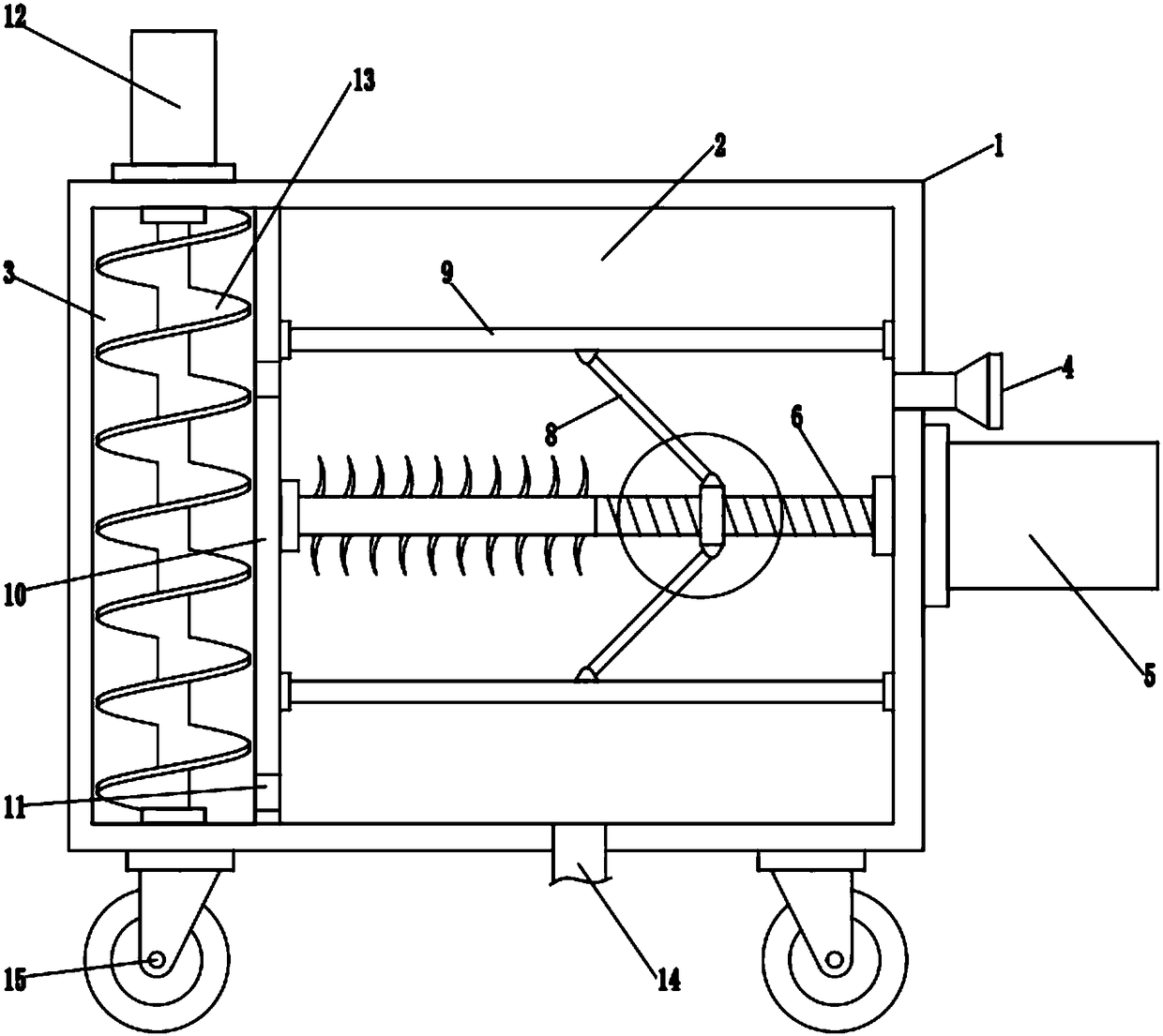

D-type pulping equipment which is based on airflow vortex and conducts stirring and pulping

ActiveCN107100024AAchieve homogeneity controlAvoid cloggingPaper recyclingRaw material divisionDecompositionEngineering

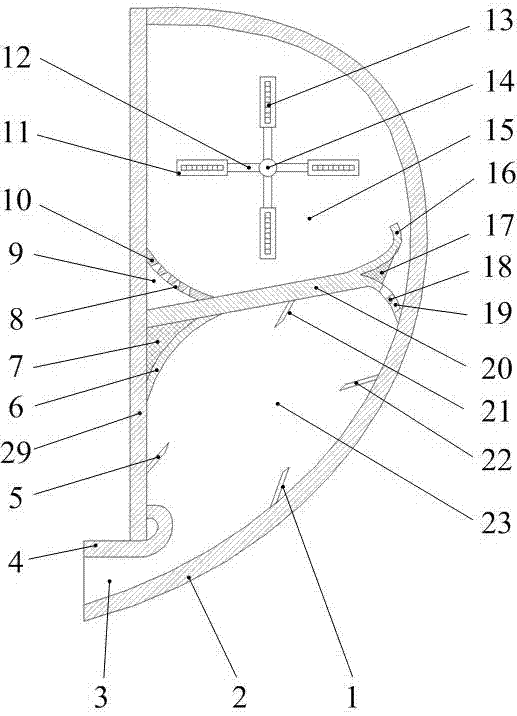

The invention provides D-type pulping equipment which is based on airflow vortex and conducts stirring and pulping. The D-type pulping equipment mainly comprises a D-type feed cylinder device, an airflow vortex pulping device, a stirring pulping device and a fine pulp storage device. The D-type pulping equipment has the advantages of conducting air pulping, liquid pulping and filter pulping in sequence. According to the D-type pulping equipment which is based on the airflow vortex and conducts stirring and pulping, the airflow vortex pulping device achieves primary rotor-free airflow vortex smashing of smashed feed, the stirring smashing device achieves secondary stirring, decomposition and smashing of the smashed feed, and the fine pulp storage device achieves refining and screening of the smashed feed.

Owner:UNIV OF JINAN

Mechanical turbulence milling tools

InactiveCN1295021CImprove energy savingReduce crushing efficiencyGrain treatmentsDrive shaftMechanical equipment

Owner:杨富茂

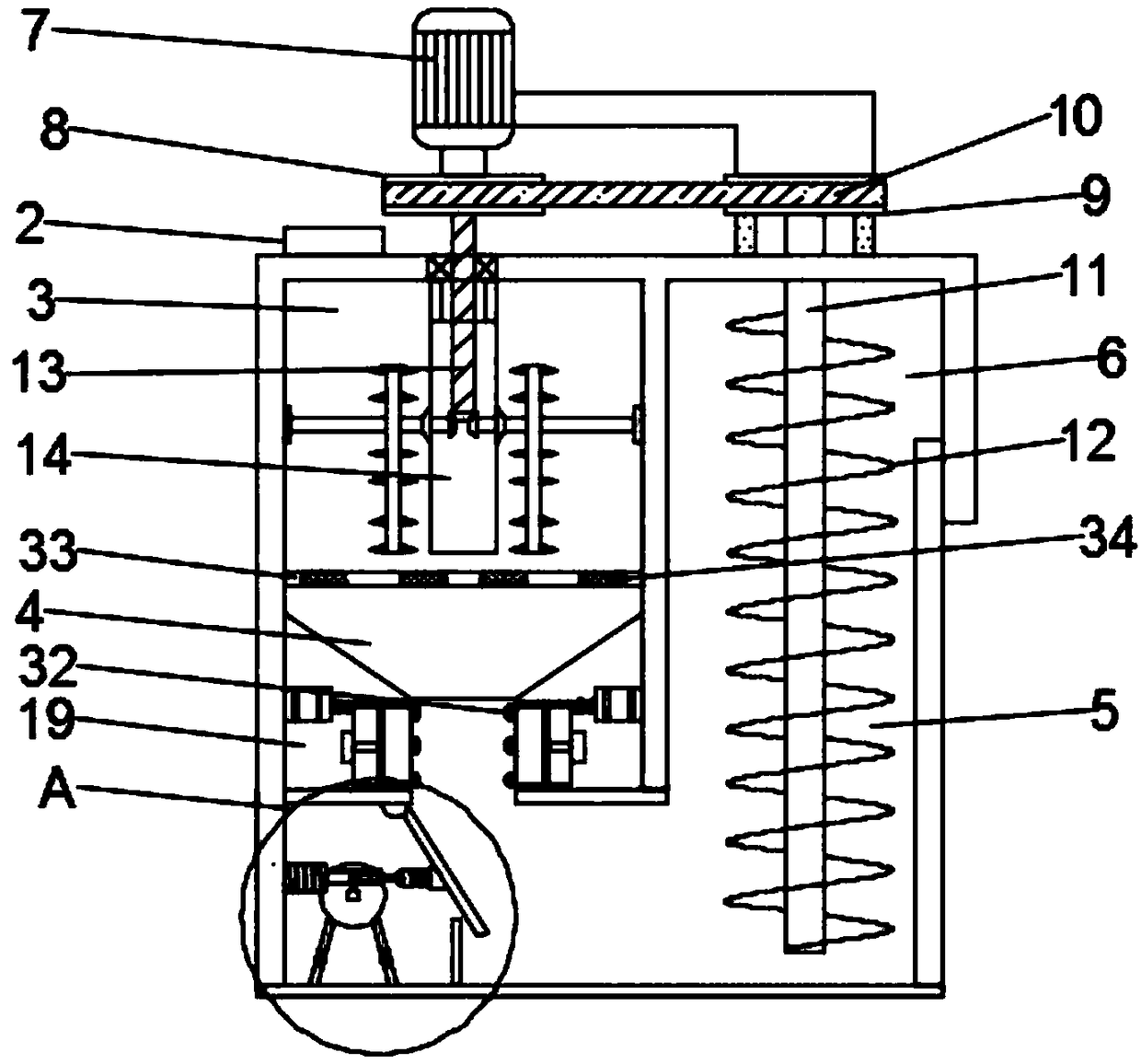

Drink label removing machine

The invention discloses a drink label removing machine. The machine comprises a bottom plate, a damping base, a main body, a shifting shaft and an air blower, wherein a motor seat is mounted at one side of the top part of the bottom plate, and a protecting cover is fixed to the top end of the motor base; the damping base is mounted at the other side of the top part of the bottom plate, and the main body is fixed to the top end of the damping base; a feeding port is formed in one side, close to the protecting cover, of the top end of the main body, and a control panel is mounted on the main body at the lower part of the feeding port; repairing covers are uniformly hinged with two ends of the main body, and bumps are uniformly arranged at the inner sidewalls of the repairing covers; a labeloutlet is formed in the top end of the main body between the repairing cover; and a discharging port is formed in one side, far away from the motor seat, of the main body. According to the drink labelremoving machine, the damping base is mounted, so that the damping performance of the machine can be improved; the noise is reduced during use; and the practicability is high.

