Patents

Literature

350 results about "Dissolved hydrogen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The manner in which hydrogen gas is dissolved in the water has an effect on its stability and rate of exsolution (coming out of solution) and dissipation. Hydrogen gas can exist in water as fully dissolved gaseous solutes, colloidal and suspension forms, as well as large macrobubbles that exit almost immediately.

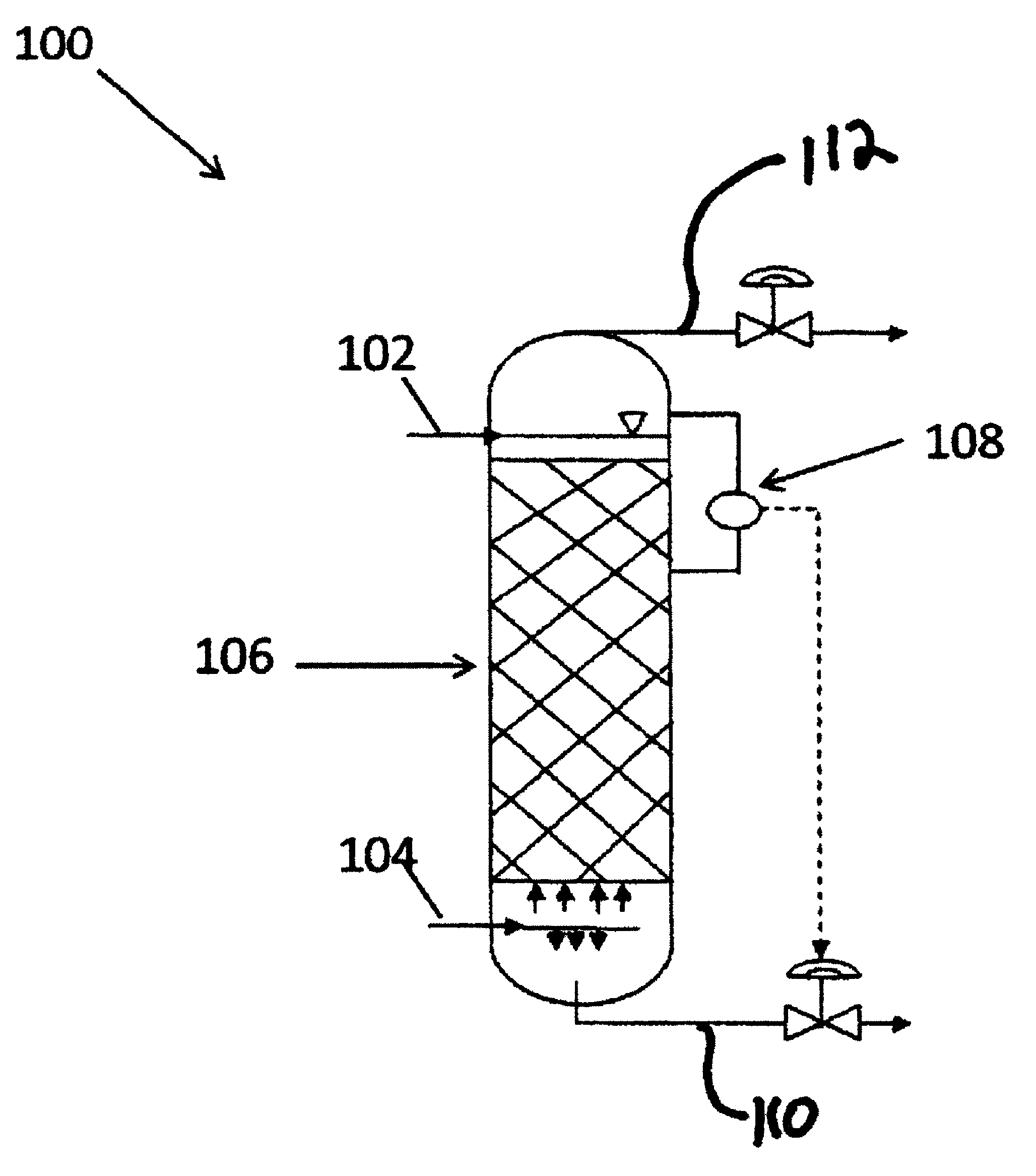

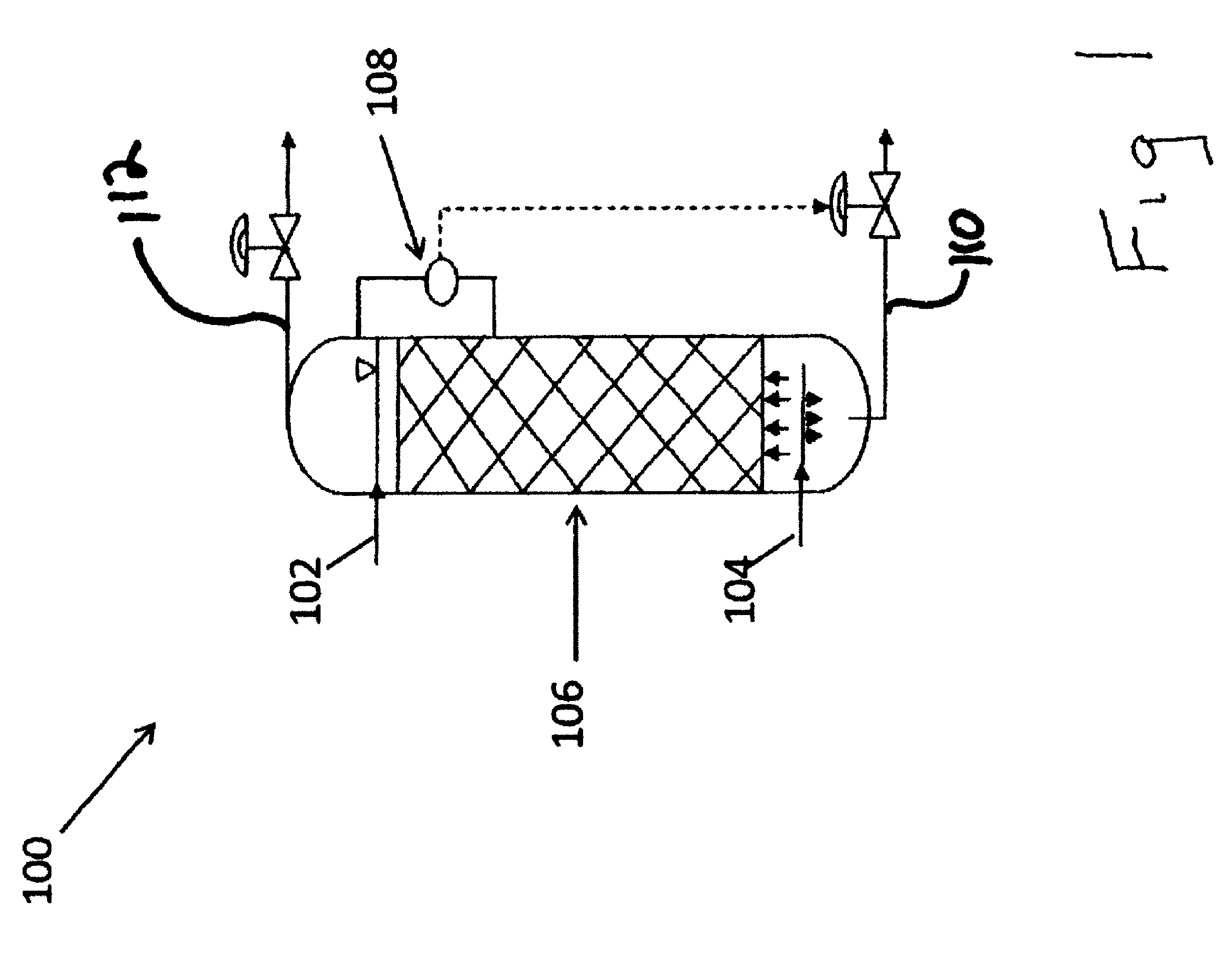

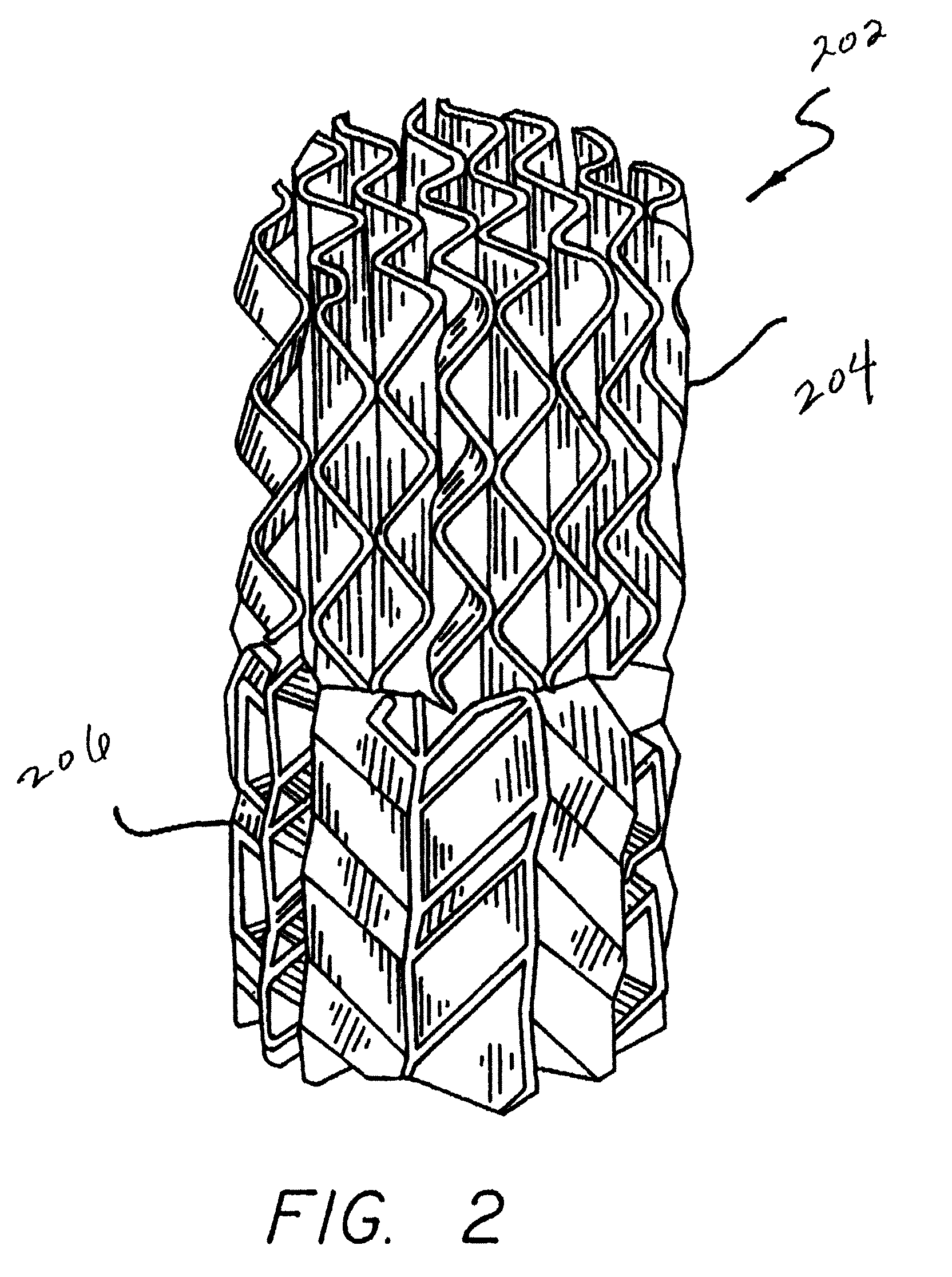

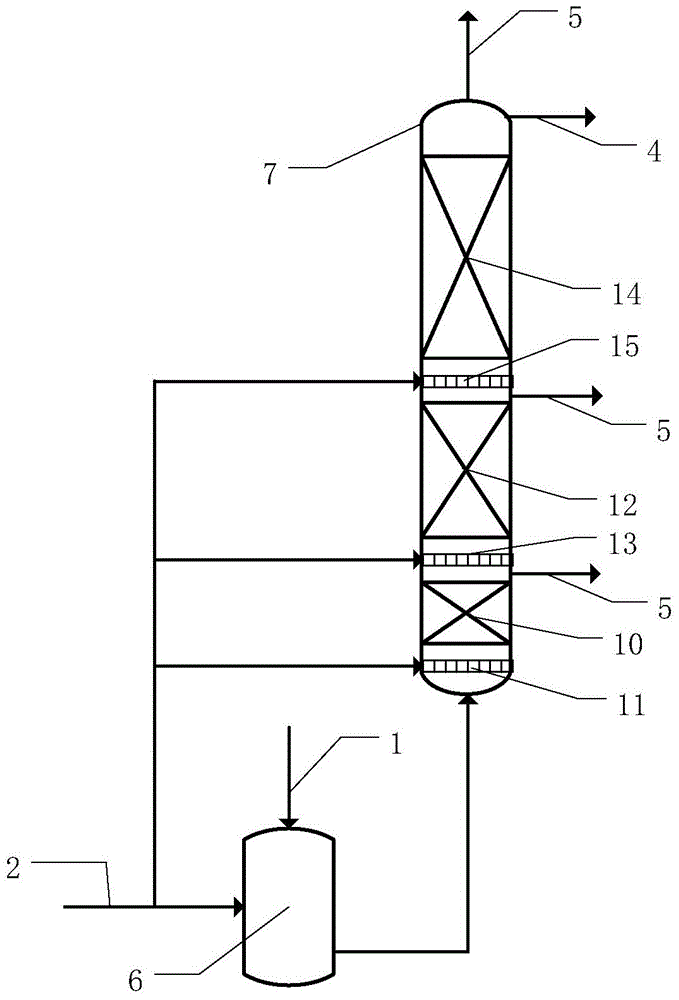

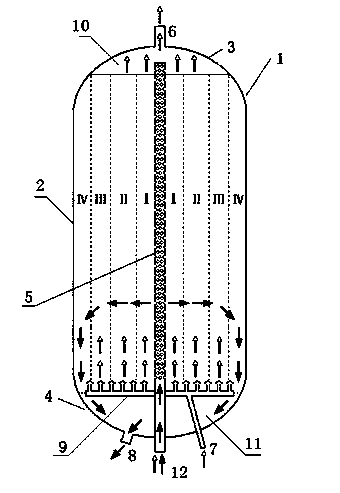

Reactor, a retained catalyst structure, and a method for improving decomposition of polysulfides and removal of hydrogen sulfide in liquid sulfur

ActiveUS8361432B2Increase contactImprove decomposition rateCombination devicesExhaust apparatusDecompositionSulfide

Disclosed is a reactor, a retained catalyst structure, and a method for increasing the rate of decomposition of polysulfides and removal of hydrogen sulfide in liquid sulfur. The reactor, the retained catalyst structure, and the method include a retained catalyst structure arranged and disposed for contacting a first stream and a second stream in a reactor including a catalyst. The catalyst increases the rate of decomposition of polysulfides and facilitates the removal of hydrogen sulfide in the liquid sulfur of the first stream with the second stream. The first stream includes liquid sulfur containing polysulfides and dissolved hydrogen sulfide. The second stream includes an inert gas or a low oxygen-containing gas.

Owner:FLUOR ENTERPRISES +1

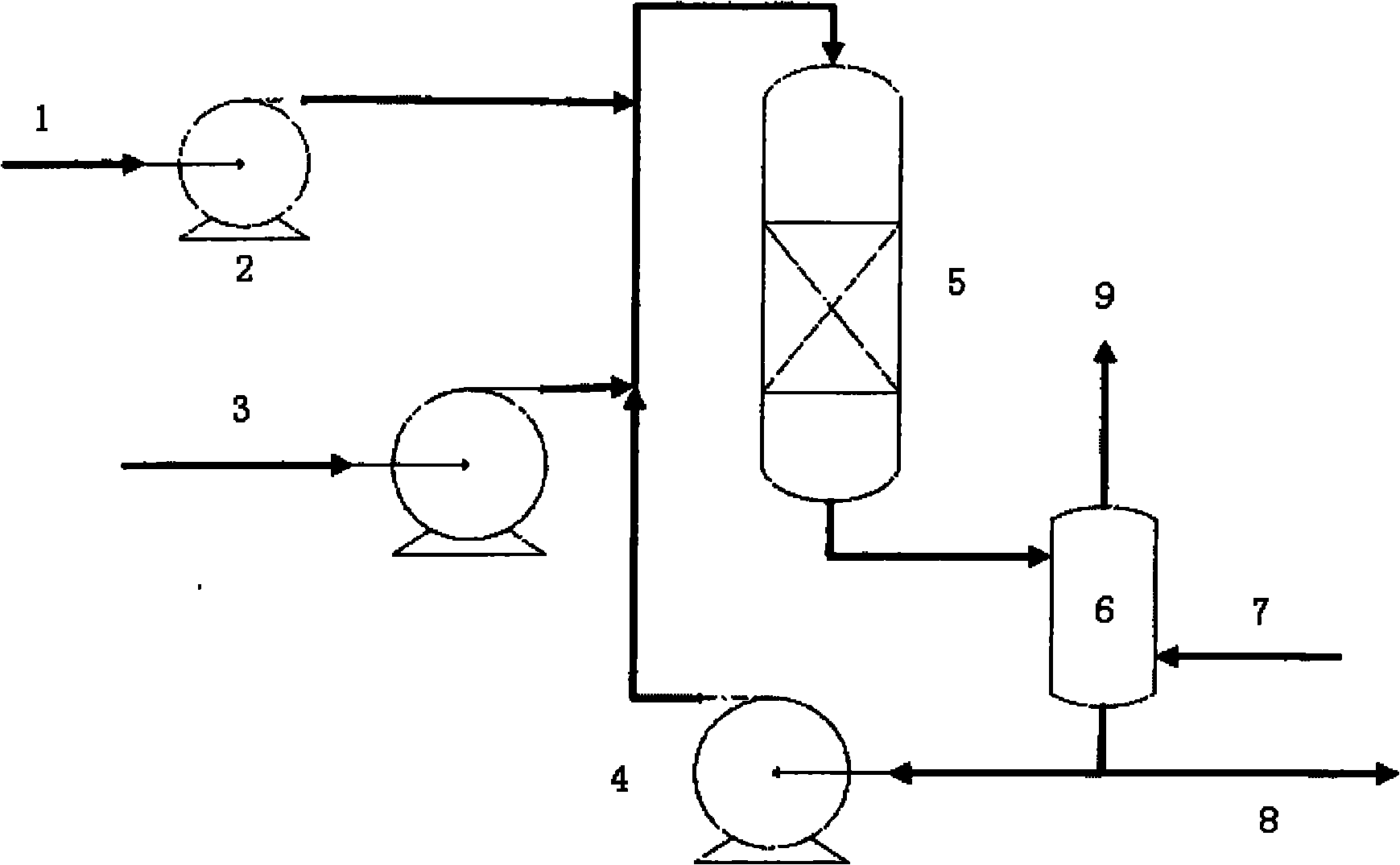

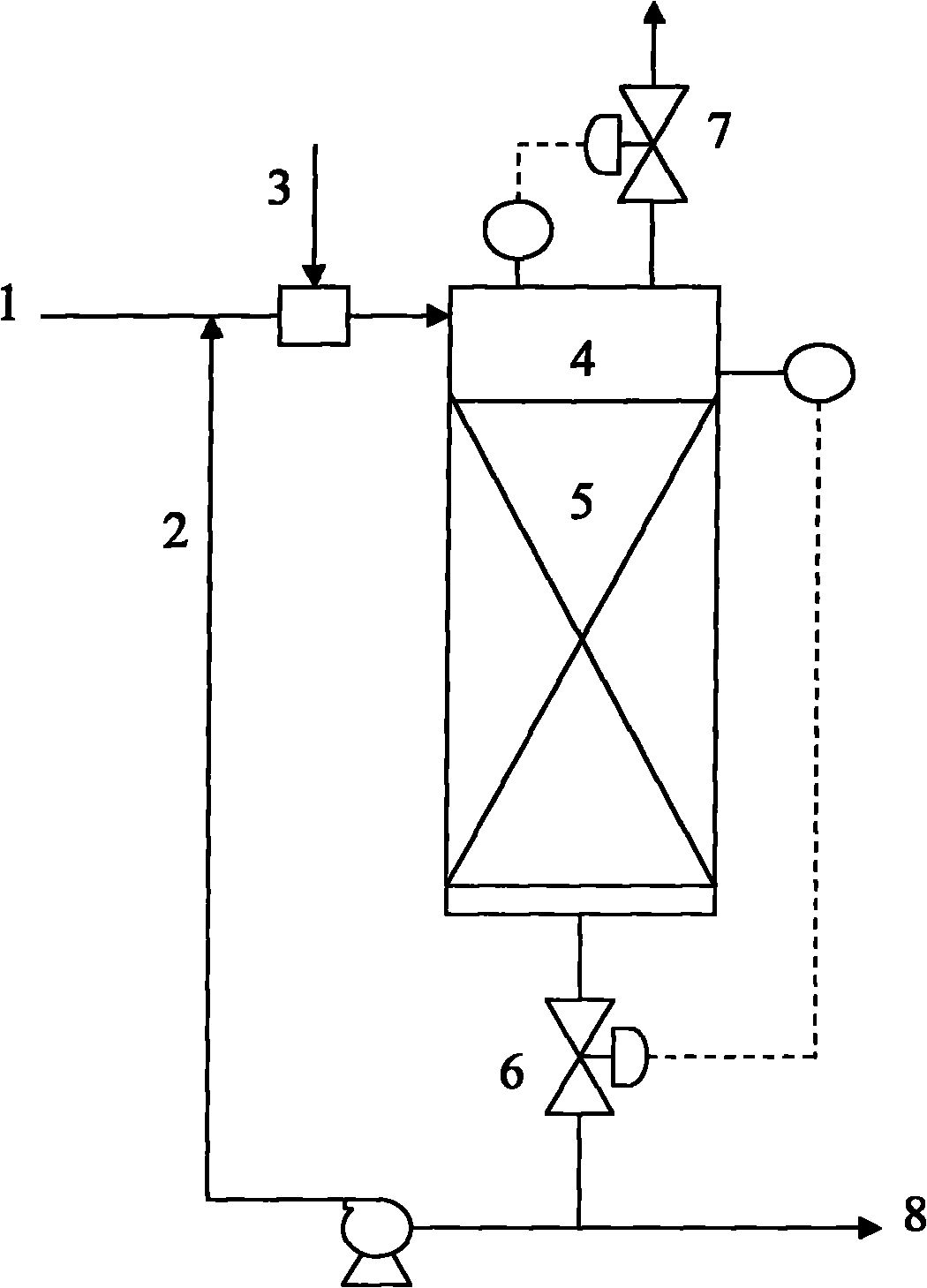

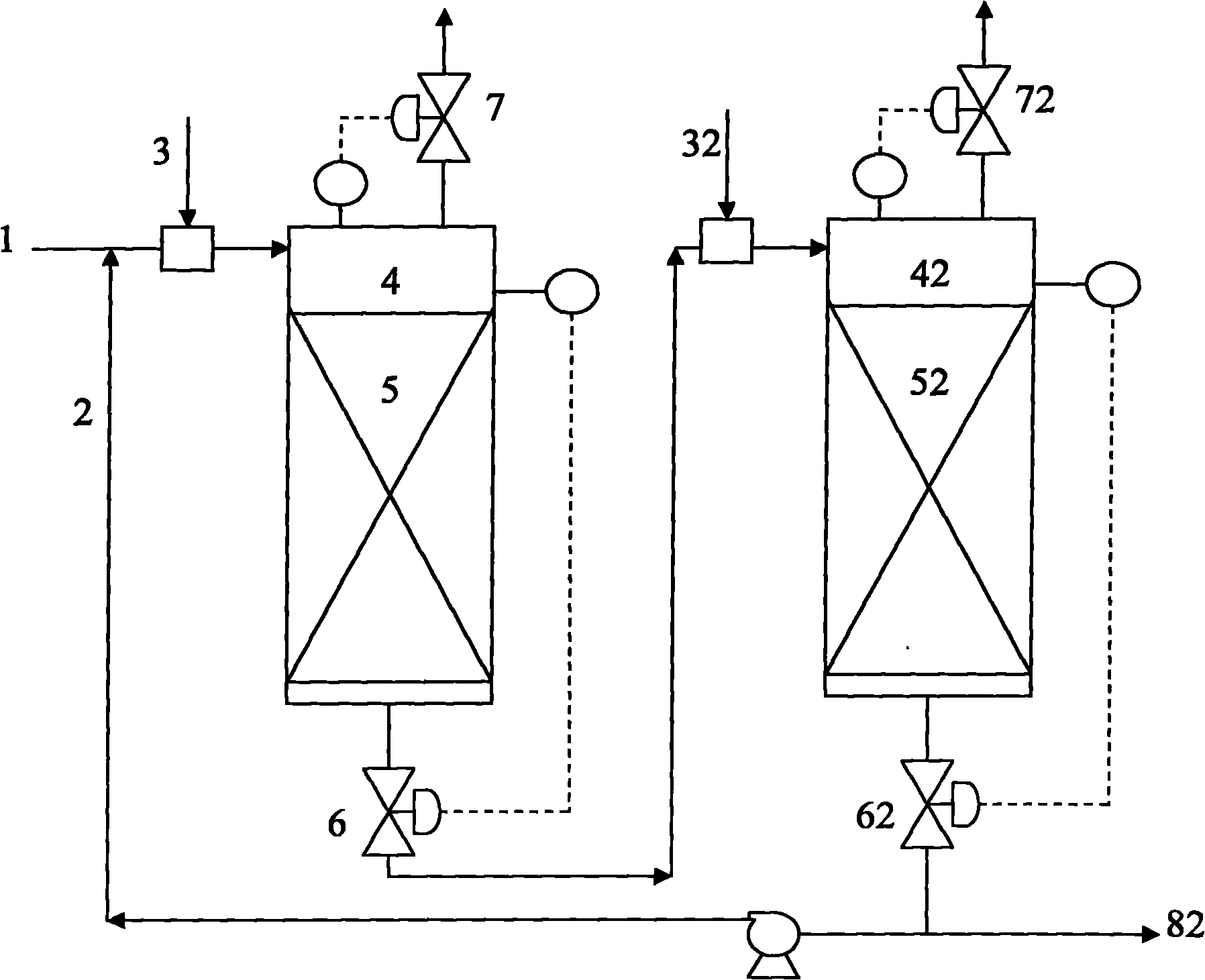

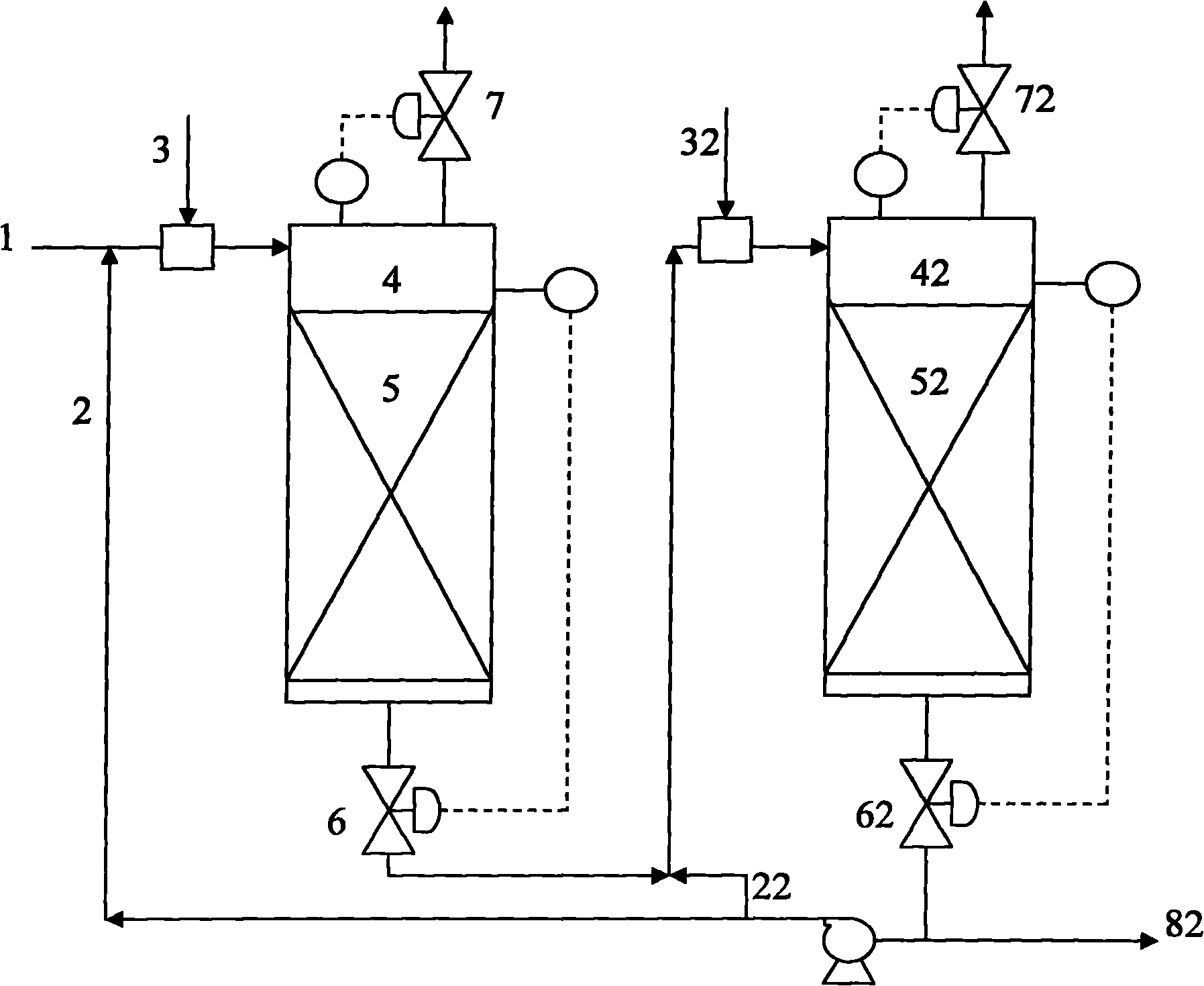

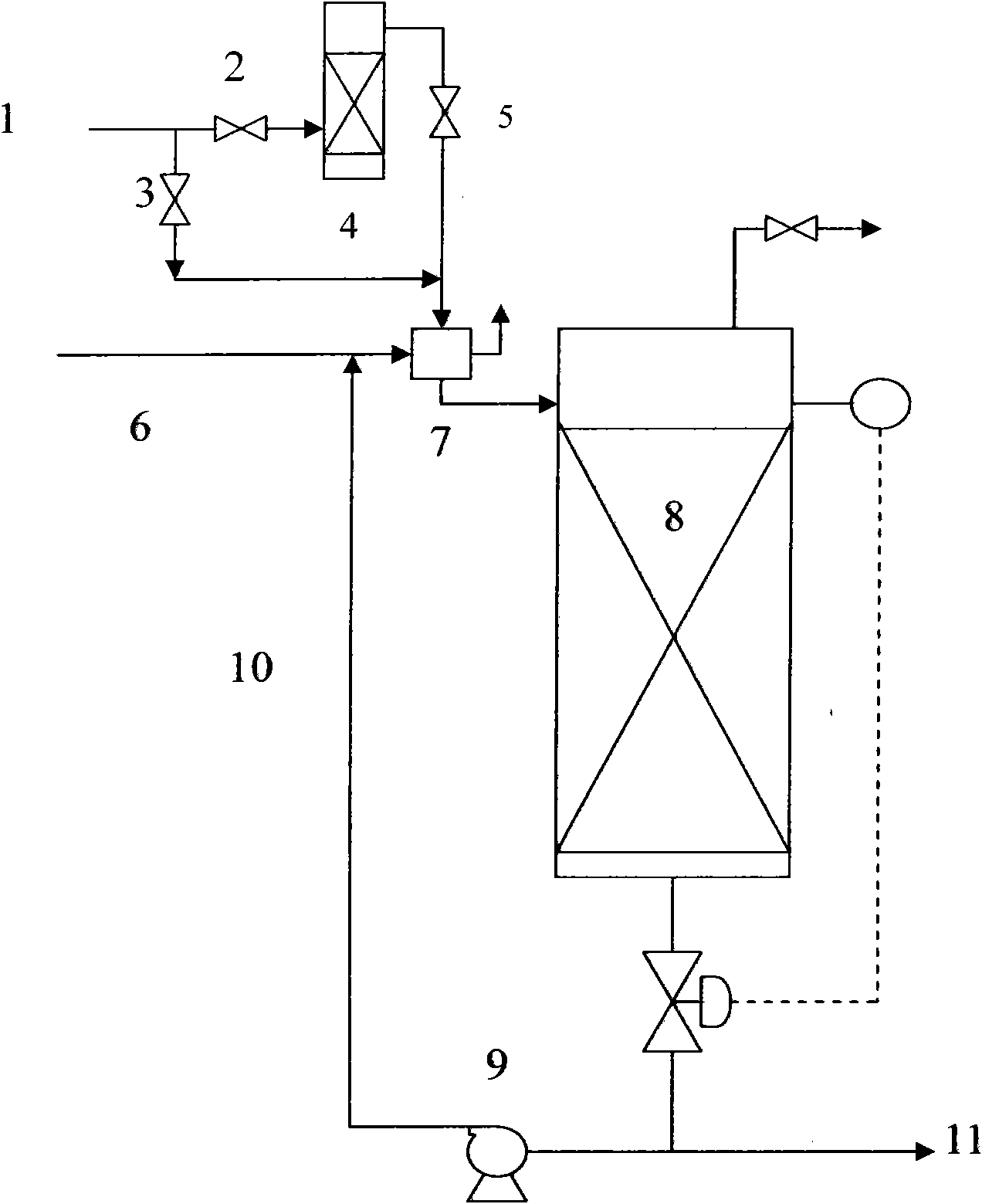

Method of liquid phase circulation hydrotreatment and reaction system

ActiveCN101787305AMaintain active stabilityEliminate the effect of wetting factorHydrocarbon oils treatment control/regulationLiquid productGas phase

The invention discloses a method of liquid phase circulation hydrotreatment. A part of liquid product after hydrotreatment circulates and is mixed with raw material to form liquid phase material, the hydrogen is mixed in the liquid phase material, the mixing volume of the hydrogen is increased by below 20 times of the dissolved hydrogen volume of a reaction system under the reaction condition based on the chemical hydrogen consumption in the reaction process, the liquid phase material mixed with the hydrogen enters the upper part of a reactor, the upper part of the reactor is provided with a gas phase space and an exhaust system which is communicated with the gas phase space, the pressure and the liquid level in the reactor are controlled by controlling the displacement of the exhaust system, the liquid phase material dissolved with the hydrogen enters a hydrogenation catalyst bed at the lower part of the reactor for hydrotreatment reaction, a part of the liquid phase reaction productis discharged from the reaction system, and the other part circulates and is mixed with the raw material. The method can ensure good reaction effect and leads the liquid phase circulation hydrotreatment to be stably controlled and operated.

