Method of liquid phase circulation hydrotreatment and reaction system

A liquid-phase circulating hydrogenation and reaction system technology, which is applied in the treatment of hydrocarbon oil, hydrocarbon oil treatment control/regulation, petroleum industry, etc. Effect of wet factor, maintain activity stability, reduce adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

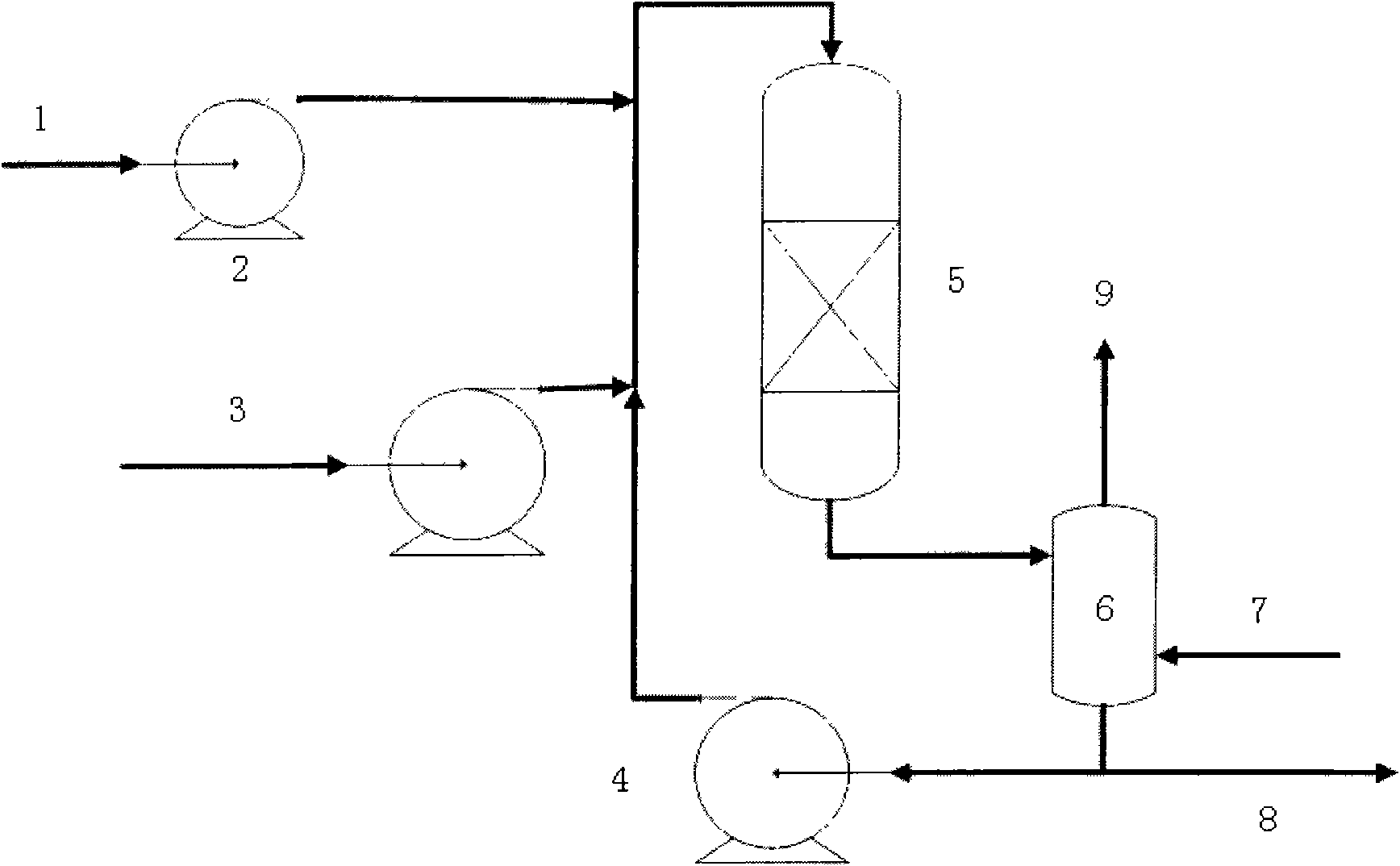

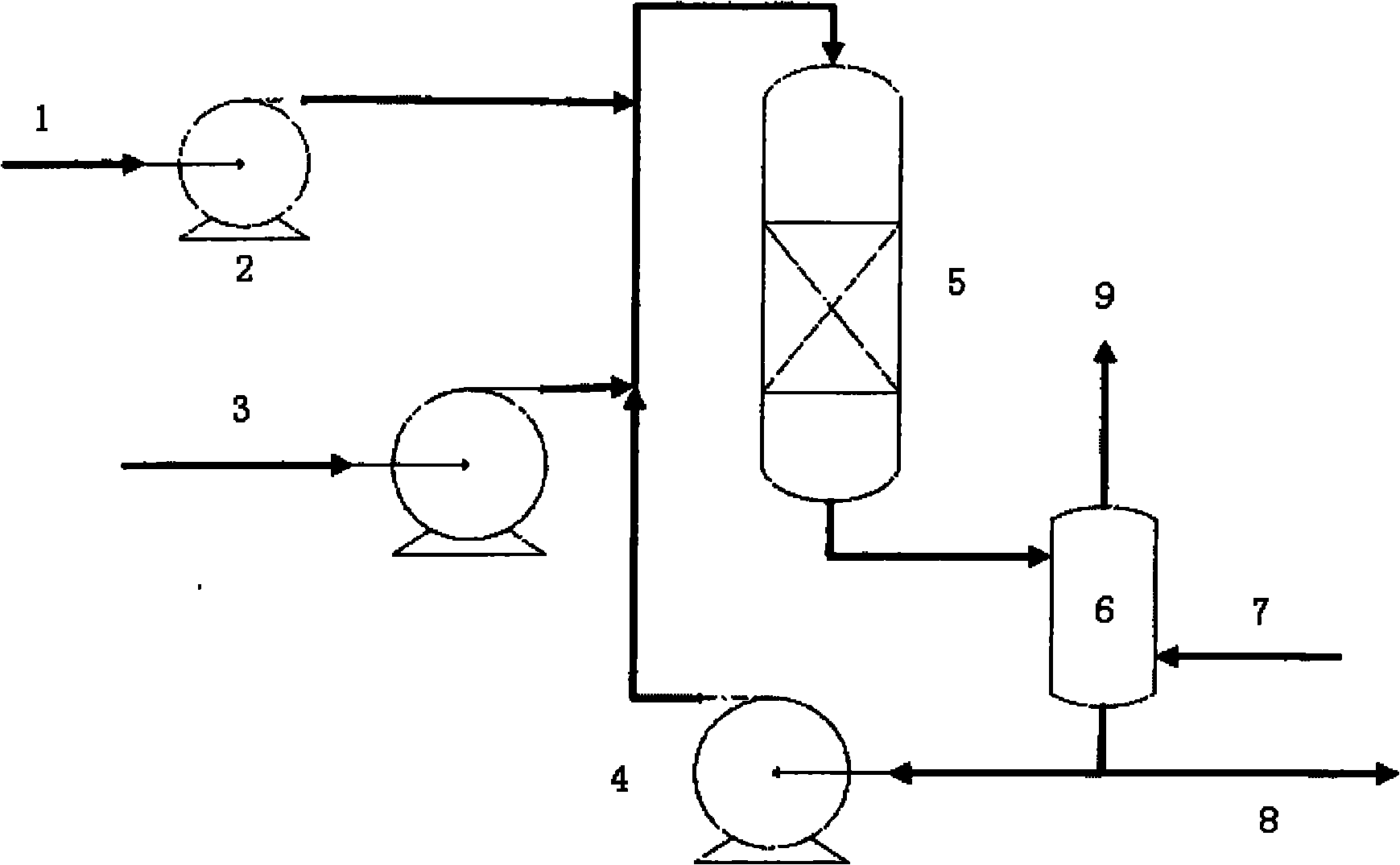

[0037] according to figure 1 The operation process is often second-line oil hydrotreating desulfurization, and the catalyst is the FH-UDS catalyst developed and produced by Fushun Petrochemical Research Institute. The chemical hydrogen consumption (0.27wt% for fresh raw materials) and the system theoretical dissolved hydrogen (0.18wt%) of the reaction are tested first, and then the method process of the present invention is carried out. The reaction pressure is 6.4MPa, and the volumetric space velocity of the reaction raw material oil is 6h -1 . The amount of hydrogen mixed in the fixed control oil is 0.19wt% (mixed hydrogen amount / feed amount), and is a constant amount, and the circulation ratio (circulation oil volume: fresh raw material volume) is 2: 1, by controlling the reactor exhaust and The discharge volume is used to control the liquid volume and pressure in the reactor. The reaction result shows that the sulfur content of the refined oil is 5 μg / g, which is basica...

