Patents

Literature

77results about How to "Reduce recycling efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

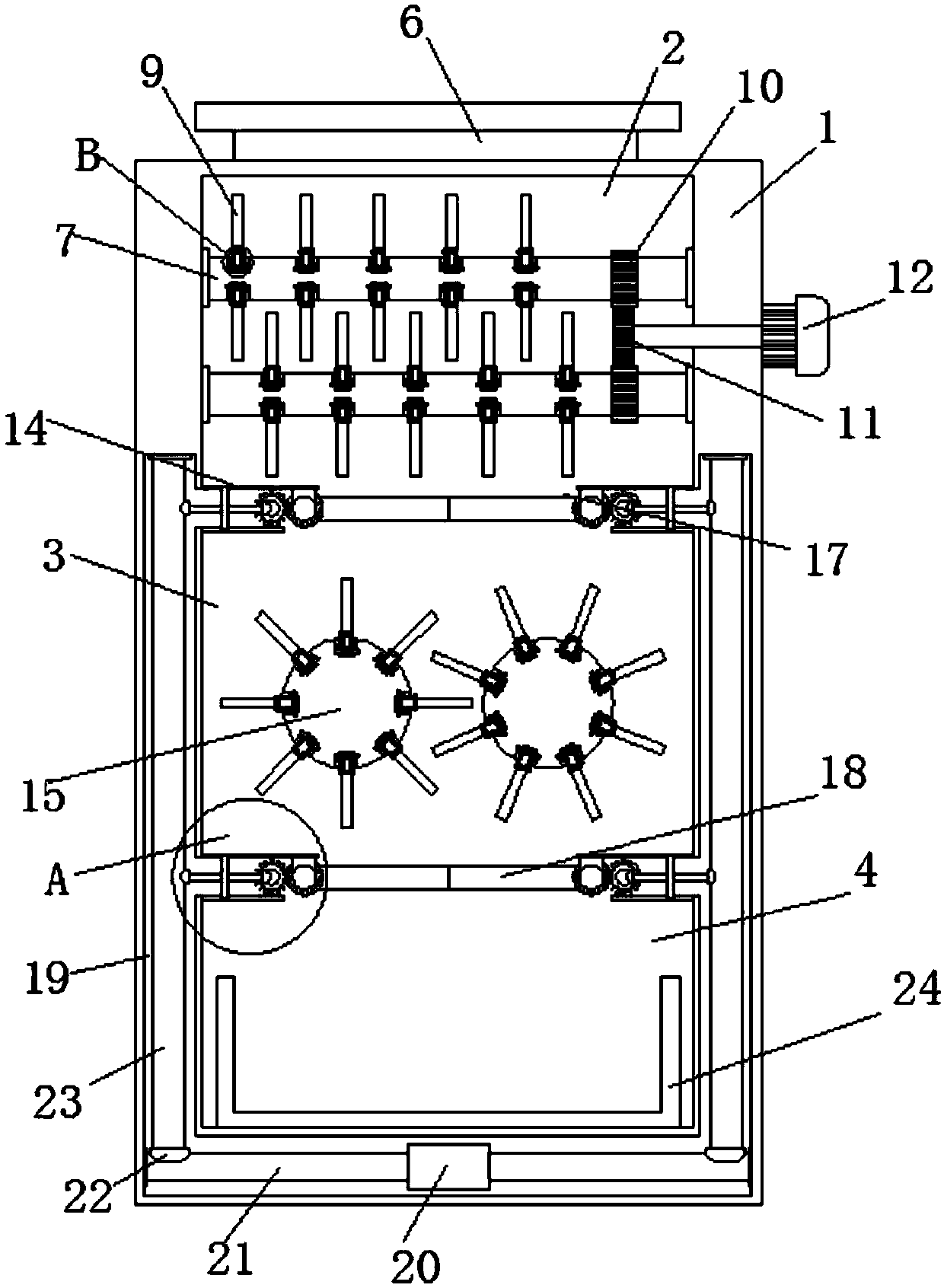

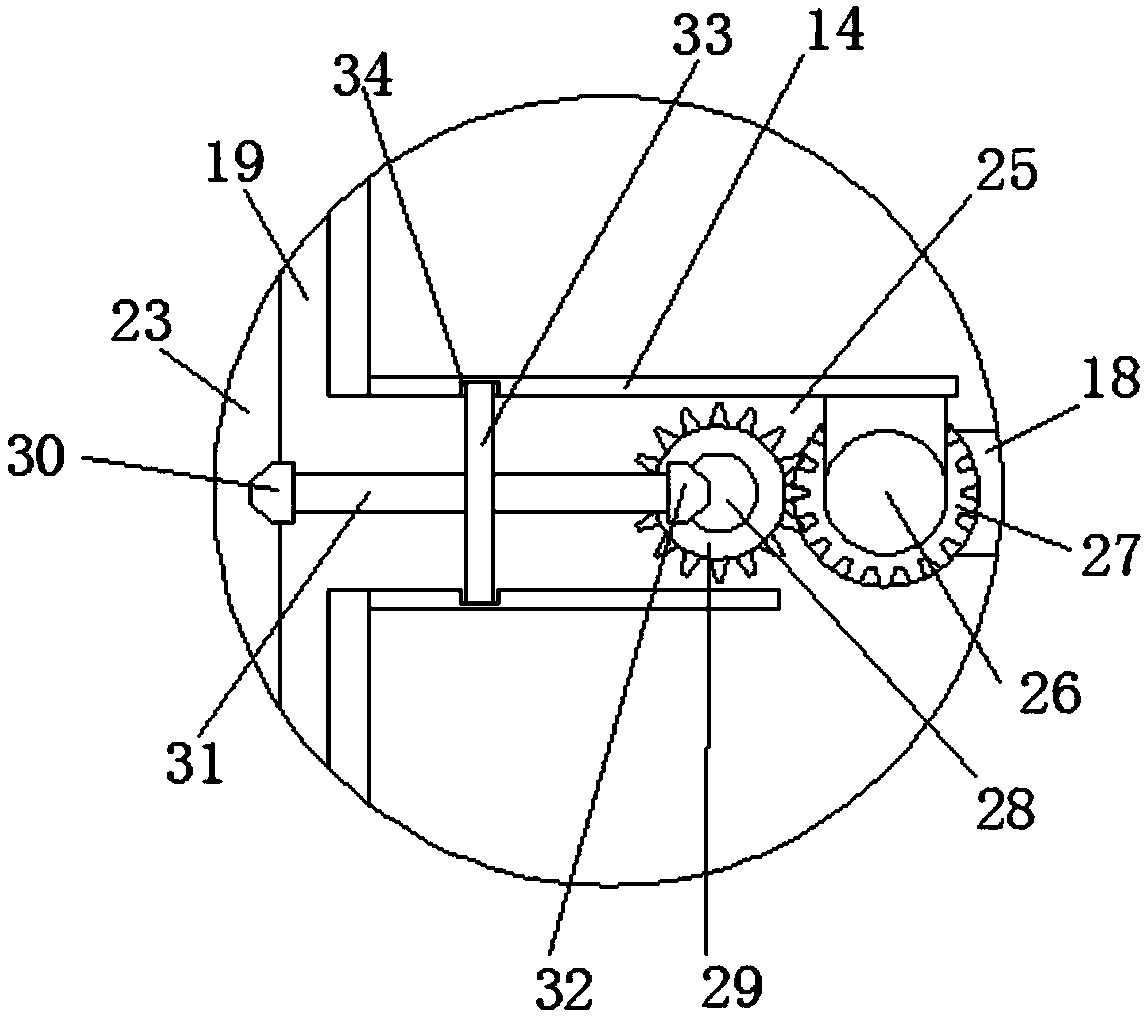

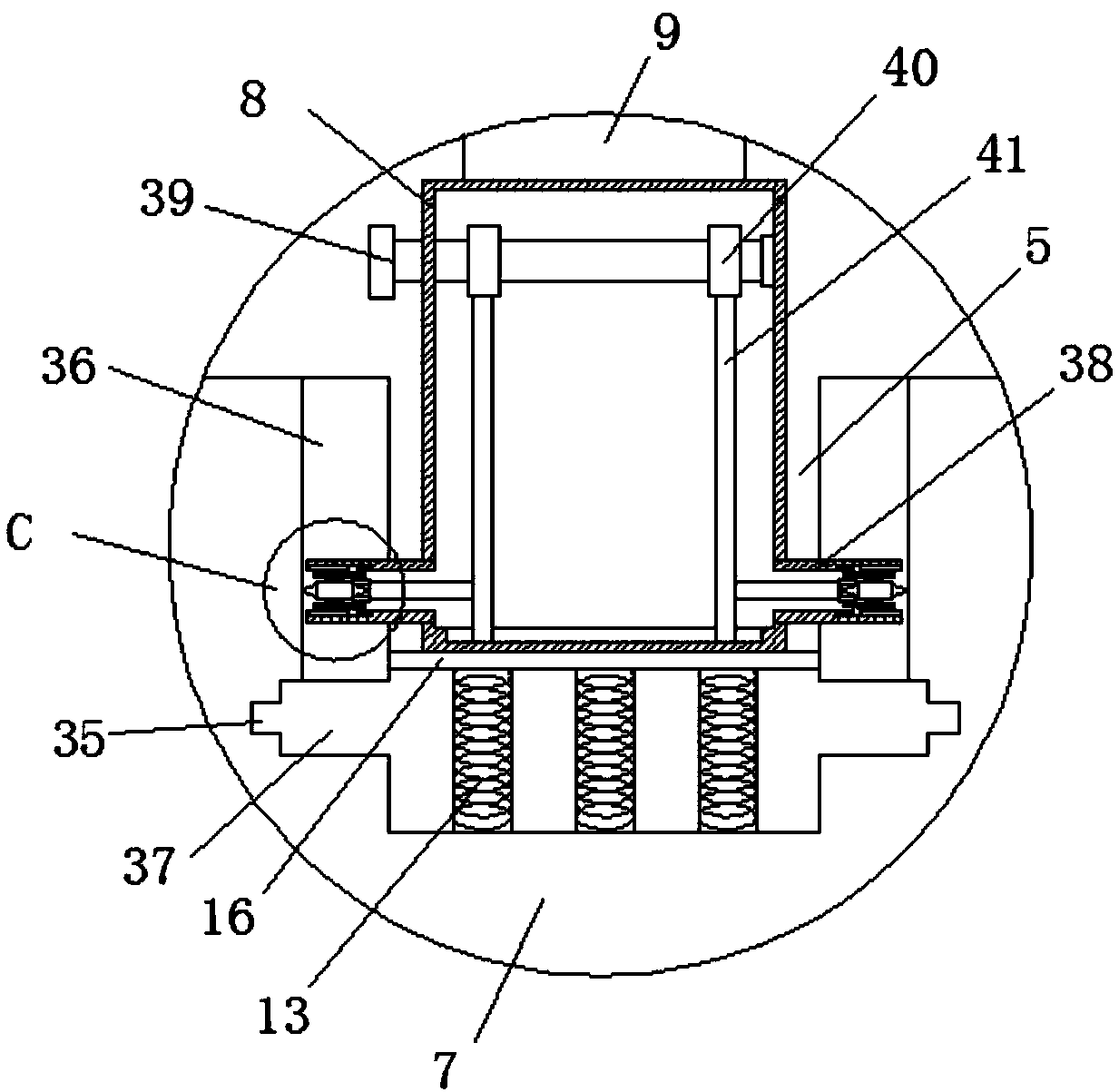

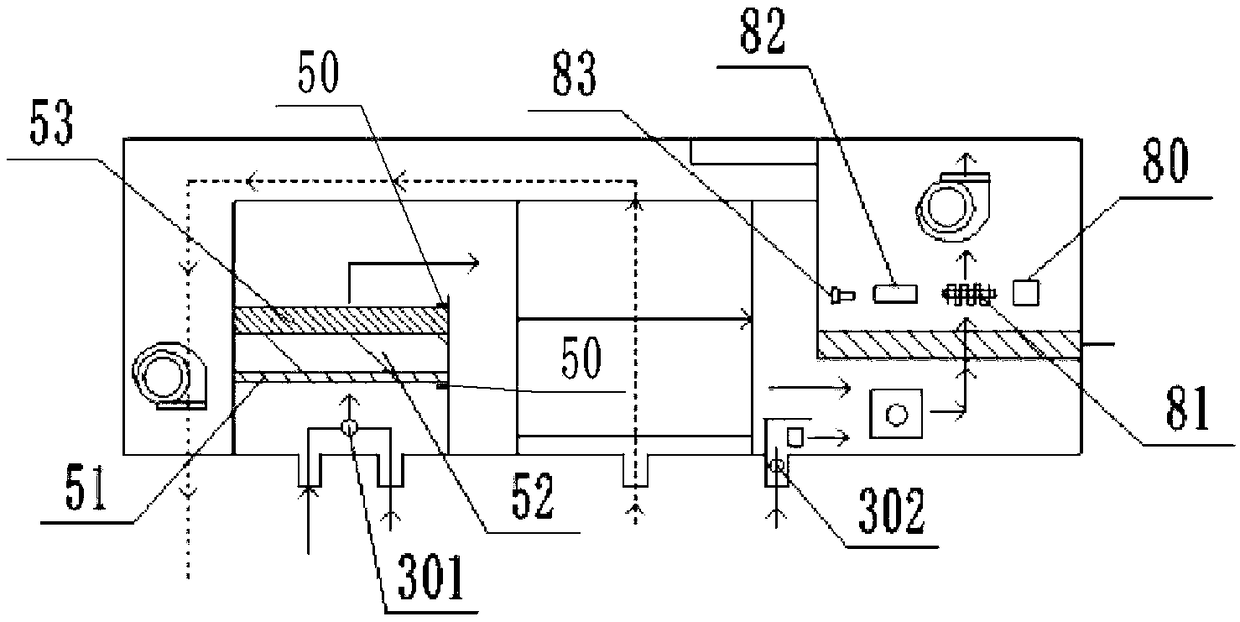

Plastic product recycling machine

InactiveCN108015927ACompletely brokenReduce recycling efficiencyPlastic recyclingGrain treatmentsEngineeringPlastic recycling

The invention discloses a plastic product recycling machine. The plastic product recycling machine comprises a shell, wherein the shell is of a hollow structure; the interior of the shell is divided into a first crushing cavity, a second crushing cavity and a collecting cavity through two partition plates which are arranged in parallel; discharge ports are formed in the partition plates; the firstcrushing cavity, the second crushing cavity and the collecting cavity communicate with one another through the discharge ports; two first rotating rollers which are arranged in parallel are connectedin the first crushing cavity in a rotating mode; and a plurality of cutting blades are arranged on the two first rotating rollers and are arranged in a staggered mode. According to the plastic product recycling machine, waste plastic can be fully crushed so that the plastic can be crushed more thoroughly, the space, occupied by the plastic, of a collecting box can be decreased, and the phenomenonthat the collecting box is frequently replaced can be avoided; and meanwhile, the cutting blades on the rotating rollers can be conveniently replaced, and the phenomenon that the plastic recycling efficiency is reduced due to the fact that the crushing efficiency is influenced by blade passivation can be avoided.

Owner:YINGSHANG LONGYUYANG IND & TRADE

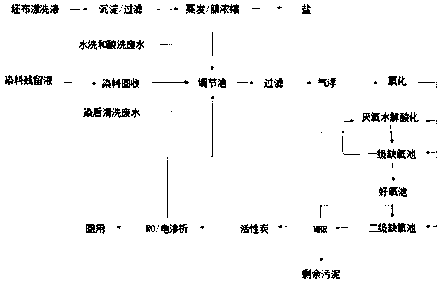

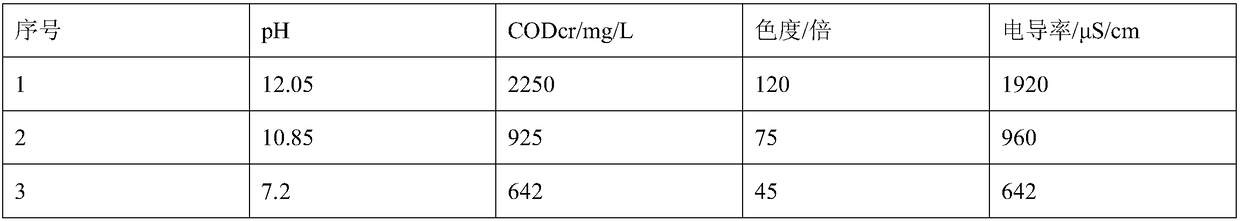

Fabric dyeing wastewater treatment method

ActiveCN108558140AReduce recycling efficiencyHigh recovery rateWater contaminantsMultistage water/sewage treatmentTextile printerSocial benefits

The invention relates to the field of textile printing and dyeing and in particular relates to a fabric dyeing wastewater treatment method. The treatment method comprises the following steps: collecting gray fabric wash liquid wastewater and wastewater produced in washing and pickling steps after rinsing, classifying and recovering dye residue liquid according to different dyes, collecting cleaning wastewater after dyeing, and treating the collected wastewater by adopting processes such as homogeneous adjustment, screen or filtering net filtration, air flotation, oxidization, biochemical treatment and advanced treatment performed in sequence. According to the technical scheme in the invention, the dyes can be recovered to the greatest degree, the wastewater treatment burden is reduced, recovery benefits are increased, the treatment cost is reduced, and good economic benefits and social benefits are achieved.

Owner:杭州富瑞司纺织有限公司

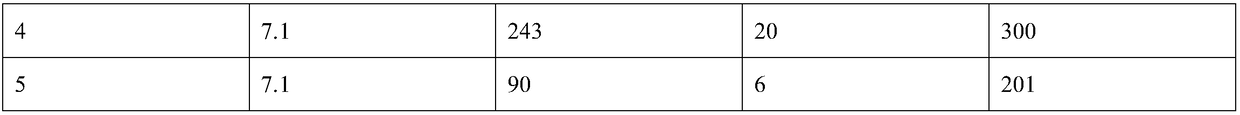

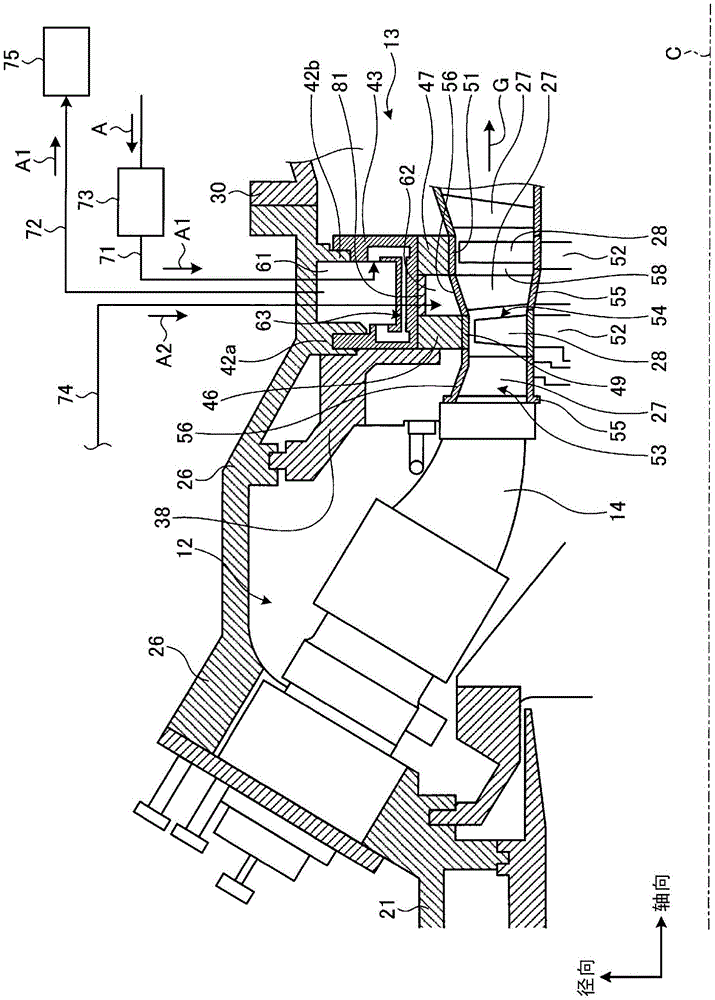

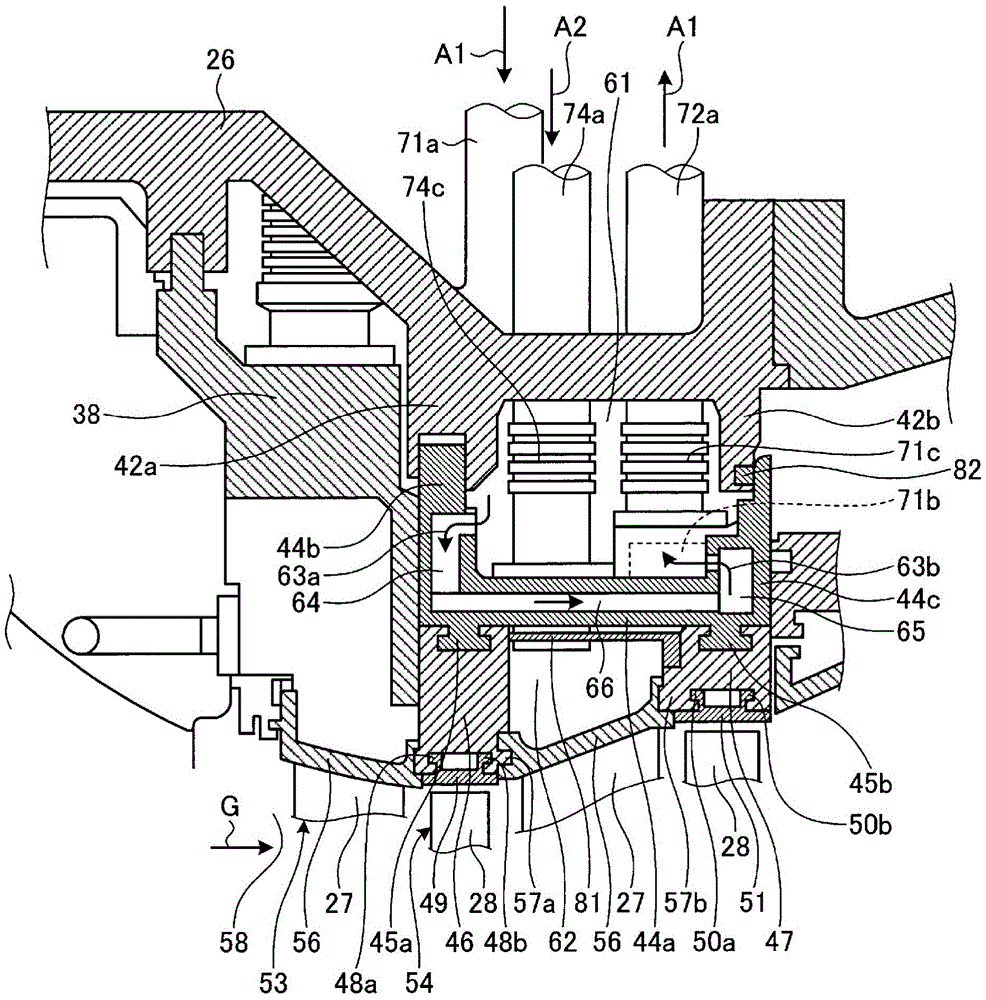

Gas turbine

ActiveCN105637200ASuppresses reduction in recovery efficiencyImprove performanceEngine fuctionsTurbine/propulsion engine coolingStatorGas turbines

A gas turbine provided with: a blade ring (43) that marks off an annular first cavity (61) as a result of being connected to the inner periphery of a turbine casing (26); a plurality of heat-insulating rings (46, 47) that are connected to the inner periphery of the blade ring (43) at a predetermined axial direction interval; a plurality of partitioning rings (49, 51) that are connected to the inner periphery of the plurality of heat-insulating rings (46, 47); a plurality of rotor blade bodies (54) that are spaced at a predetermined axial direction interval, are affixed to the outer periphery of a rotor (32), and are arranged so as to face the plurality of partitioning rings (49, 51) in the radial direction; a plurality of stator blade bodies (53) that mark off an annular second cavity (62) as a result of an exterior shroud (56) being affixed to the heat-insulating rings (46, 47) between the plurality of rotor blade bodies (54); a second cooling-air supply route (74) that supplies compressed air to the second cavity (62); a first cooling-air supply route (71) that supplies cooling air that has a lower temperature than the compressed air to the first cavity (61); and a cooling-air discharge route (72) that discharges the cooling air from the first cavity (61). The gas turbine thereby provides an appropriate amount of clearance between rotor blades and the side of a turbine casing and has improved performance.

Owner:MITSUBISHI POWER LTD

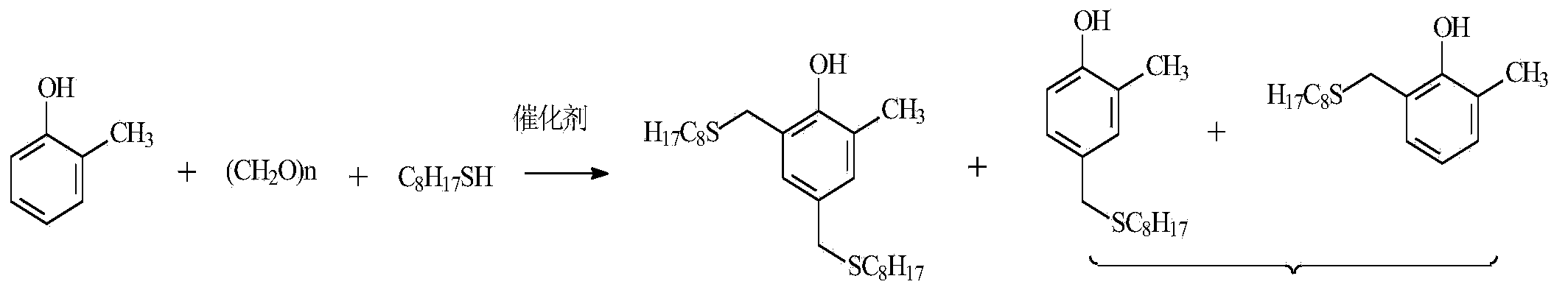

Preparation method of liquid antioxidant 4,6-di(octylsulfanylmethyl) o-cresol

The invention relates to a preparation method of a liquid antioxidant 4,6-di(octylsulfanylmethyl) o-cresol. The preparation method comprises the following steps of: casting o-cresol, n-octyl mercaptan and paraformaldehyde in specified amount to a reaction kettle; adding a reaction solvent or then adding into water; casting a solid catalyst strong alkali and weak acid salt; then, starting stirring; continuously introducing or dropping an organic amine catalyst with a certain time; then, heating to reflux and performing reaction; after reaction, treating to obtain a product with high purity, less smell and low content of formaldehyde. The process is simple in industrial operation, low in cost and easy to realize. The yield based on o-cresol is greater than or equal to 98.0%, and the product obtained is approximately colorless. APHA is less than or equal to 10, and the product is transparent and the product purity is greater than or equal to 98.0%.

