Method of preparing hydrogen peroxide from all-acid working solution system by anthraquinone process

A working fluid and working fluid technology, applied in chemical instruments and methods, peroxide/peroxy hydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, etc., can solve the problem of increasing the total amount of process equipment, The increase of daily operating costs, the risk of safety production accidents, etc., achieve high regeneration effects, ensure long-term stable and efficient operation, and stable production and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing hydrogen peroxide by anthraquinone method full-acid working liquid system of the present invention, the device used is the laboratory simulation device of the 30,000 tons / year hydrogen peroxide industrialization test device of Guangxi Tiandong Dasheng Chemical Technology Co., Ltd., the method comprises the following step:

[0039] (1) Preparation of weakly acidic working fluid: There are many working fluid formulations in the production process of hydrogen peroxide. In the present invention, it can be prepared according to the current domestic hydrogen peroxide production common working fluid formula. In this example, 50kg of the working fluid was prepared, and in terms of mass fraction, it included 59.61% of heavy aromatics (heavy aromatics come from platinum reforming units in the petroleum industry, mainly C9 fractions), 8.32% of trioctyl phosphate, and 12.82% of 2-methylcyclohexyl acetate, 19.25% 2-ethylanthraquinone, that is, the total effect...

Embodiment 2

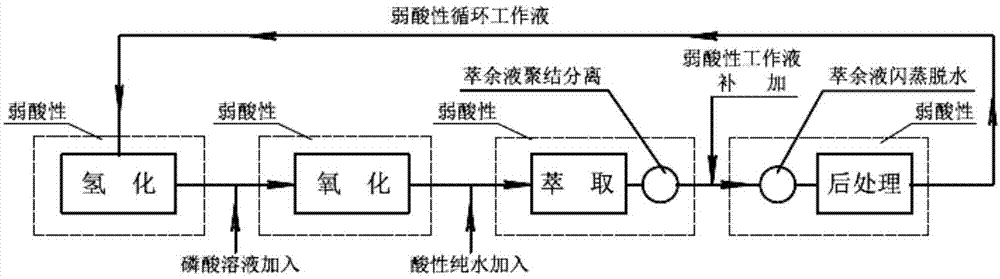

[0052] A method for preparing hydrogen peroxide by anthraquinone method full-acid working liquid system of the present invention, the device used is the 30,000 tons / year hydrogen peroxide industrialization test device of Guangxi Tiandong Dasheng Chemical Technology Co., Ltd., and the operation process is as follows figure 1 shown, including the following steps:

[0053] (1) Preparation of working fluid: According to the current general working fluid formula of domestic hydrogen peroxide production plants, 187,000kg of working fluid was prepared, including 40.91% of heavy aromatics, 19.82% of trioctyl phosphate, and 23.23% of 2-methyl Cyclohexyl acetate, 16.04% of 2-alkylanthraquinones, that is, the total effective anthraquinone content in the working solution is 180g / L; the prepared working solution is washed with desalted water and dilute hydrogen peroxide, and then vacuum flashed ( 45°C, -0.090MPa) to remove the washing water, and then use a phosphoric acid solution with a m...

Embodiment 3

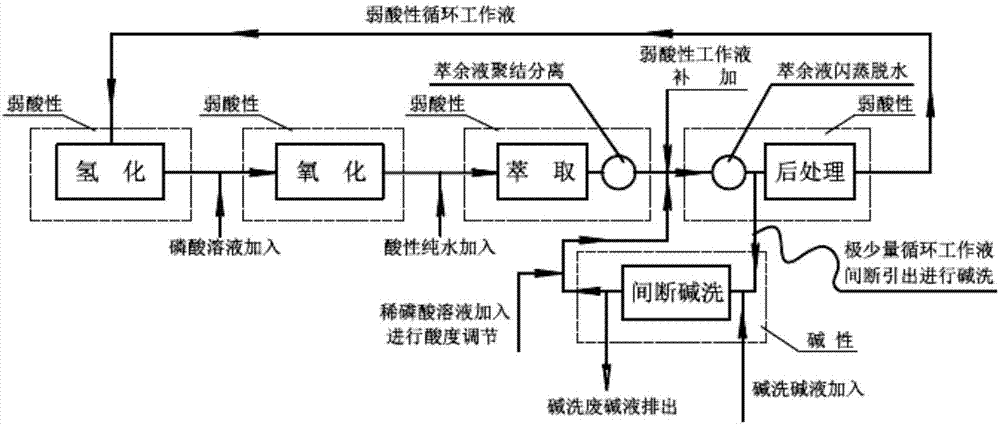

[0062] A method for preparing hydrogen peroxide by anthraquinone method fully acidic working liquid system of the present invention, the main process is the same as that of Example 1, the only difference is that an intermittent washing step is also provided outside the main process, and the intermittent washing step includes:

[0063] (a) Pure water washing: Take out 1750g of the raffinate after vacuum flash evaporation from step (5) of the main process, that is, the circulating working fluid. According to chemical analysis, the hydrogen peroxide content in the circulating working fluid is 0.15g / L; wash the circulating working fluid with 390g of pure water (generally, the mass ratio of circulating working fluid to pure water is 4-6:1), and stir while washing to remove traces of hydrogen peroxide in the circulating working fluid. The temperature was 50°C, and the washing time was 30 minutes; after washing, let stand to separate layers, remove the water layer, and use the potass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com