Owner:CHINA PETROLEUM & CHEM CORP +1

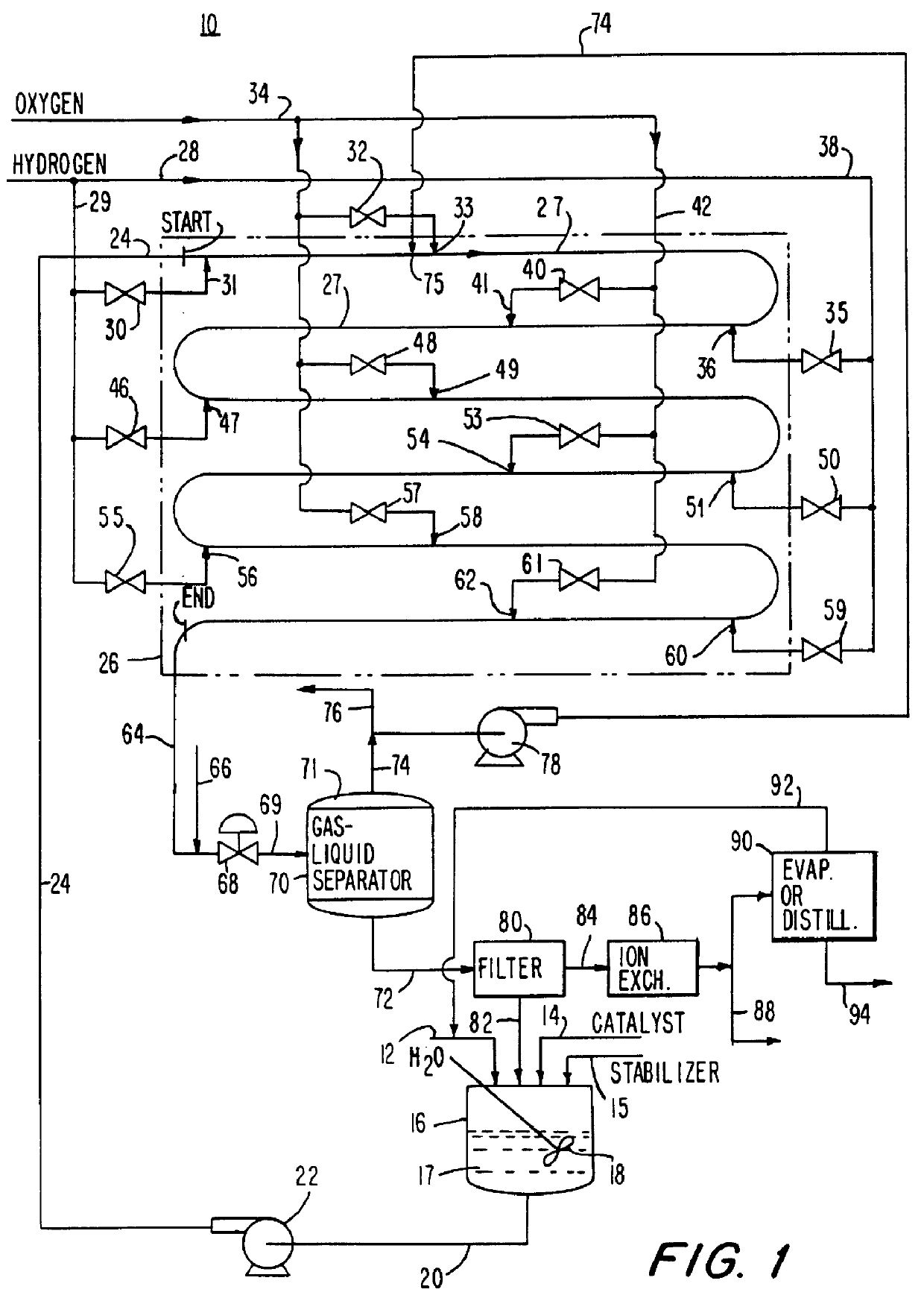

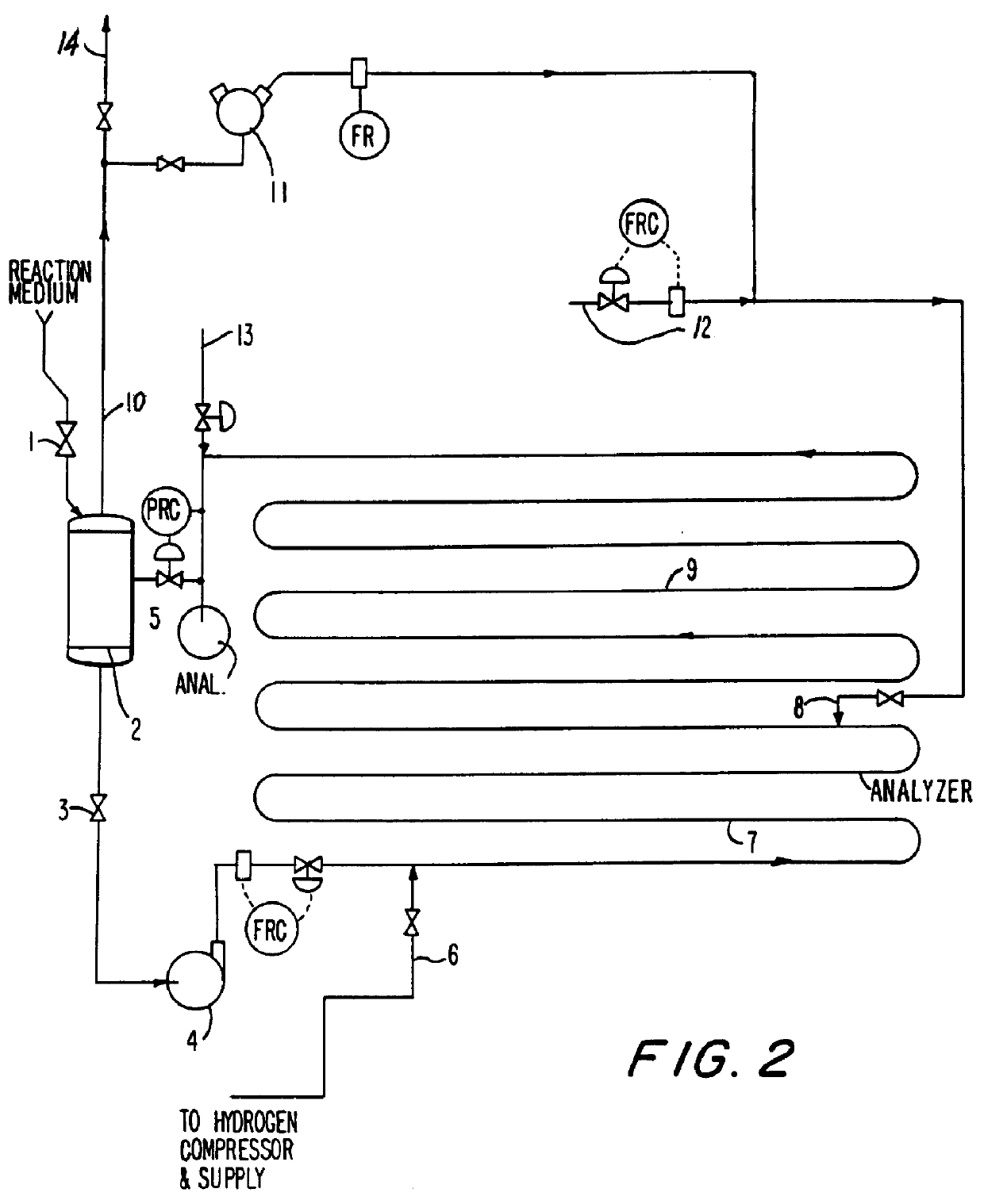

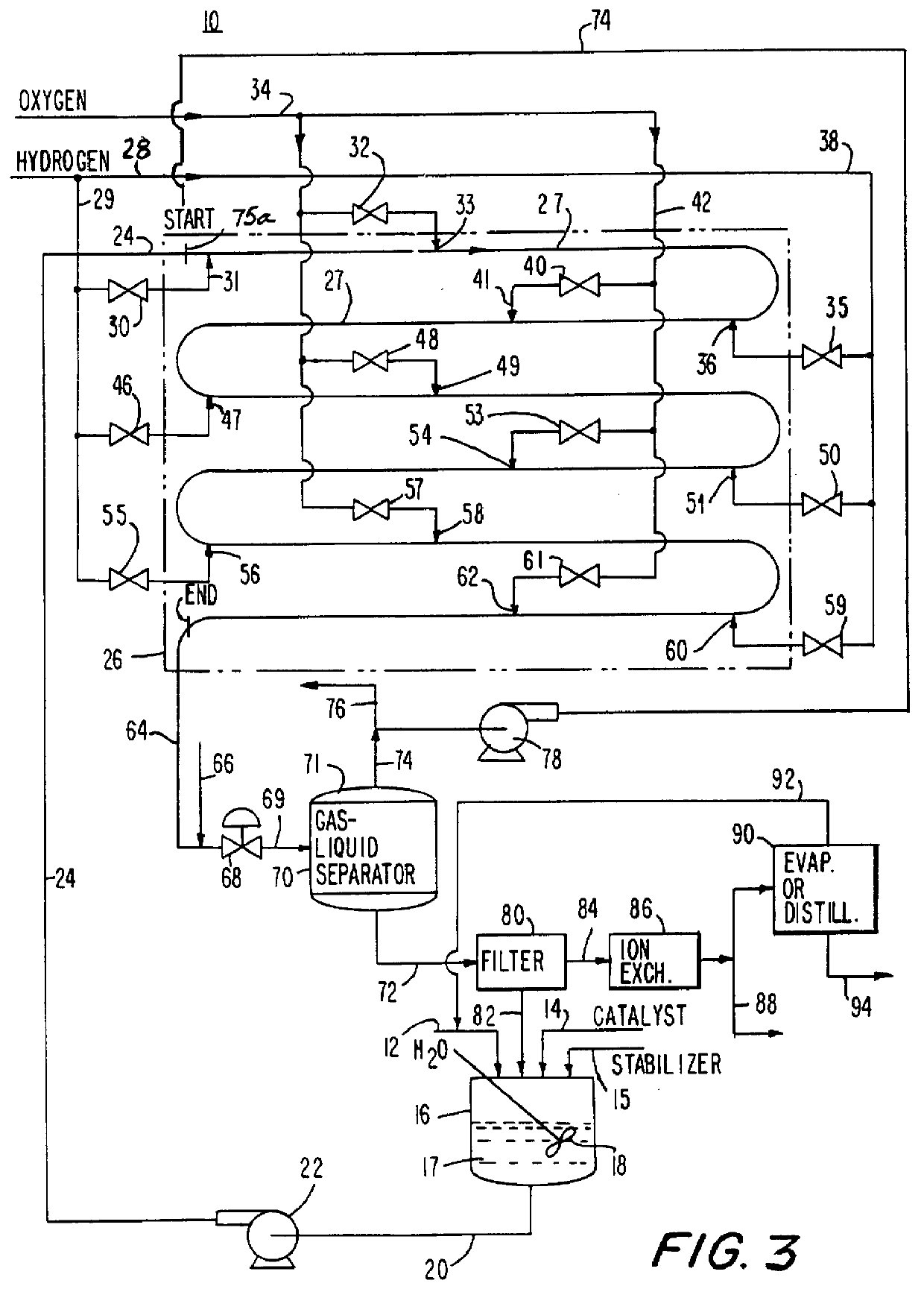

Method for producing hydrogen peroxide from hydrogen and oxygen

InactiveUS6042804ASafe and efficientFull utilization of entire volume of reactorHydrogen peroxideGas-gas reaction processesPtru catalystLiquid medium

The invention relates to a method and apparatus for safely producing hydrogen peroxide by injecting dispersed minute bubbles of hydrogen and oxygen into a rapidly flowing liquid medium. The minute bubbles are surrounded by the liquid medium of sufficient volume for preventing an explosive reaction between the hydrogen and oxygen. The liquid medium is formed of an acidic aqueous solution and a Group VIII metal catalyst. Hydrogen is sparged into the flowing medium for dissolution of the hydrogen in the medium. Oxygen bubbles are reacted with the dissolved hydrogen for producing hydrogen peroxide. Preferably, the liquid medium has a velocity of at least 10 feet per second for providing a bubbly flow regime in the reactor. The invention allows the direct combination of oxygen and hydrogen while preventing propagation of an explosive condition within the reactor. The method and apparatus provide for the safe production of hydrogen peroxide with low manufacturing costs.

Owner:PRINCETON ADVANCED TECH

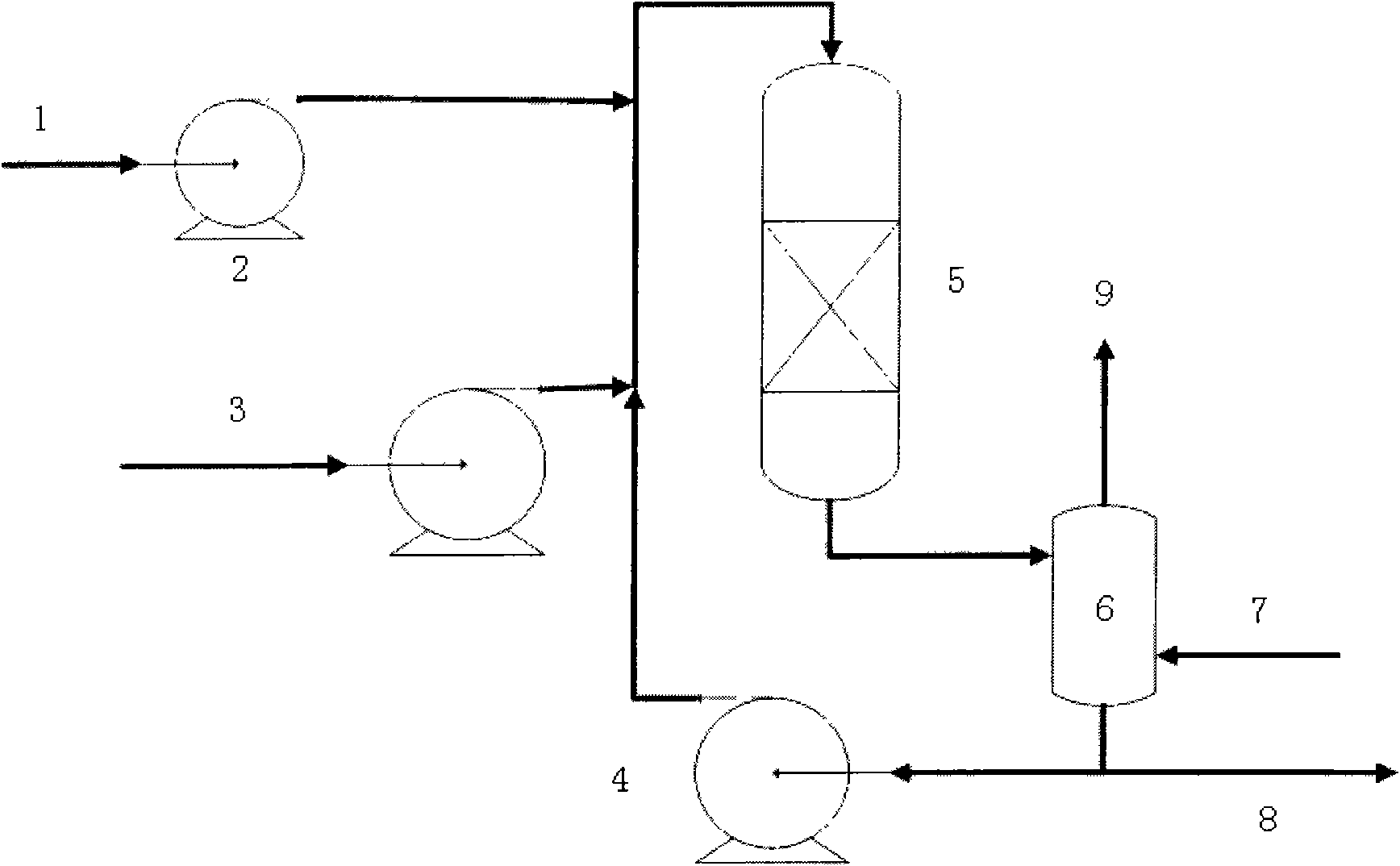

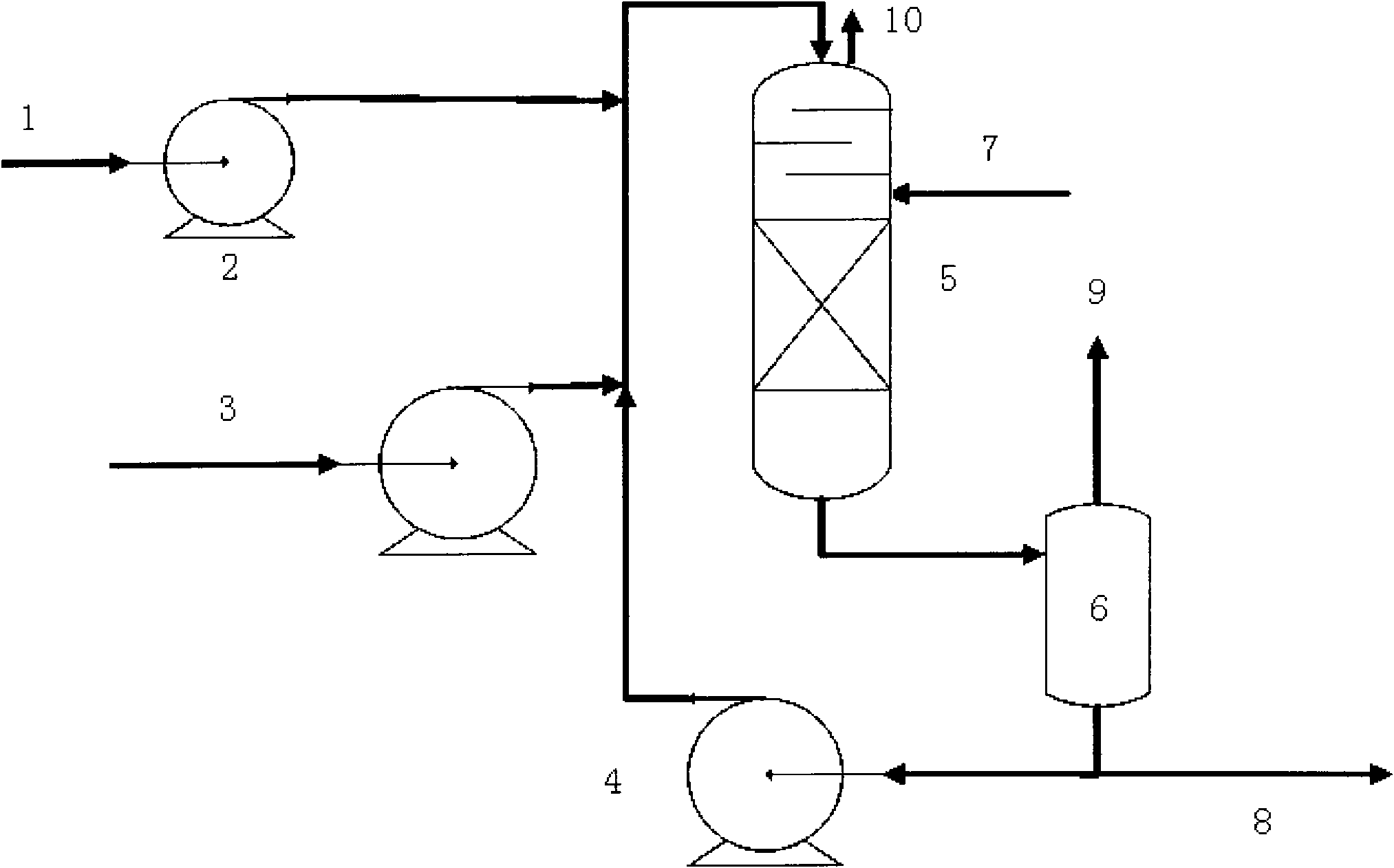

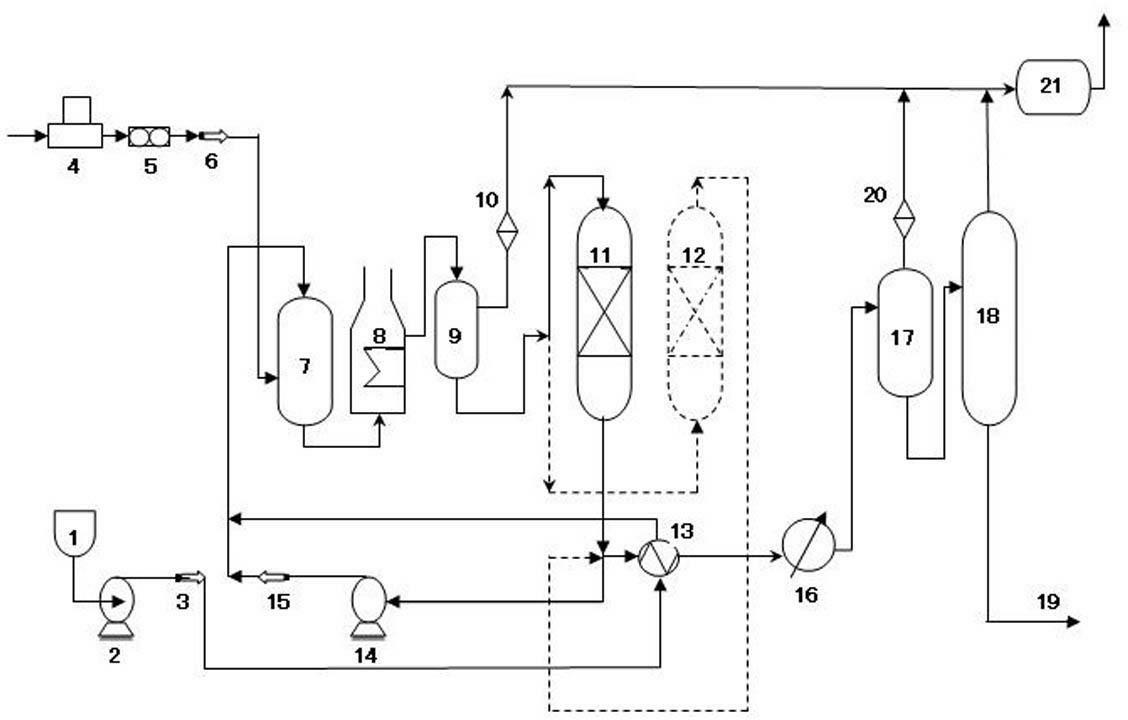

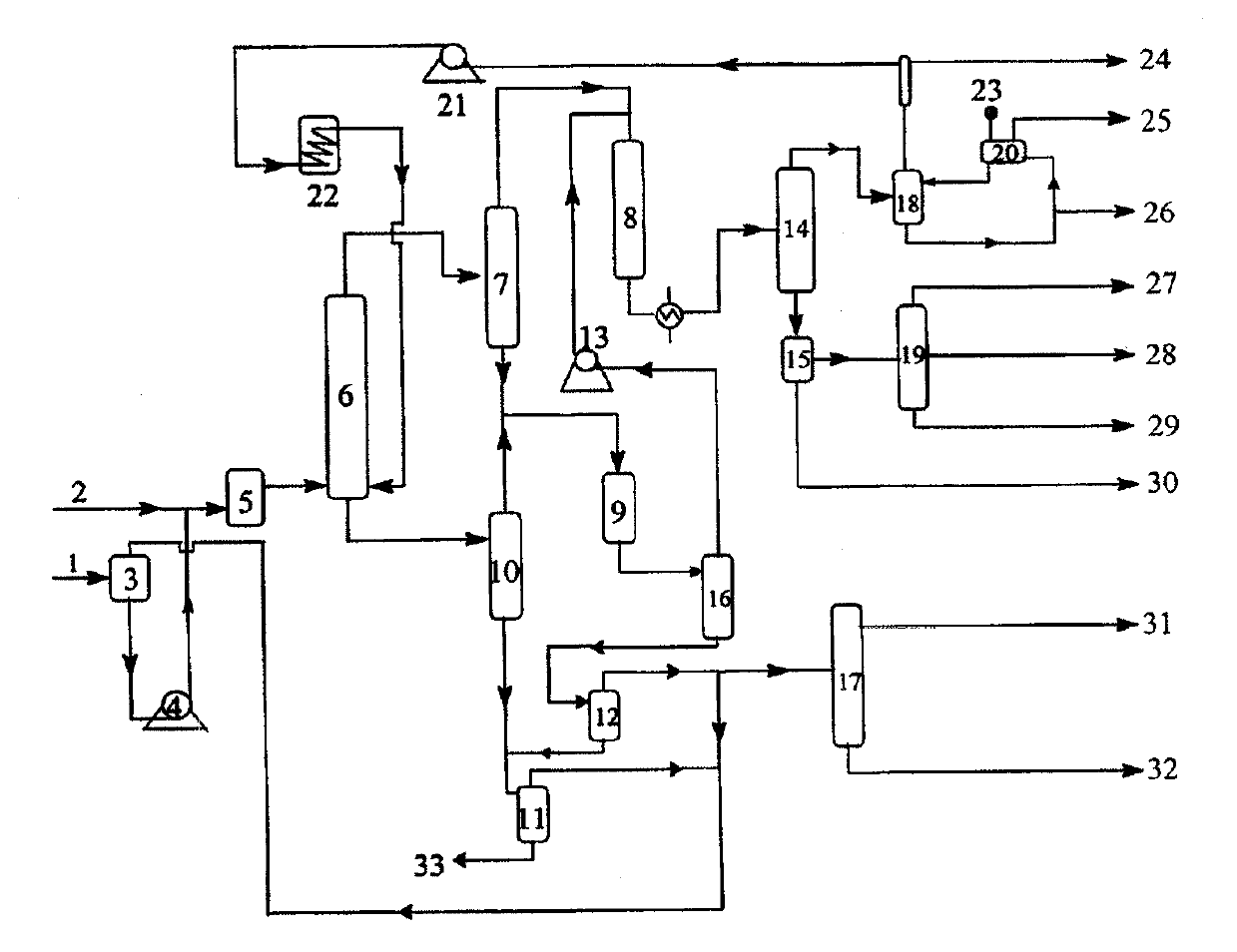

Method and reaction system for liquid phase cycling hydrotreatment

ActiveCN101993721AMaintain active stabilityImprove effective utilizationHydrocarbon oils treatment control/regulationTreatment with hydrotreatment processesGas phaseControl system

The invention discloses a method and a reaction system for liquid phase cycling hydrotreatment. In the method, part of a liquid phase product after the hydrotreatment is mixed with fresh raw oil in a cycling mode to form a liquid phase material; hydrogen is mixed into the liquid phase material; the hydrogen mixed amount is 1 to 20 times that of the dissolved hydrogen which makes the reaction system saturated under a reaction condition; the liquid phase material mixed and dissolved with the hydrogen is put into a reactor; a hydrogenation catalyst bed is arranged in the reactor and is immersed in the liquid phase material; the upper part of the reactor is provided with a gas phase space; a pressure control system communicated with the gas phase space is arranged on the reactor and controls the pressure in the reactor by controlling the gas exhaust quantity; and the liquid phase material dissolved with the hydrogen is put into the hydrogenation catalyst bed of the reactor to perform hydrogenation reaction. Compared with the prior art, the method ensures that the liquid phase cycling hydrotreatment can be controlled and operated stably, and obtain an ideal reaction effect.