Owner:RIANLON

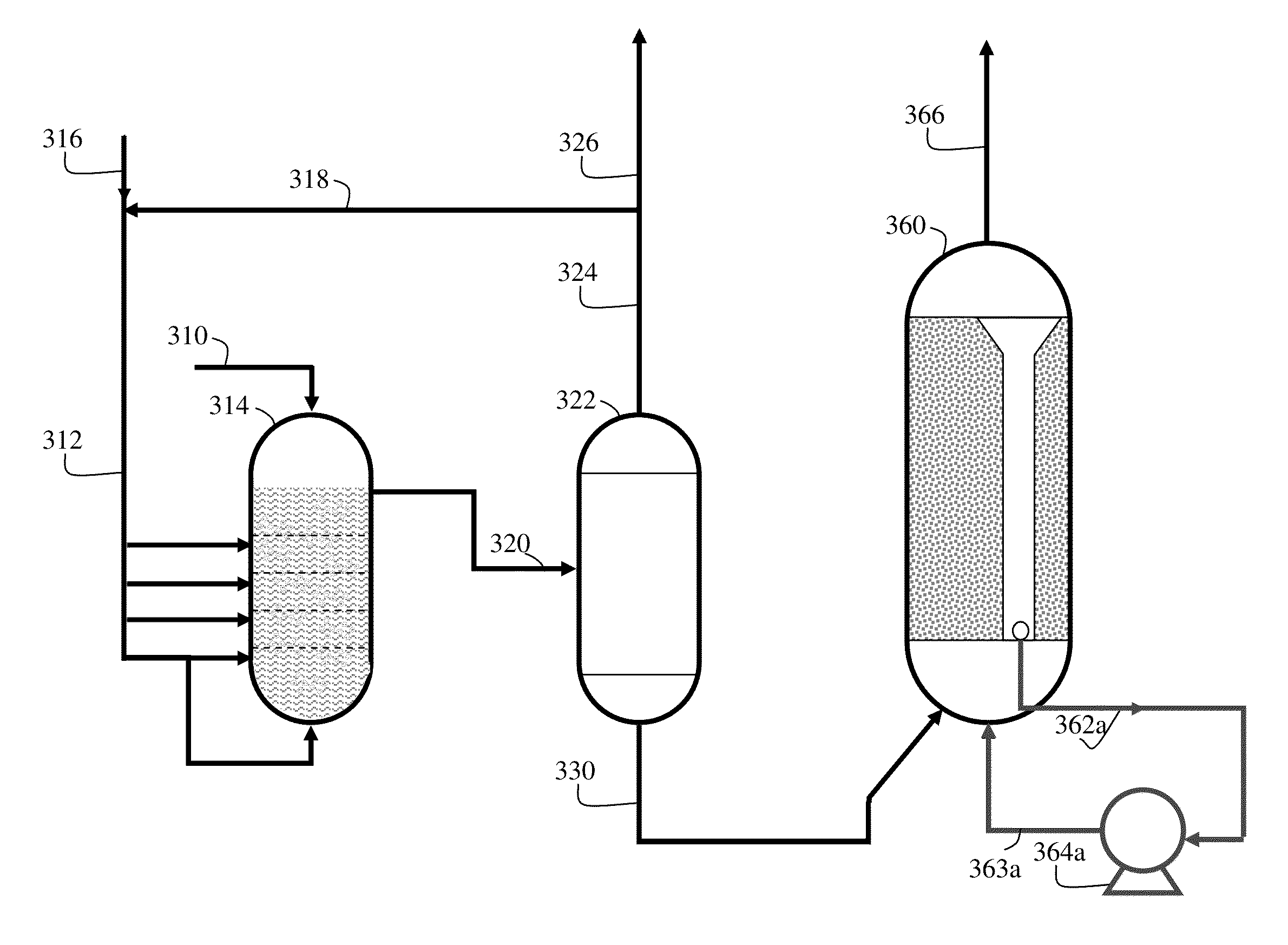

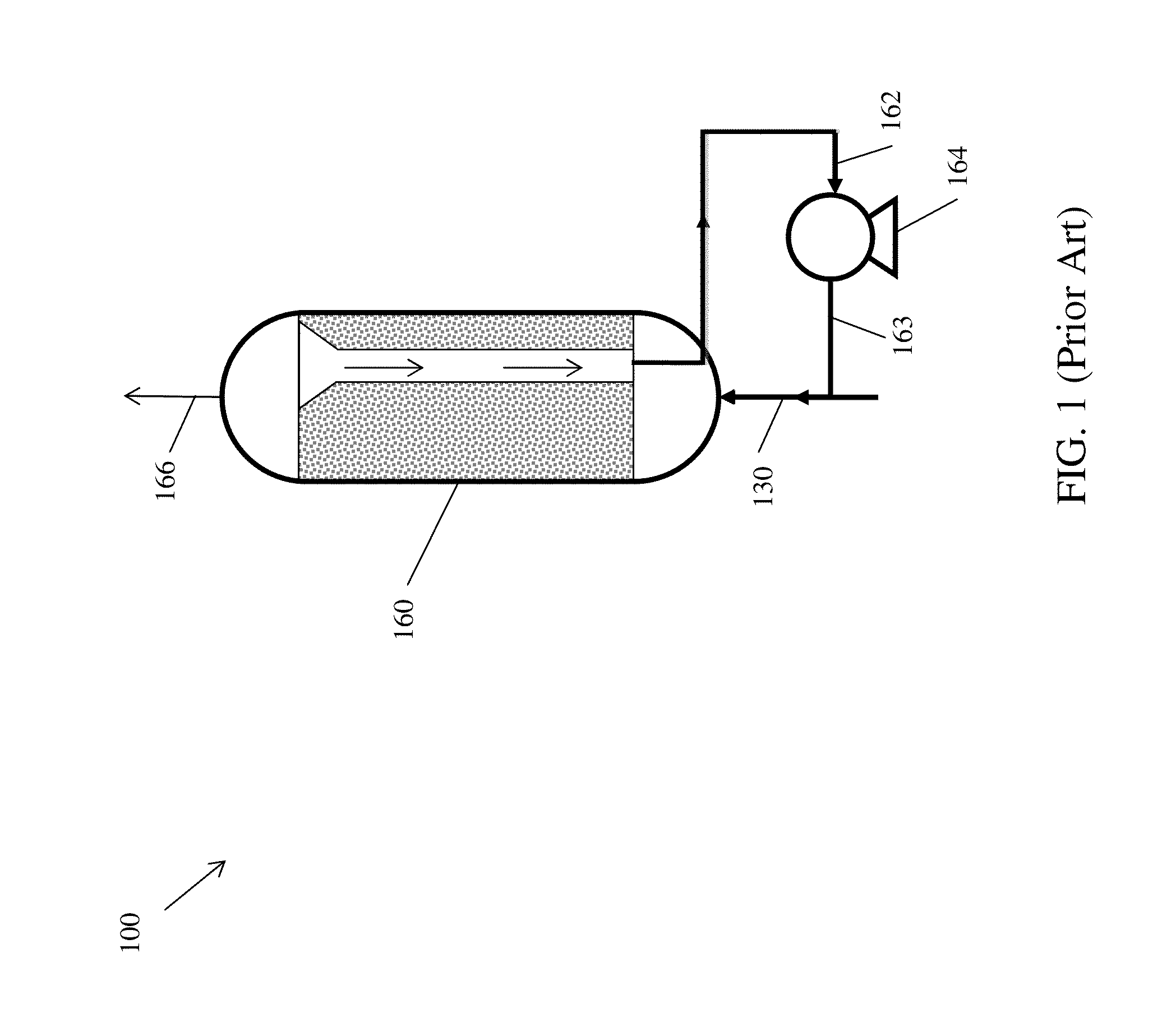

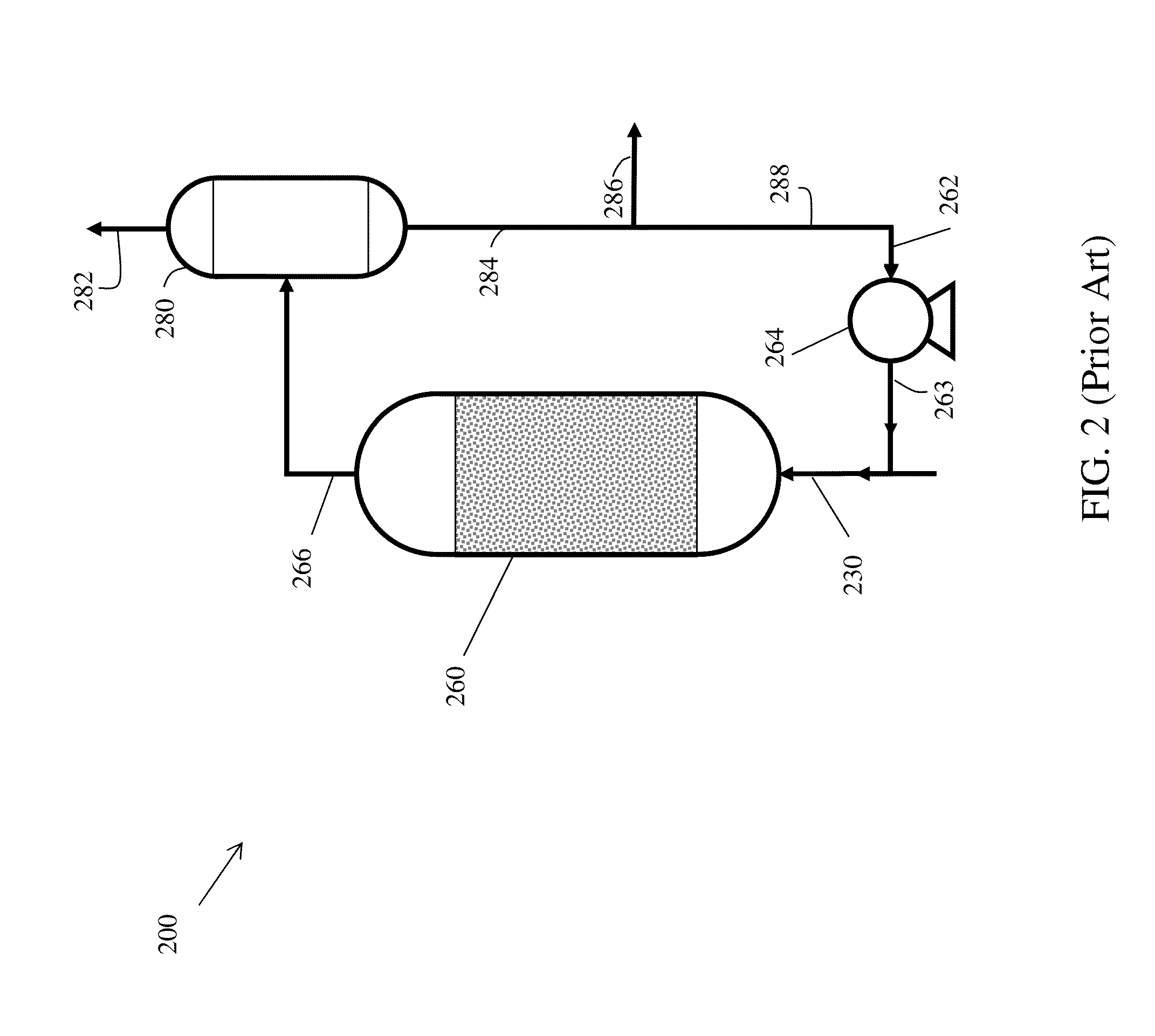

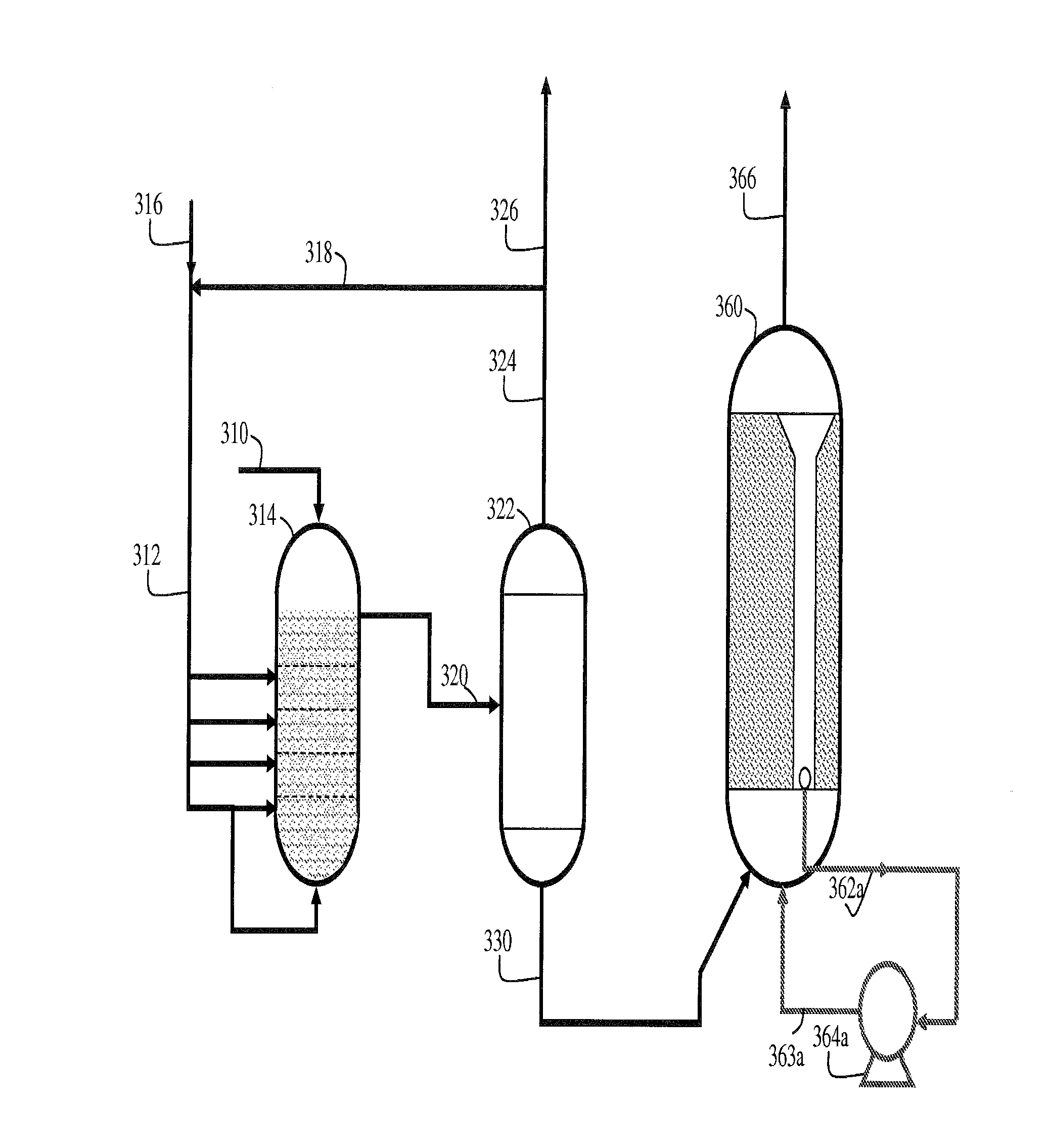

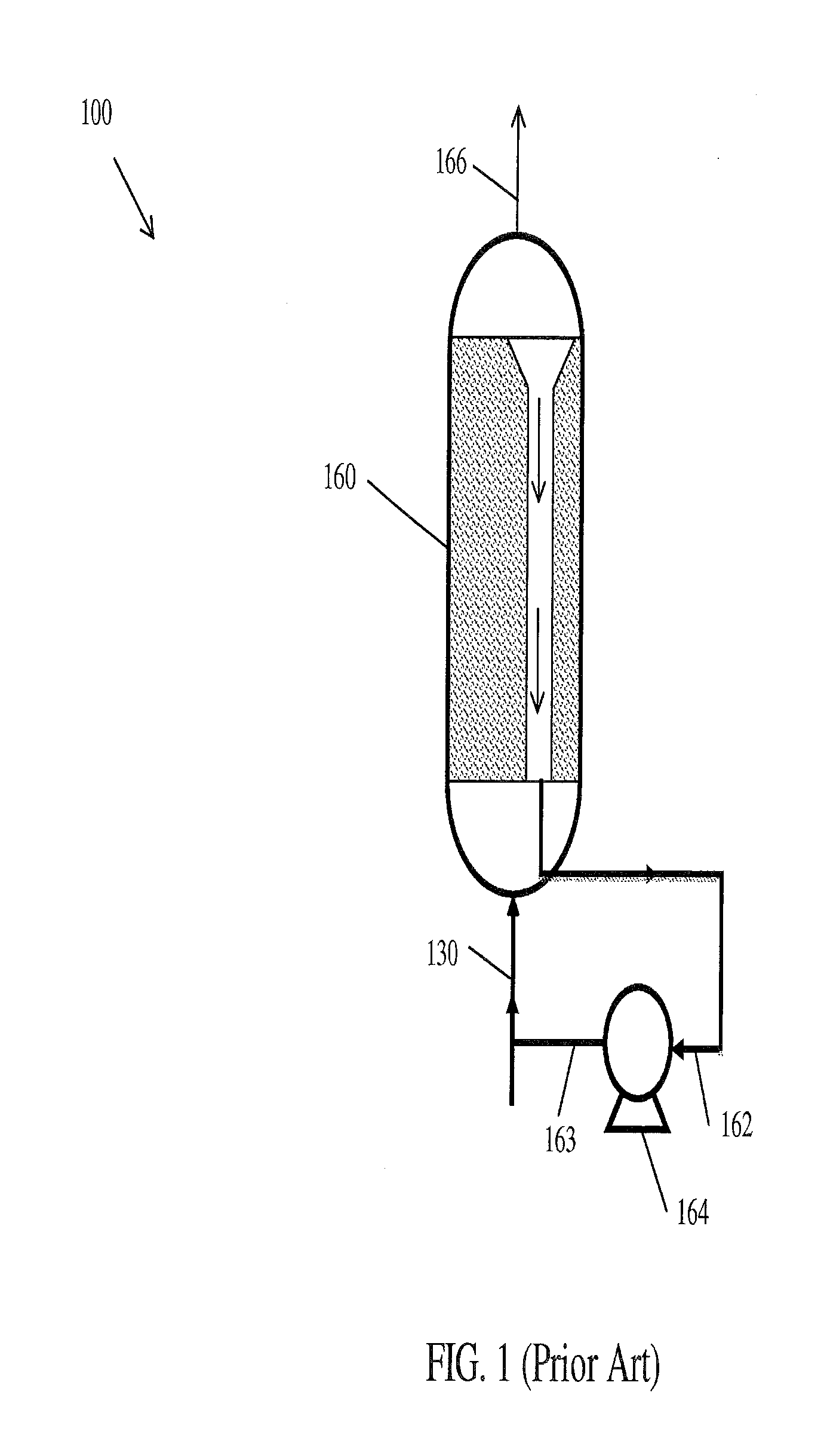

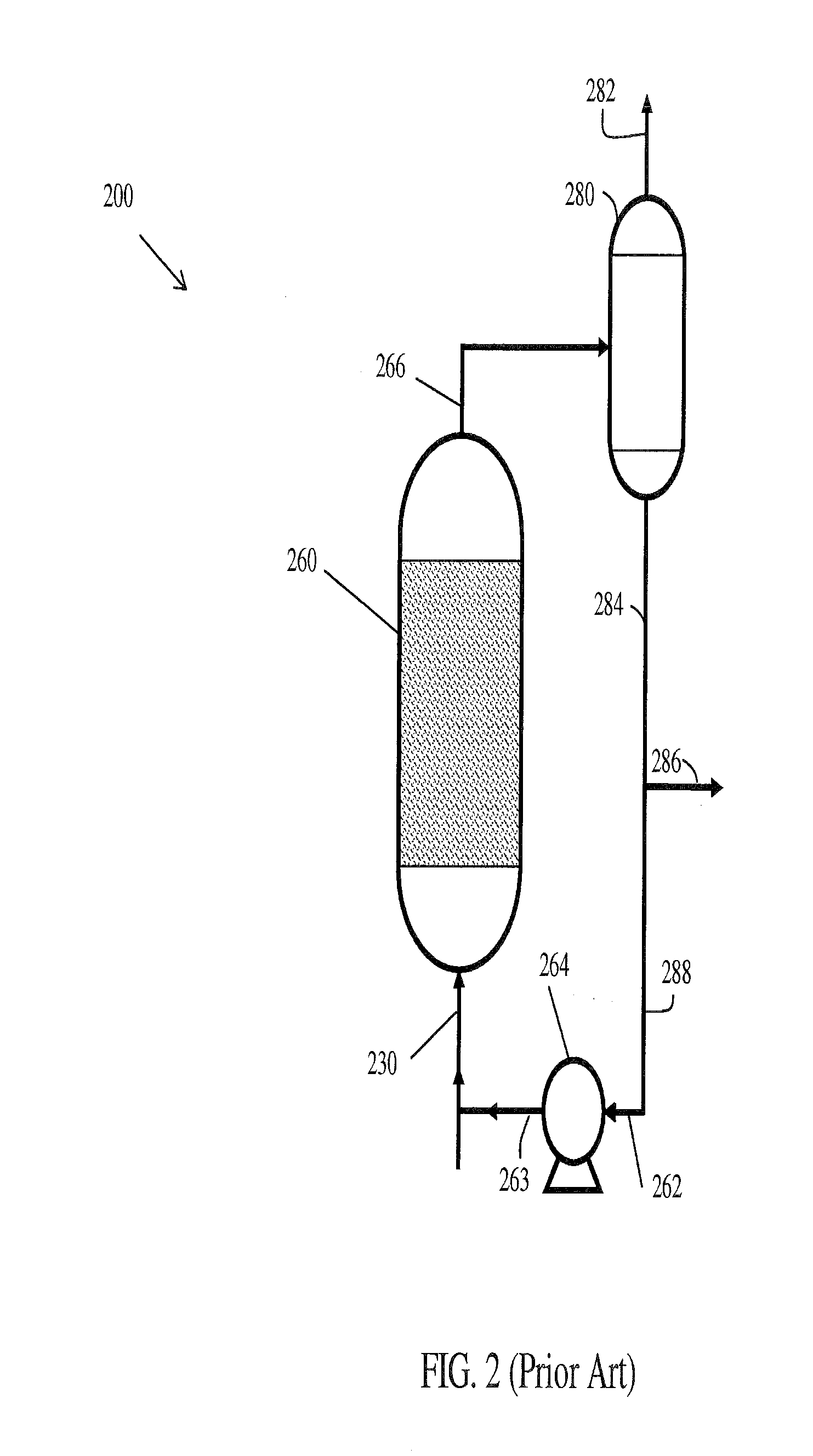

Ebullated-bed process for feedstock containing dissolved hydrogen

ActiveUS20130026068A1Reduce recycling efficiencyLiquid hydrocarbon mixture productionHydrocarbon oil crackingChemistryDissolved hydrogen

An improved system and method for processing feedstocks in an ebullated-bed hydroprocessing reactor is provided in which hydrogen gas is dissolved in the fresh and recycled liquid feedstock by mixing and / or diffusion of an excess of hydrogen, followed by flashing of the undissolved hydrogen upstream of the reactor inlet, introduction of the feed containing dissolved hydrogen into the ebullated-bed hydroprocessing reactor whereby the dissolved hydrogen eliminates or minimizes the prior art problems of gas hold-up and reduced operational efficiency of the recycle pump due to the presence of excess gas in the recycle stream when hydrogen gas was introduced as a separate phase into the reactor.

