Patents

Literature

31results about How to "Realize continuous regeneration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

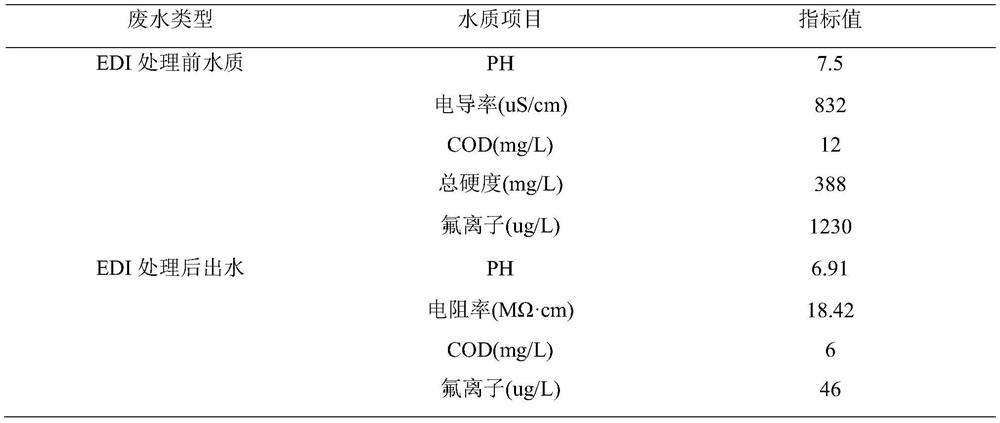

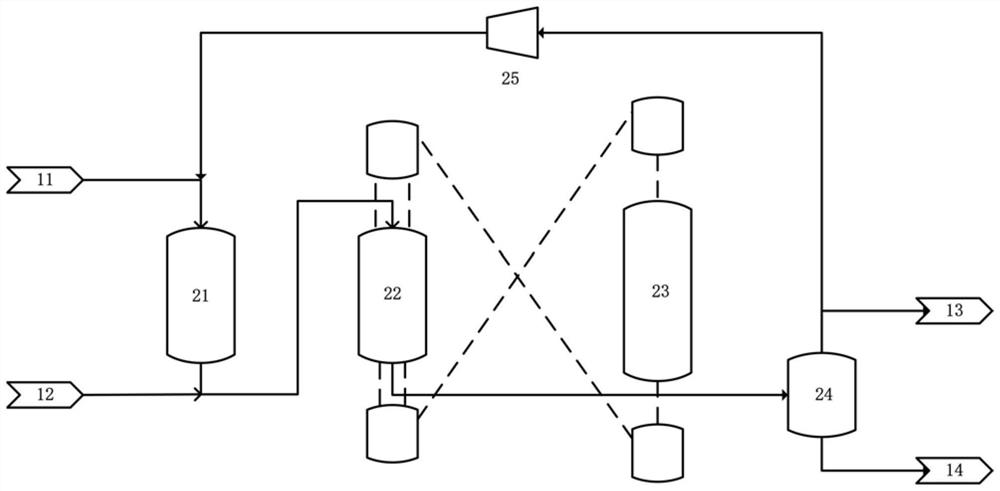

Reaction technology for converting oxygen-containing compound into aromatic hydrocarbons by using moving bed process

ActiveCN103664482ARealize continuous regenerationHigh activityHydrocarbon from oxygen organic compoundsHydrocarbon by hydrocarbon and non-hydrocarbon condensationDiluentAromatization