Owner:CHINA PETROLEUM & CHEM CORP +2

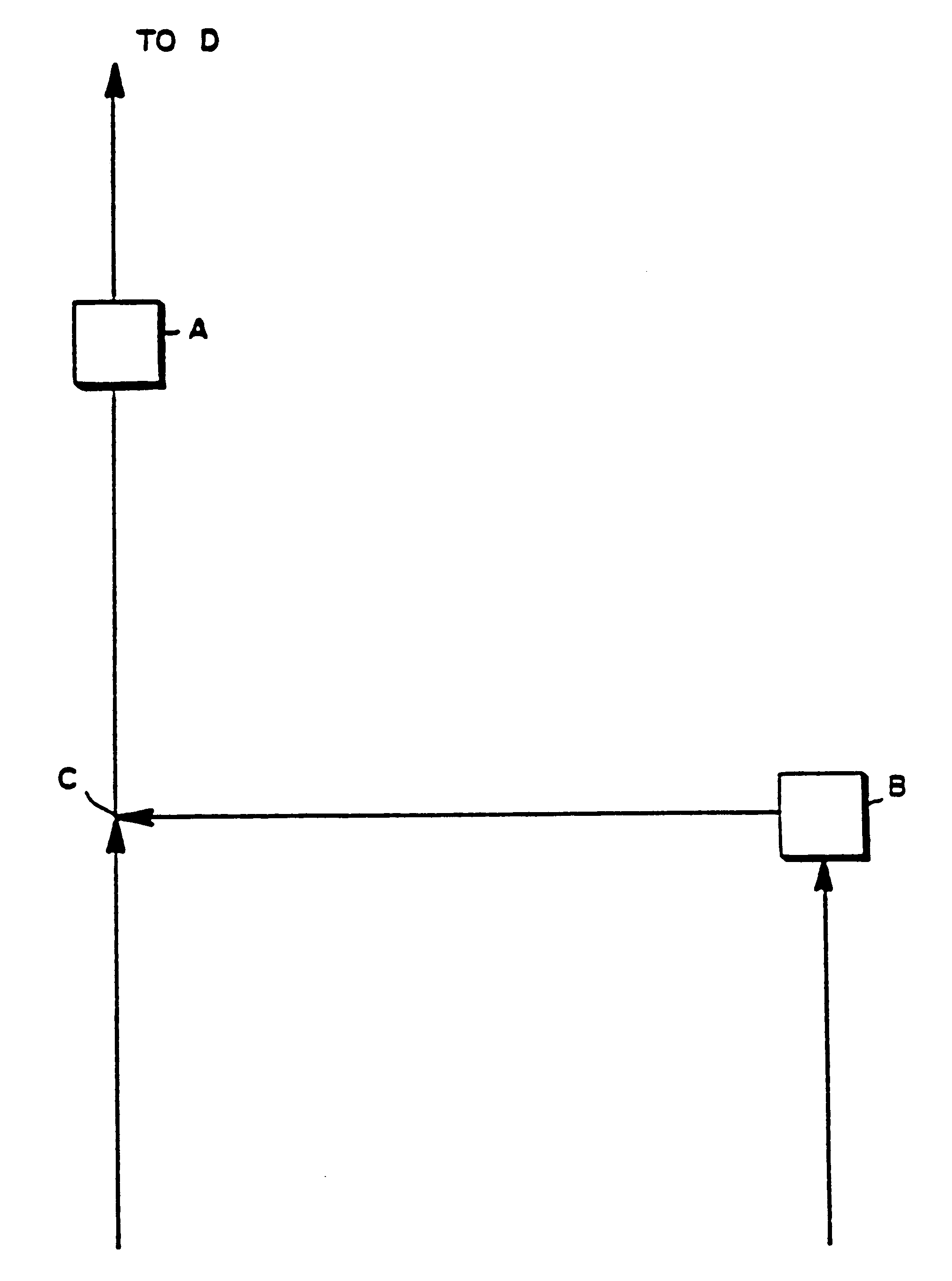

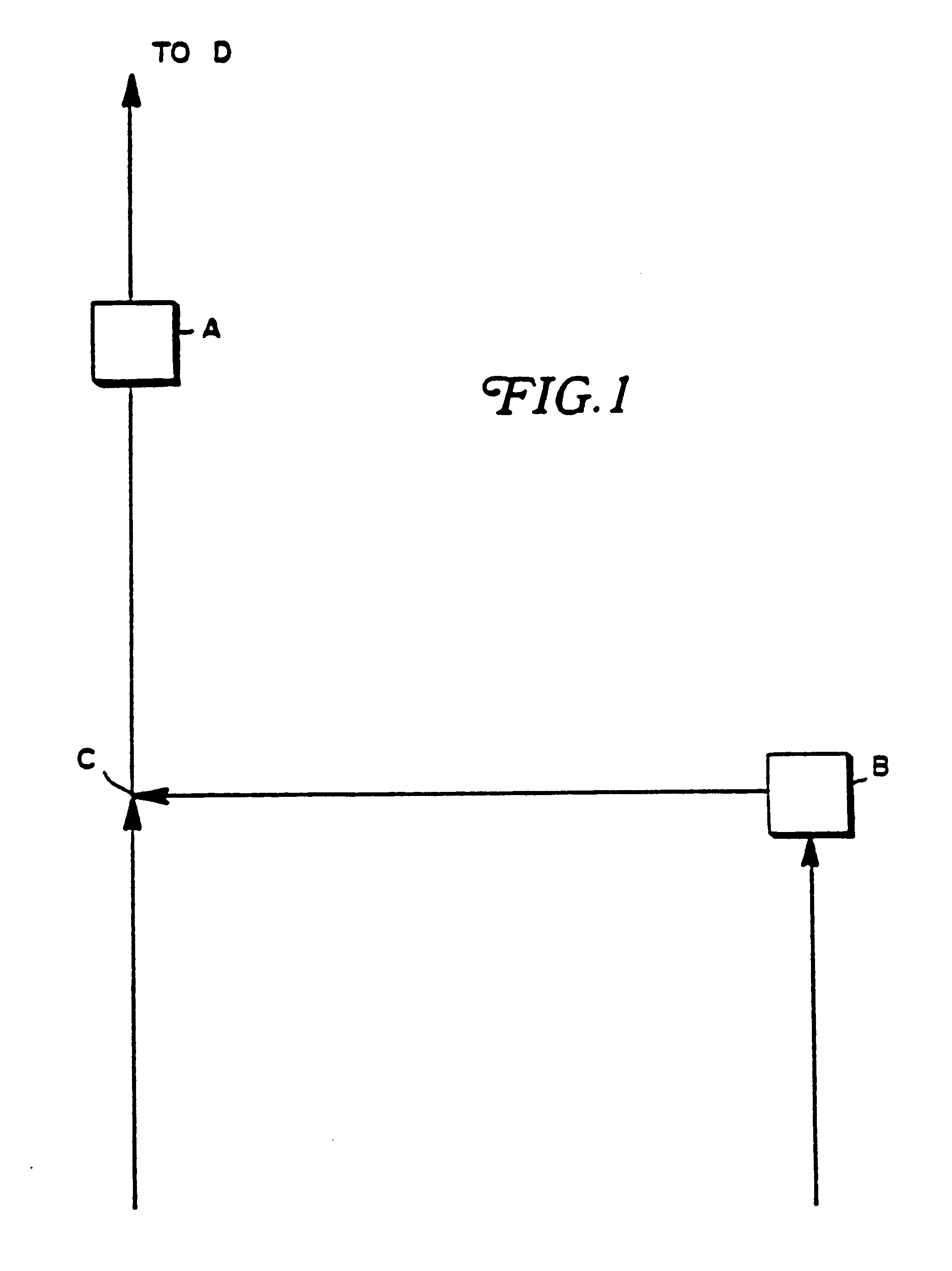

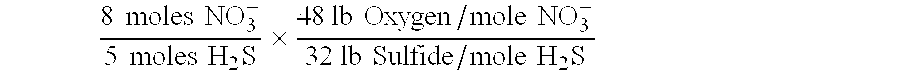

Process for removal of dissolved hydrogen sulfide and reduction of sewage BOD in sewer or other waste systems

InactiveUSRE37181E1Substantial eliminationEliminate the problemTreatment using aerobic processesSpecific water treatment objectivesSulfideSewage

Removal of dissolved hydrogen sulfide and a reduction in BOD is achieved by the addition of nitrate ions to waste systems in an amount sufficient to stimulate growth of bacteria which utilize dissolved hydrogen sulfide in their metabolism. Specifically, about 2.4 lbs. <INS-S DATE="20010522" ID="INS-S-00001">nitrate <INS-E ID="INS-S-00001">oxygen per lb. of sulfide is required.

Owner:UNITED STATES FILTER CORPORATION

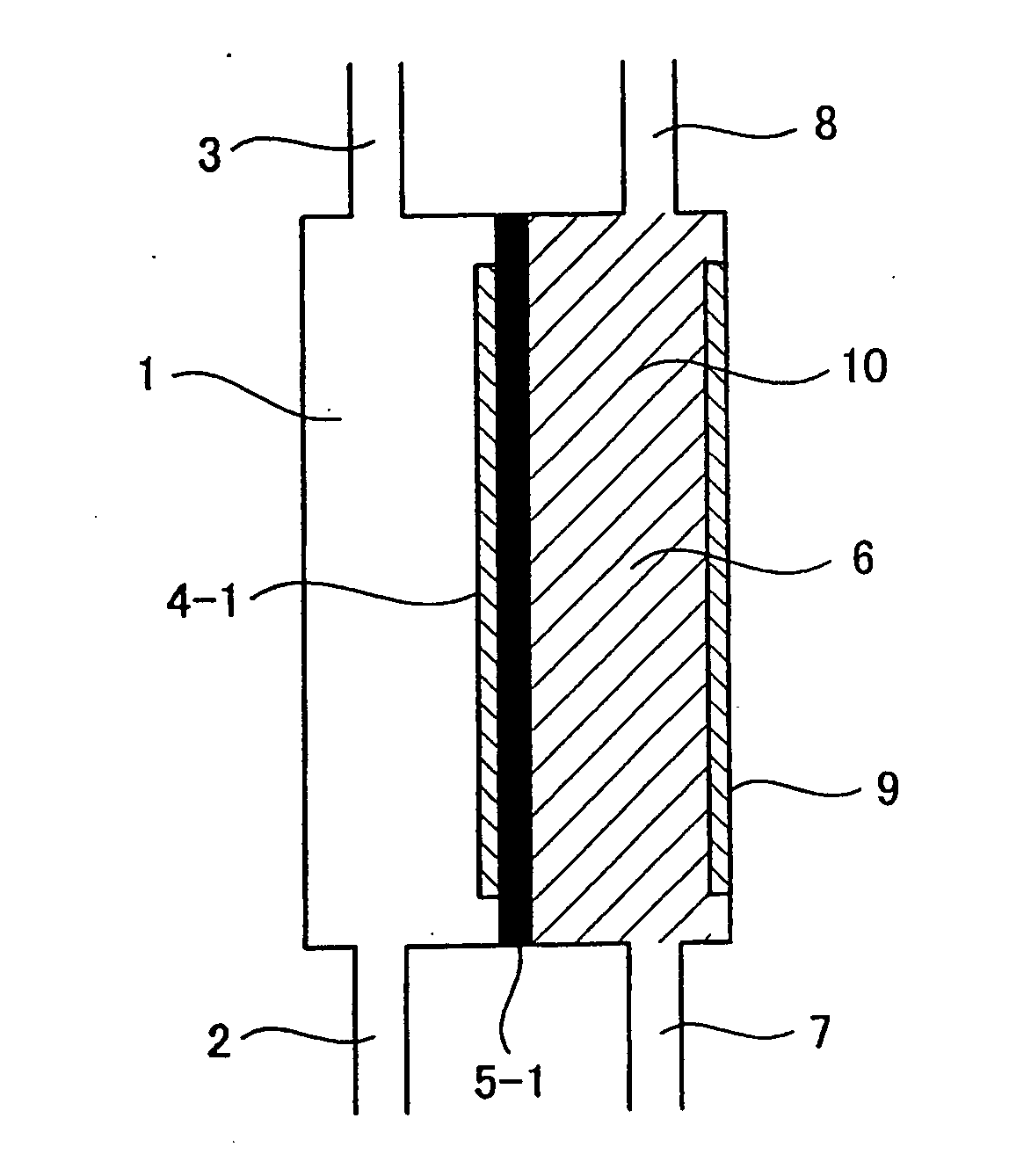

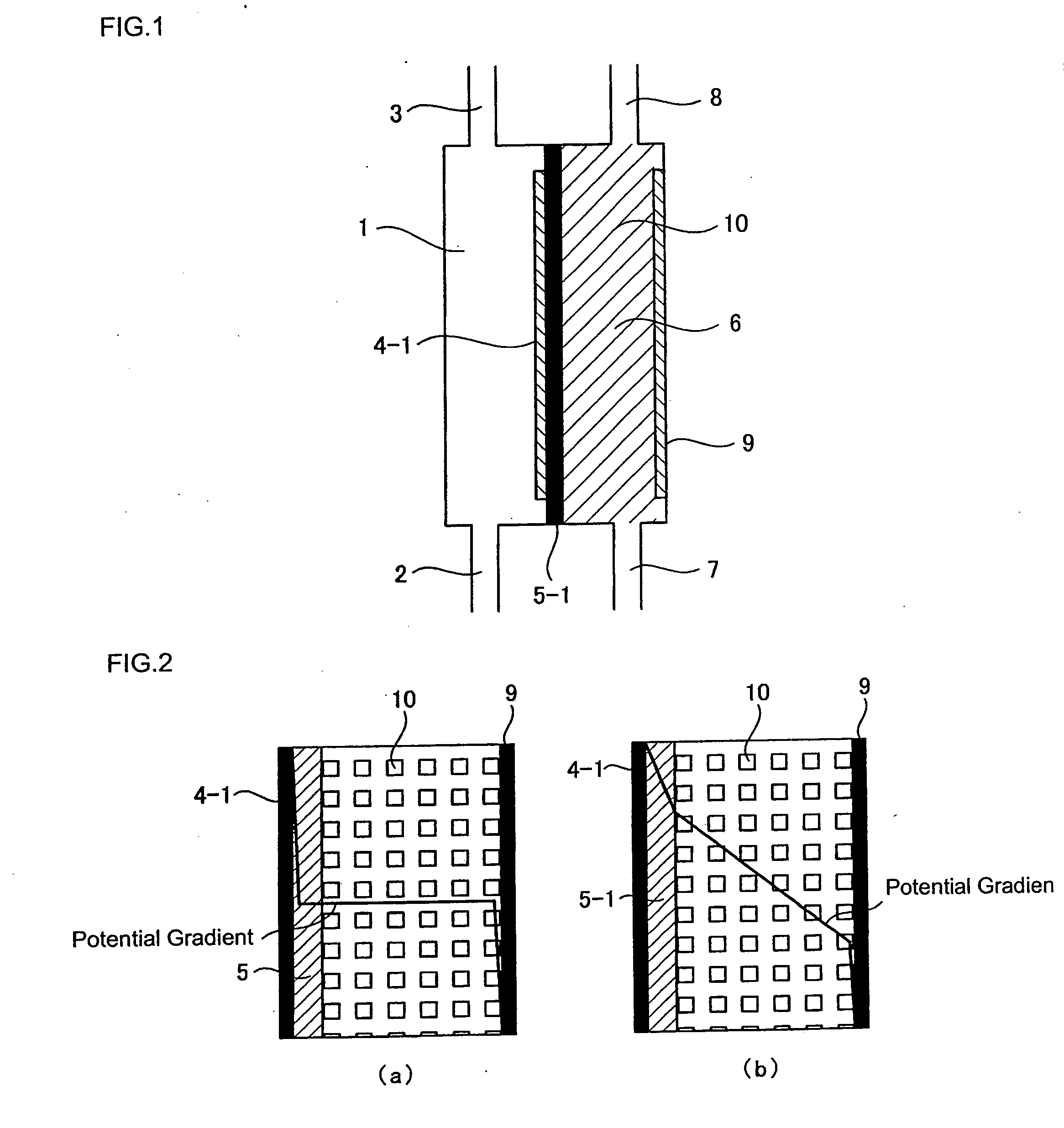

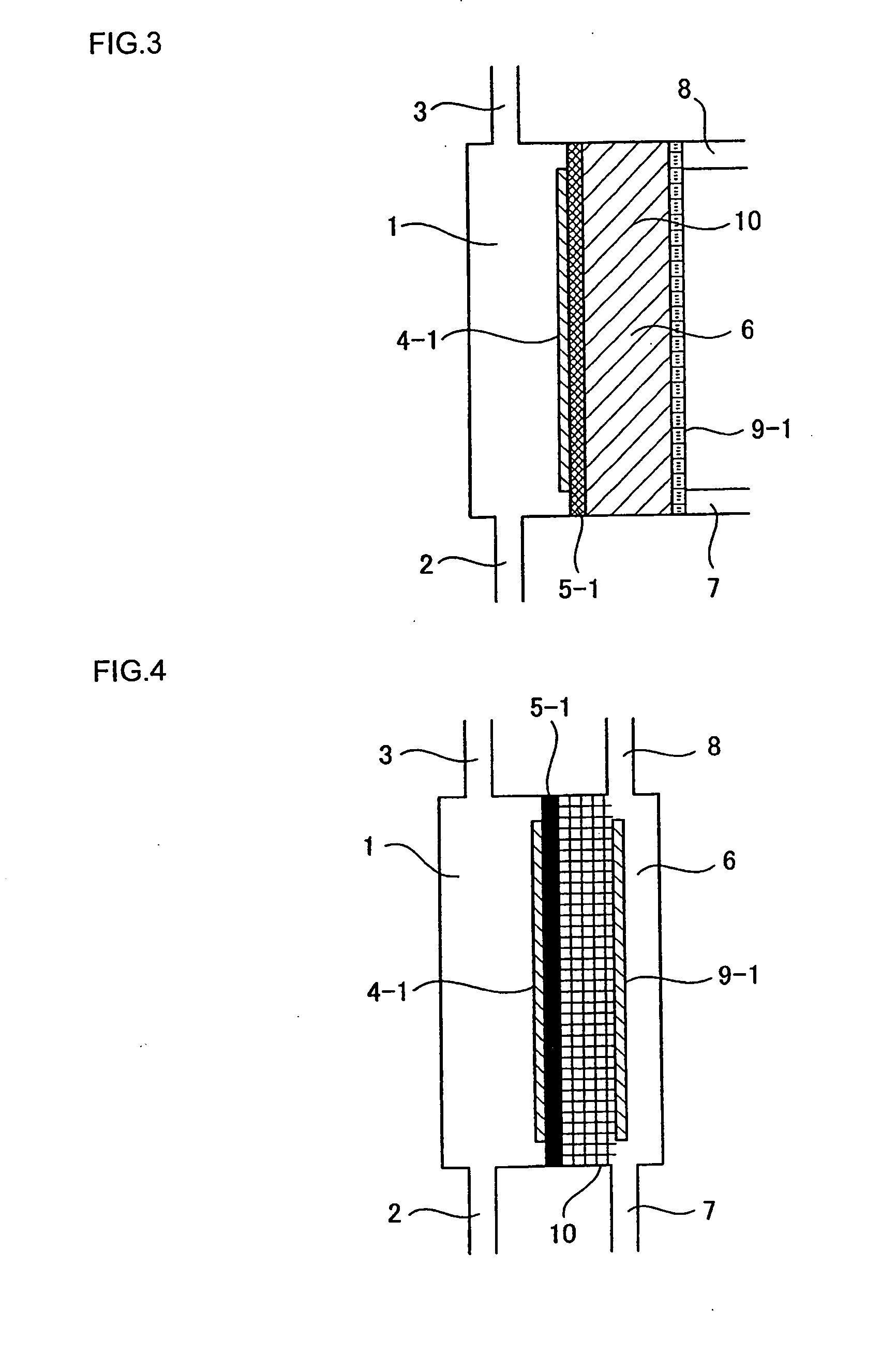

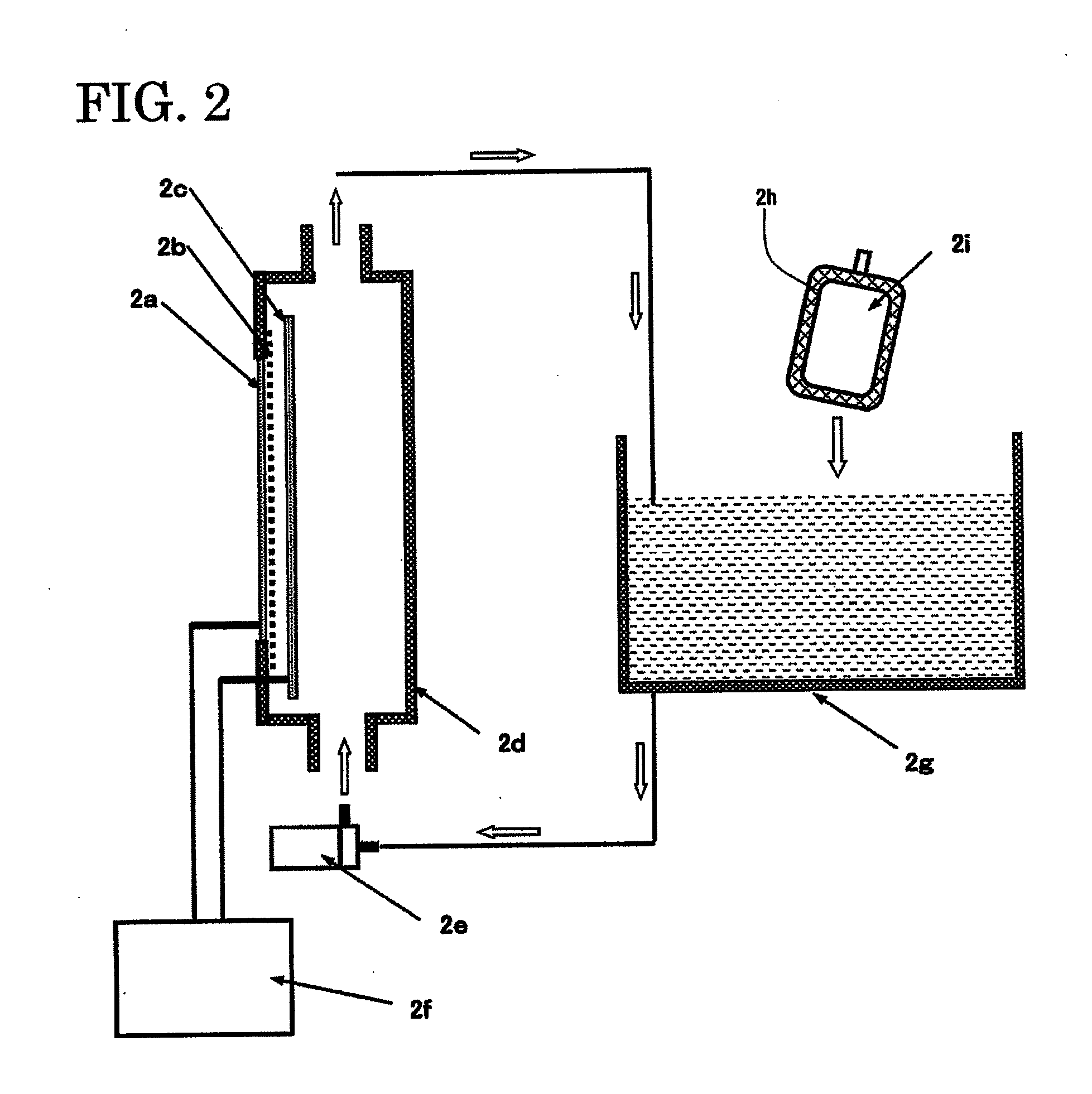

Apparatus and method for producing hydrogen-dissolved drinking water

ActiveUS20110198236A1High dissolved hydrogen concentrationLong dissolved hydrogen concentrationCellsMembranesWater productionIon-exchange resin

An apparatus for producing in the home hydrogen-dissolved drinking water that is suitable for drinking, has a high dissolved hydrogen concentration, and a long dissolved hydrogen life. A hydrogen-dissolved drinking water production apparatus includes an electrolytic cell through which water can pass for producing drinking water having a pH in a range of 2.5 to 8.5, and in particular, in a range of 5.8 to 8.5, and a dissolved hydrogen concentration of 0.1 ppm or more by supplying high-purity water having a conductivity of 50 μS / cm or less. The hydrogen-dissolved drinking water production apparatus is characterized in that the electrolytic cell includes a vertical anode chamber having a water-permeable plate-like anode electrode and a vertical cathode chamber having a plate-like cathode electrode, the anode chamber and the cathode chamber are separated by a diaphragm formed from a fluorine-based cation exchange membrane, the water-permeable plate-like anode electrode is closely adhered to the diaphragm formed from the fluorine-based cation exchange membrane, and an ion-exchange resin is filled in a space between the diaphragm and the cathode electrode.

Owner:TECH CORPORATION CO LTD +1

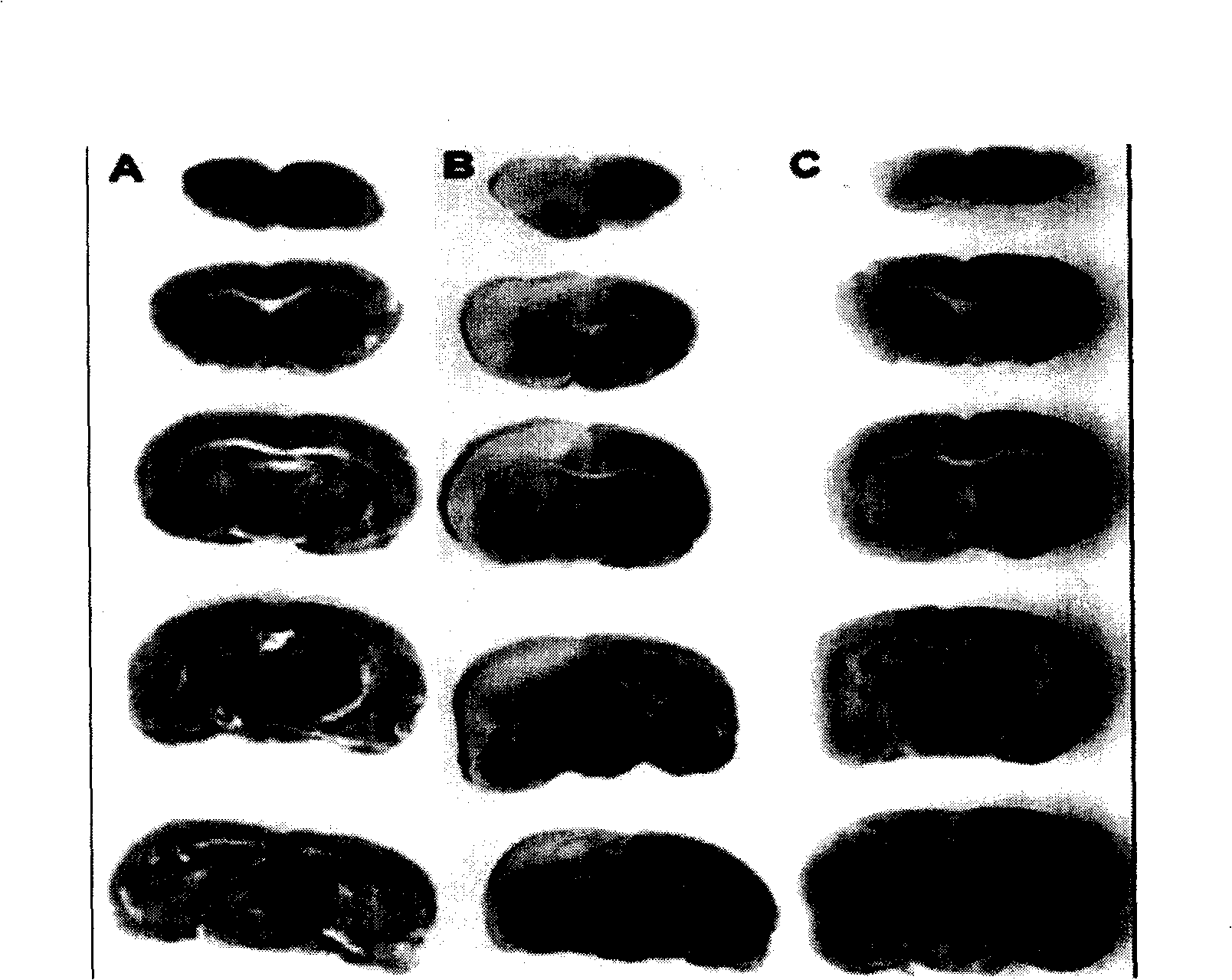

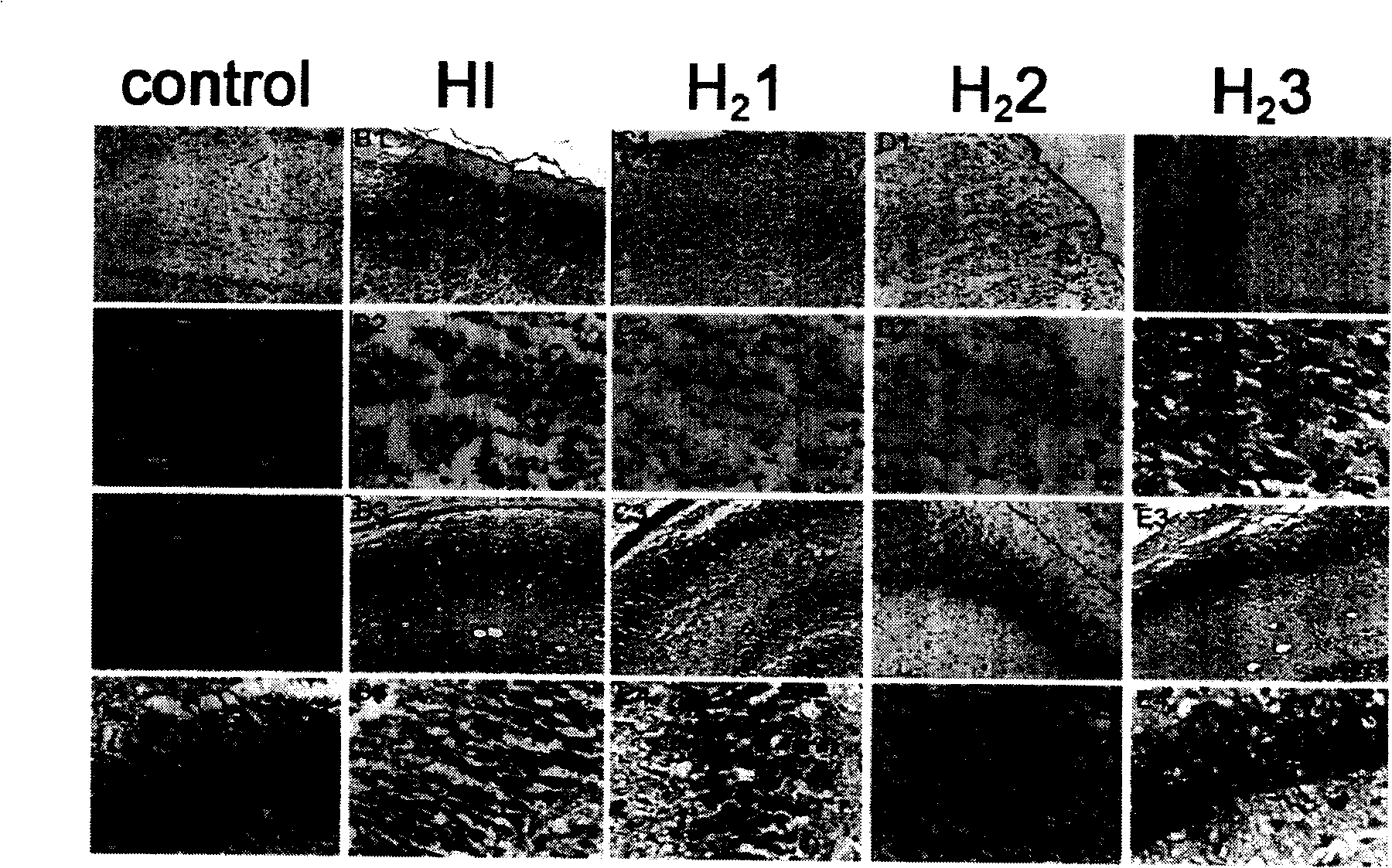

Hydro-treating method of reformate

ActiveCN103666544AReduce lossesSemi-permeable membranesFlow mixersHydrogenation reactionAromatic hydrocarbon

The invention provides a hydro-treating method of reformate. The method comprises the following step: under a liquid-phase hydro-treating condition, enabling reformate and a catalyst with catalytic hydrogenation effect to contact in a hydrogenation reaction, wherein a hydrogen gas used in the hydro-treating is at least partly from dissolved hydrogen in the reformate. According to the method disclosed by the invention, the reformate obtained by separating in a reforming product separating tank is directly subjected to liquid-phase hydro-treating, so that not only can dissolved hydrogen in the reformate sufficiently be utilized, but also olefin in the reformate can be removed; meanwhile, needs for recycling hydrogen and recycling equipment thereof are eliminated. The reformate obtained by the hydro-treating method disclosed by the invention can have a bromine index lower than 50 mgBr2 / 100g and aromatic hydrocarbon loss amount less than 0.5wt%.

