Hydrocarbon continuous liquid phase hydrogenation process method and device

A technology of liquid-phase hydrogenation and process method, which is applied in the direction of hydrogenation treatment process, chemical instruments and methods, petroleum industry, etc. It can solve the problems of high energy consumption of equipment and large reactor volume, and achieve small volume and high reaction efficiency , The effect of reducing the carbon deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

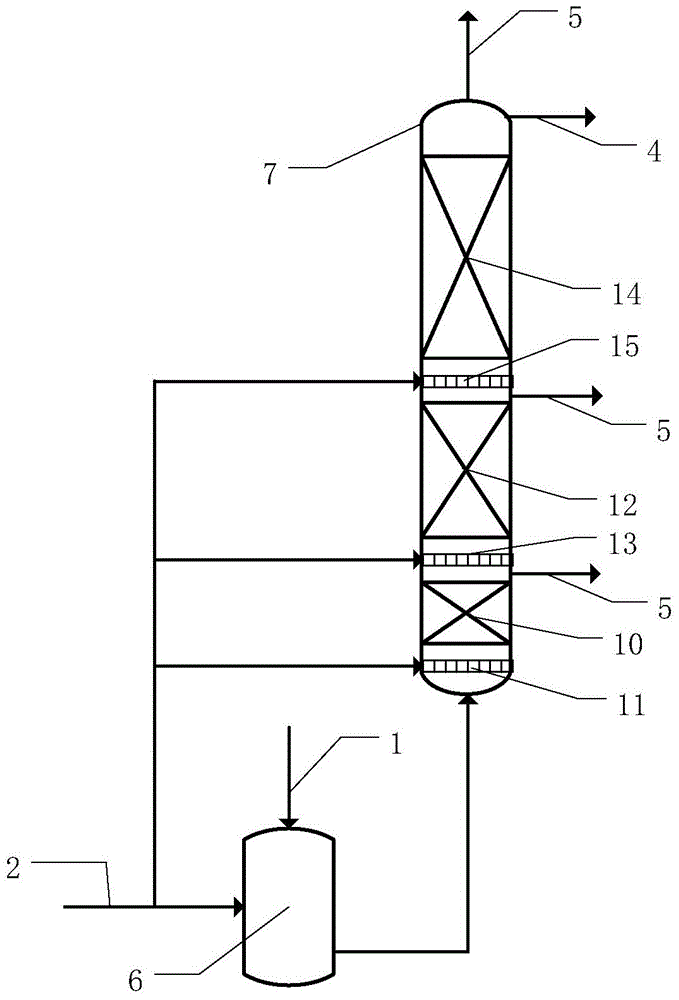

[0051] The hydrogenation method provided by the present invention is a method for continuous liquid-phase hydrogenation of hydrocarbons (hydrocarbon oil or hydrocarbon compounds), wherein the hydrocarbon reactants remain in the liquid phase state, although the dissolved hydrogen in the hydrocarbons is in the reaction Gradually consumed, but efficiently replenished in the catalyst bed with new hydrogen measured according to stoichiometric hydrogen consumption, the process does not require hydrogen to be recycled through the catalyst, nor the reaction products to be recycled through the catalyst.

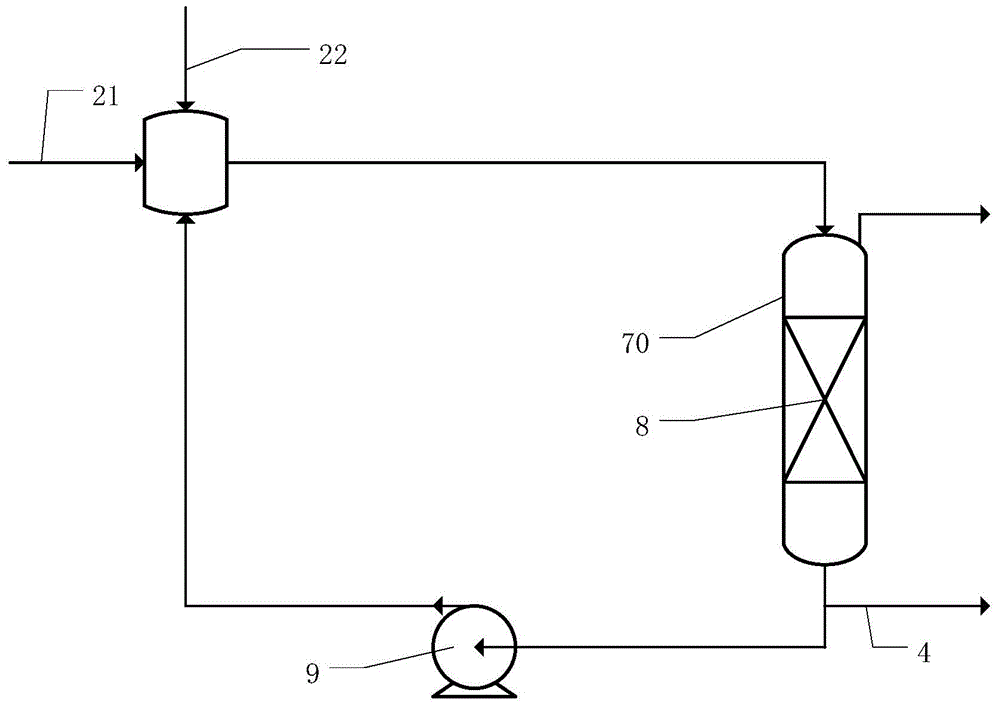

[0052] figure 2 It is a schematic flow sheet of the hydrogenation process method of the present invention, such as figure 2 As shown, a hydrocarbon continuous liquid-phase hydrogenation process met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com