Mechanical turbulence milling tools

A turbulent flow and mechanical technology, applied in the field of powder engineering, can solve problems such as high energy consumption, failure to achieve the use effect of ultrafine materials, and difficulty in preparing ultrafine powders.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

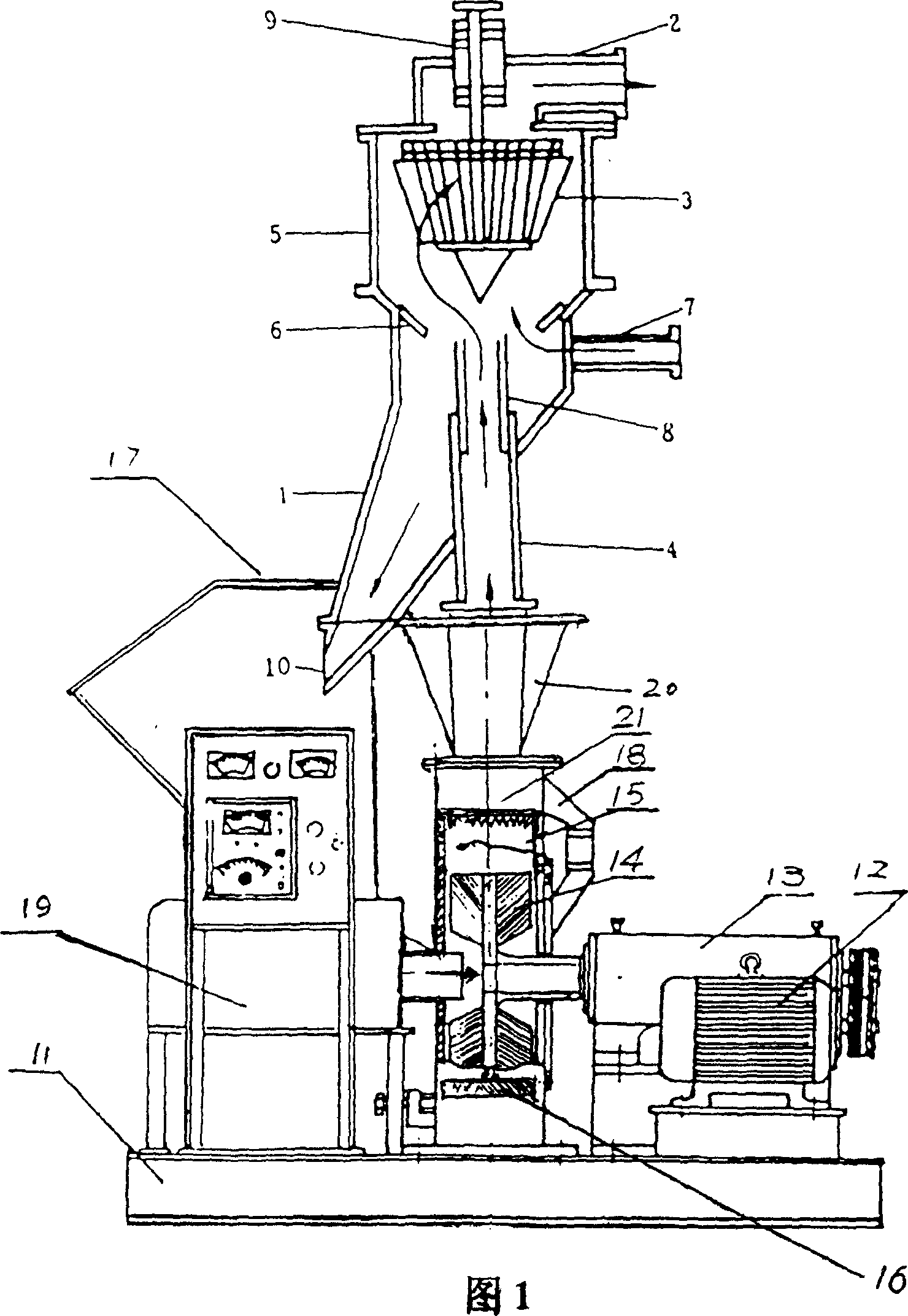

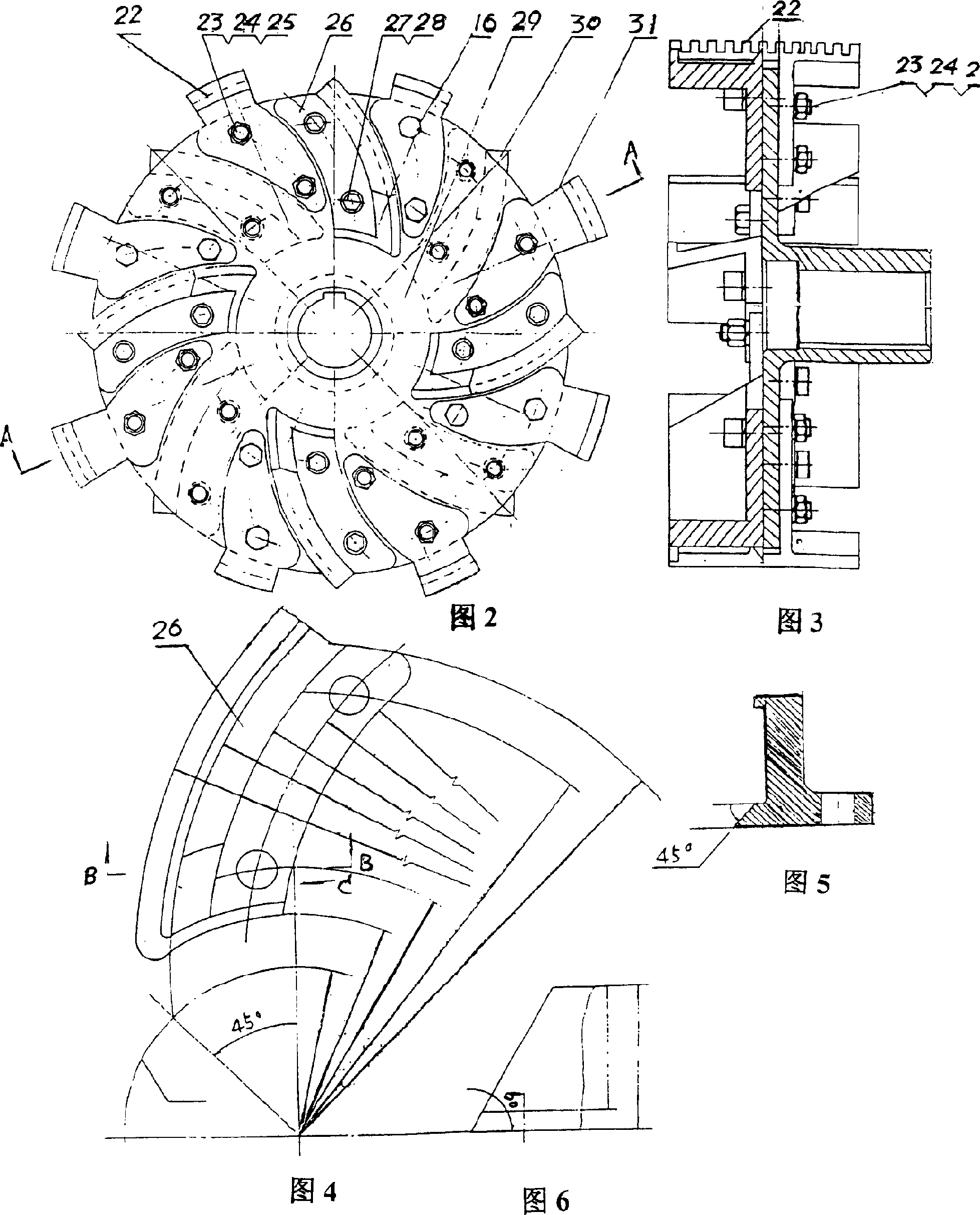

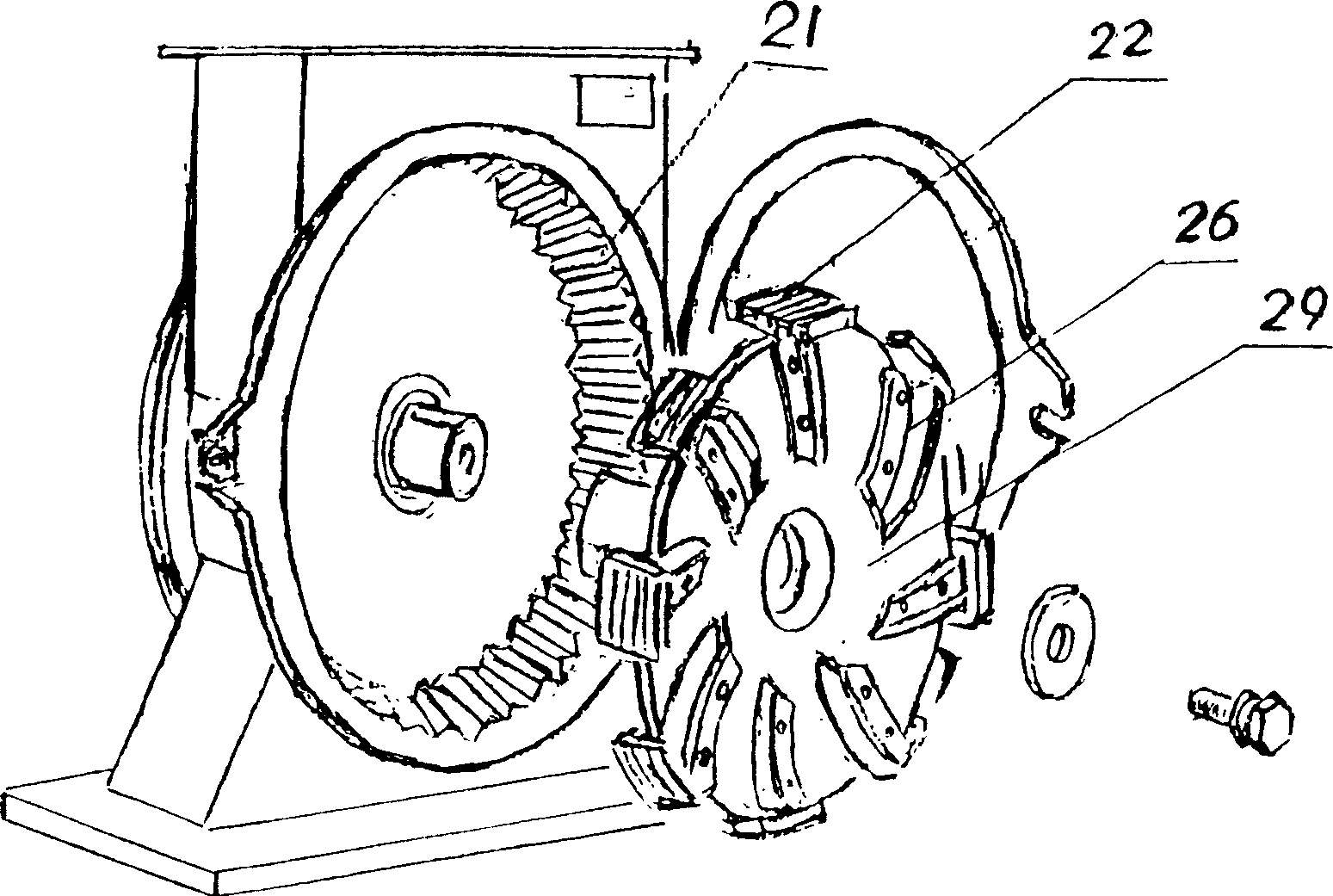

[0041] An ultra-fine, ultra-micro, wet and dry mechanical turbulent mill, the mill is mainly composed of a base 11, a frequency conversion motor 12, a double negative pressure impeller 14, a grinding chamber 15, a hopper 17, a return pipe 18, a screw conveyor It is composed of a device 19, a separator 20, a stator guide ring gear 21, a classifier, and an electrical control cabinet. The mill is of a horizontal type, and the feeding pipe 4 connected to the grinding chamber 15 extends into the chamber connected to the feeding pipe 1, the annular body 6 and the middle body 5, and is opposite to the impeller 3 connected to the impeller shaft 9 in the chamber, The impeller shaft 9, the separator 20, and the grinding chamber 15 are vertical, are seated on the base 11, and are on the same center line. The fine powder outlet 2 is connected to the cyclone receiver 1, 2 and the cloth bag receiver. There are two flange covers on the left and right sides of the grinding chamber 15, wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com