Zn-Li series zinc alloy as well as preparation method and application thereof

A zinc alloy, zn-li technology, used in prosthesis, surgery, medical science, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Embodiment 1, preparation as-cast Zn-Li alloy

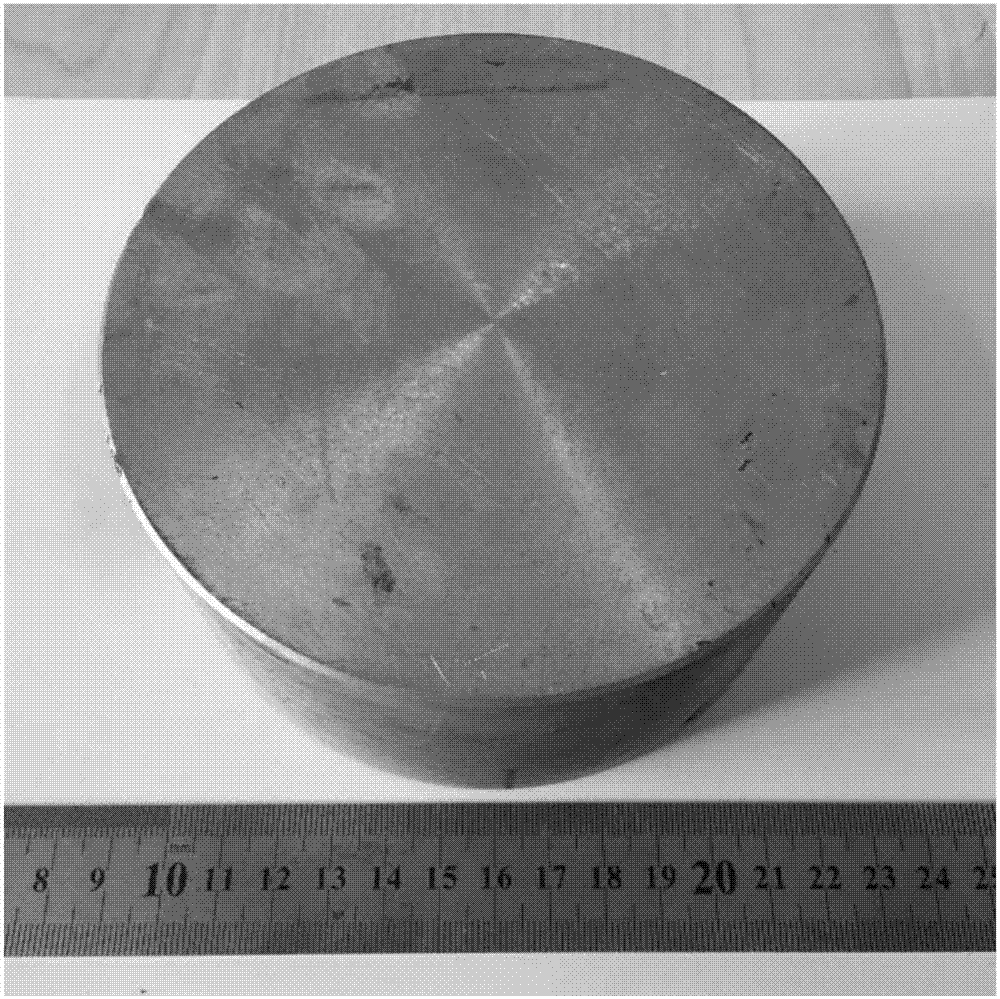

[0082] Using pure Zn (99.99wt.%) and pure Li (99.95wt.%) (purchased from Huludao Zinc Industry Co., Ltd.) as raw materials, according to different mass ratios (the mass ratios of Zn and Li are 99:1, 99.2 : 0.8, 99.4: 0.6, 99.5: 0.5, 99.65: 0.35, 99.7: 0.3, 99.75: 0.25, 99.8: 0.2, 99.85: 0.15, 99.9: 0.1) mixing, in CO 2 +SF 6 Under atmosphere protection, smelting at 800 ° C, after the raw materials are fully melted, after 10 minutes of heat preservation, the circulating water is rapidly cooled, and the Zn-Li alloy ingot (that is, the Zn-Li zinc alloy of the present invention, such as figure 1 shown), wherein, Zn-0.1Li means that the mass ratio of Zn to Li is 99.9:0.1, Zn-0.4Li means that the mass ratio of Zn to Li is 99.6:0.4, and Zn-0.8Li means that the mass ratio of Zn to Li is 99.6:0.8.

