Low-concentration acetic acid recovery method

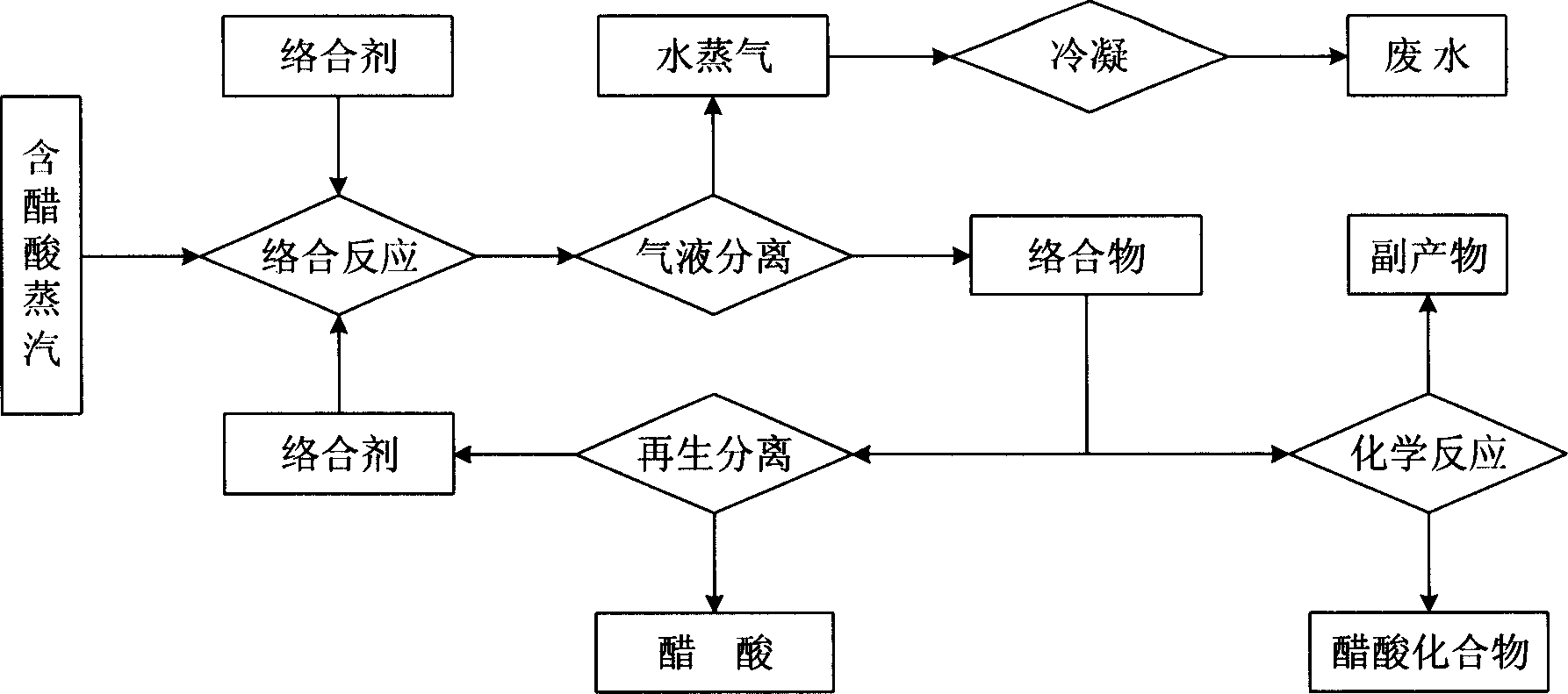

A low-concentration acetic acid and recovery method technology, applied in the field of recovery of acetic acid, can solve the problems of unsatisfactory recovery effect, complex extraction process, low recovery efficiency, etc., and achieve the effects of avoiding a large amount of evaporation, short process flow and high recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

