Junked-tire fluidized gasification device and junked-tire fluidized gasification method based on blast furnace slag waste heat utilization

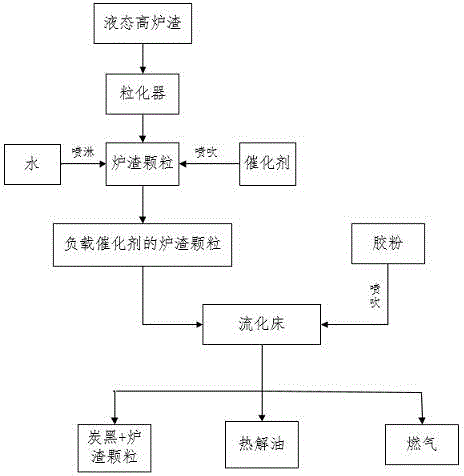

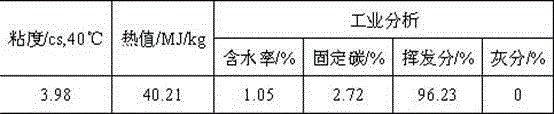

A waste tire and fluidized bed gasification technology, which is applied in the field of waste tire fluidization gasification device, can solve the problems of poor quality and quality of pyrolysis oil products, low energy recovery rate of pyrolysis process, low heating rate of tire pyrolysis, etc. problems, to achieve the effect of improving heat and mass transfer efficiency, promoting mass transfer efficiency, and reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

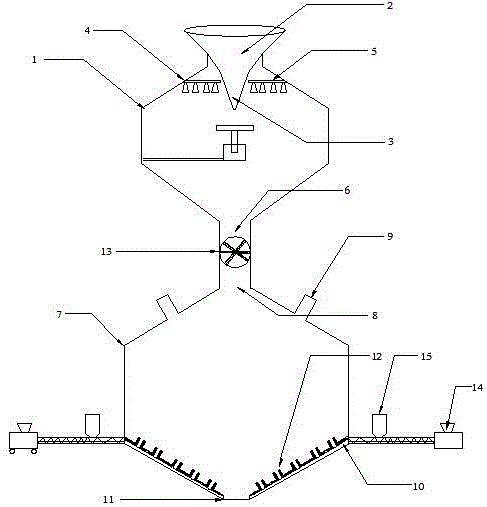

[0019] Such as figure 2 As shown in this example, a waste tire fluidization gasification device based on blast furnace slag waste heat utilization described in this embodiment, the device includes a slag granulator 1 and a fluidized bed gasification reactor 7, respectively for liquid slag granulation and Tire rubber powder fluidization gasification.

[0020] The top of the slag granulator 1 is equipped with a liquid blast furnace slag inlet 2, and the inside is provided with a granulation tray 3. The upper part of the granulation tray is equipped with a catalyst powder spraying device 4 and a water spraying device 5, and the bottom is provided with a granulated slag outlet 6.

[0021] The fluidized bed gasification reactor 7 is provided with a granulated slag inlet 8 and a gasification gas outlet 9 at the top, an air distributor 10 and a solid residue outlet 11 at the bottom, and a rubber powder injection pipe 12 on the surface of the air distributor.

[0022] The granulated...

Embodiment 2

[0030] The method for fluidizing and gasifying waste tires based on blast furnace slag waste heat utilization described in this embodiment is as follows:

[0031] (1) The liquid blast furnace slag discharged from the blast furnace is divided into multiple slag streams with a diameter of 10mm through the slag ditch, and enters the granulator for granulation. During the granulation process, it is sprayed on the surface of the slag particles according to the mass ratio of water to slag of 1:1. Water and spray catalyst powder on the slag surface according to 80% of the slag mass, so that the surface of the slag particles forms porous and catalyst-loaded high-temperature slag particles. The slag temperature is controlled at 900 ° C, and the particle size is between 3 and 4 mm. Enter the fluidization device ;

[0032] (2) When the slag particles wrapped by the catalyst enter the fluidization device, open the air compressor and the rubber powder feeder at the same time, from the bott...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com