Owner:CHINA PETROLEUM & CHEM CORP +1

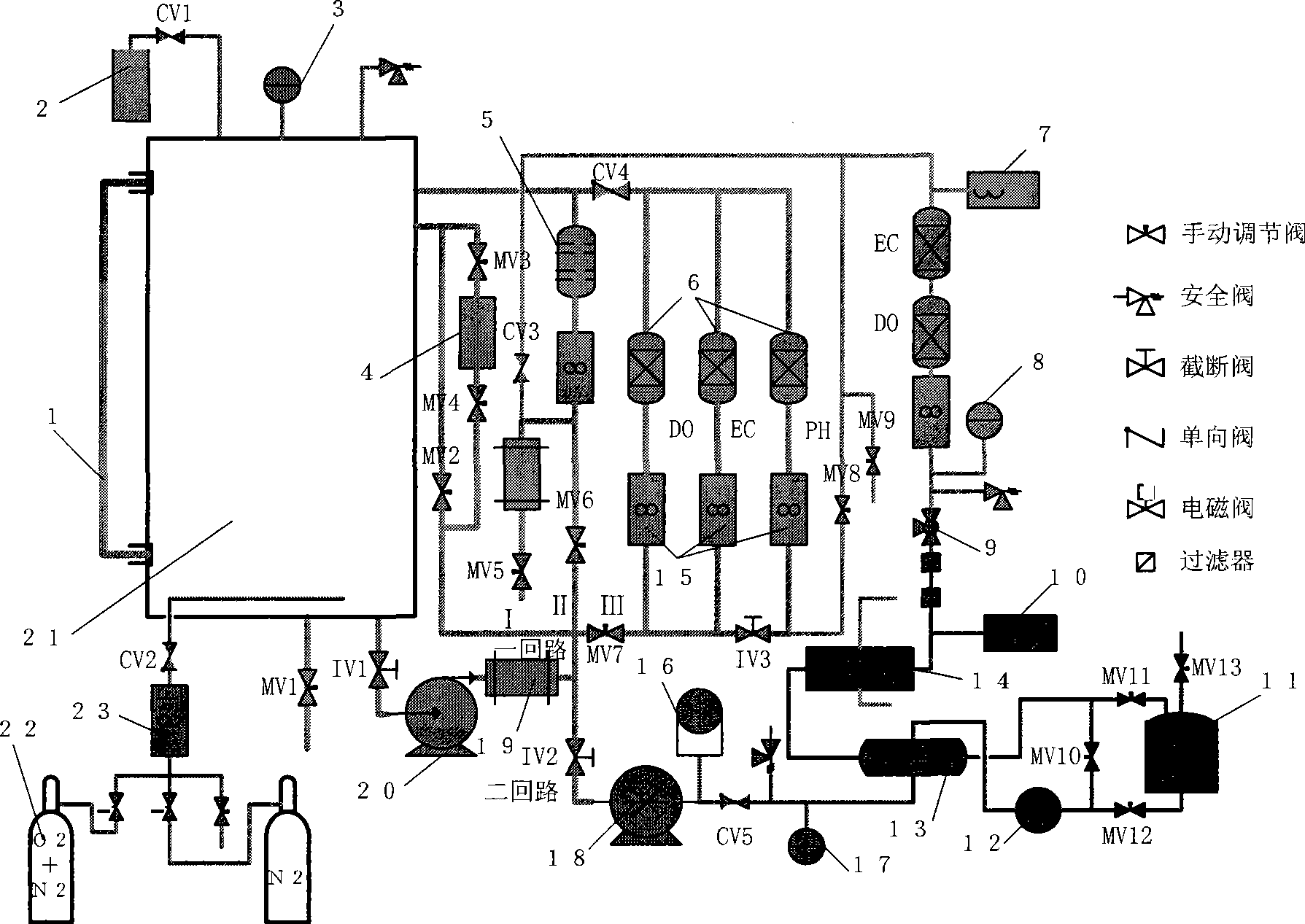

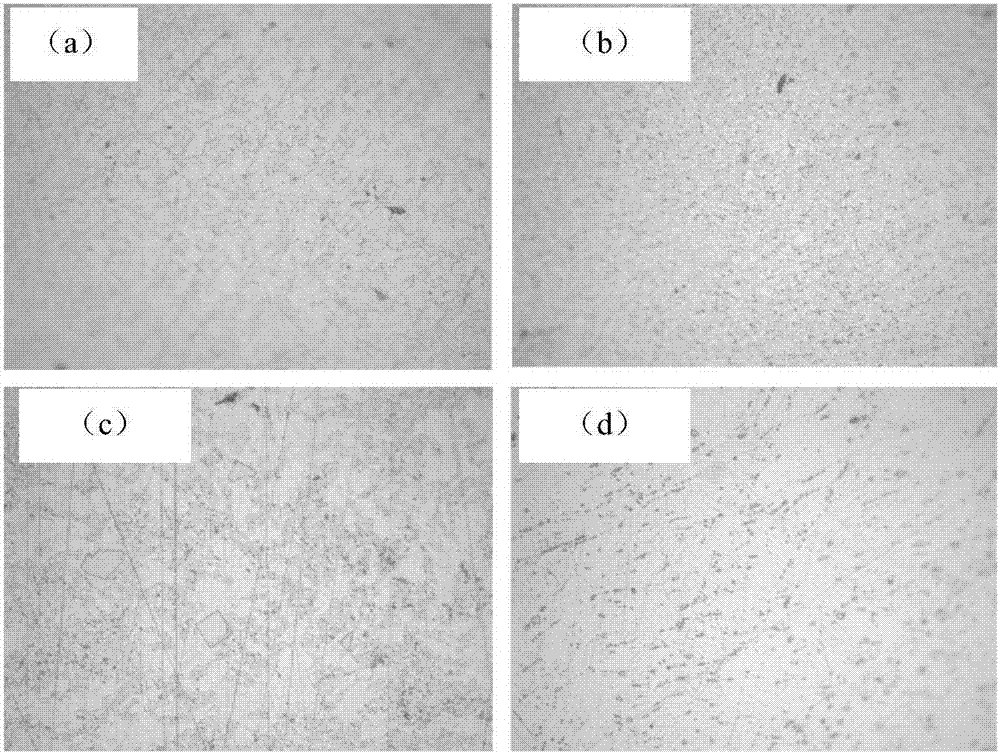

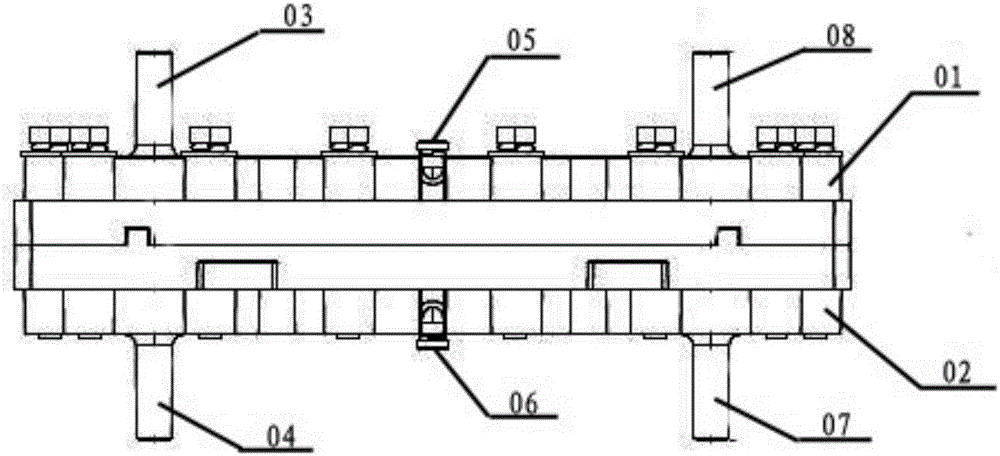

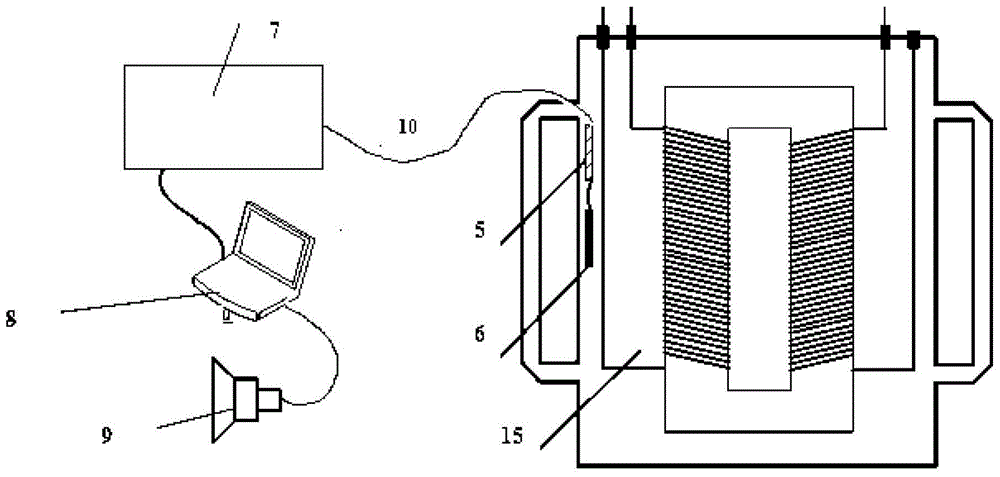

High temperature high pressure water circulation system

ActiveCN101477843AReduce conductivityControl contentNuclear energy generationCooling arrangementNuclear powerNuclear engineering

The invention relates to water circulation systems, in particular to a water circulation system which can control hydrochemistry and meet high temperature and high pressure conditions, and solves problems such as the measurement and the control of a hydrochemistry parameter in the high temperature and high pressure water circulation system and the like. The system mainly consists of two loops; a primary loop is in a normal temperature and pressure state; through continuous circulation in the primary loop, the conductivity of water can be caused to reach a needed index; dissolved oxygen content and dissolved hydrogen content in the water can be comparatively precisely controlled; the PH value and temperature changes of the water can be detected in an on-line manner; and solutions containing special ions can be added in the primary loop according to the needs of an experiment; a high pressure pump and a preheater in a secondary loop can cause water in an autoclave to reach a state of high temperature and high pressure (320 DEG C, 12 MPa), and simulate practical service environments (such as a nuclear power high temperature water environment) to conduct an environment damage experiment on a material; and after heat transfer and cooling, water out of the autoclave can return to the primary loop to be continuously recycled and used.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Process for removal of dissolved hydrogen sulfide and reduction of sewage BOD in sewer or other waste systems

InactiveUSRE36651E1Elimination and substantial reductionEliminate the problemTreatment using aerobic processesBiochemical fibre treatmentSewageOxygen

Removal of dissolved hydrogen sulfide and a reduction in BOD is achieved by the addition of nitrate ions to waste systems in an amount sufficient to stimulate growth of bacteria which utilize dissolved hydrogen sulfide in their metabolism. Specifically, about 2.4 lbs. nitrate oxygen per lb. of sulfide is required.

Owner:UNITED STATES FILTER CORPORATION

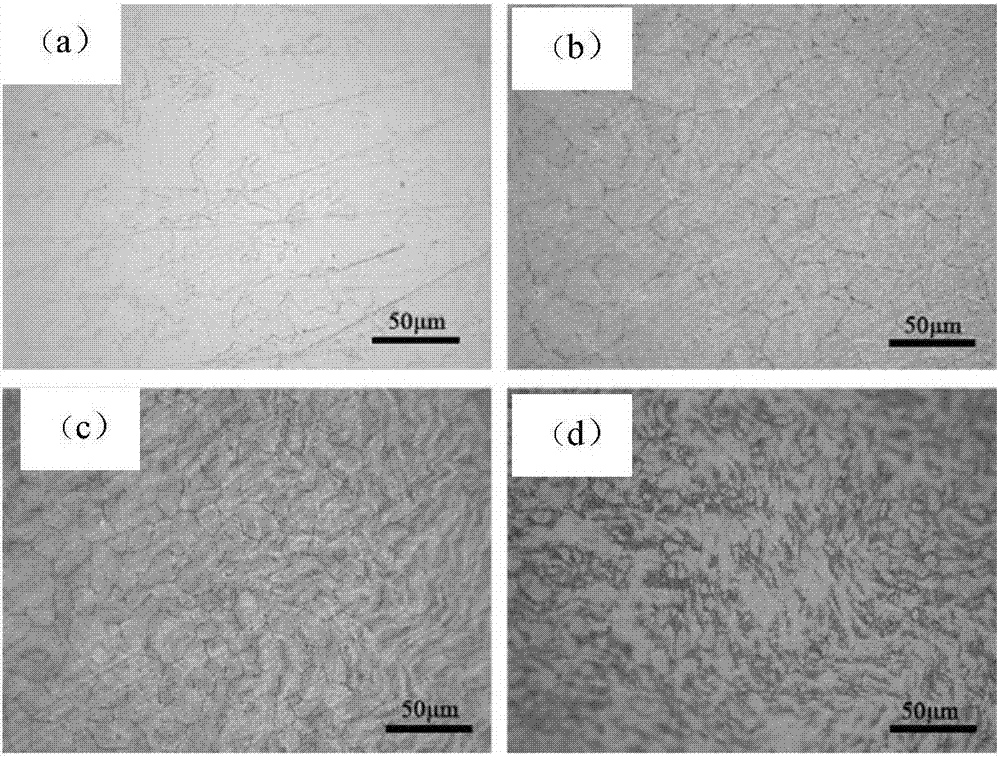

Zn-Li series zinc alloy as well as preparation method and application thereof

ActiveCN107460371AImprove mechanical propertiesHigh strengthSuture equipmentsProsthesisZinc alloysMechanical property

The invention discloses a Zn-Li series zinc alloy as well as a preparation method and application thereof. The Zn-Li series zinc alloy comprises Zn and Li; and based on weight percent, the mass percent content of the Li in the zinc alloy accounts for 0 to 30%, but not including 0. The preparation method of the Zn-Li series zinc alloy comprises the following steps: (1) mixing the Zn and the Li to obtain a mixture; (2) treating the mixture according to the following step a) or step b) and then cooling the mixture to obtain the zinc alloy: a) under the protection of a CO2 and SF6 atmosphere, carrying out smelting or sintering on the mixture; and b) under the protection of a vacuum atmosphere, dissolving hydrogen gas into the mixture and carrying out the smelting. The zinc alloy prepared by the preparation method disclosed by the invention has an excellent mechanical property and can provide a long-term effective supporting force in vivo; and the zinc alloy has excellent cellular compatibility, blood compatibility and tissue and organ compatibility and can be used for preparing biomedical implant materials.

Owner:PEKING UNIV +1

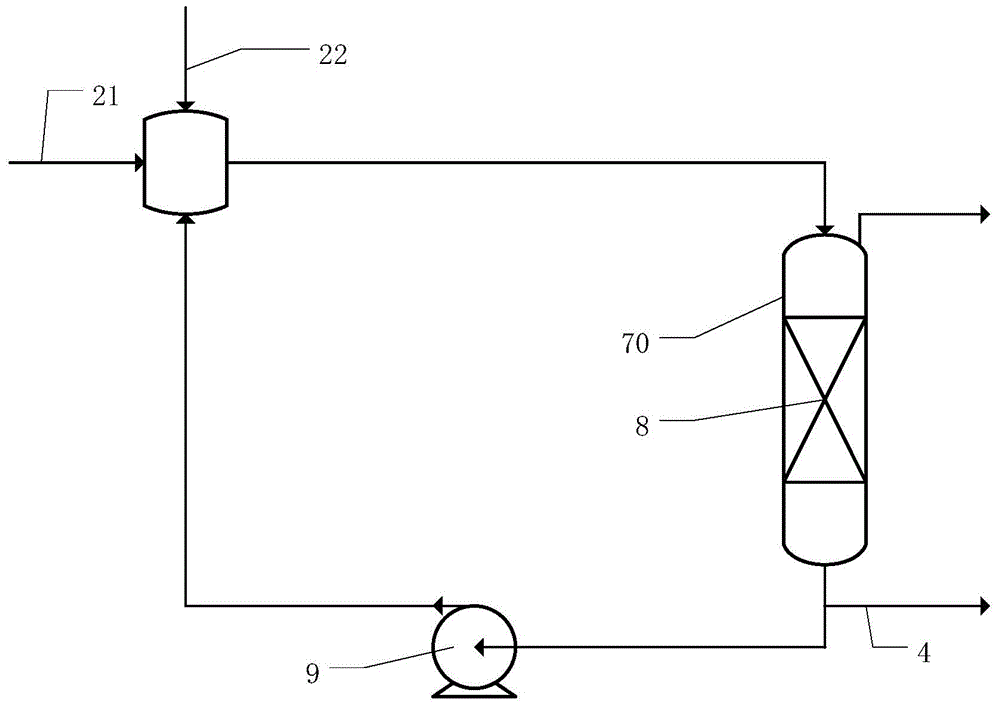

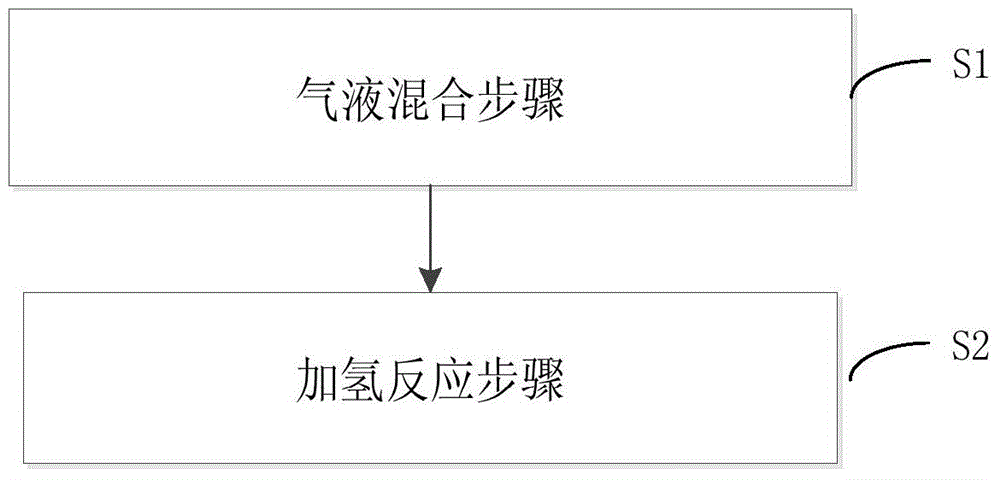

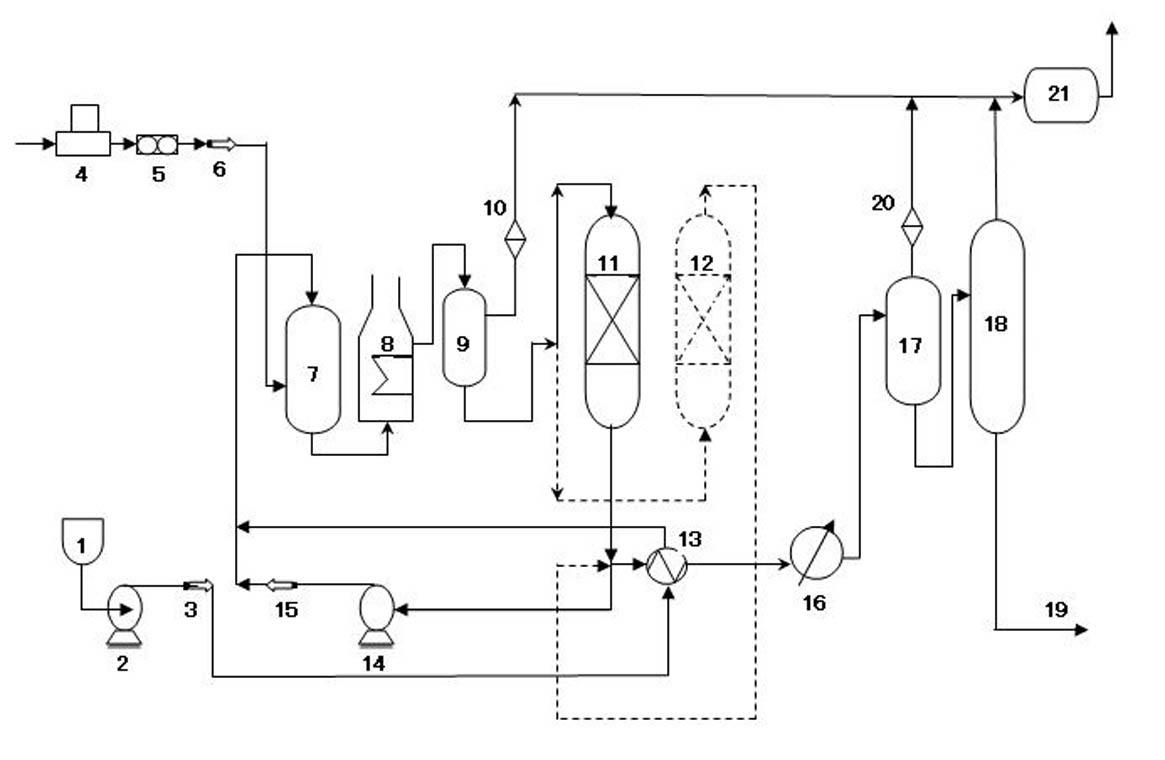

Hydrocarbon continuous liquid phase hydrogenation process method and device

ActiveCN105647577AReduce volumeThe possibility of "flying temperature" is reducedTreatment with hydrotreatment processesChemical/physical processesHydrogenation reactionHydrogenation process

The invention discloses a hydrocarbon continuous liquid phase hydrogenation process method which includes a gas-liquid mixing step, to be more specific, a liquid phase material flow is fully mixed with hydrogen to obtain a dissolved-hydrogen-saturated liquid phase material flow by use of a gas-liquid mixer; and a hydrogenation reaction step, to be more specific, the dissolved-hydrogen-saturated liquid phase material flow flowing into a reactor flows in the direction of from the top of the reactor to the bottom of the reactor for liquid phase contact reaction with every stages of catalyst bed layers, and at the same time, new hydrogen is injected into the liquid phase material flow by a hydrogen distributor so as to realize the efficient hydrocarbon reaction of the liquid phase material flow. The present invention also discloses a hydrocarbon continuous liquid phase hydrogenation device which includes one gas-liquid mixer and one multiplestage reactor, the multiplestage reactor is connected with the gas-liquid mixer, each stage of the reactor comprises at least two stages of catalyst bed layers, and one hydrogen gas distributor is arranged between adjacent catalyst bed layers,.

Owner:PETROCHINA CO LTD

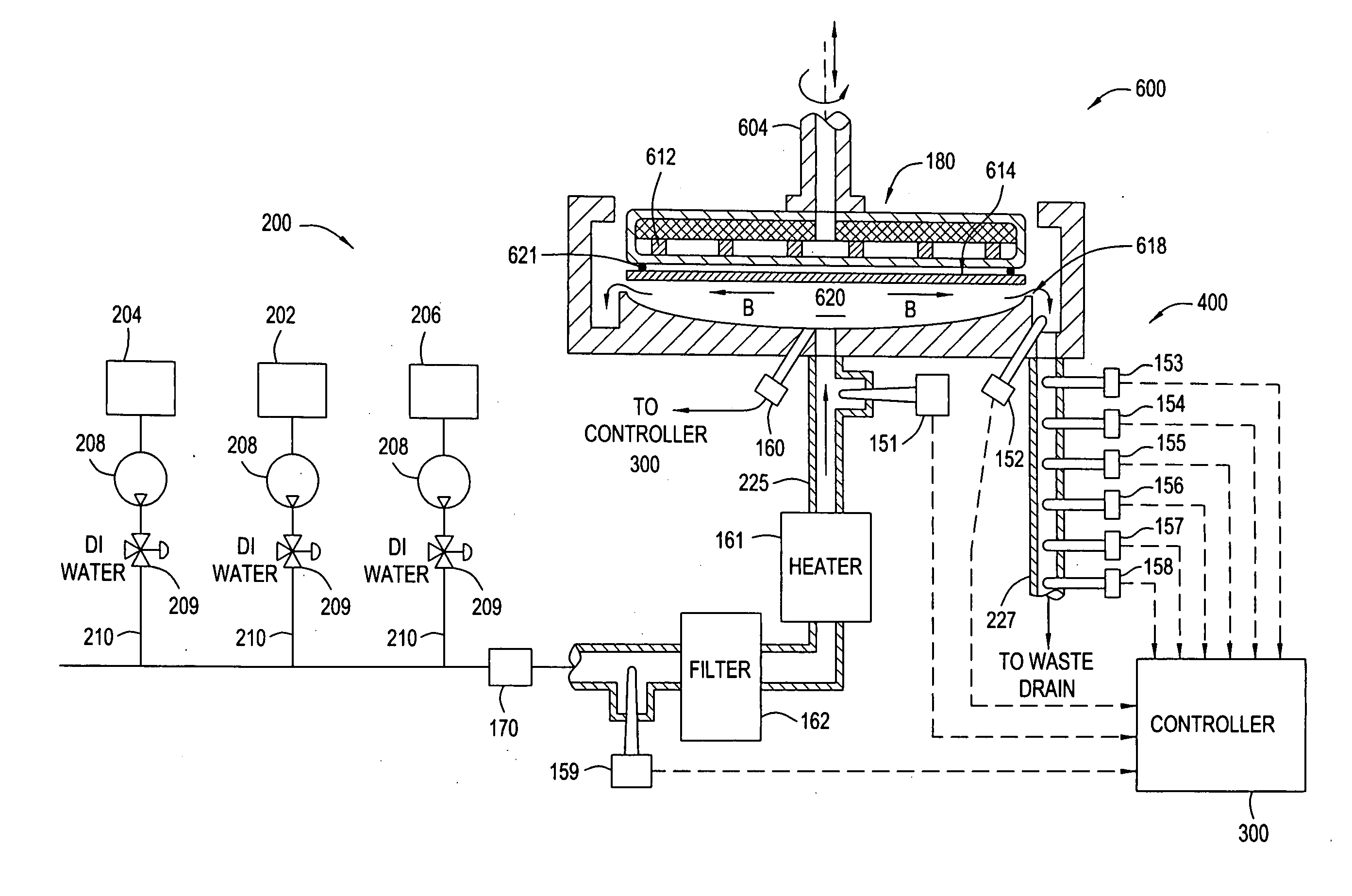

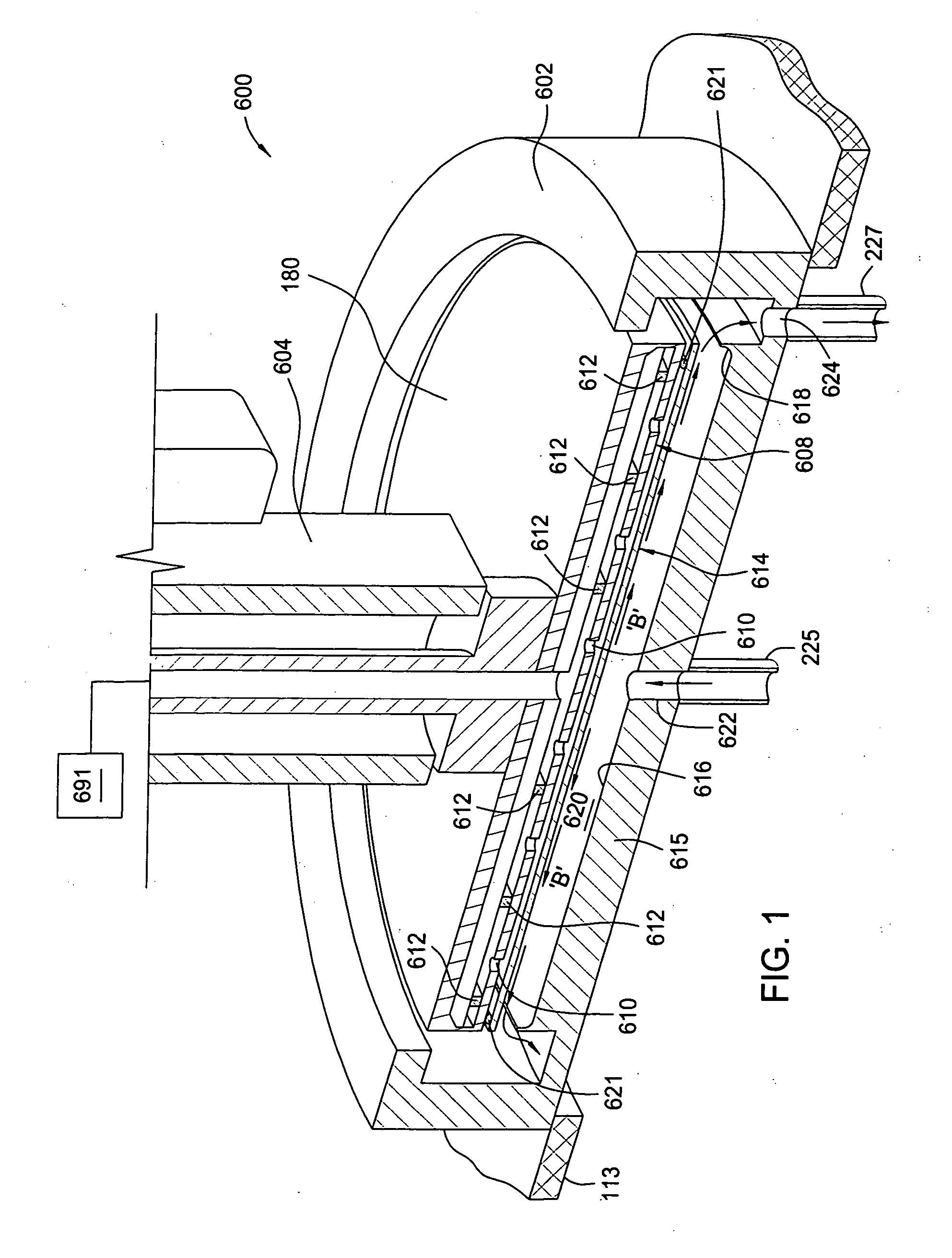

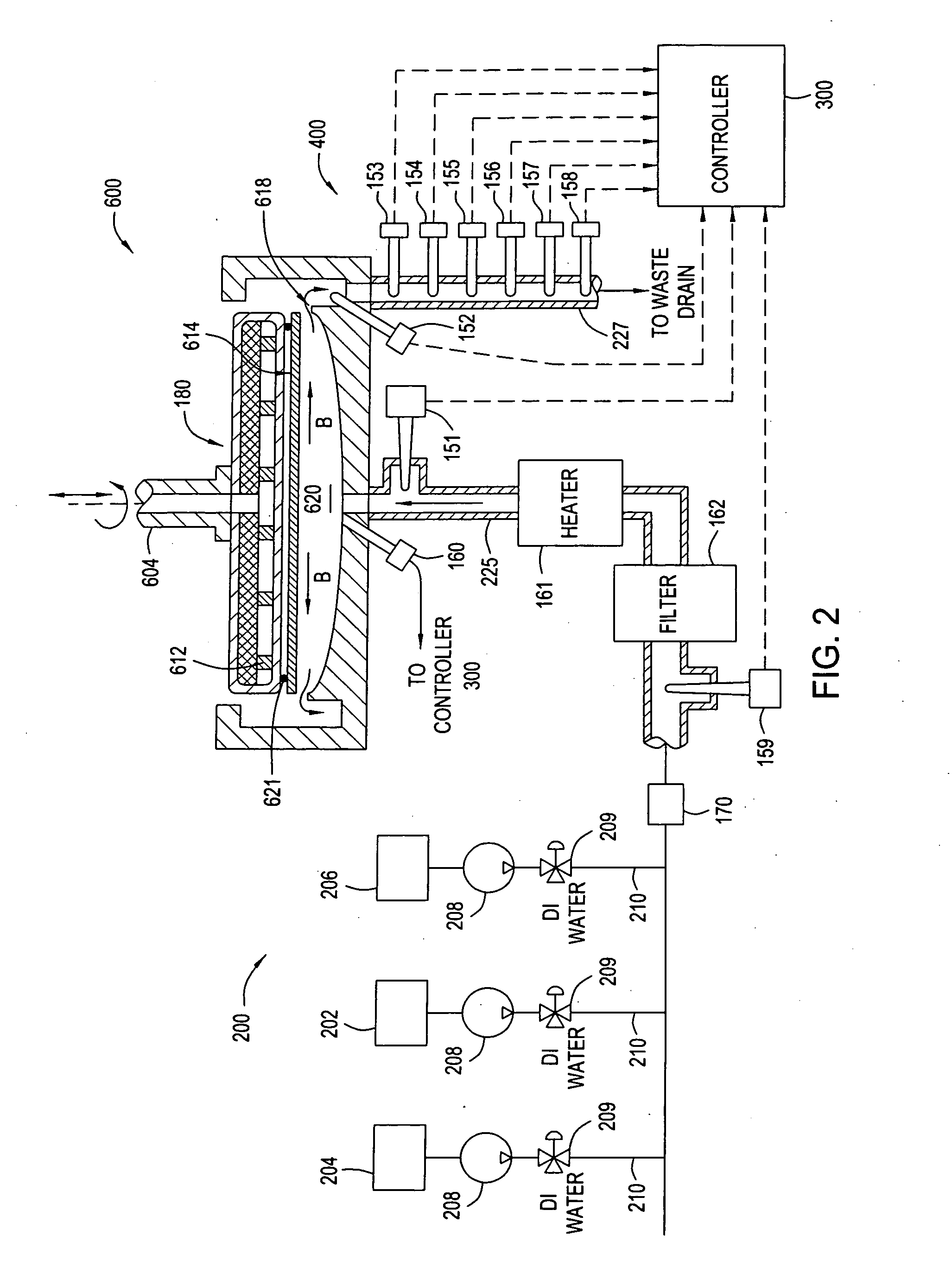

Measurement techniques for controlling aspects of a electroless deposition process

InactiveUS20050084615A1Speed up the processPretreated surfacesSemiconductor/solid-state device manufacturingElectricityOxygen sensor

Embodiments of the invention generally provide a fluid processing chamber, sensors and a controller and method for using the same. The fluid processing chamber includes an inlet region, a processing region and an outlet region. The inlet region generally contains one or more sensors and an external controller to monitor the characteristics of the processing fluid at the inlet to the processing region. The outlet region generally contains one or more sensors and an external controller to monitor the characteristics of the processing fluid leaving the processing region of the chamber. In one embodiment the processing region contains one or more sensors and an external controller to monitor the characteristics of the processing fluid in the processing region. The sensors may include, for example, an ORP probe, a temperature sensor, a conductivity sensor, a dissolved hydrogen sensor, a dissolved oxygen sensor, and a pH sensor. The fluid processing chamber is generally useful for all process steps done to deposit an electroless deposited film on a substrate including, for example, all pre-clean process steps (substrate preparation steps), all electroless activation process steps, all electroless deposition steps, and all post electroless deposition cleaning steps.