Owner:SAUDI ARABIAN OIL CO

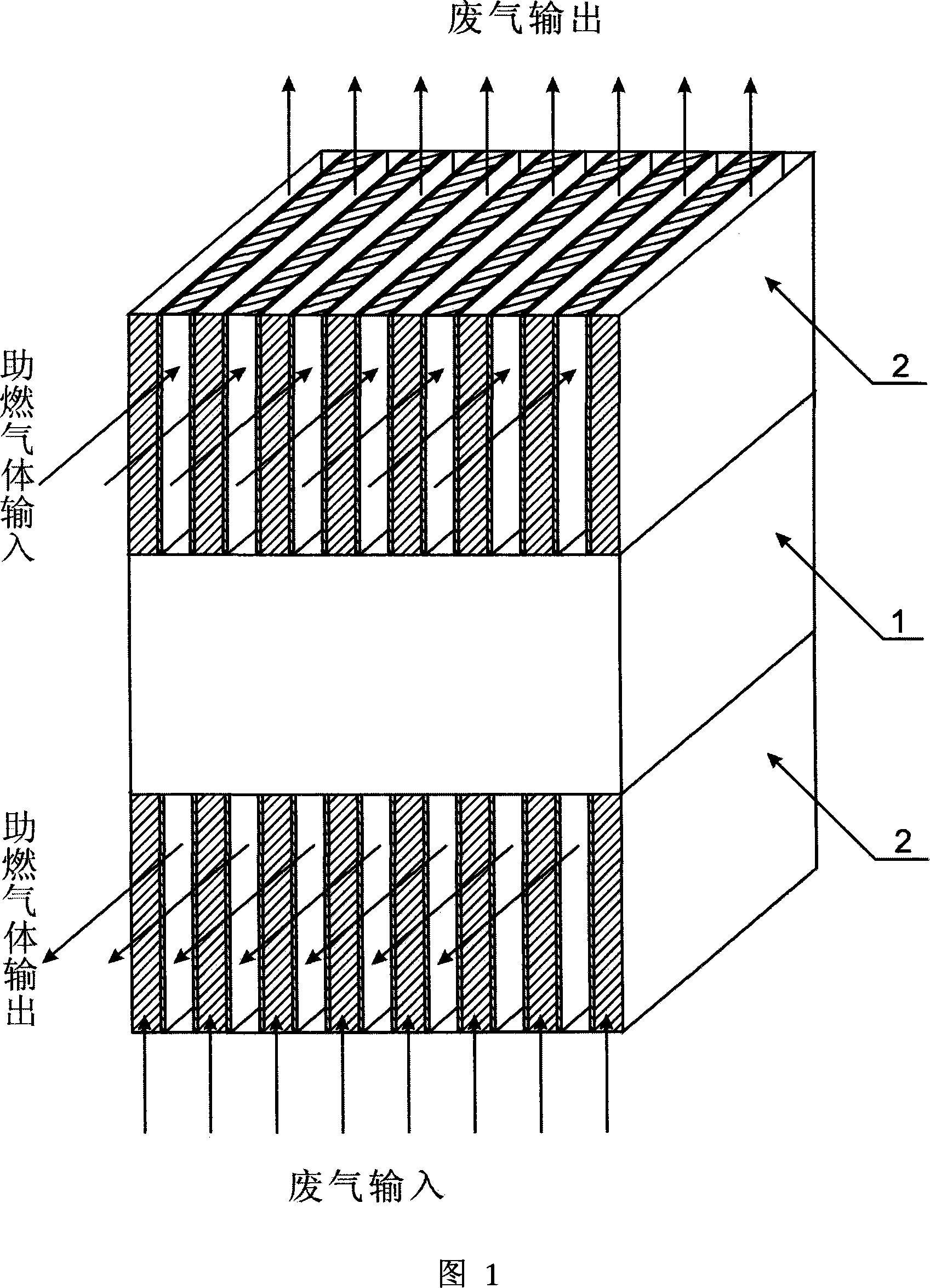

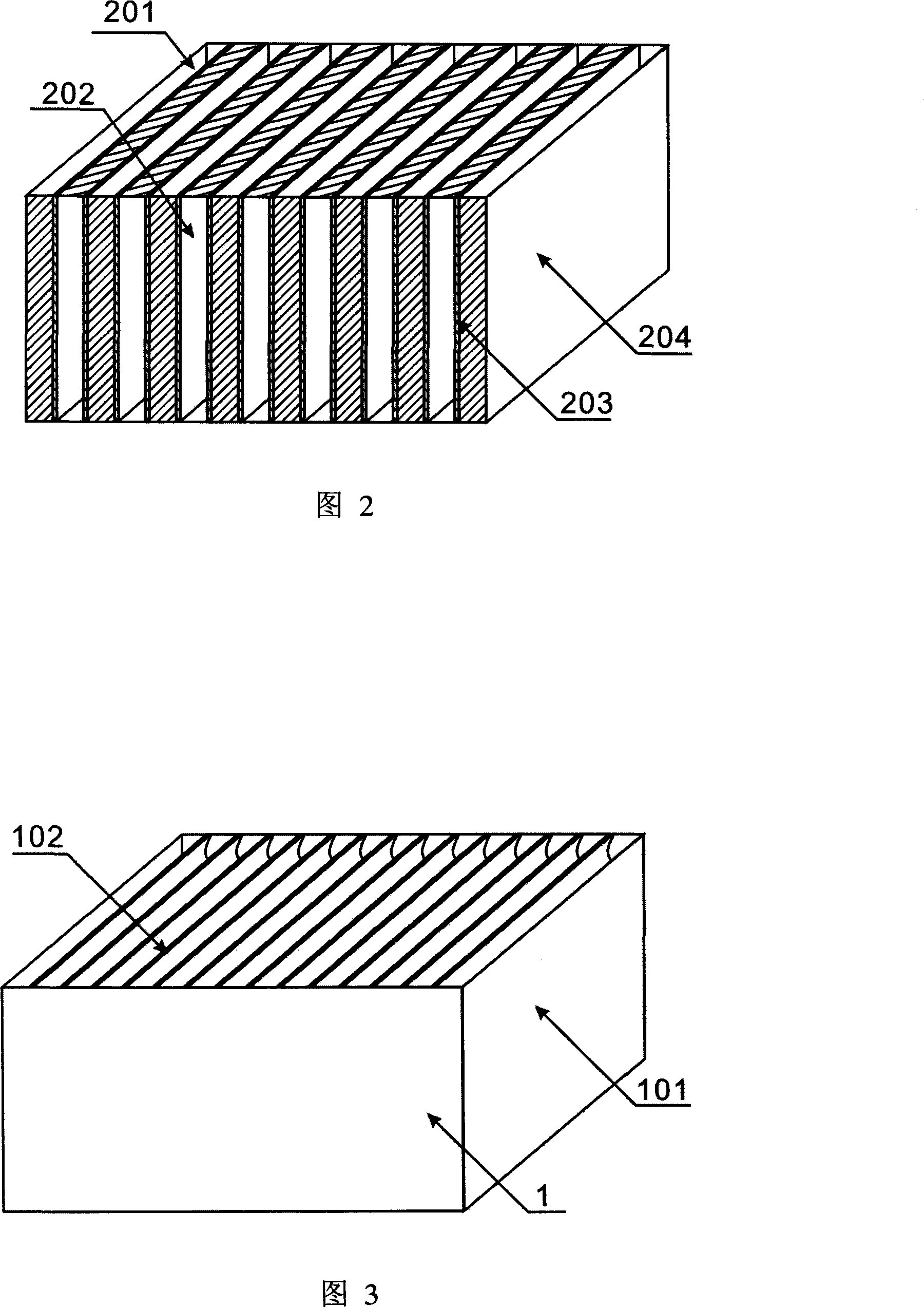

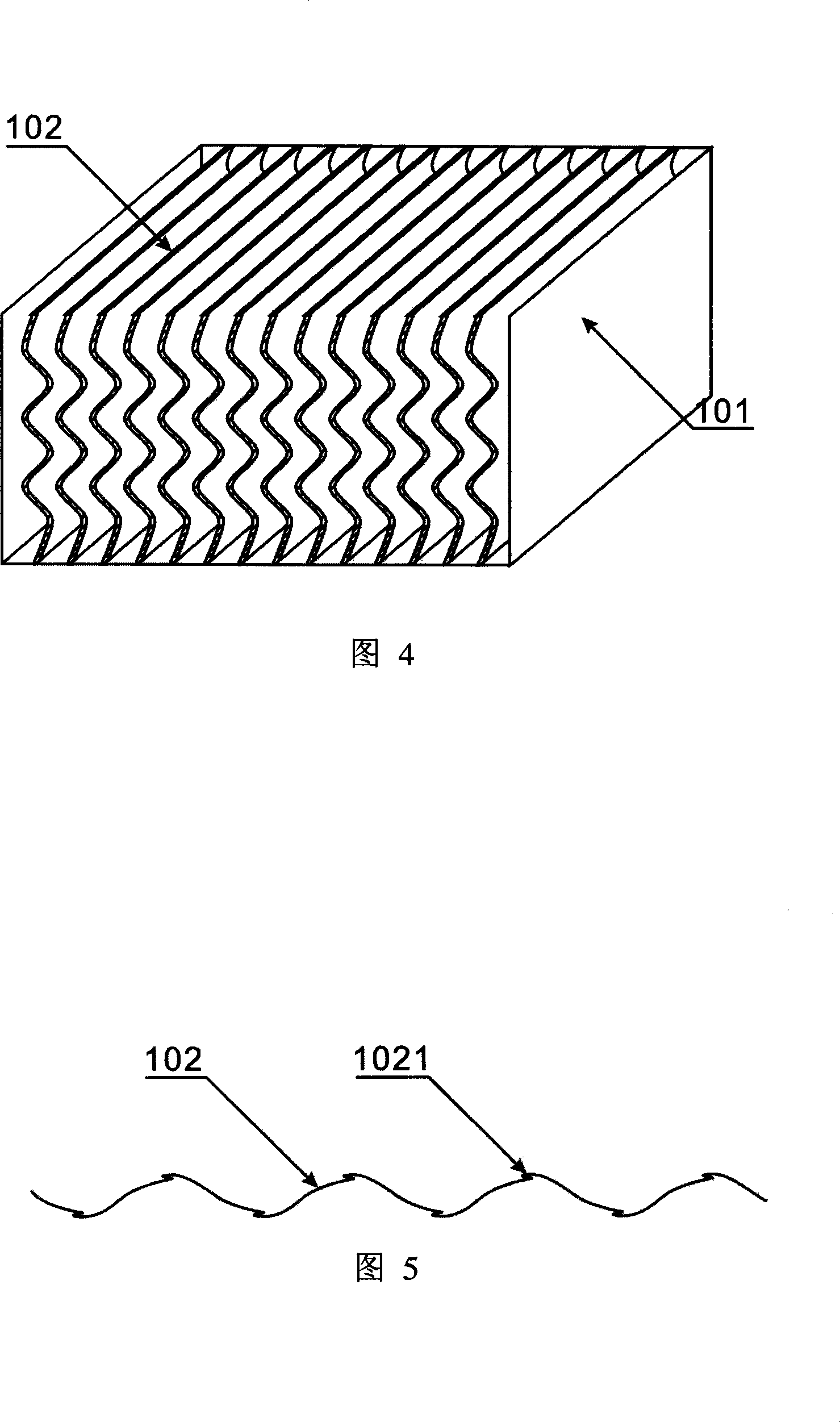

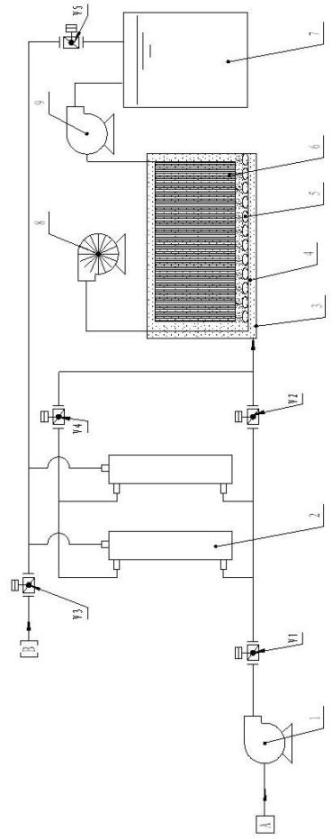

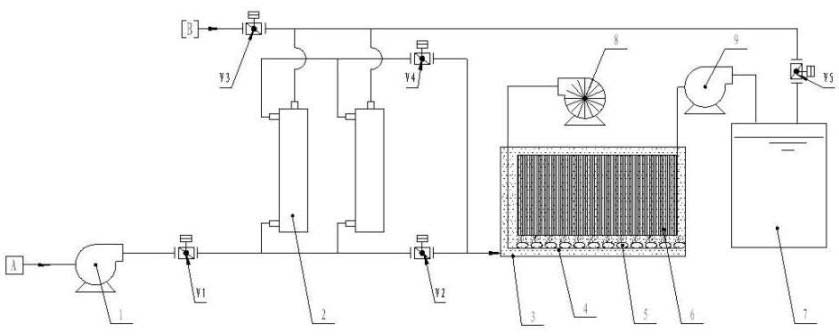

Discharge gas and waste heat recovery heat converter

ActiveCN101216266AShort construction periodIncrease profitStationary plate conduit assembliesCombustionExhaust fumes

The invention discloses a heat exchanger for recovering exhaust gas and waste heat, which comprises a heat exchanger and a fluid diverter. The heat exchanger comprises a case body and corrugated heat exchange plates. The case body has a cuboid structure with opened up and down end surfaces; the corrugated heat exchange plates are laminated together and fixed inside the case body; and a gas passage is provided between adjacent corrugated heat exchange plates, and the inlet and outlet of the gas passage are provided on one of the opened end surfaces. The fluid diverter comprises a case body and passage partitioning plates; the partitioning plates are parallelly disposed and fixed inside the case body of the fluid diverter to divide the space of case body into an exhaust gas passage and a combustion supporting gas passage; the fluid diverter is installed at the inlet and outlet of the heat exchanger; and the exhaust gas passage and the combustion supporting gas passage are separated from each other. The inventive heat exchanger can recover exhaust gas and waste heat on site; and has the advantages of small volume, light weight, simple structure, remarkably improved unit volume heat exchange efficiency, good reliability, saved energy consumption and environmental friendliness.

Owner:刘启端

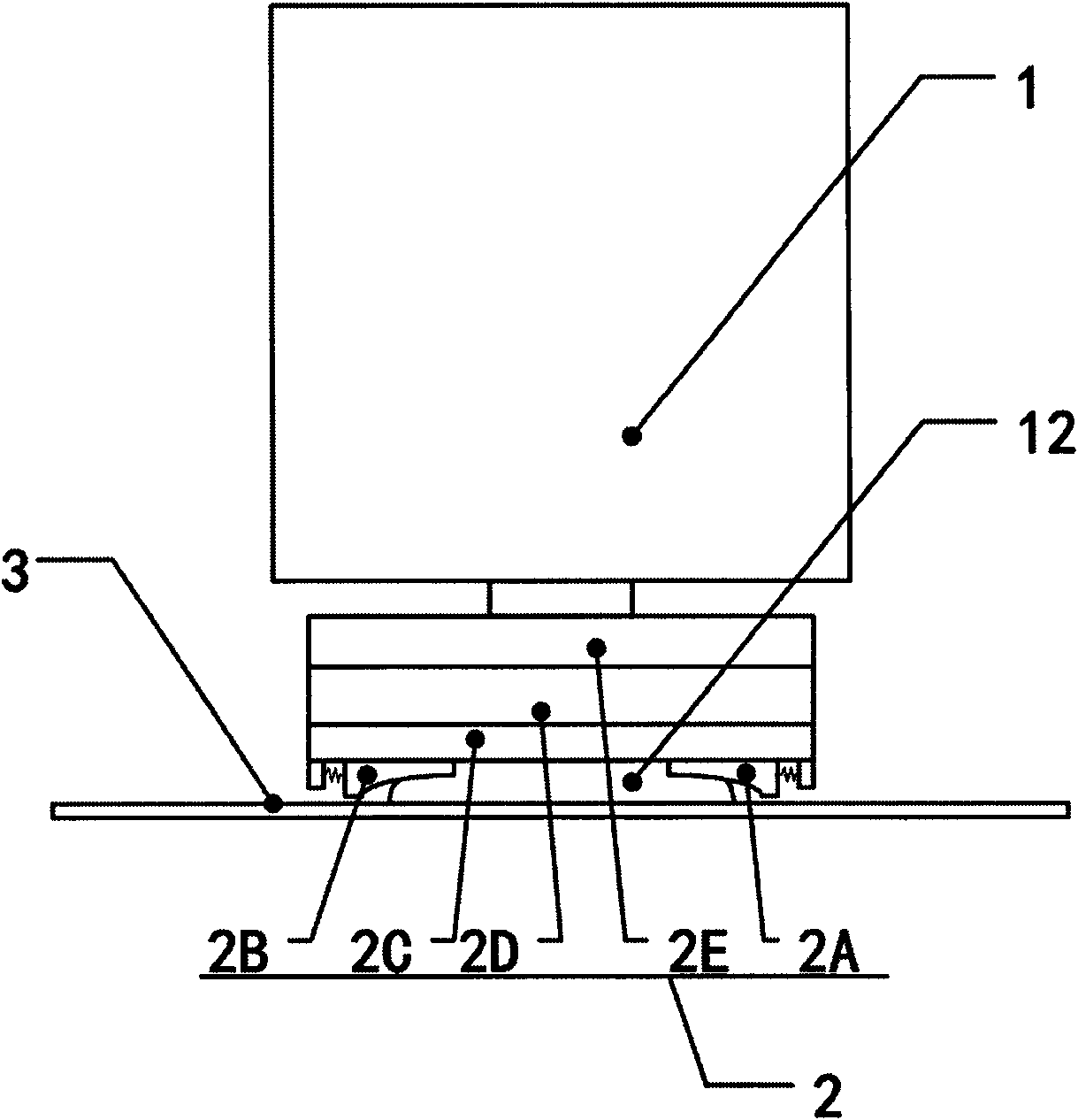

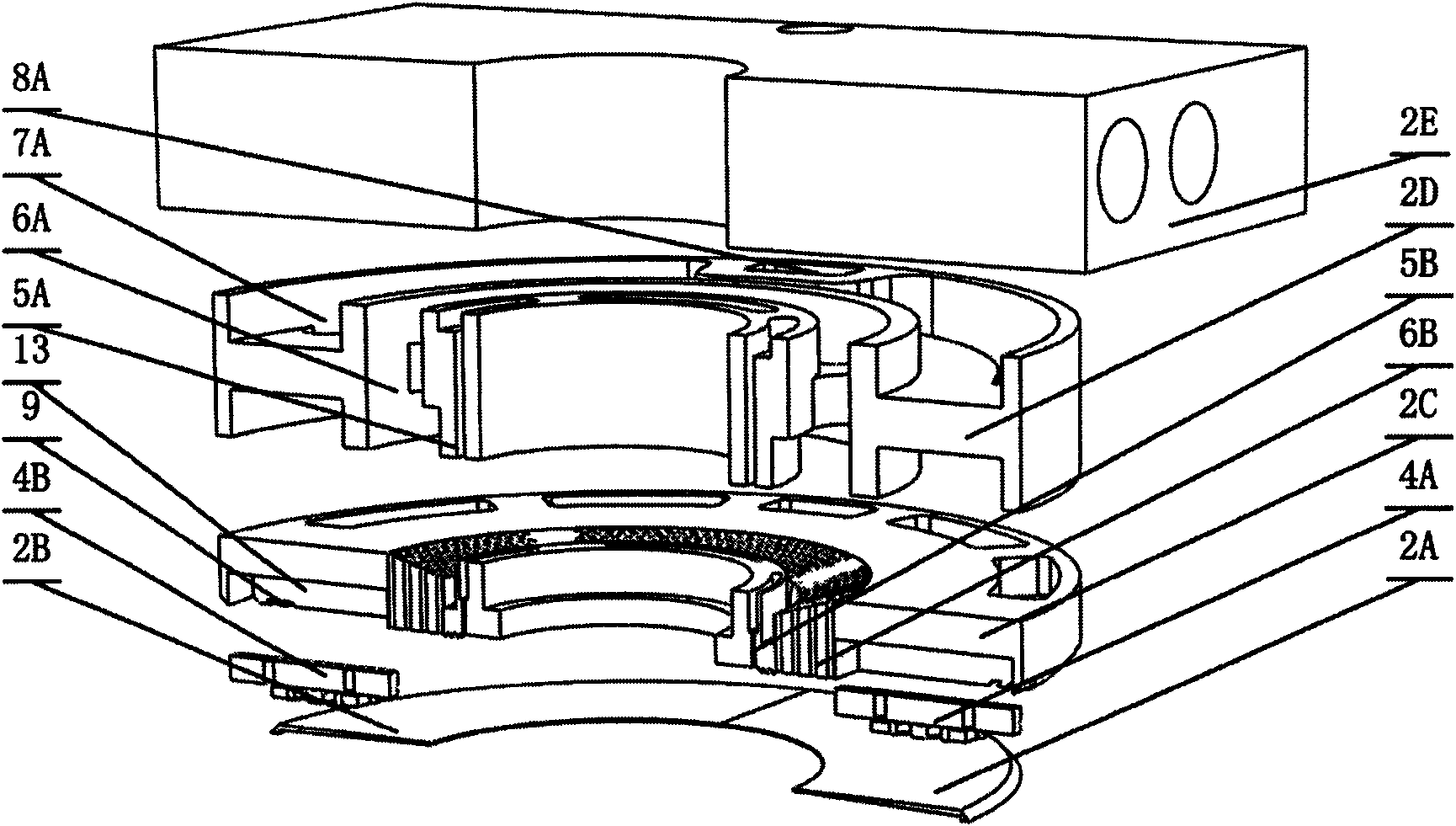

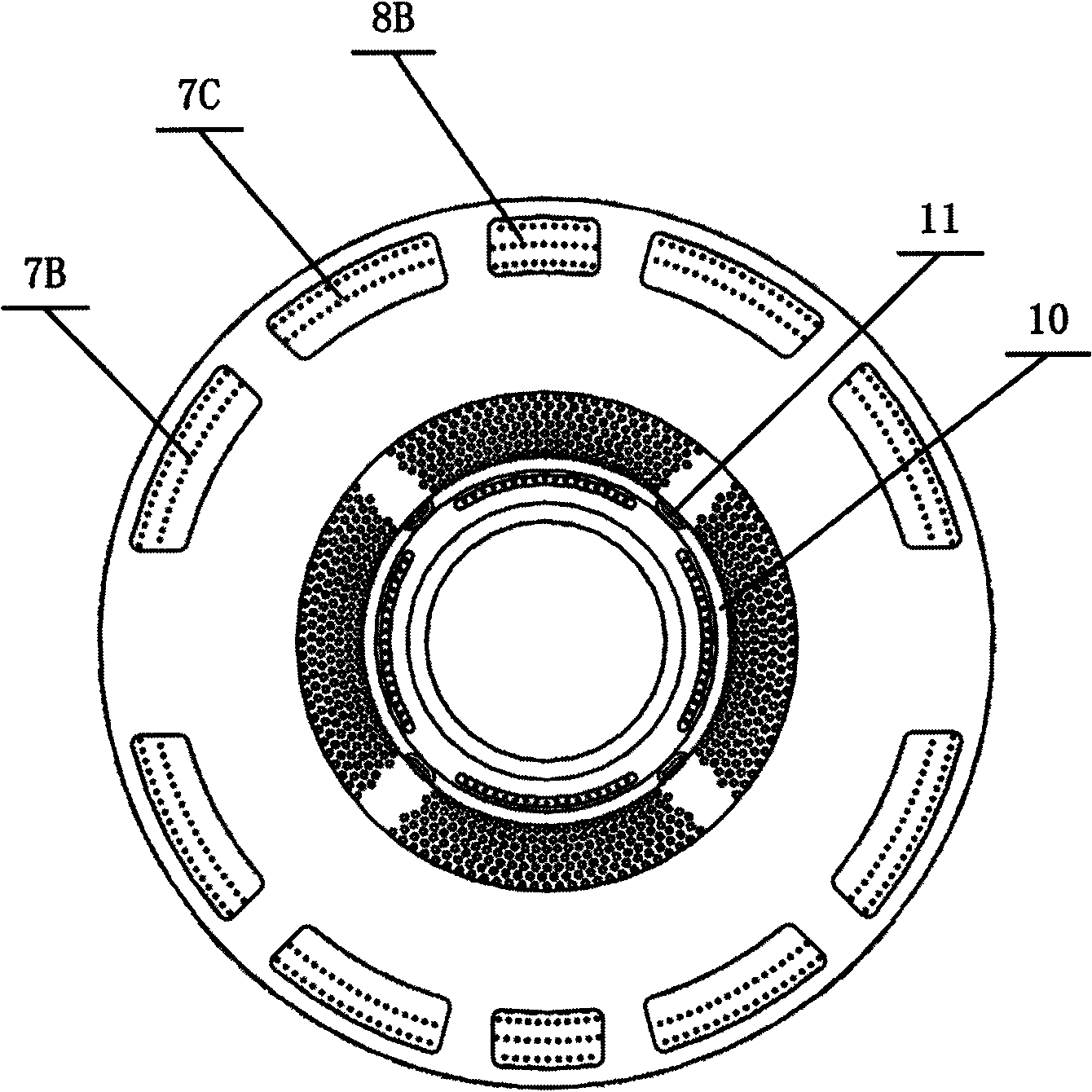

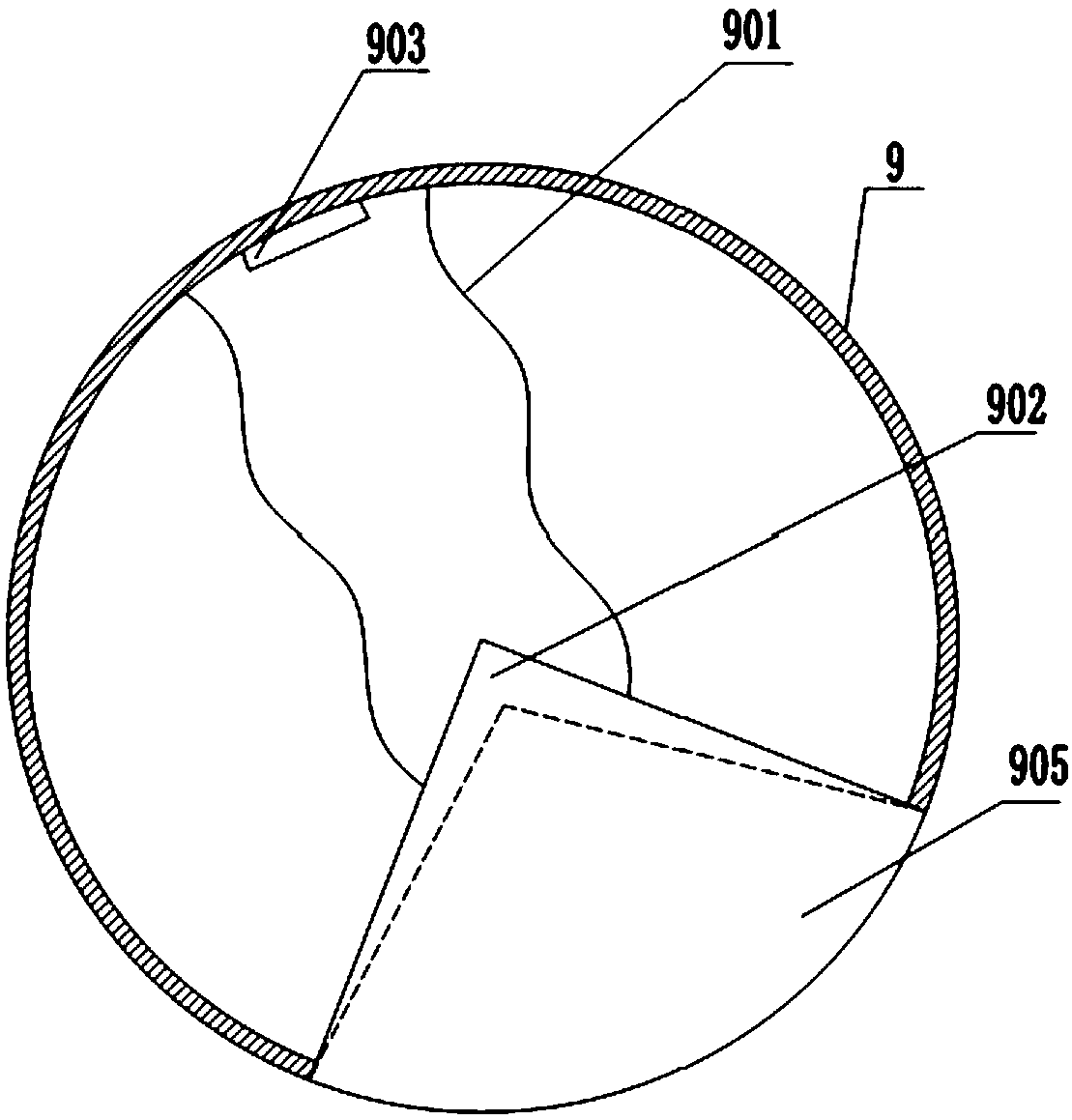

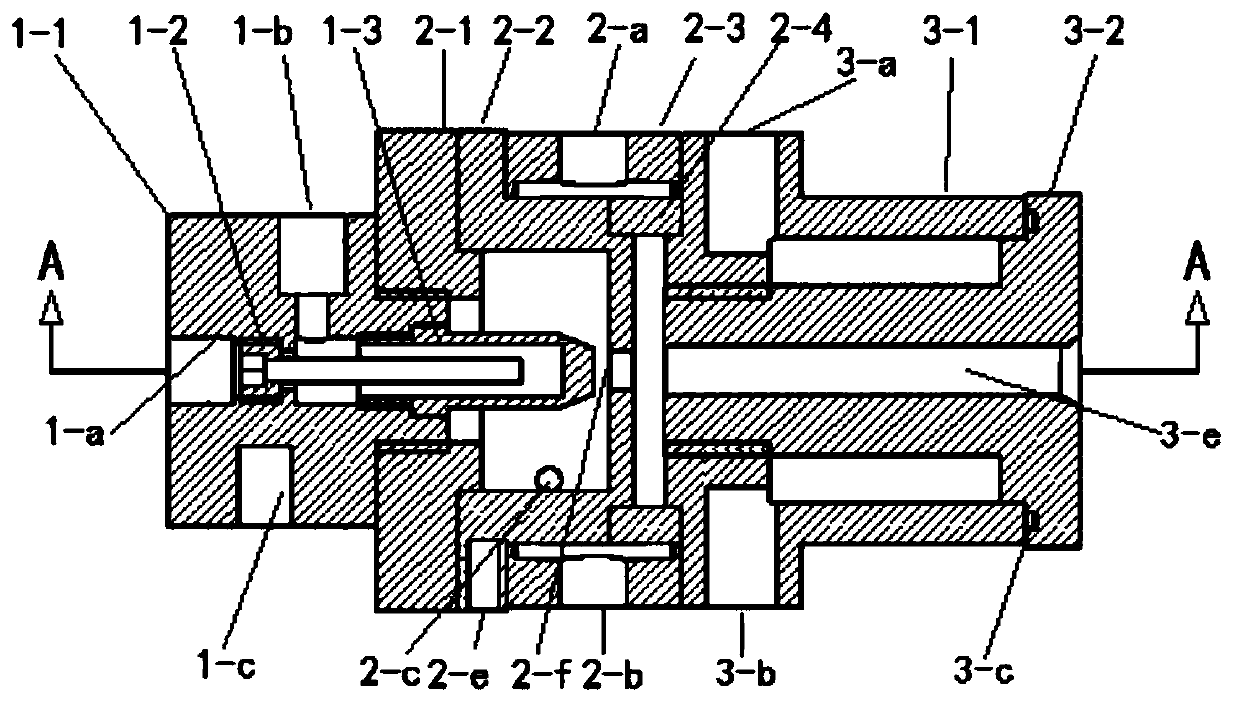

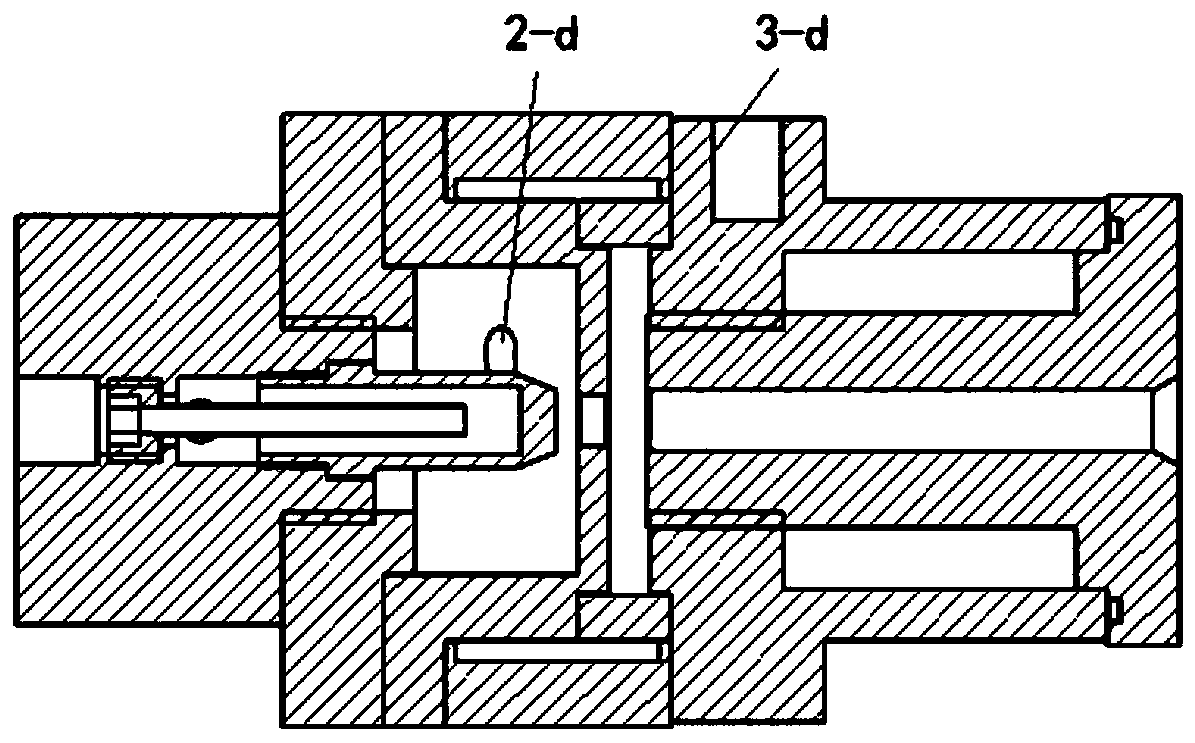

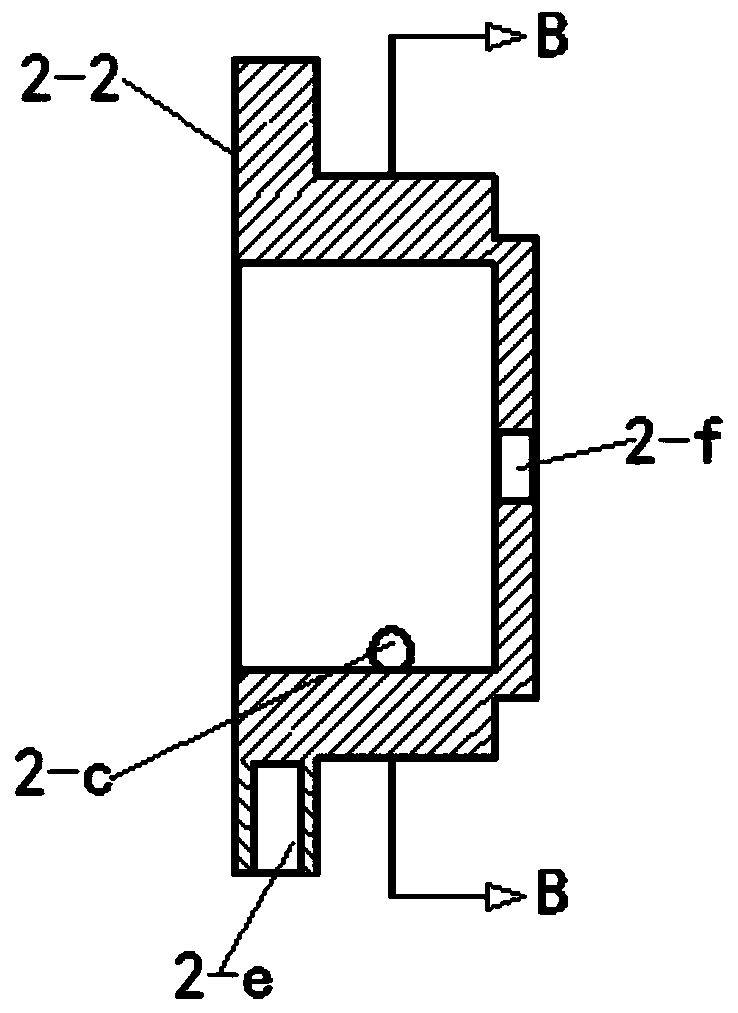

Flexible seal and self-adaption recycling device for immersed photoetching machine

InactiveCN101634811AReduce entrainmentReduce exposurePhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringMechanical engineering

The invention discloses a flexible seal and self-adaption recycling device for an immersed photoetching machine. The device is placed between a projecting lens group and a silicon wafer, comprises an injected liquid recycling component and a following disk piece and is used for restraining the boundary of an immersed liquid flow field. When liquid generates impact on the following disk piece due to the high-speed motion of the silicon wafer, the following disk piece can generate a certain offset along the direction of motion, thereby relieving the pressure of the boundary of the flow field and increasing the quantity of recycling openings to accelerate recycling; conversely, when the high-speed motion of the silicon wafer leads the pressure at one side of the flow field to be reduced, the flexible seal disk piece at the side can generate a certain offset along the direction of motion to carry out pressure compensation and reduce the quantity of the recycling openings and the liquid recycling amount at the same side. The self-adaption recycling of the liquid can be realized by adaptively the contact quantity of the recycling openings and the flow field, the recycling efficiency is effectively improved, and the vibration and the noise brought by recycling are reduced.