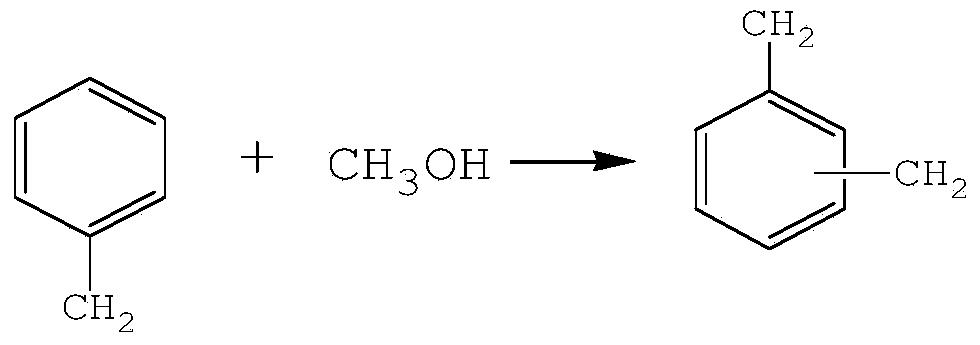

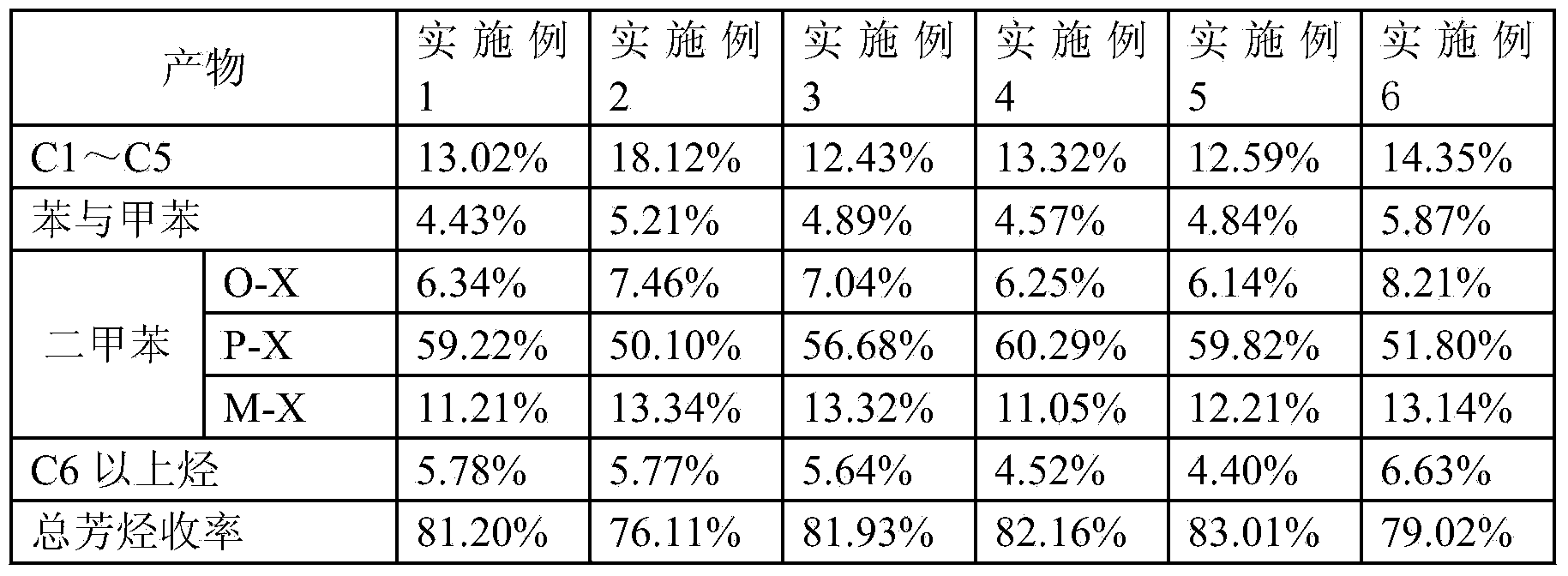

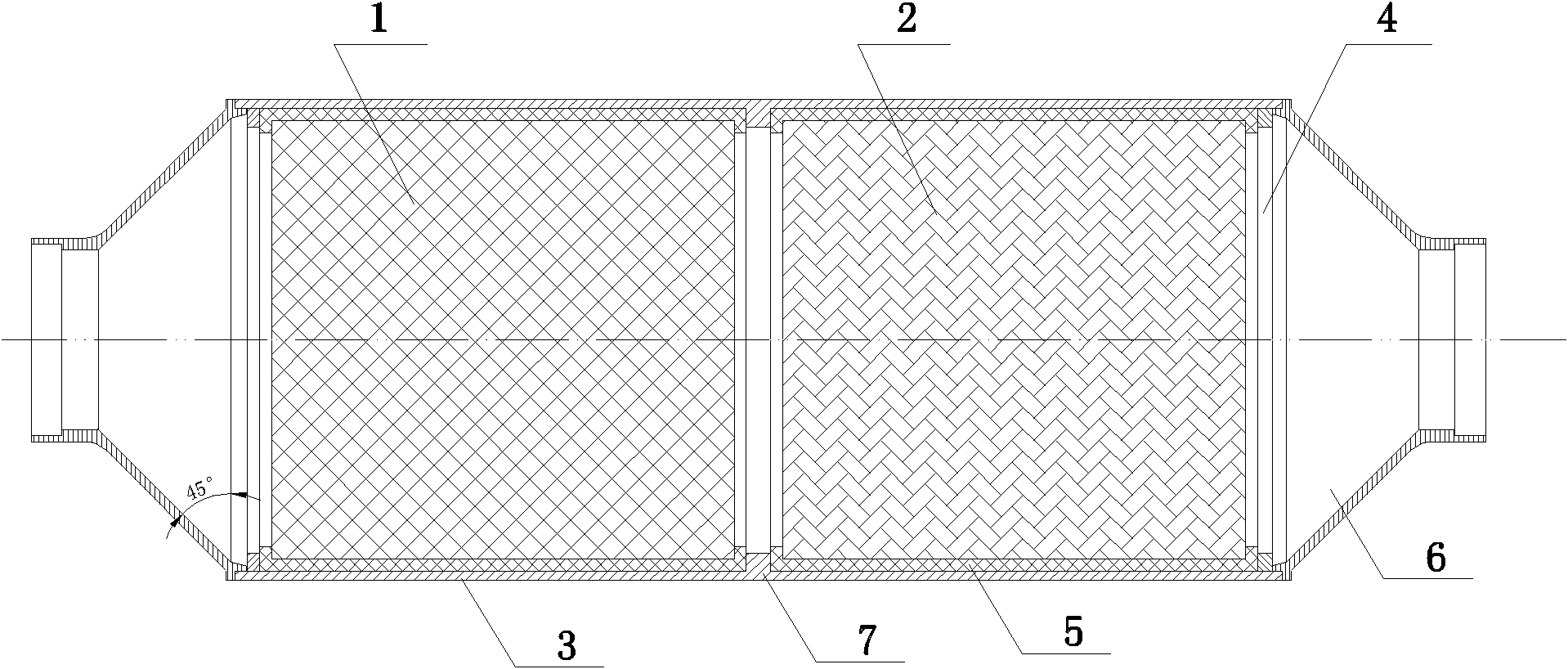

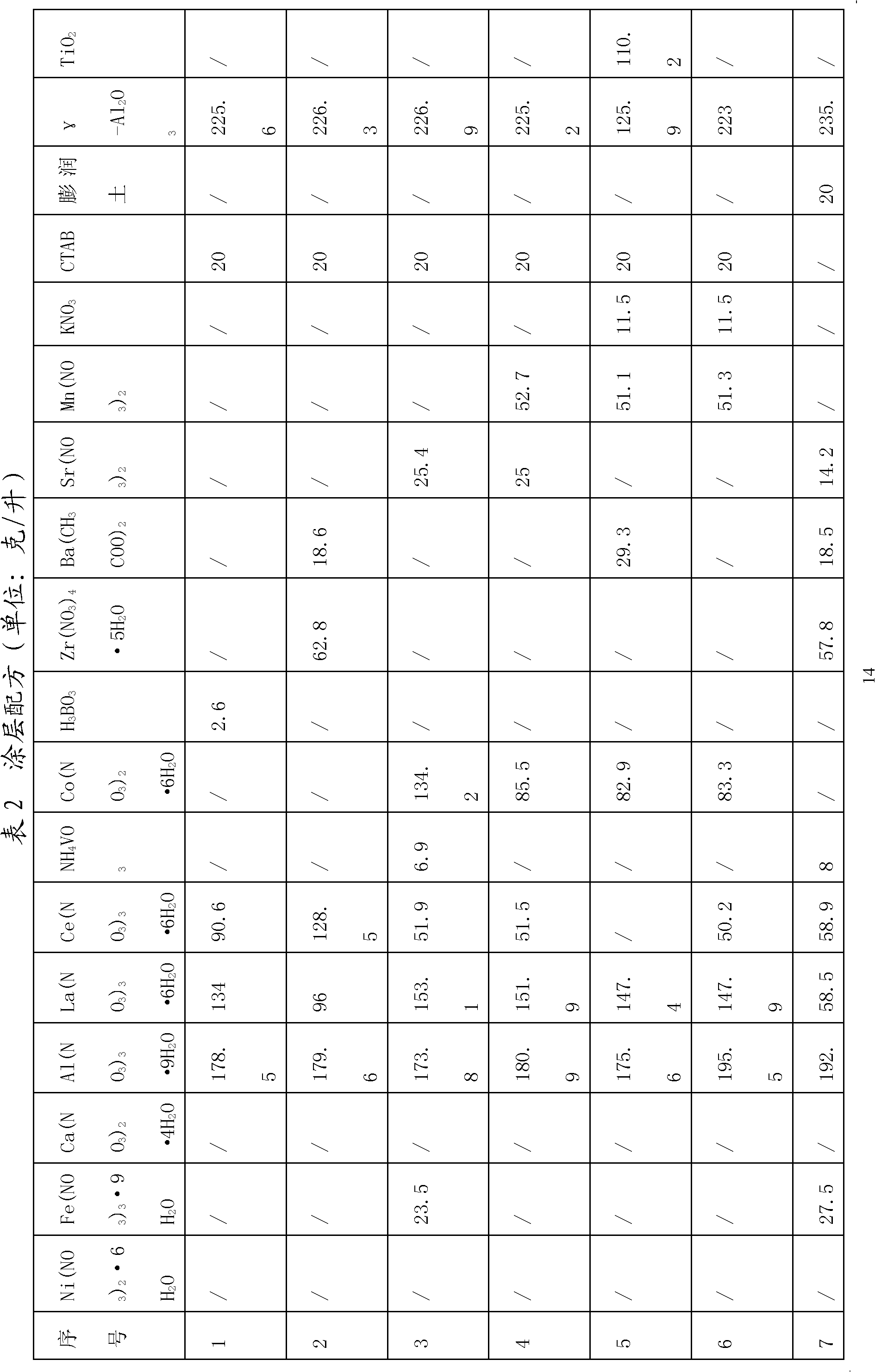

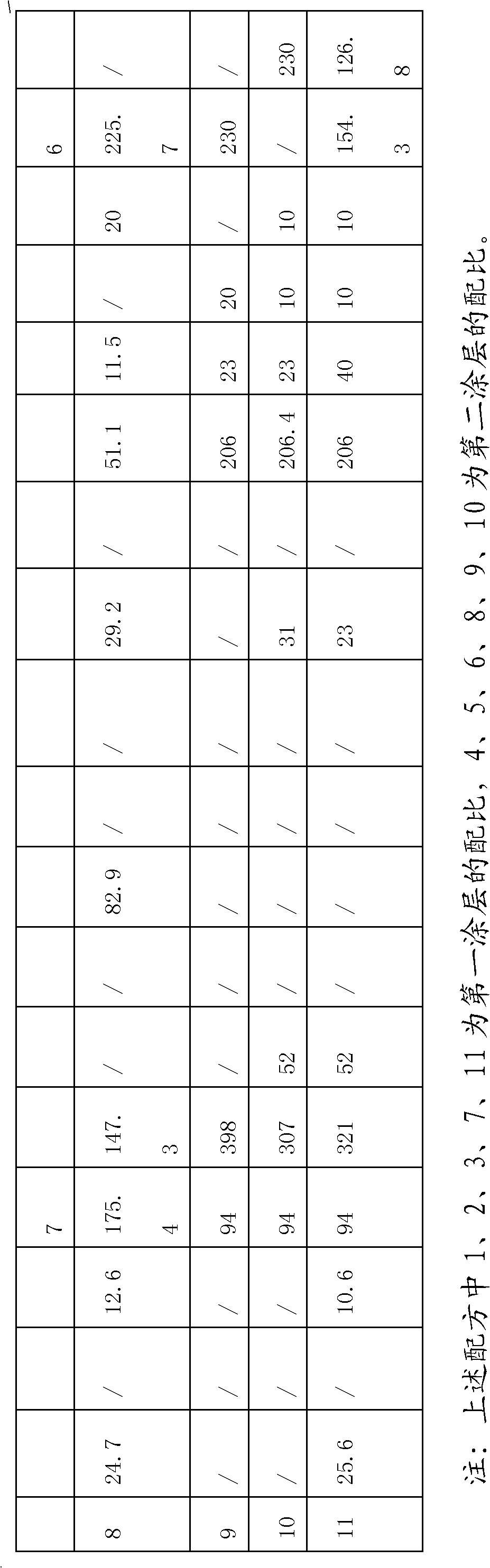

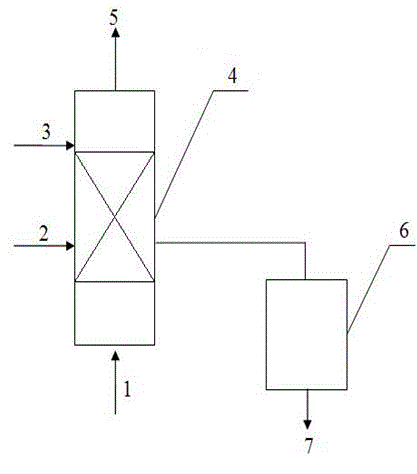

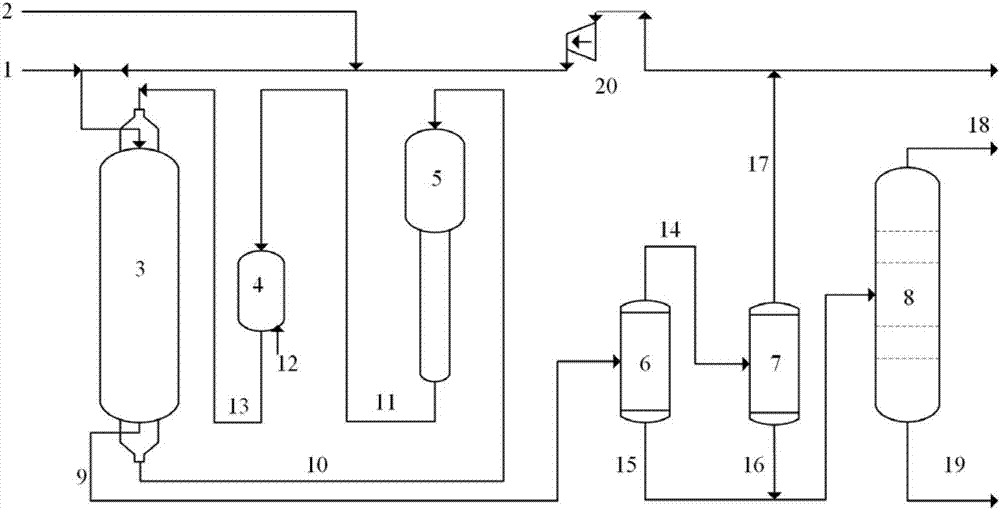

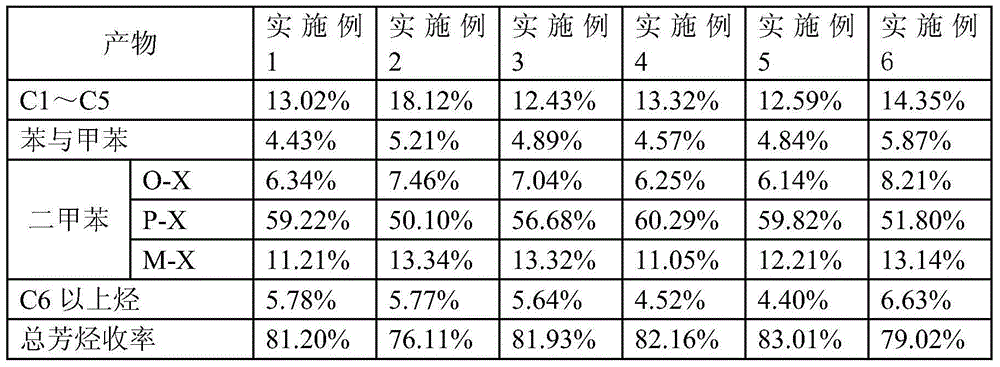

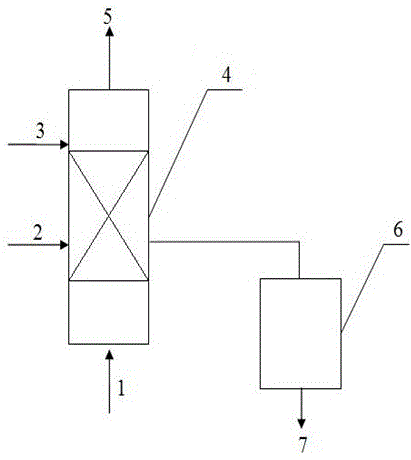

The invention discloses a reaction technology for converting an oxygen-containing compound into aromatic hydrocarbons by using a moving bed process. The technology comprises the following steps: preheating the oxygen-containing compound and a diluent, carrying out mixing preheating, reacting in the presence of an aromatization catalyst in an aromatization reactor in order to generate a mixed effluent, sending the mixed effluent to a cooling separation unit, carrying out dehydration and oxide removal, separating to obtain main products comprising benzene, toluene, xylene and other byproducts; circulating the other byproducts, benzene and toluene to the aromatization reactor as return hydrocarbons for a reaction; removing carbon-deposited aromatization catalyst particles from the aromatization reactor when the conversion rate of the oxygen-containing compound under the catalyst in the aromatization reactor is lower than 99%, regenerating in a regenerator, and adding the regenerated catalyst to the aromatization reactor. The technology improves the stability and the activity of the catalyst, and improves the selectivity of the aromatic hydrocarbons especially xylene through recycling product hydrocarbons.

Owner:ZHEJIANG UNIV

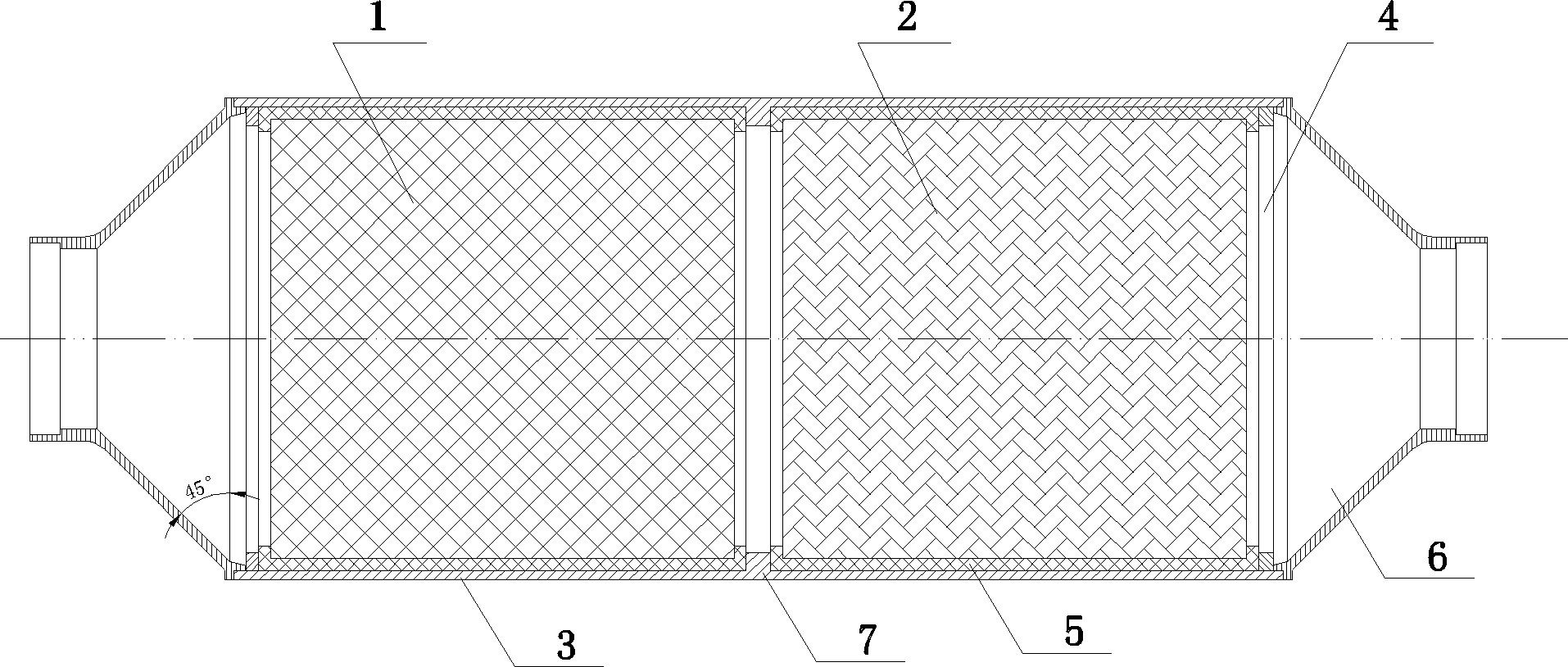

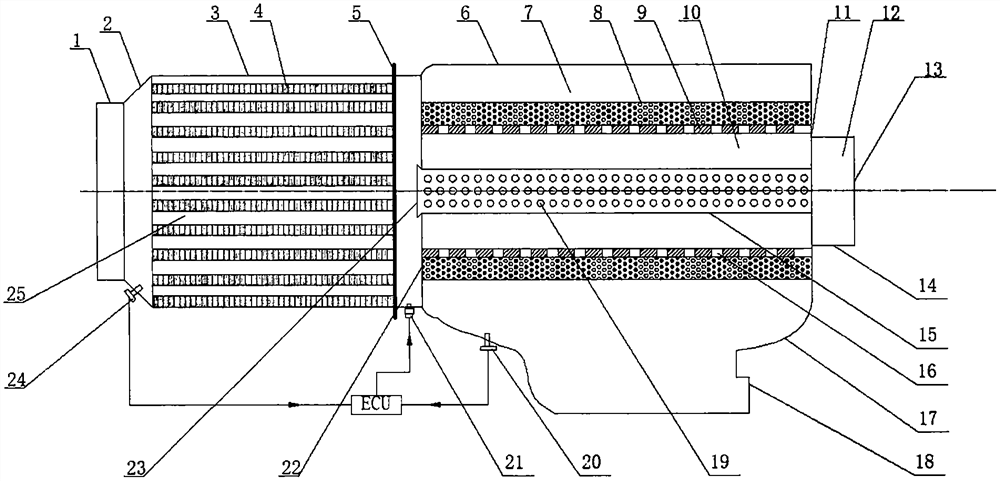

Catalyst for purifying tail gas of diesel automobiles, preparation method and purification device thereof

ActiveCN102489322ANo sheddingImprove uniformityExhaust apparatusDispersed particle separationOrganic fractionCombustion

The invention relates to a catalyst for purifying tail gas of diesel automobiles, a preparation method and a purification device thereof. The catalyst comprises a first carrier taking cordierite honeycomb ceramics as a matrix, and a second carrier taking SiC or a cordierite wall-flow structure as a matrix, a first coating and active components on the first carrier, as well as a second coating and active components on the second carrier. In the invention, coating, roasting and reduction processes are adopted for preparing the coatings composed of composite oxides. The catalyst and the device in the invention employ a technology combining a DOC (diesel oxidation converter) and a CDPF (catalyzed diesel particulate filter). By means of the DOC at a front end, HC, CO as well as the soluble organic fractions (SOF) in PM are removed through oxidation. Meanwhile, NO is converted to NO2 that has stronger reducibility so as to be good for the reaction of NO2 and C, thus reaching the purposes of removing NO and lowering the combustion temperature of C simultaneously. Depending on the self-temperatures of diesel automobiles to realize regeneration of a particulate filter, the purification device in the invention has the characteristics of high purification efficiency and convenient usage, etc.

Owner:CHONGQING MATERIALS RES INST

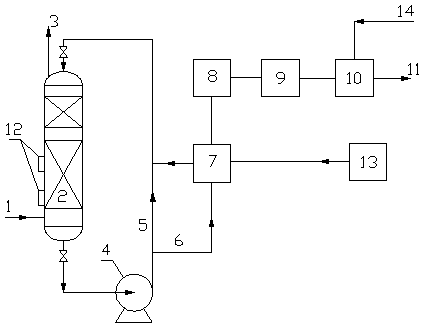

Oxidative desulfurization process for continuous regeneration of desulfurizing agent

ActiveCN104548934AWide variety of sourcesImprove solubilityDispersed particle separationFixed bedProcess engineering

The invention discloses an oxidative desulfurization process for continuous regeneration of a desulfurization agent. The process is characterized by comprising the following steps: hydrogen sulfide-containing gas and oxygen-containing gas are in contact with the desulfurization agent at a desulfurization agent bed layer in a fixed bed reactor for oxidative desulfurization and desulfurization agent regeneration reaction, purified gas is discharged from the top of the reactor, catalytic cracking diesel is introduced in a reaction process for dissolving elemental sulfur generated in the regeneration reaction, and the catalytic cracking diesel in which elemental sulfur is dissolved flows out of the reactor and is subjected to solid-liquid separation for recycling. According to the process, the desulfurization precision is high, the desulfurization agent is long in service life, the operation is simple, and the cost is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

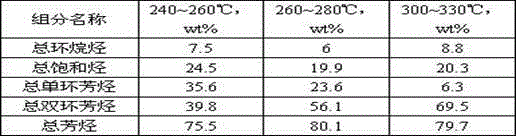

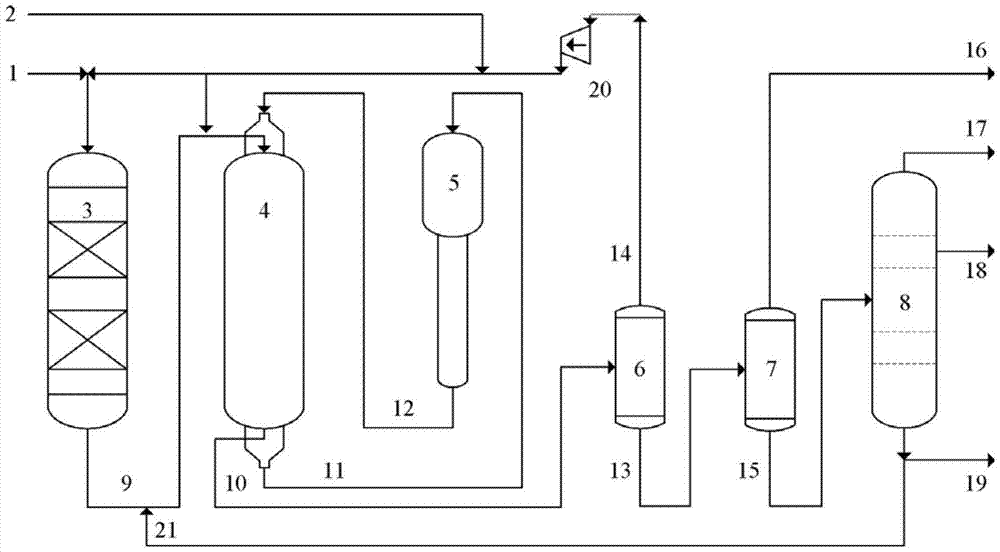

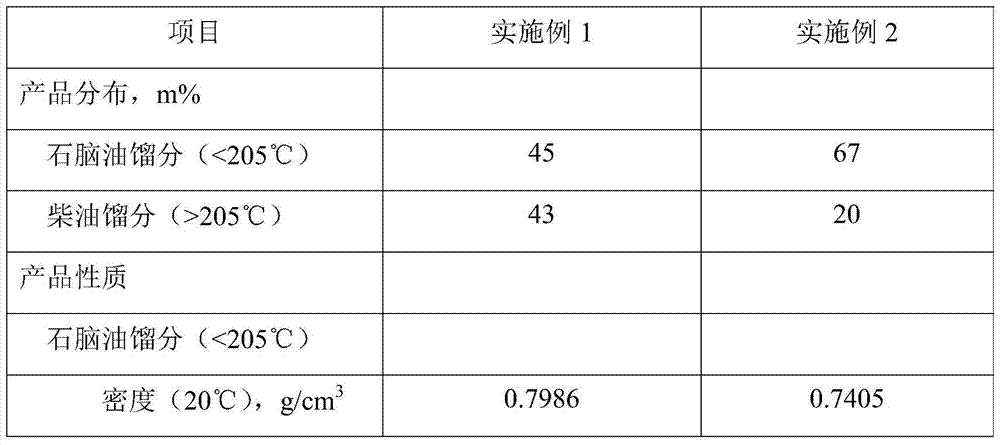

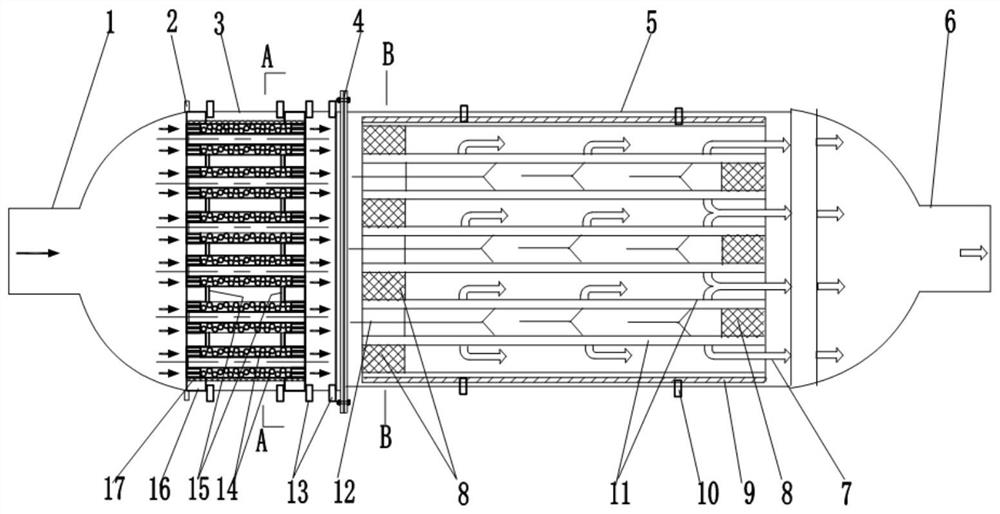

A method for producing light aromatics and clean fuel oil by hydrocracking in a moving bed

ActiveCN105647573BIncrease the depth of hydrocrackingReduce overhydrogenationHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsVulcanizationFractionation

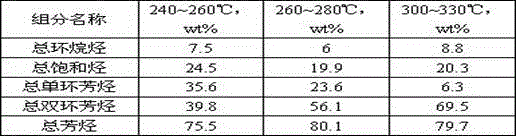

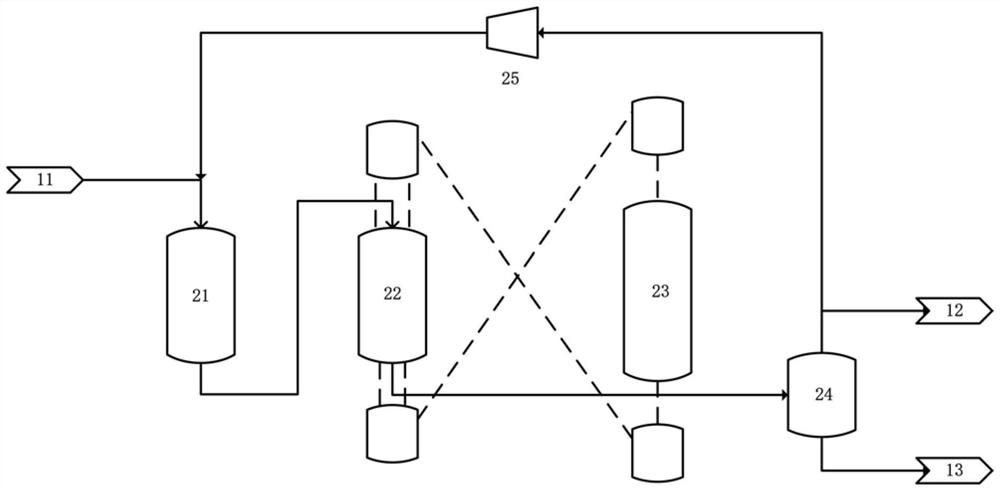

The invention relates to a process for producing light aromatics and clean fuel oil by hydrocracking catalytic cracking diesel oil through moving bed. The process comprises the following steps: 1) mixing catalytic cracking diesel oil and hydrogen into a fixed bed hydrotreating reactor Hydrofining reaction to remove sulfur and nitrogen impurities, and carry out hydrogenation saturation of olefins and hydrogenation saturation of partial aromatic rings of condensed aromatic hydrocarbons; After mixing, enter the moving bed hydrocracking reactor for deep hydrocracking reaction, and realize the separation of hydrocracking products and deactivated catalyst at the outlet of the reactor; 3) The deactivated catalyst recovers the hydrocracking activity through online charring and sulfidation 4) Hydrocracking products are separated and fractionated to obtain liquefied gas, light aromatics, high-octane clean gasoline blending components and clean diesel blending components.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