Owner:APPLIED MATERIALS INC

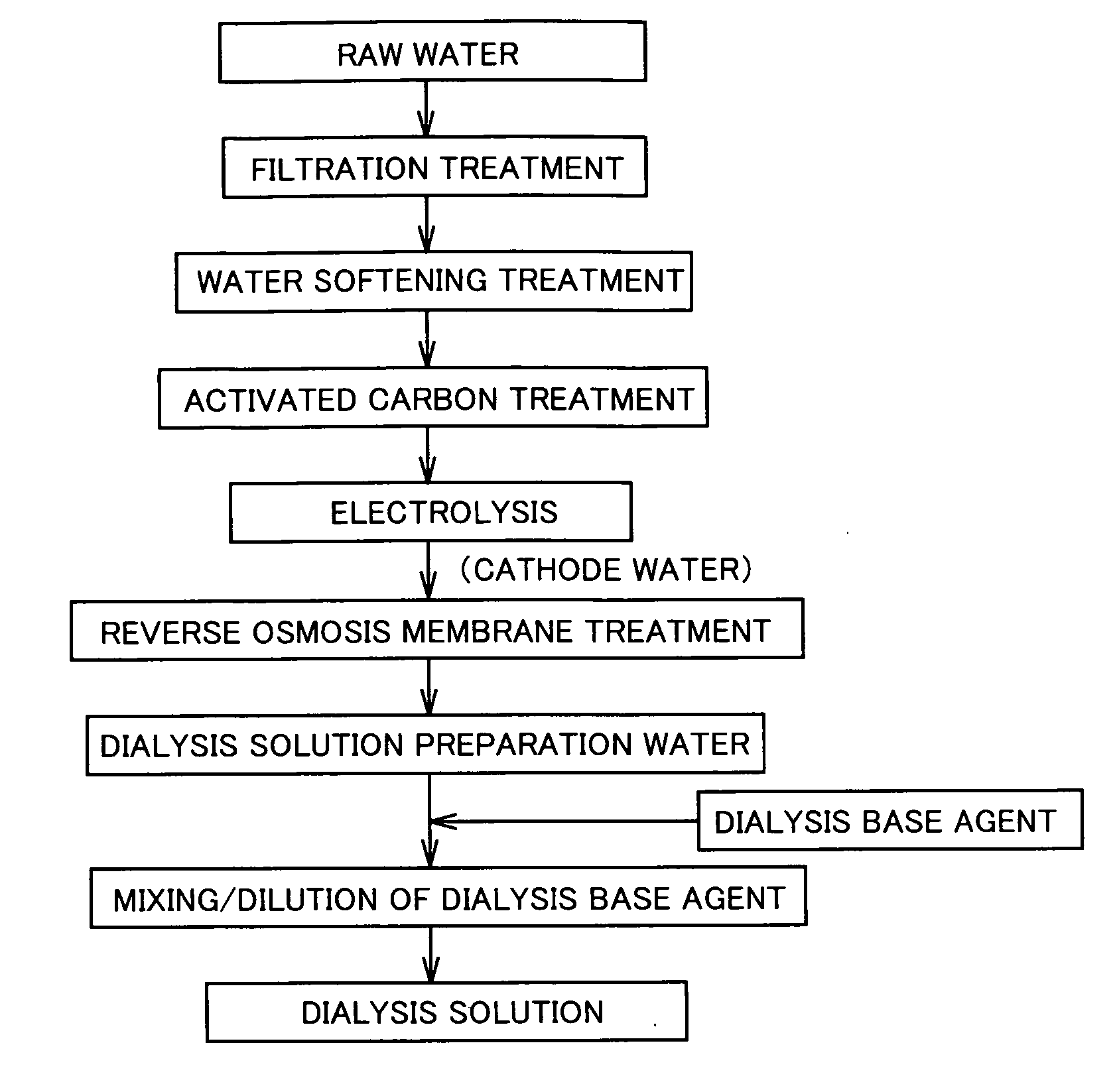

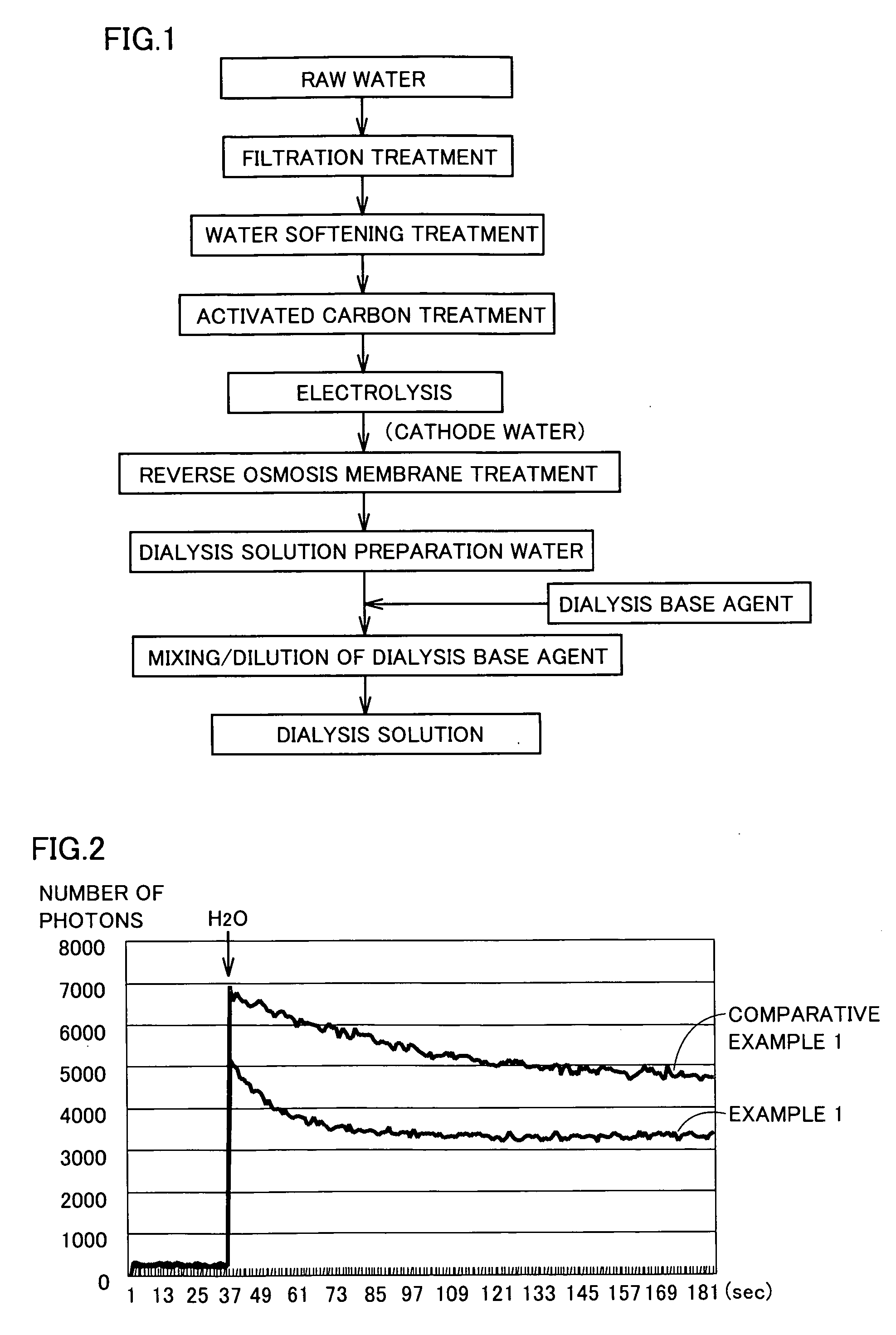

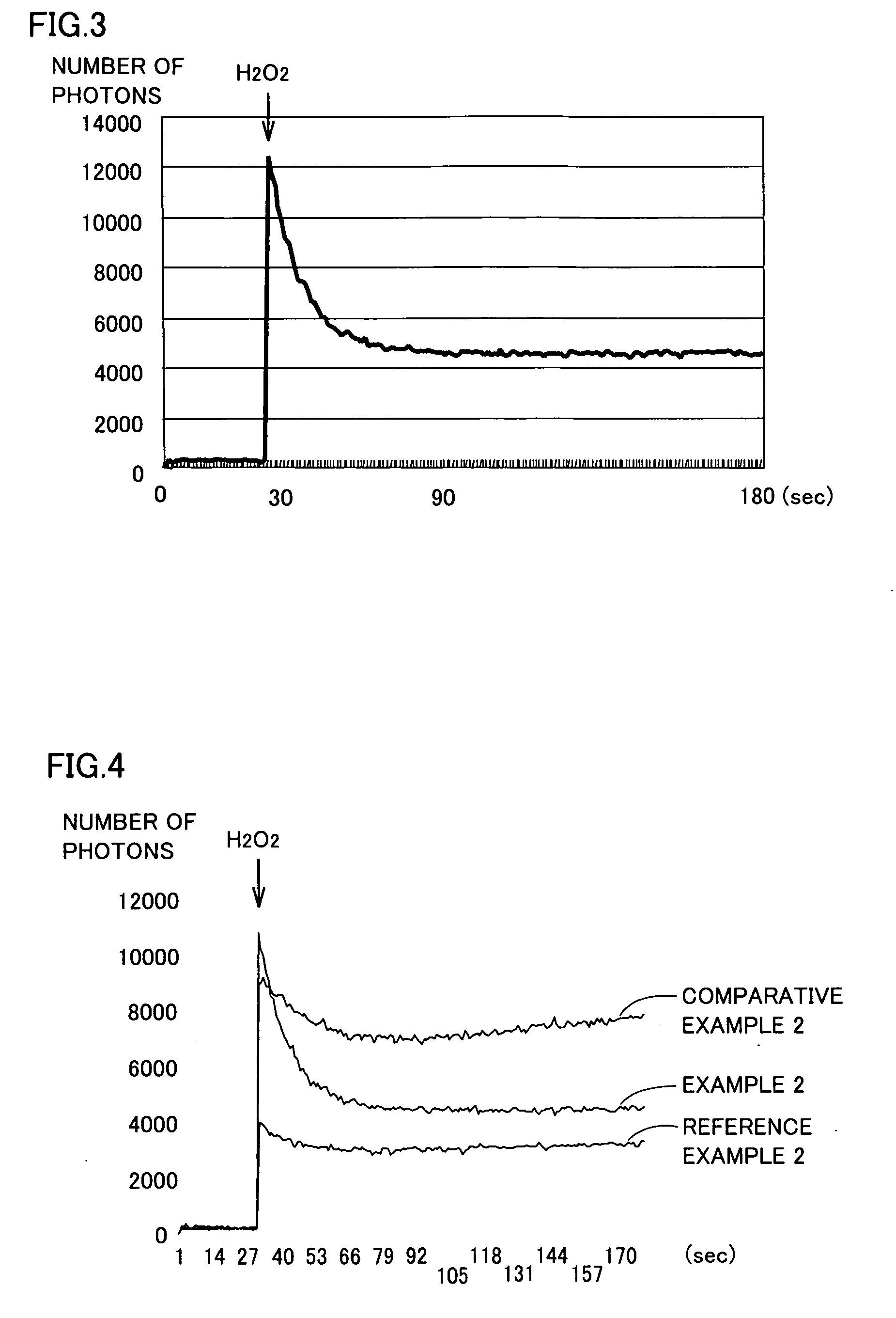

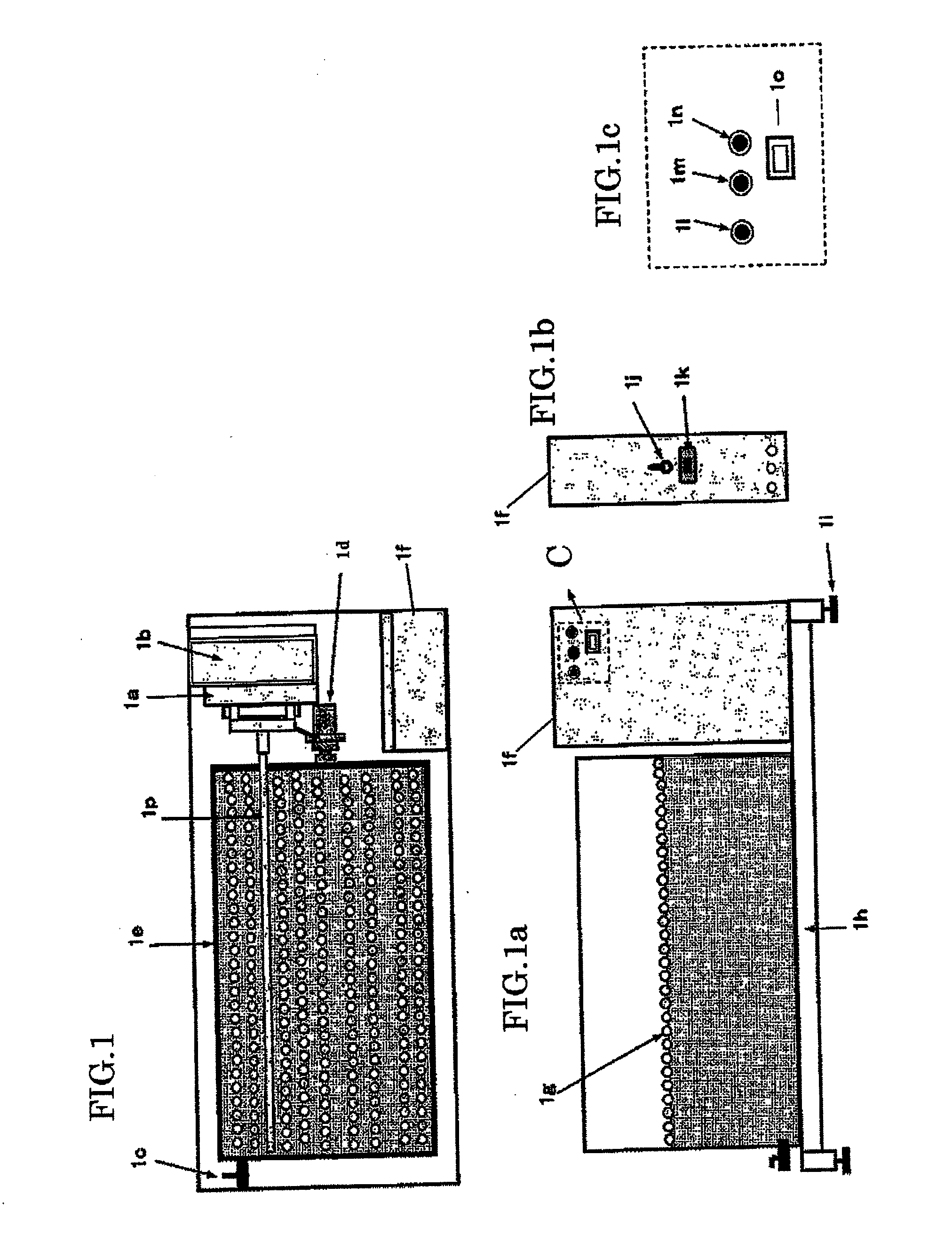

Dialysis Solution Preparation Water, Dialysis Solution Using Such Water, Method of Producing Dialysis Solution, and Dialysis Equipment

InactiveUS20090045121A1Reduce adverse effectsBiocideOrganic active ingredientsWater useBiological body

Dialysis solution preparation water having a dissolved hydrogen concentration of 50 to 600 ppb, a pH of 7 to 10, and satisfying the water quality criterion defined at ISO 13959, used to prepare a dialysis solution by diluting a dialysis base agent including at least 50 ng / mL of a glucose degradation product, a method of preparing a dialysis solution by diluting a dialysis base agent using the dialysis solution preparation water, and a dialysis solution obtained thereby. By dialysis equipment comprising means for supplying dialysis solution preparation water having a dissolved hydrogen oxygen of 50 to 600 ppb, a pH of 7 to 10, and satisfying a water quality criterion defined at ISO 13959, means for storing a dialysis base agent including at least 50 ng / mL of a glucose degradation product, and means for preparing a dialysis solution by diluting the dialysis base agent with the dialysis solution preparation water, there can be provided a dialysis solution that can prevent the adverse effect of glucose degradation products on the biological body, a dialysis solution preparation water used therefor, a method of producing a dialysis solution, and dialysis equipment.

Owner:NIKHON TRIM KO LTD

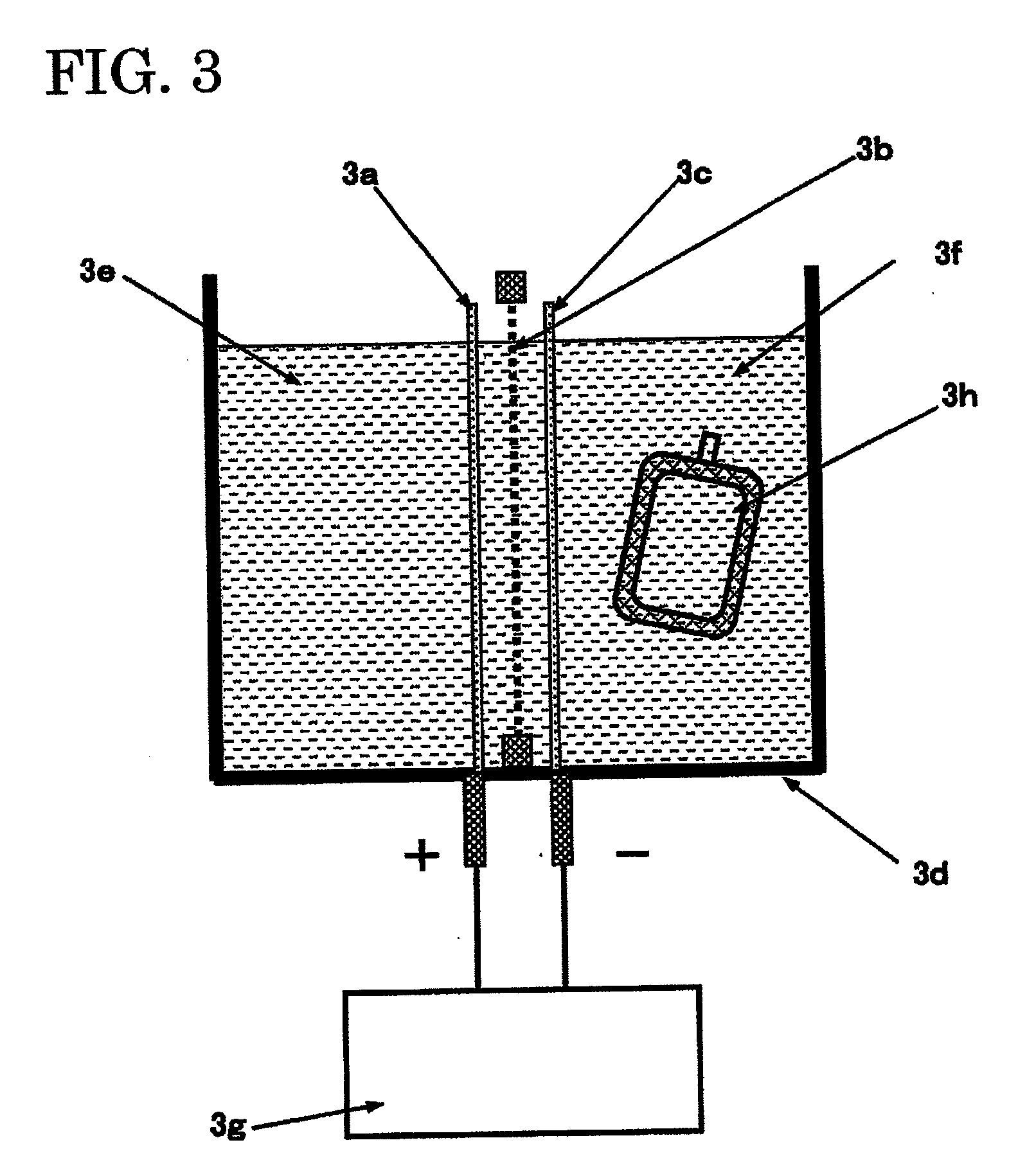

Producing method for living organism-applicable hydrogen-contained fluid and producing apparatus for the same

InactiveUS20110111048A1Without any changeEasily includedBioreactor/fermenter combinationsSenses disorderBiological bodySaline water

A producing method for a living organism-applicable hydrogen-contained fluid, which includes hydrogen molecules in living organism-applicable fluid enclosed in a container (2i) with hydrogen molecule permeability, is provided. This method includes a hydrogen exposing step of exposing hydrogen molecules to the container (2i) in which the living organism-applicable fluid is enclosed from the outside of the container without opening the container. The container with hydrogen molecule permeability is one that allows a dissolved hydrogen concentration of a normal saline solution to be 1 ppb or greater when the container filled with the normal saline solution is immersed for 5 hours in a volume of hydrogen water, which stably maintains an approximately saturated state (1.6 ppm at 20 C degrees under 1 barometric pressure) and is 20 times the content volume of the container.