Owner:ZHEJIANG UNIV

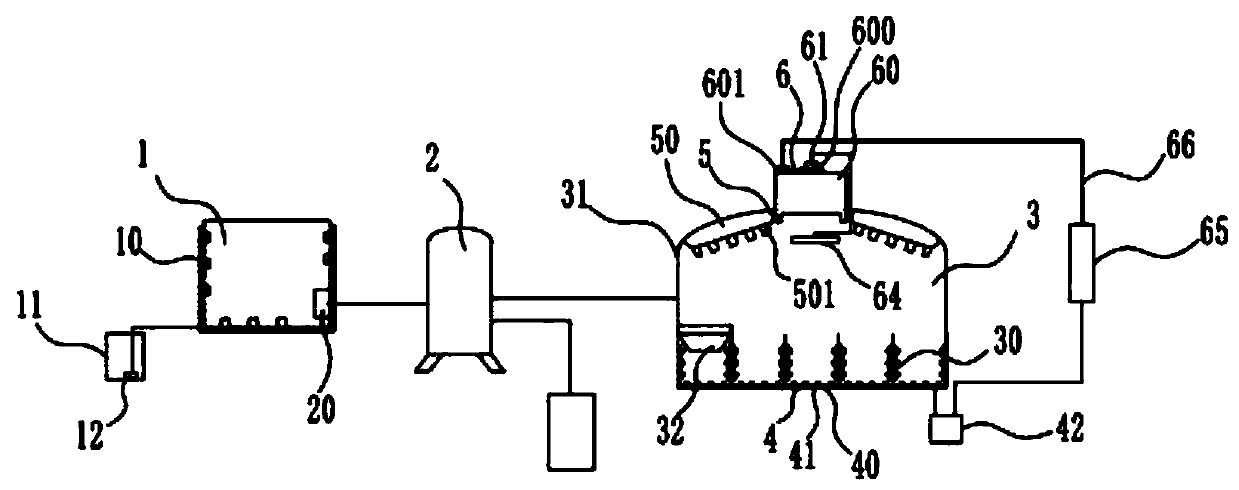

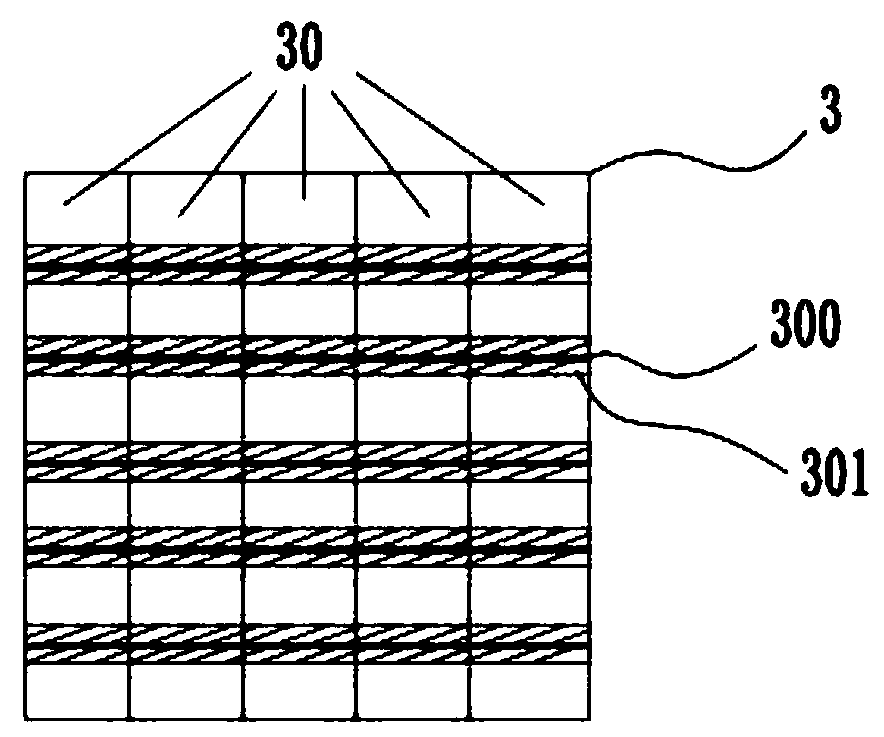

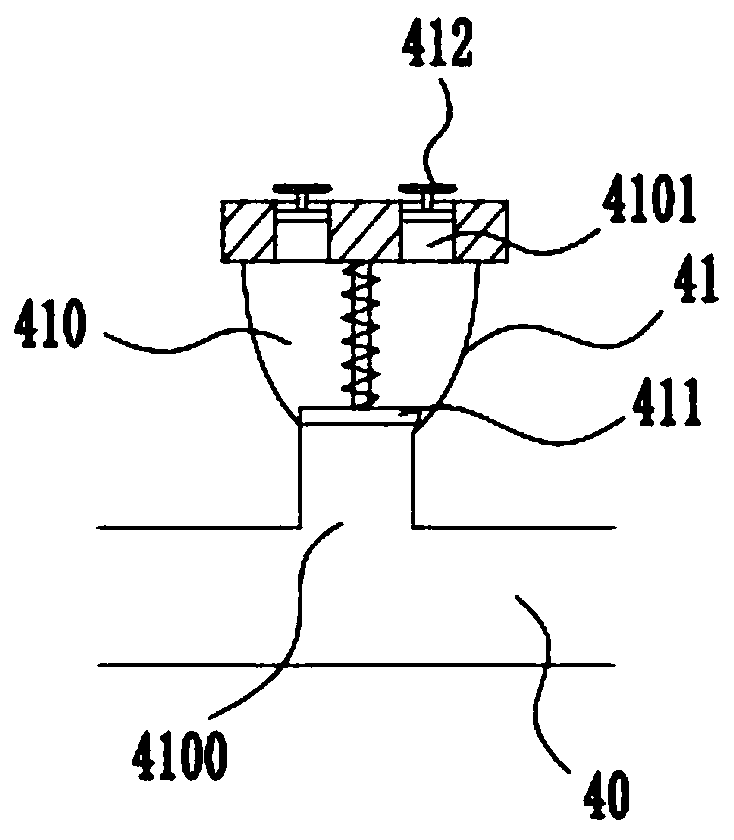

Water-saving ultra/microfiltration purification device for water

InactiveCN102583651ALow investment costLow running costUltrafiltrationWater/sewage treatment bu osmosis/dialysisWater savingActivated carbon

The invention discloses a water-saving ultra / microfiltration purification device for water. The water-saving ultra / microfiltration purification device for water comprises a water-feeding pump 1, ultra / microfiltration membrane purification units 2, an ultra / microfiltration membrane concentrated water and backwashing water recovery tank 3, a clean water reservoir 7, an aeration blower fan 8, a water suction pump 9 and associated pipe valves. The water-saving ultra / microfiltration purification device for water is characterized in that activated carbon particles 4, an aeration device 5 and flat membrane members 6 are arranged in the ultra / microfiltration membrane concentrated water and backwashing water recovery tank 3; the aeration device 5 is located at the bottom of the ultra / microfiltration membrane concentrated water and backwashing water recovery tank 3; and the flat membrane members 6 are located in the ultra / microfiltration membrane concentrated water and backwashing water recovery tank and on the aeration device 5. The water-saving ultra / microfiltration purification device for water can realized purification of water and recovery of concentrated water and backwashing water simultaneously. Product water obtained by the water-saving ultra / microfiltration purification device for water has quality reaching the national drinking water quality standard. Through the water-saving ultra / microfiltration purification device for water, membrane backwashing water and concentrated water can be recycled so that a water recovery rate of a membrane system is greatly improved; a waste water discharge amount is reduced; and a large amount of a water resource is saved. The water-saving ultra / microfiltration purification device for water can be widely utilized for purification of drinking water.

Owner:BEIJING CRYSTEC TECH

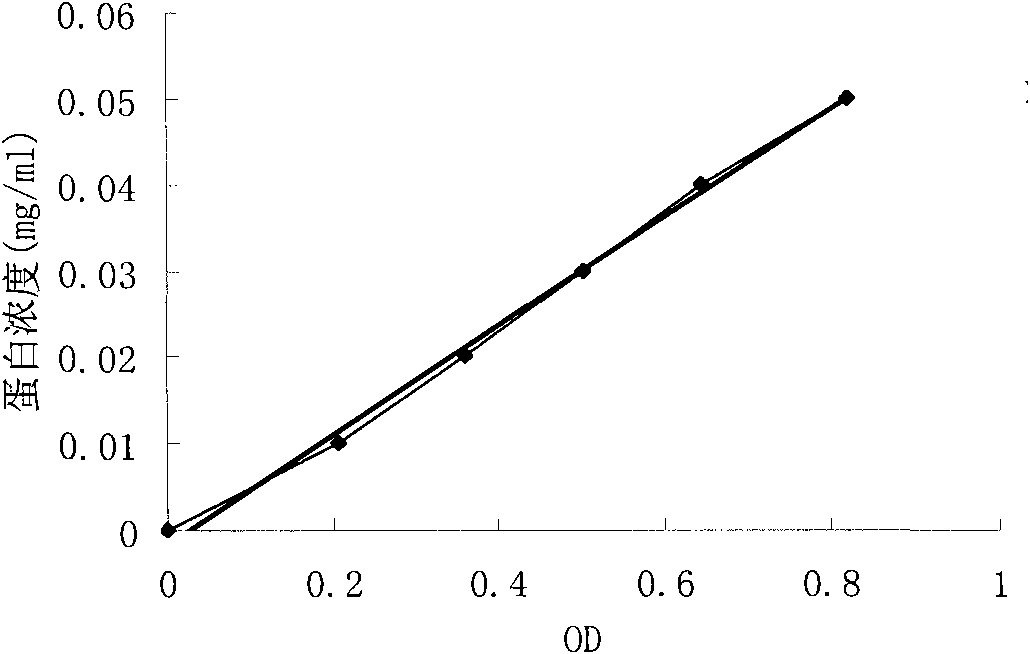

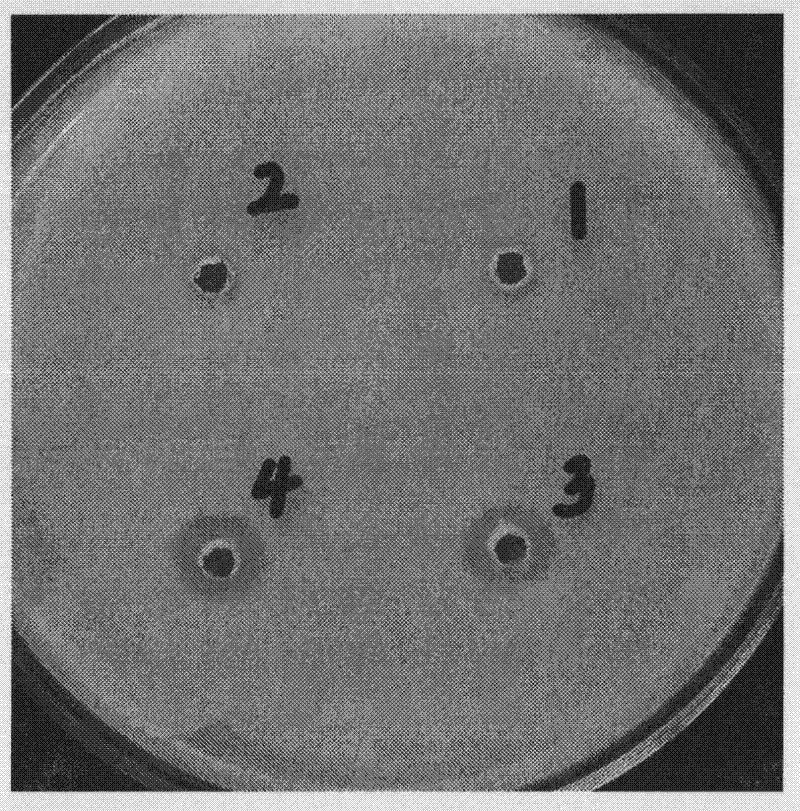

Animal intestinal mucosa extract and preparation method as well as application thereof

InactiveCN101773522AReduce recycling efficiencyReduce pollutionAntibacterial agentsUnknown materialsIntestinal structureEscherichia coli

The invention discloses an animal intestinal mucosa extract and a preparation method as well as application thereof. The animal intestinal mucosa extract is prepared by the method comprising the following steps: (1) taking small intestine of an in vitro animal, scraping the mucosa layer on the intestinal wall, centrifuging and collecting precipitates; (2) adding the precipitates into water, then adding trypsin into the redistilled water for carrying out enzymolysis I, and after the enzymolysis is finished, inactivating enzymes and cooling; then, adding papain into the redistilled water for carrying out enzymolysis II, and after the enzymolysis is finished, inactivating enzymes and cooling; finally, centrifuging and taking the supernatant solution to obtain an intestinal mucosa enzymolysis solution; and (3) adding an acetic acid solution of which the mass concentration is 5%-10% into the intestinal mucosa enzymolysis solution for stirring and leaching, then centrifuging the leaching solution, and collecting the supernatant solution, and regulating the pH value of the supernatant solution to be 6.0-7.0, freezing and drying to obtain the animal intestinal mucosa extract. The test proves that the intestinal mucosa extract has antibacterial activity to bacteria (such as Escherichia coli).

Owner:FEED RESEARCH INSTITUTE CHINESE ACADEMY OF AGRICULTURAL SCIENCES +1

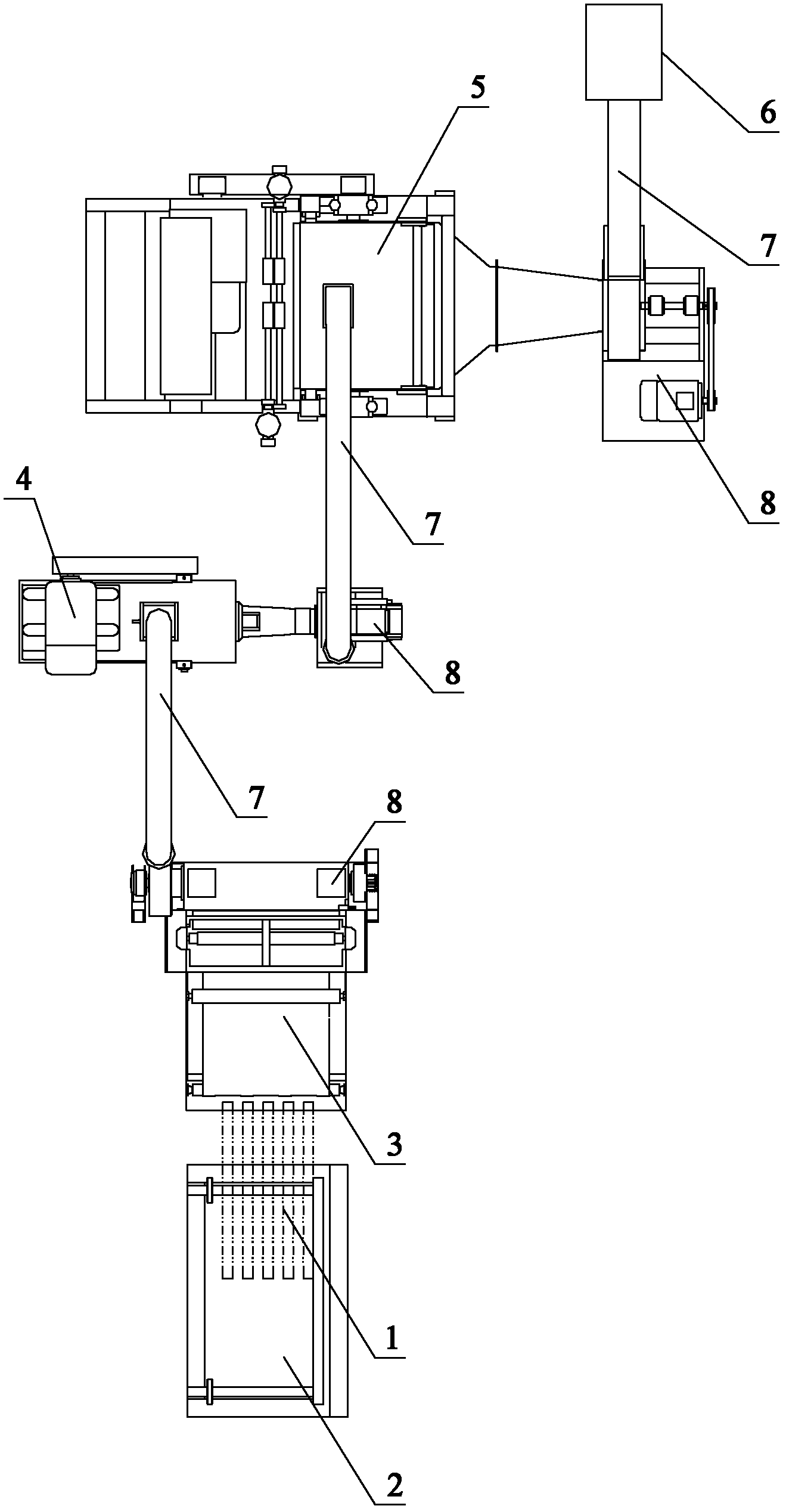

Chemical co-production device of preparing organic fertilizer from livestock and poultry manures

InactiveCN110803946AImprove filtration efficiencyWith energy saving and emission reductionClimate change adaptationExcrement fertilisersAgricultural engineeringPoultry manure

The invention discloses a chemical co-production device of preparing an organic fertilizer from livestock and poultry manures, and belongs to the technical field of organic fertilizer production equipment. The chemical co-production device comprises a homogenization storage tank, a solid-liquid separator, a groove type fermentation tank, a ventilation aeration element, a heat collection element, and a power supply. Through the ventilation aeration element, manures will not enter an aeration pipeline, the aeration pipeline will not be obstructed, the aeration process is guaranteed, and enough oxygen is supplied to the organic fertilizer to ensure the quality of the produced organic fertilizer. By utilizing the ventilation aeration element, air flows out in a spiral form, the wind power is increased, the air ejected in a spiral form is broken into a plurality of air bubbles, and the aeration efficiency is improved therefore. Through a deodorizing element, the odor generated by the fermentation in the groove type fermentation tank is processed centrally; the manures are recycled and reused, the energy consumption and discharge are reduced, and the provided device has the advantages ofuniform aeration, high production efficiency, energy saving, and reduced emission, and is suitable for popularization.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Process for recycling waste dustfree paper and equipment thereof

InactiveCN102304864ASufficiently crushedMeet the production process requirementsPaper recyclingRaw material divisionSingle fiberPulp and paper industry

The invention provides a process for recycling waste dustfree paper and equipment thereof. The process comprises the following steps of: 1, collecting and processing waste dustfree paper into a waste roll; 2, feeding the waste roll into a rough pulverizer through a feeding device; 3, pulverizing the waste roll into lamellar bulk material by the rough pulverizer ; 4, pulverizing the lamellar bulk material into fiber material by a first-grade fine pulverizer, wherein the content of single fibers in the fiber material is 60%-80%; 5, pulverizing the fiber material in which the content of the single fibers is 60%-80% into fiber material in which the content of the single fibers is 90% by a second-grade fine pulverizer; and 6, directly feeding the fiber material in which the content of the single fibers is 90% into a dusfree paper forming head. The process has the beneficial effect that the proportion of waste materials can be controlled accurately, and therefore the recycling quality of the pulverized materials and product quality can be improved.

Owner:FITESA CHINA AIRLAID

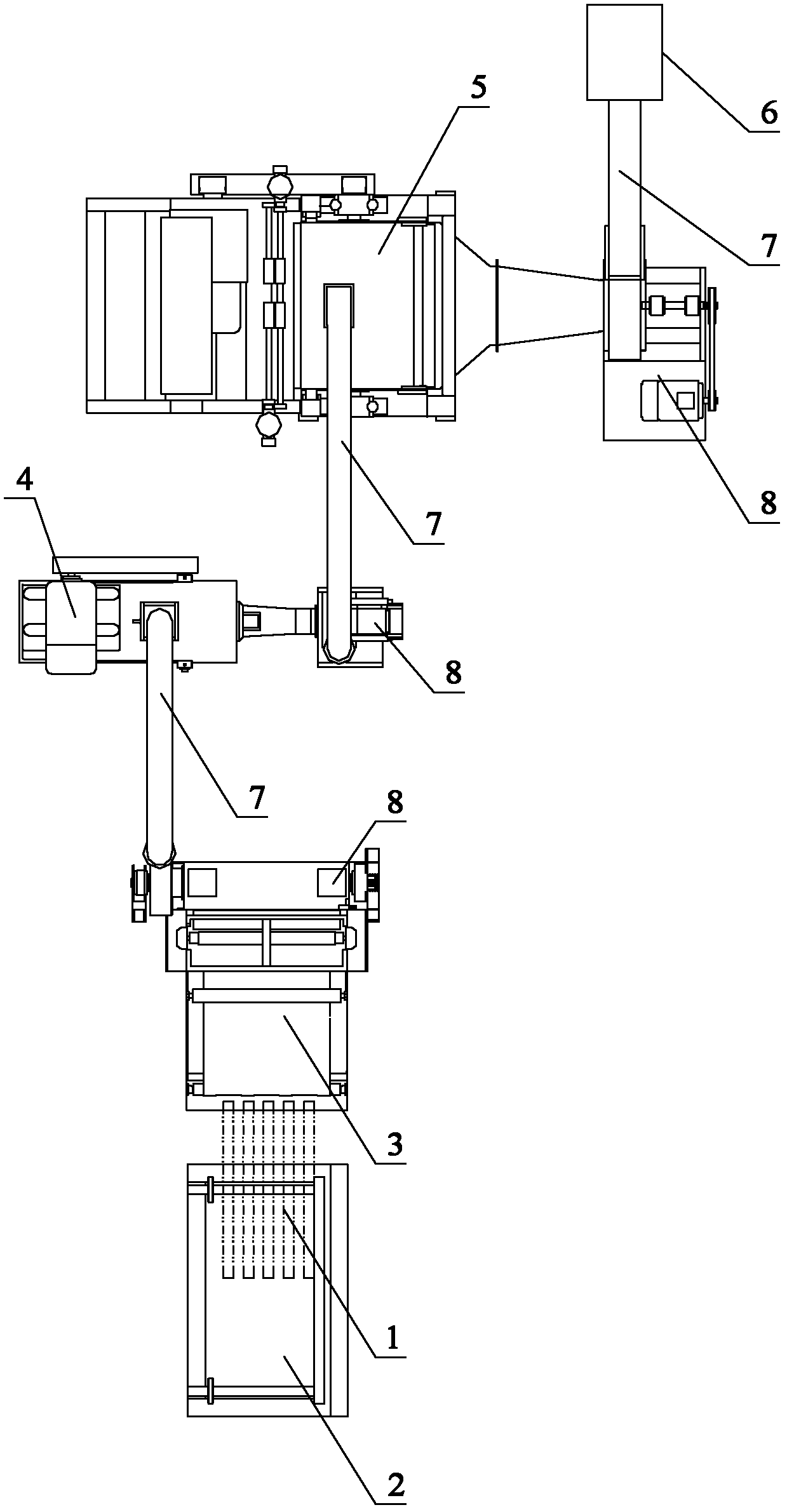

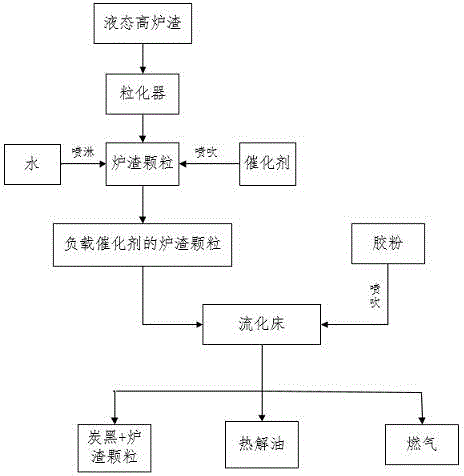

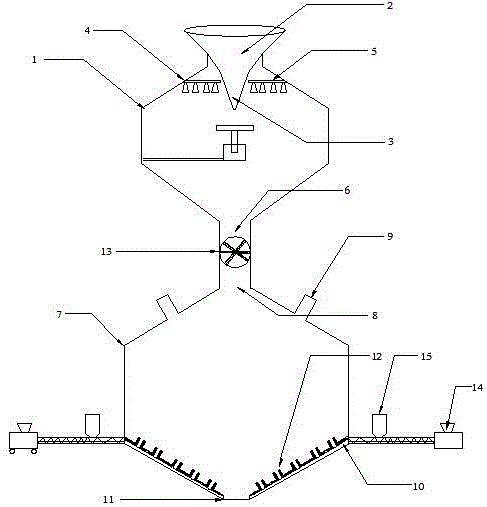

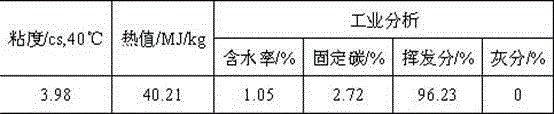

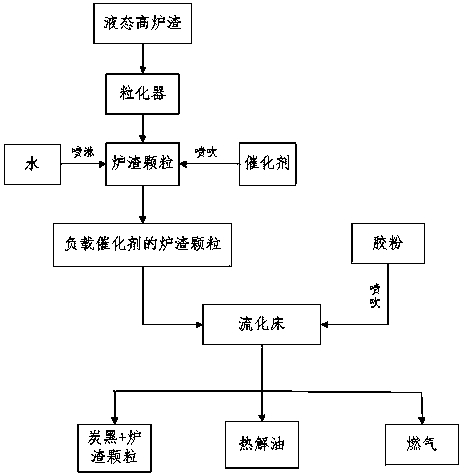

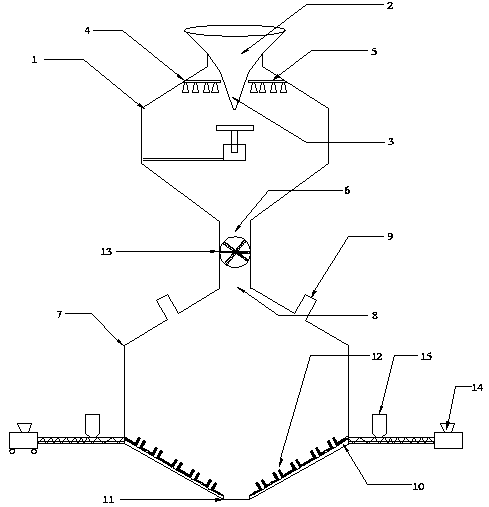

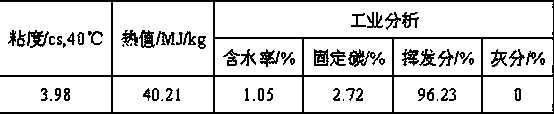

Junked-tire fluidized gasification device and junked-tire fluidized gasification method based on blast furnace slag waste heat utilization

The invention provides a junked-tire fluidized gasification device and a junked-tire fluidized gasification method based on blast furnace slag waste heat utilization. The device comprises a slag granulator and a fluidized-bed gasification reactor. After liquid blast furnace slags are granulated into high-temperature slag particles by the device and catalysts are loaded to surfaces of the high-temperature slag particles, fluidized heat exchange between the high-temperature slag particles and tire rubber powder is performed in the fluidized-bed gasification reactor; a gasification reaction of the rubber powder is generated under the action of slag heat carriers and the catalysts to achieve oil-gas coproduction. The junked-tire fluidized gasification device and the junked-tire fluidized gasification method have the advantages that blast furnace waste heat is taken as a heat source for tire gasification, using waste to treat waste is realized, and accordingly, recycling and reducing of junked tires as well as efficient recovery and utilization of the blast furnace waste heat are achieved; moreover, by the heat exchange mode of fluidized gasification, caloric transfer in the reaction process of tire gasification can be promoted obviously, and quality of pyrolytic oil products can be improved remarkably.

Owner:山东中科能人工环境有限公司

A device and method for fluidization and gasification of waste tires based on blast furnace slag waste heat utilization

ActiveCN105779017BIncrease heating rateReduce recycling efficiencyProductsReagentsHeat carrierFluidized bed

The invention provides a junked-tire fluidized gasification device and a junked-tire fluidized gasification method based on blast furnace slag waste heat utilization. The device comprises a slag granulator and a fluidized-bed gasification reactor. After liquid blast furnace slags are granulated into high-temperature slag particles by the device and catalysts are loaded to surfaces of the high-temperature slag particles, fluidized heat exchange between the high-temperature slag particles and tire rubber powder is performed in the fluidized-bed gasification reactor; a gasification reaction of the rubber powder is generated under the action of slag heat carriers and the catalysts to achieve oil-gas coproduction. The junked-tire fluidized gasification device and the junked-tire fluidized gasification method have the advantages that blast furnace waste heat is taken as a heat source for tire gasification, using waste to treat waste is realized, and accordingly, recycling and reducing of junked tires as well as efficient recovery and utilization of the blast furnace waste heat are achieved; moreover, by the heat exchange mode of fluidized gasification, caloric transfer in the reaction process of tire gasification can be promoted obviously, and quality of pyrolytic oil products can be improved remarkably.