Embodiment 2

[0083] Embodiment 2, preparation extruded state Zn-Li series alloy

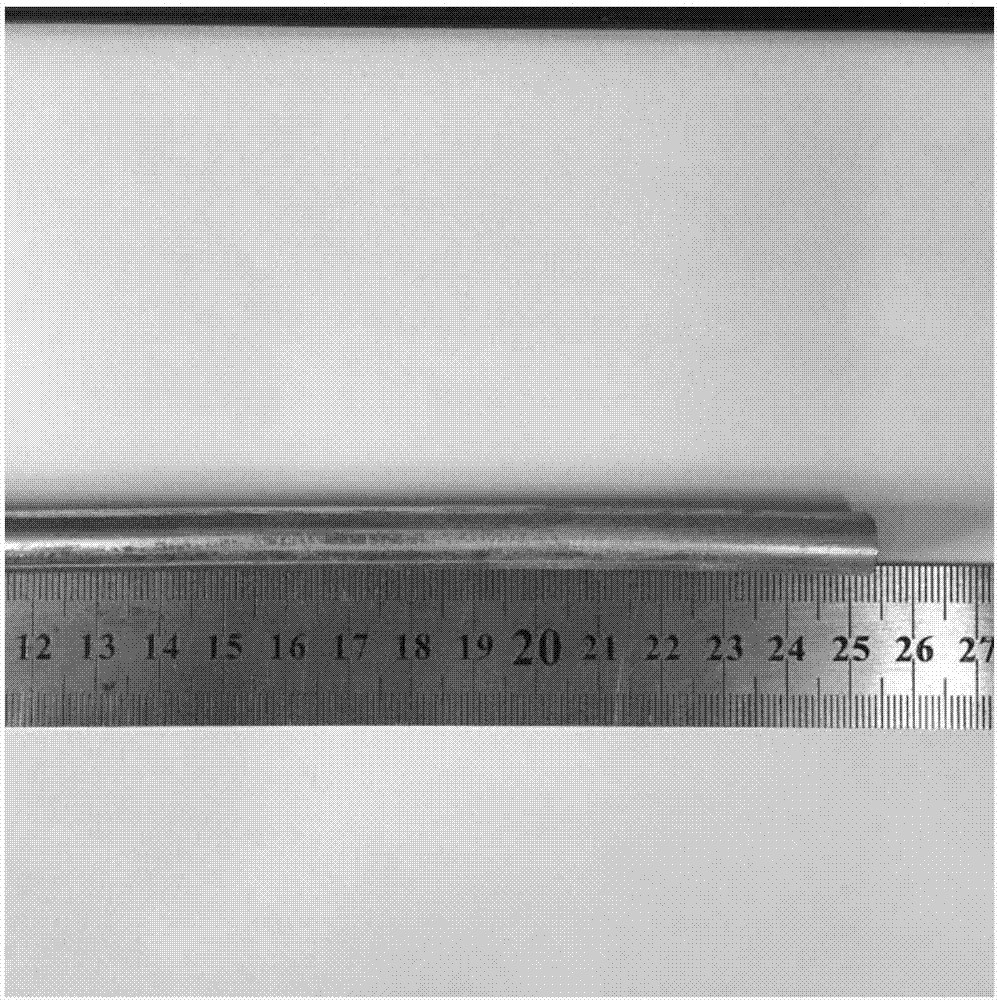

[0084] First, according to the steps in Example 1 of the present invention, the cast Zn-Li alloy ingot is prepared, and the Zn-Li alloy bar is prepared by extrusion (that is, the Zn-Li zinc alloy of the present invention, such as figure 2 As shown), radial extrusion is adopted, the ingot is held for 2 hours, the holding temperature is 260°C, the extrusion temperature is 260°C, the extrusion ratio is 36, and the extrusion speed is 1mm / s to prepare a Zn-Li alloy with a diameter of 10mm bar.