Owner:汤以骋

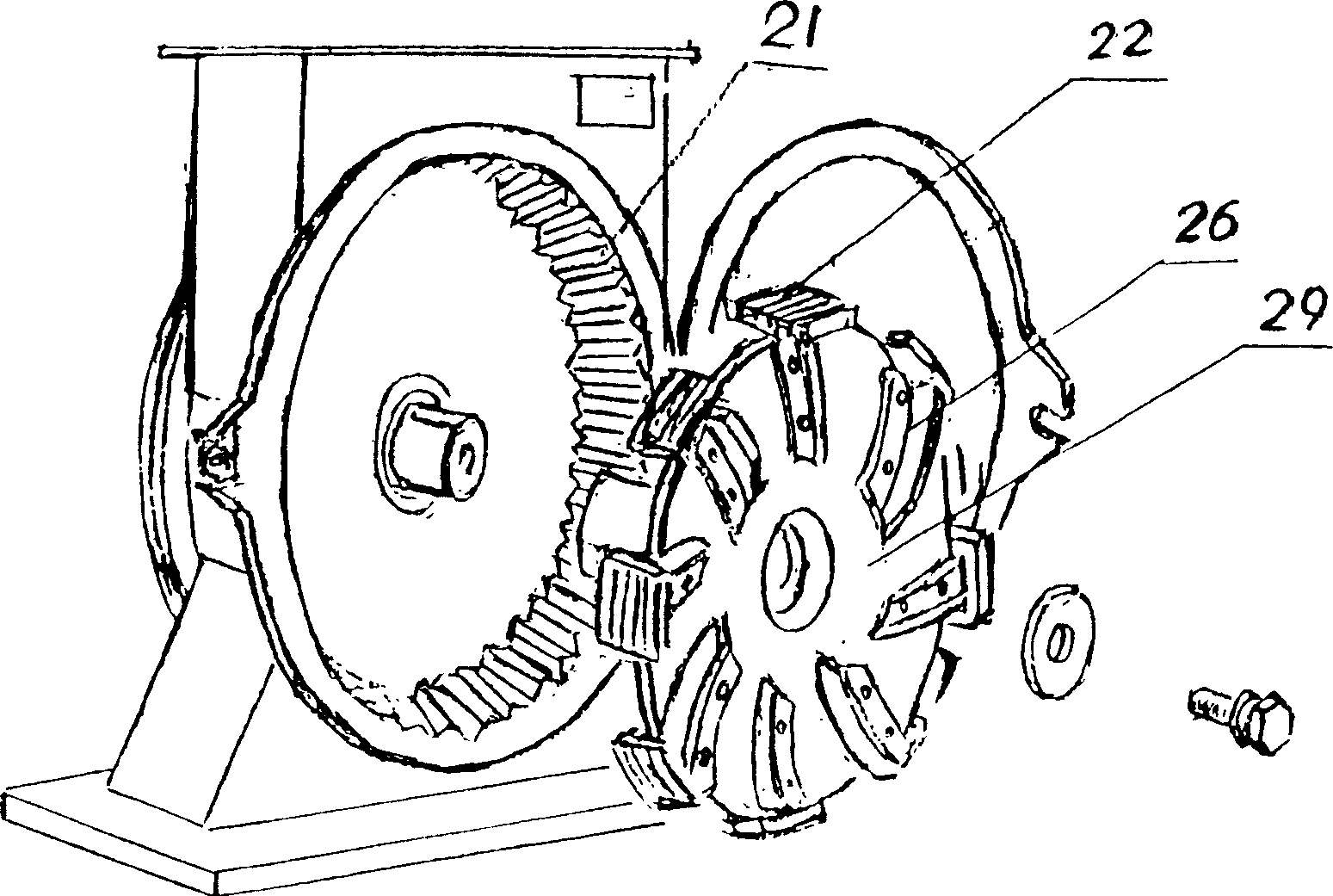

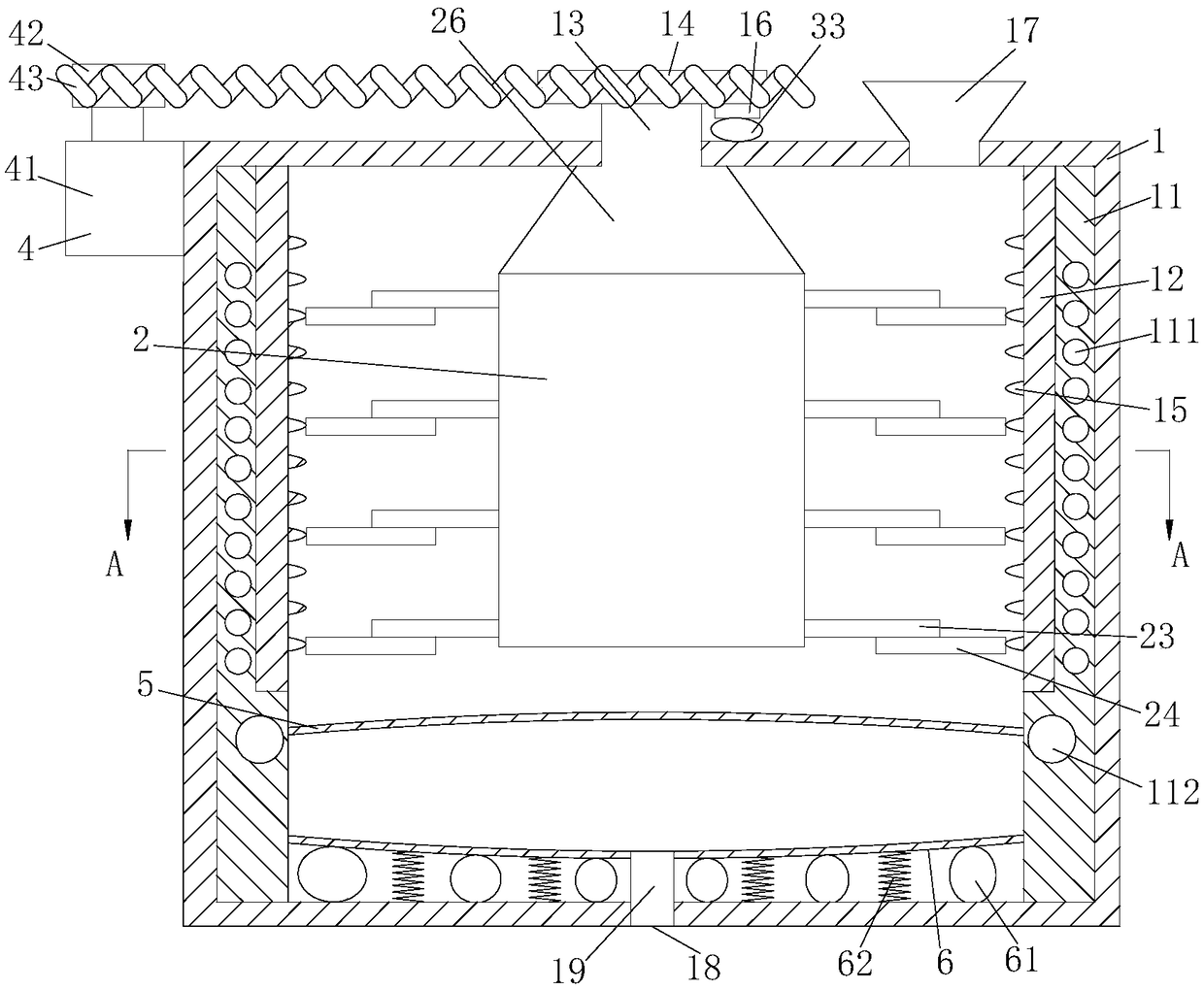

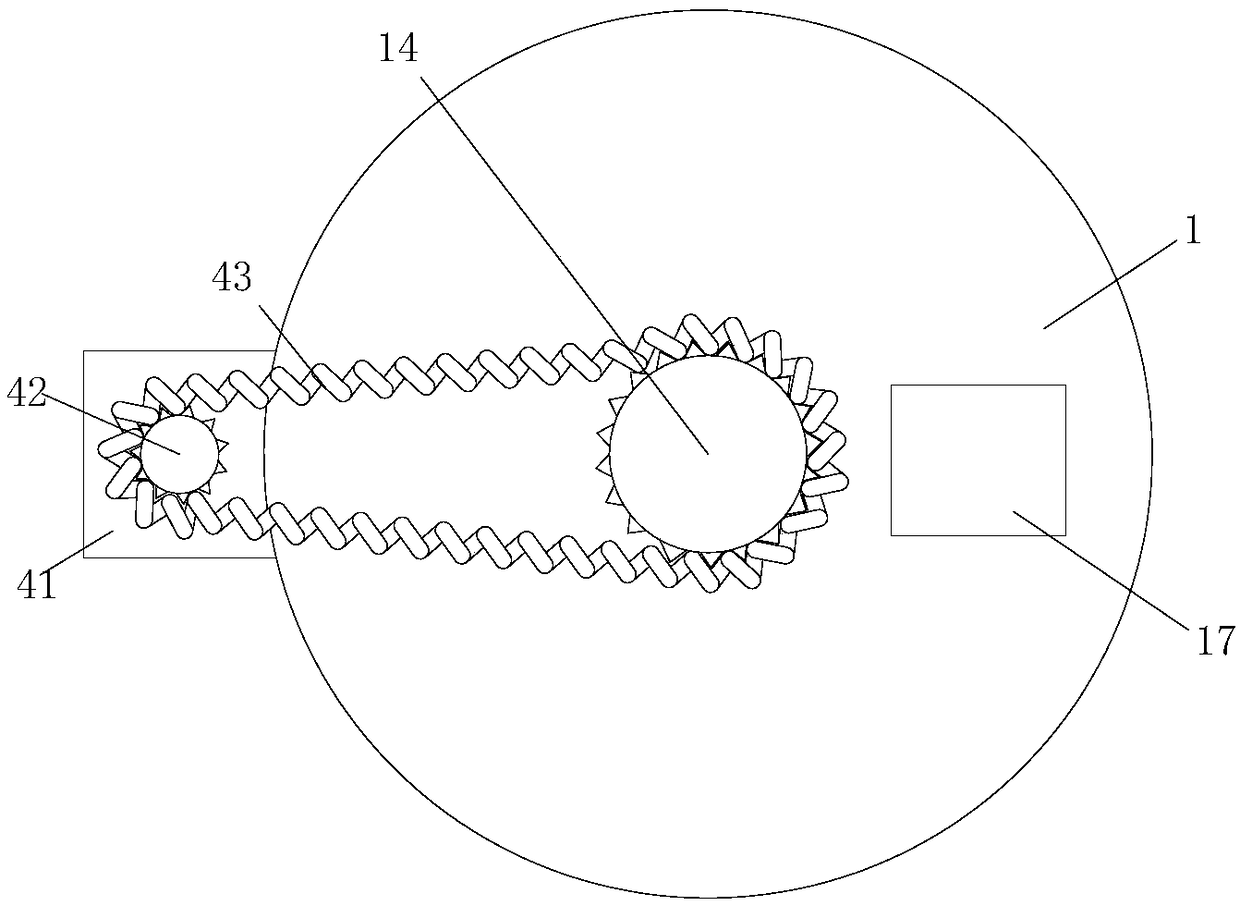

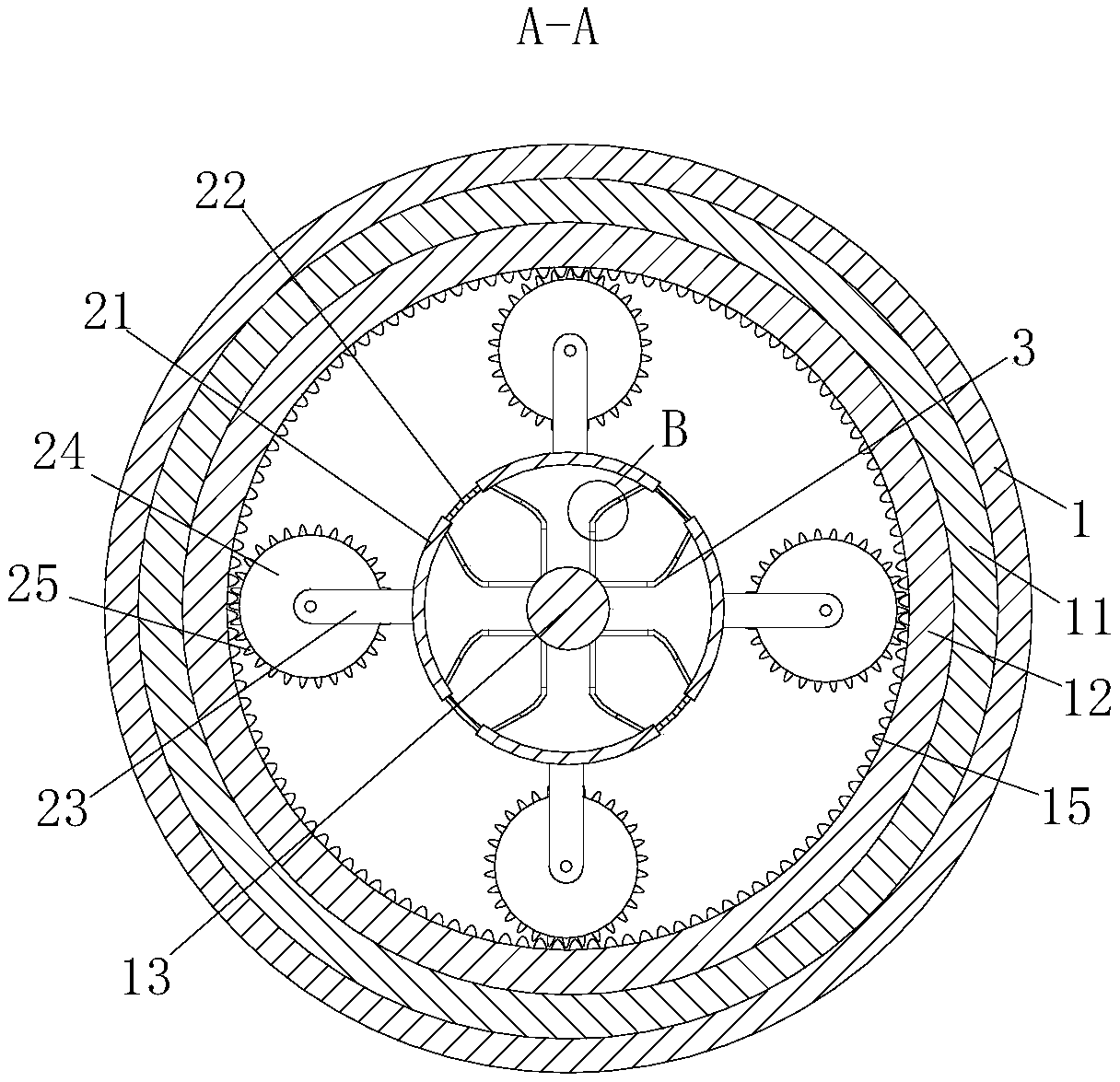

Building material grinding device

ActiveCN109289993AImprove crushing efficiencyReduce crushing efficiencySievingScreeningEngineeringGrinding wheel

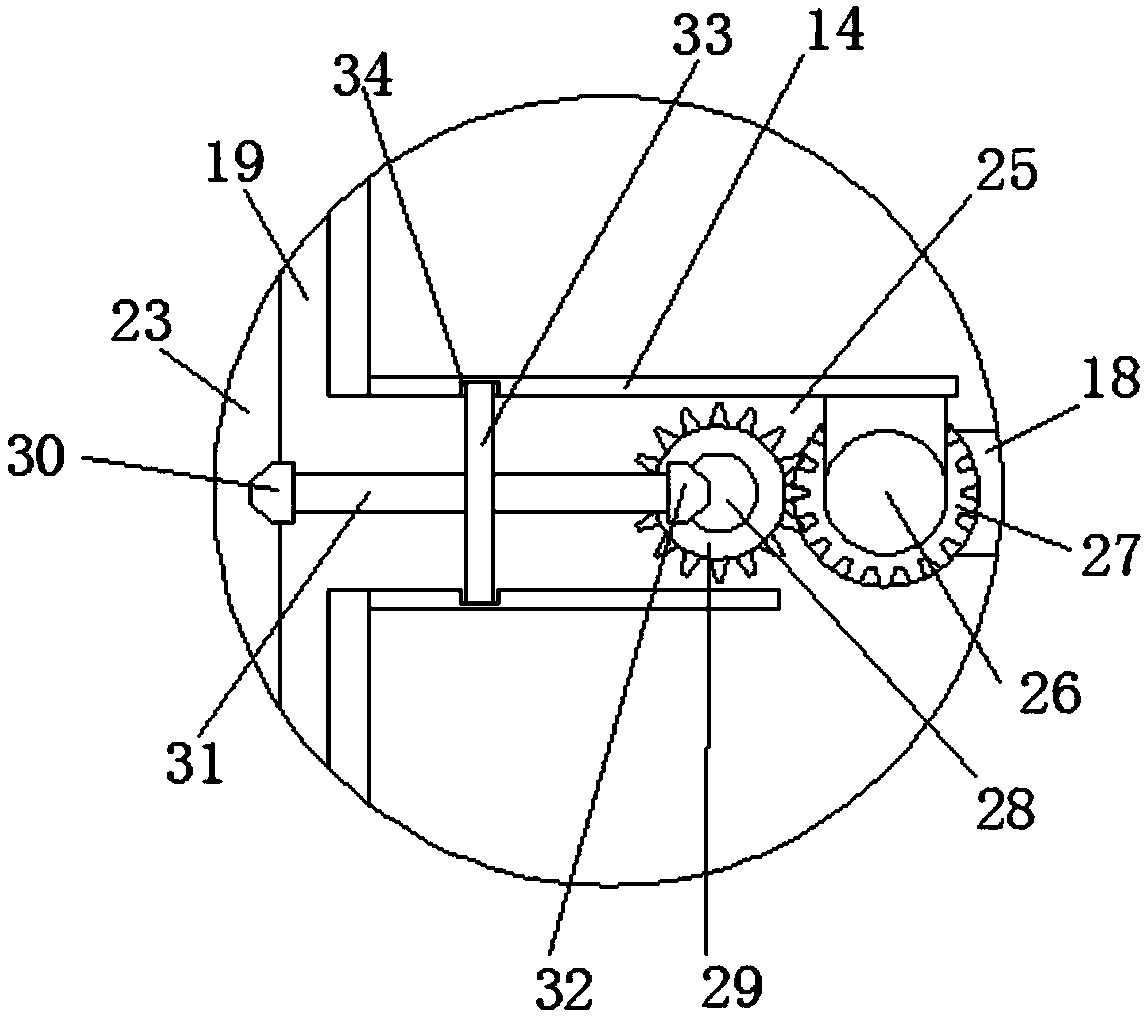

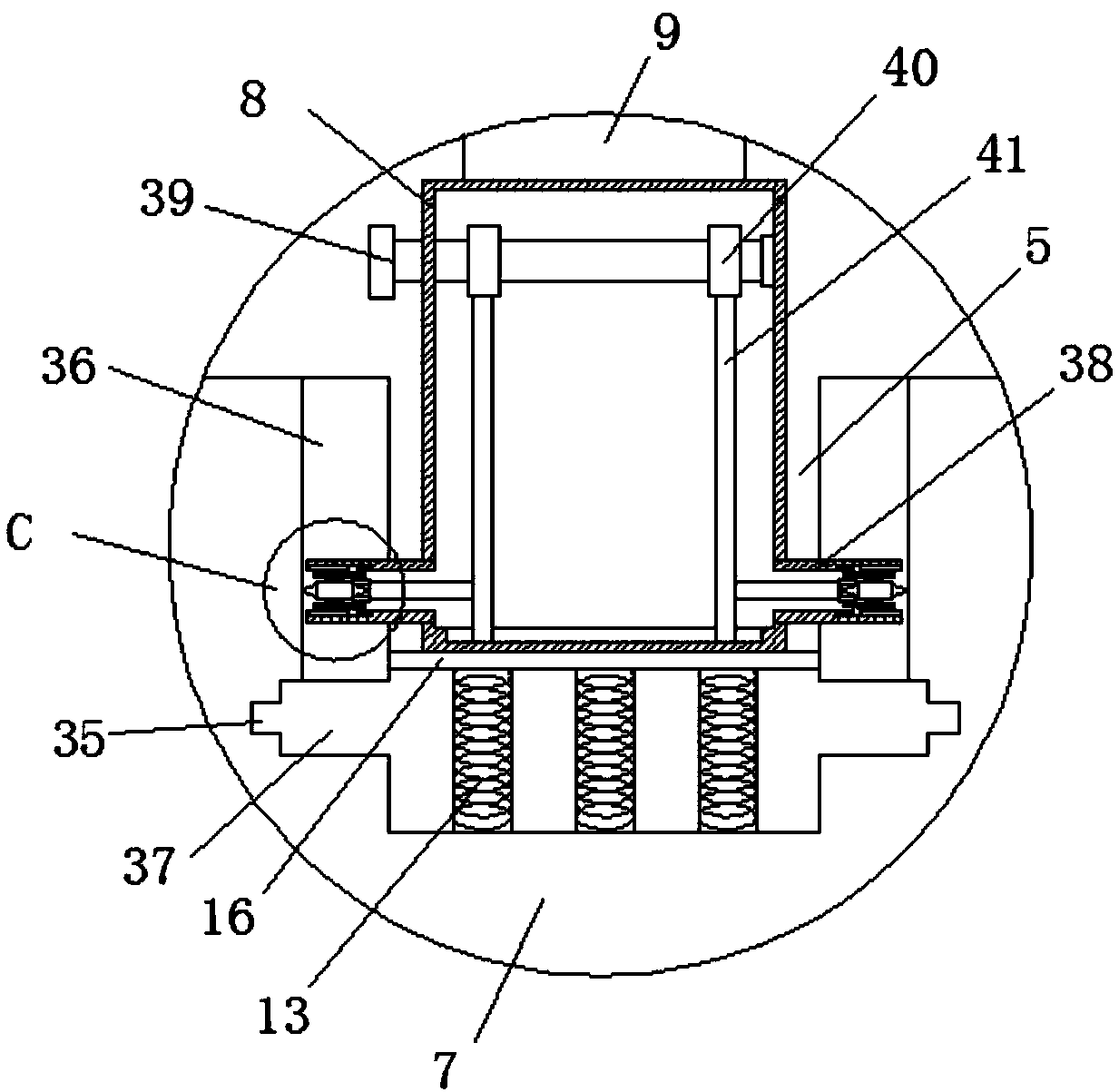

The invention belongs to the technical field of engineering, and particularly discloses a building material grinding device. The building material grinding device comprises a frame body and a power unit, and a second gear is fixedly connected to the upper end of a motor; the second gear and a first gear are driven by a power spring; a rotating wheel is divided into two parts of push plates and elastic cloths, the push plates and the elastic cloths are arranged in a staggered mode, and each push plate is fixedly connected with a rotating shaft through two supporting rods; fixed rods are fixedlyconnected to the outer surfaces of the push plates; grinding wheels are rotatably connected to the ends, away from the push plates, of the fixed rods; first grinding teeth are evenly arranged on thegrinding wheels; second grinding teeth are evenly arranged on the inner walls of the fixed plates; a grinding chamber is formed in a filter screen, and grinding blocks arranged evenly are arranged onthe upper and lower inner walls of the grinding chamber; and filter holes arranged evenly are formed in the upper and lower parts of the grinding chamber. The building material grinding device is simple in operation, convenient for a worker to observe the grinding conditions of building materials, high in grinding efficiency of the building materials and not prone to being damaged.

Owner:台州中利建设有限公司

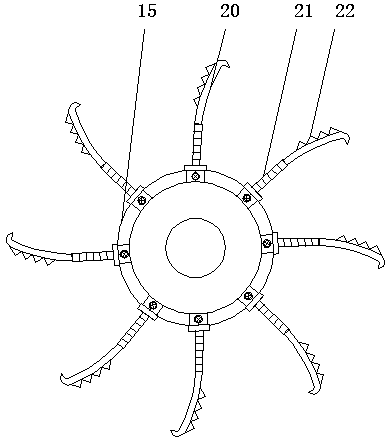

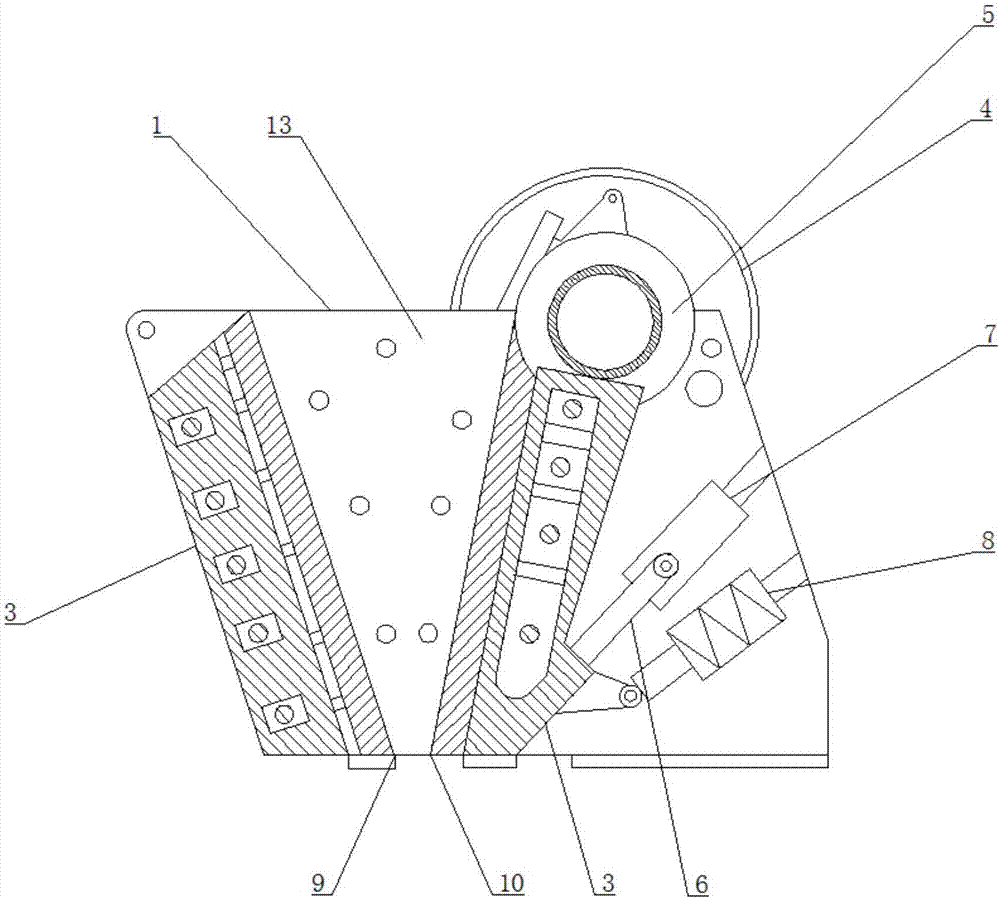

Corn grinder device for agricultural machining

The invention discloses a corn grinder device for agricultural machining. The corn grinder device comprises a shell, wherein the shell is of a hollow structure, and the inner wall of the shell is partitioned into a grinding cavity and a collecting cavity through a transversely arranged partition plate; a first installation groove is formed in the inner wall of the shell; a rotating shaft is rotationally connected with the inside of the first installation groove; the partition plate is rotationally connected with the inner wall of the shell through the rotating shaft; a through hole is formed in the partition plate, and a screen is arranged in the through hole; the grinding cavity is located above the collecting cavity and communicates with the collecting cavity through the through hole; a feeding hole communicating with the grinding cavity is also formed in the side wall of the shell; and a corn kernel discharge hole and a corncob discharge hole communicating with the collecting cavity are also formed in the side wall of the shell. The corn grinder device is simple in structure and convenient to operate, and is capable of preventing corncobs from blocking the screen to affect the feeding efficiency of the screen, and preventing smashing teeth from being seriously abraded to affect the grinding efficiency, so that the work efficiency of the device can be improved.

