Hydro-treating method of reformate

A technology of reforming to generate oil and hydrotreating, which is applied in the fields of hydrotreating process, hydrocarbon oil treatment, naphtha treatment, etc., which can solve the problem of huge reaction equipment, achieve simplified process route, high-efficiency and low-consumption industrial production , Reduce investment costs and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

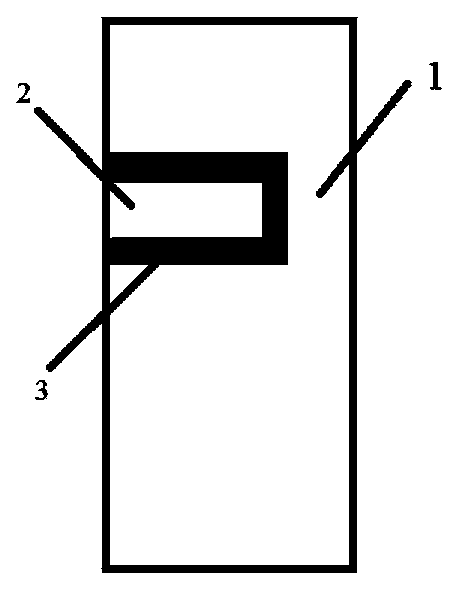

[0077] (1) if Figure 5 As shown, the catalytic reforming mixture output from the reforming reactor is injected into the reformed product gas-liquid separation tank for gas-liquid separation, and reformed oil is obtained from the bottom of the separation tank. Wherein, the temperature in the separation tank is 40° C., and the pressure is 0.7 MPa; based on the total amount of the obtained reformed product oil, the reformed product oil contains 0.015% by weight of dissolved hydrogen.

[0078] (2) Inject supplemental hydrogen into the reformed oil through the mixing device, and send the hydrogen-carrying reformed oil into the tubular fixed-bed reactor (the inner diameter of the tubular reactor is 65mm; there is one Catalyst bed, the height-to-diameter ratio of the catalyst bed is 25; the catalyst with catalytic hydrogenation effect is commercially purchased from the Sinopec Fushun Petrochemical Research Institute's brand HDO-18 catalyst), shown in Table 1 The hydrogenation treat...

Embodiment 2

[0083] The reformed oil is hydrotreated in the same manner as in Example 1, except that no hydrogen is introduced into the gas channel of the hydrogen mixing device (that is, no supplementary hydrogen is injected into the reformed oil), and the obtained The aromatics content and bromine index of the hydrogenated products are shown in Table 2.

Embodiment 3

[0085] Adopt the method identical with embodiment 1 to carry out hydrotreating to reformed oil, difference is:

[0086] In step (1), the temperature in the gas-liquid separation tank is 40°C and the pressure is 0.3MPa, based on the total amount of reformed oil obtained, the reformed oil contains 0.01% by weight of dissolved hydrogen;

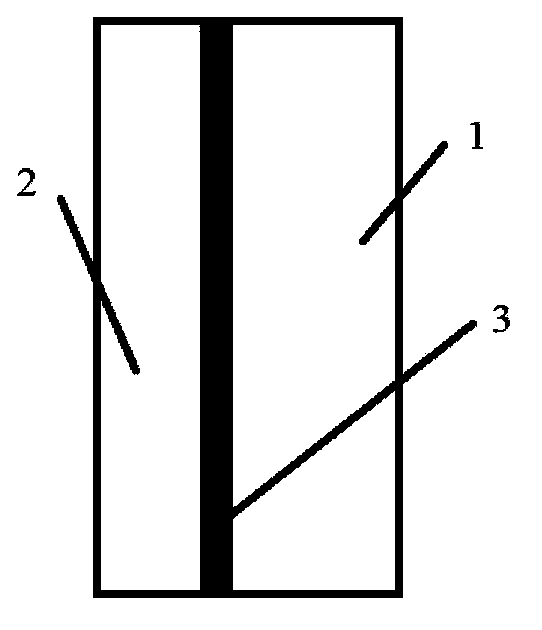

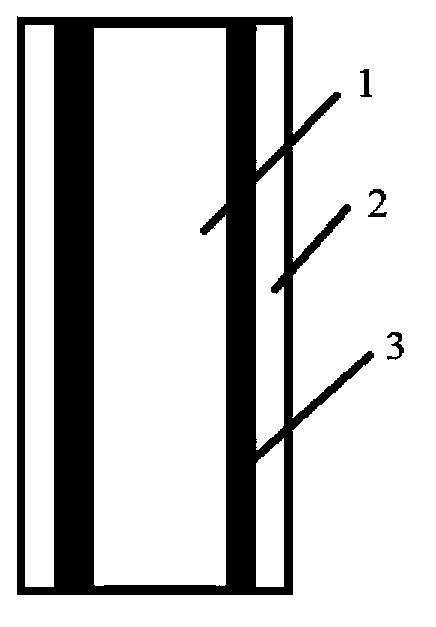

[0087] In step (2), the mixing device includes a membrane tube (commercially purchased from Beijing Zhongtianyuan Environmental Engineering Co., Ltd., with an outer diameter of 25.4 mm, the average pore diameter of the through holes on the substrate is 100 μm, and the average pore diameter of the through holes on the porous membrane is 250nm) and a housing (inner diameter of 40mm) used in conjunction with the pipeline; the porous membrane is located on the outer wall of the membrane tube; the cross-section of the membrane tube is as Figure 4 As shown, there are 7 liquid channels evenly distributed, and the inner diameter of each liquid channel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com