Owner:MIZ CO LTD

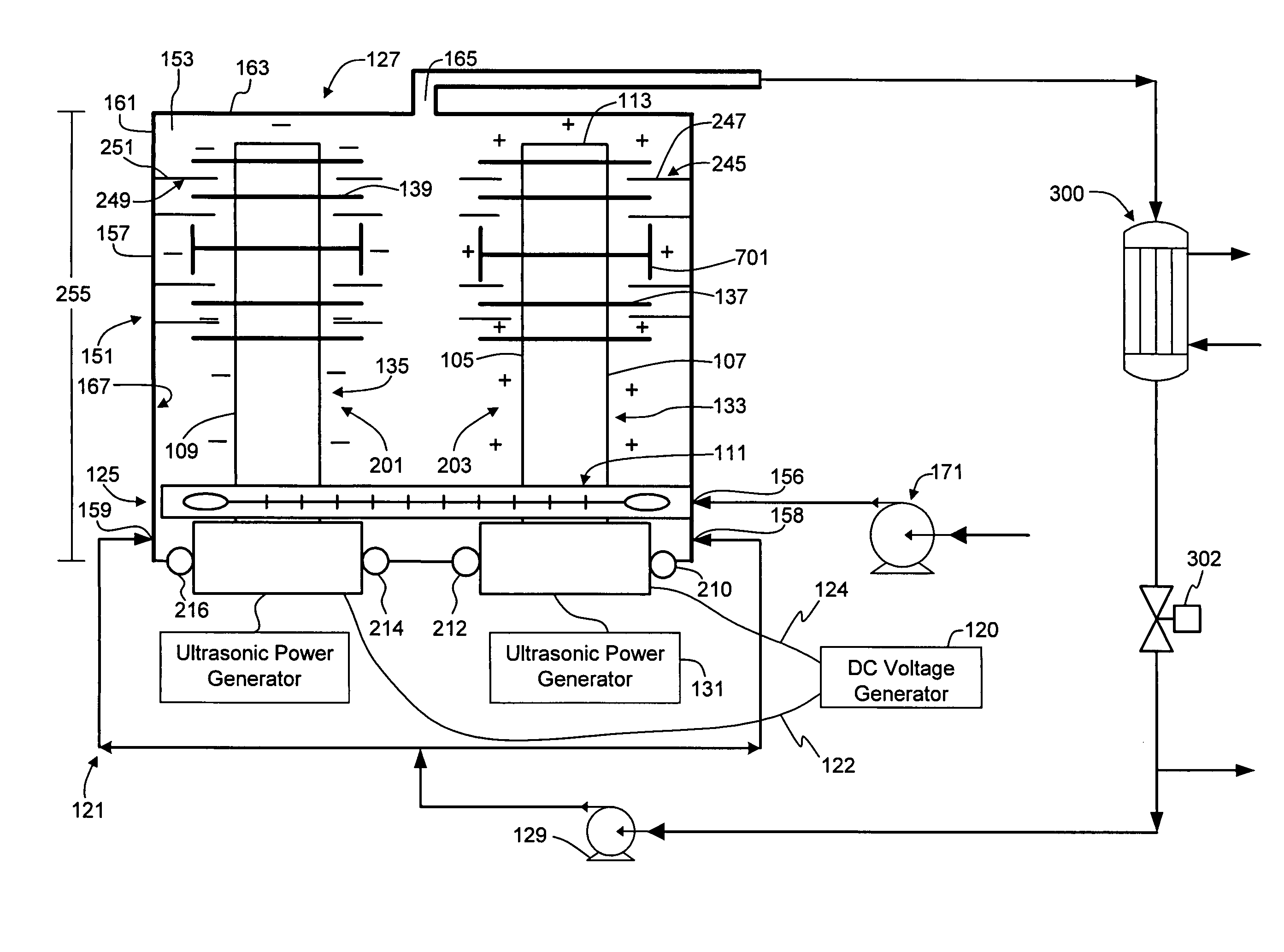

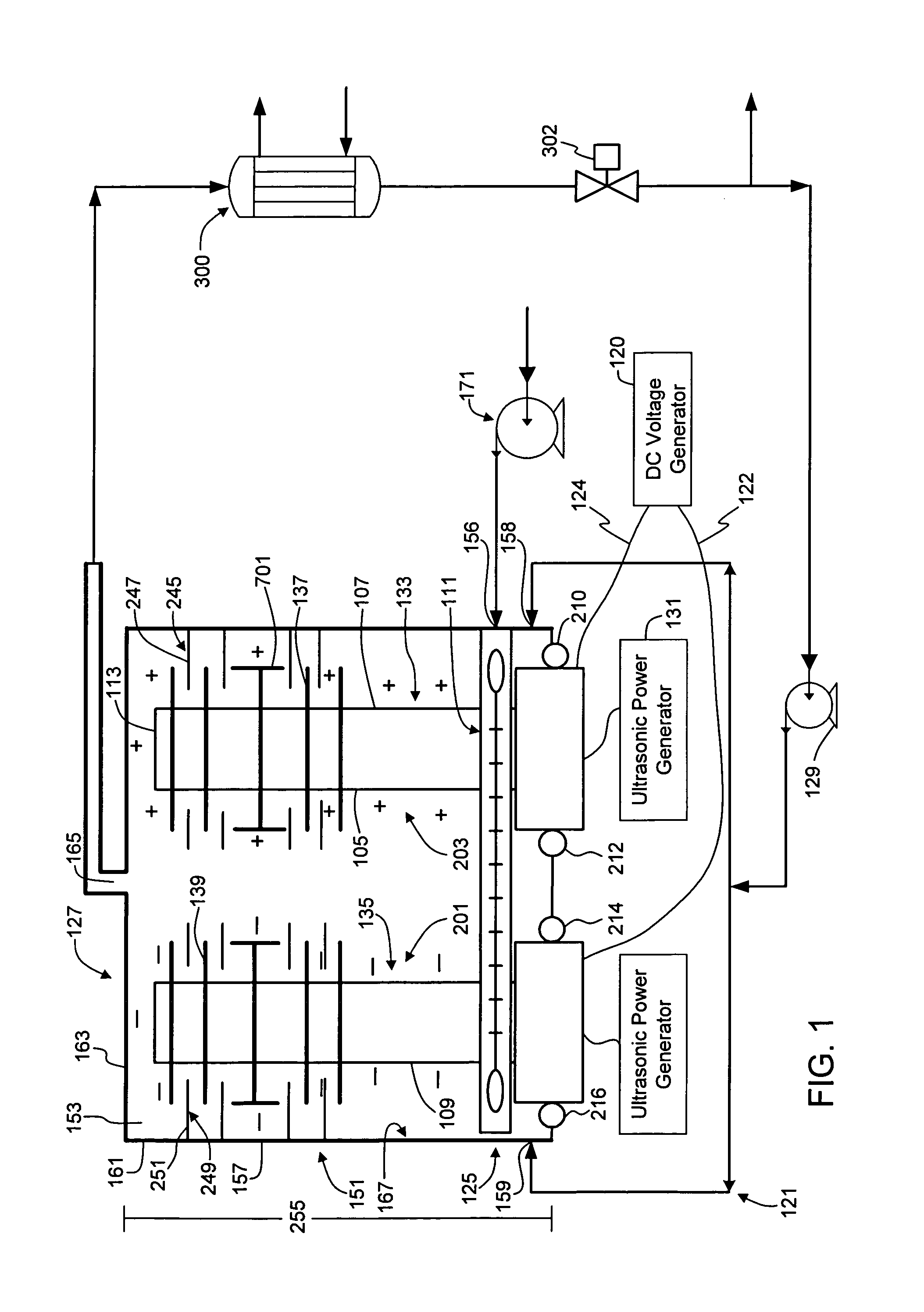

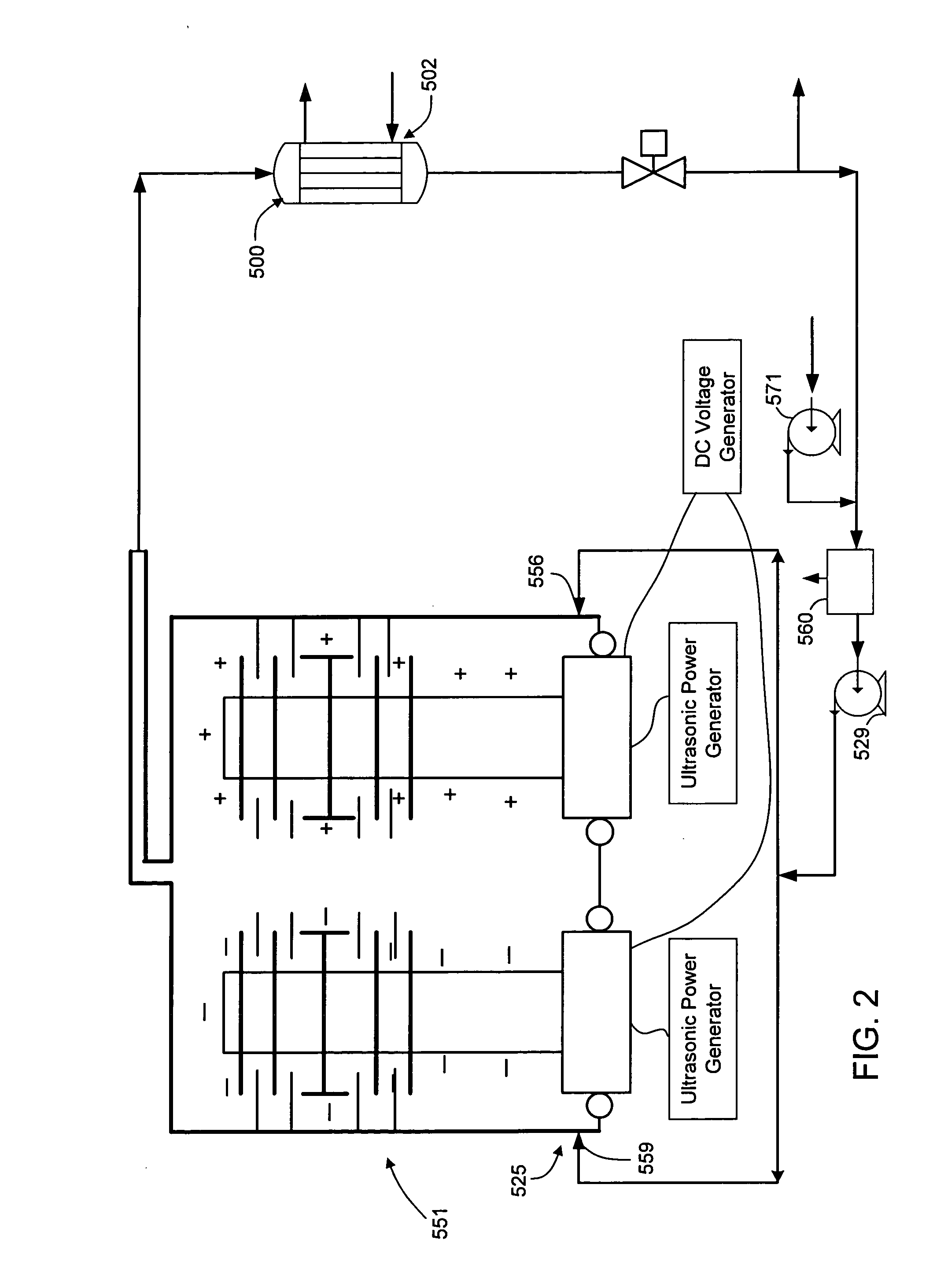

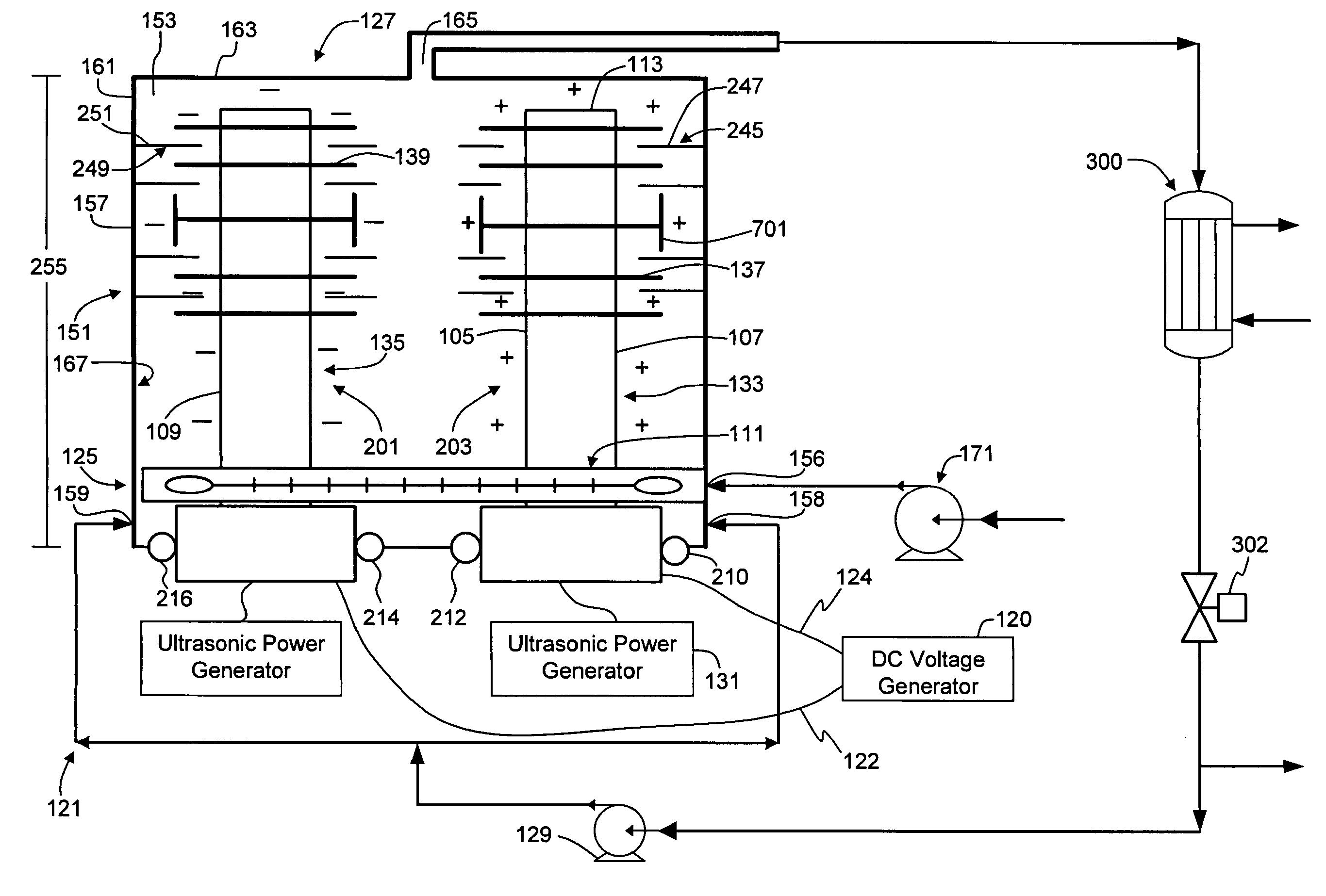

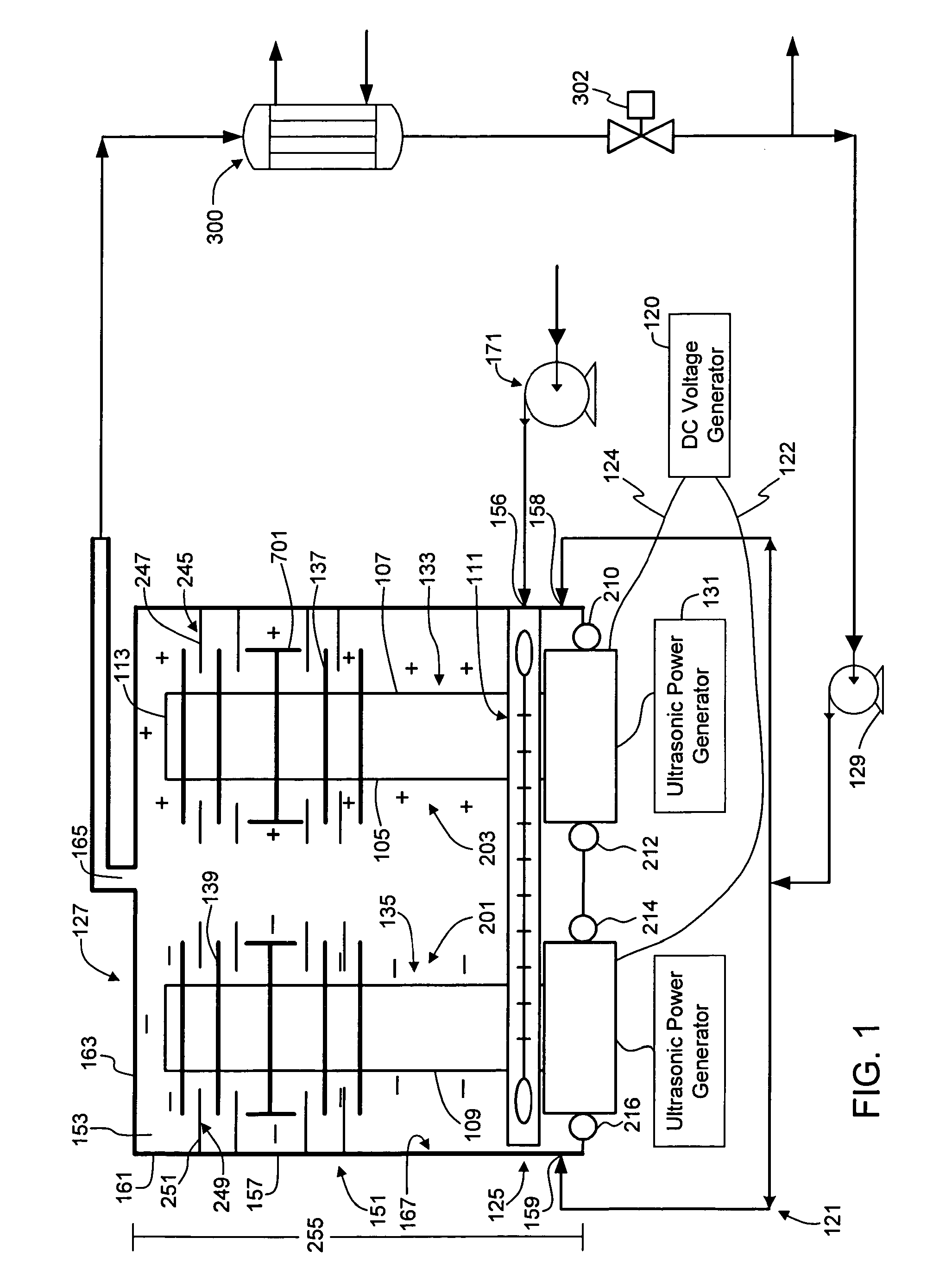

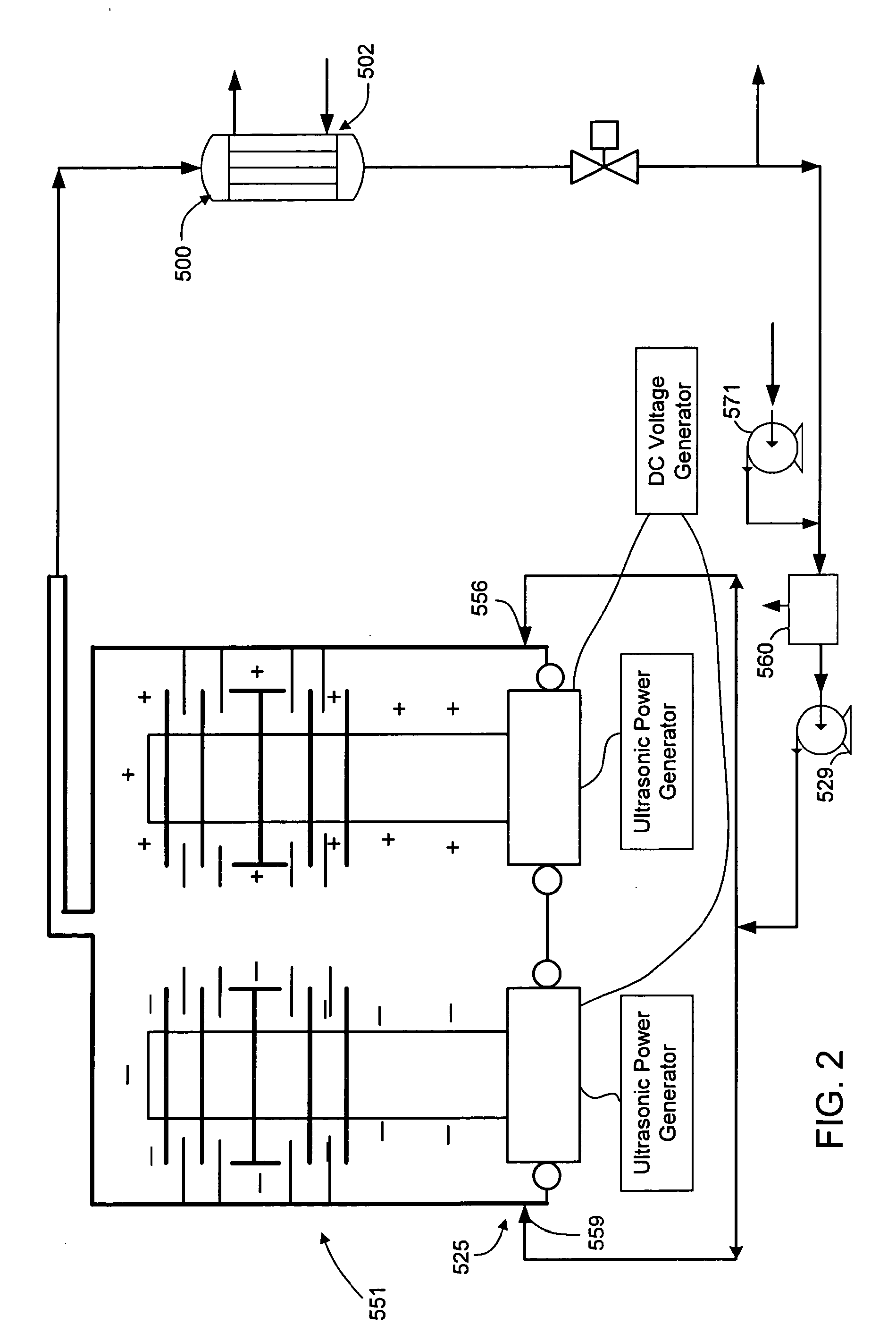

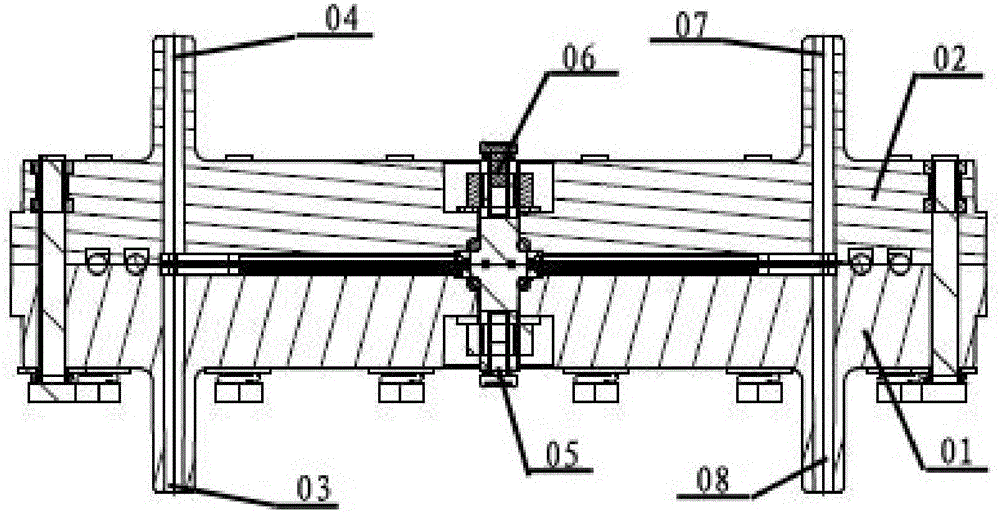

Ultrasonic treatment chamber for initiating thermonuclear fusion

InactiveUS20090147905A1Nuclear energy generationLow temperature fusion reactorElectrode potentialUltrasonic cavitation

A thermonuclear fusion system having a treatment chamber in which gas isotopes are fused to initiate a thermonuclear fusion reaction is disclosed. Specifically, the treatment chamber has an elongate housing through which liquid and gas isotopes flow longitudinally from an inlet port to an outlet port thereof. An elongate ultrasonic waveguide assembly extends within the housing and is operable at a predetermined ultrasonic frequency and a predetermined electrode potential to ultrasonically enhance the concentration of dissolved hydrogen gas isotopes within the housing or energize and electrolyze the liquid and gas isotopes within the housing. An elongate ultrasonic horn of the waveguide assembly is disposed at least in part intermediate the inlet and outlet ports, and has a plurality of discrete agitating members in contact with and extending transversely outward from the horn intermediate the inlet and outlet ports in longitudinally spaced relationship with each other. The horn and agitating members are constructed and arranged for dynamic motion of the agitating members relative to the horn at the predetermined frequency and to operate in an ultrasonic cavitation mode of the agitating members corresponding to the predetermined frequency and the liquid and gas isotopes being treated in the chamber.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Ultrasonic treatment chamber for treating hydrogen isotopes

A system is disclosed for treating hydrogen isotopes. Specifically, the system includes a treatment chamber that has an elongate housing through which liquid and gas isotopes flow longitudinally from an inlet port to an outlet port thereof. An elongate ultrasonic waveguide assembly extends within the housing and is operable at a predetermined ultrasonic frequency and a predetermined electrical potential to ultrasonically enhance the concentration of dissolved hydrogen gas isotopes within the housing or energize and electrolyze the liquid and gas isotopes within the housing. An elongate ultrasonic horn of the waveguide assembly is disposed at least in part intermediate the inlet and outlet ports, and has a plurality of discrete agitating members in contact with and extending transversely outward from the horn intermediate the inlet and outlet ports in longitudinally spaced relationship with each other.

Owner:KIMBERLY-CLARK WORLDWIDE INC

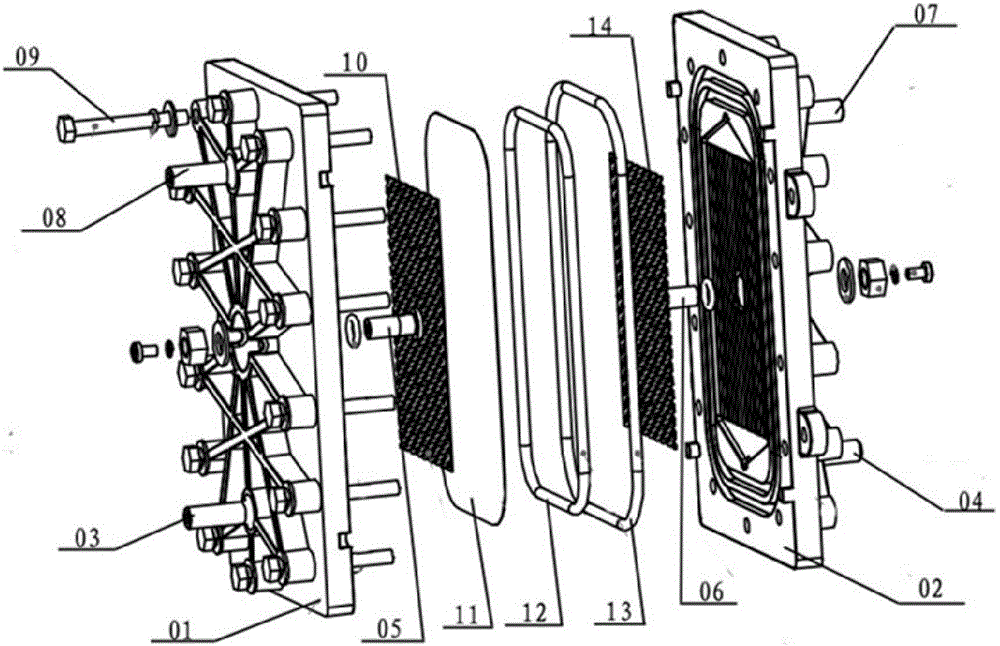

Hydrogen-rich water electrolytic bath

InactiveCN106365260AIncrease water pressureImprove solubilityWater/sewage treatment by substance additionWater/sewage treatment apparatusElectrolysisWater quality

The invention discloses a hydrogen-rich water electrolytic bath. The electrolytic bath is formed by an anode chamber and a cathode chamber which are formed inside an anode housing and a cathode housing which are fixed by screws; the anode chamber and the cathode chamber are separated by an ion exchange membrane; the anode chamber is connected with an anode water inlet and an anode water outlet which are formed on the anode housing; the cathode chamber is connected with a cathode water inlet and a cathode water outlet which are formed on the cathode housing; narrow flow passages for water to pass through are respectively formed inside the anode housing and the cathode housing; an anode electrode plate and a cathode electrode plate are respectively arranged inside the anode chamber and the cathode chamber; the cathode electrode plate is connected with a cathode interface formed on the cathode housing; the anode electrode plate is connected with an anode interface formed on the anode housing. The technical scheme disclosed by the invention can effectively improve concentration of dissolved hydrogen generated by electrolysis in water, and meanwhile, also improves water quality of the water.

Owner:康亦健(集团)有限公司

Zn-Cu series zinc alloy as well as preparation method and applications thereof

ActiveCN107456601AGood biocompatibilityGood blood compatibilitySuture equipmentsCoatingsCorrosionDissolved hydrogen

The invention discloses Zn-Cu series zinc alloy as well as a preparation method and applications of the Zn-Cu series zinc alloy. The Zn-Cu series zinc alloy comprises Zn and Cu, specifically, the weight percentage of Cu in the Zn-Cu series zinc alloy is 0-30 %, but is not 0. The preparation method comprises the following steps: (1) mixing Zn and Cu, thus obtaining a mixture; (2) carrying out treatment on the mixture according to the following step (a) or (b), and carrying out cooling, thus obtaining the Zn-Cu series zinc alloy: (a) carrying out smelting or sintering on the mixture under the protection of the atmosphere of CO2 and SF6; and (b) under the protection of vacuum atmosphere, dissolving hydrogen in the mixture, and carrying out smelting. The prepared Zn-Cu series zinc alloy has the suitable mechanical property, adjustable corrosion rate, good cell compatibility, good blood compatibility and excellent antibacterial property, and can be used for preparing biomedical implantation materials.

Owner:湖南华翔医疗科技有限公司

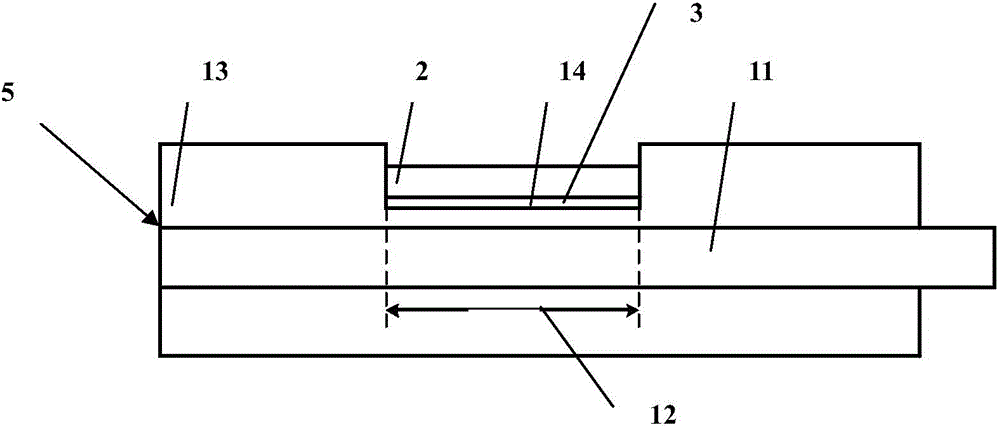

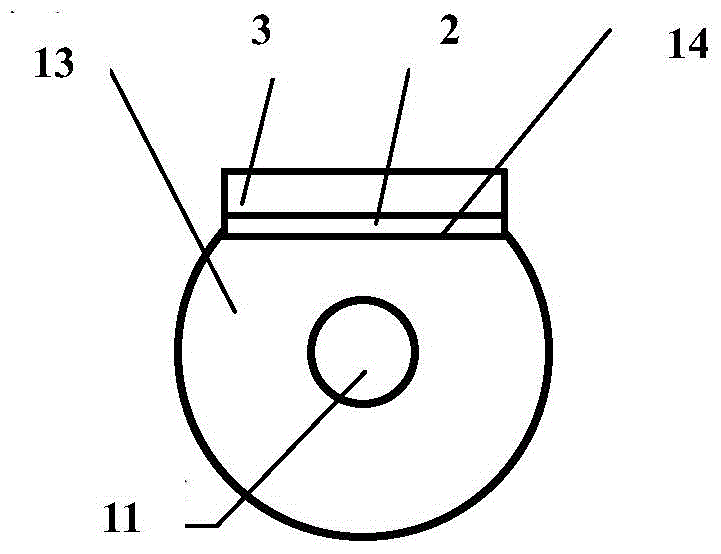

Dissolved hydrogen limited value sensor in power transformer oil and detection system

InactiveCN104406885AKnow the concentrationAvoid influenceMaterial analysisGratingInterference resistance

The invention discloses a dissolved hydrogen limited value sensor in power transformer oil and a detection system. The dissolved hydrogen limited value sensor comprises an optical fiber, wherein a grating is engraved on a fiber core of the optical fiber; a region, which corresponds to the grating, on the optical fiber is an optical fiber grating region; one side surface of a wrapping layer of the optical fiber grating region is polished into a planar polished surface; a hydrogen sensitive metal layer is attached to the polished surface. The limited value sensor is high in sensitivity and high in timeliness; once the concentration of dissolved hydrogen reaches a limited value, the wavelength change amount quickly reaches the limited value, so that a worker can timely and effectively find a fault to prevent further development of the fault. By adoption of an optical signal, the influence on a measurement result due to a complicated environment in a transformer can be avoided, the interference resistance is high, a detection signal is a wavelength, and the influence caused bv the factors such as the intensity of a light source signal, aging of a detector and connection loss is avoided. The dissolved hydrogen limited value sensor is simple in structure and is prepared based on the optical fiber; the diameter is small, and the limited value sensor is easily arranged in the transformer oil and convenient for detection; furthermore, normal operation of the transformer cannot be affected, and the limited value sensor is suitable for on-site application of the transformer.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