Owner:山东中科能人工环境有限公司

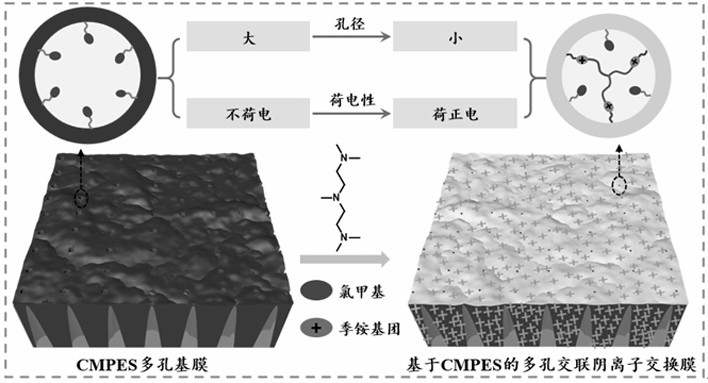

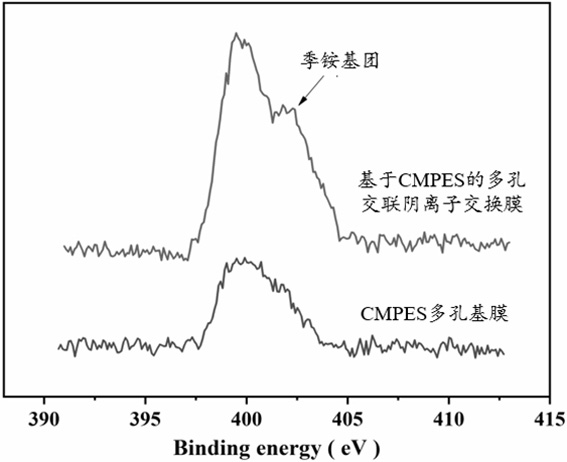

Preparation method of porous cross-linked anion exchange membrane for diffusion dialysis

InactiveCN113041850AIncrease transfer rateAccelerated acid dialysis coefficientMembranesDialysisIon-exchange membranesPorous membrane

The invention discloses a preparation method of a porous cross-linked anion exchange membrane for diffusion dialysis, which comprises the following steps: dissolving chloromethylated polyethersulfone in an organic solvent to form a membrane casting solution, coating a substrate with the membrane casting solution, and performing a phase inversion method to obtain a porous base membrane; and soaking the porous base membrane in a pentamethyldiethylenetriamine solution to carry out synchronous crosslinking and quaternization modification so as to prepare the porous crosslinking anion exchange membrane suitable for diffusion dialysis. Based on the special microstructure of the porous membrane, especially the sufficient free space in the internal porous structure of the porous membrane, the ion transmission rate is greatly improved, and meanwhile, three tertiary amine groups contained in pentamethyldiethylenetriamine are used for achieving synchronous crosslinking and quaternization modification of the porous base membrane. Therefore, the porous cross-linked anion exchange membrane with both high acid dialysis coefficient and high acid / salt separation factor is prepared, and the use requirements of diffusion dialysis are met.

Owner:FUZHOU UNIVERSITY

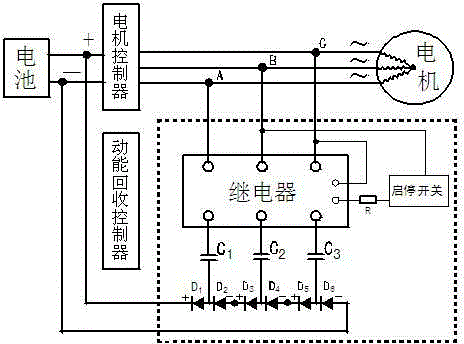

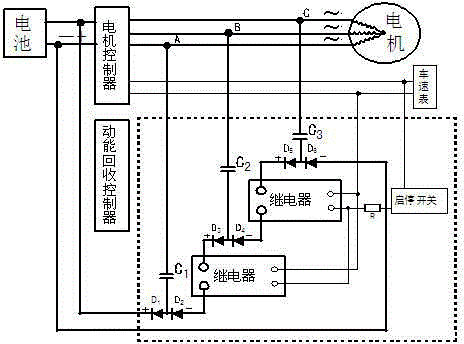

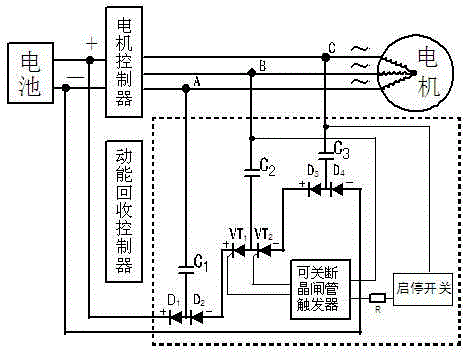

Kinetic energy recovery controller for electric vehicle

ActiveCN104410140ACompliant with streamlined design requirementsImprove securityBatteries circuit arrangementsElectric powerMoving averageCapacitance

The invention provides a kinetic energy recovery controller for an electric vehicle, and belongs to the technical field of energy recovery of the electric vehicle. The controller and a motor controller are jointly connected in parallel onto three output wires of a motor stator; a start-stop switch is mounted on a speed regulating assembly of the electric vehicle; during freewheeling, kinetic energy of the vehicle is converted into three-phase alternating current electric energy through the motor; and the controller can automatically select and recover gliding kinetic energy produced when the vehicle speed is close to or exceeds the average moving speed per hour in the city, capacitors are connected in series firstly, three-phase bridge rectification and direct current bridge type series connection boosting are performed, and the energy is fed back to batteries for storage finally. The kinetic energy recovery controller is characterized in that: 1), a control switch power supply adopts kinetic energy power; 2), a three-phase bridge rectification and direct current bridge type series connection circuit is adopted to design kinetic energy rectification and kinetic energy boosting; and 3), the capacitors are adopted to design kinetic energy recovery degree. The controller has simple design and comes onto the market in an embedded module manner, a safe and energy-saving mode is provided for medium-and-high-speed gliding of the electric vehicle in gear, the safety factor and the control performance of the electric vehicle can be improved, and the endurance mileage of the electric vehicle can be increased by about 20%.

Owner:华贻科技(深圳)有限公司

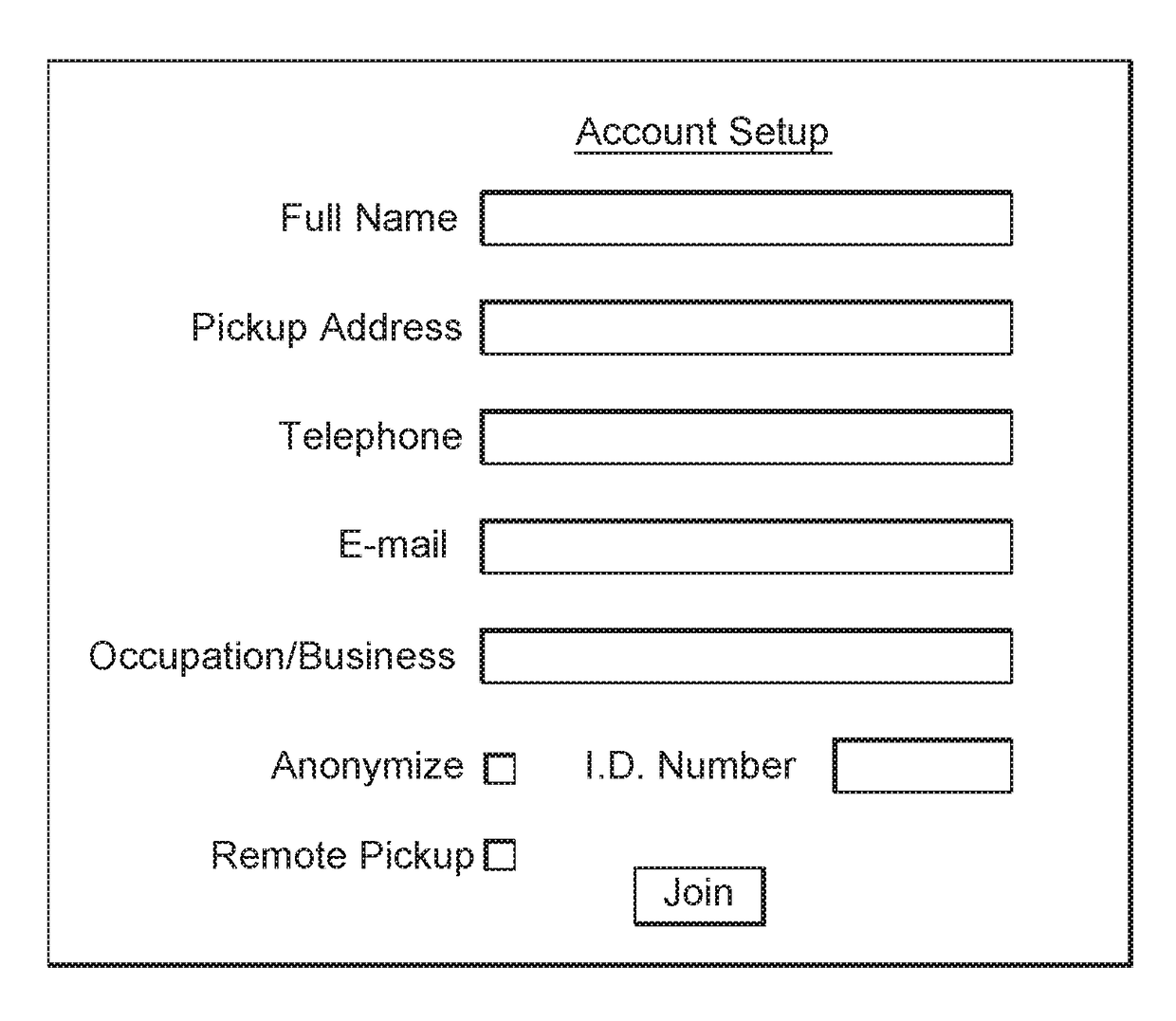

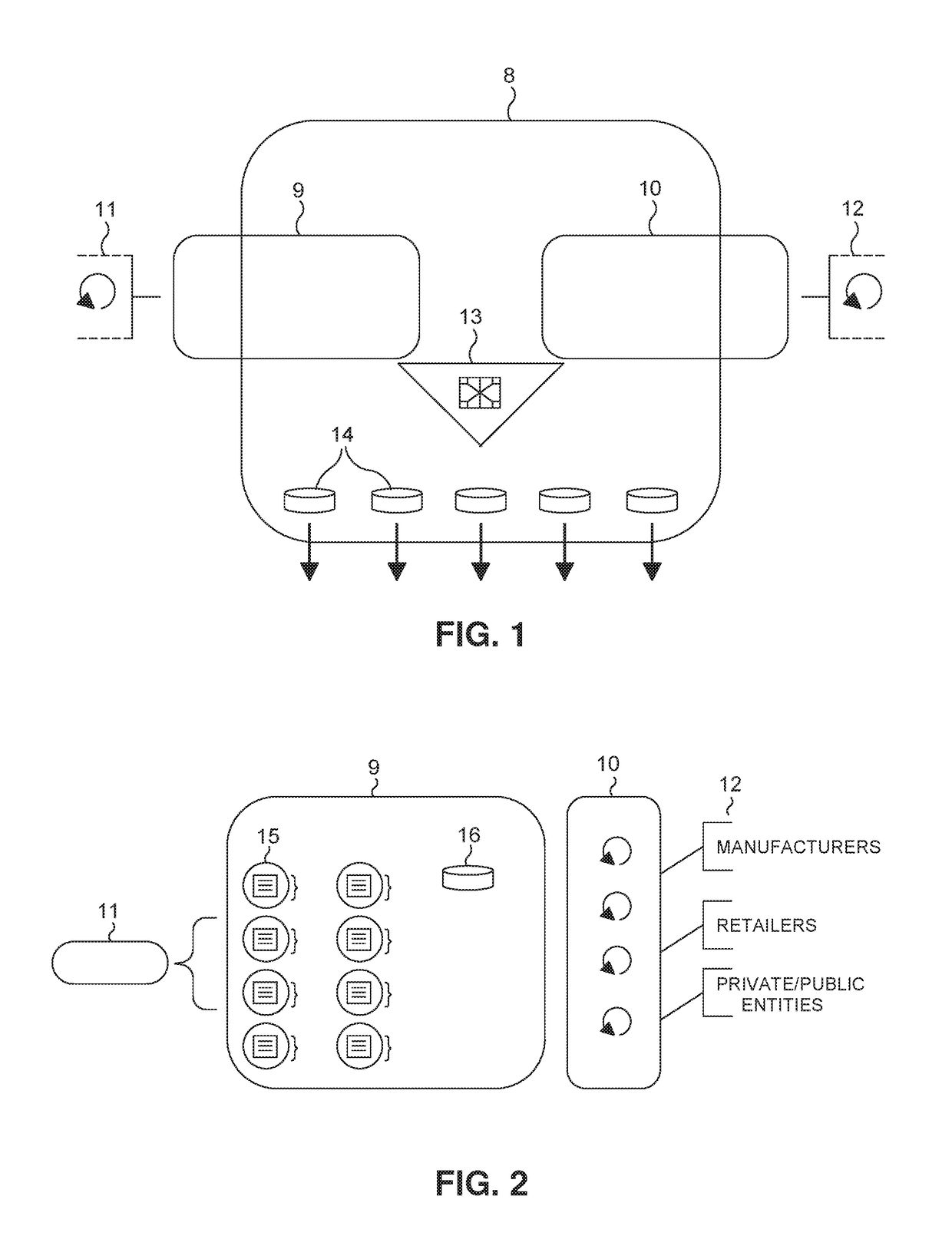

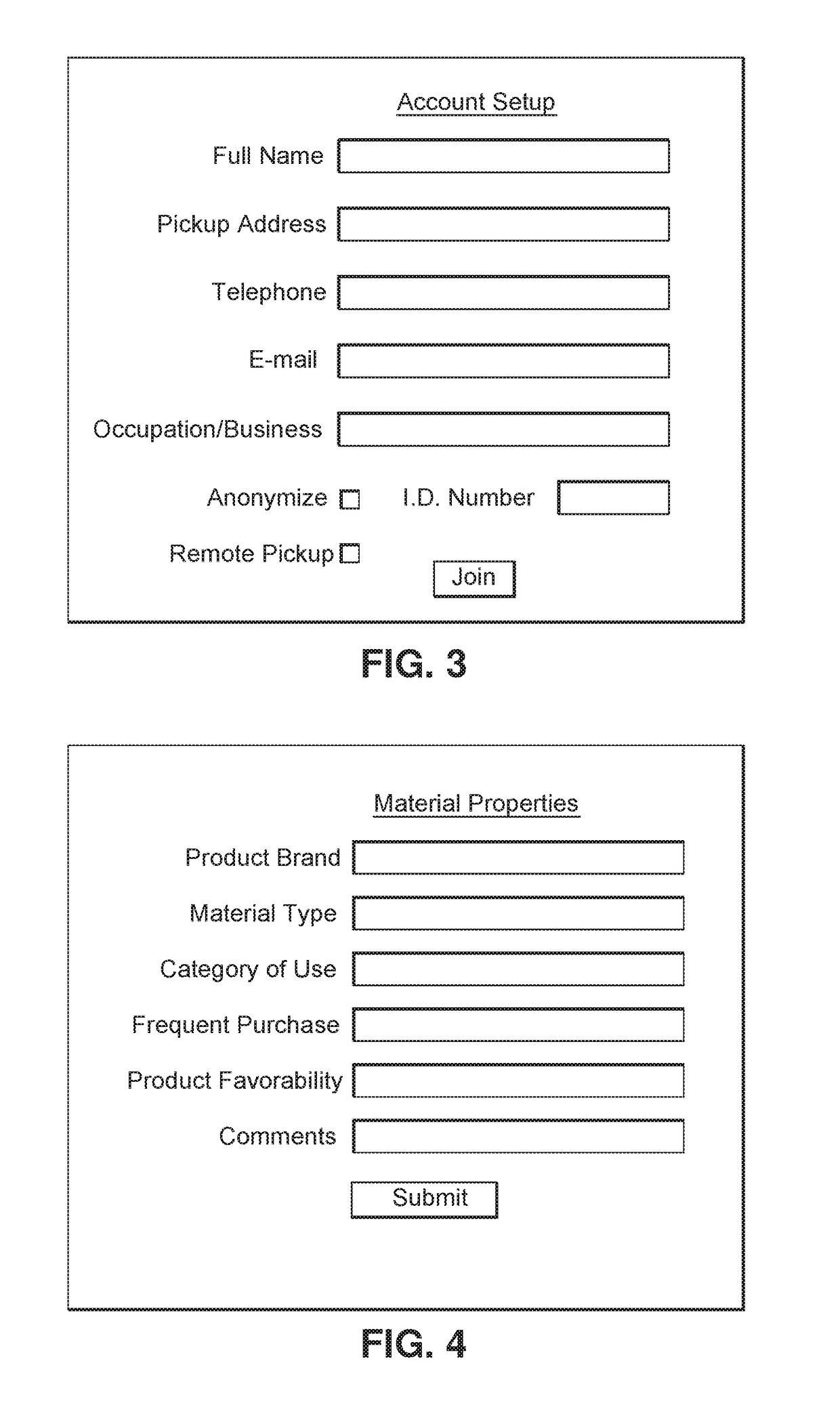

System and method for facilitating the recycling of materials

InactiveUS20180025375A1Increasing waste productionRapidly and efficiently identified and resolvedMarketingInput/output processes for data processingData setHabit

Systems, methods, and articles of manufacture are contemplated by which the recycling program of a community can be improved. A consumer data set corresponding to the purchasing habits of a community is collected, along with a data set corresponding to the characteristics of waste materials collected from the individuals within the community. The community and individual waste material data sets are analyzed, and points of reduced recycling efficiency are determined for both the community as a whole and for the individuals within the community. These points of reduced efficiency are used to generate incentivization for the individuals, such as aspirational goals, monetary compensation, or promotional offer. The individuals have access to an account for monitoring their recycling statistics and to receive the incentivizations. The individuals may transmit to the database, via the online account, information on their waste materials, to improve the precision of the recycling program, or individual pickup requests.

Owner:ARMEN MARK JOSEPH

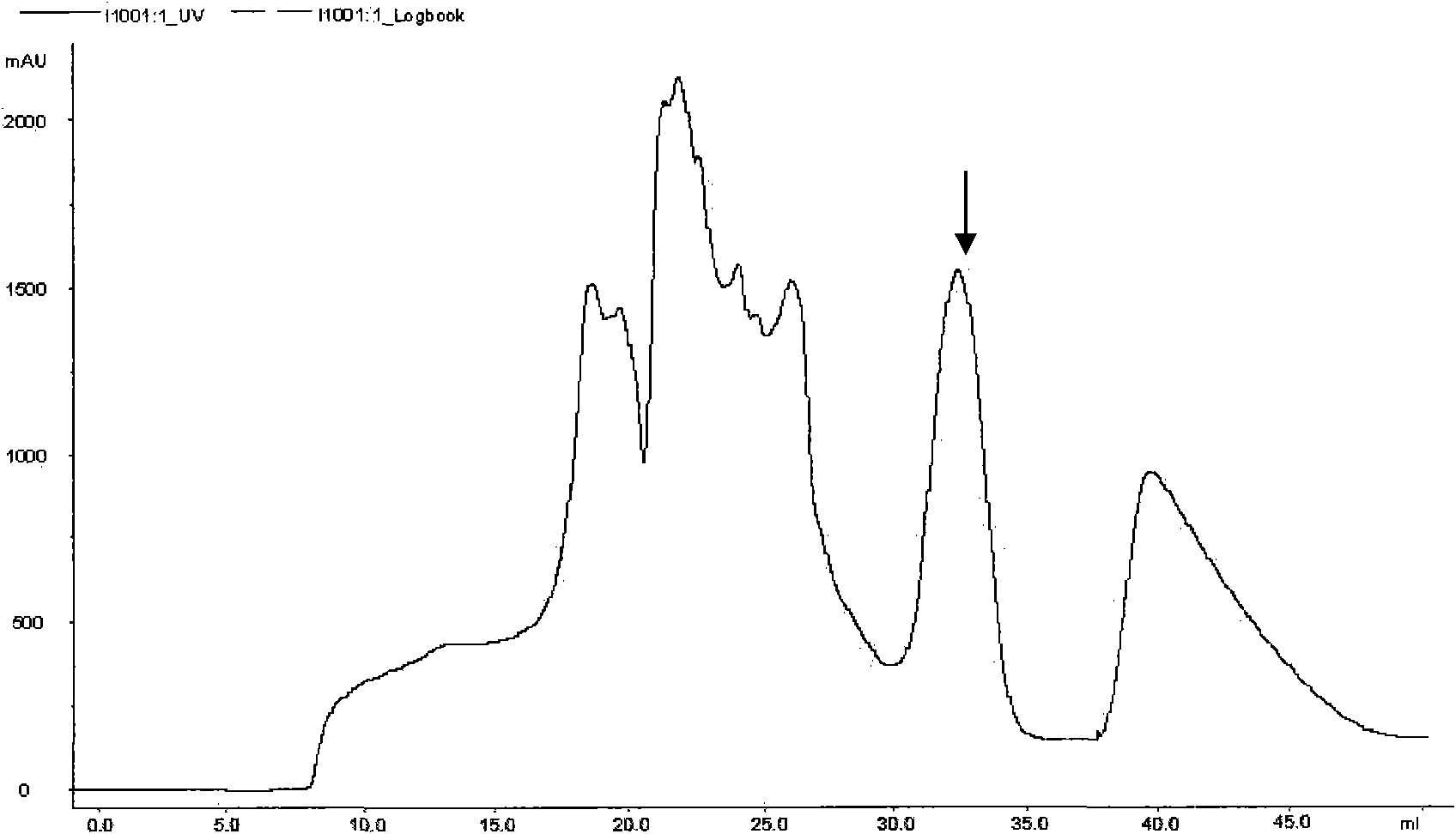

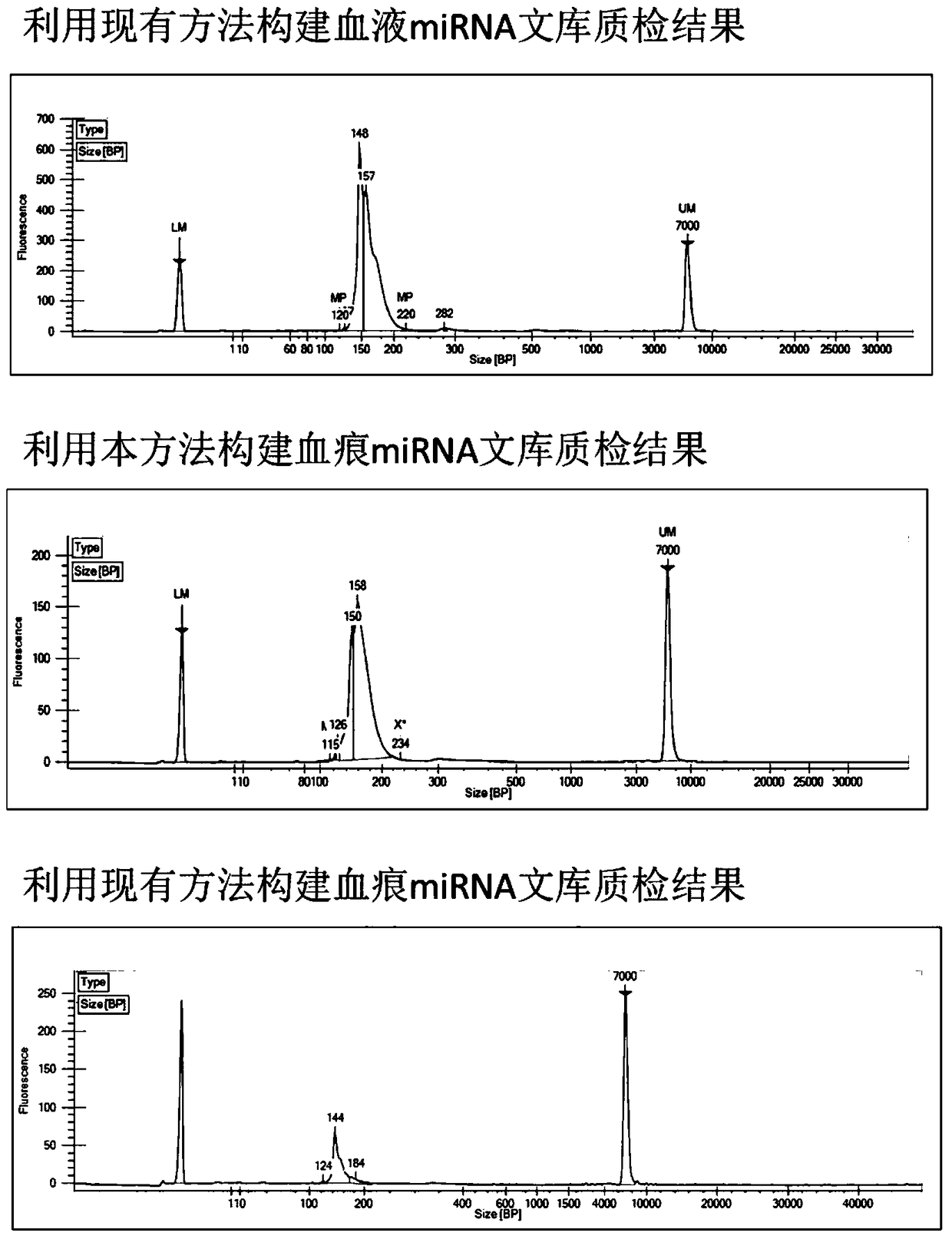

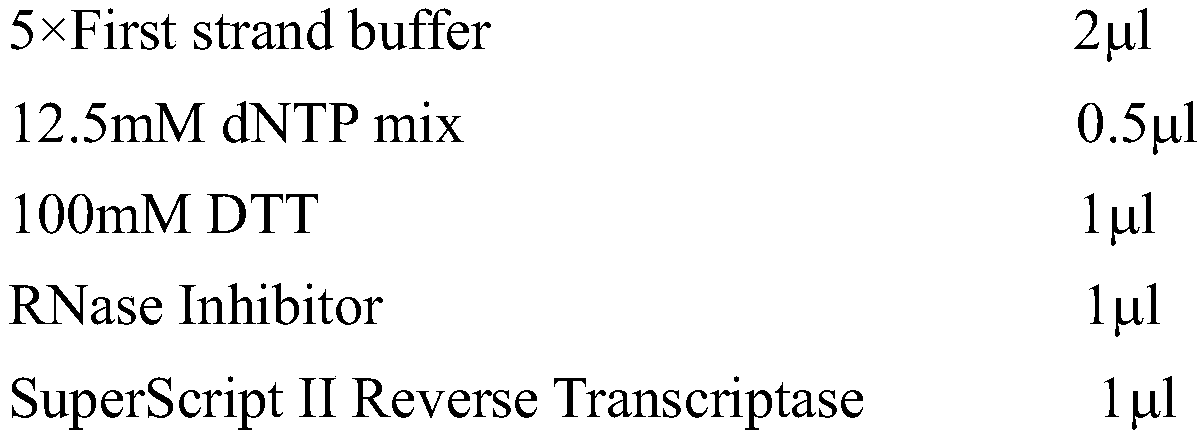

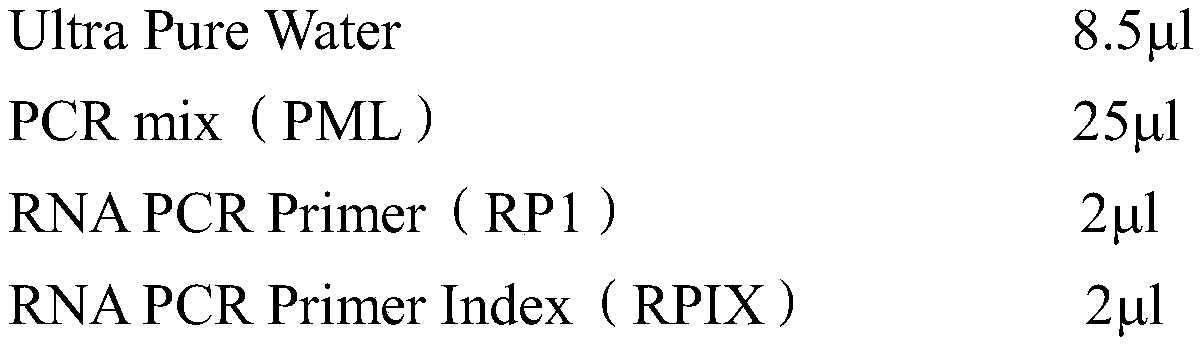

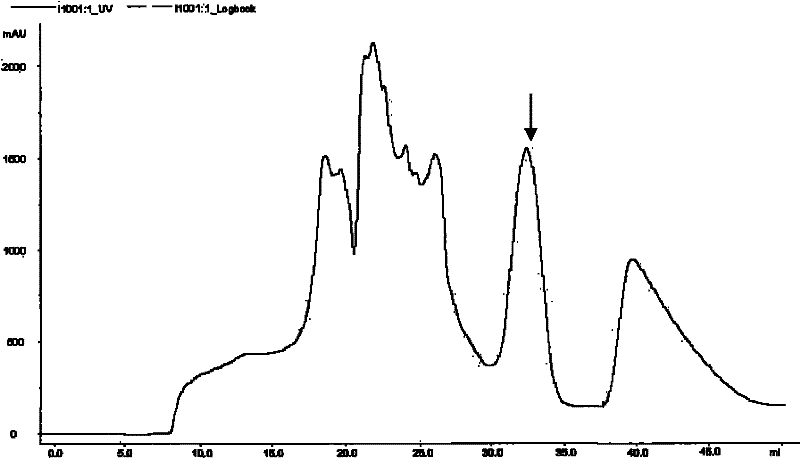

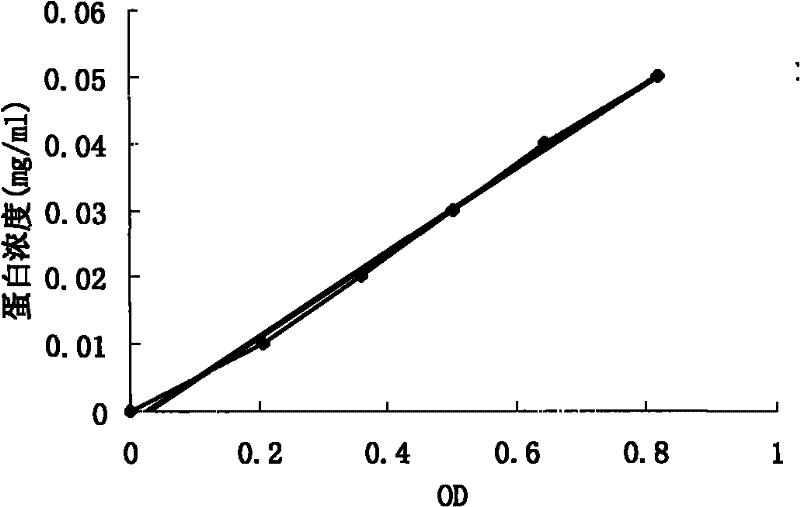

Construction method of dated bloodstain miRNA high-throughput sequencing library

ActiveCN108977435AEasy to reuseIncrease lysis timeMicrobiological testing/measurementLibrary creationTechnical supportForensic science

The invention discloses a construction method of a dated bloodstain miRNA high-throughput sequencing library. The method comprises the steps of pretreatment of a dated bloodstain sample, extraction ofmiRNA and construction of a miRNA sequencing library, wherein the library construction includes: (1) connection of miRNA 5' and 3' junctions; (2) reverse transcription; (3) PCR (Polymerase Chain Reaction) amplification; (4) agarose gel electrophoresis on a PCR amplification product, gel cutting and recovery of fragments of 145 to 160 bp to obtain the sequencing library. By adopting the method disclosed by the invention, construction of the dated bloodstain miRNA library can be finished within 48 hours, and only a 5cm<2> dated bloodstain (containing about 10 to 100ng RNA) sample is needed at least. Reuse of dated forensic evidence is facilitated, the reuse of dated forensic evidence appears in the field of forensic medicine for the first time, and strong technical support is provided for expanding the application of miRNA in forensic medicine.