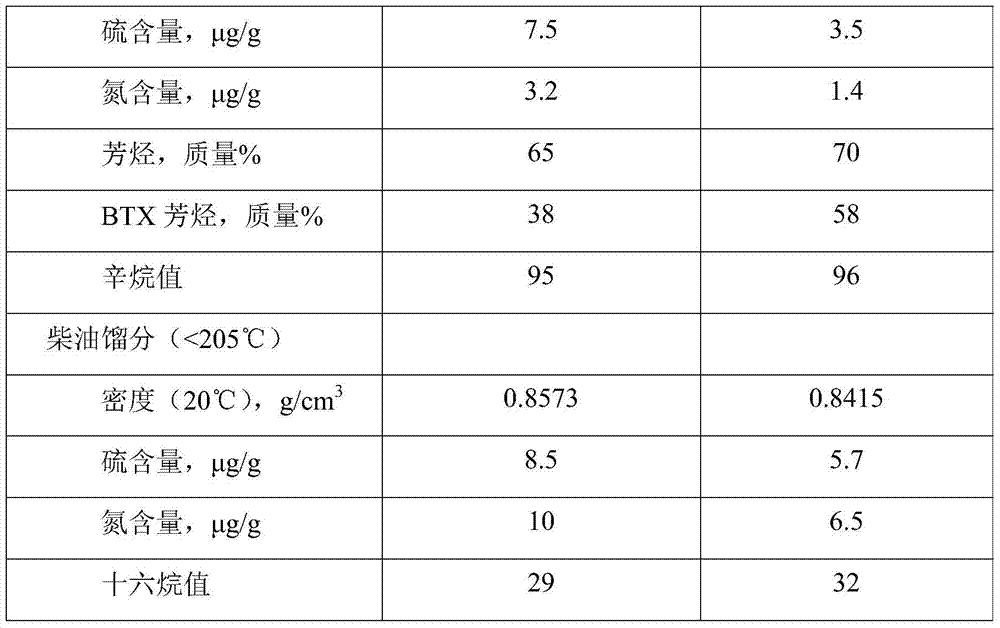

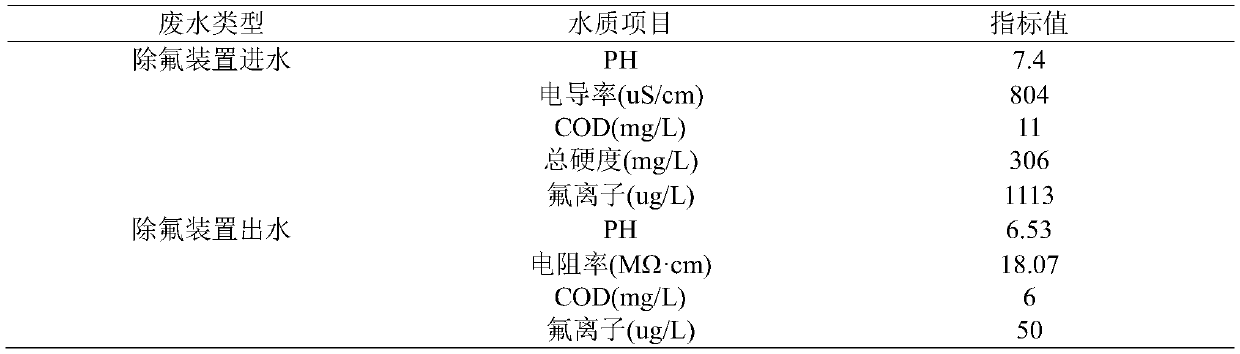

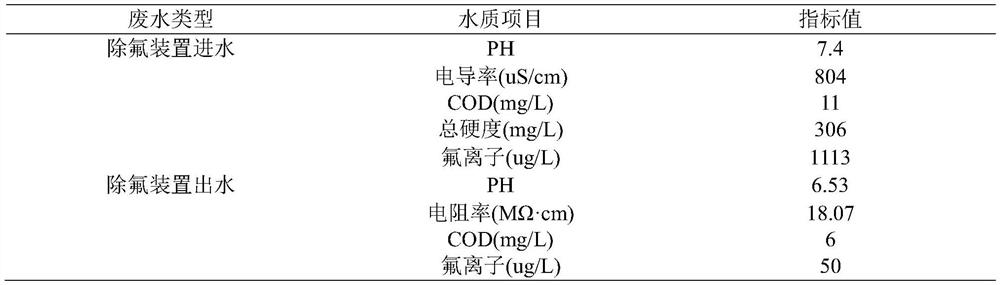

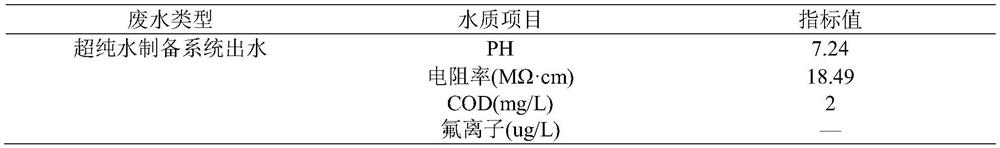

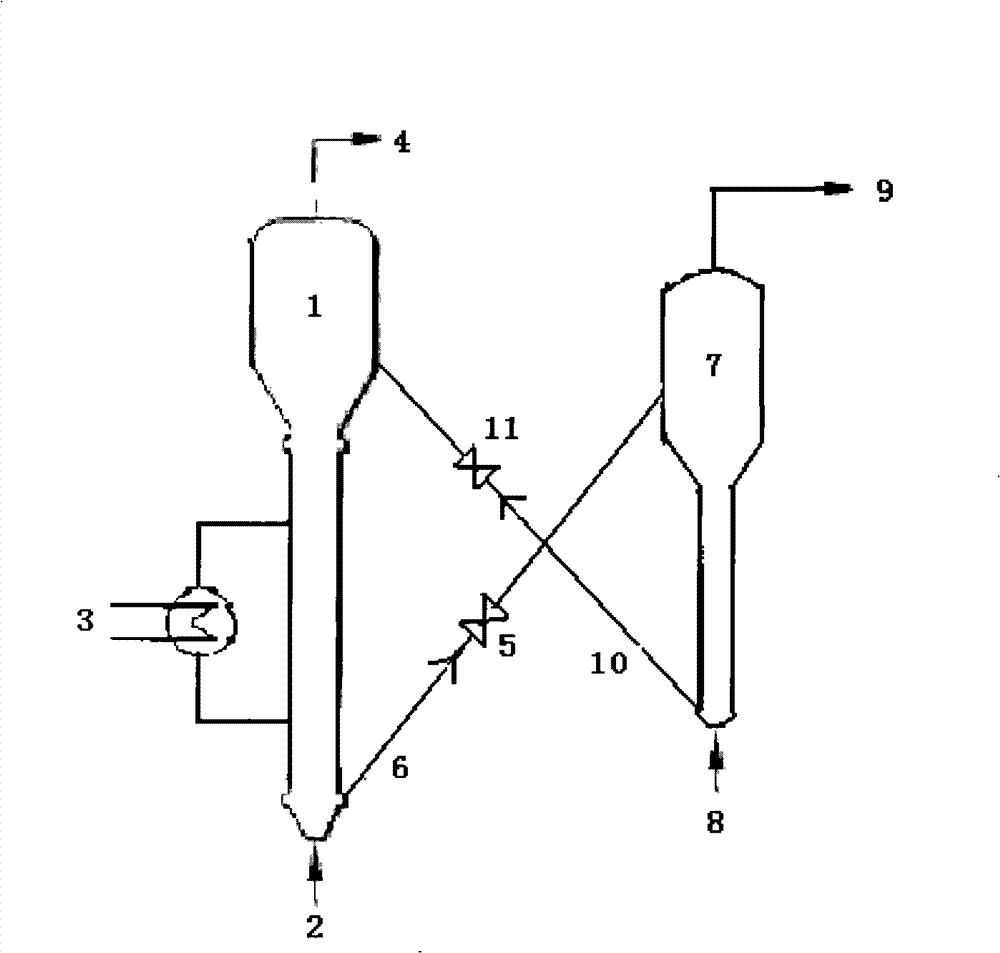

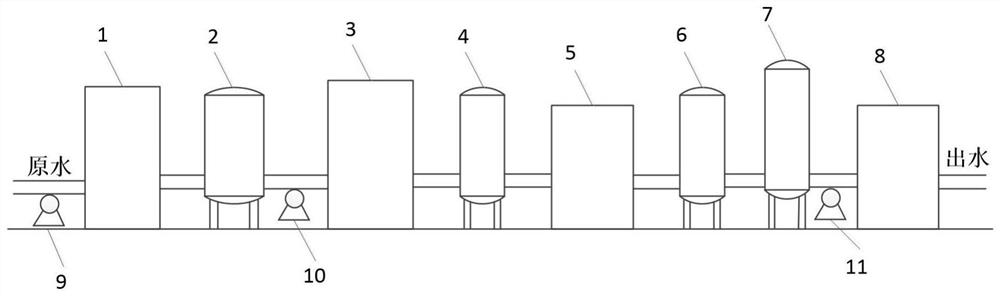

Method for treating fluorine-containing reuse water

ActiveCN110451704AImprove recycling ratesHigh removal rateWater/sewage treatment by irradiationWater contaminantsFlocculationFiltration

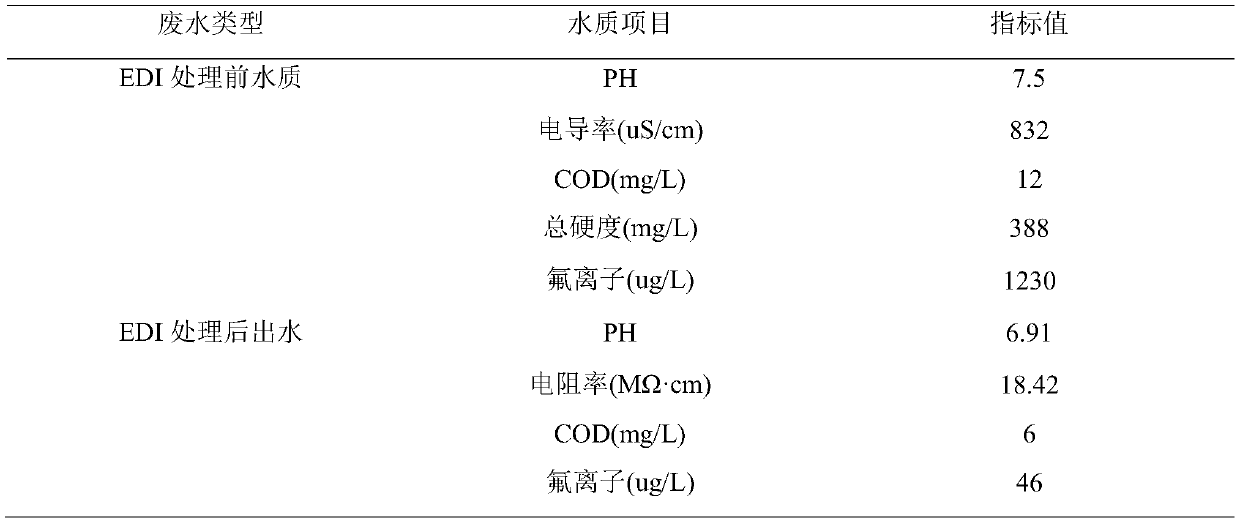

The invention discloses a method for treating fluorine-containing reuse water. The method comprises the following specific steps: (1) pretreatment; (2) flocculation precipitation; (3) filtration-reverse osmosis membrane filtration; (4) total organic carbon (TOC) degradation and ultraviolet sterilization; (5) electrodeionization (EDI) treatment; (6) TOC degradation and ultraviolet sterilization; and (7) precise filtration. The invention has the advantages that water quality of an effluent can reach a standard of ultra-pure water, fluorine removal efficiency is high, the recycling rate of wastewater is high, and operation cost is low.

Owner:NANJING UNIV +1

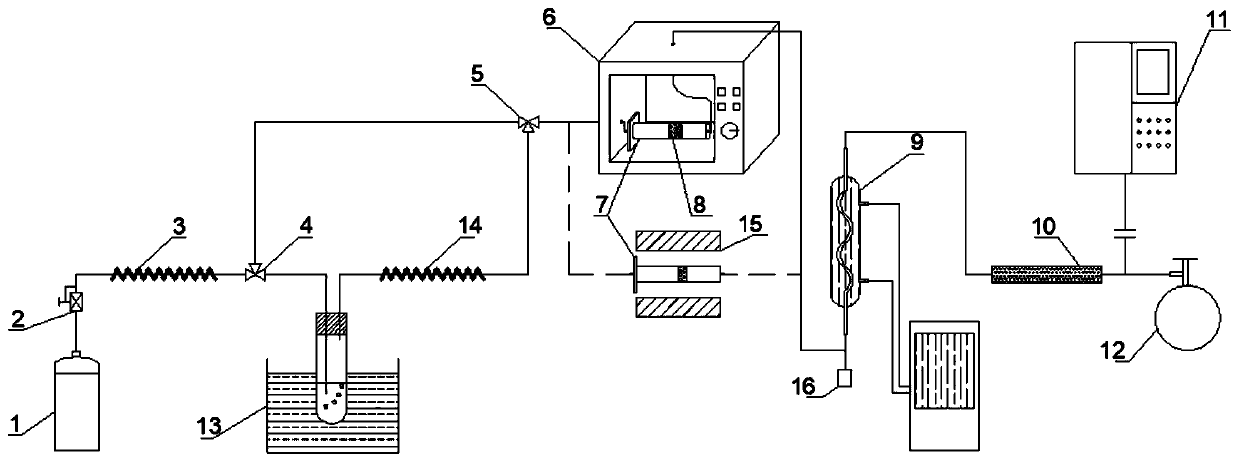

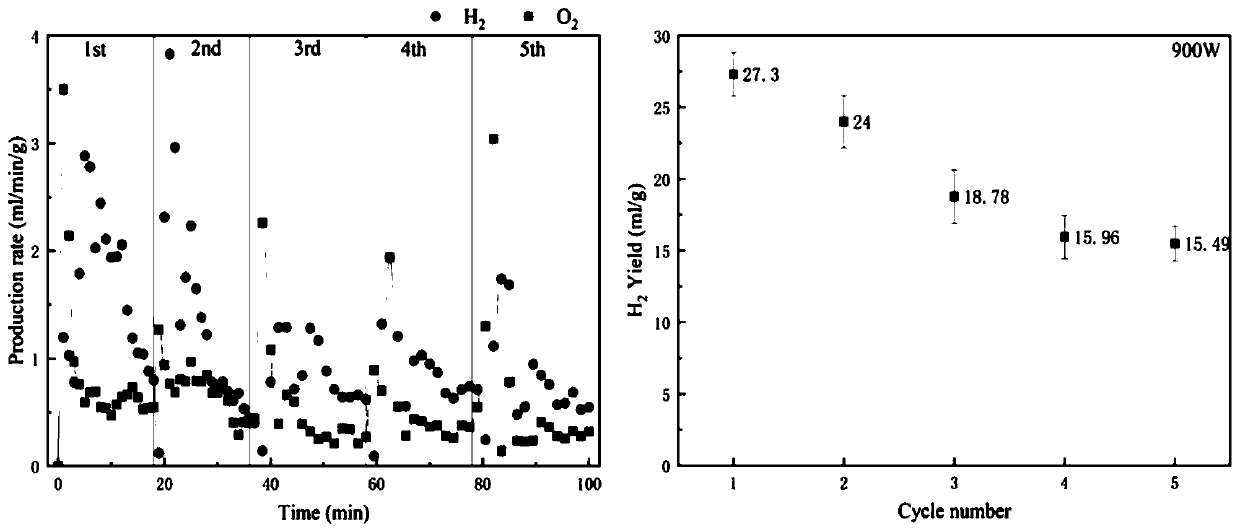

Thermochemical hydrogen production system based on microwave heating and hydrogen production method and application thereof

ActiveCN111302302ARealize continuous regenerationSolve the problem of long heat treatment timeHydrogen productionThermodynamicsMicrowave pyrolysis

The invention belongs to the technical field of thermochemical hydrogen production, and particularly relates to a thermochemical hydrogen production system based on microwave heating and a hydrogen production method and application thereof. A hydrogen production device is characterized in that an inlet of a preheater is communicated with a carrier gas storage device, a flow controller is arrangedbetween the preheater and the carrier gas storage device, an outlet of the preheater is respectively communicated with an inlet of the steam generator and one end of a second three-way valve through afirst three-way valve, the other two ports of the second three-way valve are respectively communicated with an outlet of a superheater and an inlet of the reactor, the reactor is arranged in a microwave generation device, an outlet of the steam generator is communicated with the outlet of the superheater through a pipeline, an outlet of the reactor, a condenser, a drying device and a collecting device are sequentially communicated, and a chromatographic instrument is arranged on the communicating pipeline between the drying device and the collecting device. The microwave pyrolysis of the metal oxide is short in heating time, low in power consumption and low in experiment cost, the repeated experiment period is shortened, and the effective energy utilization rate is greatly improved.