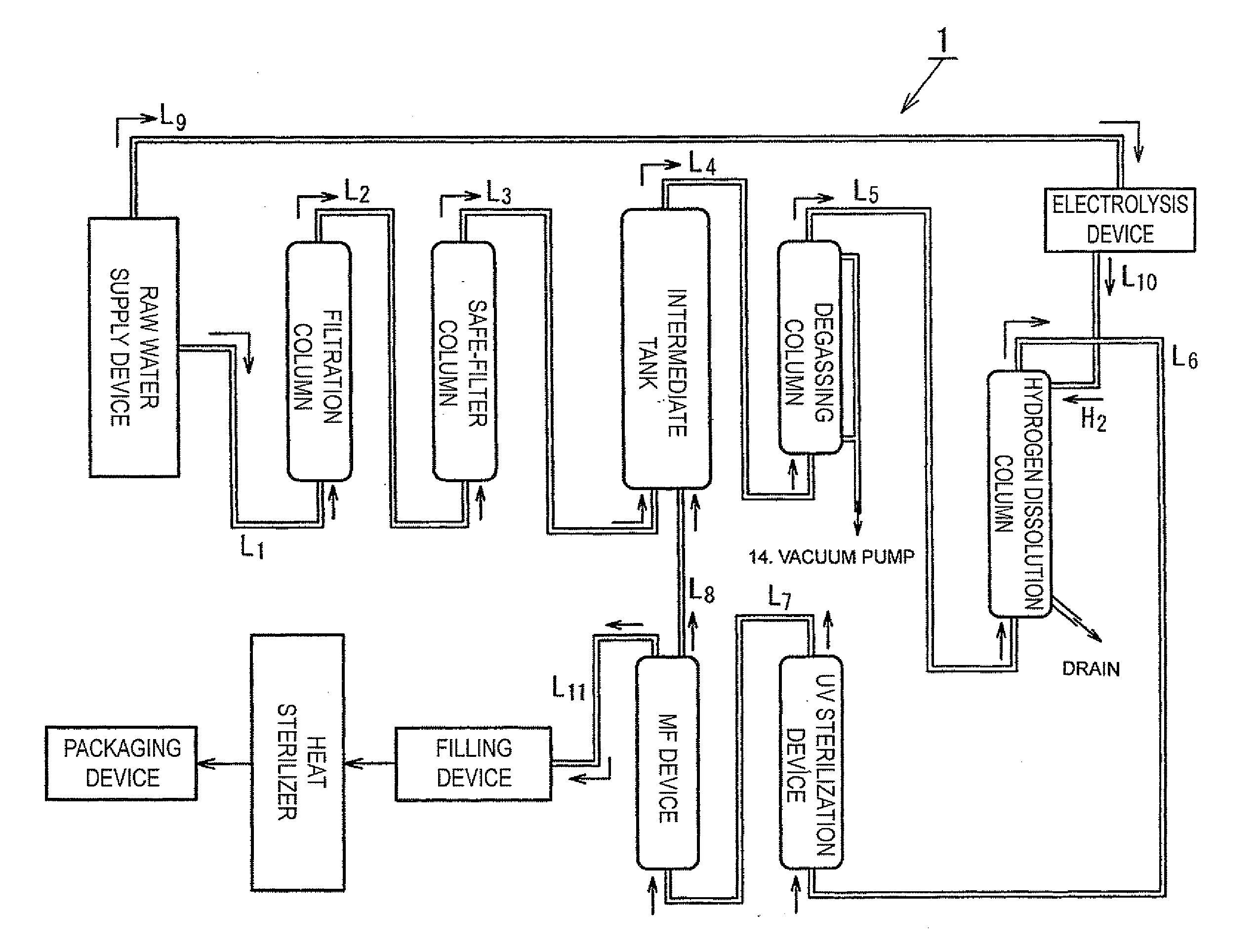

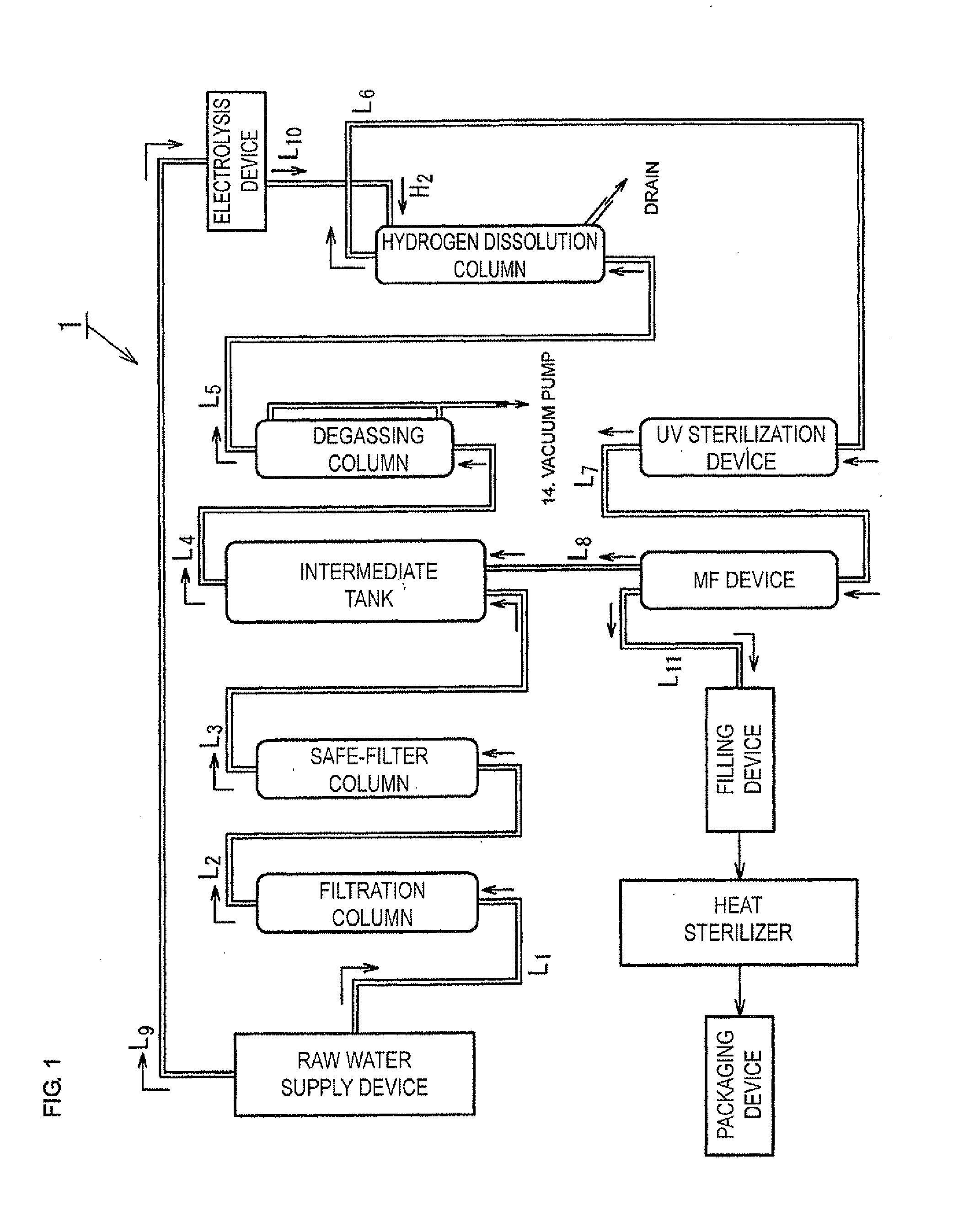

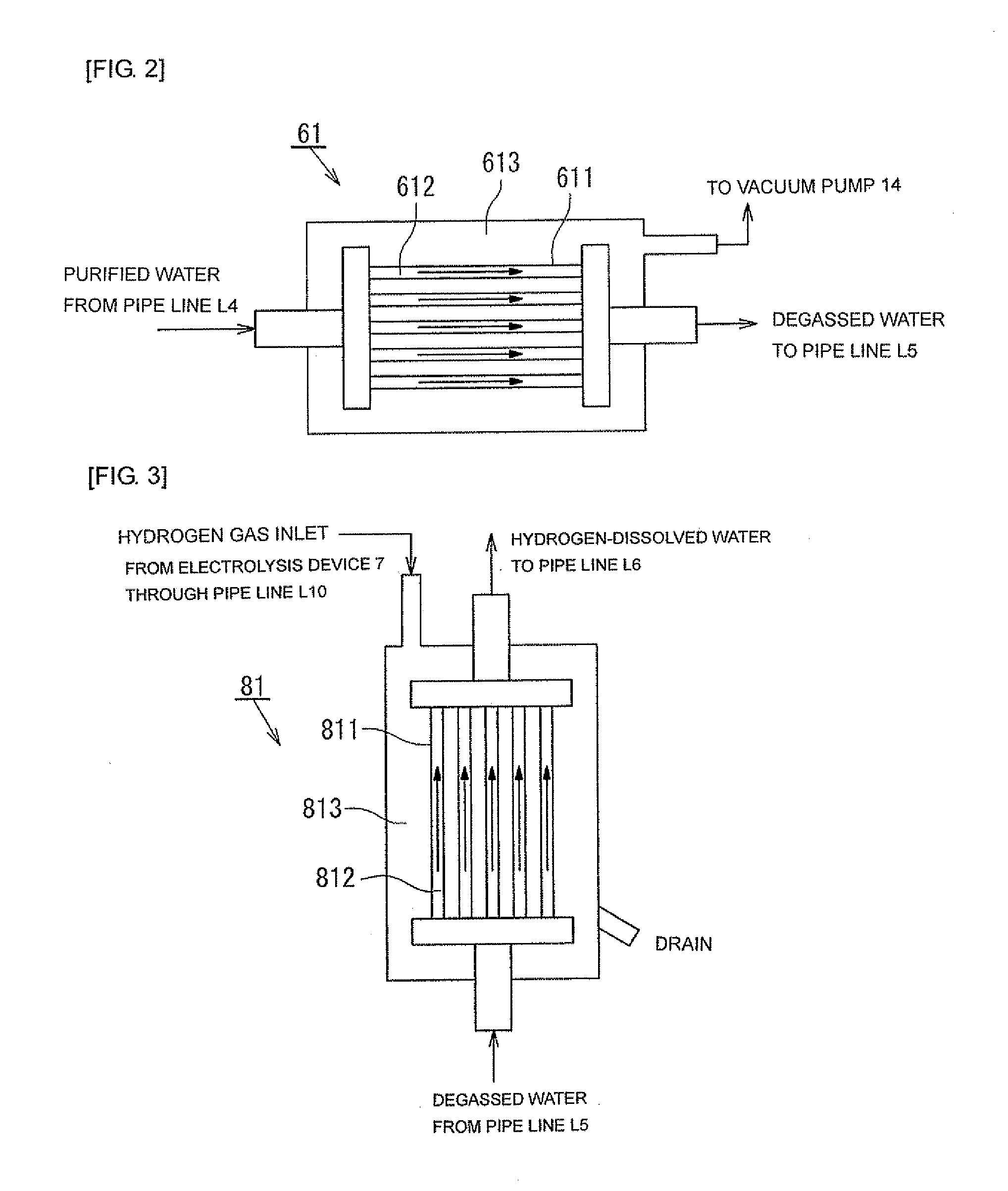

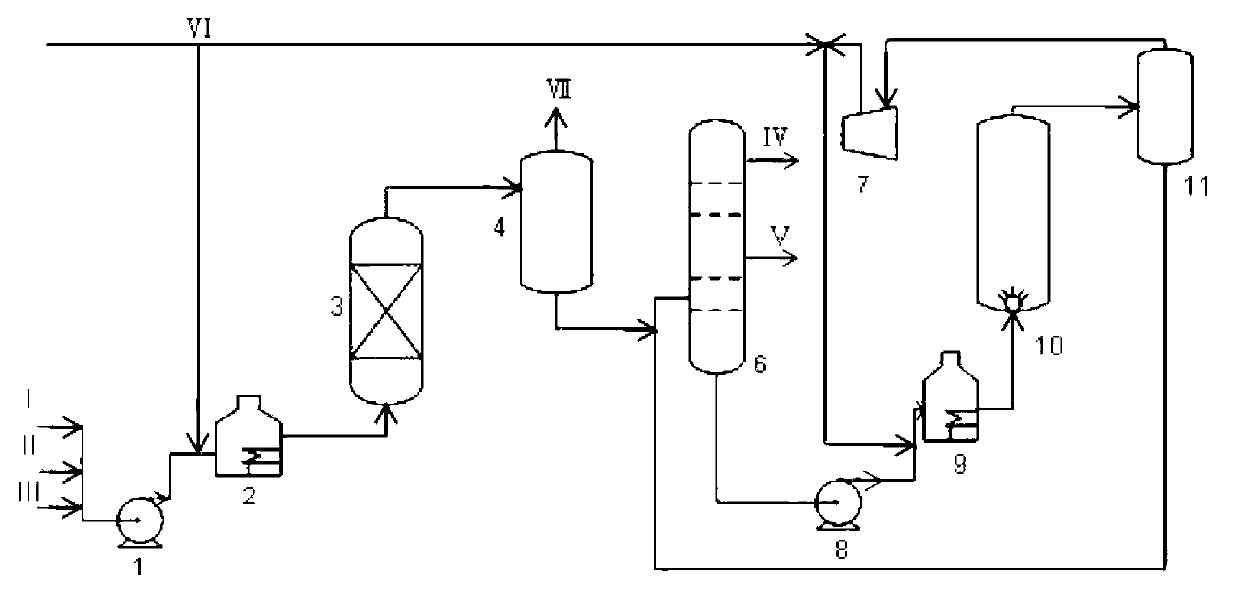

Process for producing hydrogen-containing water for drinking

InactiveUS20120070540A1Efficiently dissolving hydrogenEffective dissolutionFlow mixersLiquid degasification by filtrationDegasserDissolution

There is provided a process for producing hydrogen-containing water for drinking, by which the dissolved hydrogen concentration of the obtained hydrogen water can be more efficiently increased. A process for continuously producing hydrogen-containing water for drinking, comprising (a) a purifying step of filtering and purifying water as a raw material; (b) a degassing step of degassing the purified water supplied to a degasser; (c) a hydrogen-dissolving step of dissolving hydrogen gas in the degassed water supplied to a hydrogen dissolution device; (d) a sterilizing step of sterilizing the hydrogen-dissolved water supplied to a sterilizer; (e) a filling step of filling the hydrogen-containing water supplied to a filling device in a sealed container and transferring the filled water product to a heat sterilizer; and (f) a heat-sterilizing step of heat-sterilizing the water product supplied to the heat sterilizer, wherein part of the hydrogen-containing water obtained in the step (d) is returned to the degasser in the step (b) and the water is circulated through the steps (b) to (d).

Owner:SHEFCO

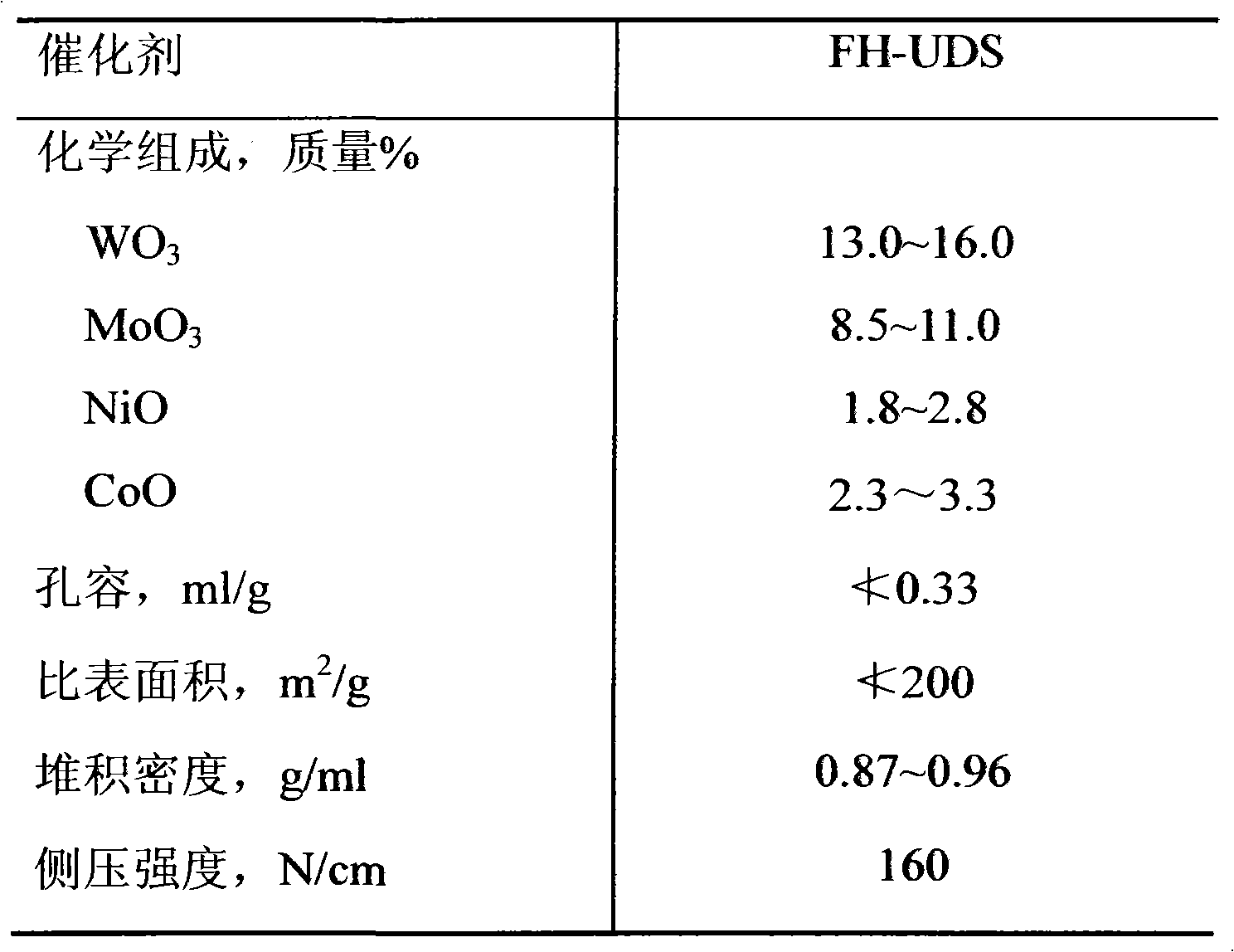

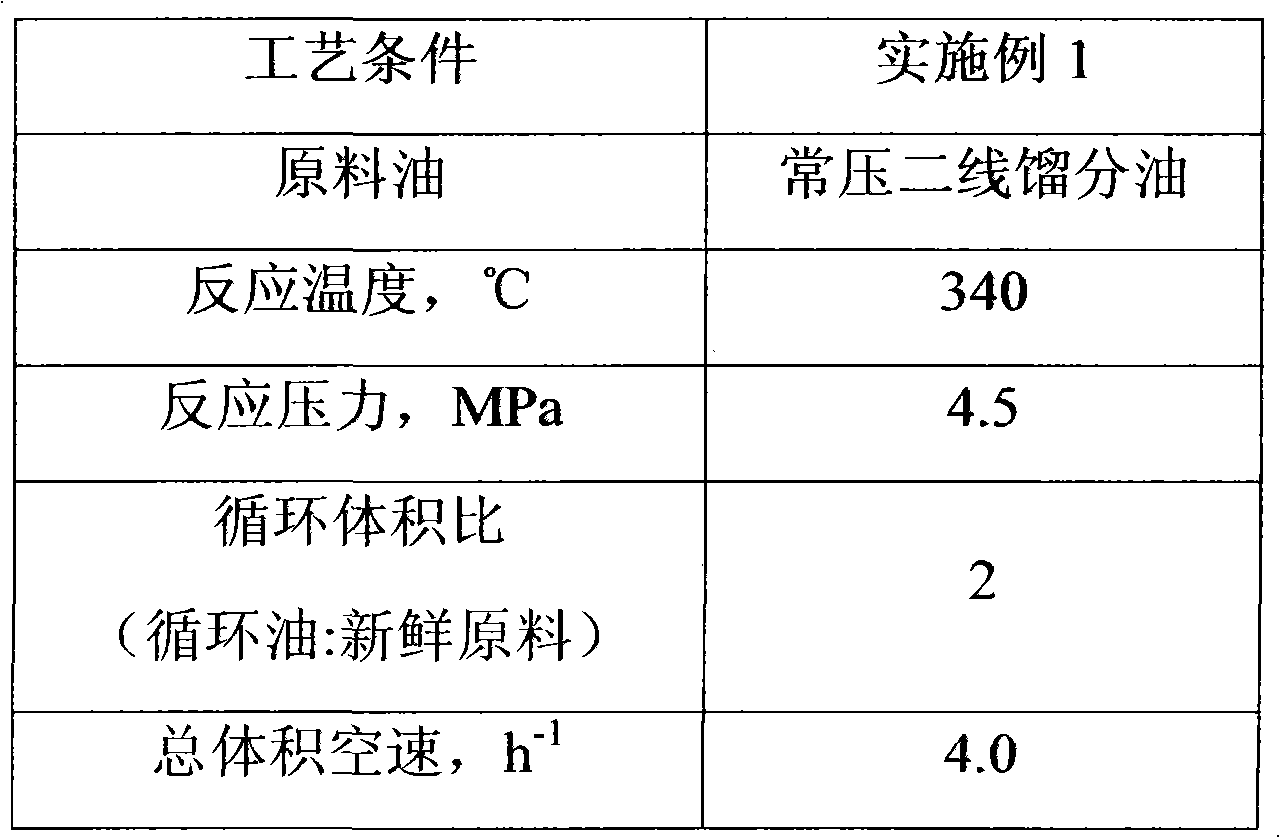

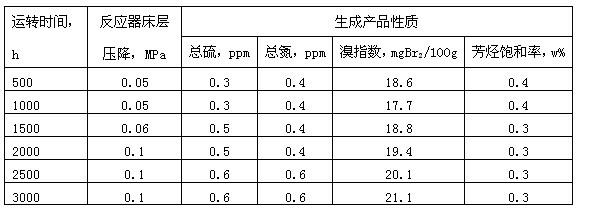

Residual oil hydrotreating method

ActiveCN103773429AReduce differential pressureSmall circulation resistanceRefining to eliminate hetero atomsPtru catalystHydrogenation reaction

Owner:CHINA PETROLEUM & CHEM CORP +1

Sulfidizing agent supply method for use in catalyst wet sulfidizing process

ActiveCN102049318AFacilitate vulcanization operationCatalyst activation/preparationRefining to eliminate hetero atomsHydrogenation reactionStart up

The invention discloses a sulfidizing agent supply method for use in a catalyst wet sulfidizing process, which comprises the following steps of: arranging a hydrogen sulfide generator; allowing a sulfidizing agent and hydrogen gas to enter the hydrogen sulfide generator; reacting the hydrogen gas and the sulfidizing agent under the hydrogen sulfide generating conditions so as to generate a hydrogen sulfide-containing material; introducing the hydrogen sulfide-containing material and starting-up oil into a hydrogenization reactor for the sulfidizing of a hydrogenization catalyst. The method provided by the invention is best used in the sulfidizing process of the hydrogenation catalyst of liquid phase hydrogenization technology, can supply the hydrogen sulfide according to the demands of the sulfidizing process, and solves the problems of low sulfidizing agent decomposing speed, incomplete catalyst sulfidizing and the like caused by limited dissolved hydrogen amount in the catalyst sulfidizing process of the liquid phase hydrogenization technology.

Owner:CHINA PETROLEUM & CHEM CORP +1

Crude benzene hydrogenation method

ActiveCN102320910AGuarantee quality requirementsInhibit cokingHydrocarbon purification/separationHydrocarbonsFluid phaseHydrogenation reaction

The invention discloses a crude benzene hydrogenation method, which comprises the steps that: crude benzene full-fractional raw materials, hydrogen and cyclic products generated through hydrogenation are fully mixed in a hydrogen mixing tank so that the hydrogen is dissolved in hydrogenation raw materials to the maximum degree; then, the crude benzene full-fractional hydrogenation raw materials with rich dissolved hydrogen enter one section of hydrogenation reactor in a full liquid phase form; and in addition, the whole hydrogenation reaction is carried out under the full liquid phase condition through controlling the pressure of a system. After the crude benzene hydrogenation method is adopted, the coking problem in the crude benzene hydrogenation process can be perfectly solved, the long-term operation of a crude benzene hydrogenation device is realized, the crude benzene full-fractional hydrogenation refining can also be realized, crude benzene is completely converted into important chemical products such as clean benzene, toluene, dimethylbenzene and the like, and the comprehensive utilization value of the crude benzene is improved. In addition, the hydrogenation reaction in the method is liquid phase reaction, the hydrogen circulation process and the adoption of a hydrogen circulation compressor are not needed, in addition, the raw material pretreatment link is omitted, and simultaneously, one section of hydrogenation reactor is used, so the energy consumption and the investment can be effectively reduced.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

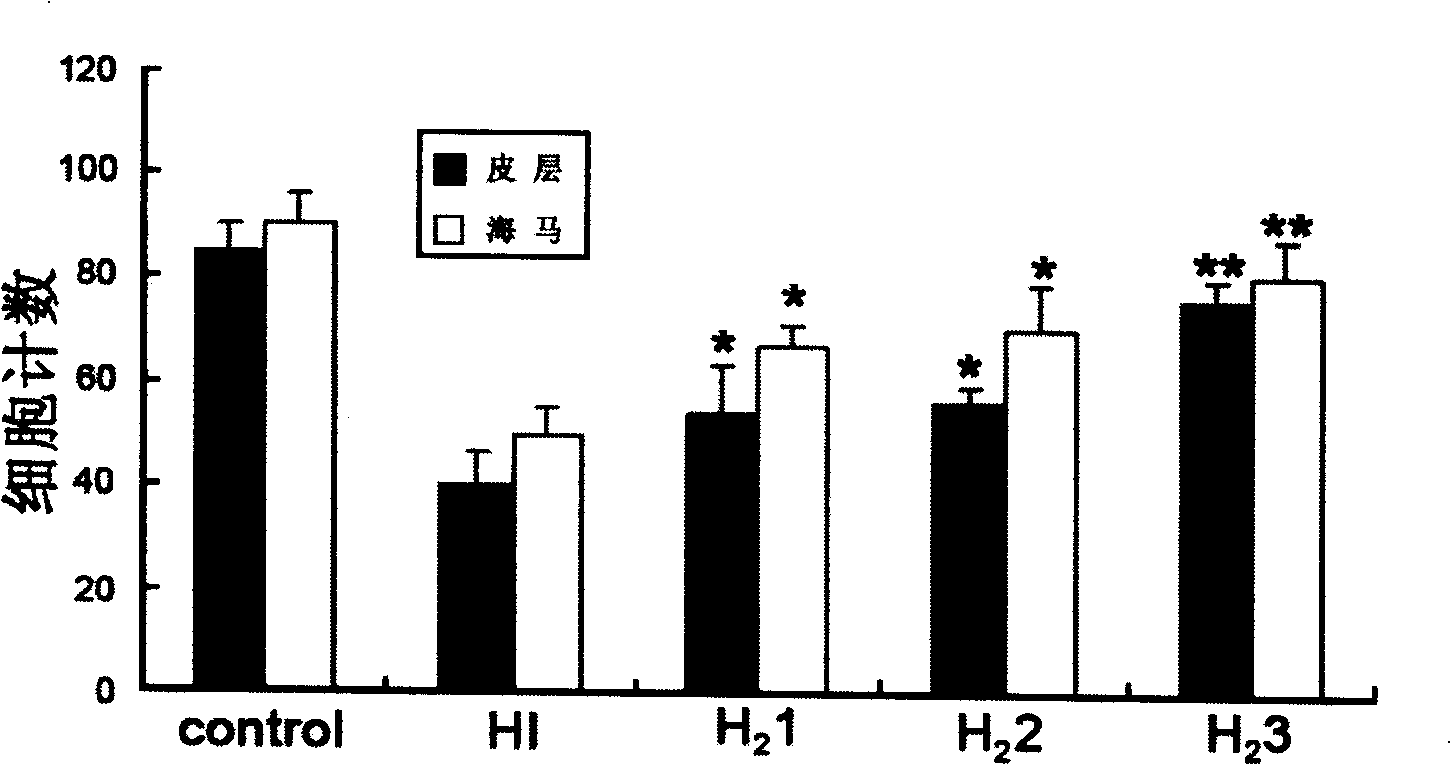

Hydrogenous injection having function for treating ischemia-reperfusion injury

InactiveCN101347451AReduce the number of apoptoticAvoid damageInorganic active ingredientsPharmaceutical delivery mechanismRenal ischemia reperfusionApoptosis

The invention relates to the field of medicine technology and provides an injection for curing ischemic-reperfusion damage of brain, heart, kidney and other tissue organs. The preparation method includes placing a medical injection flexible bag under low pressure for degasification, carrying out low-temperature pretreatment after air extraction, then injecting hydrogen for pressurized dissolution and dissolving hydrogen in the injection and storing under constant pressure and about 4 DEG C for standby. The injection can be used after 24-hour stabilization. The animal experiment proves that the injection of the invention can reduce focal cerebral ischemic-reperfusion damage in rats, neuron injuries and apoptosis number, decrease the activity of apoptosis enzyme in pallium and hippocampus, reduce the ischemic-reperfusion damage extent of heart and kidney and protect the function of ischemic-reperfusion heart and kidney. The hydrogen-included injection can be used as the medicine for curing the ischemic-reperfusion damages of brain, heart, kidney and other important organs.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

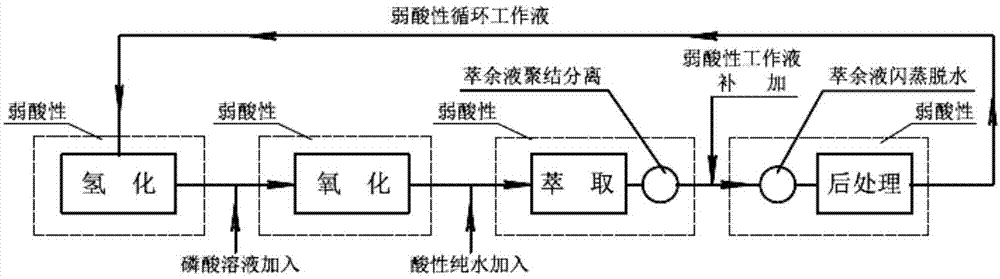

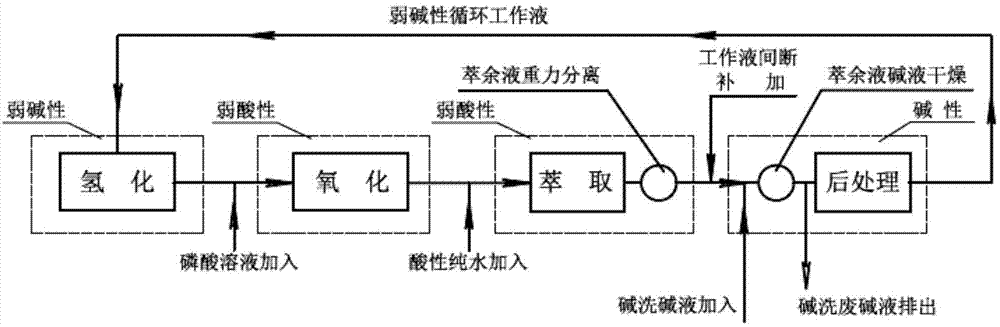

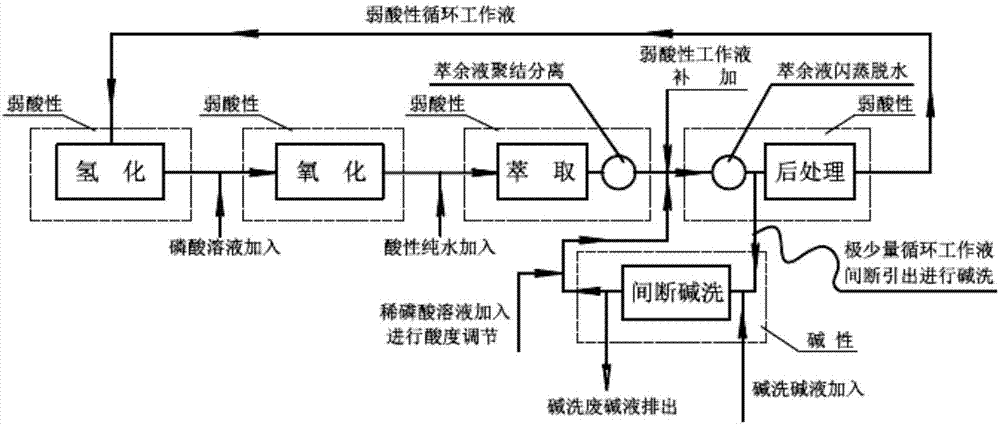

Method of preparing hydrogen peroxide from all-acid working solution system by anthraquinone process

ActiveCN103496674AGuaranteed outputQuality assurancePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesOperational costsPurified water

The invention discloses a method of preparing hydrogen peroxide from an all-acid working solution system by the anthraquinone process. The method includes hydrogenation, oxidization, extraction and post-treatment of working solution. During the method, the whole working solution system is faintly acid constantly. The method includes: hydrogenating prepared faintly acidic working solution to obtain hydrogenated solution; mixing the hydrogenated solution with acid, and performing air oxygenation to obtain oxidized liquid; extracting the oxidized liquid with purified water; purifying extract to obtain finished hydrogen peroxide; removing free water and free hydrogen peroxide from the extract, performing vacuum flashing to remove dissolved water and dissolved hydrogen peroxide, and using vacuum-flashed residual extract as circulating working solution. Very little circulating working solution can further be intermittently guided out of a main process for alkali washing by the method. The method has the advantages that safety and reliability of the production process of hydrogen peroxide can be improved effectively and fixed capital input and production operational cost can be reduced.