Owner:徐州佳联农业发展有限公司

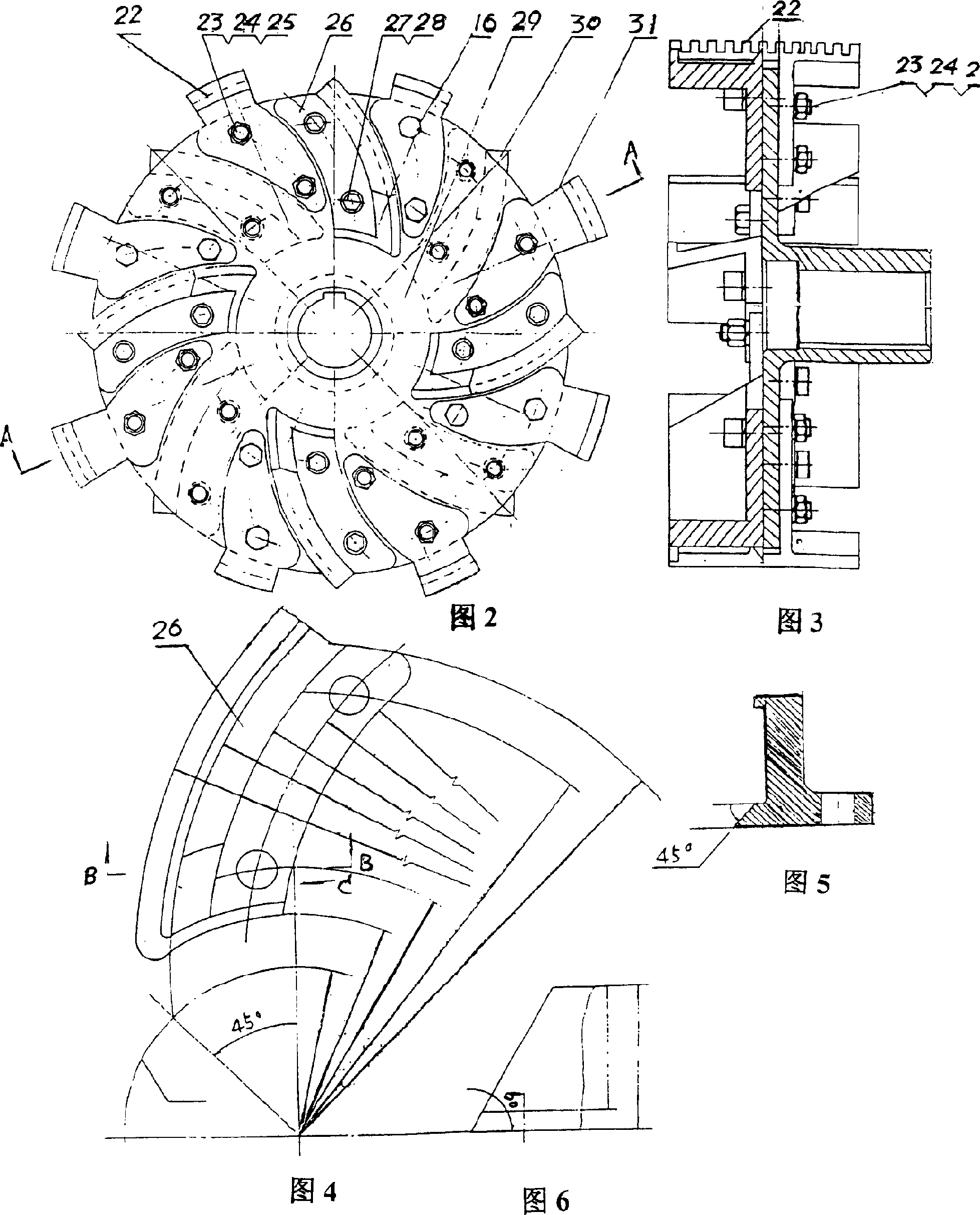

Novel jaw-type crusher

The invention discloses a novel jaw crusher, which belongs to the field of molybdenum ore processing and solves the problem of poor crushing effect of ore extrusion. The invention includes a frame, on which a fixed jaw, a movable jaw and an eccentric wheel are arranged, the eccentric wheel is connected with the rotating shaft of the main motor through a belt, an eccentric drive shaft is arranged on the eccentric wheel, an eccentric drive shaft is connected to the upper end of the movable jaw, and the eccentric drive The shaft is hinged on the frame, the lower end of the movable jaw is connected to the front end of the toggle plate, the rear end of the toggle plate is connected to the adjustment seat, the adjustment seat is connected to the frame, the lower end of the movable jaw is connected to the movable pull rod, and the fixed jaw is set on the fixed jaw. The movable jaw plate is set on the movable jaw plate, the fixed tooth plate is set on the fixed jaw plate, and the movable tooth plate is set on the movable jaw plate. There are fixed teeth with a T-shaped cross-section. The fixed teeth include fixed tooth roots and fixed tooth tops. The distance between adjacent fixed tooth tops is greater than the cross-sectional width of the movable teeth. The invention is used for crushing molybdenum ore.

Owner:SICHUAN S Y MOLY TECH CO LTD

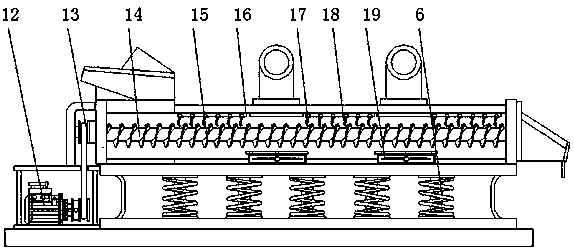

Drying and crushing integrated device and using method

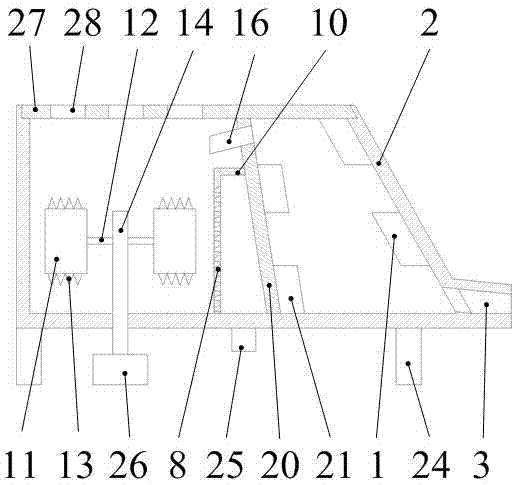

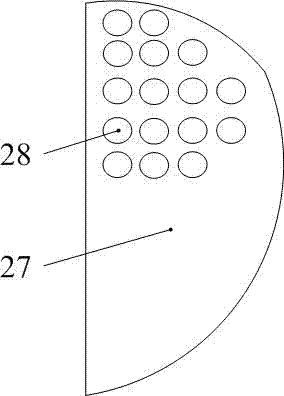

ActiveCN108889436ARealize the integrated treatment of drying and crushingImprove production efficiencyDrying gas arrangementsGrain treatmentsBaghouseClosed loop

The invention discloses a drying and crushing integrated device and a using method, and belongs to the field of coal processing and utilization. The device comprises an air compressor, a cabinet bodyand a bag-type dust remover, a partition plate used for dividing the cabinet body into left and right box bodies is arranged in the cabinet body, and the left box body is an air collecting box; the right box body is a screening box, the bag-type dust remover connected with an output pipeline of the air compressor is arranged on the upper portion of the screening box, and a heating wire controlledby a heating wire power switch is arranged in the air collecting box; a screening plate arranged aslant is arranged below a feed inlet, crushing hammers corresponding to the inclination angle of the screening plate are arranged on the upper portion of the screening plate, and a product chamber is formed in the lower portion of the screening plate; the flow of air entering into the device is adjusted through a mass flowmeter, the temperature of dry gas is adjusted through the heating wire power switch, and the dried air achieves closed-loop circulation through the bag-type dust remover and an air inlet pipeline. Not only can low-rank coal be dried and smashed, but also it can be avoided that coal particles block the screening plate and leak in the crushing process, and the efficient dryingand crushing of coal are achieved.

Owner:CHINA UNIV OF MINING & TECH

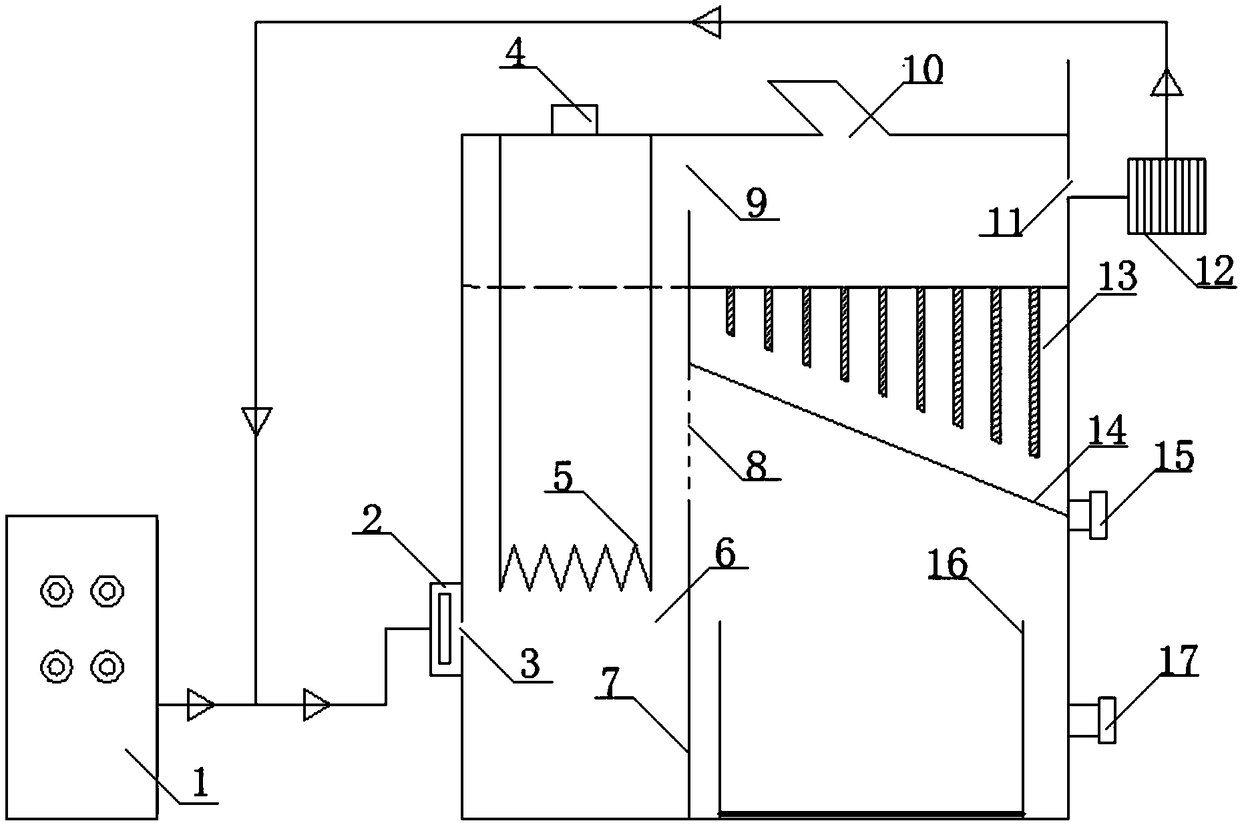

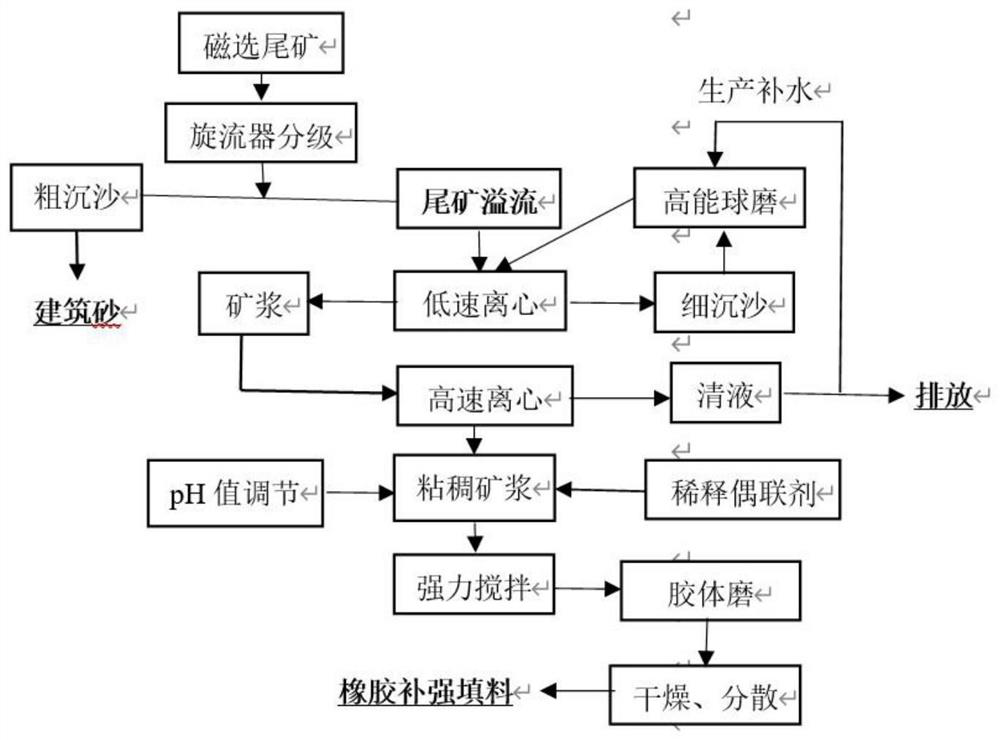

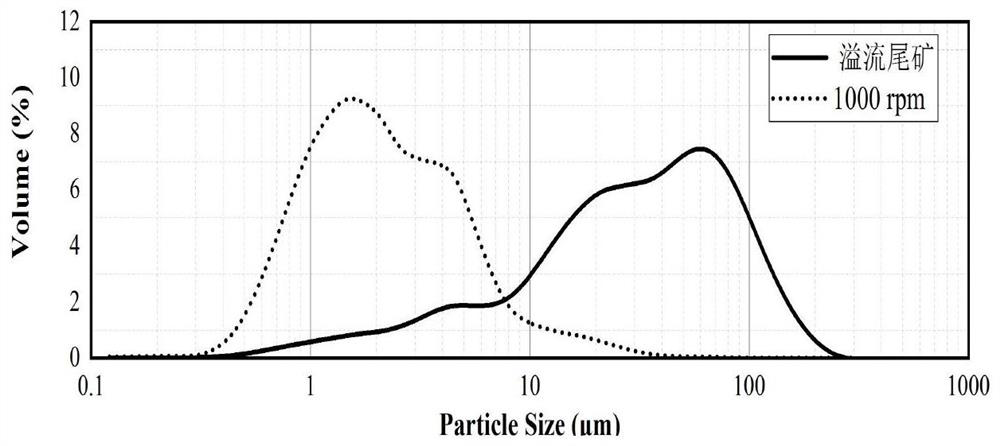

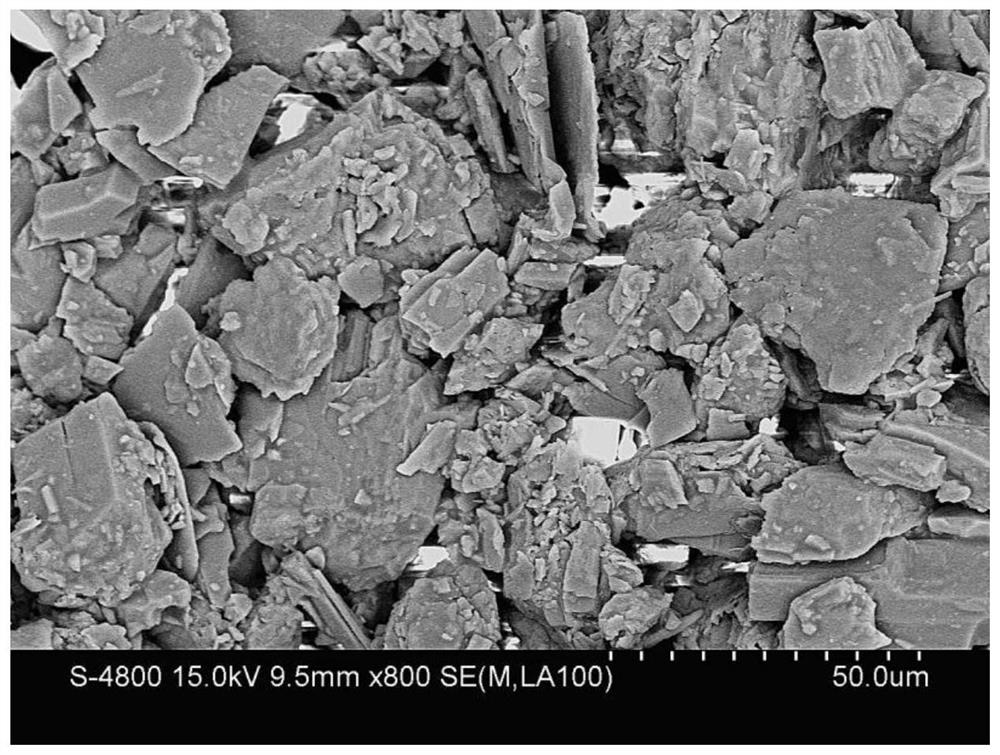

Preparation method of iron tailing reinforced rubber functional filler

ActiveCN113929969ASolve the problem of effective combinationLarge particle sizeSolid waste managementColloid millReinforced rubber

The invention relates to a preparation method of an iron tailing reinforced rubber functional filler. According to the method, firstly, a low-speed centrifugal machine is adopted, coarse particles in ore pulp are effectively separated out through an artificial gravity field, then the coarse particles are subjected to superfine grinding through a high-energy ball mill, and therefore the grinding and smashing efficiency of powder can be greatly improved; directly surface modification is performed on the dehydrated concentrated ore pulp; and finally, secondary agglomerated particles formed in the ultrafine crushing process are re-dispersed by means of a high-shear colloid mill with the plane shear crushing distance of 0.01-0.10 mm, and finally the modified iron tailing powder with fine particles and uniform particle size is obtained. According to the method, the use amount of carbon black can be reduced or saved, grinding is carried out through separation and quality separation, the ore grinding cost can be effectively reduced, and the production efficiency and the resource utilization rate are improved.