Owner:SHANDONG UNIV

Catalytic cracking gasoline adsorption desulfurizing agent as well as preparation method and application thereof

InactiveCN107159096AReduce hydrogenation saturationReduced chemical hydrogen consumption and octane lossOther chemical processesHydrocarbon oils refiningSulfur contentAdsorption reaction

The invention relates to an adsorption desulfurizing method for catalytic cracking gasoline. The method comprises the following steps: S201, carrying out an adsorption desulfurizing reaction between the catalytic cracking gasoline and an adsorption desulfurizing agent under a hydrogen present condition, and obtaining a desulfurization product and an inactivated desulfurizing agent; S202, separating and purifying the adsorption desulfurizing product, thereby obtaining gasoline components with the sulfur content of less than or equal to 10<mu>g.g<-1>. With the adoption of the method provided by the invention, hydrogenation saturation of olefins can be effectively reduced while realizing ultra-deep reaction adsorption desulfurization of high-sulfur inferior catalytic cracking gasoline, and chemical hydrogen consumption and octane loss are reduced. Moreover, the adsorption desulfurizing agent provided by the invention has the advantages of high sulfur capacity, low wear rate, low adsorption reaction temperature, capability of obviously reducing operating cost and the like. Meanwhile, the adsorption desulfurizing agent provided by the invention can realize continuous regeneration on line, so that the defect that the running period of the adsorption desulfurizing agent is low due to inactivation is overcome.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

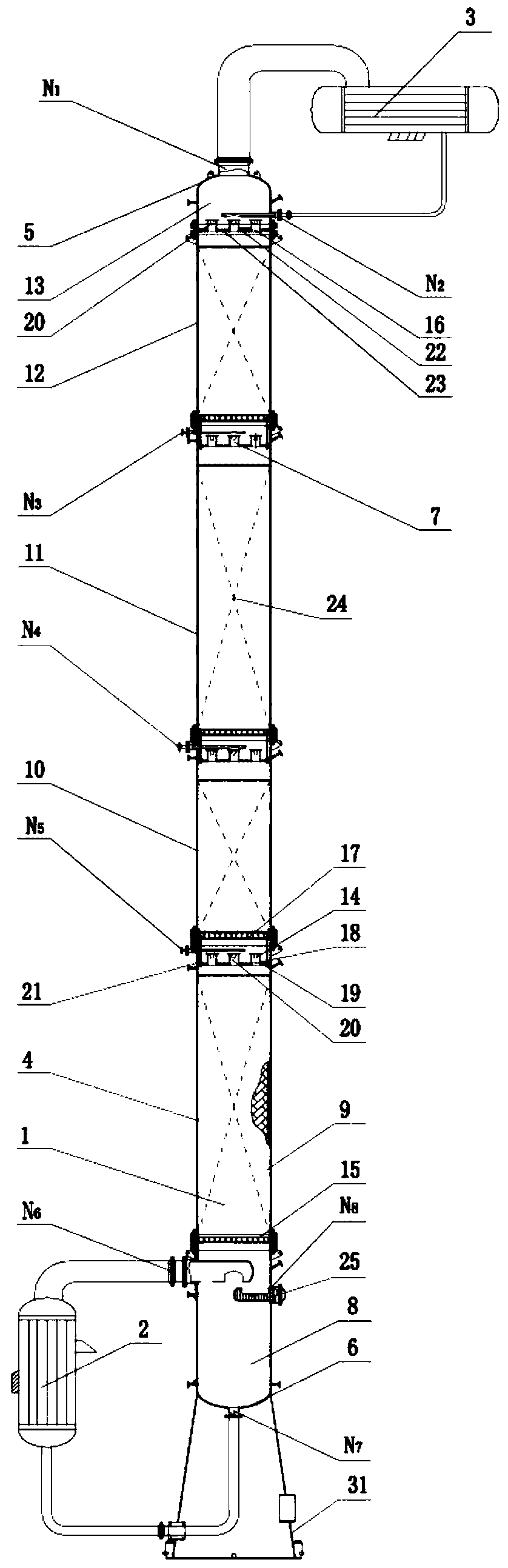

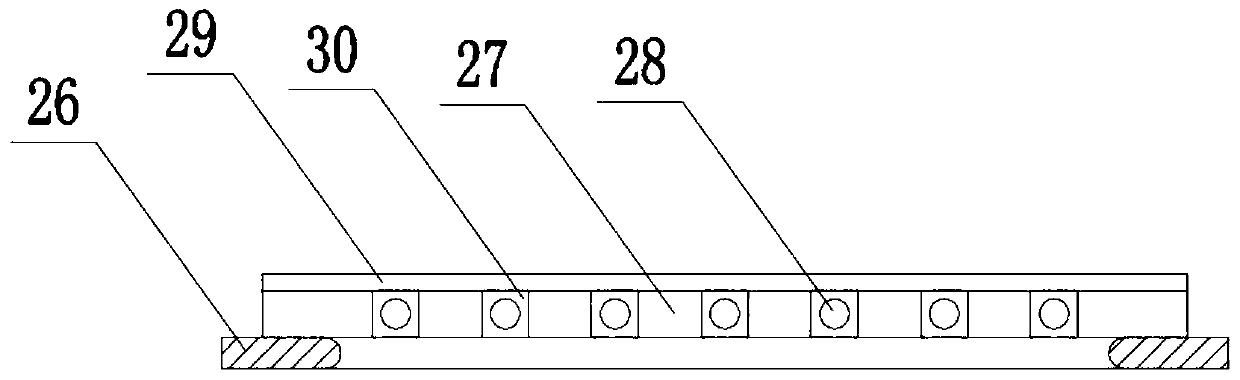

Integrated production tower of ethyl acetate

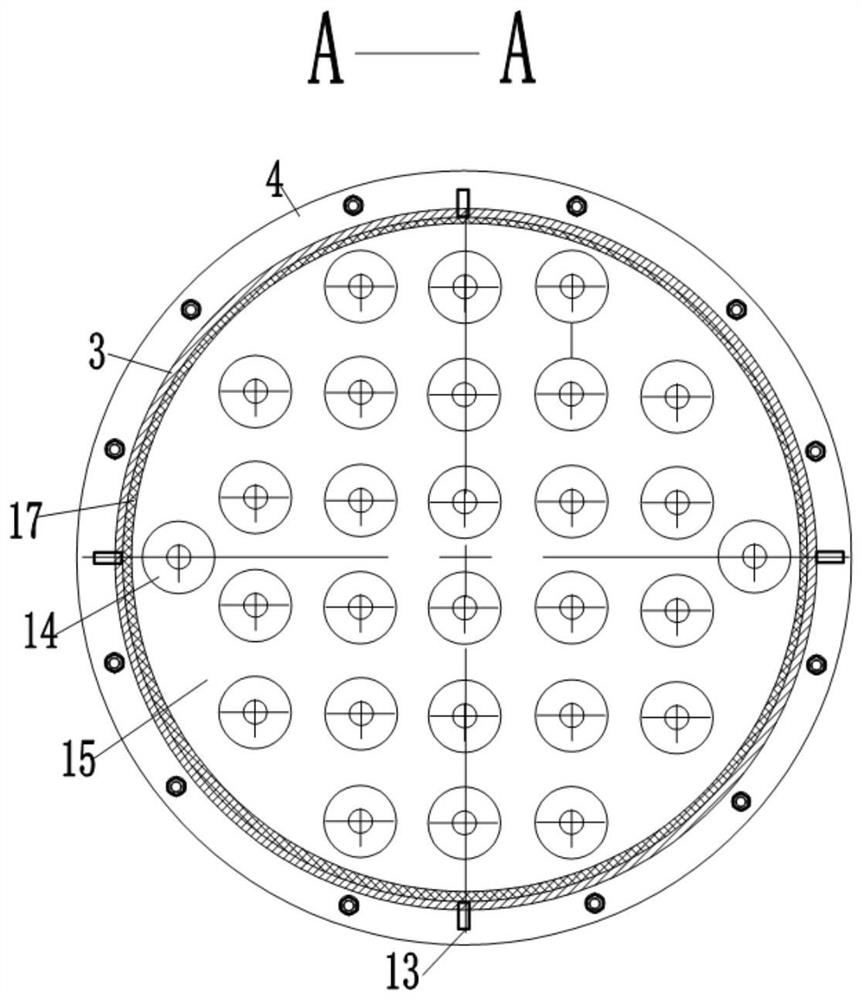

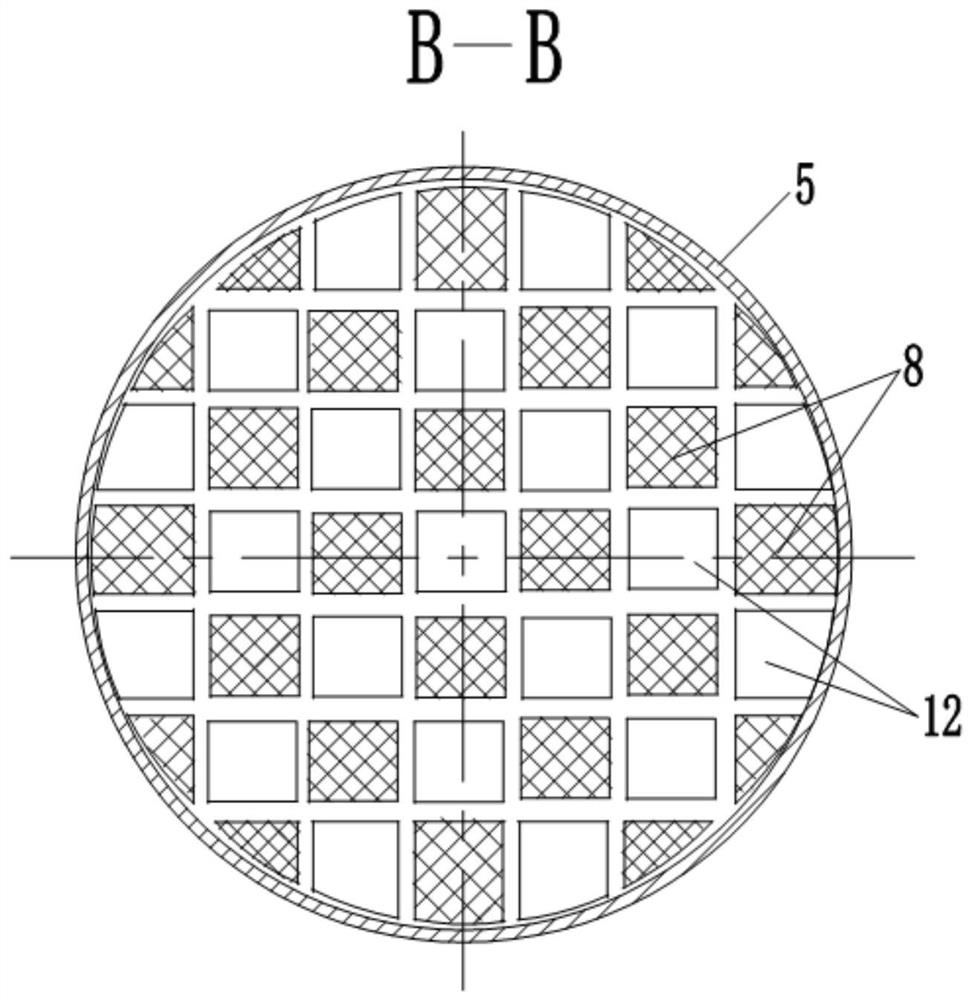

PendingCN109851501AReduce water contentIncrease contact surfaceOrganic compound preparationCarboxylic acid esters preparationAcetic acidBiochemical engineering

The invention discloses an integrated production tower of ethyl acetate. The integrated production tower of the ethyl acetate comprises a tower body, a tower bottom reboiler and a tower top condenser,wherein the tower body is a cylindrical pressure container, and comprises a cylinder, an upper end socket and a lower end socket, and the tower body is divided into a tower bottom segment, a stripping segment, a reaction segment, an extraction segment, a rectification segment and a tower top segment by tower internals from bottom to top in sequence. The production tower is compact in equipment, the total occupied area is reduced by more than 60%, running energy consumption is low, and is saved by more than 40% compared with that of a conventional technology, and the device wastewater quantityis little, and is reduced by more than 80% compared with that of an existing technology.

Owner:JIANGSU SOPO CHEM +1

Catalyst for purifying tail gas of diesel automobiles, preparation method and purification device thereof

ActiveCN102489322BNo sheddingImprove uniformityPhysical/chemical process catalystsAir quality improvementOrganic fractionCombustion

The invention relates to a catalyst for purifying tail gas of diesel automobiles, a preparation method and a purification device thereof. The catalyst comprises a first carrier taking cordierite honeycomb ceramics as a matrix, and a second carrier taking SiC or a cordierite wall-flow structure as a matrix, a first coating and active components on the first carrier, as well as a second coating and active components on the second carrier. In the invention, coating, roasting and reduction processes are adopted for preparing the coatings composed of composite oxides. The catalyst and the device in the invention employ a technology combining a DOC (diesel oxidation converter) and a CDPF (catalyzed diesel particulate filter). By means of the DOC at a front end, HC, CO as well as the soluble organic fractions (SOF) in PM are removed through oxidation. Meanwhile, NO is converted to NO2 that has stronger reducibility so as to be good for the reaction of NO2 and C, thus reaching the purposes of removing NO and lowering the combustion temperature of C simultaneously. Depending on the self-temperatures of diesel automobiles to realize regeneration of a particulate filter, the purification device in the invention has the characteristics of high purification efficiency and convenient usage, etc.