Owner:北京凯迪森科技有限公司

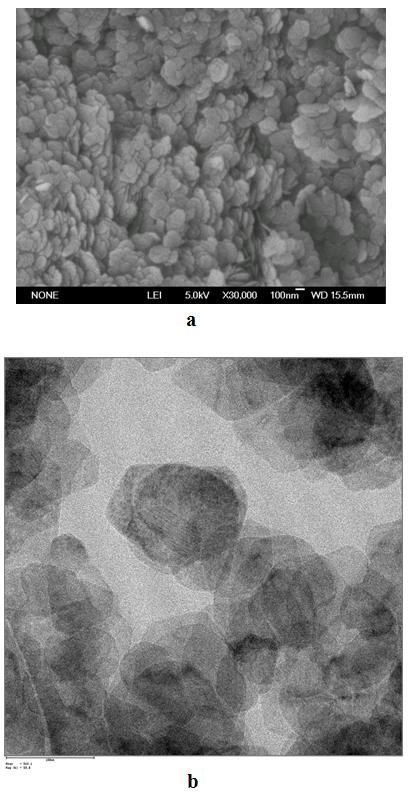

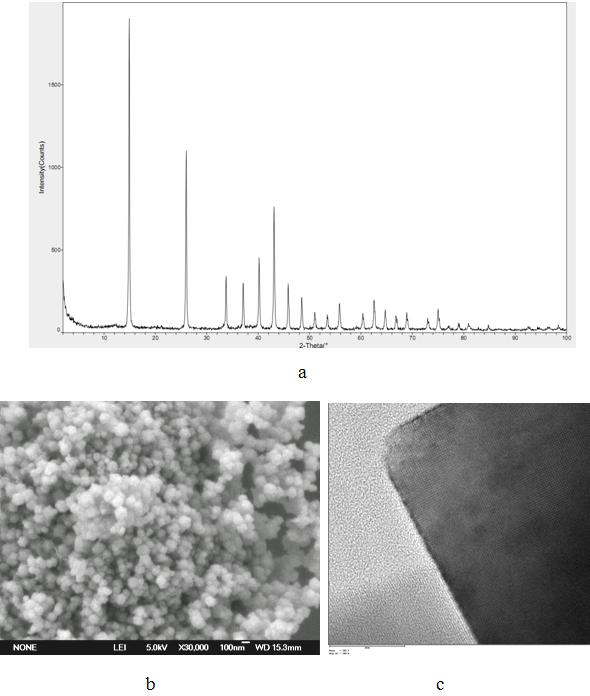

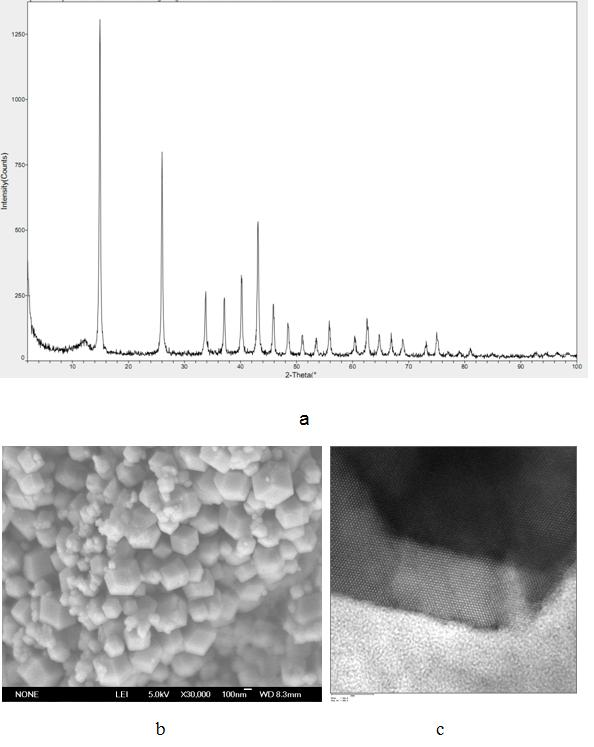

Method for preparing nano nickel bicarbonate

The invention relates to a method for preparing nano nickel bicarbonate, which comprises the following steps of: adding water into urea or urotropine for dissolving, adding nickel salt or nickel hydroxide and stirring, wherein the mole ratio of the urea or the urotropine to nickel is 1:1-16:1, and the concentration of the nickel salt in solution is 0.1-1.0mol / L; shifting the obtained solution into a hydrothermal reactor; after reacting at 90-240 DEG C for 1-96 hours, cooling; and filtering obtained reaction mixed liquid, washing with distilled water and anhydrous ethanol and placing in a vacuum drying box at 60 DEG C for drying to obtain a cubic phase nano nickel bicarbonate square block with the size of 100nm or so. The invention uses the urotropine or the urea as a precipitator, NH3 andCO2 generated by the precipitator dissolve nickel hydroxide, and the pure cubic phase Ni(HCO3)2 nano crystal is prepared finally.

Owner:NANJING UNIV OF TECH

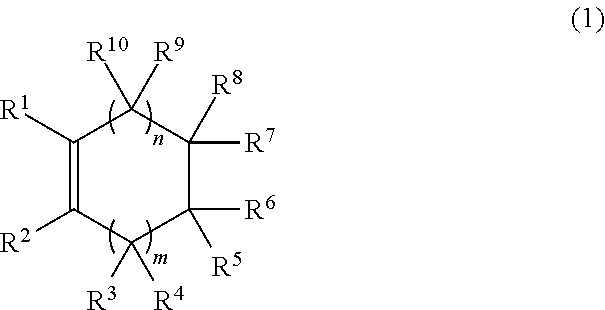

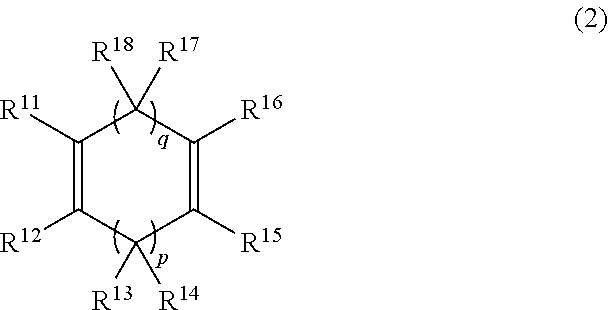

Process for production of hydrogenated polymers and hydrogenated polymers

Provision of, in a process of producing a hydrogenated polymer, which comprises steps of sequentially performing, in the presence of a ruthenium carbene complex, a ring-opening metathesis polymerization reaction of a cyclic olefin and a hydrogenation reaction of a ring-opening metathesis polymer produced by the polymerization reaction to give a hydrogenated polymer, a simple and economic process of obtaining a hydrogenated polymer having an extremely small content of residual ruthenium derived from the ruthenium carbene complex.A process of producing a hydrogenated polymer, which comprises, in the presence of a ruthenium carbene complex, subjecting a cyclic monoolefin and / or a cyclic diolefin to a ring-opening metathesis polymerization, hydrogenating the resulting ring-opening metathesis polymer to give a hydrogenated polymer, and bringing the hydrogenated polymer in contact with a poor solvent of the hydrogenated polymer in the presence of dissolved hydrogen to allow precipitation. As the poor solvent of the hydrogenated polymer, alcohol having 1 to 6 carbon atoms, ketone having 3 to 6 carbon atoms and the like are preferable.

Owner:KURARAY CO LTD

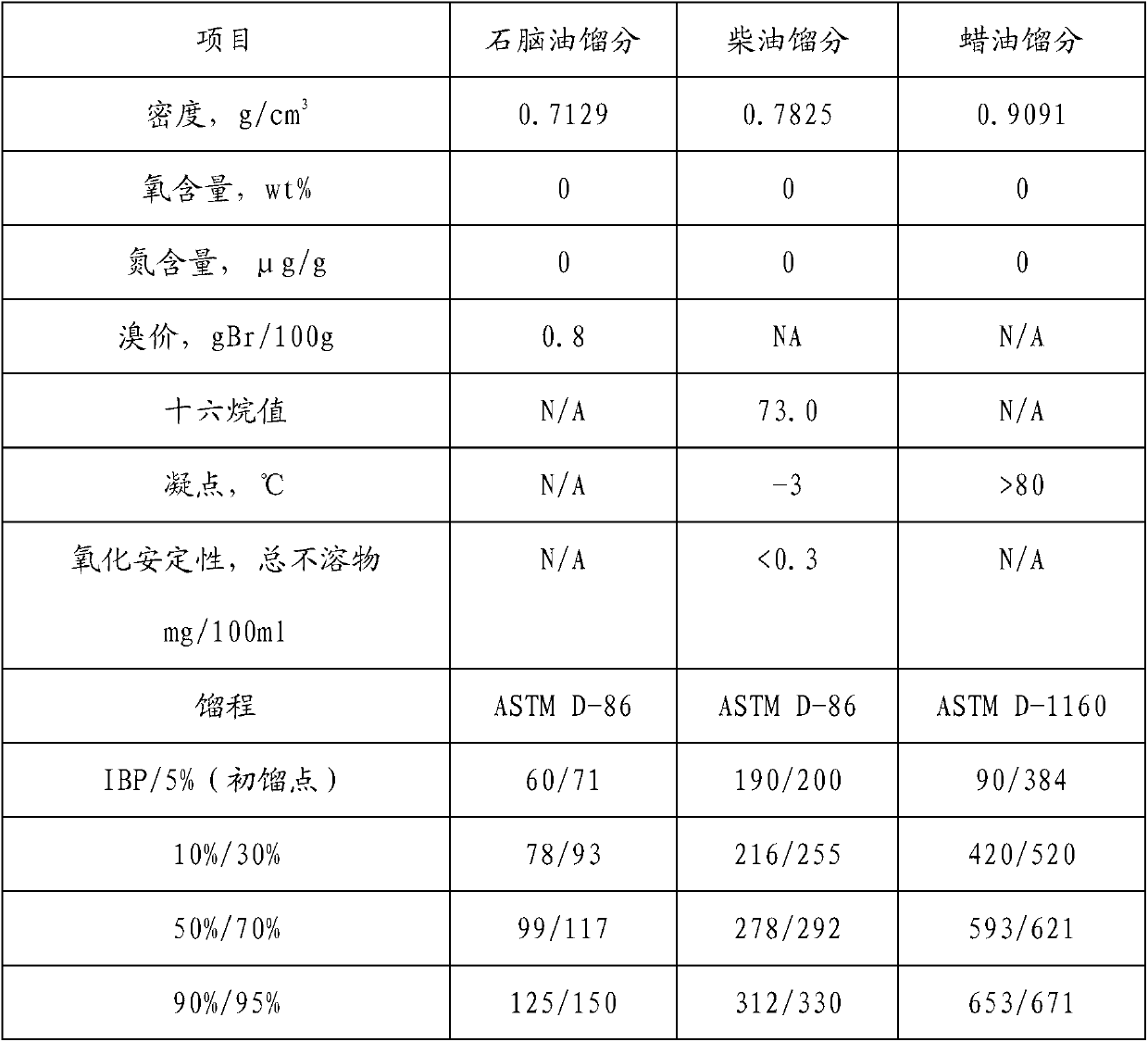

Low temperature Fischer-tropsch synthetic oil hydrofining and / or hydrogenation heterogeneous cracking system and technology

ActiveCN103131468AReduce temperature gradientAxial distribution is reasonableTreatment with hydrotreatment processesHydrogen concentrationHydrogen compressor

The invention relates to a low temperature Fischer-tropsch synthetic oil hydrofining and / or hydrogenation heterogeneous cracking system and a technology thereof. A hydrofining unit uses a liquid phase hydrogenation mode and a downward feeding mode, and thus the distribution of hydrogen concentration along the axial direction of a reactor is more reasonable. Besides, due to the fact that hydrogen consumed in a liquid phase hydrofining reaction process is from liquid phase saturated dissolved hydrogen, a circulating hydrogen compressor can be eliminated when the hydrofining unit is operated separately, and thus device investment and operating cost are reduced.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

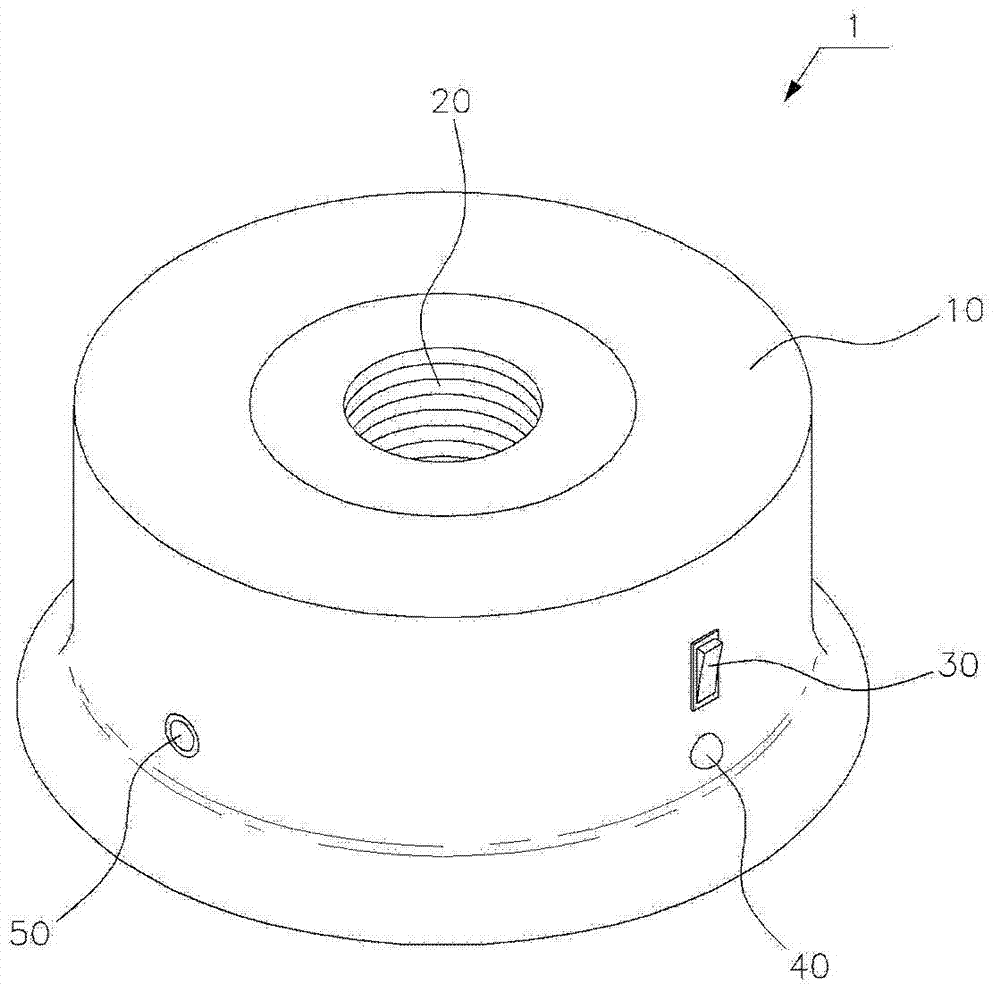

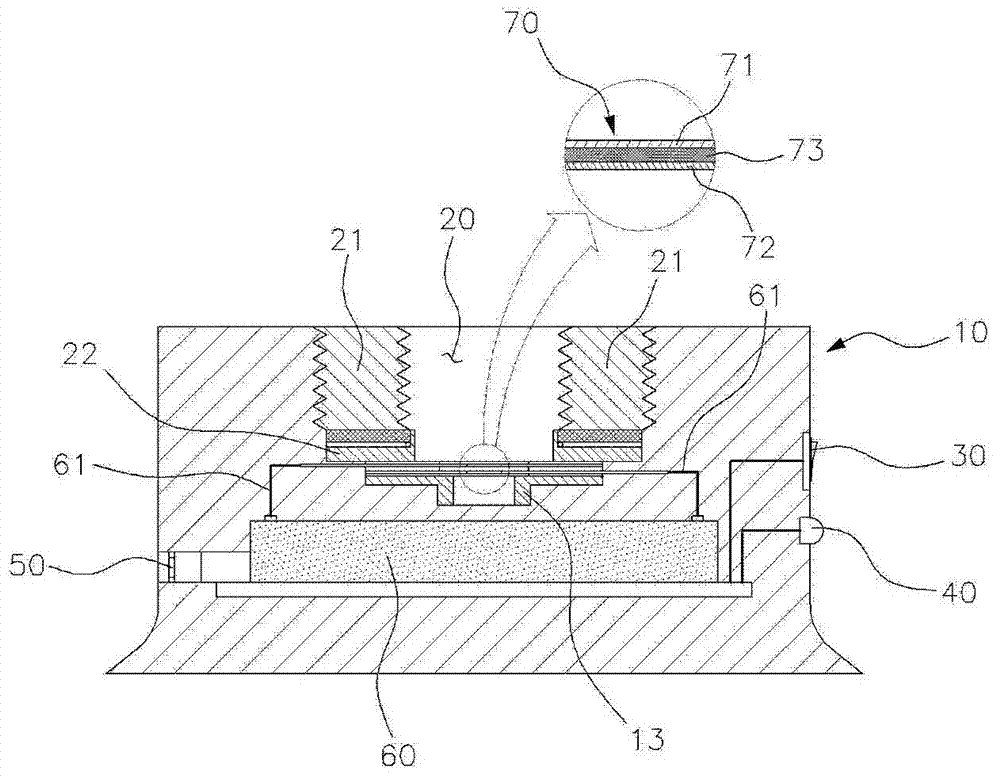

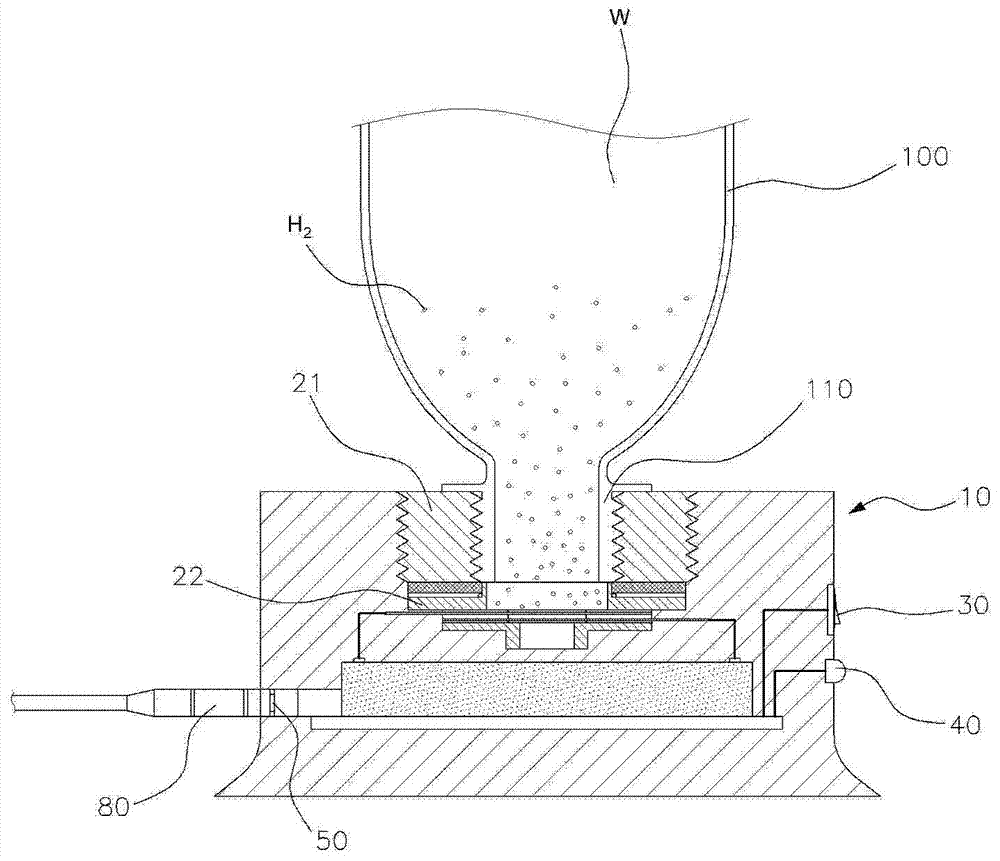

Portable apparatus for producing hydrogen water

InactiveCN104775131AImprove portabilityPrevent leakageCellsWater treatment parameter controlProcess engineeringDissolved hydrogen

The present invention relates to an apparatus for producing hydrogen water, and more particularly, to a portable apparatus for producing hydrogen water including: a container held at an upper side to store water; a hydrogen generating unit positioned at a lower part of the container, and for dissolving hydrogen generated by electrolyzing water stored in the container in the water stored in the container, and converting the water in the container to hydrogen water; and a power supply unit for applying power to the hydrogen generating unit. The portable apparatus for producing hydrogen water of the present invention may enable a user to conveniently drink hydrogen water regardless of the time and the place.

Owner:SOLCO BIOMEDICAL

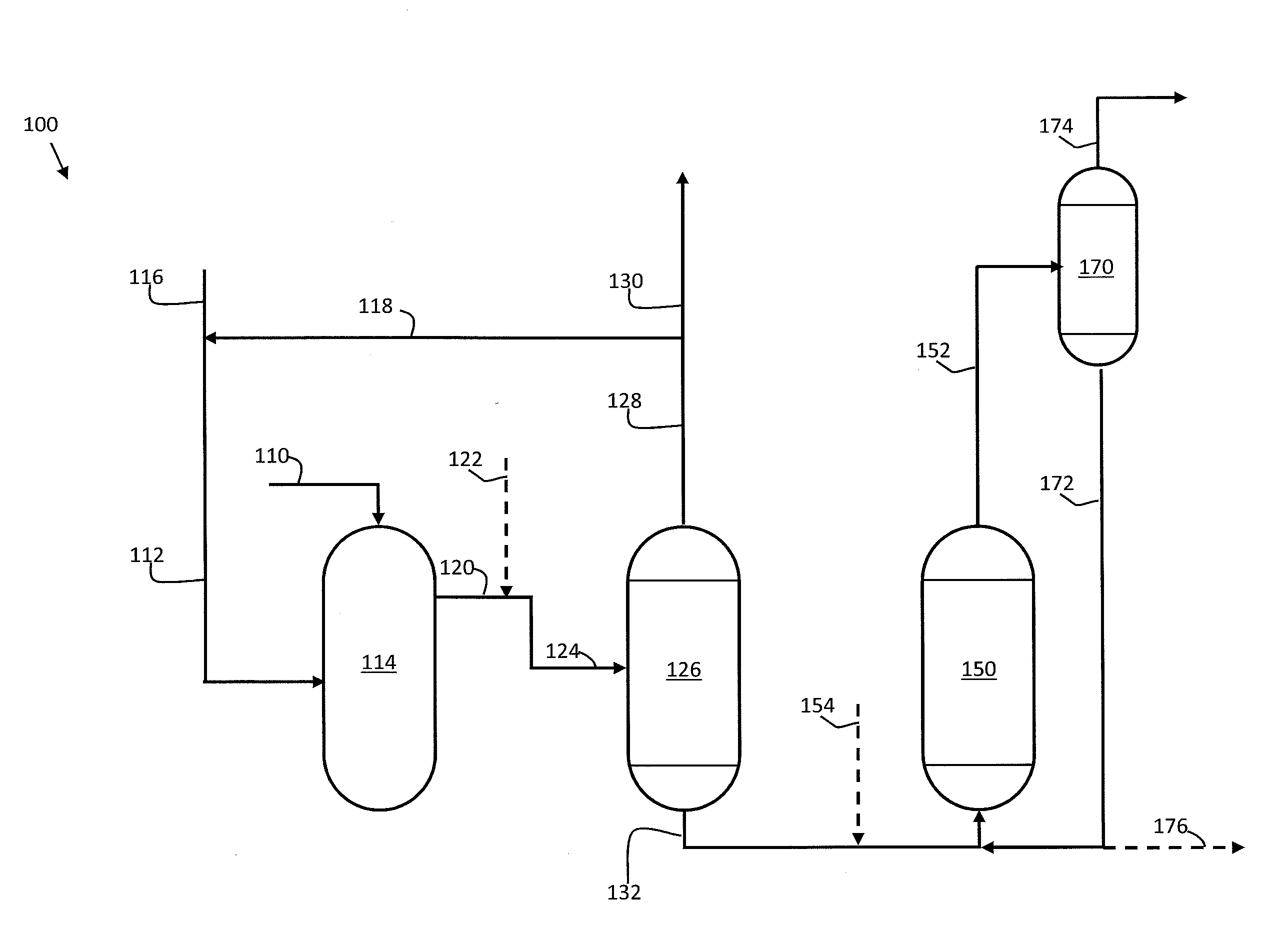

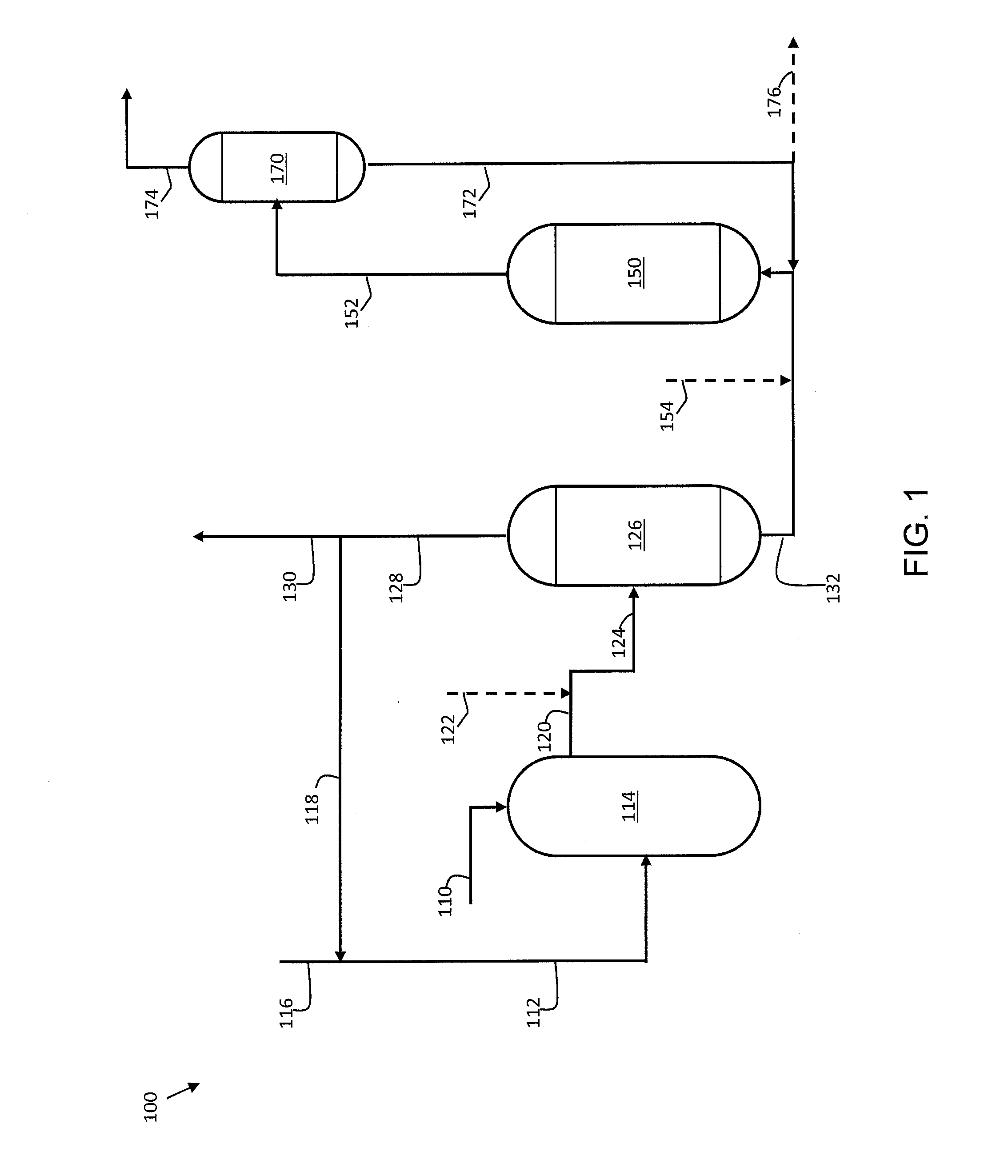

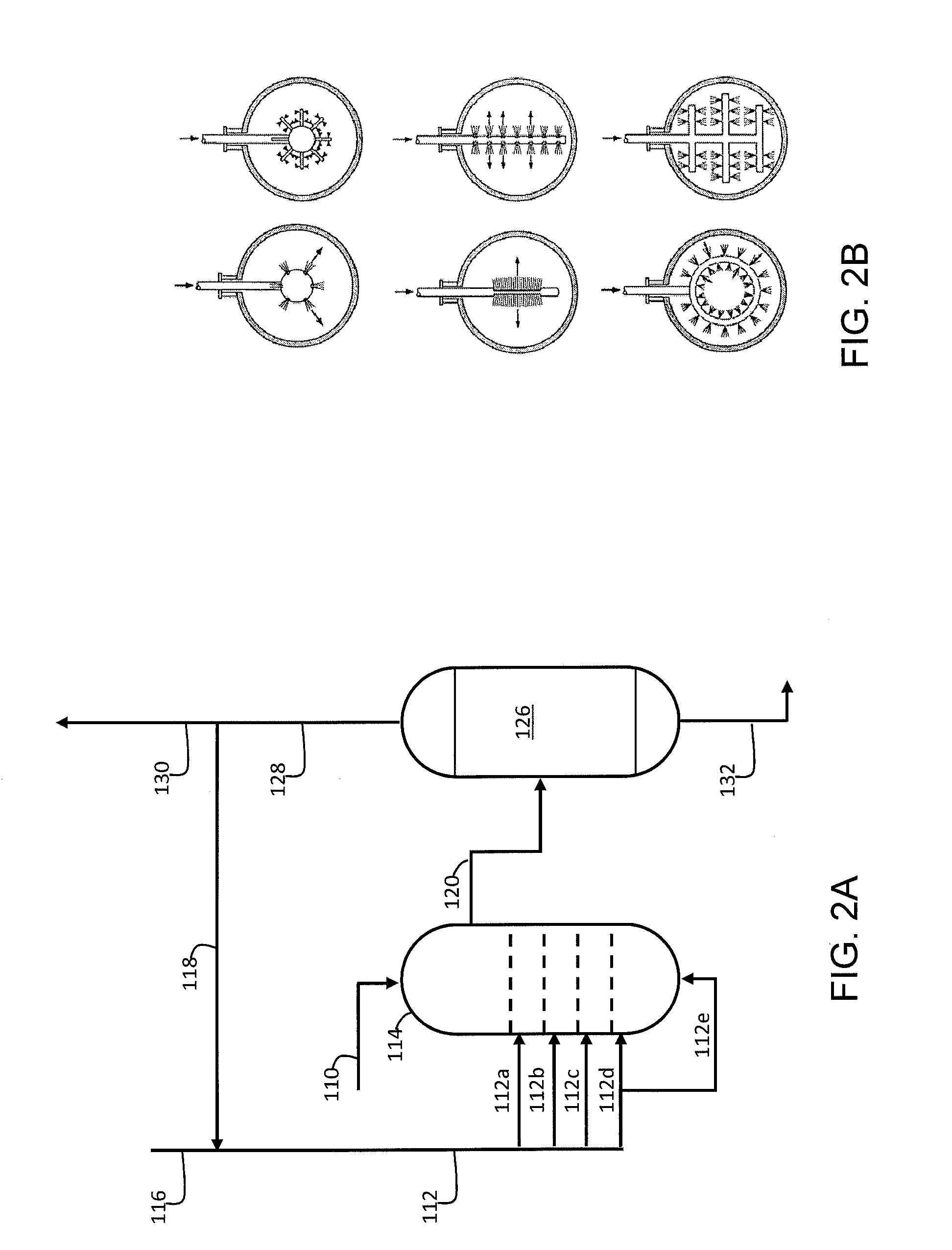

Slurry bed hydroprocessing and system using feedstock containing dissolved hydrogen

ActiveUS20130126392A1Reduce size requirementsHydrocarbon oil crackingTreatment with hydrotreatment processesSlurryHomogeneous catalysis

A system and process for conversion of heavy feedstocks in a slurry bed hydroprocessing reactor is provided in which (a) hydrogen gas is dissolved in the liquid feedstock by mixing and / or diffusion, (b) the mixture is flashed to remove and recover any light components and hydrogen, leaving a hydrogen-enriched feedstock. A homogenous and / or heterogeneous catalyst is added to the feedstock upstream of the inlet of the slurry bed hydroprocessing reactor.

Owner:SAUDI ARABIAN OIL CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com