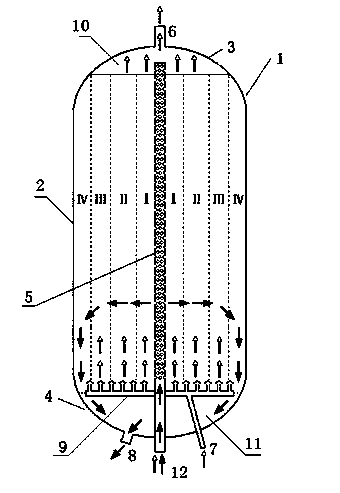

Residual oil hydrotreating method

A technology of residual oil hydrogenation and treatment method, which is applied in refining to remove heteroatoms, etc., can solve the problems of waste of post catalyst activity resources, etc., and achieve the effects of good operating flexibility, increased ratio, and reduced circulation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The same catalyst type and its loading method were used to compare the operating elasticity of the radial-flow fixed bed of the present invention and the existing fixed bed residue hydrogenation technology.

[0039] In this example, the residue hydrogenation catalyst developed and produced by Fushun Petrochemical Research Institute (FIRPP) was used. The protective agent was FZC-13, the hydrodemetallization catalyst was FZC-21, and the hydrodesulfurization catalyst was FZC-30. , the hydrodenitrogenation catalyst is FZC-41, and in the catalyst bed, the loading ratio of various functional catalysts is FZC-13:FZC-21:FZC-30:FZC-41=13:32:20:35. The raw material oil is a Middle Eastern atmospheric residue, and its impurity content is as follows: S=2.78m%, N=0.29m%, CCR=12.1m%, Ni+V=110μg / g. The reaction conditions are: reaction pressure 15.7MPa, reaction temperature 370°C, hydrogen-to-oil volume ratio 700, and the oil feed rate is 0.2h at the existing fixed bed space velocity ...

Embodiment 2

[0048] Using the same catalyst species and loading method as in Example 1, the stability comparison between the radial-flow fixed bed technology of the present invention and the existing fixed bed residual oil hydrogenation technology was carried out.

[0049] In this example, a batch of residual oil hydrogenation catalysts prepared by FIRPP laboratory is used. The protective agent is FZC-14, the hydrodemetallization catalyst is FZC-28, the hydrodesulfurization catalyst is FZC-34, and the hydrodenitrogenation catalyst is FZC-34. The catalyst is FZC-42, and the gradation of each catalyst in the reactor is FZC-14:FZC-28:FZC-34:FZC-42=13:32:23:32. The raw material oil is another Middle Eastern atmospheric residue, and its impurity content is as follows: S=2.67m%, N=0.31m%, CCR=13.57m%, Ni+V=126μg / g. The reaction conditions are: reaction pressure 15.7MPa, reaction temperature 375°C, hydrogen-to-oil volume ratio 700, and the oil feed rate is 0.2h at the space velocity of the existi...

Embodiment 3

[0058] Using the same catalyst type and its loading method, the relationship between the running time and temperature of the radial-flow fixed bed of the present invention and the existing fixed bed residual oil hydrogenation technology is carried out.

[0059] Adopt the same raw material and catalyzer among the embodiment 1 among the embodiment 3. The reaction pressure is 15.7MPa, the volume ratio of hydrogen to oil is 700, and the space velocity is 0.2h -1 , The reaction temperature is 365°C.

[0060] Table 5 Results of residual oil hydrogenation method of the present invention

[0061] running time, h 1000 2000 4000 Reaction temperature, °C 365 365 365 Desulfurization rate, % 80.20 80.23 80.31 Nitrogen removal rate, % 46.23 46.27 46.38 Carbon residue removal rate, % 53.62 53.66 53.71 Stripping (nickel + vanadium) rate, % 81.35 81.40 81.51 Differential pressure, kPa 0 0 0

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com