Owner:HEBEI UNIV OF TECH

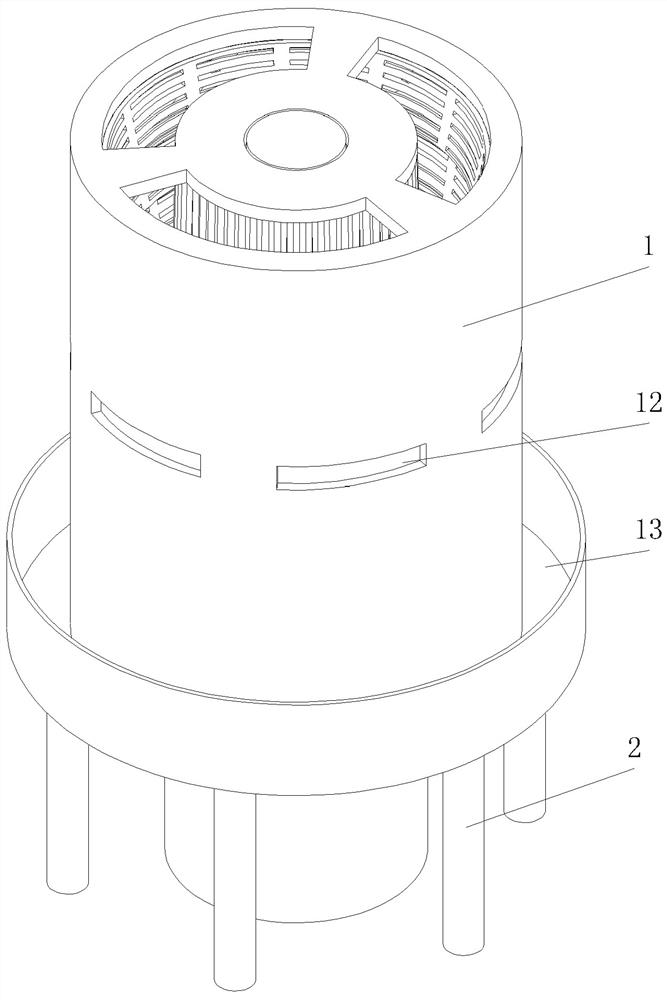

Chemical raw material pulverizing device

InactiveCN109926187AGo out fastSolve sticky raw materialsGrain treatmentsRound tableCompound (substance)

The invention discloses a chemical raw material pulverizing device. The device comprises a pulverizing box body, the pulverizing box body is a cylindrical hollow structure with an opening formed in the bottom, a motor is vertically arranged in the center of the top of the pulverizing box body, the bottom of the motor is connected with an output shaft, the bottom of the output shaft penetrates through the top of the pulverizing box body to extend to the interior of the pulverizing box body to be connected with an eccentric pulverizing wheel, the upper portion of the eccentric pulverizing wheelis provided with a discharging round table, pulverizing blocks are uniformly arranged on the outer wall of the eccentric pulverizing wheel, and the bottom of the eccentric pulverizing wheel is fixedlyconnected with a bearing. The device has the advantages that the structure is simple, the designing is novel, the inner wall of the pulverizing box can be heated to allow the pulverizing of the chemical engineering raw material to be more efficiently, low pulverizing efficiency which takes place when a wetter chemical engineering raw material is bonded to the inner wall of the chemical engineering raw material pulverizing device in the prior art, the inventiveness is high, and the popularization is easy.

Owner:庄汉杨

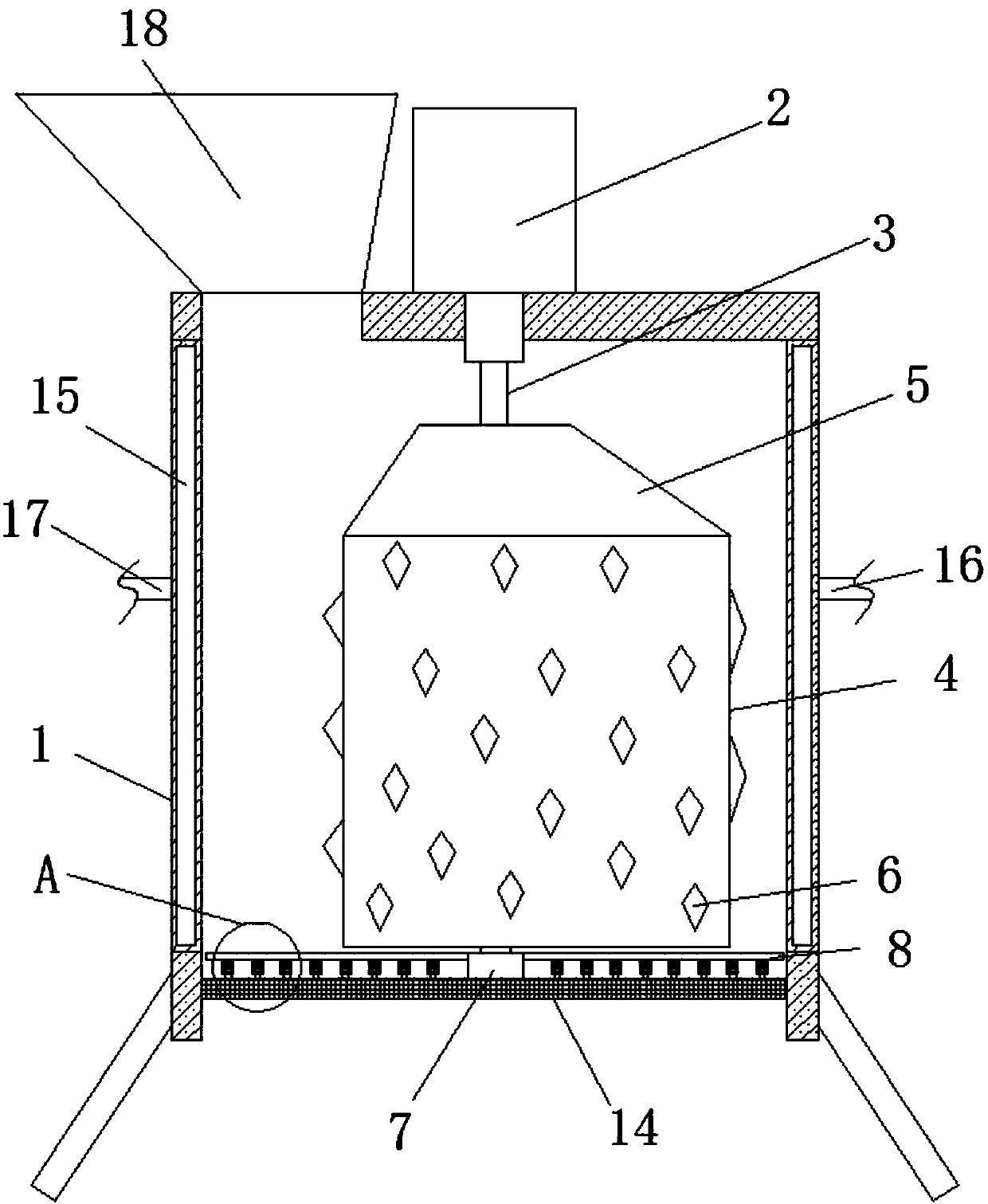

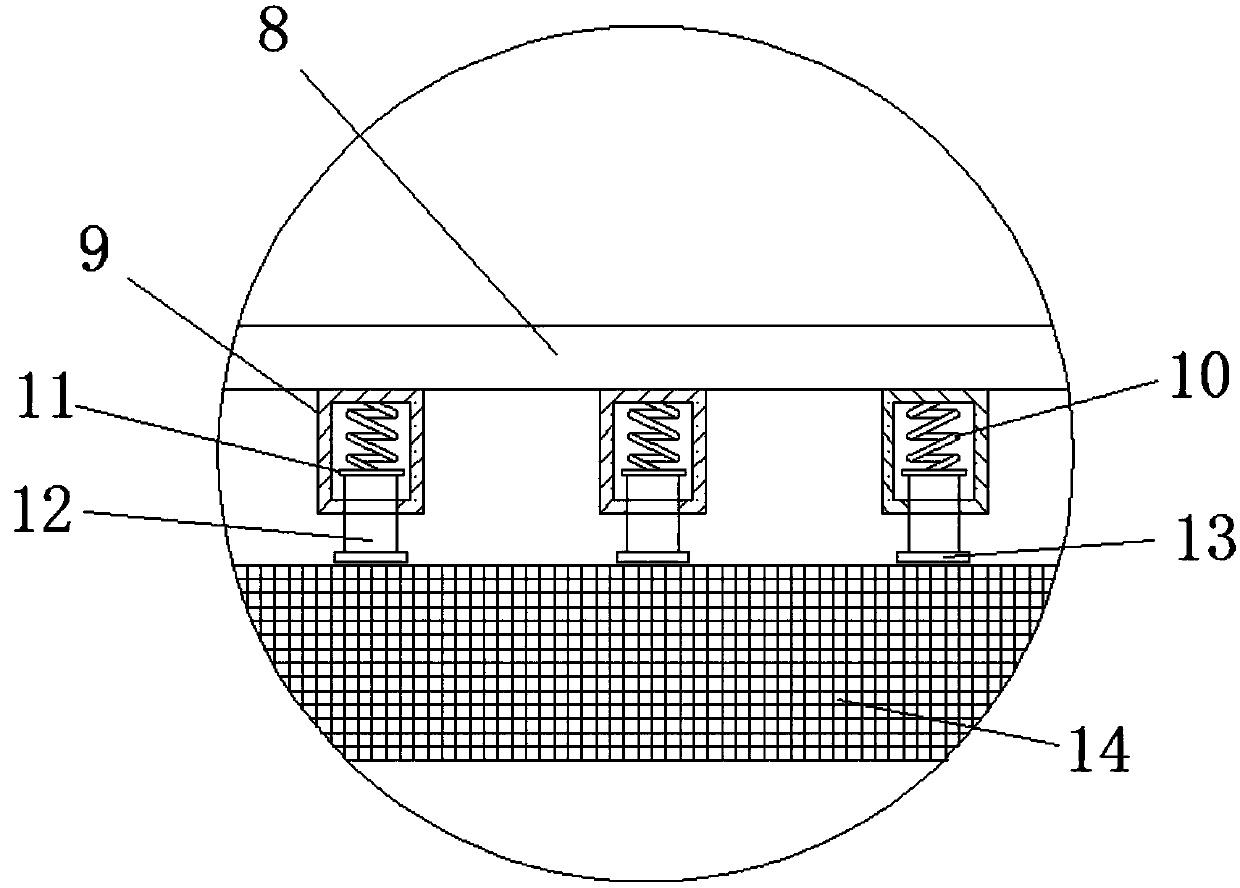

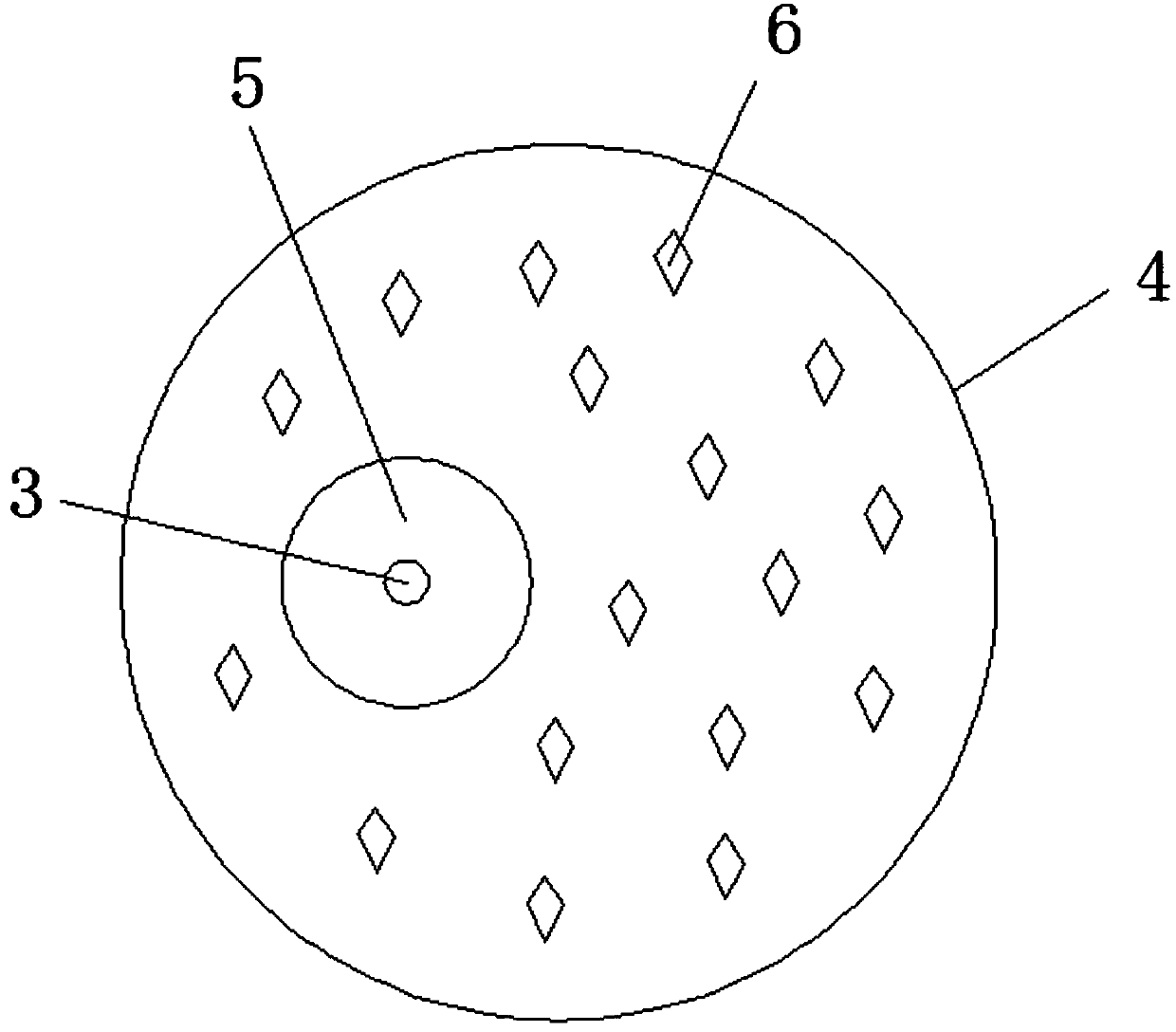

Low temperature pulverizer for crushing high oil materials

The invention discloses a low temperature pulverizer for crushing high oil materials. The low temperature pulverizer consists of a machine body, a feed inlet, a crushing chamber, a cooling chamber, amaterial conveying chamber and a discharge port. The crushing chamber is disposed at the upper part on the left side of the machine body, the left upper part of the crushing chamber is connected to the feed inlet, a servo motor is mounted above the top of the crushing chamber externally, a support plate is fixedly installed at the bottom of the crushing chamber, a plurality of material holes are symmetrically arranged on the support plate, the cooling chamber is arranged under the crushing chamber, the right side of the cooling chamber bottom is connected to the material conveying chamber, andthe upper part on the right side of the material conveying chamber is equipped with the discharge port. The low temperature pulverizer provided by the invention can achieve complete and efficient crushing and rolling treatment on materials, is conducive to processing and reutilization of the materials, at the same time can ensure the low temperature environment of the maerials during processing,thus fully absorbing the heat generated in the high-speed crushing process of the materials, and avoiding melting of oil in the materials and influence to the quality of the materials.