Owner:BEIJING CENT FOR PHYSICAL & CHEM ANALYSIS

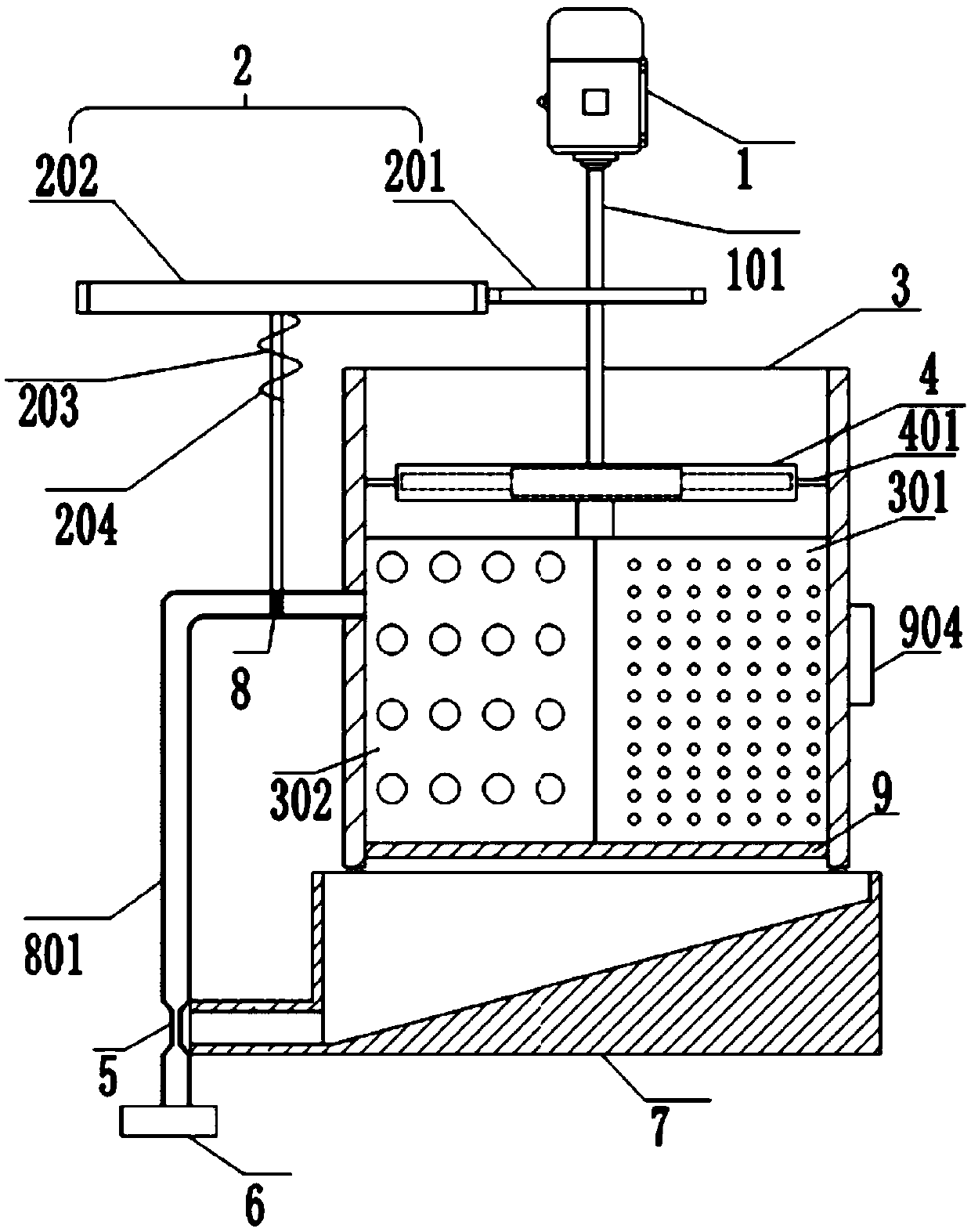

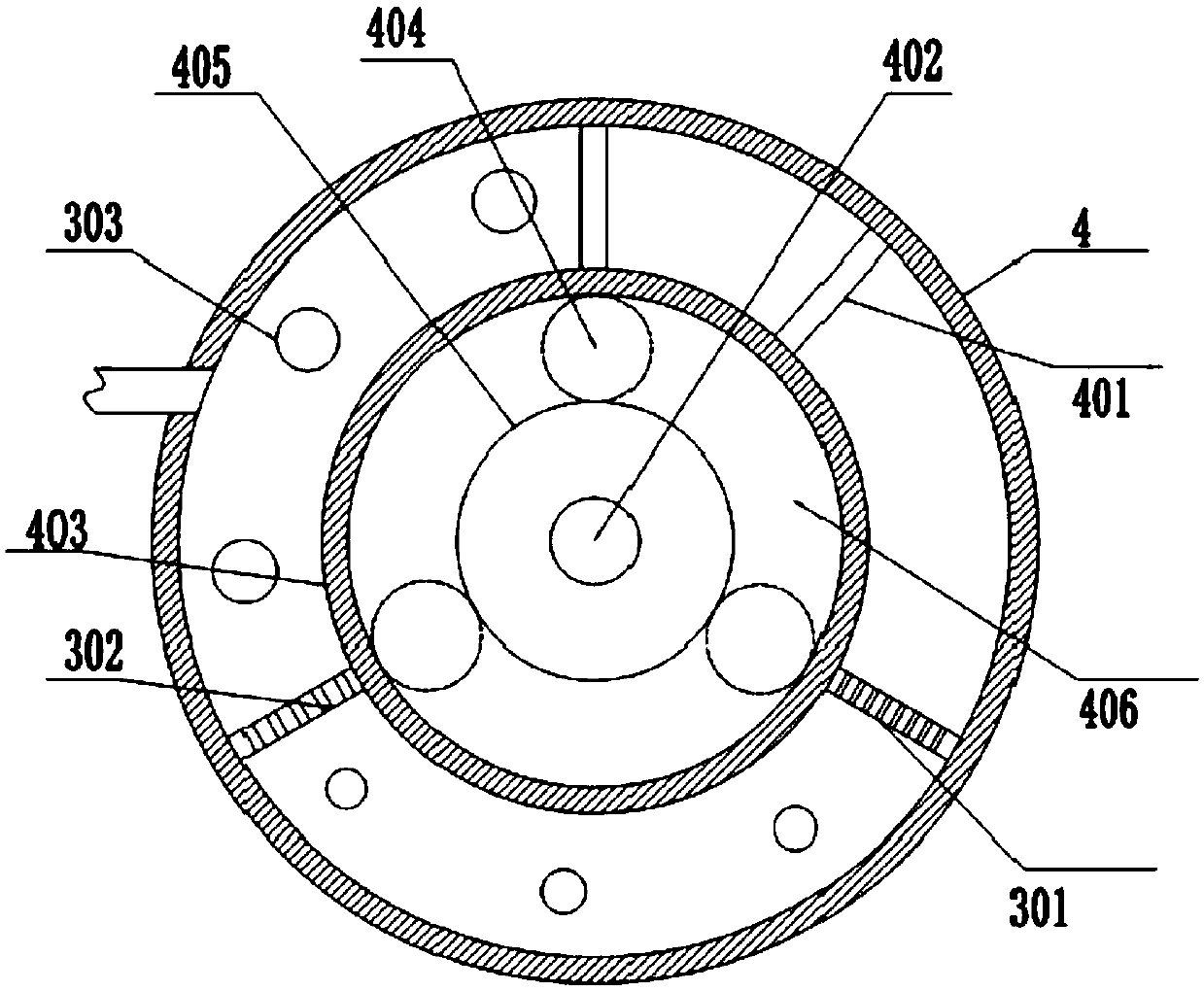

Grinding device for silica gel production

The invention relates to the field of silica gel grinding, in particular to a grinding device for silica gel production. The grinding device for the silica gel production comprises a machine frame, wherein a motor, an operation cylinder and a collection chamber are sequentially fixed to the machine frame from top to bottom. A planetary gear train, a filtering and screening part and a partition plate are sequentially arranged in the operation cylinder from top to bottom. A material pipe fixed to the motor and a blower positioned at the lower side of the material pipe are arranged on one side ofthe operation cylinder, an output shaft of the motor is coaxially connected with a gear reduction mechanism, a baffle plate is rotatably arranged in the material pipe in a matched mode, the gear reduction mechanism is connected with the baffle plate, and grinding balls are placed in the filtering and screening part. The grinding device for the silica gel production is applied to basic material grinding, the grinding degree of the base material can be sufficient, and the utilization rate of the base material can be improved.

Owner:重庆君诚硅胶有限公司

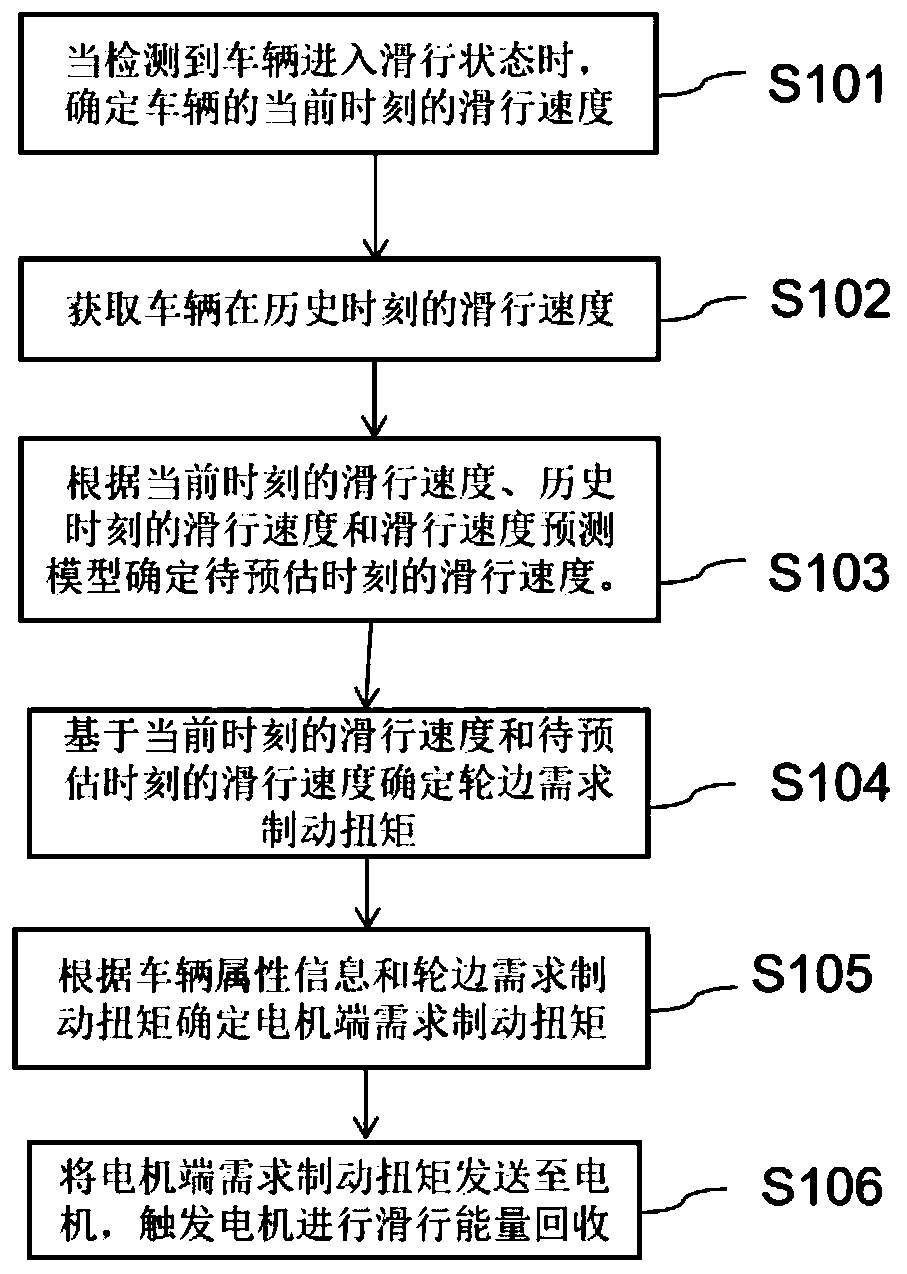

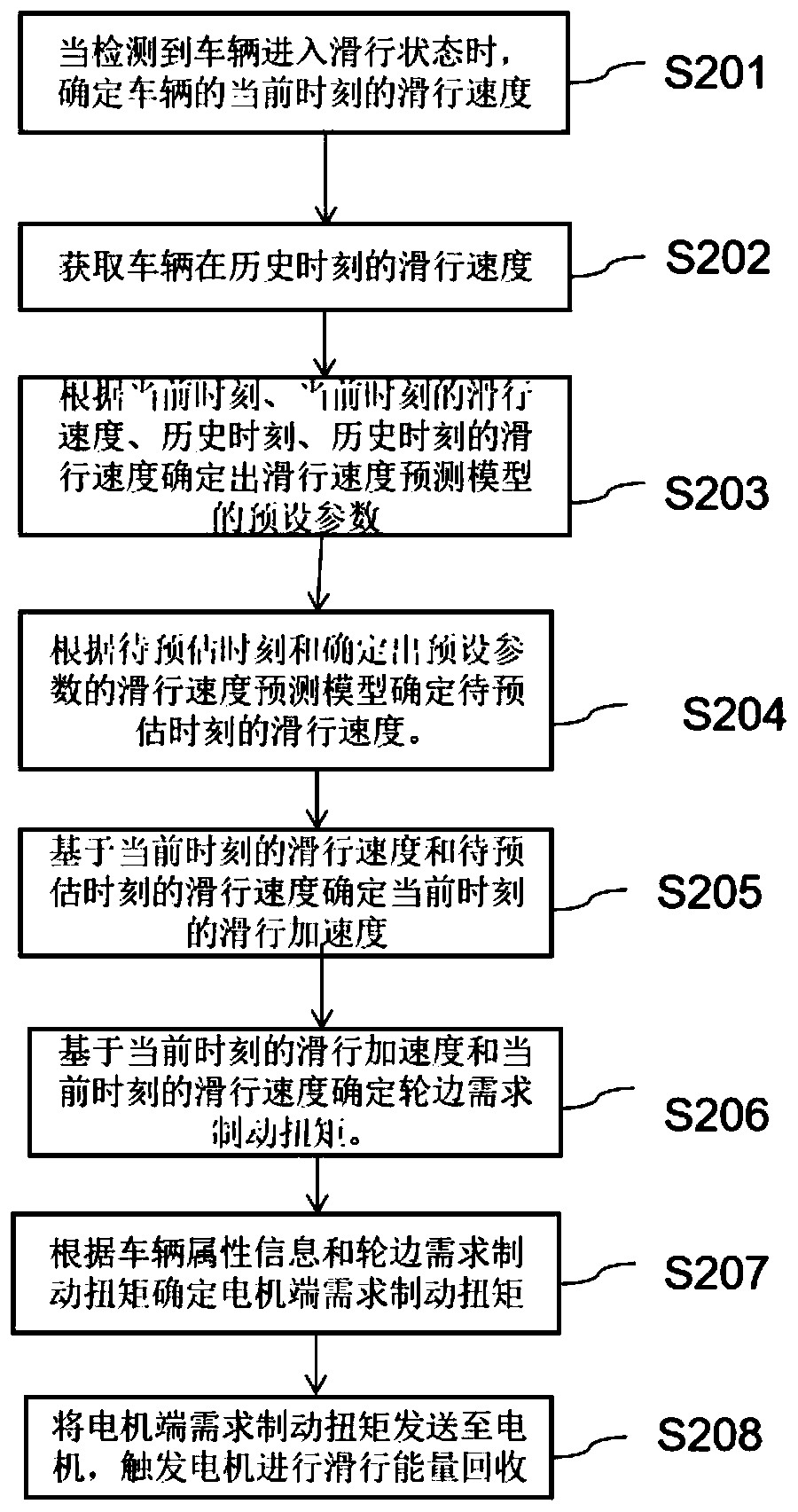

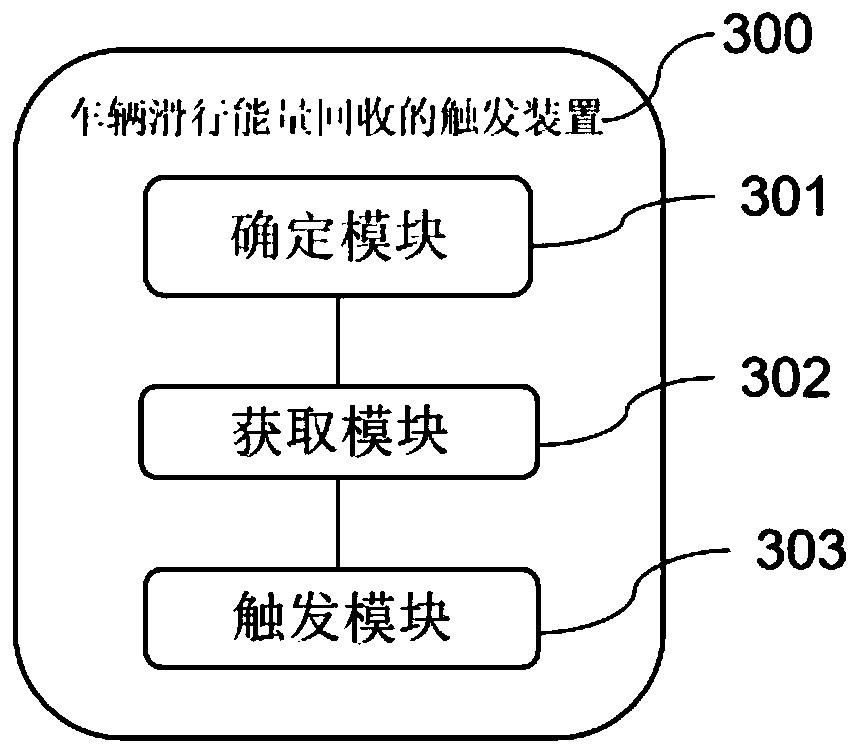

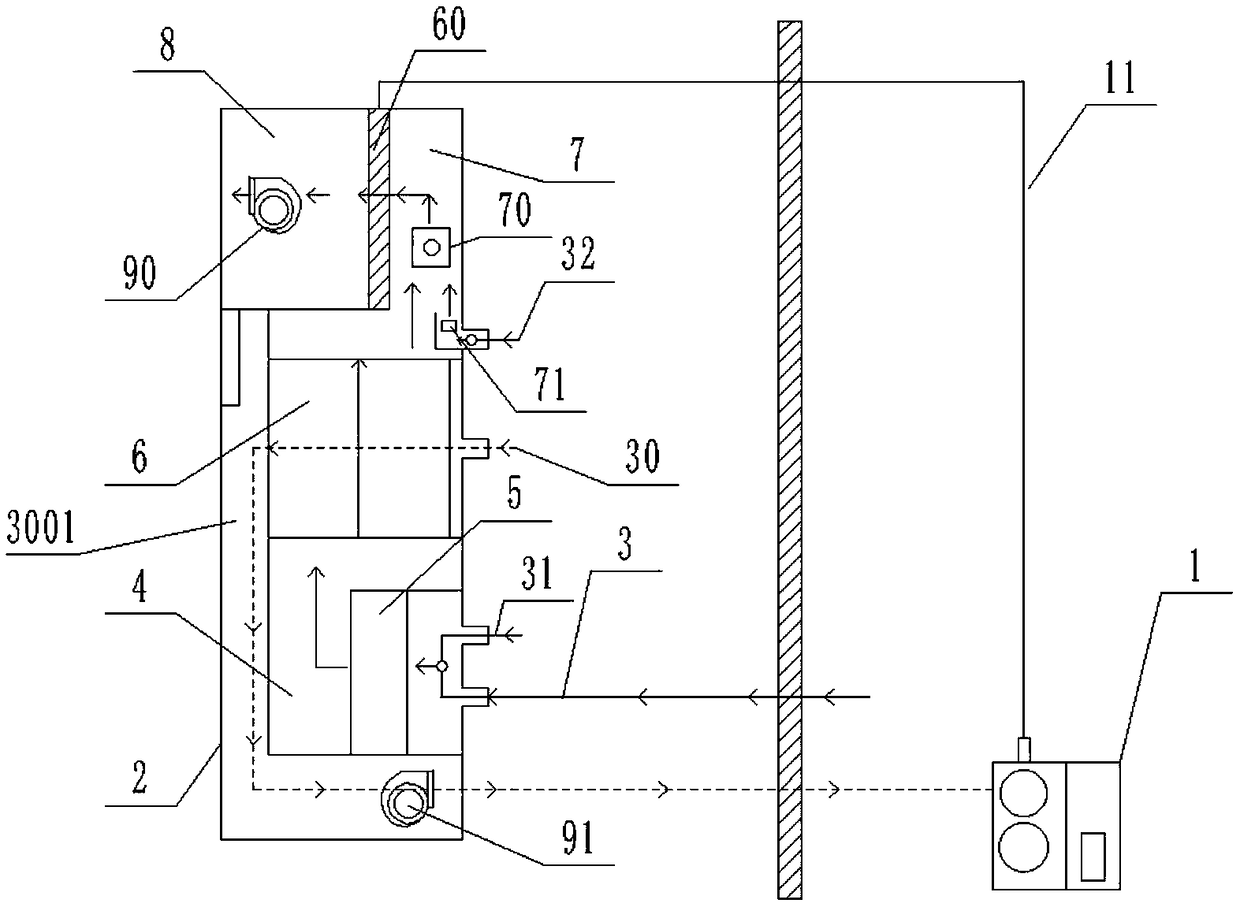

Vehicle sliding energy recovery triggering method and device, electronic equipment and storage medium

PendingCN111143940AReduce recycling efficiencyDoes not affect driving experienceGeometric CADSpeed controllerBrake torqueElectric machinery

The invention provides a vehicle sliding energy recovery triggering method and device, electronic equipment and a storage medium, and the method comprises the steps: determining the sliding speed of avehicle at a current moment when the vehicle is detected to enter a sliding state; acquiring the sliding speed of the vehicle at the historical moment; determining the sliding speed at the moment tobe estimated according to the sliding speed at the current moment, the sliding speed at the historical moment and the sliding speed prediction model; determining wheel-side required braking torque based on the sliding speed at the current moment and the sliding speed at the moment to be estimated; determining motor end required braking torque according to the vehicle attribute information and thewheel edge required braking torque; and sending the braking torque required by the motor end to the motor, and triggering the motor to recover sliding energy. Thus, the sliding energy can be properlyrecovered, the driving feeling cannot be affected by excessive recovery of the sliding energy, and the energy recovery efficiency cannot be low due to excessive recovery of the sliding energy.

Owner:NINGBO GEELY AUTOMOBILE RES & DEV CO LTD +1

A kind of animal intestinal mucosa extract and its preparation method and application

InactiveCN101773522BReduce recycling efficiencyReduce pollutionPeptide/protein ingredientsUnknown materialsBiotechnologyIntestinal walls

The invention discloses an animal intestinal mucosa extract and a preparation method as well as application thereof. The animal intestinal mucosa extract is prepared by the method comprising the following steps: (1) taking small intestine of an in vitro animal, scraping the mucosa layer on the intestinal wall, centrifuging and collecting precipitates; (2) adding the precipitates into water, then adding trypsin into the redistilled water for carrying out enzymolysis I, and after the enzymolysis is finished, inactivating enzymes and cooling; then, adding papain into the redistilled water for carrying out enzymolysis II, and after the enzymolysis is finished, inactivating enzymes and cooling; finally, centrifuging and taking the supernatant solution to obtain an intestinal mucosa enzymolysis solution; and (3) adding an acetic acid solution of which the mass concentration is 5%-10% into the intestinal mucosa enzymolysis solution for stirring and leaching, then centrifuging the leaching solution, and collecting the supernatant solution, and regulating the pH value of the supernatant solution to be 6.0-7.0, freezing and drying to obtain the animal intestinal mucosa extract. The test proves that the intestinal mucosa extract has antibacterial activity to bacteria (such as Escherichia coli).