Embodiment 2

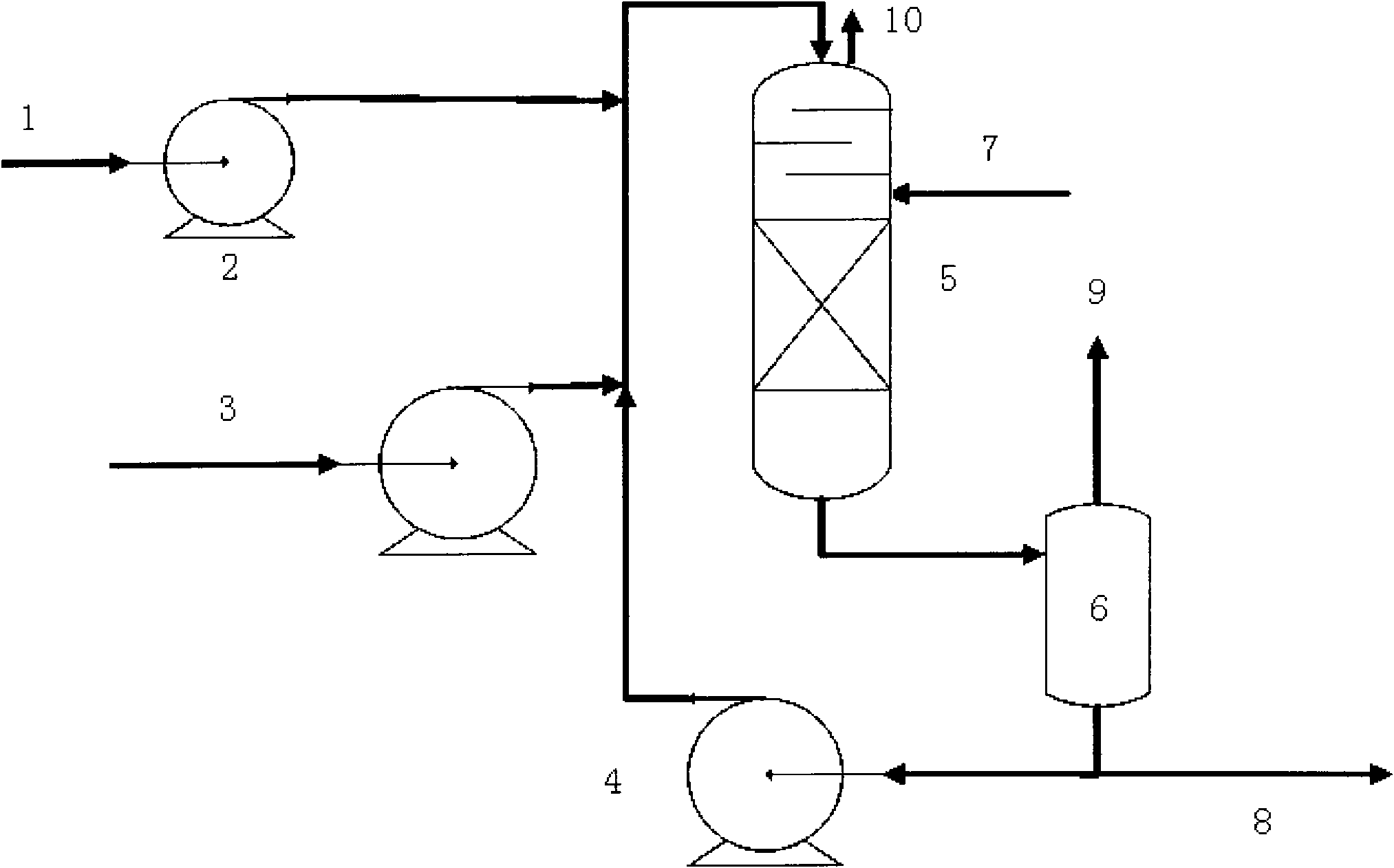

[0041] according to figure 2 As shown in the flow chart, two stripping trays are arranged on the upper part of the reactor, and the volume ratio of hydrogen to oil for stripping is 5:1. The mixed diesel feedstock is hydrotreated at 365°C for desulfurization and denitrogenation. The catalyst is FHUDS-2 catalyst developed and produced by Fushun Petrochemical Research Institute. The chemical hydrogen consumption (0.58wt% for fresh raw material) and the system dissolved hydrogen (0.18wt%) of the reaction are tested first, and then the method process of the present invention is carried out. The reaction pressure is 5.5MPa, and the volume space velocity of the reaction raw material oil is 3.2h -1 . The amount of hydrogen mixed is based on the reaction chemical hydrogen consumption plus 0.8 times the amount of dissolved hydrogen in the system, and the circulation ratio (volume of circulating oil: fresh raw material volume) is 4:1, that is, the amount of hydrogen mixed in the fixed...

Embodiment 3

[0045] according to figure 2 As shown in the flow chart, without using Gaofa 6, 3 stripping trays are arranged on the upper part of the reactor, and the volume ratio of hydrogen to oil for stripping is 1:1. Vacuum gas oil VGO was hydrotreated at 380°C to denitrify, and the catalyst was 3996 catalyst developed and produced by Fushun Petrochemical Research Institute. The chemical hydrogen consumption of the reaction and the dissolved hydrogen in the system are tested first, and then the method process of the present invention is carried out. The reaction pressure is 14.7MPa, and the volumetric space velocity of the reaction raw material oil is 1h -1 . The amount of hydrogen is based on the reaction chemical hydrogen consumption plus 3 times the amount of dissolved hydrogen in the system, and the circulation ratio (circulation oil volume: fresh raw material volume) is 3:1, that is, the hydrogen mixing amount in the fixed control oil is 1.72wt% (the hydrogen mixing amount / Fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com