Owner:NANJING TONGZE AGRI SCI & TECH

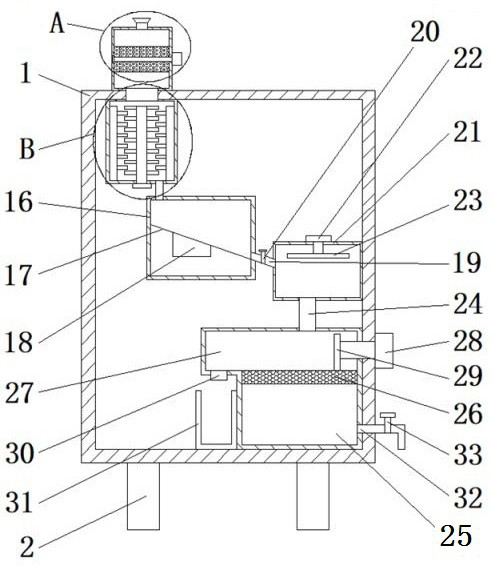

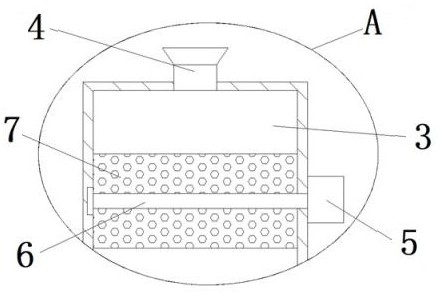

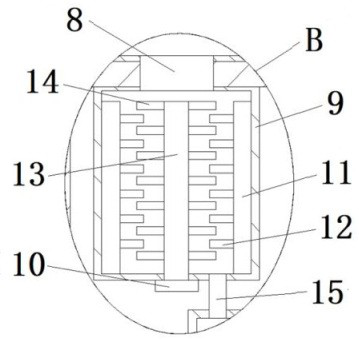

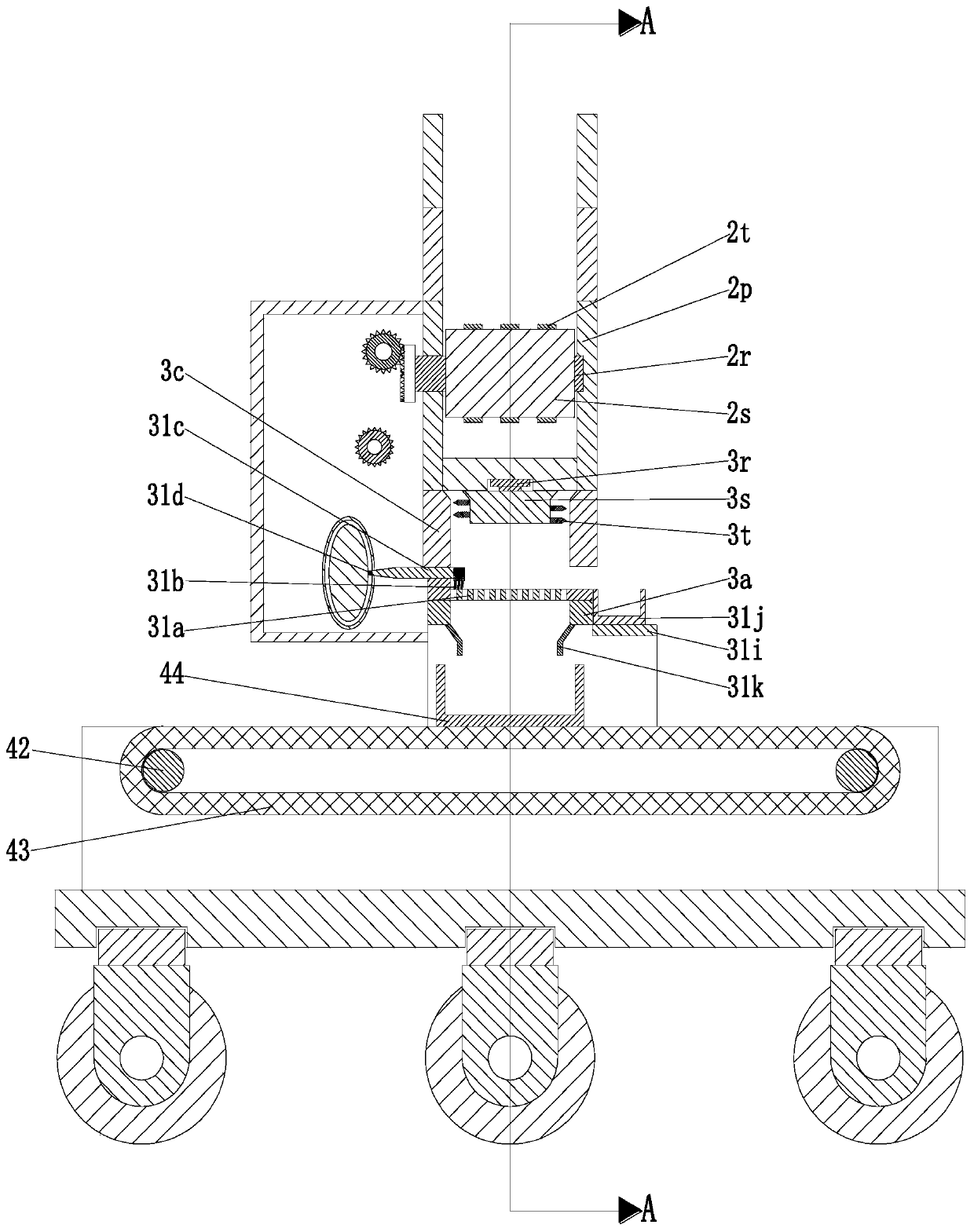

Small-compacted-volume solid waste treatment equipment

InactiveCN106824988AReduce manual operationsImprove efficiencySolid waste disposalGrain treatmentsWaste treatmentLiquid storage

The invention discloses a solid waste treatment device with small compacted volume, which relates to the field of waste treatment equipment, including a frame, a feeding mechanism, an acid and alkali liquid storage mechanism, a crushing mechanism and a compacting mechanism on the frame; The mechanism is connected in series under the feeding mechanism, the crushing mechanism is connected to the feed port of the compacting mechanism through the first pipeline; the outlet of the acid and alkali liquid storage mechanism is connected to the first pipeline through the second pipeline. The invention makes it possible to better reduce the volume of the solid waste while improving the treatment efficiency when treating the solid waste, thereby providing a solid waste treatment device with a small compacted volume.

Owner:成都君华睿道科技有限公司

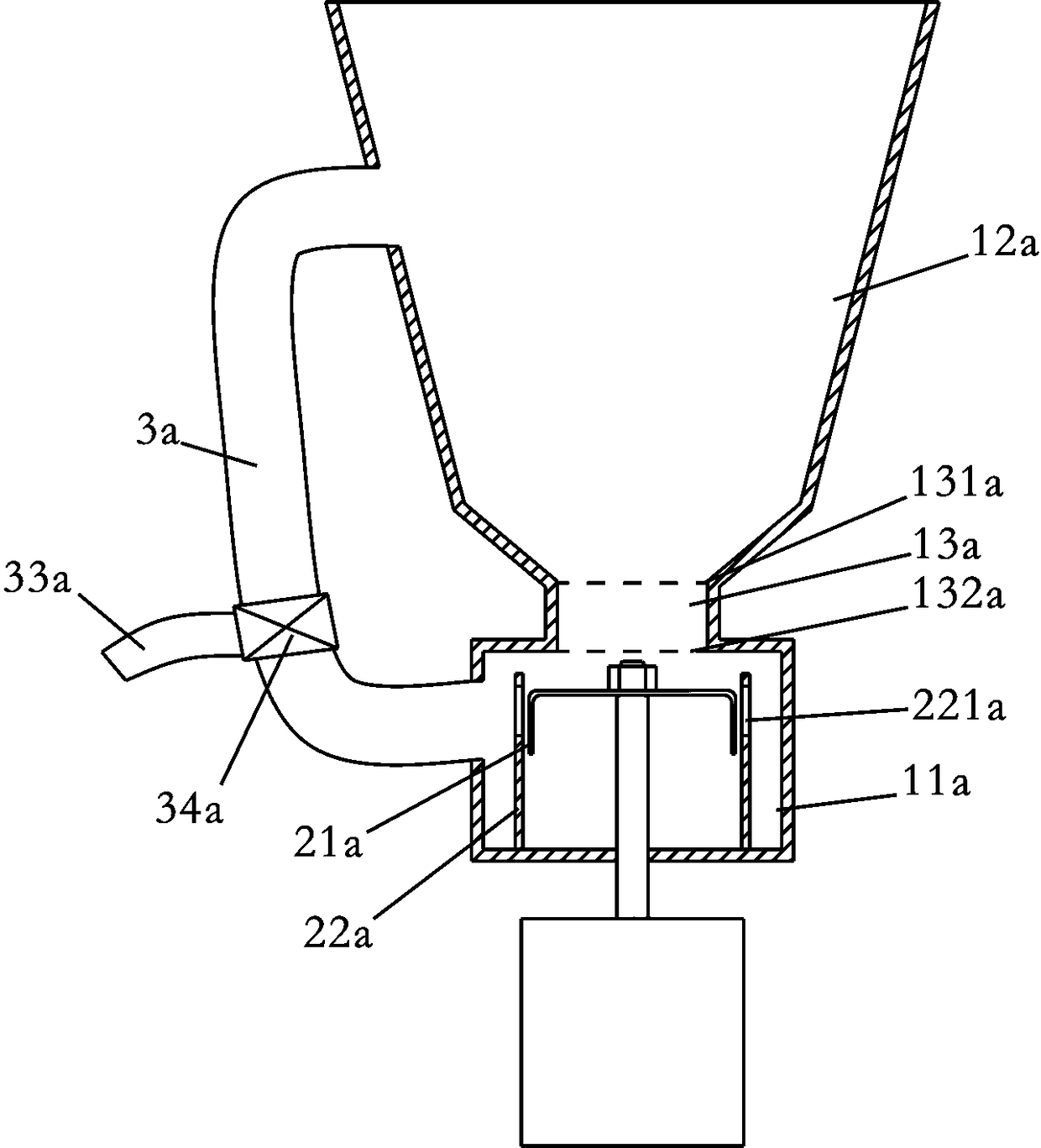

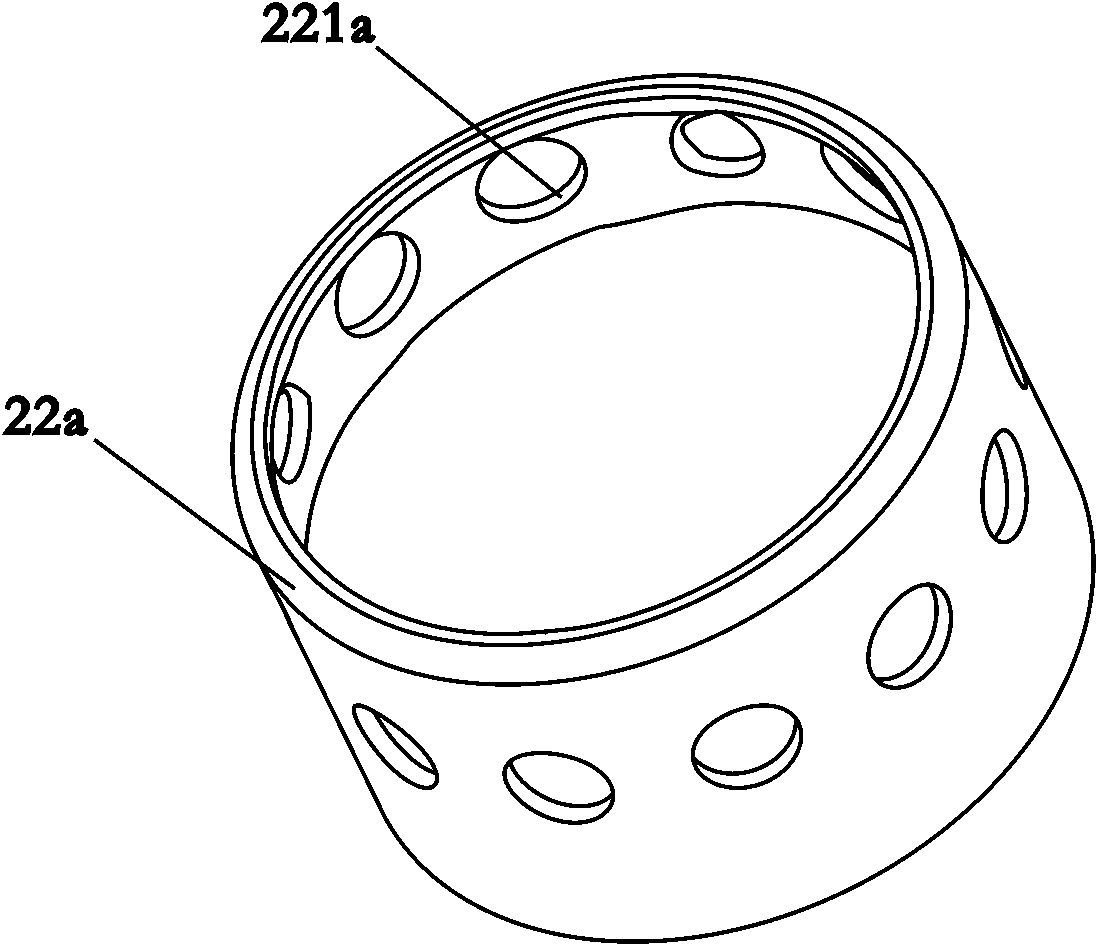

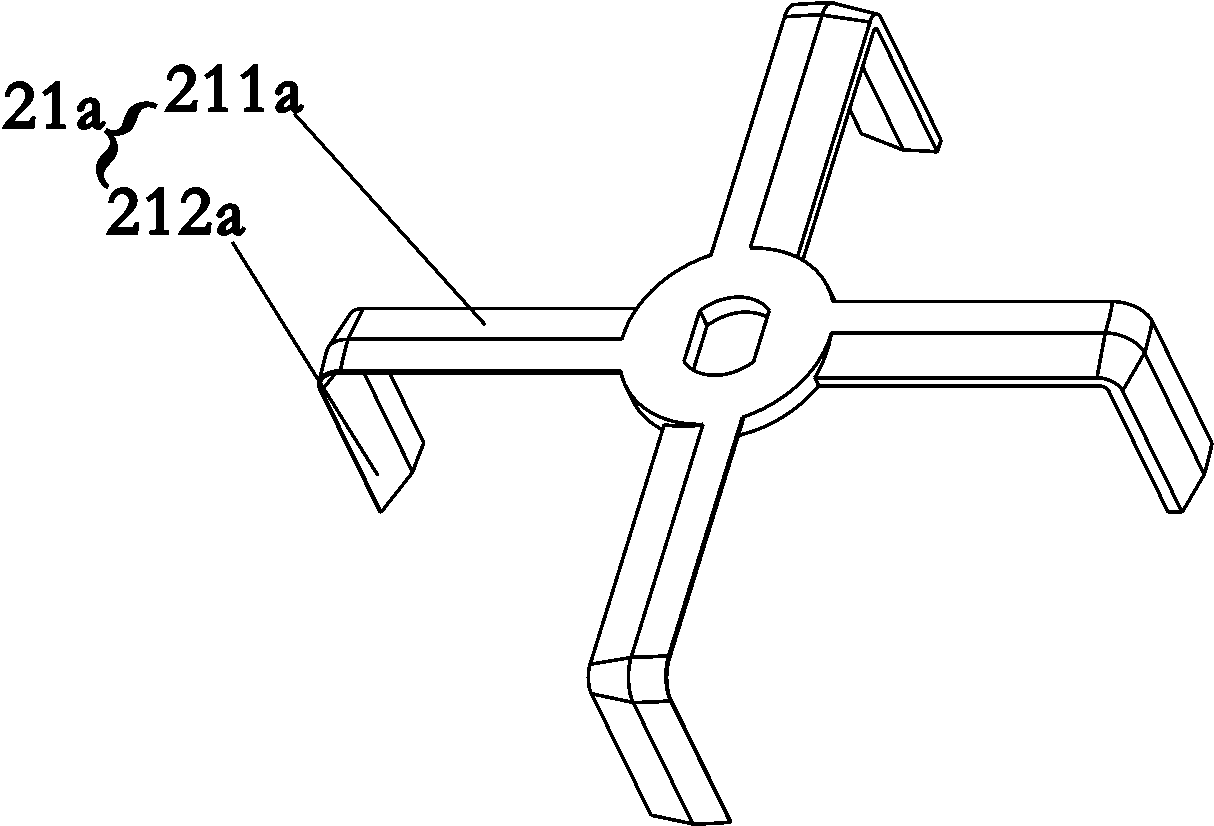

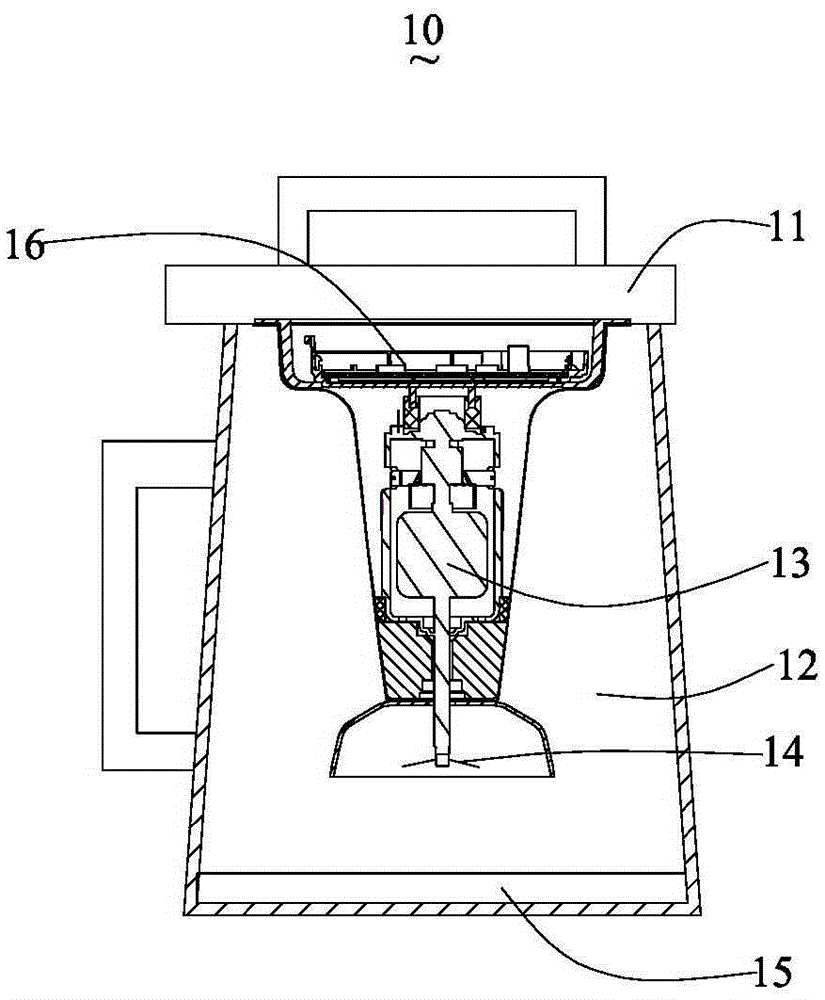

Crushing device used for food processing machine and the food processing machine

ActiveCN108309087ANot easy to escapeHigh efficiency of centralized crushingKitchen equipmentDiameter ratioEngineering

The invention relates to a small household electrical appliance in a kitchen, especially a food processing machine. A crushing device used for the food processing machine comprises a container, a crushing blade arranged in the container and a circulation pipeline communicating the container up and down. The crushing blade is driven by a motor to drive. The circulation pipeline is arranged outsidethe container. The container comprises a crushing chamber located at the bottom of the container, a backflow chamber located on the crushing chamber and a flow gathering opening communicating the crushing chamber with the backflow chamber. The capacity of the crushing chamber ranges from 30 mL to 380 mL. A crushing blade is arranged in the crushing chamber. An inlet of the circulation pipeline islocated in the crushing chamber. An outlet of the circulation pipeline is located in the backflow chamber. The diameter ratio of the diameter of an equal-area circle of the flow gathering opening to the diameter of an equal-area circle of a horizontal cross-section of a plane container where the circulation pipeline is located ranges from 0.2 to 0.75. Compared with the prior art, the food processing machine is simple in structure and relatively low in cost and capable of collectively crushing material. The crushing efficiency is high. No bulky material appears. The food processing machine is convenient to clean.

Owner:JOYOUNG CO LTD

Oil pressing device

PendingCN112009005AImprove oil extraction efficiency and oil qualityImprove oil extraction efficiencyFatty-oils/fats refiningCleaning using toolsProcess engineeringKnife blades

The invention relates to the technical field of oil pressing equipment, in particular to an oil pressing device which comprises a processing box, wherein supporting legs are arranged at the four corners of the lower side of the processing box, a feeding box is arranged at the left end of the top of the processing box, a discharging pipe is arranged at the bottom end of the right side of the processing box, and a second electromagnetic valve is arranged on the discharging pipe. The oil pressing device is simple in structure, by arranging the feeding box, raw materials are poured into the feeding box from a feeding funnel, through cooperative use of a first motor, a rotating shaft, a baffle and a feeding port, the feeding speed can be controlled, it is avoided that too many raw materials enter a cutting box at a time, the raw material smashing degree and smashing efficiency are reduced, and the oil pressing efficiency is guaranteed; a first cutting blade and a second cutting blade are arranged to cut the raw materials multiple times in a dynamic and static combination mode, so that the raw materials are crushed more thoroughly, subsequent squeezing treatment is facilitated, and the oil pressing efficiency and the oil pressing quality are improved.