Owner:FEED RESEARCH INSTITUTE CHINESE ACADEMY OF AGRICULTURAL SCIENCES +1

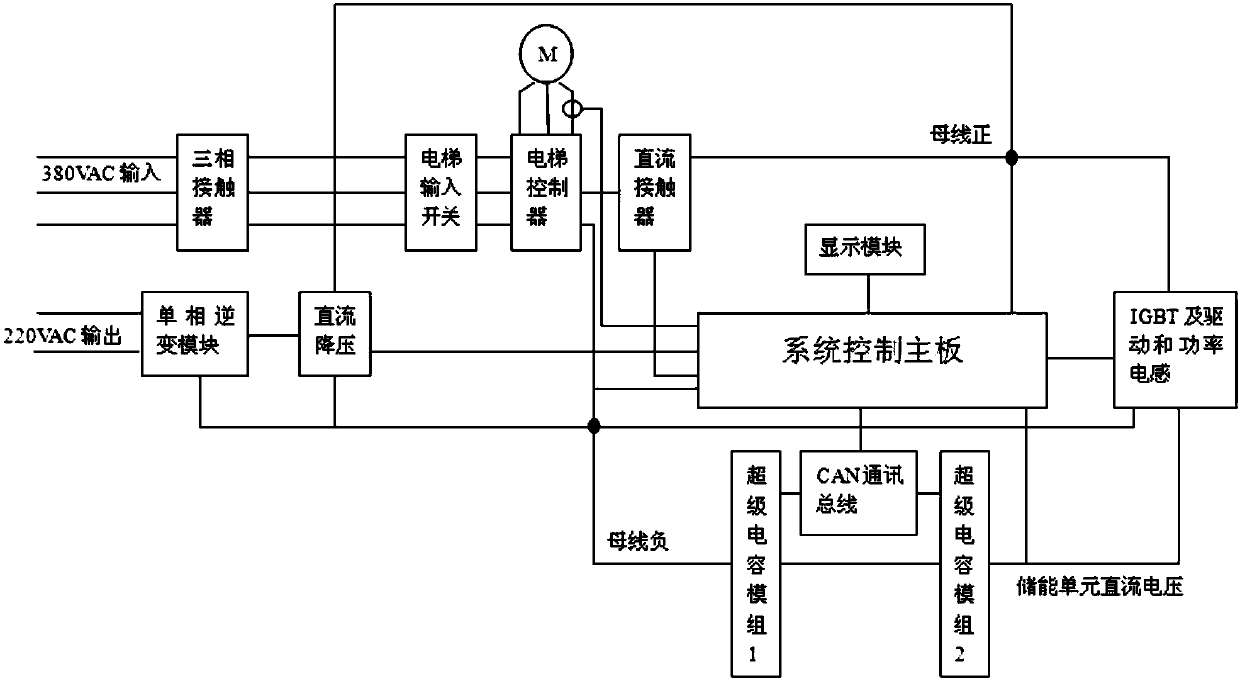

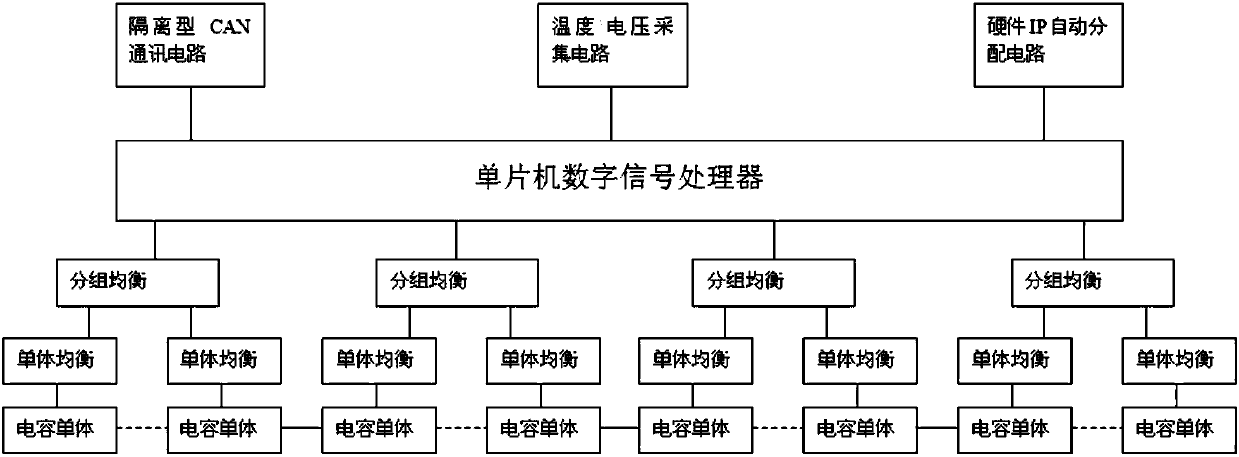

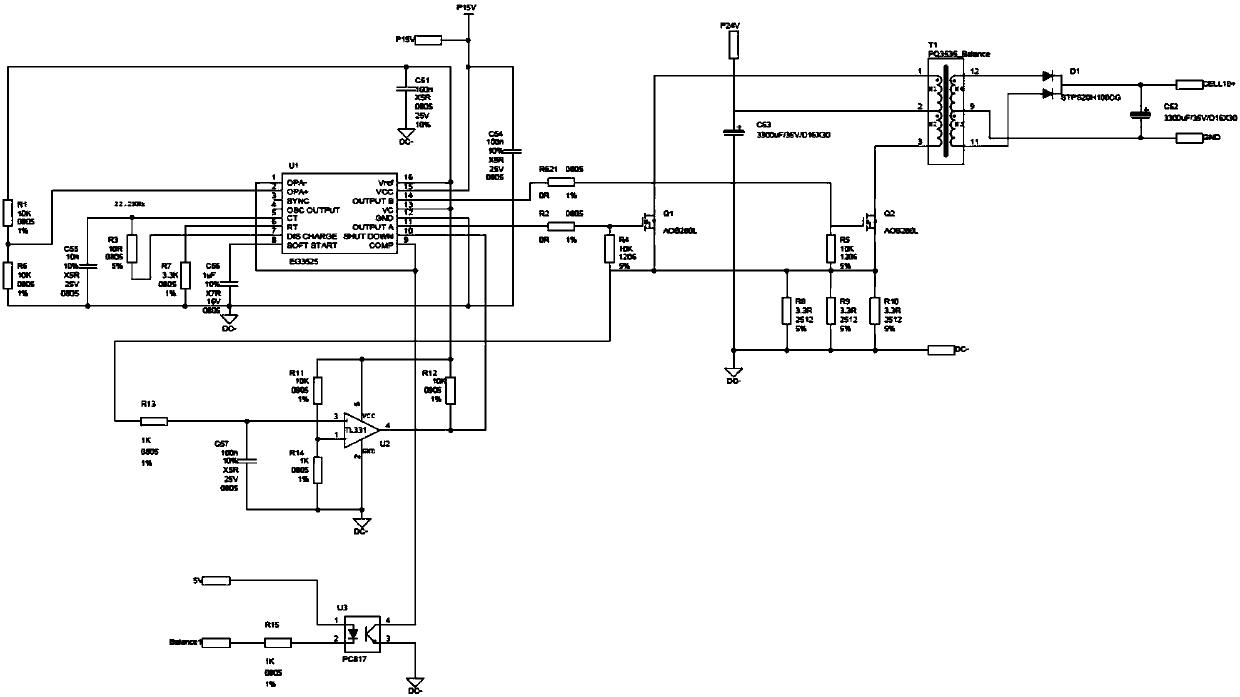

Elevator energy recovery system based on intelligent super-capacitor modules

PendingCN107591864ALimit efficiencyReduce feverBatteries circuit arrangementsElectric powerCapacitanceComputer module

The invention discloses an elevator energy recovery system based on intelligent super-capacitor modules. The elevator energy recovery system comprises a plurality of connected super-capacitor modules,wherein the super-capacitor modules are connected with a CAN communication bus respectively, and are connected with a system control main board through the CAN communication bus; the super-capacitormodules are connected with a direct current contactor through an IGBT and driving and power inductors, and the super-capacitor modules are further connected with an elevator controller; the super-capacitor modules are further connected with a single-phase inverter module, and output 220 V AC. The system control main board is connected with a display module, the IGBT, the driving and power inductors and the direct current contactor respectively; the elevator controller is connected with the direct current contactor, the elevator controller is further connected with an elevator input switch, andthe elevator input switch is connected with a 380 V AC input power supply through a three-phase contactor. The elevator energy recovery system can be accepted by more elevator users, so that the popularization of the elevator energy recovery system is promoted to a certain extent.

Owner:AVX NEW ENERGY (CHENGDU) CO LTD

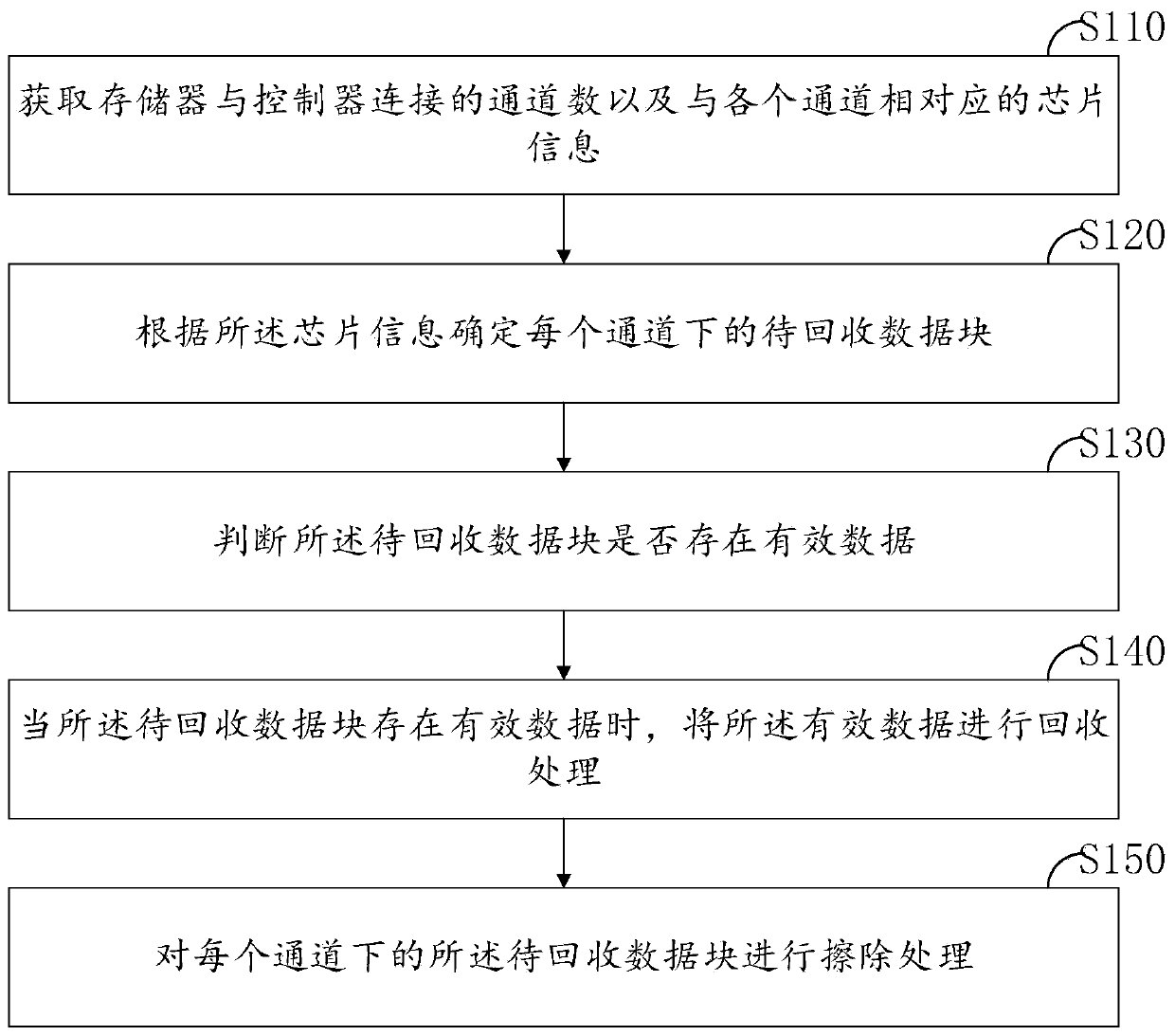

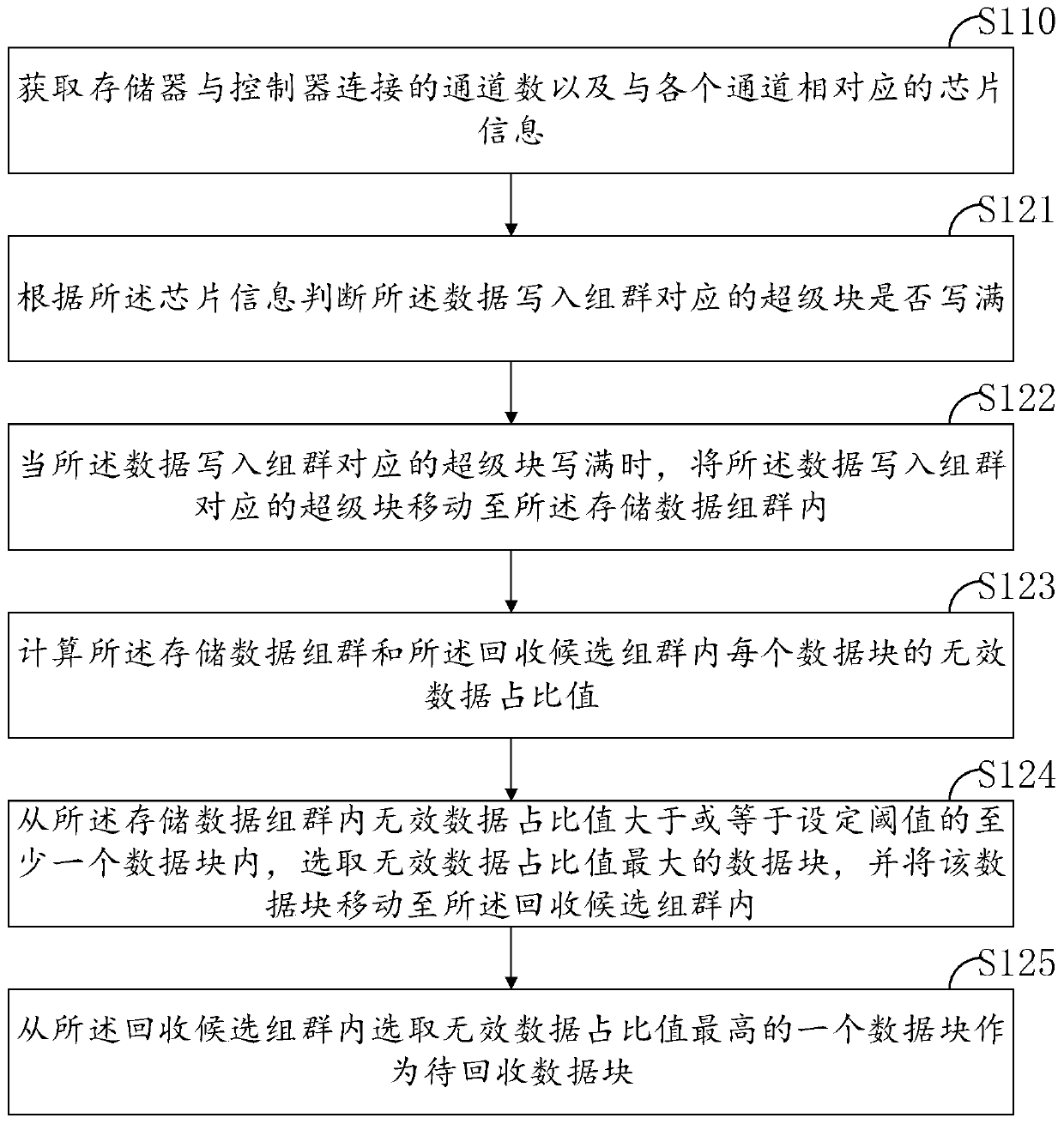

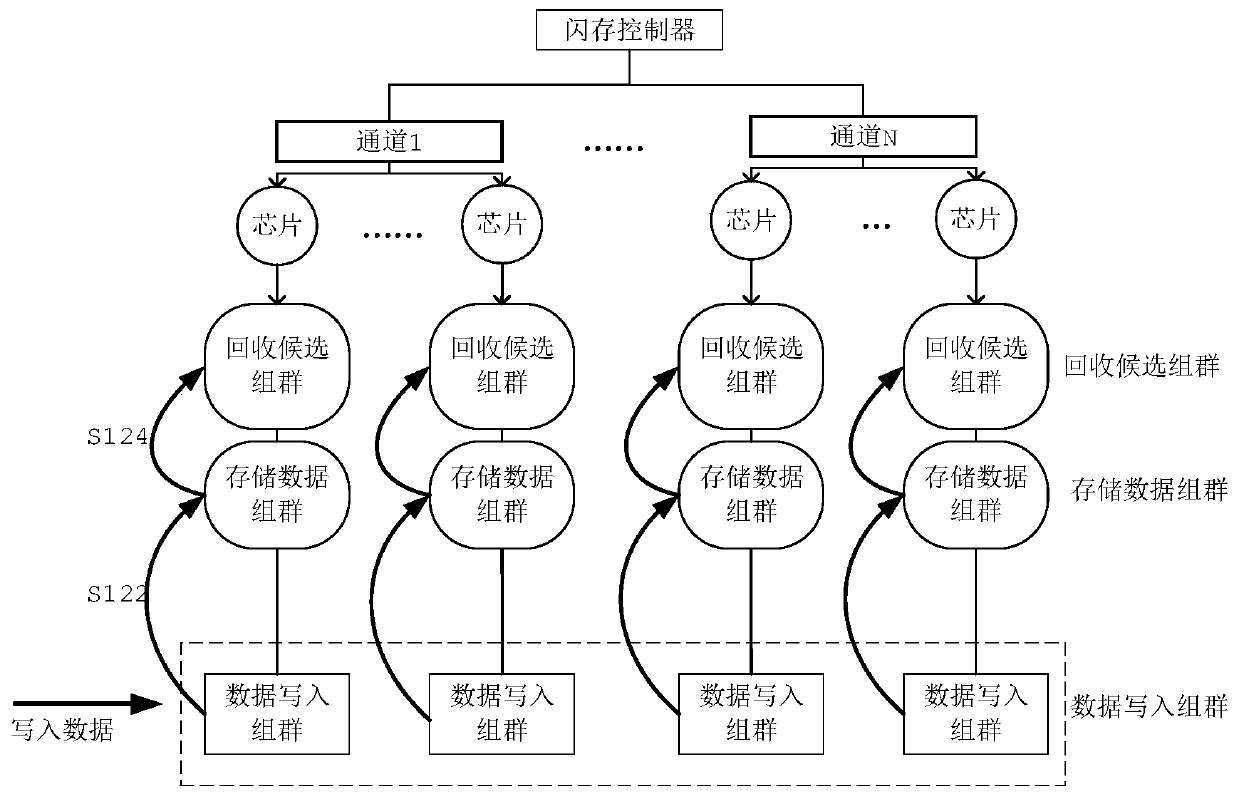

Method for cleaning storage space

ActiveCN111078137AIncreased efficiency in freeing up available spaceReduce the number of recyclingInput/output to record carriersGarbage collectionData store

The invention relates to a method for cleaning a storage space, and the method comprises the steps: obtaining the number of channels, connected with a controller, of a memory and chip information corresponding to each channel, wherein the chip information comprises data storage conditions of a plurality of data blocks; determining a to-be-recycled data block under each channel according to the chip information; judging whether the to-be-recycled data block has valid data or not; when the valid data exists in the to-be-recycled data block, recycling the valid data; and carrying out erasing processing on the to-be-recycled data block under each channel. According to the method, the to-be-recovered data block under each channel is determined by adopting a unified method, so that the difference of effective data volume in the to-be-recovered data block under each channel is relatively small, the garbage recovery frequency under each channel is reduced, and the efficiency of releasing available space for the data block is improved.

Owner:SHENZHEN TIGO SEMICON

Plasma generator

PendingCN110381660AExtend the distribution pathIncrease disturbancePlasma techniqueWaste treatmentCooling channel

The invention relates to the technical field of waste treatment, in particular to a plasma generator. The plasma generator comprises a cathode, an arc striking anode and an anode which are sequentially and coaxially connected in series. The cathode is provided with a cathode head, a cathode sleeve and a first cooling channel for cooling the cathode head. The anode is provided with an anode lining,an anode jacket and a second cooling channel for cooling the anode lining. The arc striking anode comprises an arc striking anode lining, a plasma generating chamber which is located on one side, facing towards the cathode head, of the arc striking anode lining and is used for the arc striking anode to break down the working gas to form a plasma, and a preheating chamber which is arranged aroundthe outside of the arc striking anode lining for heat exchange between the low-temperature working gas and the high-temperature arc striking anode lining, wherein the preheating chamber and the plasmagenerating chamber are communicated with each other. The plasma generator has the advantages of simple structure, few parts, small volume and high heat recovery rate.

Owner:苏州微木智能系统有限公司

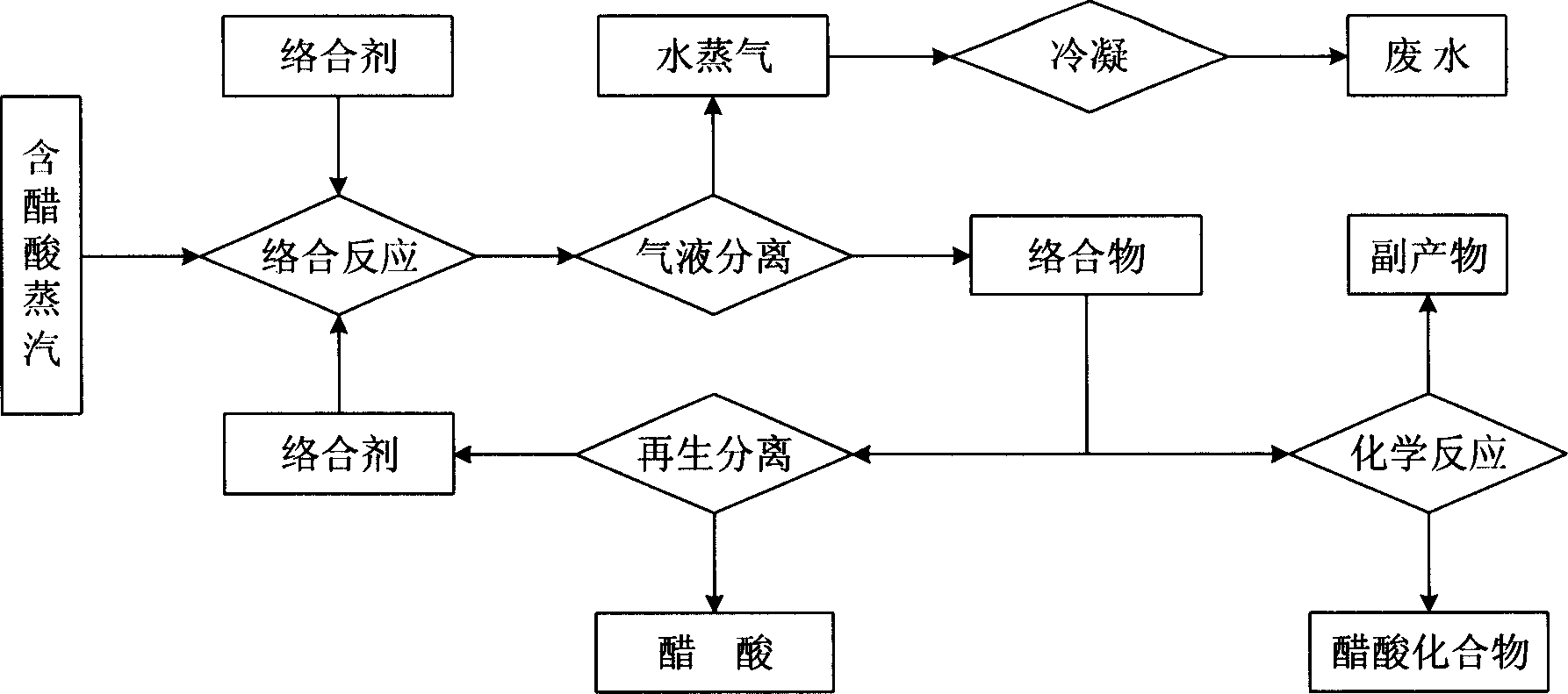

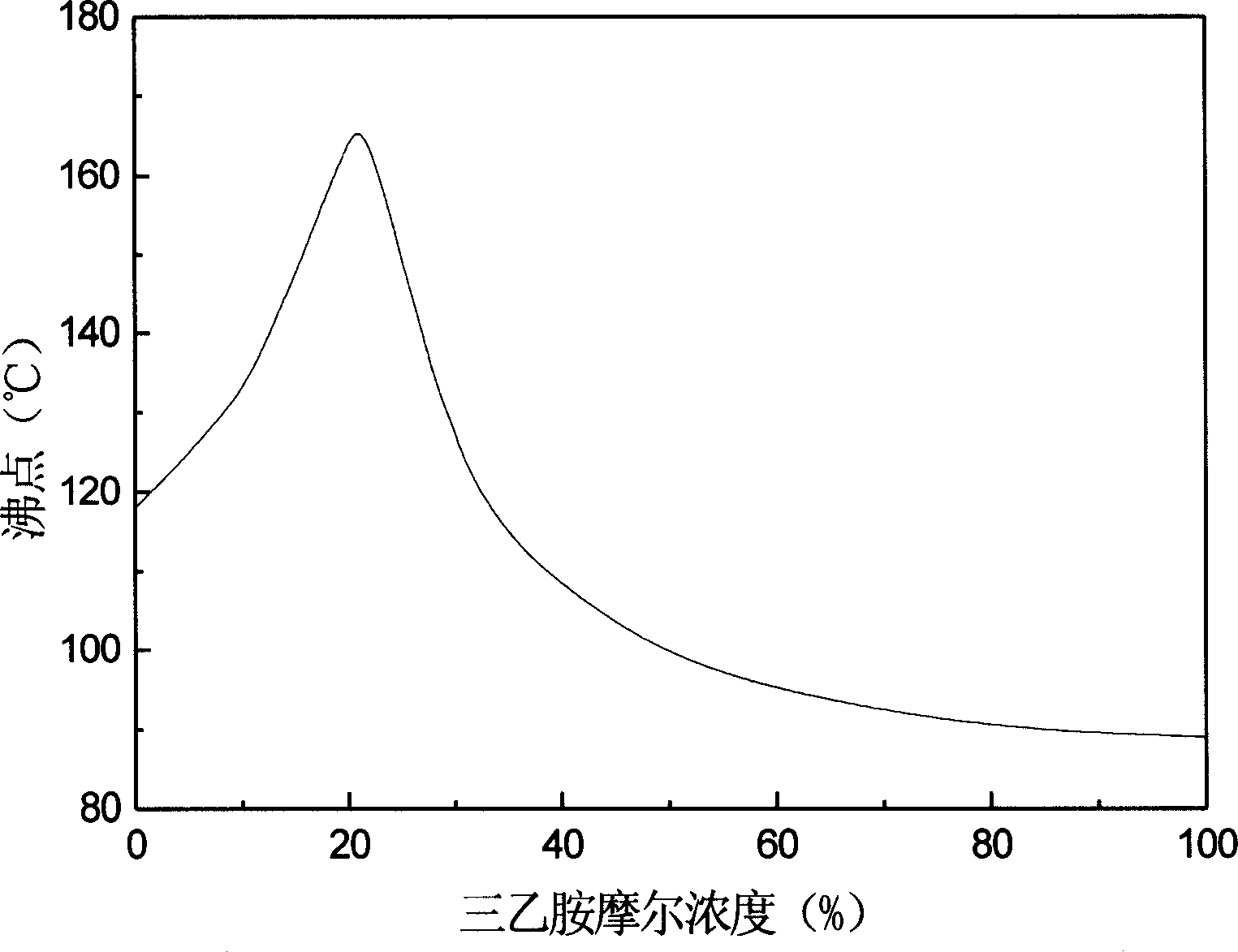

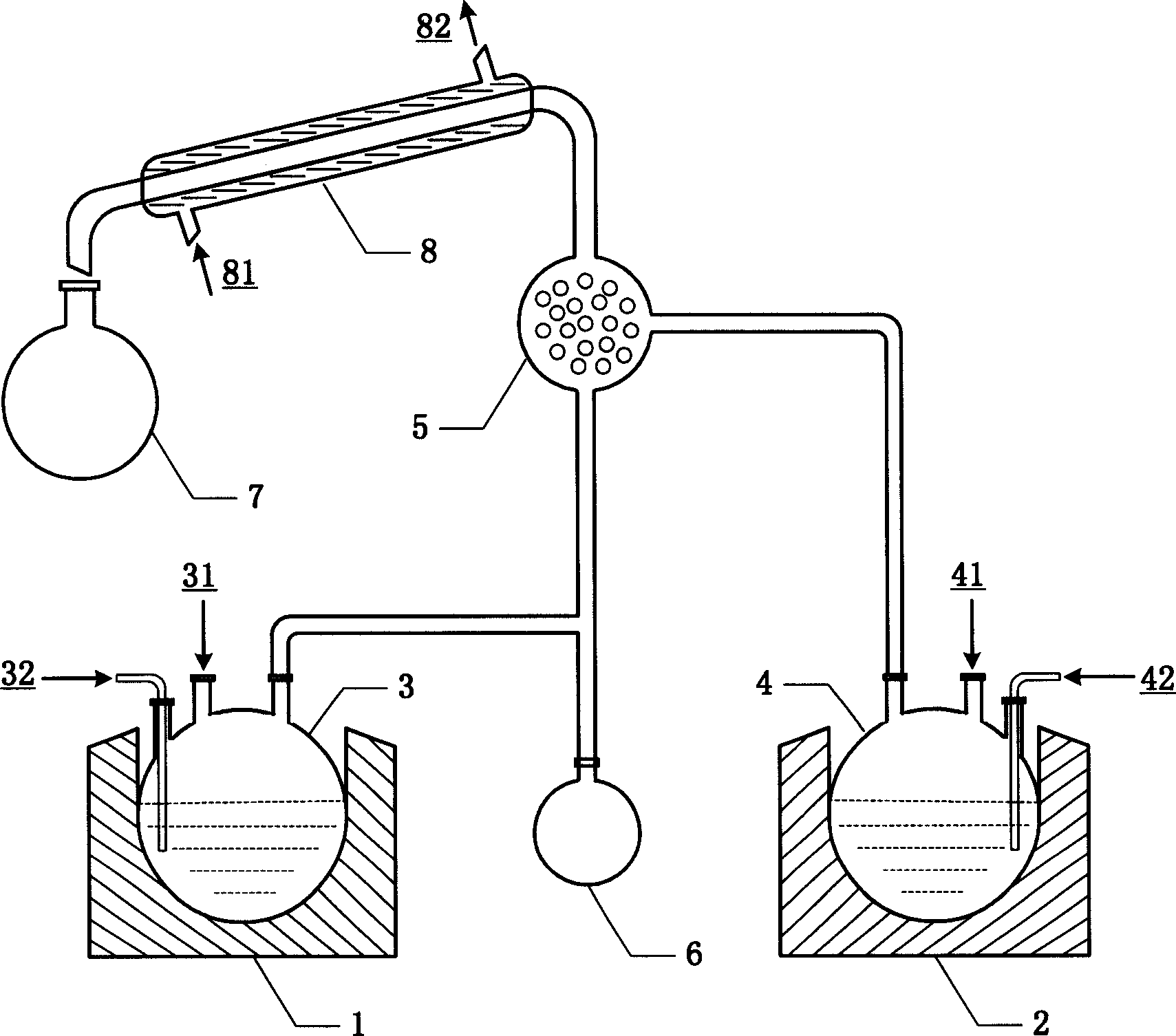

Low-concentration acetic acid recovery method

InactiveCN1743303AReduce consumptionAutomatic separationOrganic compound preparationCarboxylic compound preparationAcetic acidRecovery method

This invention relates to a method to recycle acetic acid from fluid containing low-concentration acetic acid. First, directly introduce the vapor containing low-concentration acetic acid into reactor and simultaneously feed complexing agent gas into the reactor to make the acetic acid in the steam and the complexing agent conduct complexation to generate an acetic acid complex whose boiling point is higher than that of acetic acid. Then, after gas liquid separation, the acetic acid complex is discharged from the bottom of the reactor, which is then conducted regeneration and separation to obtained the acetic acid and complexing agent, the acetic acid is recovered and the complexing agent is feedback to the reactor for circulation use. Or, make the acetic acid complex conduct to obtain the other acetic complex which can be directly used .Advantages: short technological process, low apparatus investment, low energy consumption, high acetic acid recovery rate and low acetic acid content in wastewater after recovering process.