Owner:CHONGQING MATERIALS RES INST

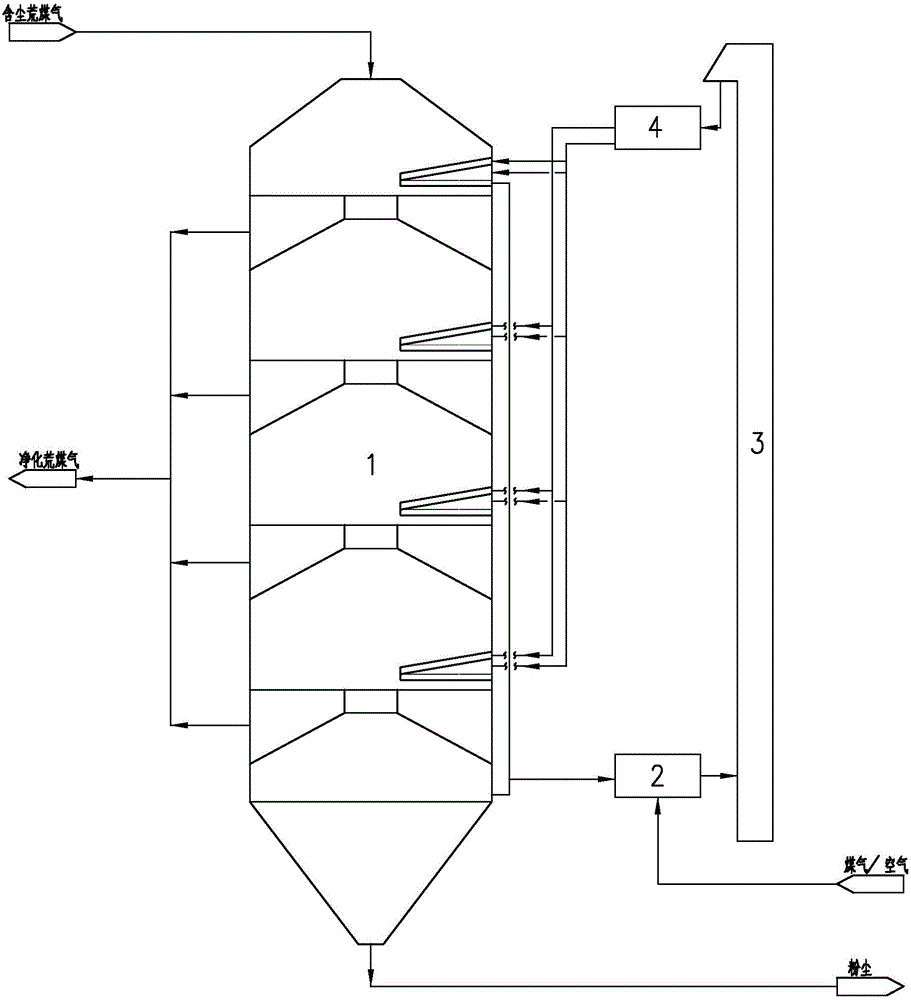

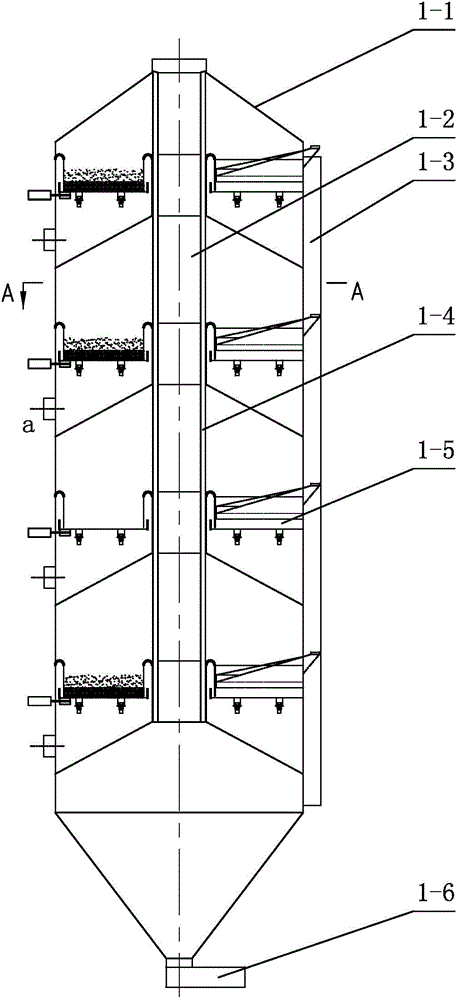

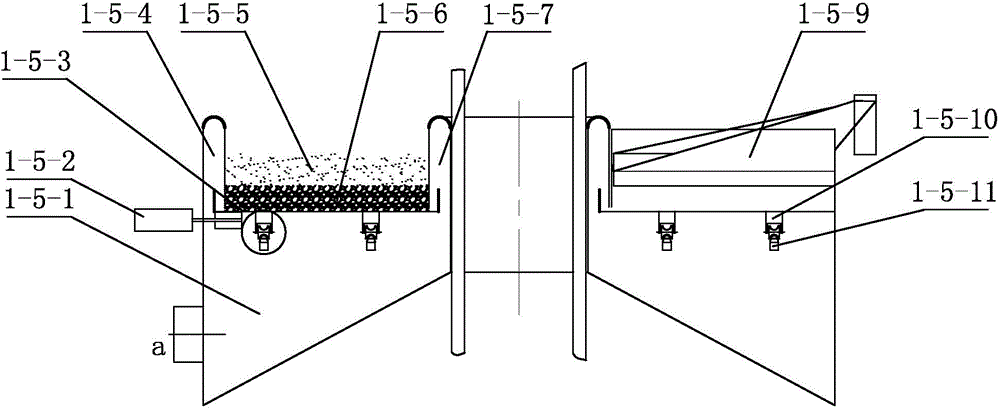

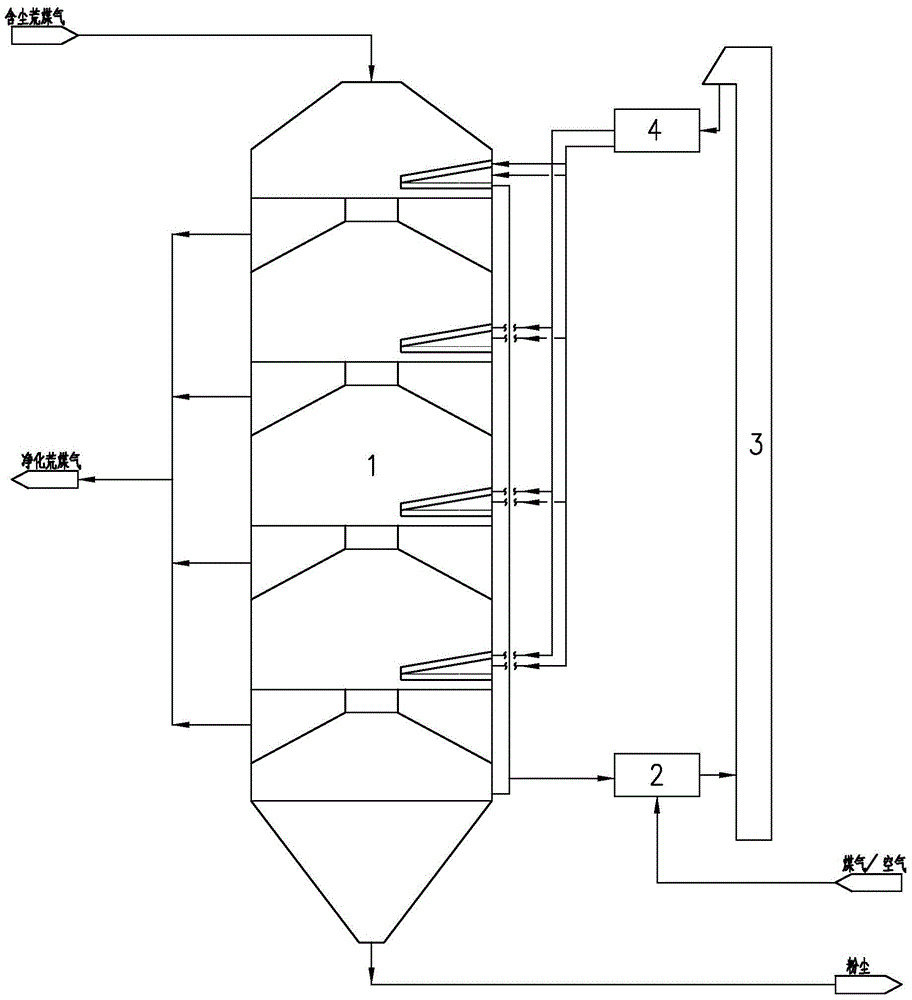

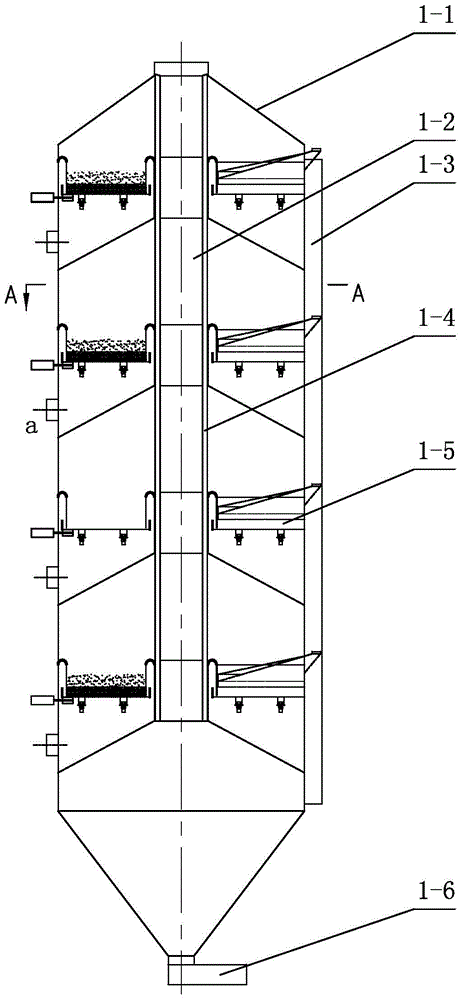

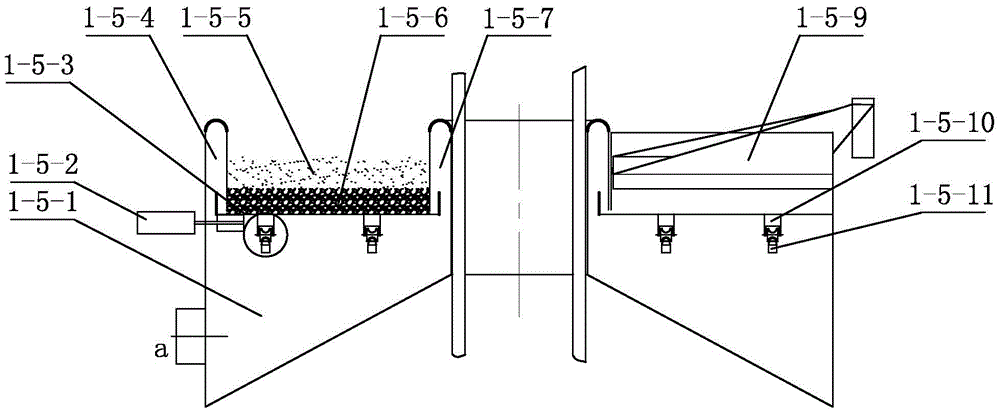

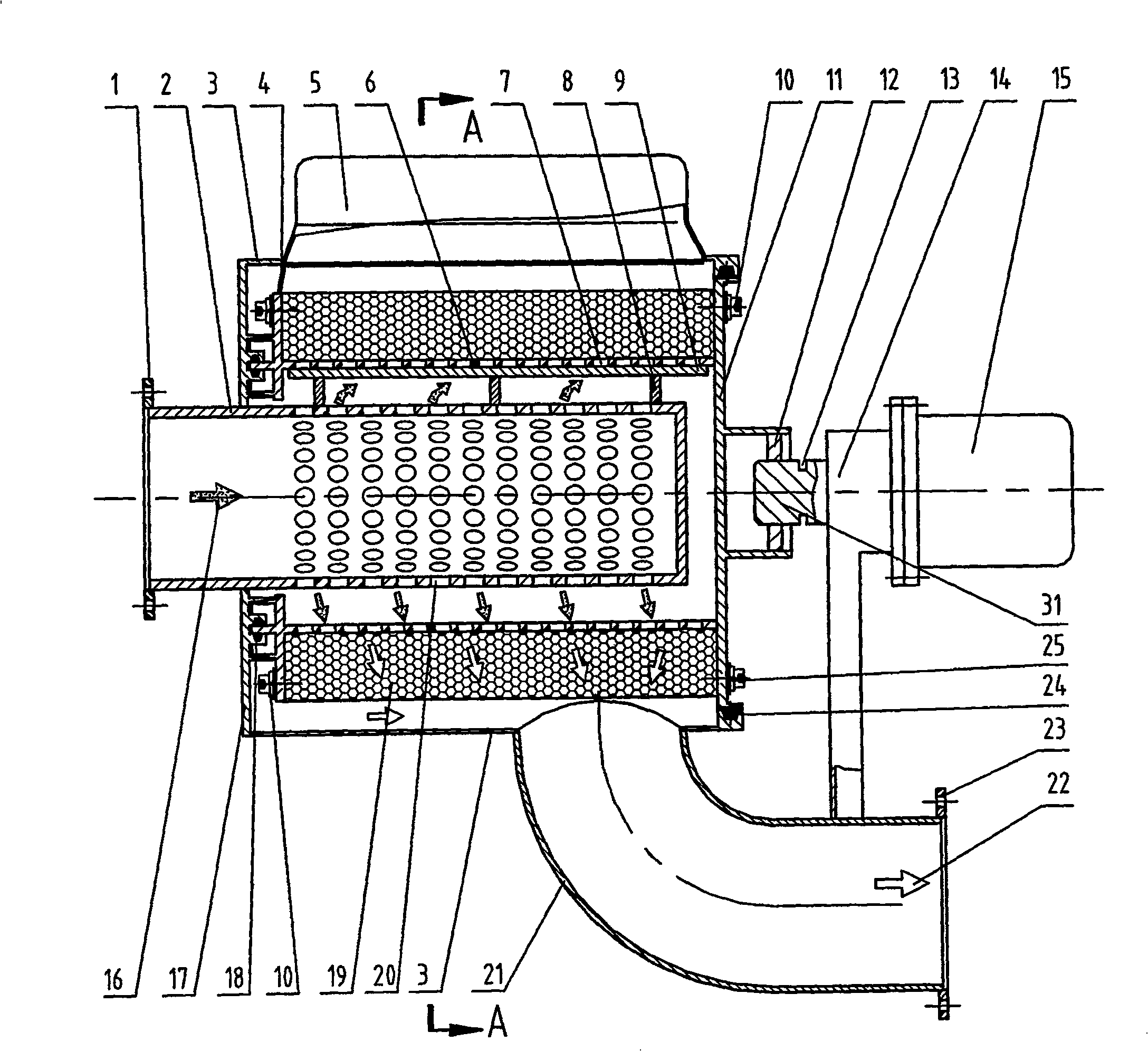

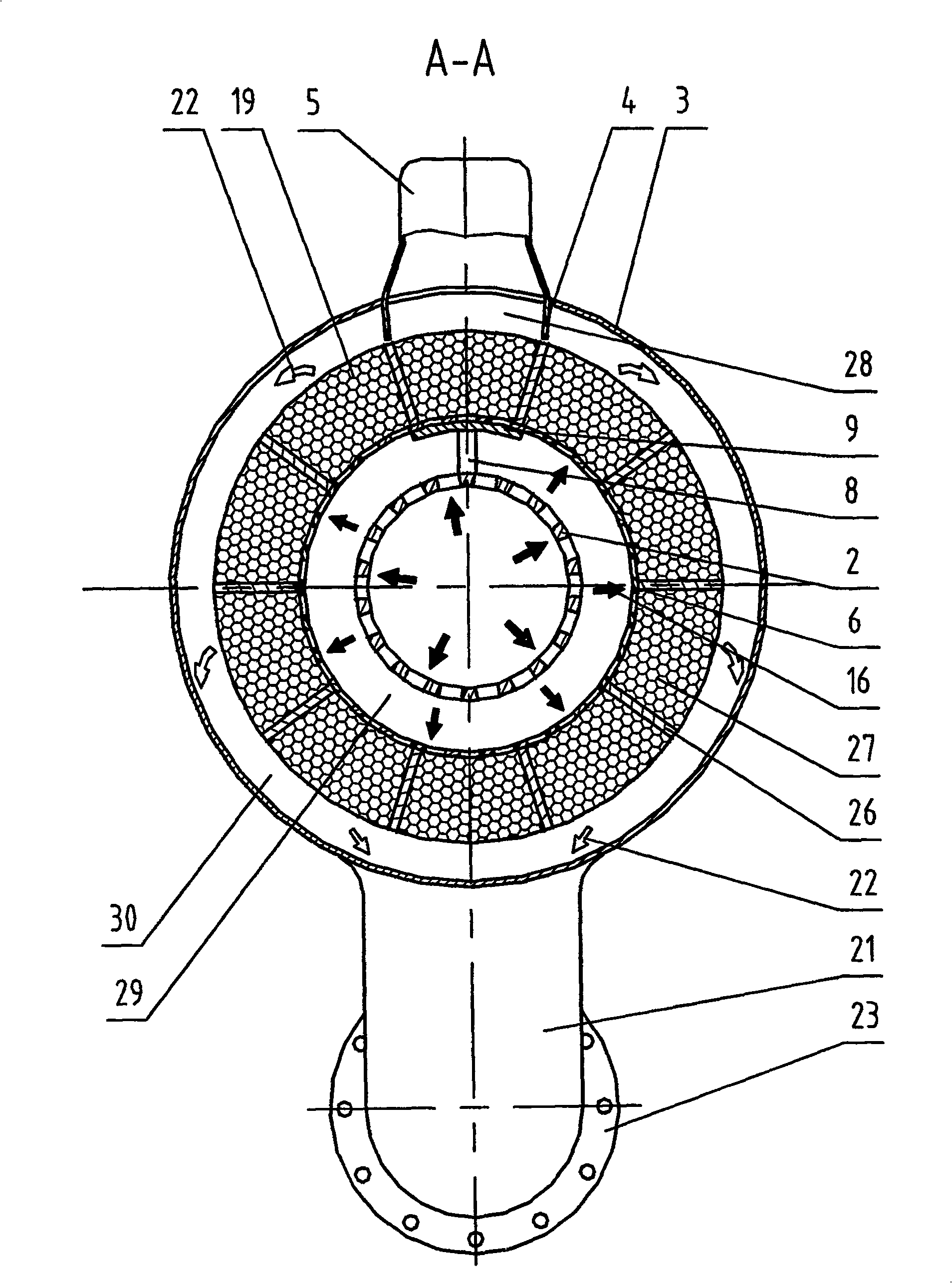

Dust removal system and method for raw coke oven gas by virtue of rotary type fixed bed

ActiveCN104449879ARealize continuous regenerationSolve the problem of difficult regeneration of carbon depositsChemical industryGas dust removalFixed bedHeat losses

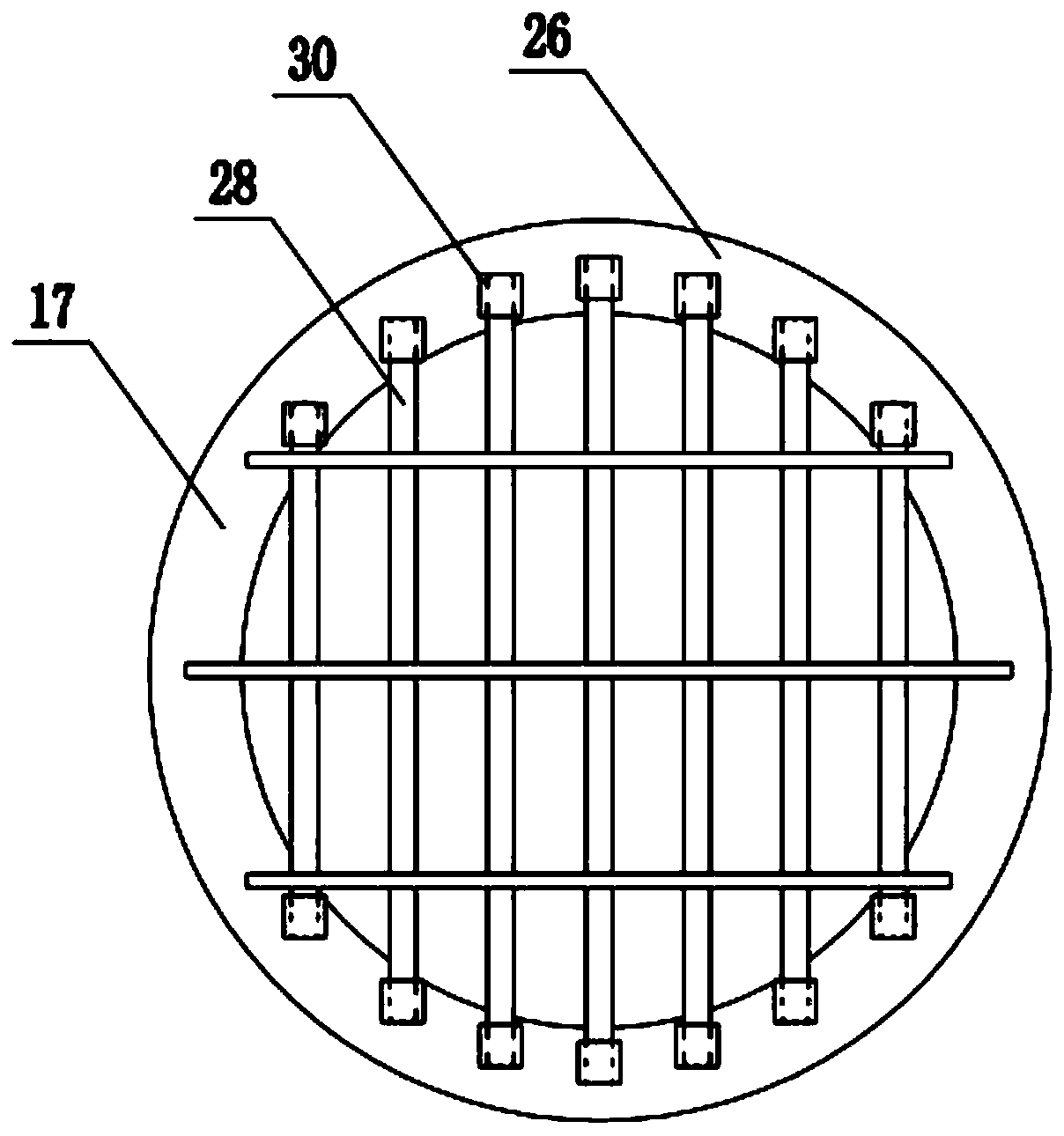

The invention relates to a dust removal system and method for raw coke oven gas by virtue of a rotary type fixed bed. The dust removal system comprises a dust remover, a filter material regeneration furnace, a high-temperature bucket elevator and a high-temperature vibrating screen, wherein the filter material outlet of the dust remover is communicated with the feeding hole of the filter material regeneration furnace; the discharge hole of the filter material regeneration furnace is communicated with the feeding hole of the high-temperature bucket elevator; the discharge hole of the high-temperature bucket elevator is communicated with the high-temperature vibrating screen; and the high-temperature vibrating screen is respectively communicated with the filter material inlet of the dust remover through a pipeline. According to the dust removal system and method, updating of the filter material is achieved by using the displacement fixing and circumference rotating mechanisms of a turntable; regeneration and sieving of the filter material are achieved through the filter material regeneration furnace, the high-temperature bucket elevator and the high-temperature vibrating screen; and continuous regeneration of the filter material is achieved, thus the problem that the fixed bed filter material is difficult to regenerate due to carbon deposition is effectively solved; the dust removal efficiency is greatly improved; heat loss is reduced; the dust removal method disclosed by the invention is simple in process, stable in operation, low in cost, and suitable for industrial production; continuous regeneration of the filter material can be achieved; and the dust removal efficiency is greatly improved.