Owner:WUHAN POLYTECHNIC UNIVERSITY

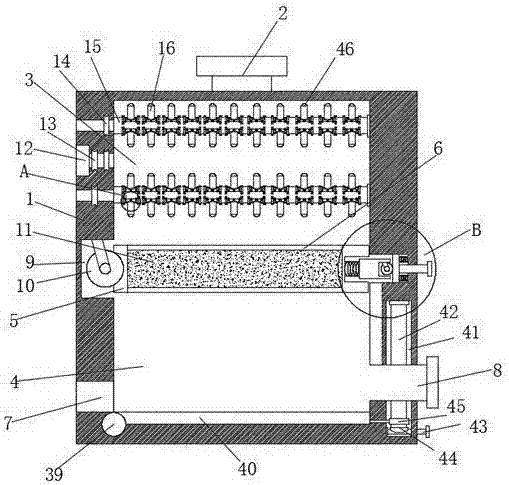

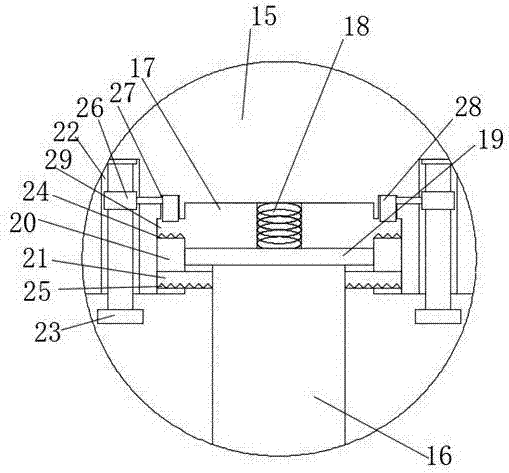

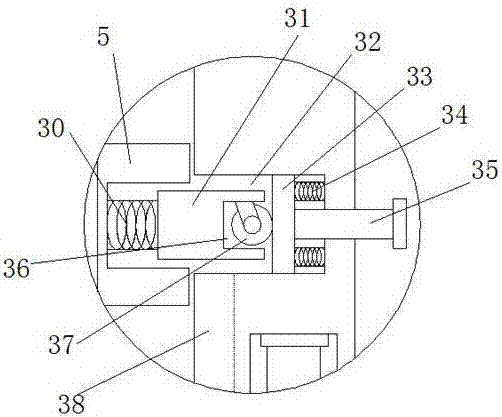

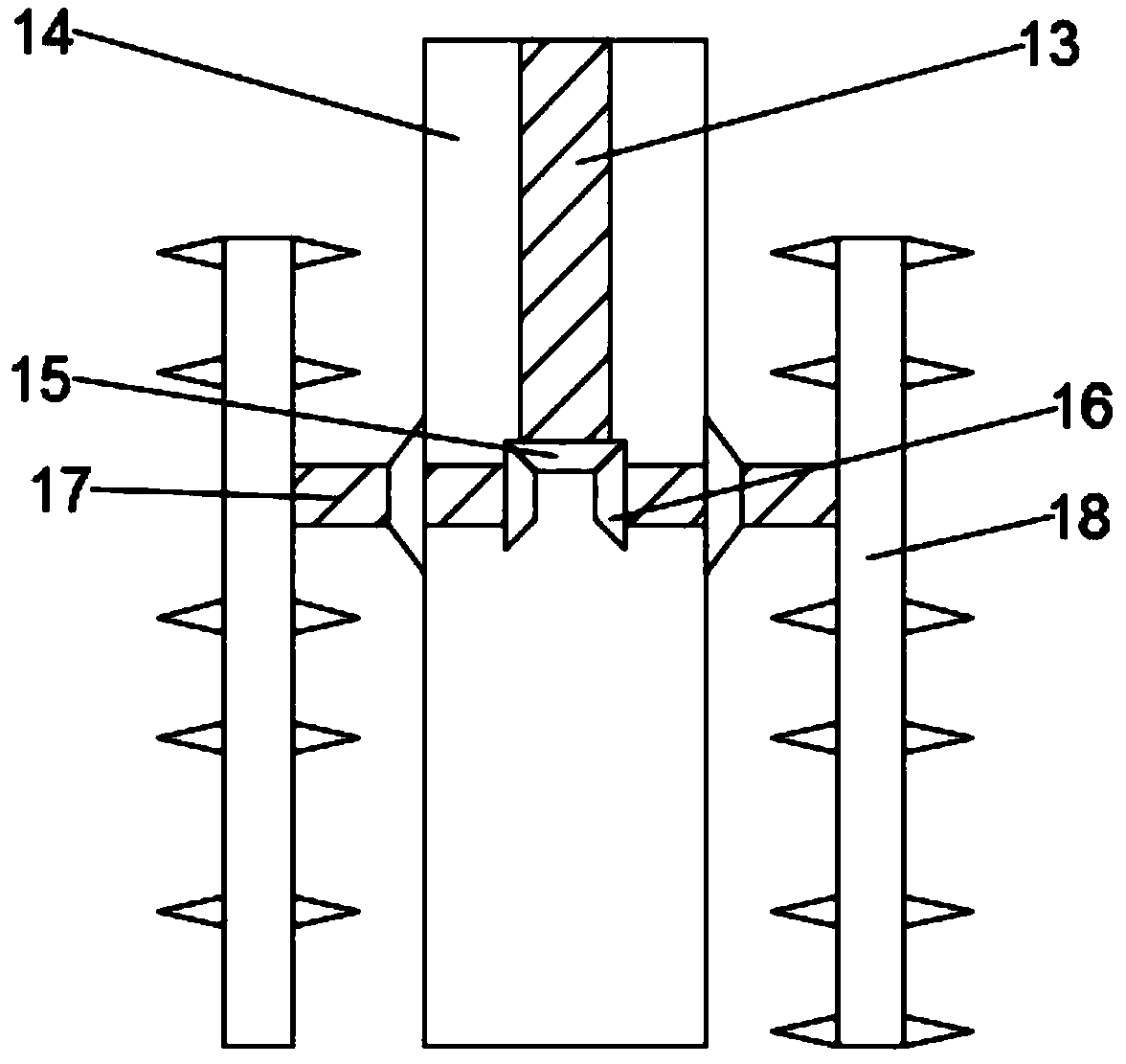

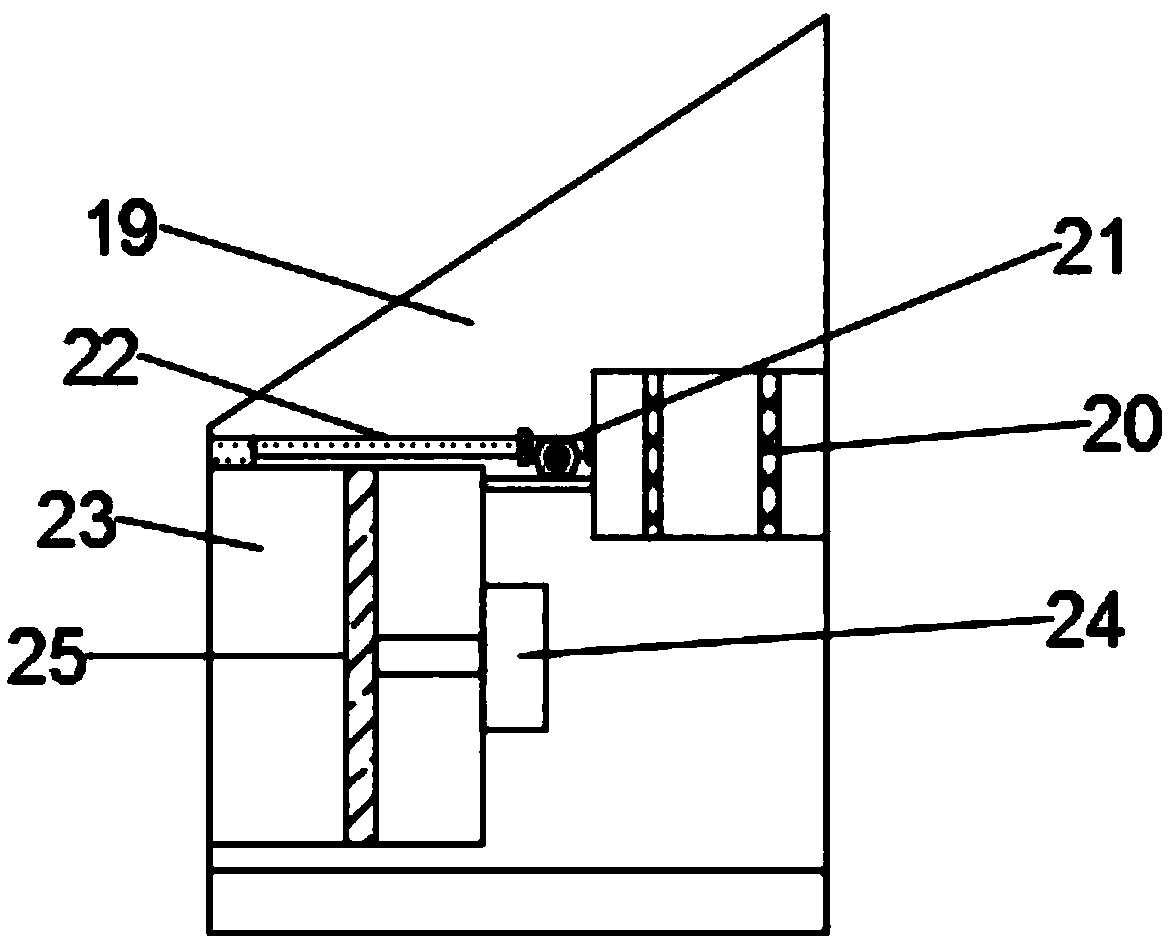

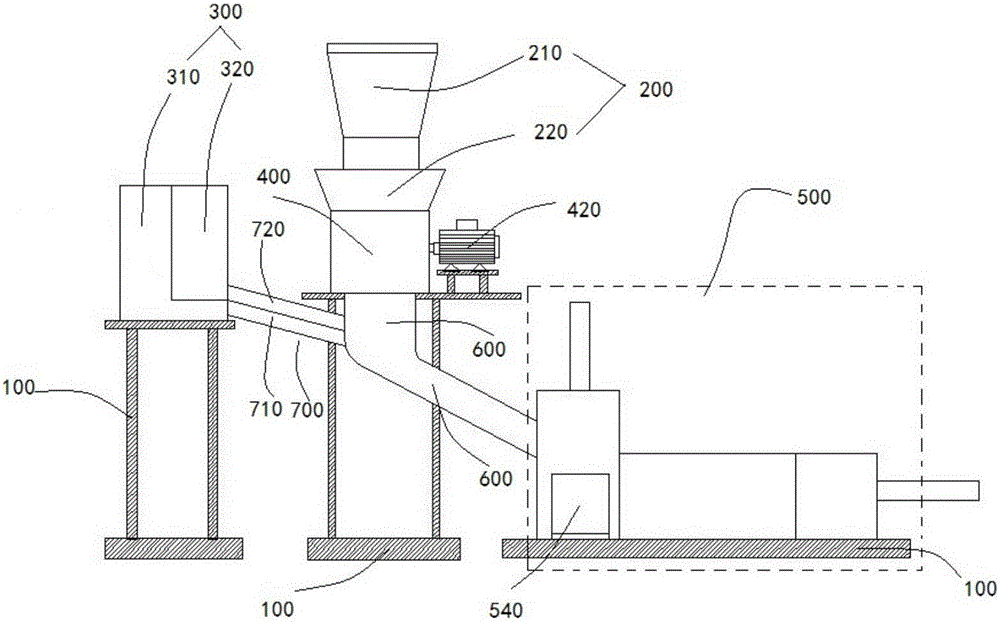

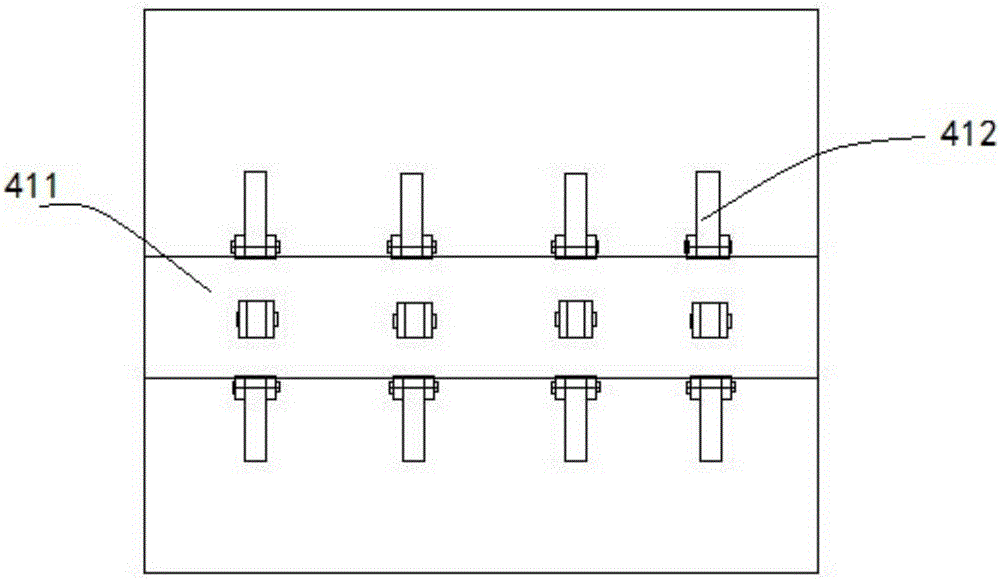

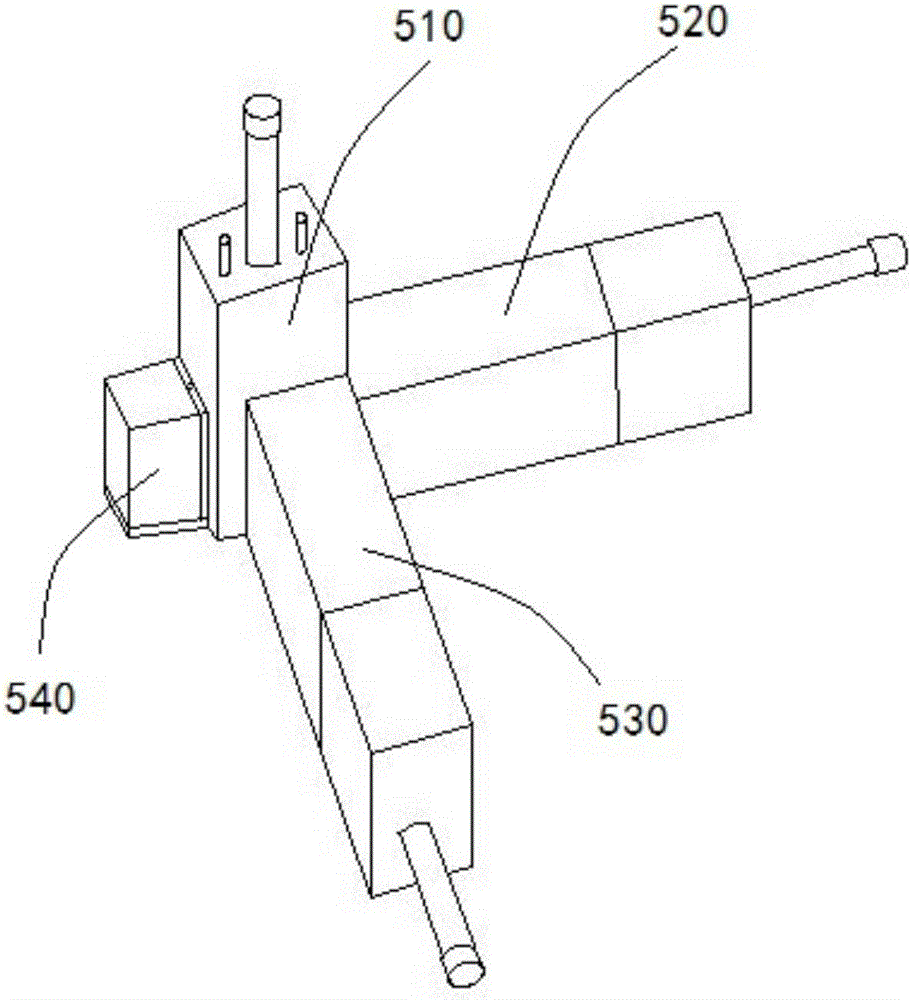

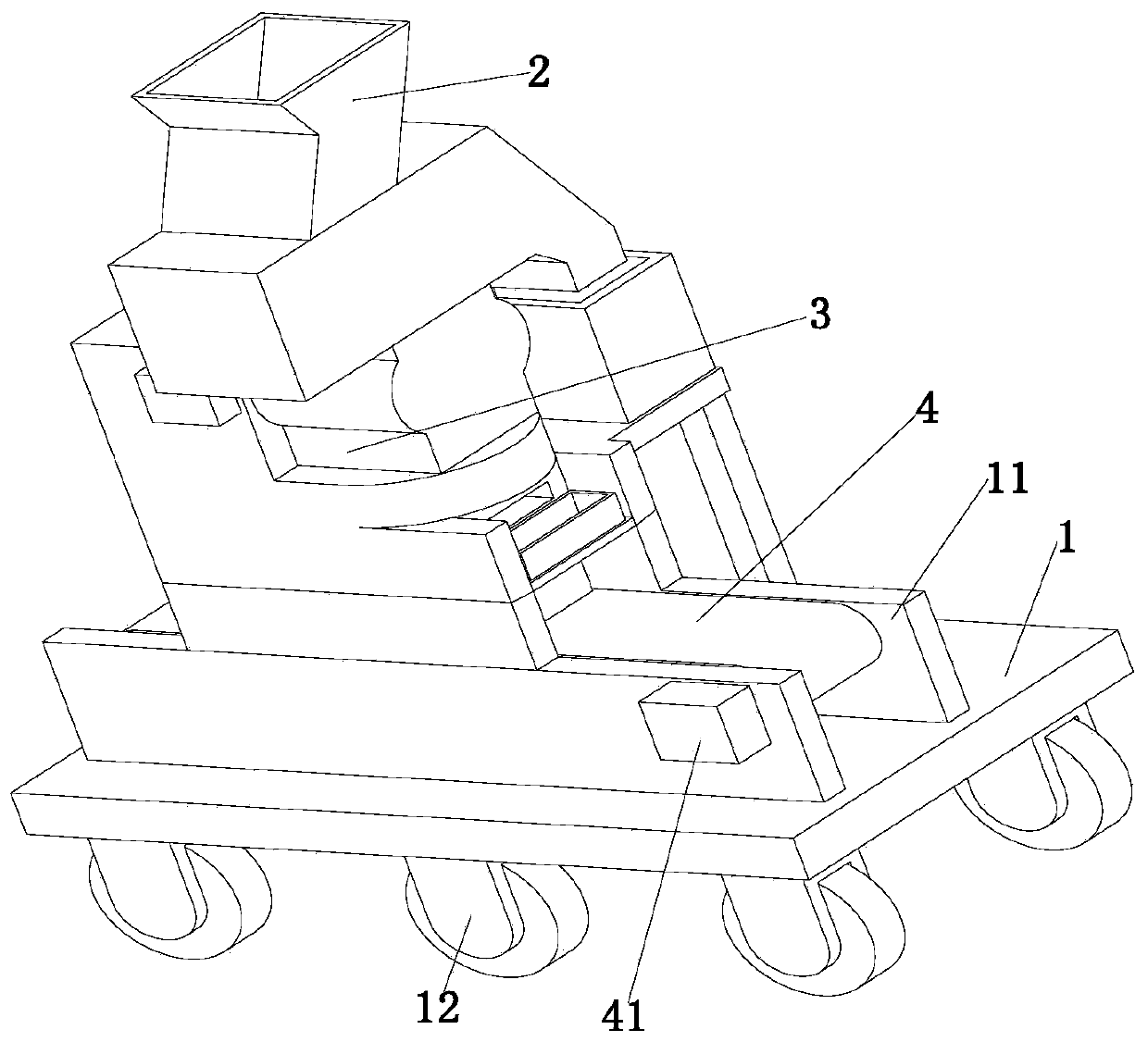

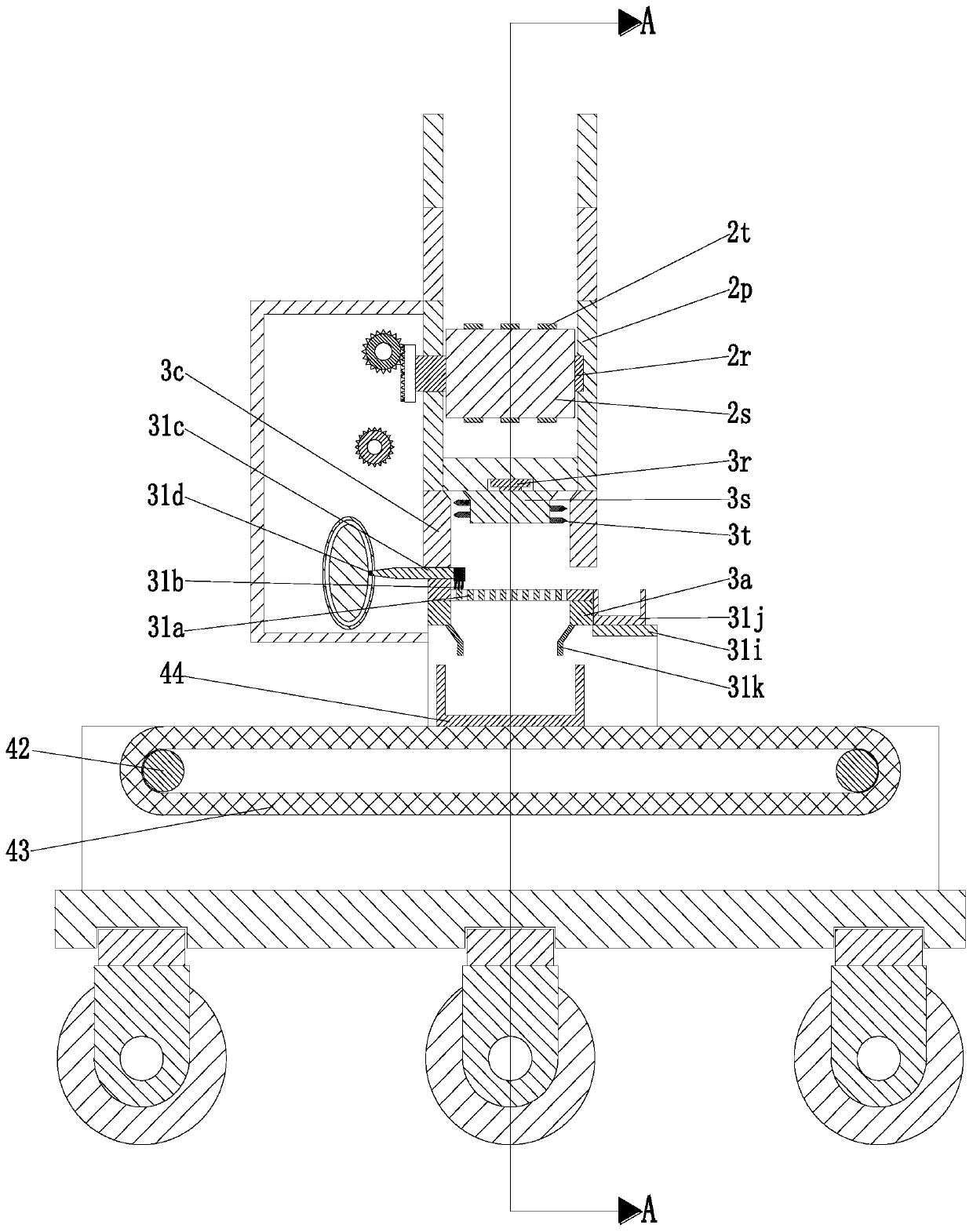

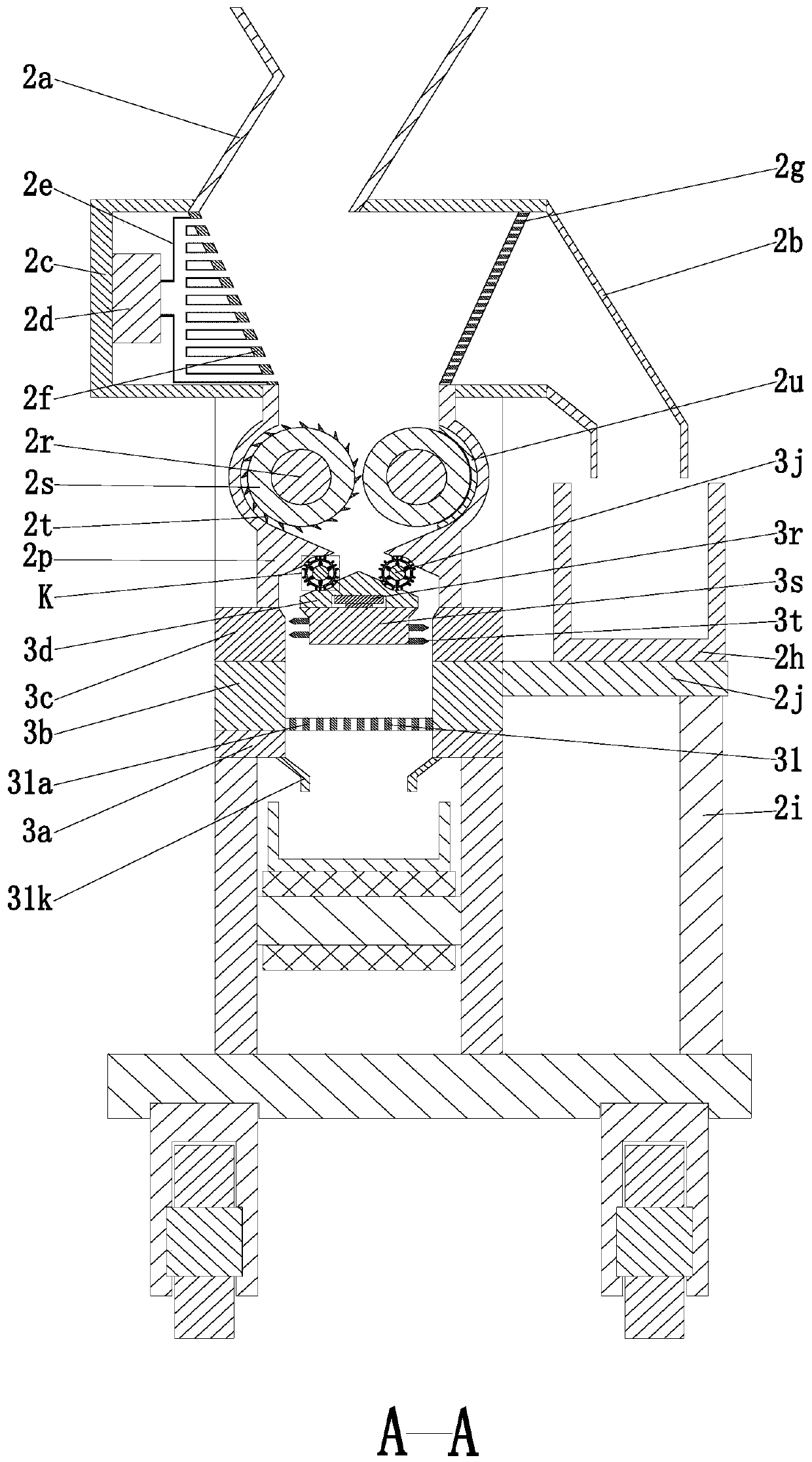

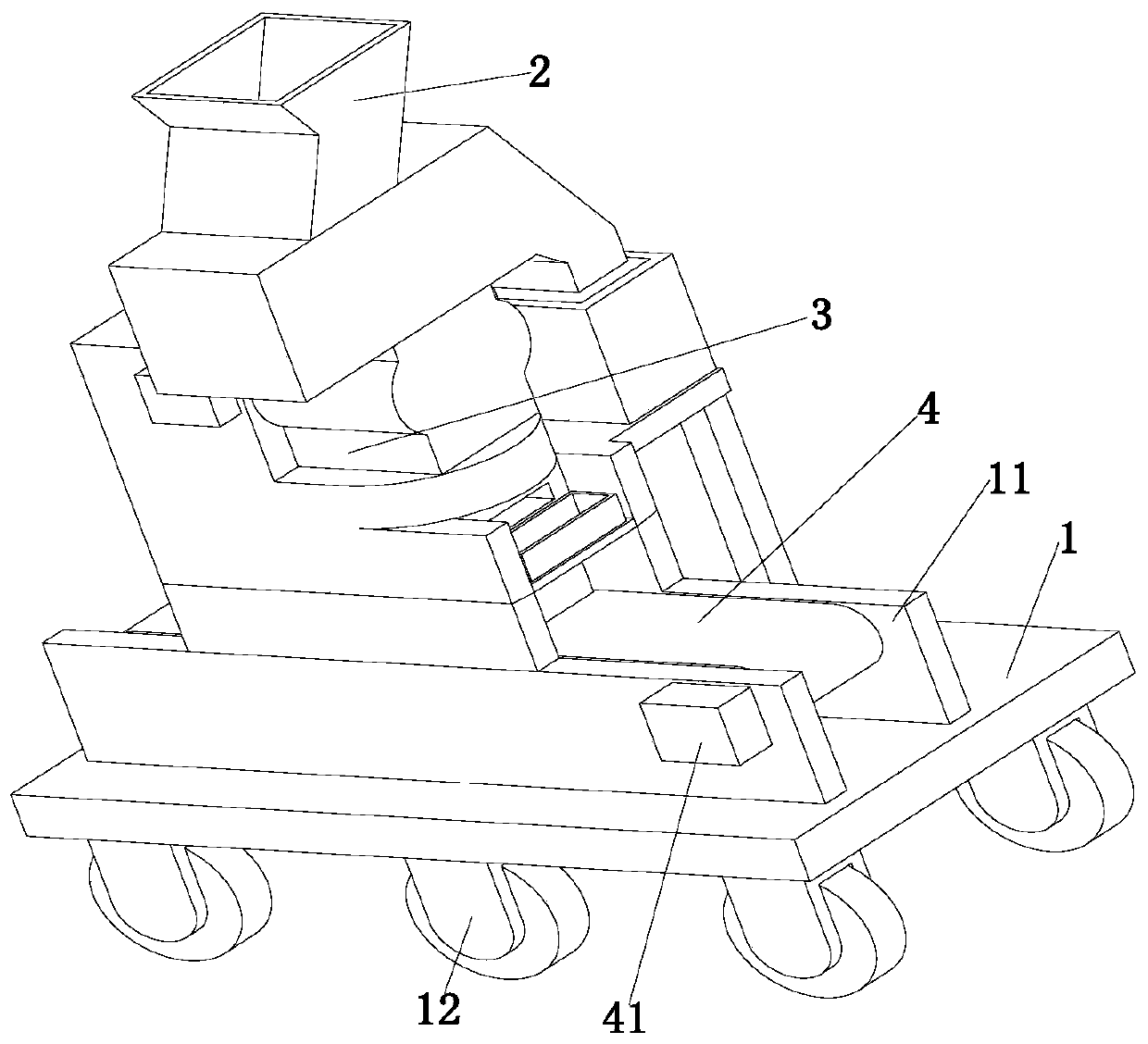

Pretreatment processing system for injection molding raw materials

ActiveCN111409210AReduce crushing efficiencyImprove crushing efficiencyProcess engineeringIndustrial engineering

The invention relates to a pretreatment processing system for injection molding raw materials. The pretreatment processing system comprises a bottom plate, a crushing device, a chopping device and a conveying device, wherein supporting plates are symmetrically arranged on the bottom plate in a front-back mode, the conveying device is arranged on the supporting plates, the chopping device is arranged at the upper ends of the supporting plates, and the crushing device is arranged at the upper end of the chopping device. According to the pretreatment processing system, the following problems existing in the crushing and screening process of injection molding raw materials in the prior art can be solved, wherein the problems are that a, when a traditional injection molding raw material crushing device is used for crushing the injection molding raw materials, the crushing quality cannot be guaranteed, moreover, a screening net can be blocked during screening, manual treatment is troublesome, and the crushing efficiency of the injection molding raw materials is reduced; and b, an existing injection molding raw material crushing device is complex in structure, the operation is tedious during use, the gaps of tearing teeth inside the crushing device are large, so that the injection molding raw materials with small structures are difficult to be crushed into small particles. The crushing efficiency and quality of the injection molding raw materials can be improved.