Owner:SINOPEC OILFIELD SERVICE CORPORATION

Novel environmental creating system

PendingCN109237634AIncrease the content of negative oxygen ionsQuality improvementEnergy recovery in ventilation and heatingMechanical apparatusOxygen ionsEngineering

The invention relates to a novel environmental creating system. The environmental creating system comprises a fresh air duct, a filtering assembly, a total heat exchanger, a plasma generating device,a heat exchanger and an air discharge assembly. The fresh air duct is used for collecting outdoor fresh air; the filtering assembly is used for filtering the collected outdoor fresh air and includes aprimary-efficient filter, a medium-efficient filter and a high-efficient filter which are connected with one another in sequence; the total heat exchanger is used for performing heat exchange betweenindoor polluted air and the outdoor fresh air passing through the filtering assembly; the plasma generating device is used for adding a large quantity of positive ions and negative ions into the outdoor fresh air passing through the total heat exchanger; the heat exchanger is used for performing cooling / heating and dehumidification adjustment on the purified fresh air; the air discharge assemblyis used for adjusting the fresh air again after temperature regulation and humidity control through the heat exchanger and then discharging the fresh air into a room. The negative oxygen ions can remove the mold, odor and smoke in the fresh air, the air humidity is increased, and heat compensation is conducted on the fresh air; at the same time, essential oil is atomized by a fragrance system andbrought into the room through the air duct.

Owner:云森威尔智能环境(深圳)有限公司

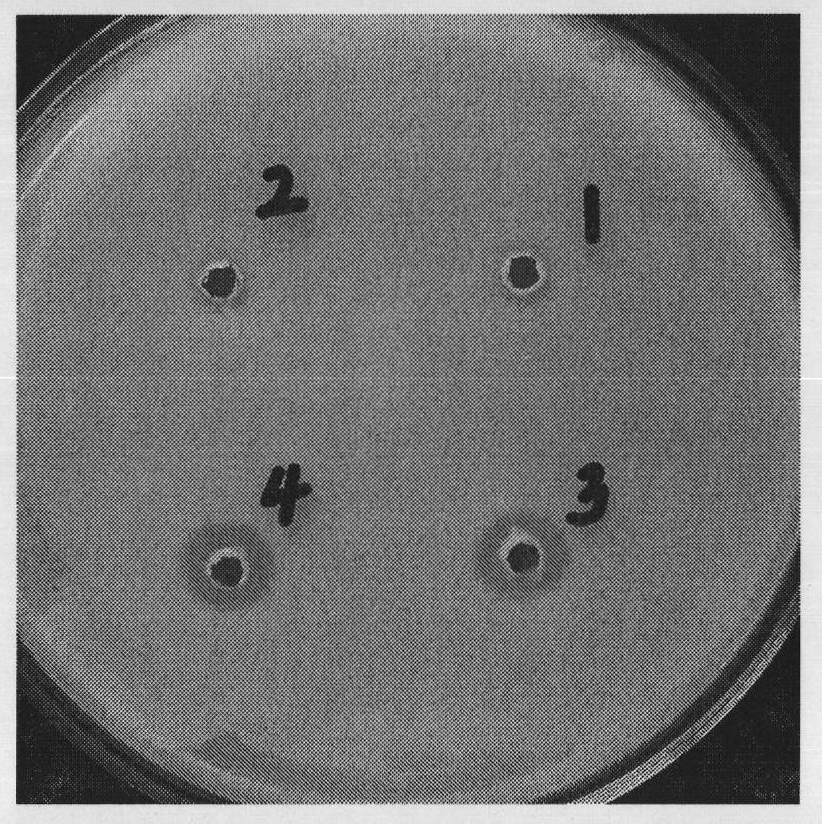

Ion-exchange recovery method for synergistic matter in Bt fermentation

ActiveCN101508656BHigh recovery rateIncrease concentrationBiocideCarboxylic acid amide separation/purificationOXALIC ACID DIHYDRATEPotassium ferricyanide

The invention discloses an ion exchange recycling method for synergistic material in fermentation of Bt, comprising steps: (1) pre-treating Bt supernatant fluid, carrying out precipitation reaction by adding protein flocculating agent zinc sulfate, yellow potassium ferrocyanide and metallic ion complexing agent oxalic acid under condition of pH value, filtering and removing precipitate by a plateframe, and adjusting the pH value to pH6 before filtrate enters a column; (2) choosing polymeric adsorbent ZJ-16 with high adsorption capacity, good selectivity, high mechanical strength and long service life to adsorb synergistic material of Bt; and (3) collecting the obtained precipitated liquid and processing as follows according to needs: A, processing and producing Bt water suspension preparation with high valence, adding thinner assistants such as sodium chloride, sodium benzoate and xanthan gum into the precipitated liquid collected through ion exchange to produce Bt water aqua; B, processing Bt raw powder with high valence; and C, processing synergistic material powder for scientific research with high purity and high content. The method is simple and practical, improves the valence yield of a product, reduces production cost and improves the quality of the product.

Owner:WUHAN KERNEL BIO-TECH CO LTD

Ebullated-bed process for feedstock containing dissolved hydrogen

ActiveUS20150191663A1Reduce recycling efficiencyHydrocarbon distillationHydrocarbon oil crackingGas retentionDissolved hydrogen

An improved system and method for processing feedstocks in an ebullated-bed hydroprocessing reactor is provided in which hydrogen gas is dissolved in the fresh and recycled liquid feedstock by mixing and / or diffusion of an excess of hydrogen, followed by flashing of the undissolved hydrogen upstream of the reactor inlet, introduction of the feed containing dissolved hydrogen into the ebullated-bed hydroprocessing reactor whereby the dissolved hydrogen eliminates or minimizes the prior art problems of gas hold-up and reduced operational efficiency of the recycle pump due to the presence of excess gas in the recycle stream when hydrogen gas was introduced as a separate phase into the reactor.

Owner:SAUDI ARABIAN OIL CO

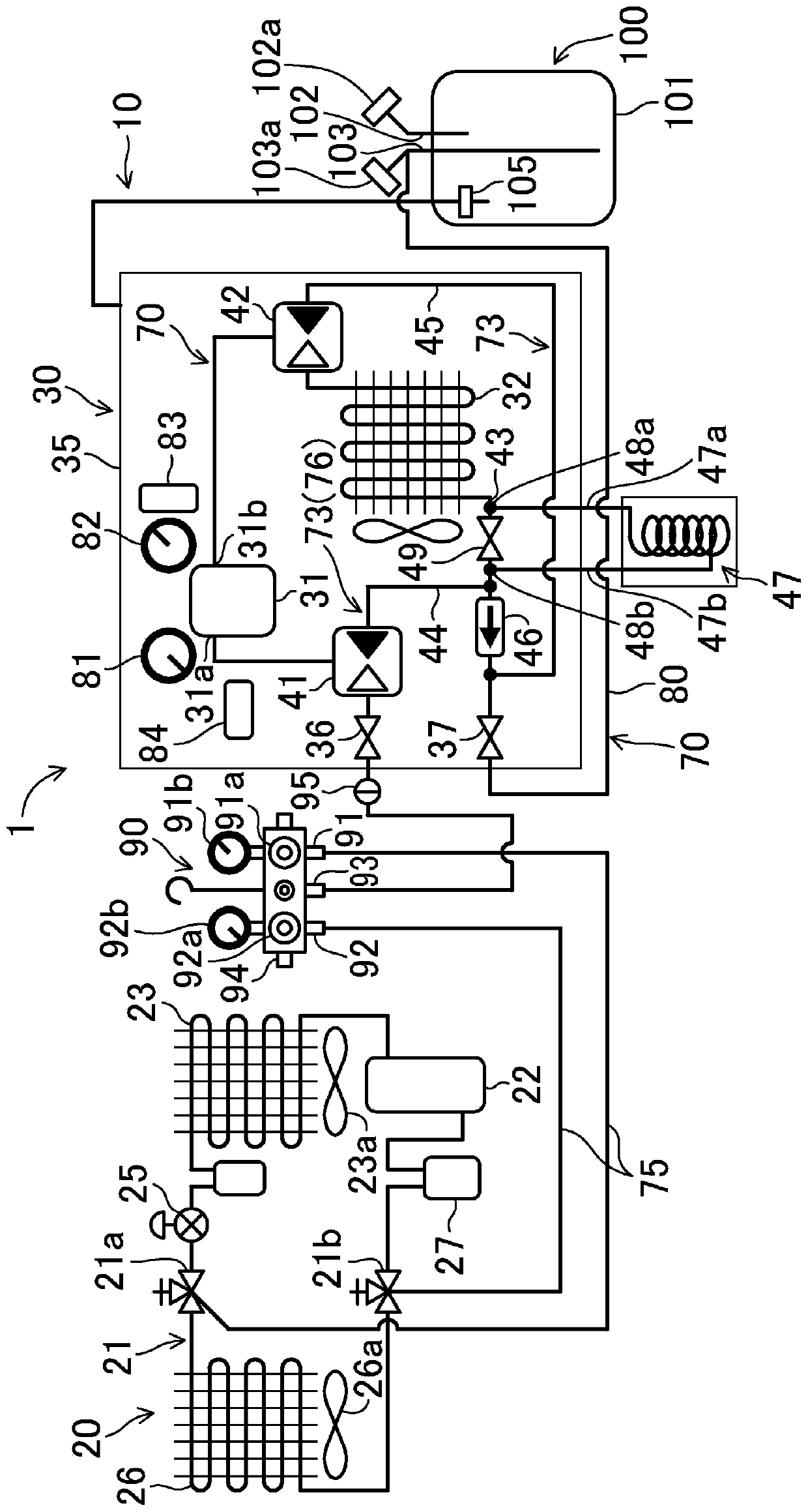

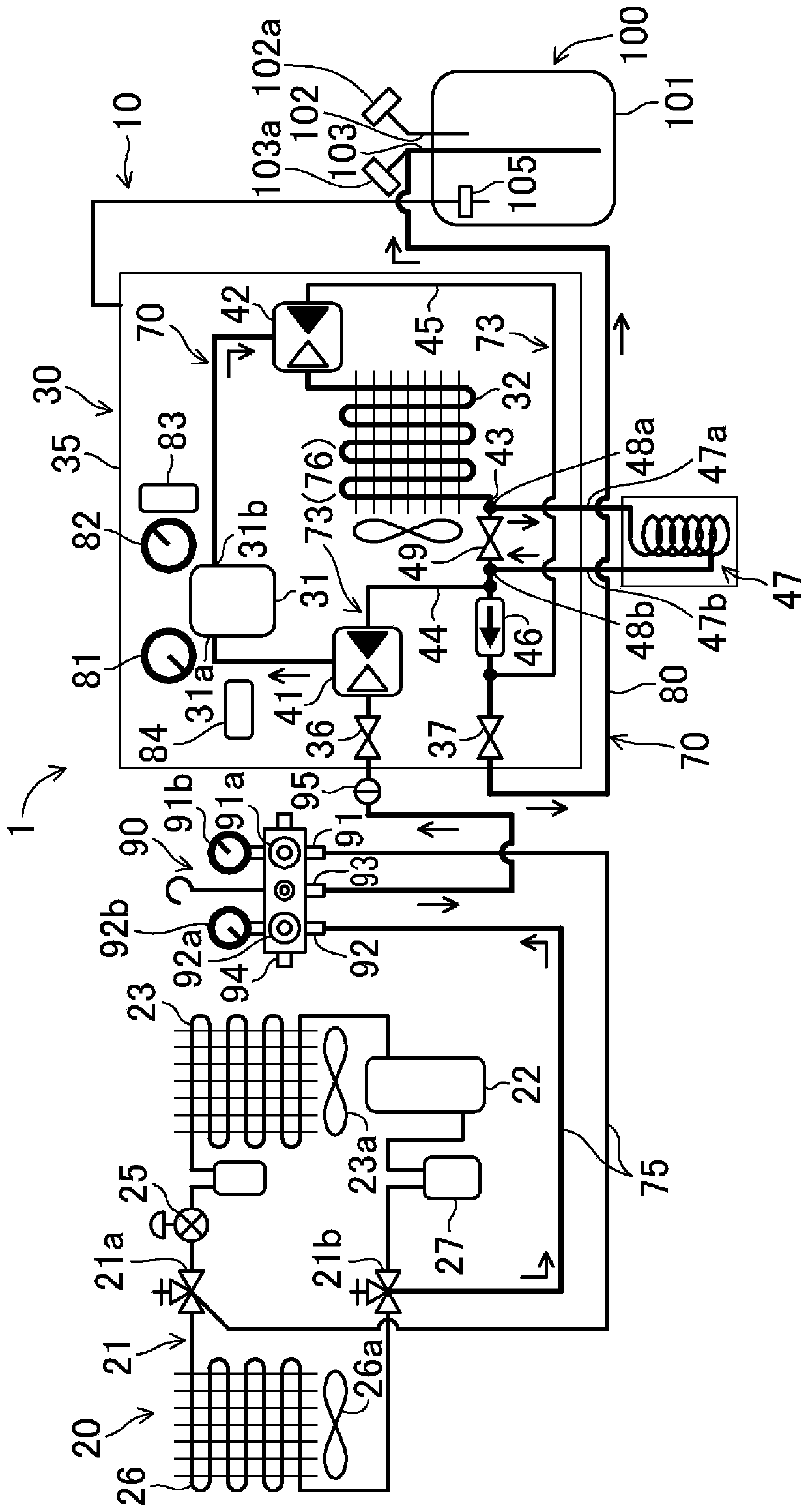

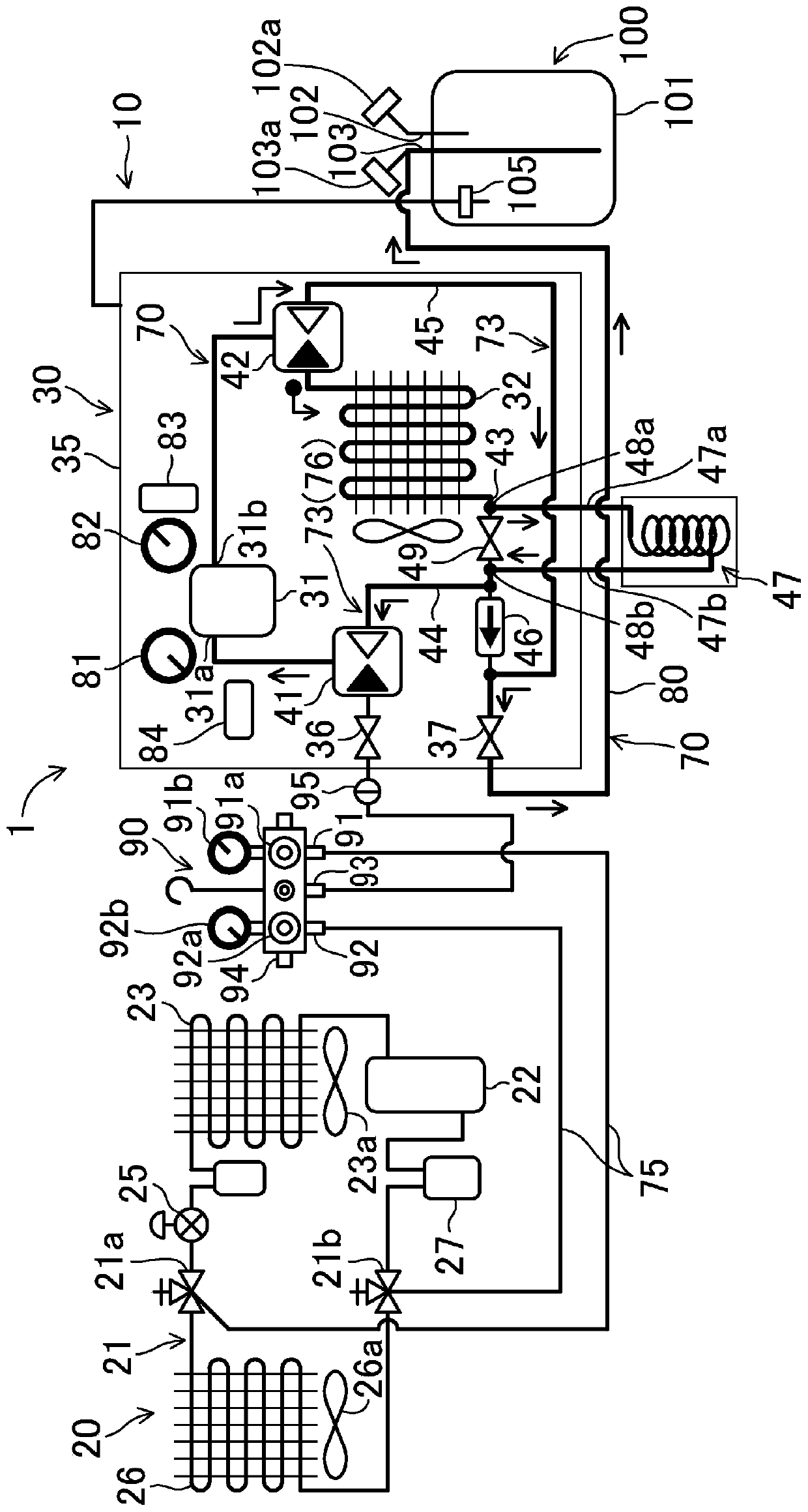

Refrigerant recovery apparatus

ActiveCN110869683AReduce recycling efficiencyReduce operating efficiencyRefrigerantsThermodynamicsRefrigerant reclamation

The present invention provides a refrigerant recovery apparatus comprising a compressor (31) which intakes refrigerant from a device (20) containing refrigerant to be recovered and a condenser (32) which sends the refrigerant discharged from the compressor (31) to a refrigerant recovery container (100) via a main refrigerant recovery path (70), wherein: a residual refrigerant recovery path (77) isprovided in which the pressure of residual refrigerant from the condenser (32) is decreased within a branch path (76) which branches off from the main refrigerant recovery path (70), the compressor (31) intakes the residual refrigerant and pressurizes the same, and the residual refrigerant is sent to the refrigerant recovery container (100); and a cooling coil is connected on the outlet side of the condenser (32) upstream of the point where the main refrigerant recovery path (70) and the branch path (76) diverge.

Owner:DAIKIN INDUSTRIES LTD

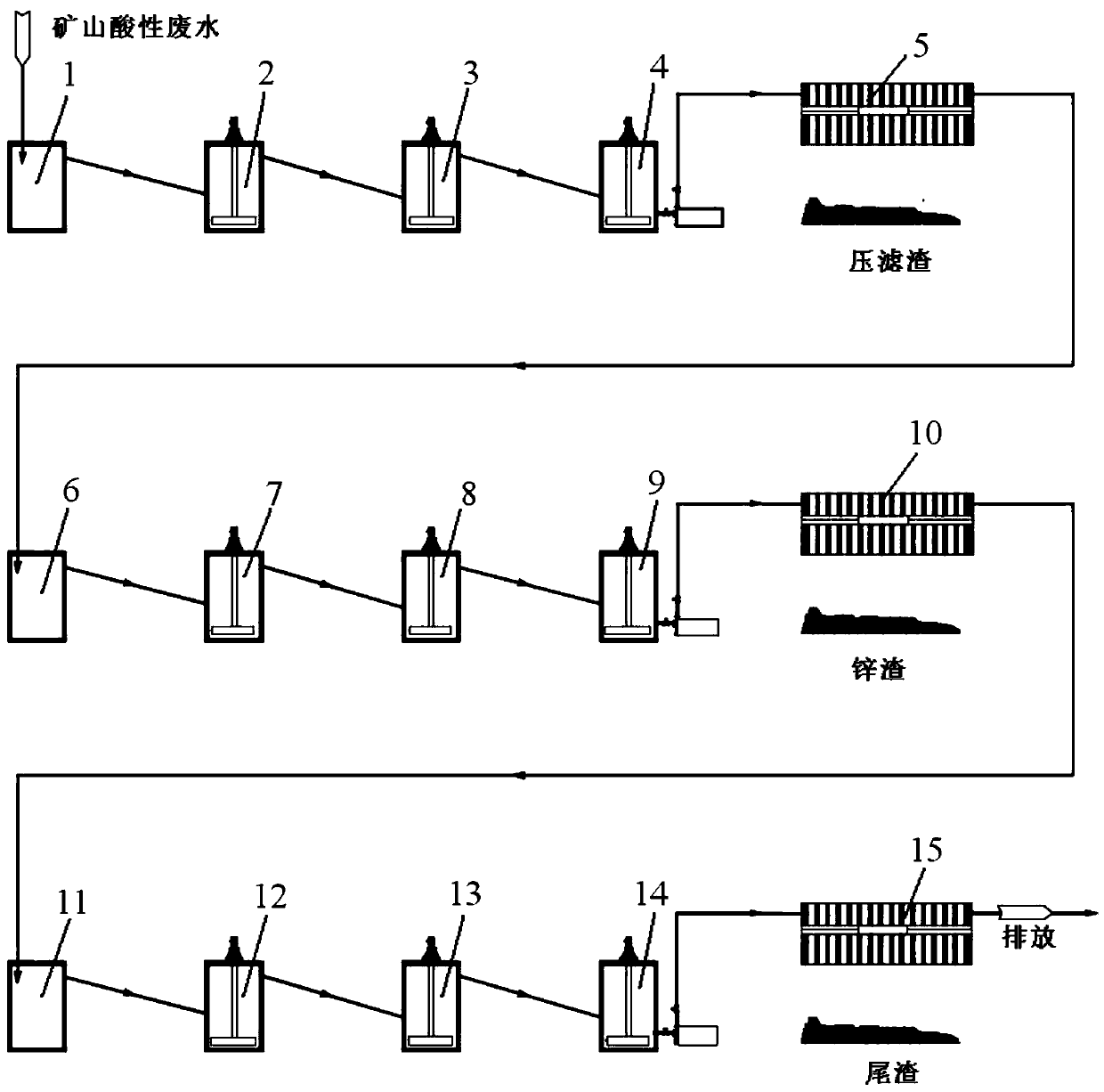

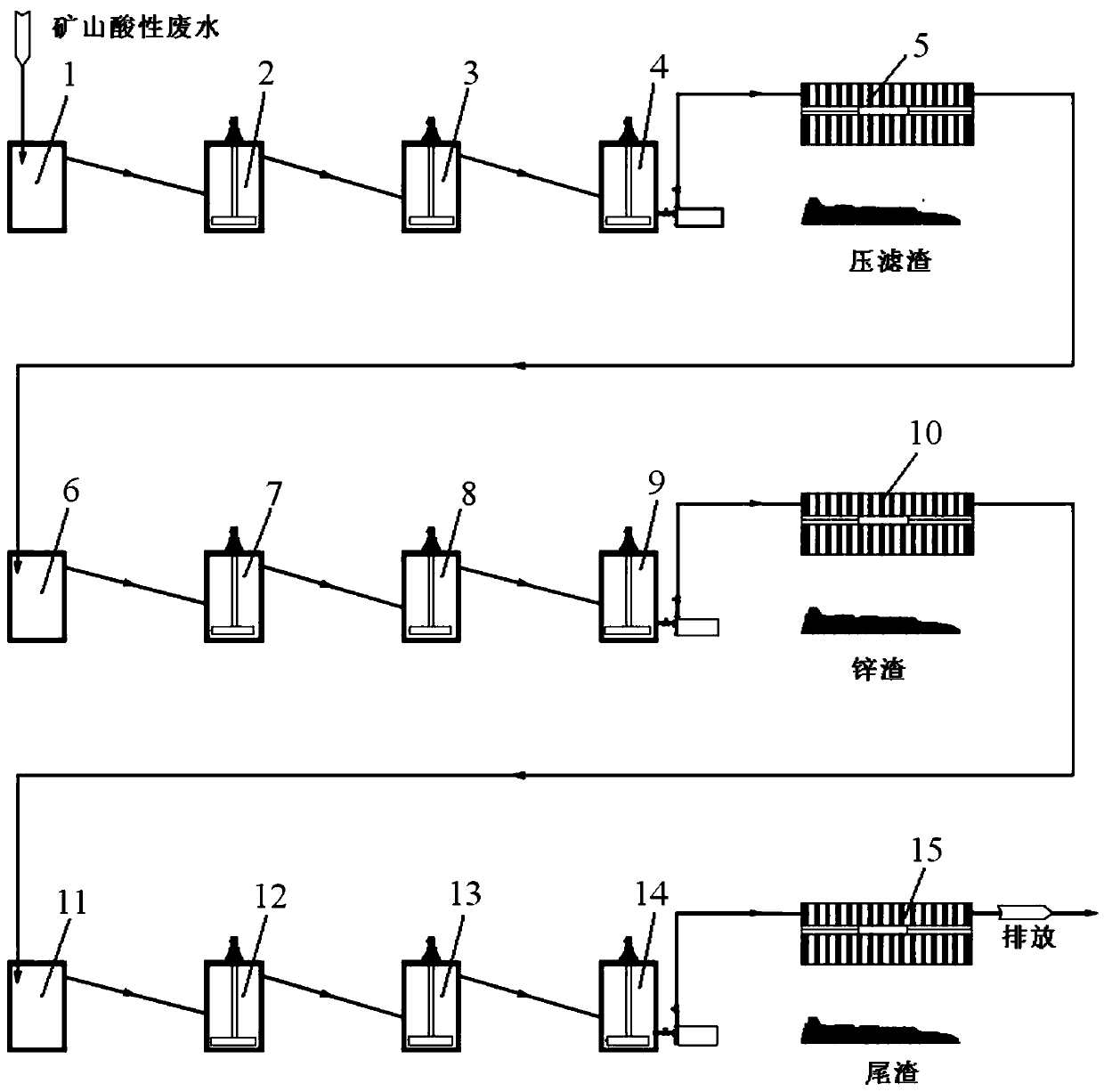

Comprehensive recycling and treating method for gold concentrate roasting enterprise mine acid waste water

InactiveCN110004296AReduce recycling efficiencyReduce stockpilesTreatment involving filtrationWaste water treatment from metallurgical processSlagWastewater

The invention relates to a comprehensive recycling and treating method for gold concentrate roasting enterprise mine acid waste water, and belongs to a gold industry water treatment method. The gold concentrate roasting enterprise mine acid waste water is pumped into a first buffering tank and sequentially flows into a first reactor, a second reactor and a second buffering tank to be subjected tofilter pressing; the gold concentrate roasting enterprise mine acid waste water obtained after filter pressing enters a third buffering tank and sequentially flows into a third reactor, a fourth reactor and a fourth buffering tank, sodium sulfide is added in the third reactor and the fourth reactor, and filter pressing is conducted; and after filter pressing, the gold concentrate roasting enterprise mine acid waste water enters a fifth buffering tank and sequentially flows into a first neutralizing tank, a second neutralizing tank and a sixth neutralizing tank, filter pressing is conducted, filter pressing slag is stacked and stored, and filter pressing liquid is discharged. The technology process is simple, the valuable element recycling efficiency is high, the product purity is high, thecomprehensive treatment effect is stable, environment friendliness is achieved, the running expense is low, and extremely high popularization value is achieved.

Owner:CHANGCHUN GOLD RES INST

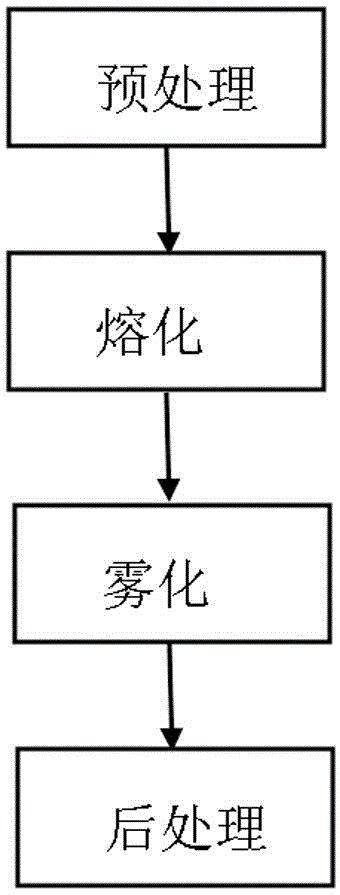

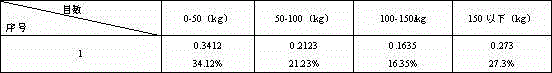

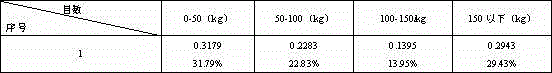

Pretreatment technology for indium and germanium extraction

The invention discloses a pretreatment technology for indium and germanium extraction. The pretreatment technology comprises the steps of melting , atomization and after-treatment, and concretely comprises the following steps: material containing In and Ge is placed in a melting pool to be melted at a temperature of 1,210-1,260 DEG C into liquid material, and the liquid material is kept at a temperature of 1,210-1,260 DEG C; the liquid material at the temperature of 1,210-1,260 DEG C flows into an atomizing chamber via a guide pipe to be atomized to obtain solid powder; the solid powder obtained by atomization is screened, and the material passing through a screen mesh is placed in a container, sealed and packed for follow-up roasting, water washing, acid treatment, drying and calcining for extraction; the material not passing through the screen mesh is returned to the melting step to circulate. The pretreatment technology provided by the invention is safe and reliable, the material granularity is low to facilitate hydrometallurgical leaching, and the recycling efficiency of In and Ge in the material is high. The pretreatment technology provided by the invention refines the material containing In and Ge by an atomizing method, not only is high in safety and low in material loss, but also is easy for processing treatment.

Owner:宣威市泓澔金属科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com