Building material grinding device

A technology for pulverizing device and building materials, applied in the engineering field, can solve the problems of easy pulverizing device, easy jamming, inability to determine the pulverization degree of building materials, etc., and achieve the effect of speeding up pulverizing efficiency and preventing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

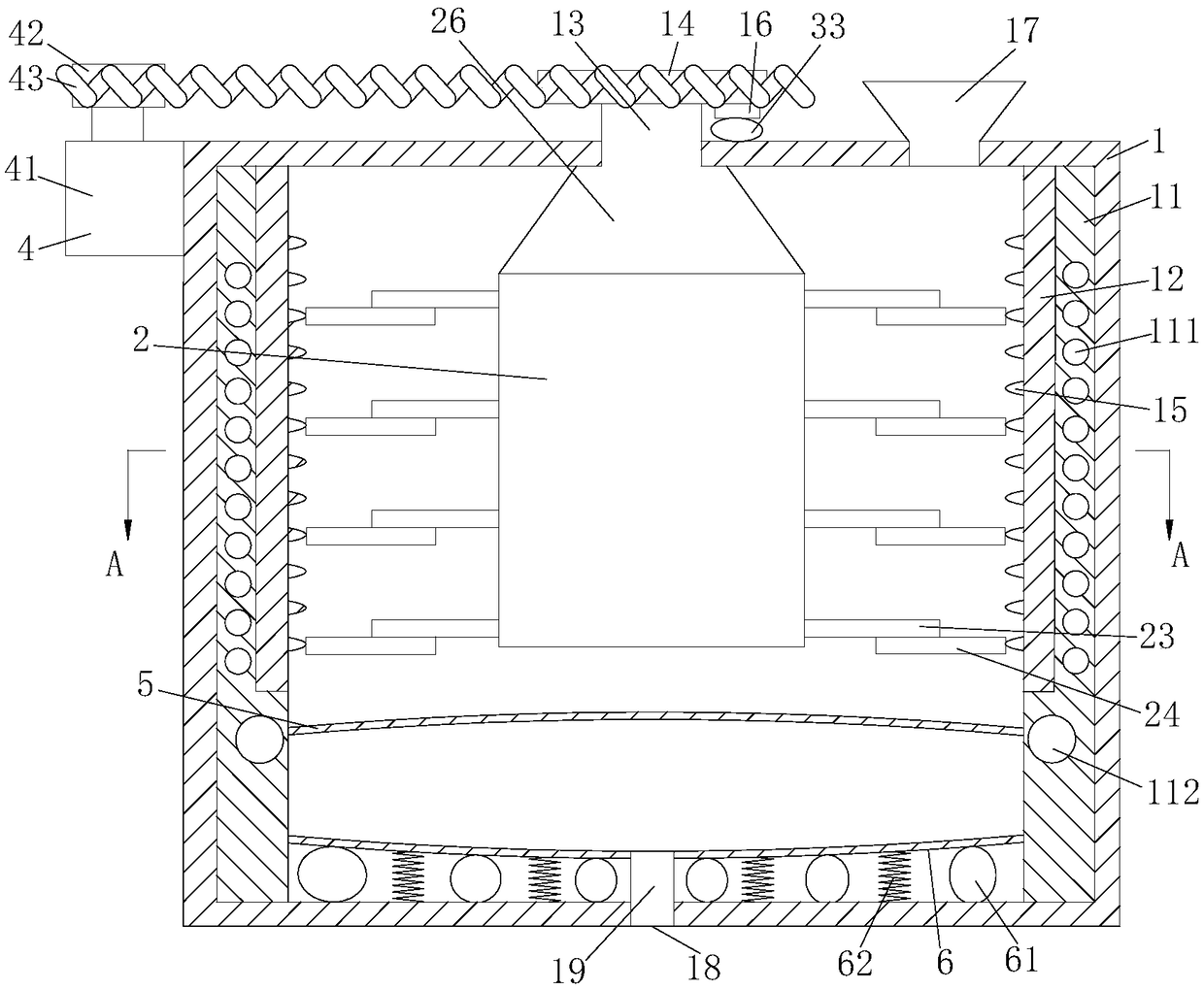

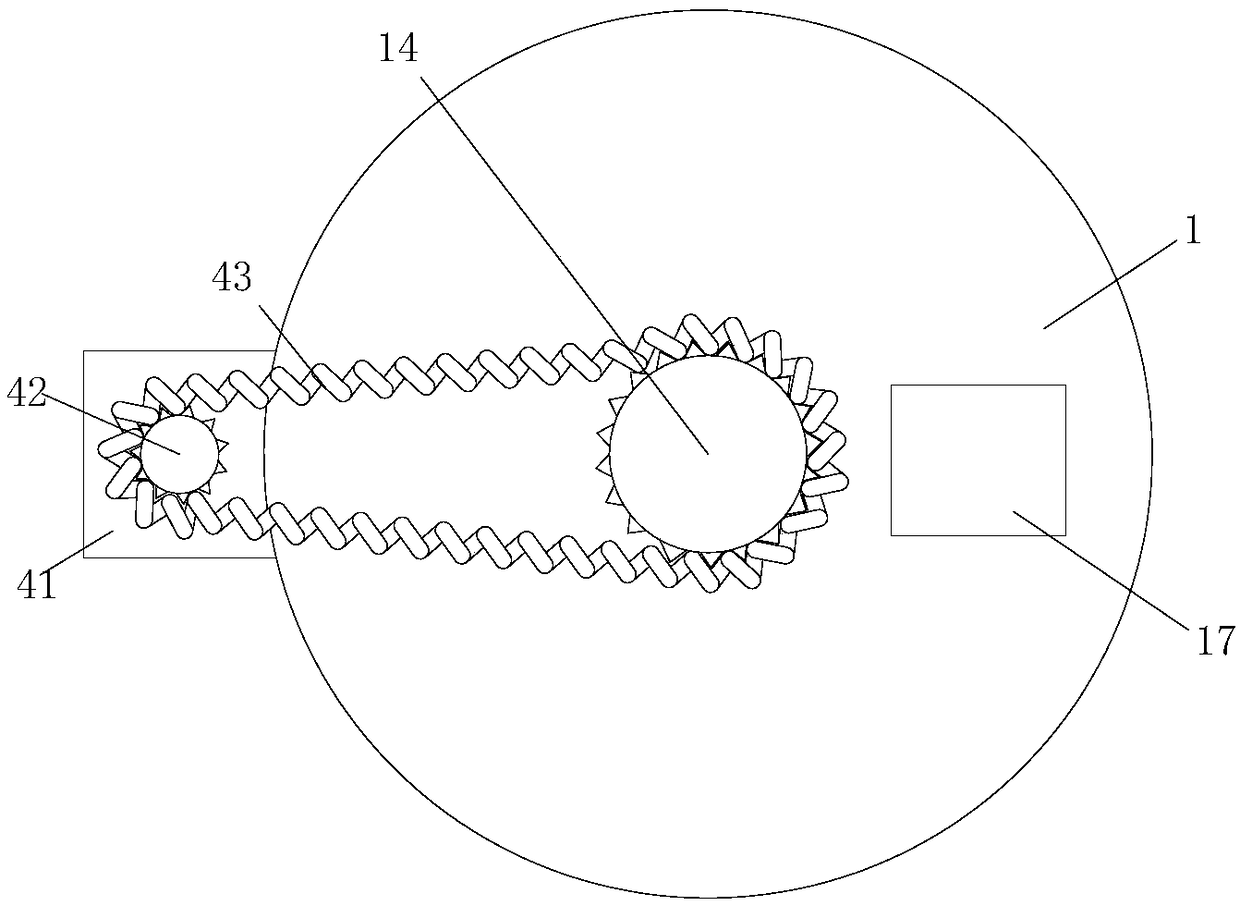

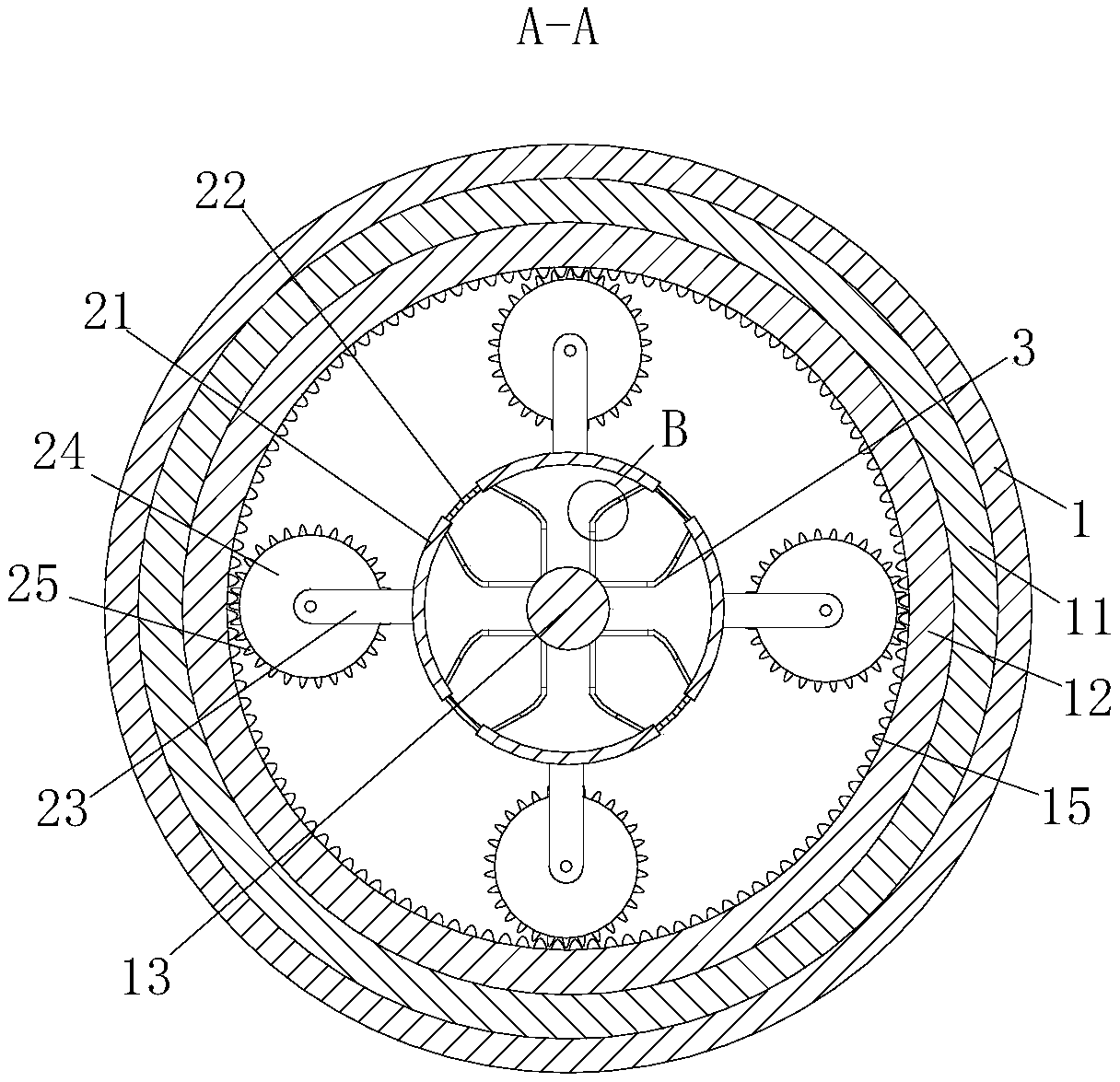

[0028] As an embodiment of the present invention, the strut 3 is divided into two parts: a straight rod 31 and a curved rod 32; Made of rubber material; the lower surface of the first gear 14 is fixedly connected with an extrusion rod 16; the upper surface of the frame body 1 is fixedly connected with a first air bag 33; the rotation of the first gear 14 can drive the extrusion rod 16 to squeeze and Loosen the first airbag 33; the strut 3 is provided with an airway 34 communicating with the first airbag 33, and the airway 34 in the curved rod 32 is biased so that the wall thicknesses of the left and right curved rods 32 of the airway 34 are unequal, and The width of the air passage 34 in the curved rod 32 is greater than the width of the air passage 34 in the straight rod 31; during work, the first gear 14 rotates, driving the extruding rod 16 to squeeze and relax the first air bag 33 intermittently, so that the first air bag 33 is aligned with the air. Road 34 is inflated and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com