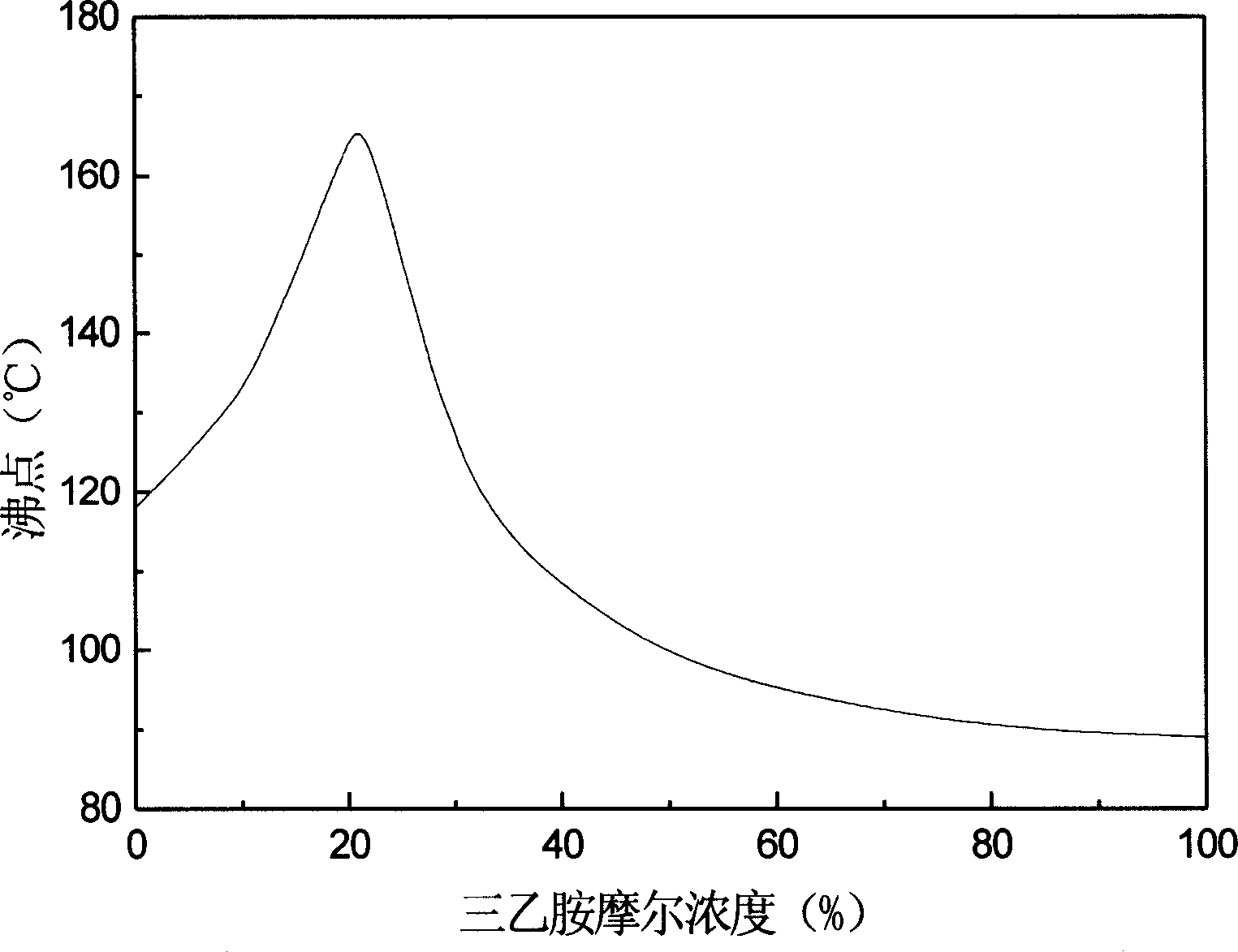

Embodiment 1

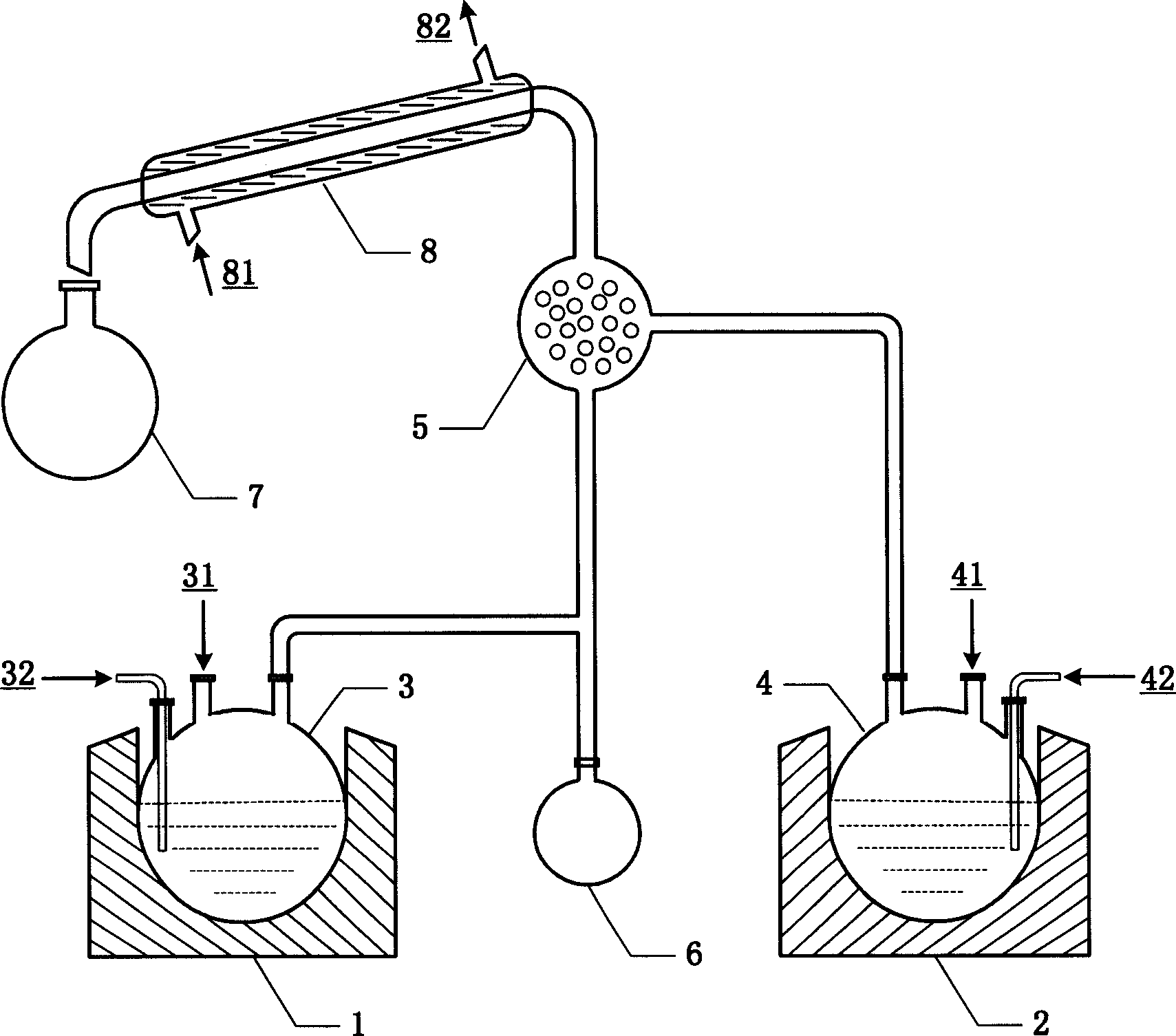

[0027]Add 100ml of acetic acid aqueous solution with a weight concentration of 3% to the three-necked flask 3, and 5ml of triethylamine into the three-necked flask 4, control the heating speed of heaters 1 and 2, so that both will evaporate to the reaction in the same time In the vessel 5, the acetic acid complex and waste water are received in the receiving bottles 6 and 7, respectively. Analyzing the waste water collected in the receiving bottle 7, the weight concentration of acetic acid is 0.29%, and the recovery rate of acetic acid is calculated to be about 90%. The acetic acid complex collected in the receiving bottle 6 is distilled under reduced pressure to obtain acetic acid and triethylamine.

Embodiment 2

[0029] Add 100ml of acetic acid aqueous solution with a weight concentration of 3% to the three-necked flask 3, add 8ml of trioctylamine to the three-necked flask 4, control the heating speed of heaters 1 and 2, so that both will evaporate to the reaction in the same time In the vessel 5, the acetic acid complex and waste water are received in the receiving bottles 6 and 7, respectively. Analyzing the waste water collected in the receiving bottle 7, the weight concentration of acetic acid is 0.68%, and the recovery rate of acetic acid is calculated to be about 77%. The acetic acid complex collected in the receiving bottle 6 is distilled under reduced pressure to obtain acetic acid and trioctylamine.

Embodiment 3

[0031] Add 100ml of acetic acid aqueous solution with a weight concentration of 8% to the three-necked flask 3, add 12ml of triethylamine to the three-necked flask 4, control the heating speed of heaters 1 and 2, so that both will evaporate to the reaction in the same time In the vessel 5, the acetic acid complex and waste water are received in the receiving bottles 6 and 7, respectively. Analyzing the waste water collected in the receiving bottle 7, the weight concentration of acetic acid is 0.78%, and the recovery rate of acetic acid is calculated to be about 90%. The acetic acid complex collected in the receiving bottle 6 is distilled under reduced pressure to obtain acetic acid and triethylamine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com