Embodiment 3

[0085] Embodiment 3, Zn-Li system zinc alloy microstructural analysis

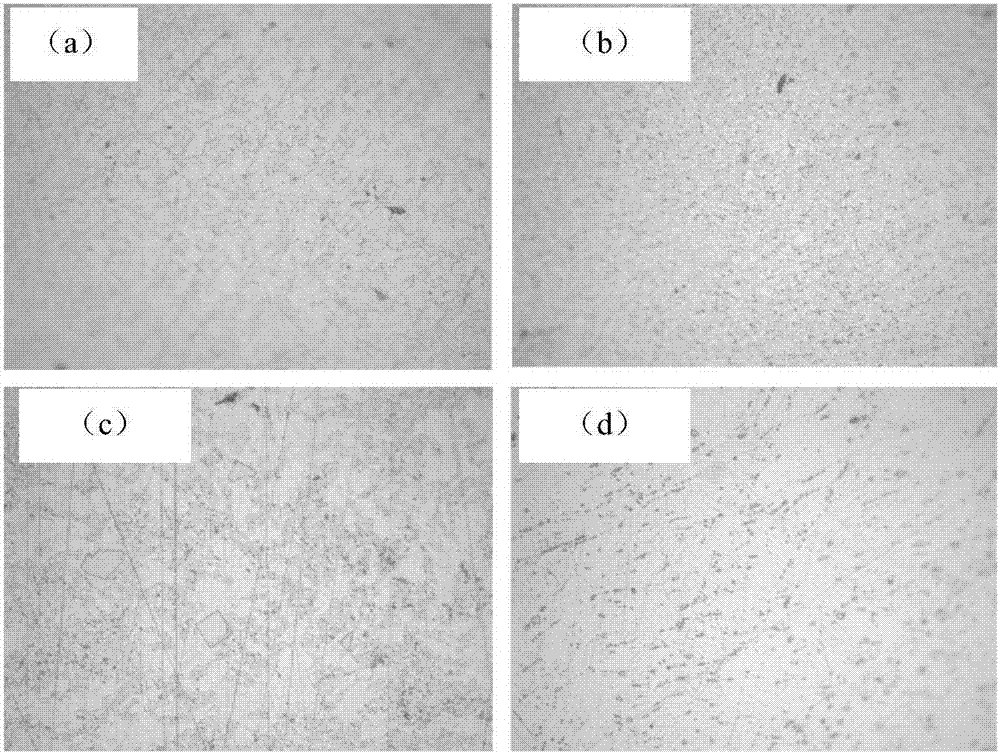

[0086] The Zn-Li alloy rod in Example 2 of the present invention was prepared by wire cutting to prepare a φ10x1mm sample, which was sequentially ground and polished by 400#, 800#, 1200# and 2000# SiC sandpaper series. After ultrasonic cleaning in acetone, absolute ethanol and deionized water for 15 min, dry at 25 °C. The sample was subjected to X-ray diffraction analysis, etched with 4% nitric acid alcohol for 5-30 seconds, washed with deionized water, dried, and observed under a metallographic microscope.

[0087] image 3 It is the metallographic picture of Zn-Li zinc alloy, from image 3 It can be seen that after extrusion, the grains are fine, and the second phase is evenly distributed on the matrix. Figure 4 is the X-ray diffraction pattern, given by Figure 4 It can be seen that after the addition of Li, the crystal structure of pure zinc changes, and many new diffraction peaks appear with the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com