Owner:南通德尔隆工程塑料有限公司

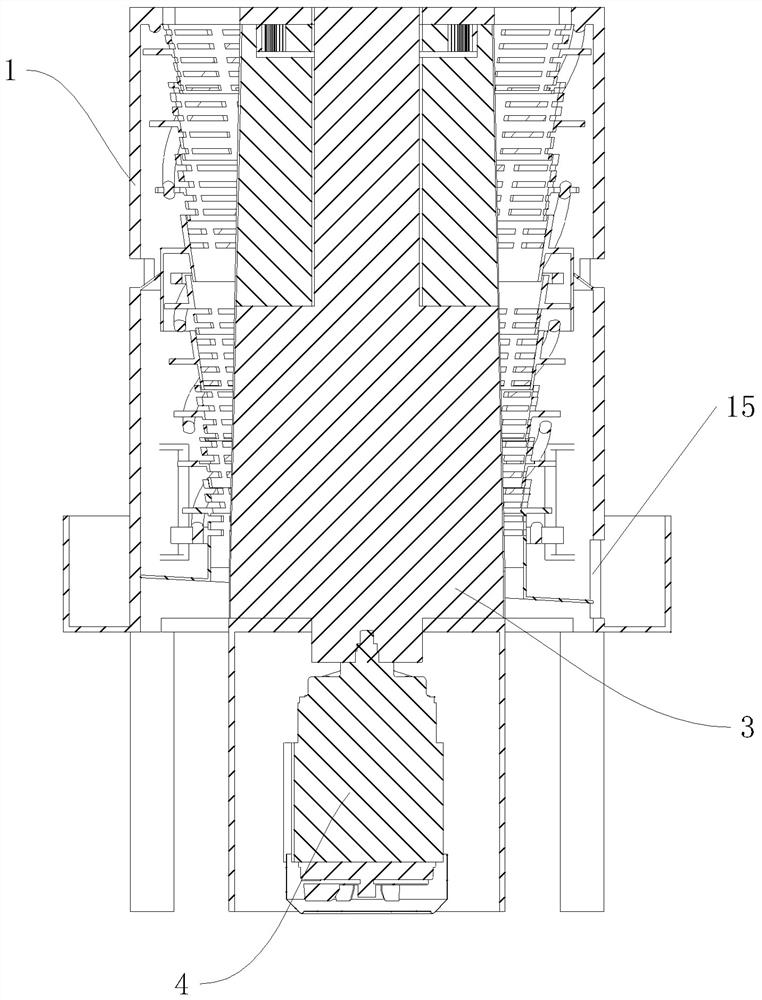

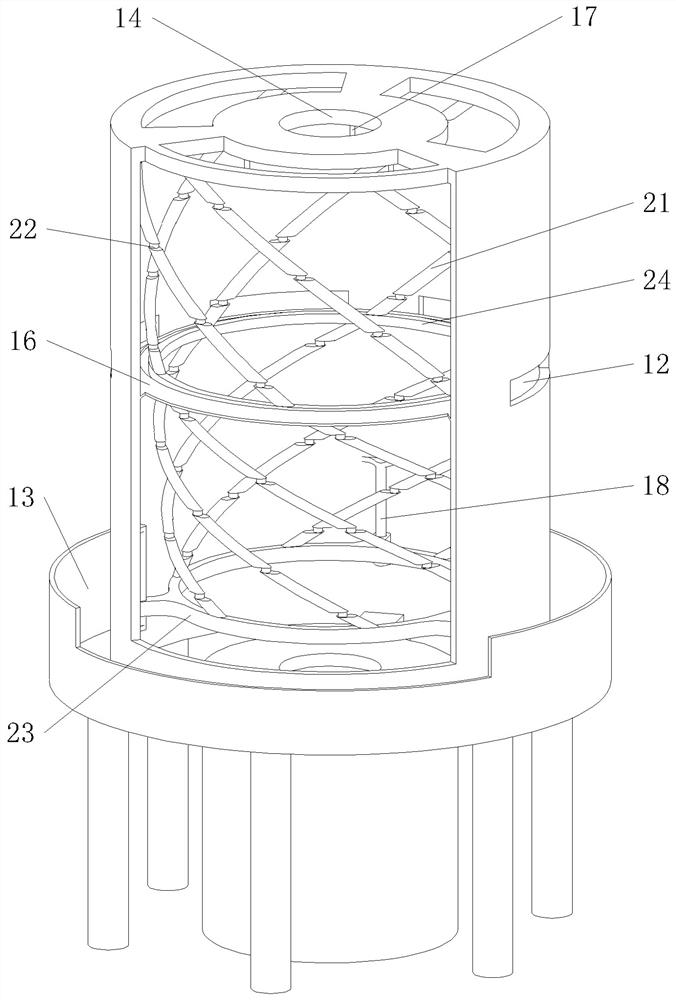

Thermal insulation filler processing equipment for building main body

ActiveCN114309016AReduce crushing efficiencyThe speed of entering the lower crushing chamber is fastSolid waste disposalGrain treatmentsThermal insulationClassical mechanics

The invention relates to the field of crushing, in particular to thermal insulation filler processing equipment for a building main body. A crushing cavity with an upward opening is formed in the crushing shell, the crushing column comprises an upper rotating column and a lower rotating column, and the transmission mechanism is used for enabling the rotating directions of the upper rotating column and the lower rotating column to be opposite. The crushing ring is sleeved on the crushing column; the multiple crushing rings are evenly distributed in the axial direction of the crushing column, and one crushing ring can be inserted into the adjacent crushing ring below the crushing ring in an up-down sliding mode. The fixing ring is coaxial with the crushing shell and is fixedly mounted at the upper end of the crushing shell; the movable ring is coaxial with the crushing shell and is mounted at the lower end of the crushing shell in a vertical sliding manner; the upper end of the elastic strip is fixed to the fixed ring, and the lower end spirally extends downwards to the movable ring; and each elastic strip penetrates through all the crushing rings and is configured to drive the adjacent crushing rings to be close to or away from each other when the elastic strips contract or expand, and the multiple elastic strips are evenly distributed in the circumferential direction of the fixing ring, so that the device can achieve self-adjustment, and the effect of avoiding jamming is achieved.