Owner:王树宽

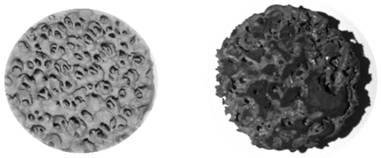

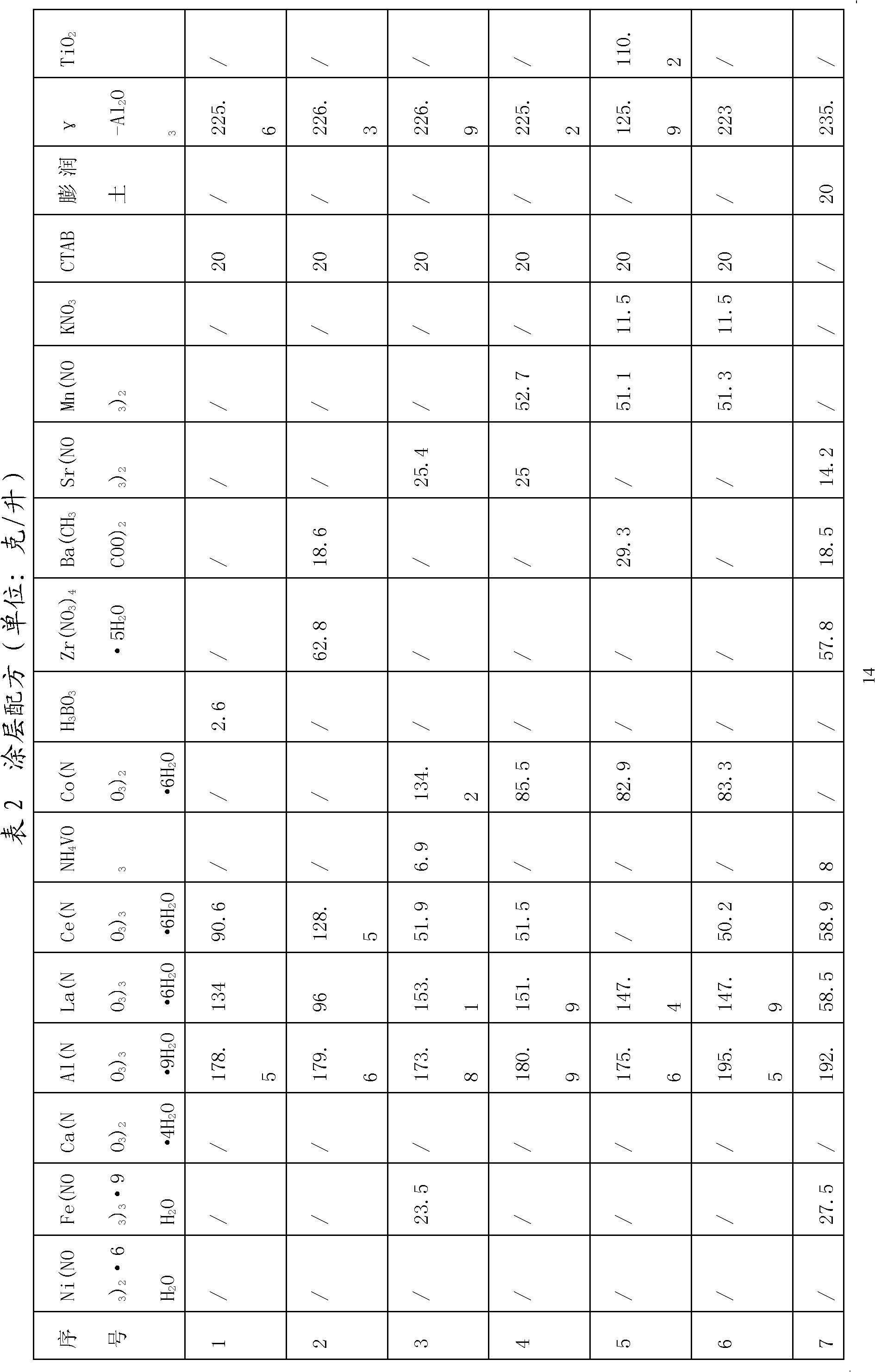

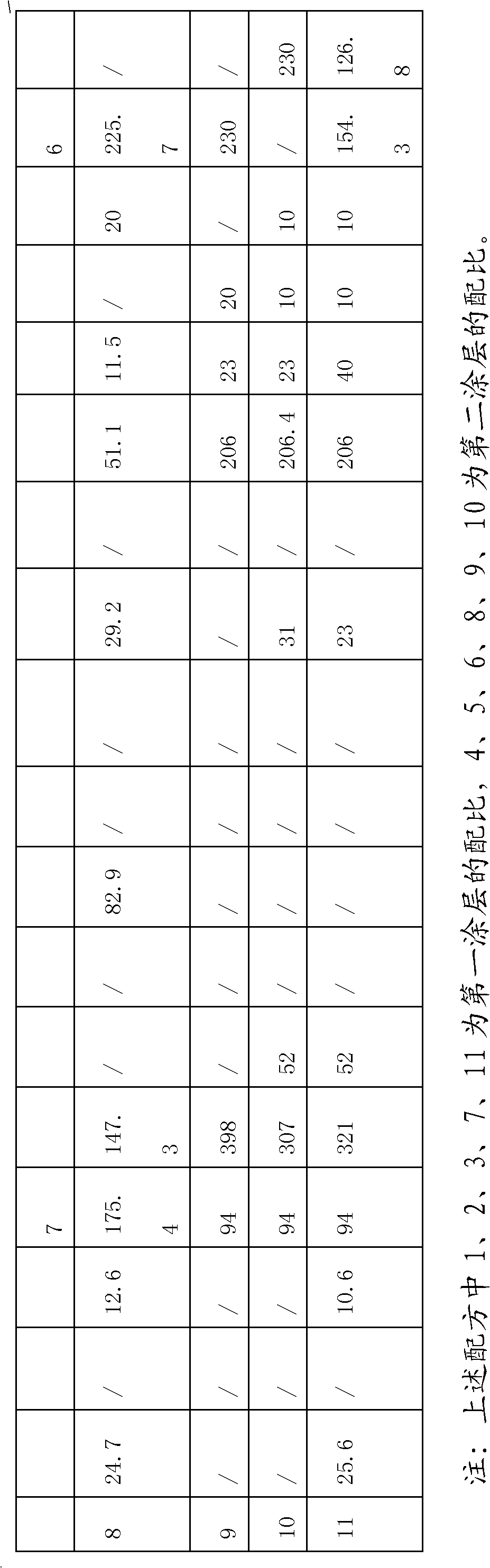

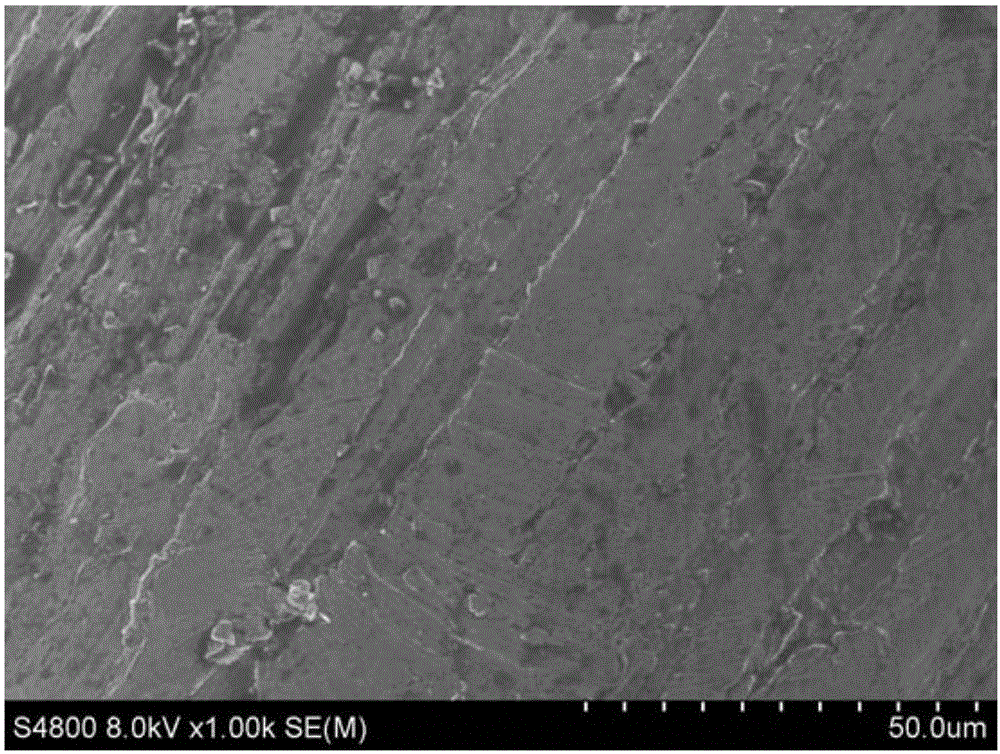

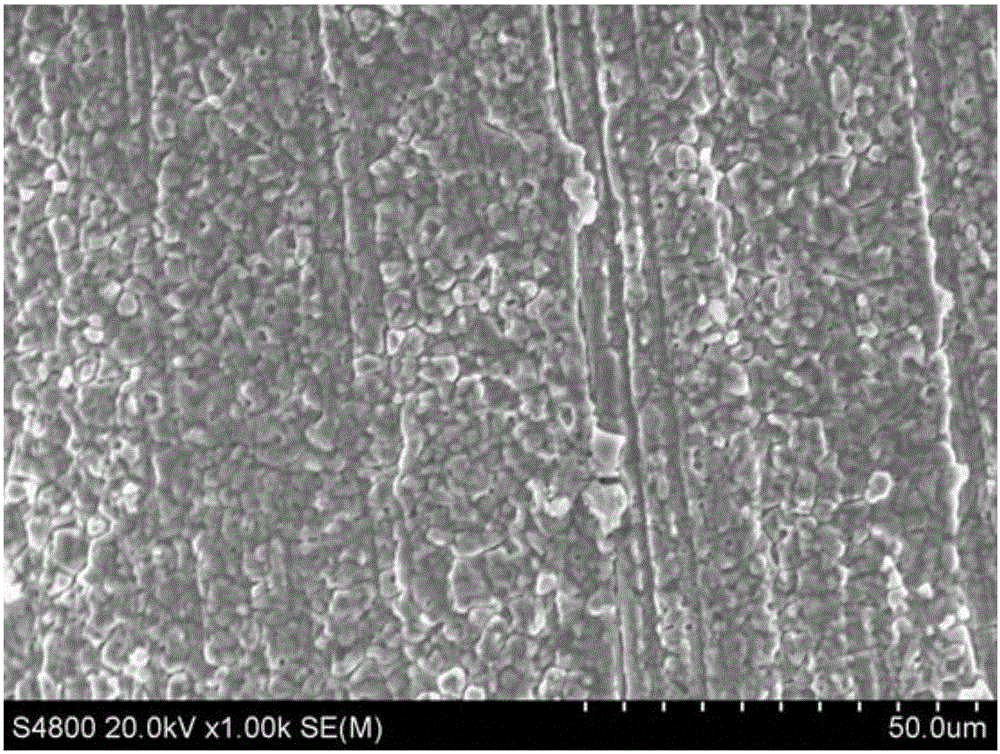

Coating method of catalyst and carbon smoke particle filter prepared with same

ActiveCN105903496ACurb churnOvercoming the problem of differences in thermal expansion coefficientsGas treatmentDispersed particle separationAdhesion forceCatalytic metal

The invention relates to a coating method of a catalyst and a carbon smoke particle filter prepared with the same and belongs to the technical field of air purification. The coating method includes the steps of: 1) activation of a metal based carrier: activating the metal based carrier at 500-1000 DEG C for 5-10 h; 2) preparation of a coating solution: weighing a catalyst source and carbon according to the weight part ratio of 1-10:1, placing the components in deionized water, and stirring the solution uniformly, wherein the catalyst source is a compound containing a catalytic metal element; 3) coating of the metal based carrier: coating the surface of the metal based carrier with the catalyst source and the carbon in the coating solution in a deposition manner; and 4) chemical deposition: roasting the metal based carrier coated with the coating solution at 550-1100 DEG C for 4-12 h, and cooling the catalyst. The coating method can effectively deposit the active catalyst components on the surface of the carrier to form a stable compound, thereby improving adhesion force of the catalyst on the carrier.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

A Rotary Fixed Bed Raw Gas Dust Removal System and Method

ActiveCN104449879BRealize continuous regenerationSolve the problem of difficult regeneration of carbon depositsCombination devicesChemical industryFixed bedHeat losses

The invention relates to a dust removal system and method for raw coke oven gas by virtue of a rotary type fixed bed. The dust removal system comprises a dust remover, a filter material regeneration furnace, a high-temperature bucket elevator and a high-temperature vibrating screen, wherein the filter material outlet of the dust remover is communicated with the feeding hole of the filter material regeneration furnace; the discharge hole of the filter material regeneration furnace is communicated with the feeding hole of the high-temperature bucket elevator; the discharge hole of the high-temperature bucket elevator is communicated with the high-temperature vibrating screen; and the high-temperature vibrating screen is respectively communicated with the filter material inlet of the dust remover through a pipeline. According to the dust removal system and method, updating of the filter material is achieved by using the displacement fixing and circumference rotating mechanisms of a turntable; regeneration and sieving of the filter material are achieved through the filter material regeneration furnace, the high-temperature bucket elevator and the high-temperature vibrating screen; and continuous regeneration of the filter material is achieved, thus the problem that the fixed bed filter material is difficult to regenerate due to carbon deposition is effectively solved; the dust removal efficiency is greatly improved; heat loss is reduced; the dust removal method disclosed by the invention is simple in process, stable in operation, low in cost, and suitable for industrial production; continuous regeneration of the filter material can be achieved; and the dust removal efficiency is greatly improved.

Owner:王树宽

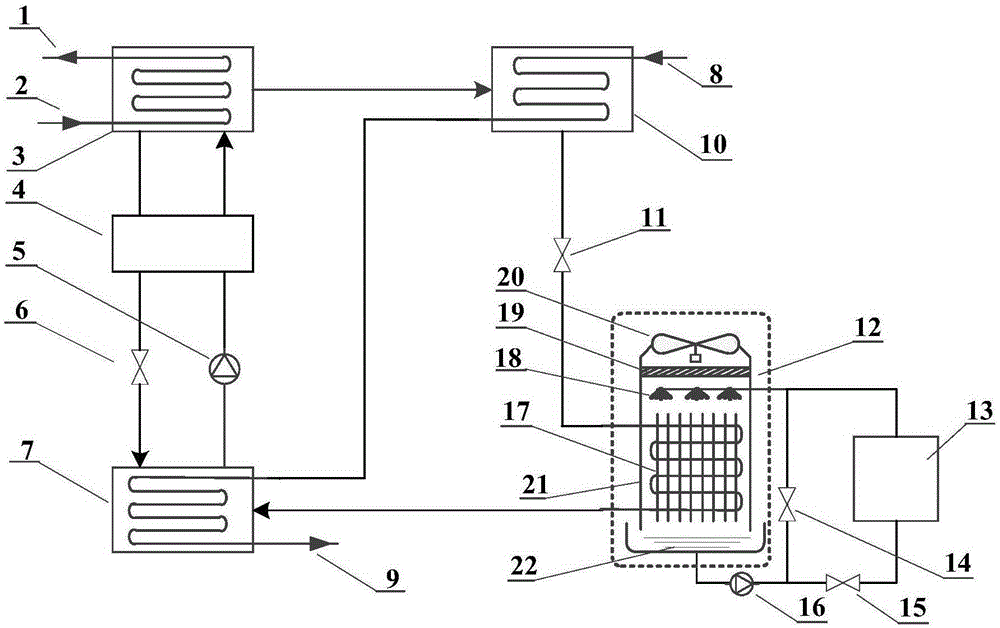

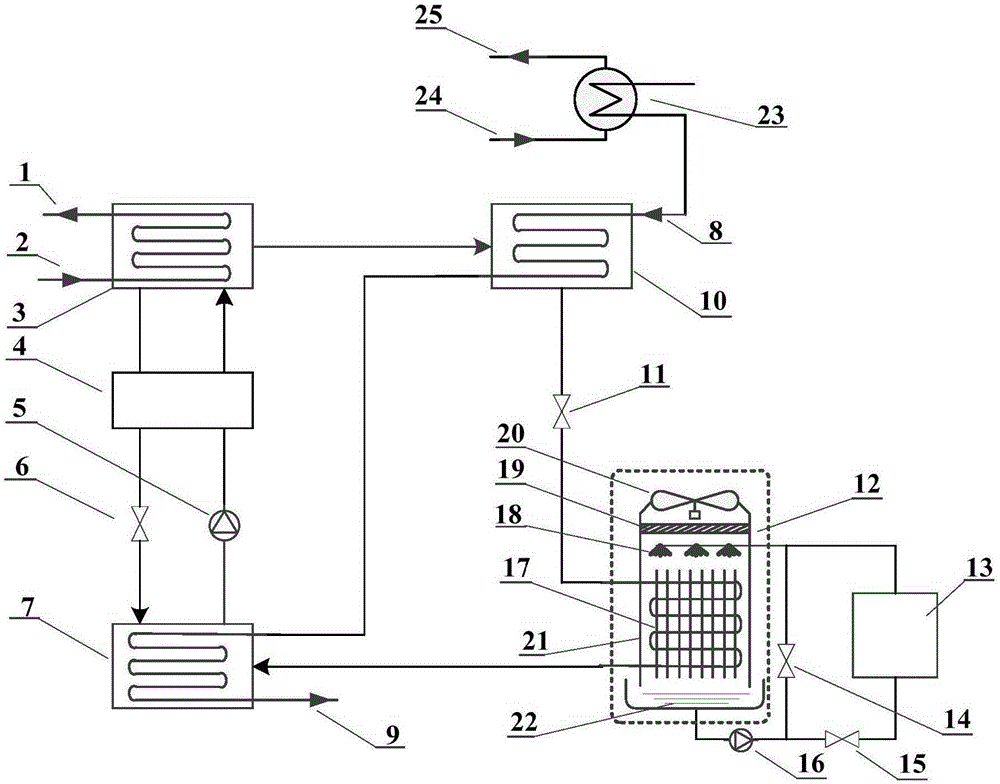

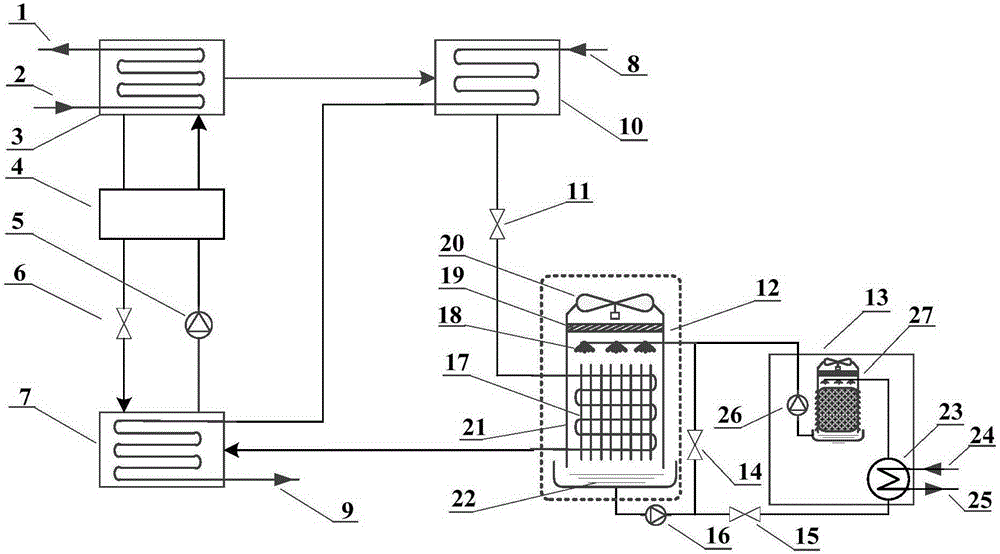

A spray type air source absorption heat pump

ActiveCN103604243BEmission reductionDoes not increase stressMechanical apparatusClimate change adaptationAbsorption heat pumpHeat energy

Owner:TSINGHUA UNIV

Method and apparatus for reducing diesel engine microparticle matter exhaust and apparatus

InactiveCN100419228COptimize layoutSmall filter resistanceExhaust apparatusSilencing apparatusParticulatesMicrowave

The invention provides a method and device for reducing diesel particulate emissions. The method is: the gas with diesel particulate is led into the cylinder filter entocoele which is made up with many filtering elements. Then through the entocole the particulates are filtered and discharged through the leading pipe of offgas. At least one filtering element is always located in the regeneration cavity and others are in work condition. Under the effect of microwave energy, the offgas particulate is eliminated on the filtering pieces, which makes the filtering pieces reborn. The cylinder filter is rotated properly and makes the every filtering piece reborn.

Owner:HUNAN UNIV

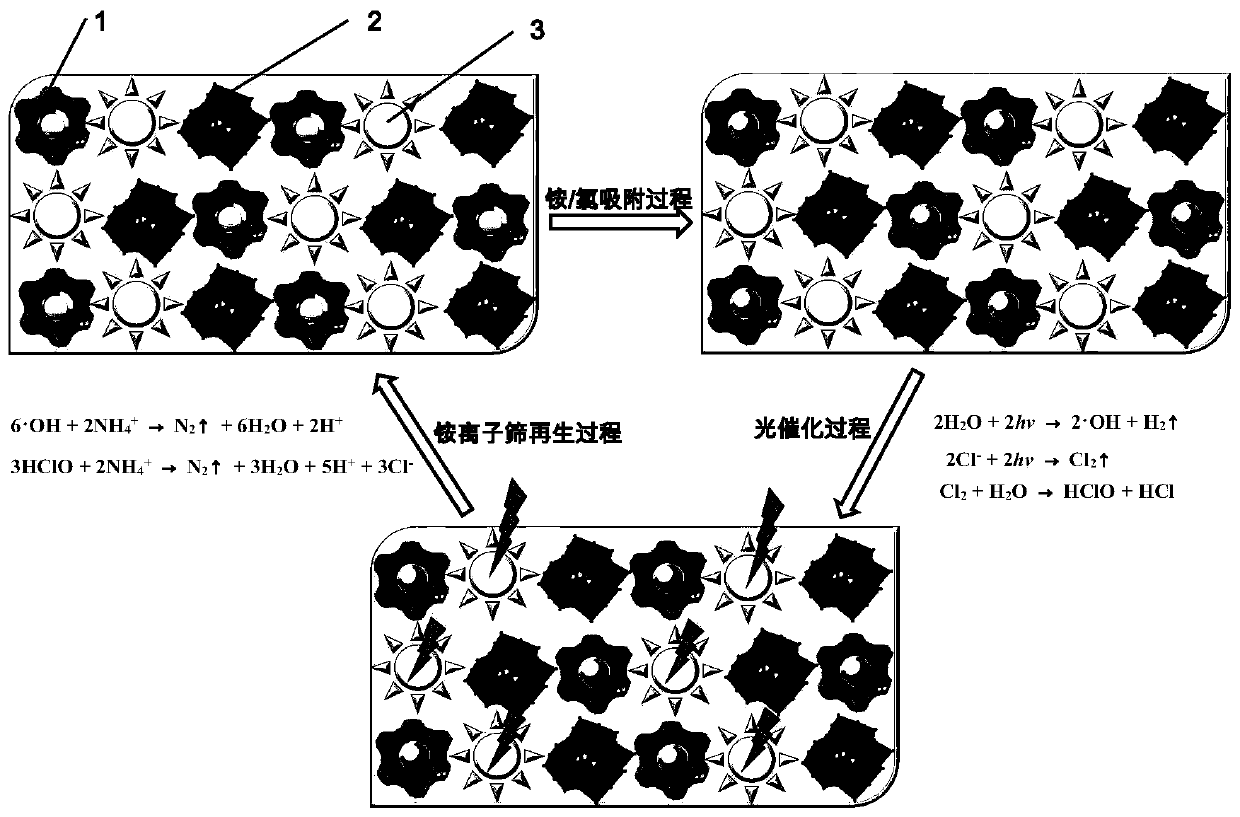

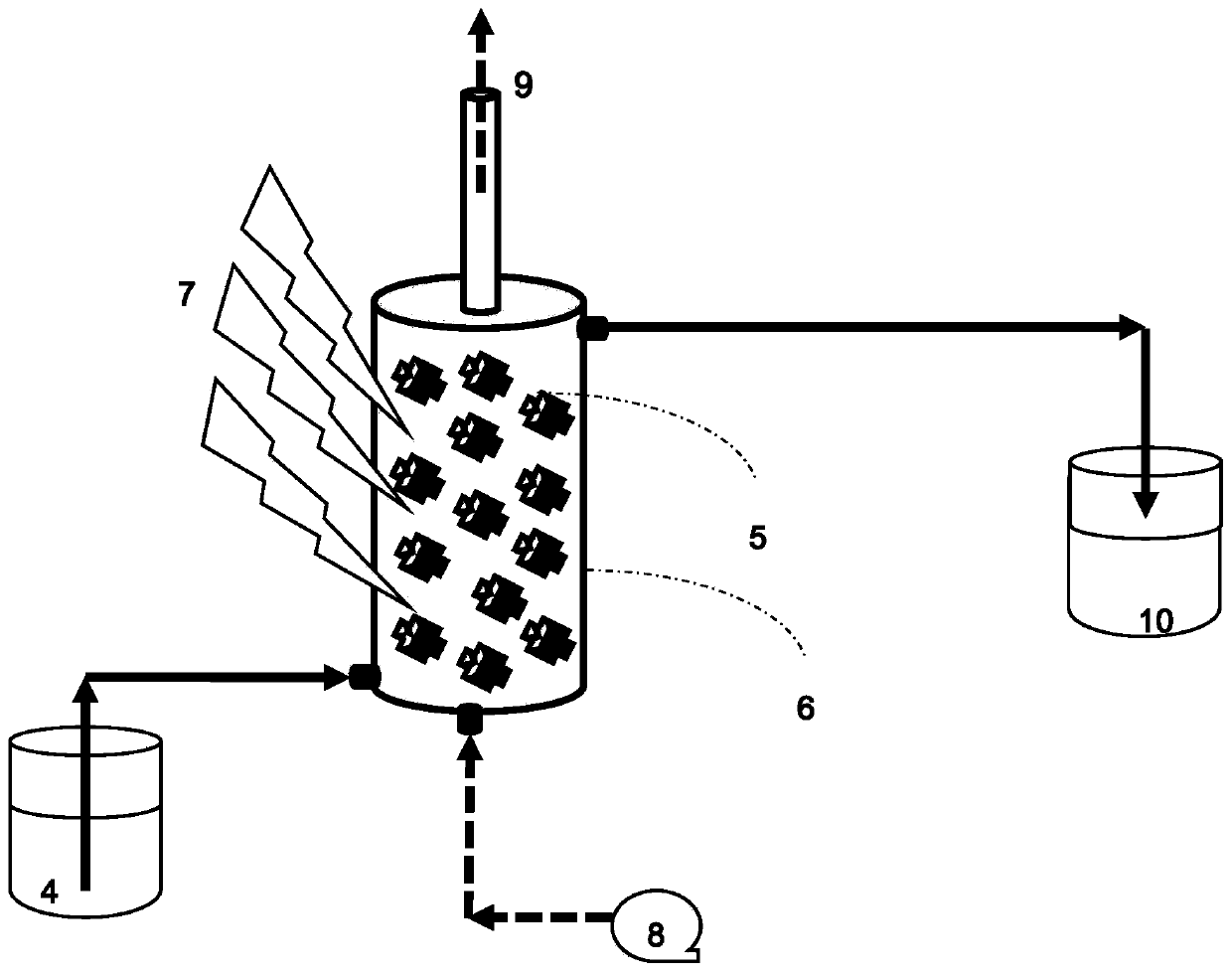

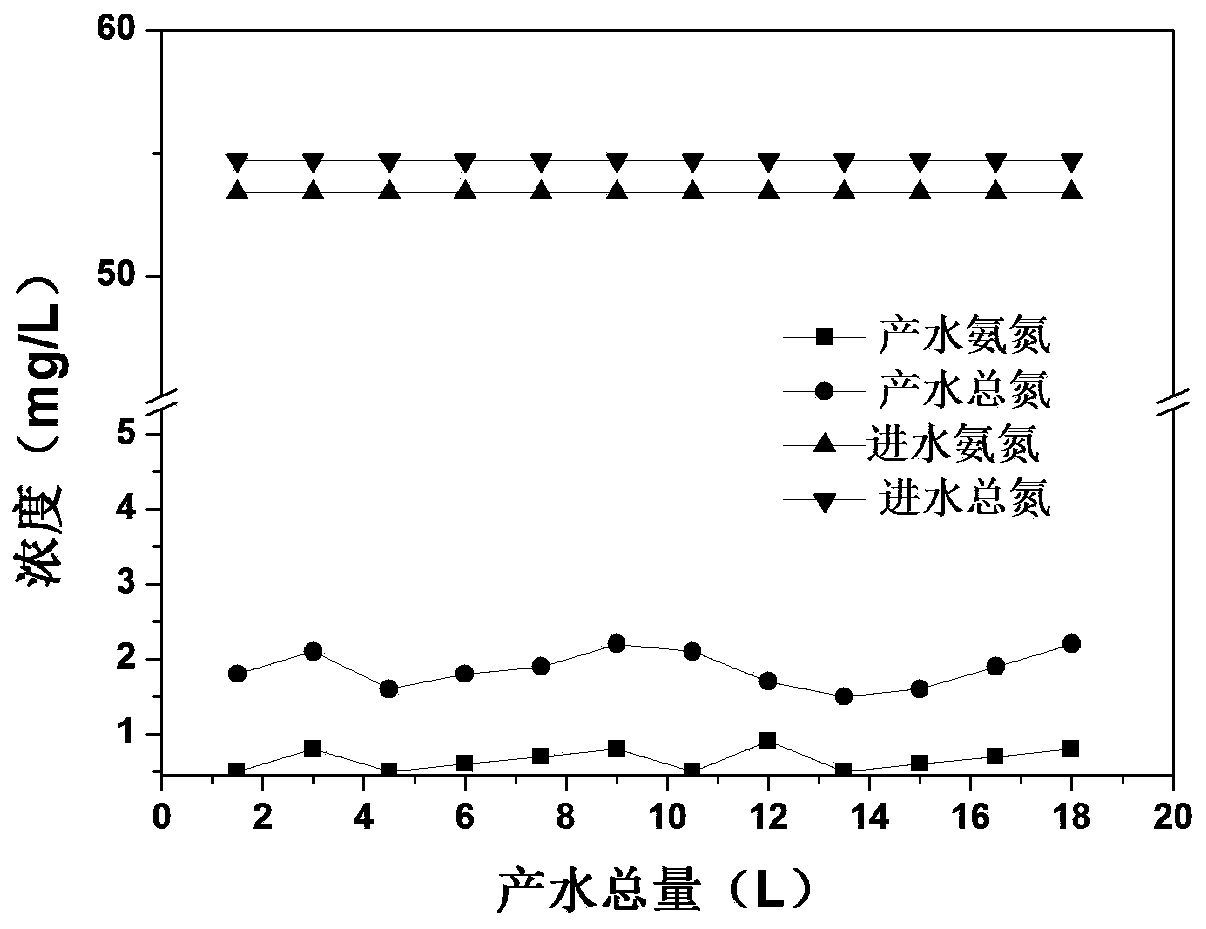

Visible light micro-nano reactor membrane for selective removal of ammonia nitrogen, preparation method and application thereof

ActiveCN110862176AEfficient removalHigh selectivityWater/sewage treatment by irradiationWater treatment compoundsPtru catalystSorbent

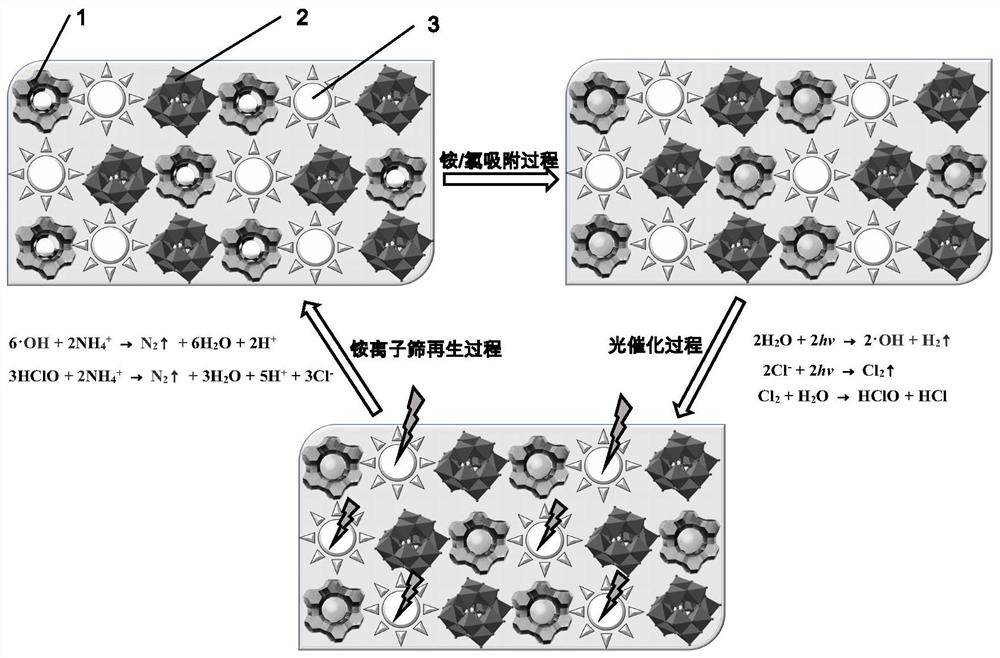

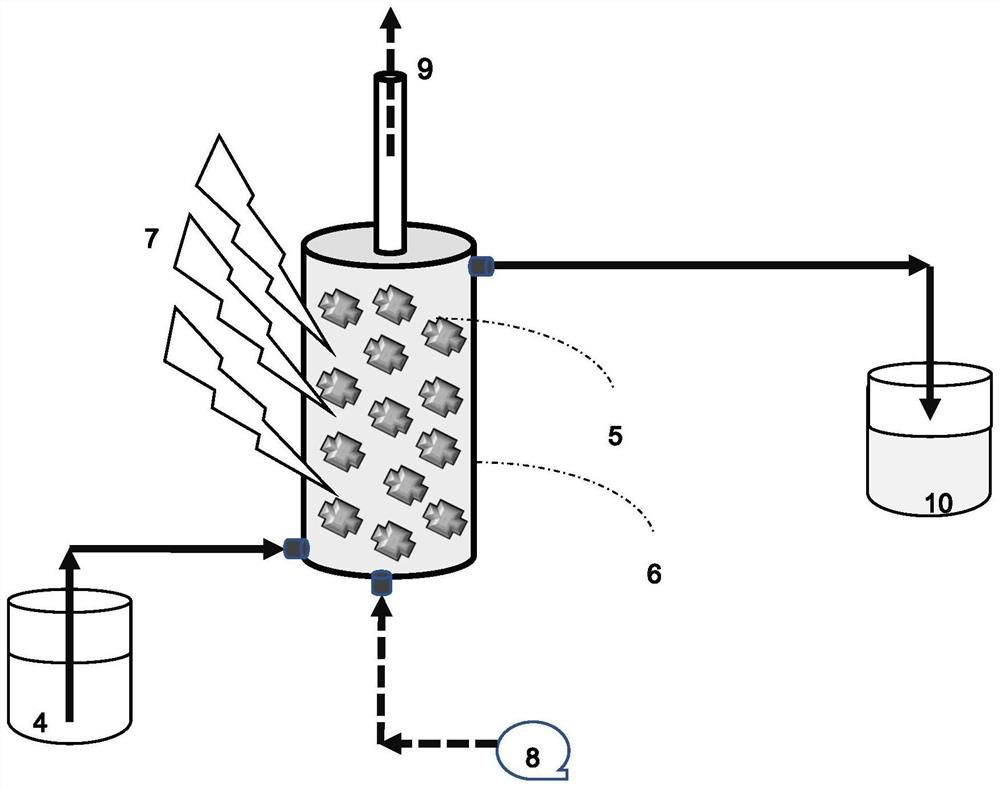

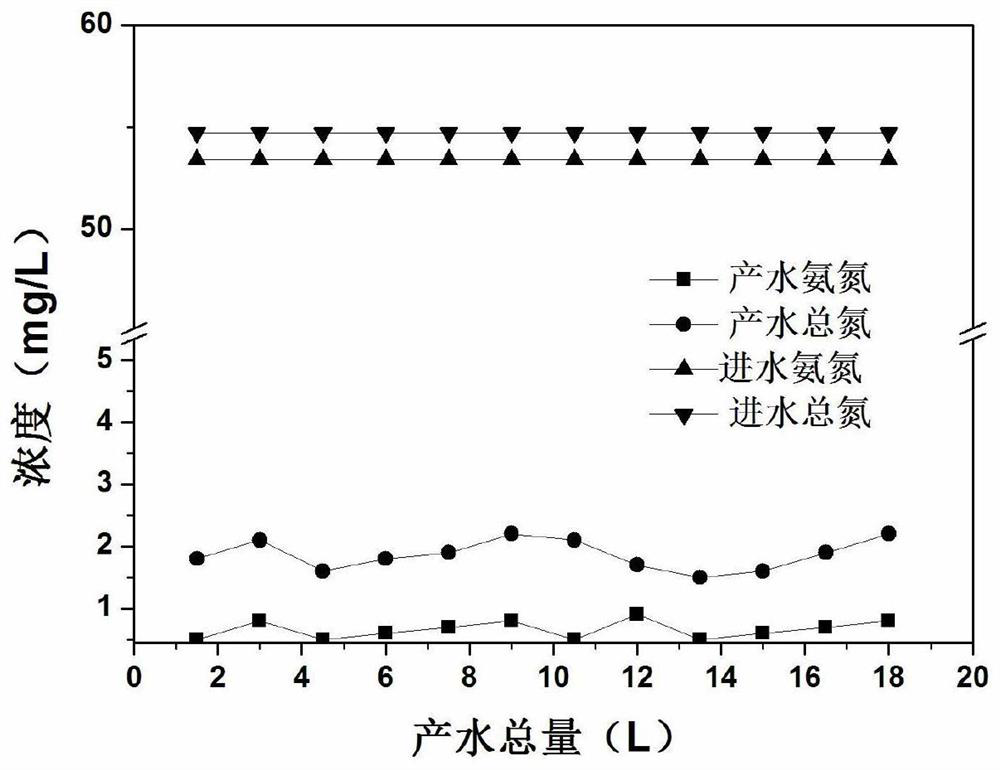

The invention provides a preparation method of a visible light micro-nano reactor membrane for selective removal of ammonia nitrogen. The method includes: taking calcium silicoaluminate hydrate, graphite-phase carbon nitride, an ammonium ion sieve material, polytetrafluoroethylene and dimethylacetamide as the main raw materials to obtain a mixed feed liquid, coating the obtained mixed feed liquidon a flat plate, and transferring dimethylacetamide into water, taking the flat plate out and performing drying to obtain the visible light micro-nano reactor membrane. By means of the ammonium ion sieve material, the visible light micro-nano reactor membrane provided by the invention can effectively realize selective exchange of ammonium ions from water, and through cooperation with a chloride ion adsorbent and a visible-light-induced photocatalyst, continuous regeneration of the ammonium ion sieve can be realized, continuous operation and stable water outflow of the membrane can be effectively realized, and the technical problems of low selectivity of conventional ion exchanger, difficult treatment of regenerated liquid, high regeneration cost, and difficult realization of in-situ real-time regeneration are solved.