Owner:新乡滨湖生态园林(集团)有限公司

Freeze wall breaking soybean milk making method of household soymilk machine and household soymilk machine

InactiveCN105249853AReduce crushing efficiencyReduced flexibilityKitchen equipmentMilk substitutesMotor driveIntercellular space

The invention relates to a freeze wall breaking soybean milk making method of a household soymilk machine. The method includes the following stages: (1) a preprocessing stage: soaking dry soybeans and allowing the dry soybeans to fully absorb water to be saturated, and freezing the soybeans into ice soybeans; (b) an unfreezing stage: putting the ice soybeans into a cup and unfreezing and softening the ice soybeans; (c) a crushing stage: a motor drives a crushing cutter to rotate to crush the soybeans into soymilk liquid. The soybeans absorb water to expand, so that cell interiors and intercellular spaces of the soybeans are filled with water. According to the temperature transfer law, ice crystals are formed from outside to inside during a freezing process, and free water in outer layers of cell walls firstly forms into the ice crystals; at this time, the internal parts of the cell walls are liquid, the cell walls are made to deform for the first time by squeezing of the internal and external pressure, and then the ice crystals are formed in the internal parts of the cells, and the volume is expanded to squeeze the cell walls to cause a second deformation of the cell walls, so that the cell walls of the soybeans are broken.

Owner:JOYOUNG CO LTD

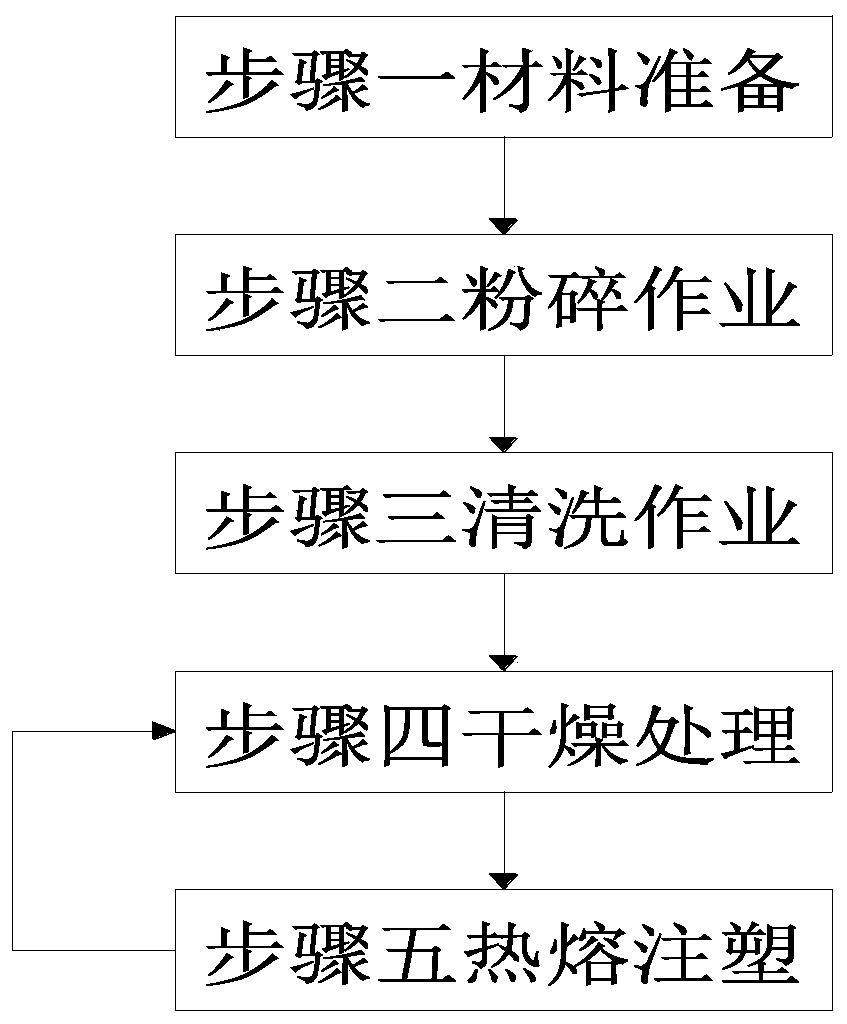

Injection molding raw materials pretreatment process

ActiveCN111391165AReduce crushing efficiencyImprove crushing efficiencyMaterials preparationProcess engineering

The invention relates to an injection molding raw materials pretreatment process. The pretreatment process mainly comprises the following steps of material preparation, crushing operation, cleaning operation, drying treatment and hot melt injection molding, wherein involved injection molding materials crushing equipment comprises a bottom plate, a crushing device, a shredding device and a conveying device. The pretreatment process disclosed by the invention can solve the following problems when the injection molding raw materials are crushed and screened by the prior art: firstly, an existingcrushing device for the injection molding raw material cannot guarantee the crushing quality when the injection molding raw materials are crushed, a screening net can be blocked during screening, andmanual processing is troublesome, so that the crushing efficiency of the injection molding raw materials is reduced; and secondly, the existing crushing device for the injection molding raw materialsis complex in structure, complicated to operate in use and large in tearing tooth gaps inside the crushing device, so that the injection molding raw materials with small structures are difficult to becrushed into tiny particles, and according to the pretreatment process disclosed by the invention, crushing efficiency and quality of the injection molding raw materials can be improved.

Owner:泰州市环球塑胶科技有限公司

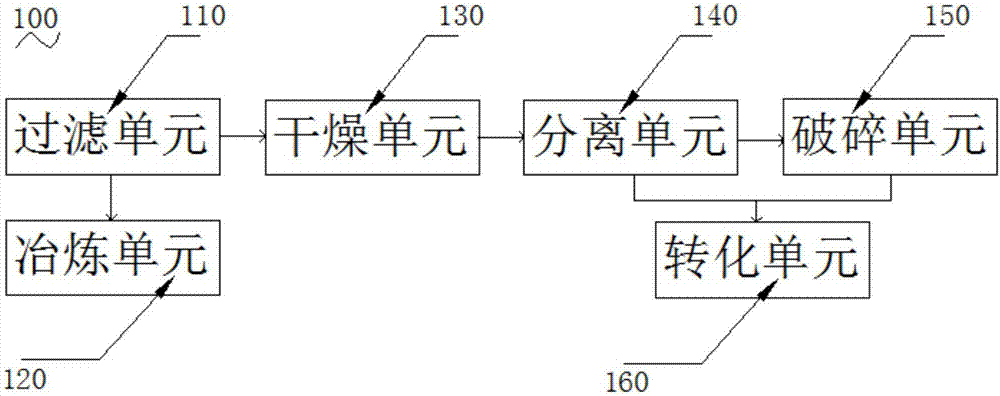

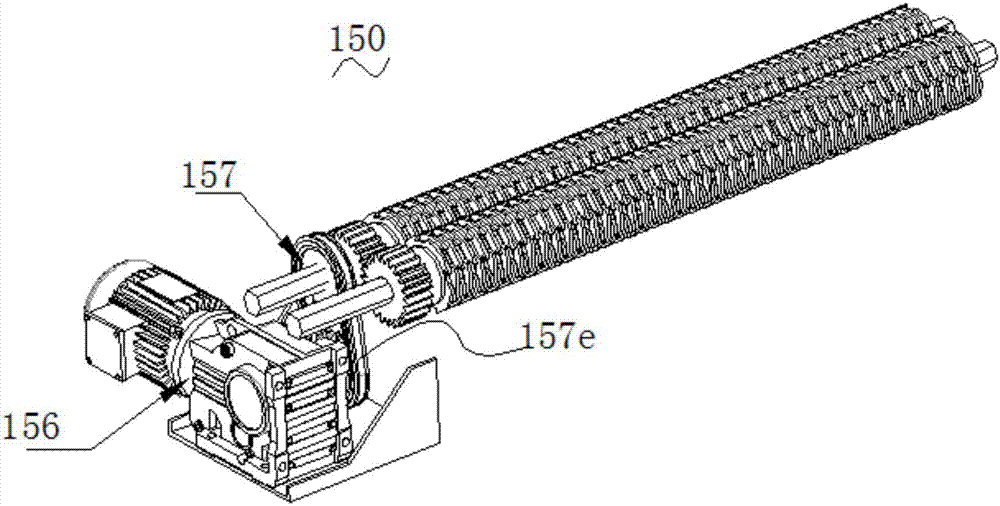

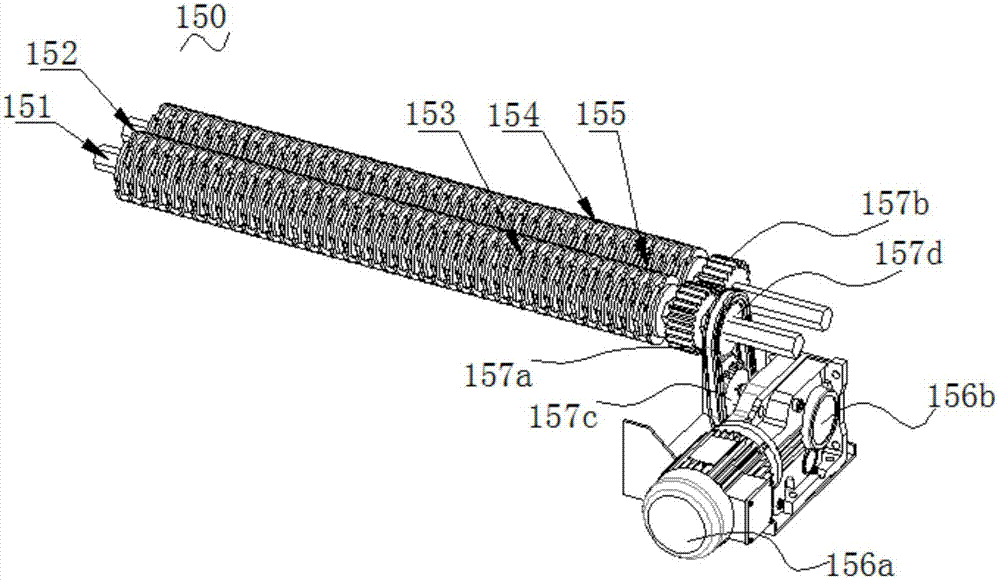

Kitchen waste treatment system

PendingCN107377588AEnable recyclingImprove protectionSolid waste disposalTransportation and packagingLiquid wasteBiodiesel

The invention relates to the field of kitchen waste treatment, in particular to a kitchen waste treatment system. The kitchen waste treatment system comprises a filtration unit, a smelting unit, a drying unit, a separation unit, a crushing unit and a conversion unit, wherein the filtration unit is used for filtering liquid waste, the smelting unit is connected with the filtration unit and is used for smelting liquid waste obtained after filtration to obtain biodiesel, the drying unit is connected with the filtration unit and is used for drying solid waste obtained after filtration, the separation unit is connected with the drying unit and is used for separating waste such as bones in the dried solid waste, the crushing unit is connected with the separation unit and is used for crushing the waste such as the bones, and the conversion unit is connected with the separation unit and the crushing unit and is used for fermenting the solid waste into feed. According to the kitchen waste treatment system, the kitchen waste can be subjected to classified recycling, the recycling efficiency is high, secondary pollution is avoided, the environment is protected, and resources are saved.

Owner:广东省绿革环保科技有限公司

Crushing device for grain processing

InactiveCN112536086AGood removal effectPrevent leakageGrain treatmentsElectric machineryStructural engineering

The invention discloses a crushing device for grain processing. The crushing device for grain processing comprises a device shell, wherein an impurity removal leaking groove is formed in the outer surface of the upper end of the device shell, a motor is arranged at the outer surface of one side of the device shell, fixing feet are arranged on the outer surface of the other side of the device shell, and a grinding column is arranged at the lower end of the impurity removal leaking groove; a partition plate is arranged at the lower end of the grinding column, a deep crushing mechanism is arranged at the lower end of the partition plate, a detachable crushing storage end is arranged at the lower end of the deep crushing mechanism, the impurity removal leaking groove comprises a pull ring, a connecting rod, a sliding groove, a leaking plate, a housing and a discharging end, and the pull ring is located on the outer surface of the upper end of the connecting rod; and the connecting rod is located on the outer surface of the upper end of the leaking plate. According to the crushing device for grain processing, through the arranged mechanism, people can conveniently and efficiently removeimpurities, so that the working efficiency of the machine is increased, the practicability of the machine is improved, and better use prospects are brought.

Owner:安徽喜乐田园食品有限公司

Pulverizing machining device for waste plastic bottles

InactiveCN108068235AGather effectivelyIncreased dispersionPlastic recyclingGrain treatmentsSpiral bladeEngineering

The invention discloses a pulverizing machining device for waste plastic bottles. The pulverizing machining device comprises a device body which is mainly composed of a pulverizing cavity and a lifting device; the pulverizing cavity is internally provided with a rotary shaft, pulverizing cutting blades are uniformly distributed on the left side of the surface of the rotary shaft, the rotary shaftis sleeved with a moving piece which is of an annular structure, and connection rods are hinged to the upper end and the lower end of the moving piece correspondingly; a gathering plate is arranged inthe pulverizing cavity; and a rotation shaft is arranged in the lifting device, connected with a lifting motor and provided with a spiral blade. The pulverizing machining device effectively gathers the plastic bottles in the plastic bottle pulverizing process, the situation that the pulverizing efficiency of the plastic bottles is reduced due to the fact that the plastic bottle scattering degreeis high is avoided, pulverized plastic particles and unpulverized plastic particles are effectively separated in the pulverizing process, the pulverizing efficiency and the pulverizing effect of the plastic bottles are improved, in addition, the plastic particles can be lifted up and then pulverized through the pulverizing machining device, the pulverizing degree of the plastic bottles is greatlyincreased, and using is facilitated.

Owner:GUANGDONG DEXIN TECH INCUBATOR CO LTD

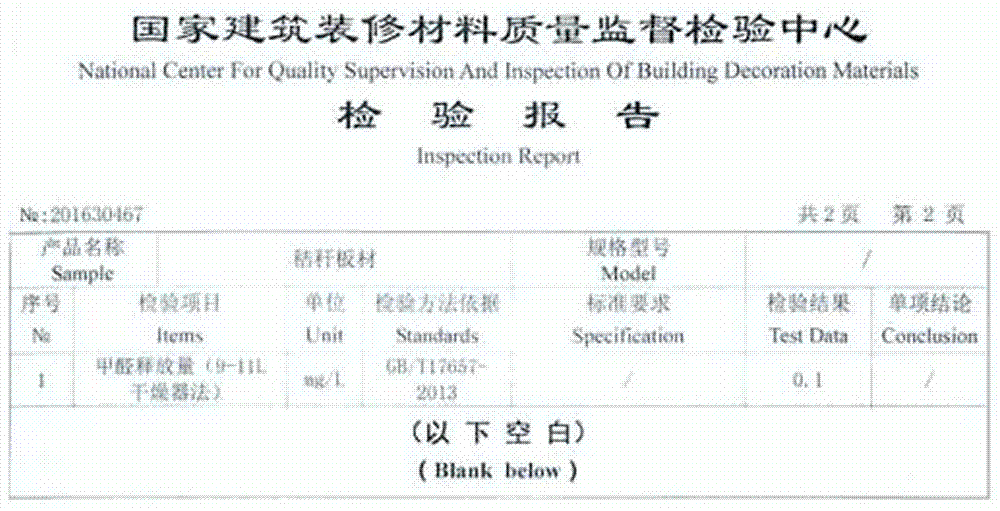

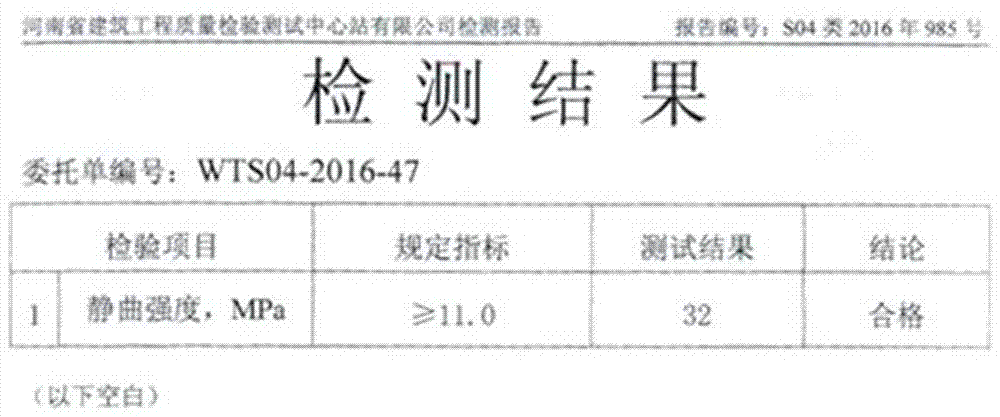

Environmental-protection rice husk and straw board production method

InactiveCN107498683AReduce crushing efficiencyReduce surface tensionWood working apparatusDomestic articlesAdhesiveSilicon oxygen

The invention discloses an environmental-protection rice husk and straw board production method. The production method comprises the preparation steps of: mixing of straw fragments and rice husks-surface treatment-treatment through physical and chemical combination methods-uniform glue mixing-pavement-prepressing-hot pressing molding-fixed length edge cutting-curing-drying-trimming and surface treatment-products; in raw materials, the mass percentage ratio of the use levels of the straws and the rice husks is (1-3): 1; in the surface treatment step, chemical raw materials containing silicon-oxygen chemical bond structures similar to wax structures on the surfaces of the straws are added; few nanomaterials pitting the wax surfaces under the temperature condition of above 90 DEG C are added; adhesives capable of forming hydrogen bonds or chemical bonds with polyhydroxyl structures are added; and finally, the uniform mixing is performed by a physical method for surface treatment. A board prepared by the method is high in strength; no harmful gas is discharged; the board is excellent in crush resistance, water resistance and environmental protection property; and the strength and the yield of the board are improved.

Owner:河南安朝板材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com