Owner:BEIJING ORIGIN WATER FILM TECH

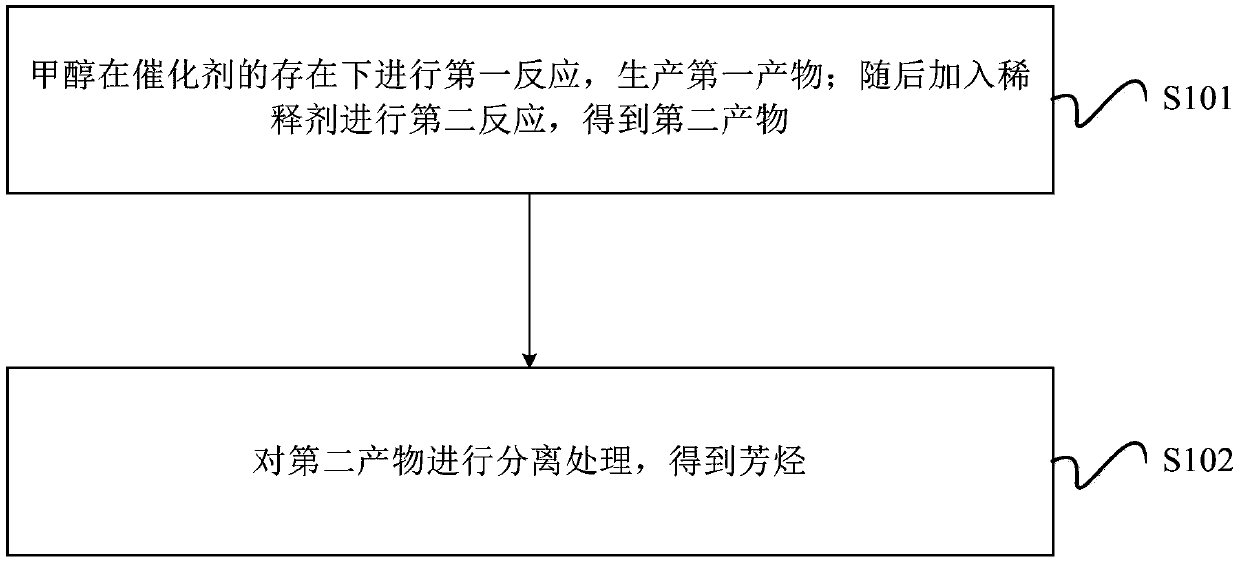

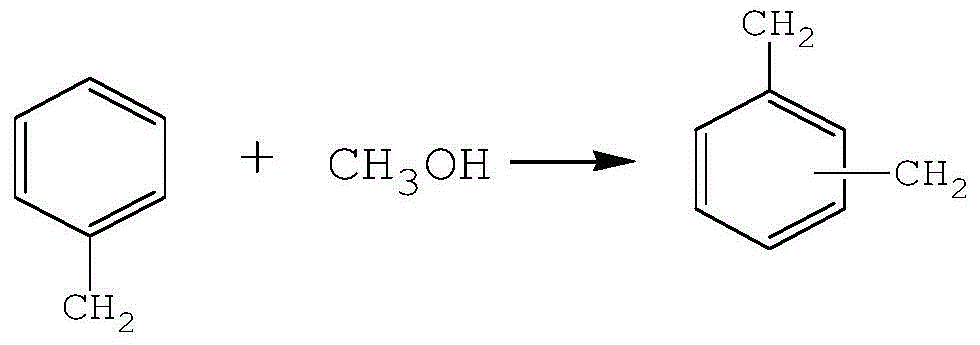

Method for producing aromatic hydrocarbon from methanol

PendingCN111377785AImprove conversion rateGood for maintaining activityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsPtru catalystAromatization

The invention provides a method for producing aromatic hydrocarbon from methanol, which comprises the following steps: 1) carrying out a first reaction on methanol in the presence of a catalyst to produce a first product; then adding a diluent to carry out a second reaction to obtain a second product; and 2) carrying out separation treatment on the second product to obtain the aromatic hydrocarbon, wherein the first product comprises dimethyl ether. According to the method, methanol is firstly converted into dimethyl ether, and then the aromatic hydrocarbon is further prepared from the reactant containing dimethyl ether, so that the heat in the whole reaction process is more controllable. By means of the method, the problem that the aromatization reaction is difficult to carry out normallydue to the fact that a large amount of heat is generated during the direct aromatization reaction of methanol is avoided.

Owner:PETROCHINA CO LTD

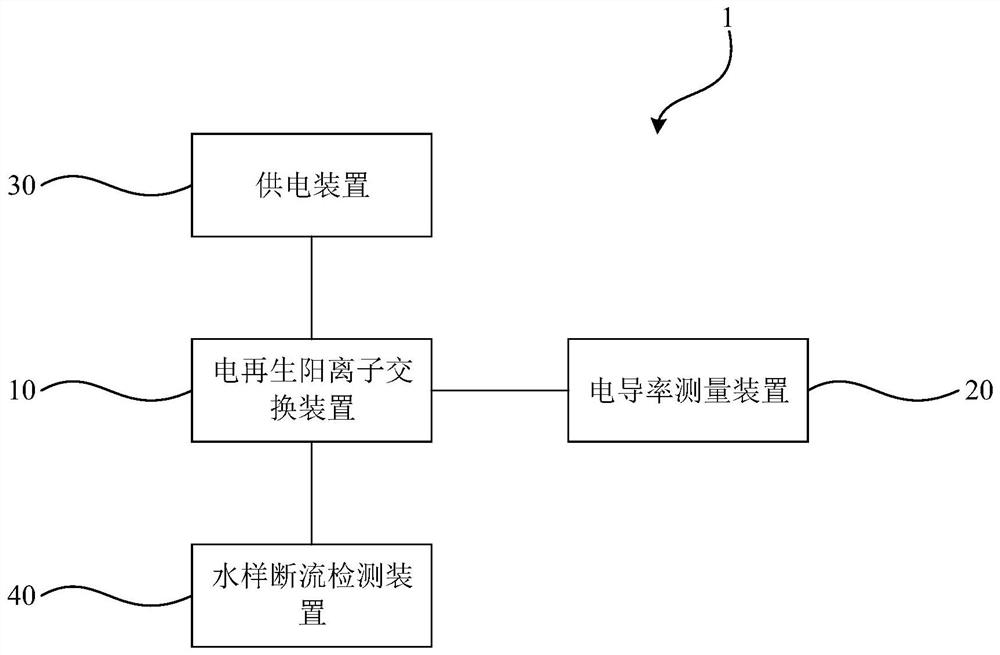

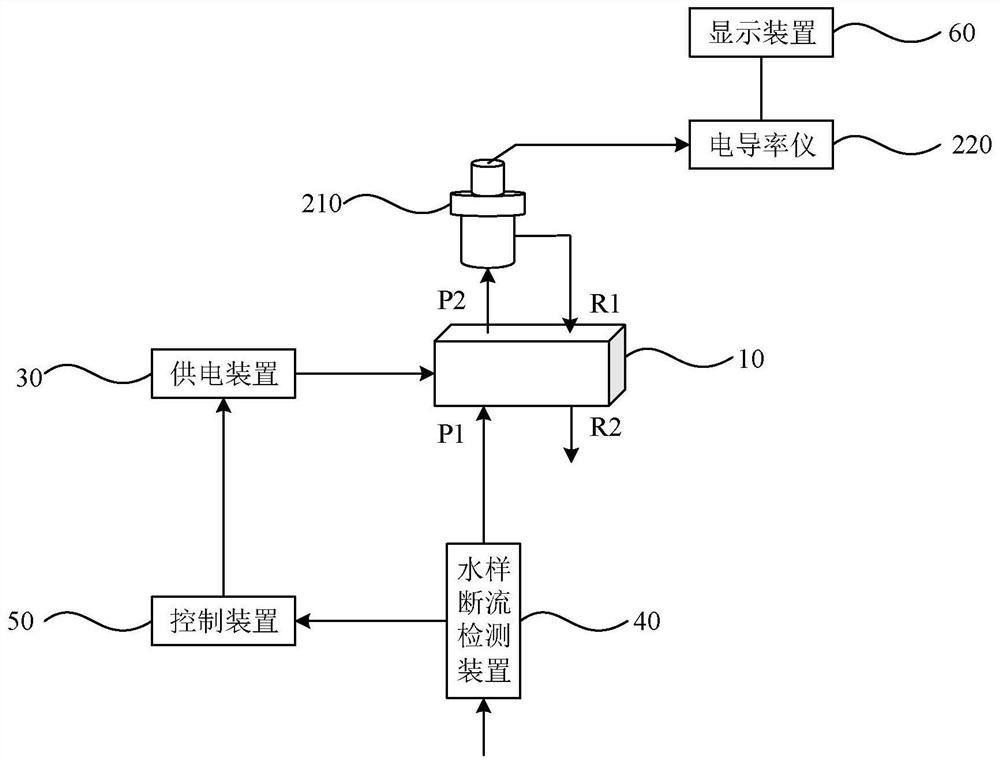

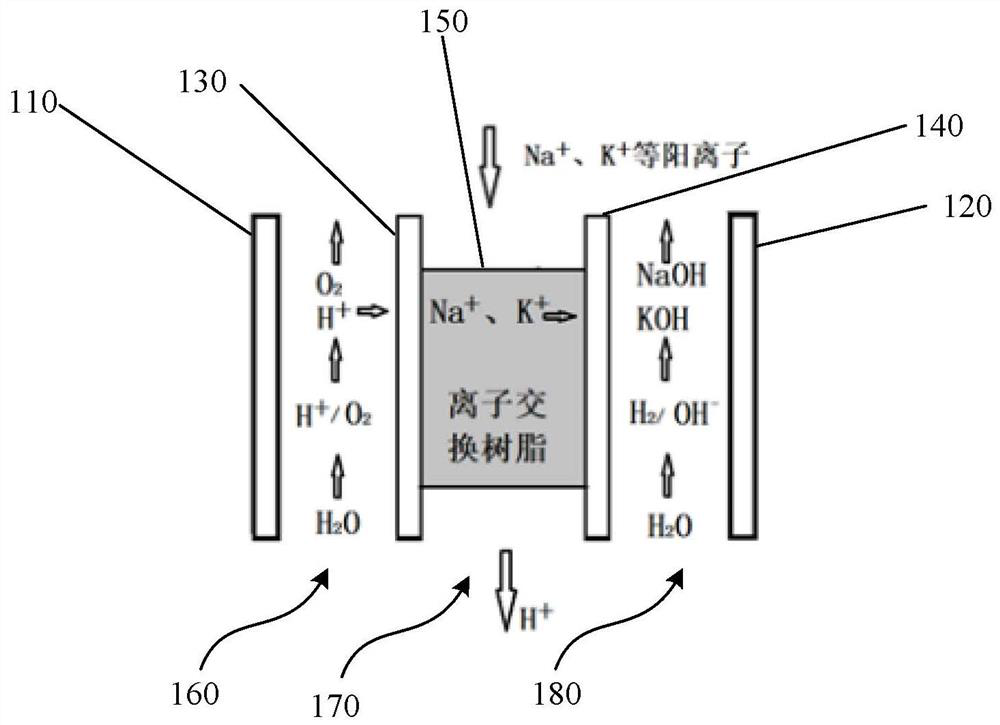

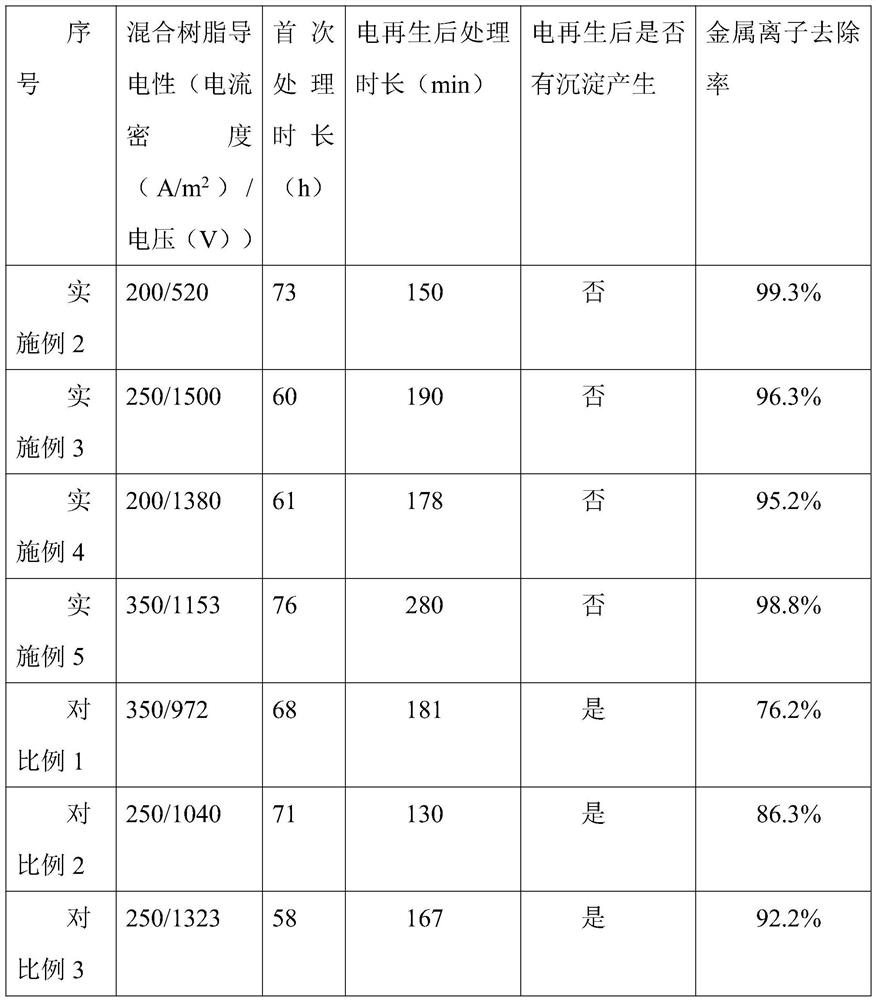

Electric regenerative system for measuring conductivity of water vapor and hydrogen

PendingCN113960118ARealize continuous regenerationEnables full continuous monitoringMaterial resistanceElectrolysisWater vapor

The invention discloses an electric regenerative system for measuring conductivity of water vapor hydrogen. The system comprises a power supply device, an electric regeneration cation exchange device connected with the power supply device, a conductivity measuring device, and a water sample cutoff detection device. In a power supply state of the power supply device, a to-be-detected water sample flowing in from a water sample inlet replaces cations in the electric regeneration cation exchange device, the to-be-detected water sample enters a conductivity cell through a water sample outlet and is subjected to conductivity measurement by a conductivity meter, and the water sample flowing out of the conductivity cell enters the regeneration cation exchange device again through the regeneration inlet to be electrolyzed; hydrogen ions are generated; the resin in the regeneration cation exchange device is regenerated through the generated hydrogen ions, and finally, the water sample is discharged through a regeneration outlet. Under the condition, the accuracy of measuring the conductivity of the hydrogen in the water vapor can be improved, the method has important significance for realizing complete continuous monitoring, and the field labor cost and the equipment maintenance cost can be saved.

Owner:国能(惠州)热电有限责任公司

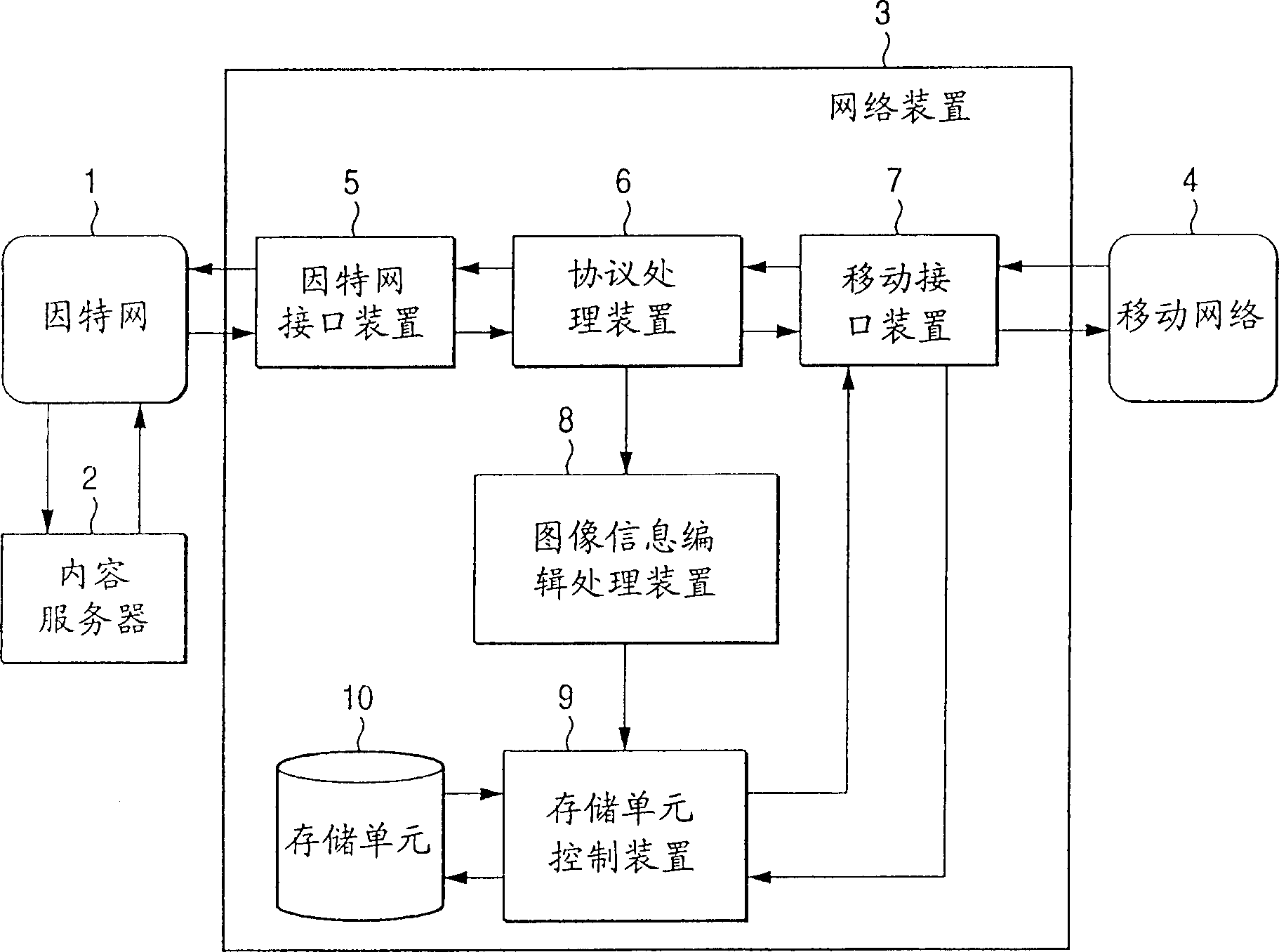

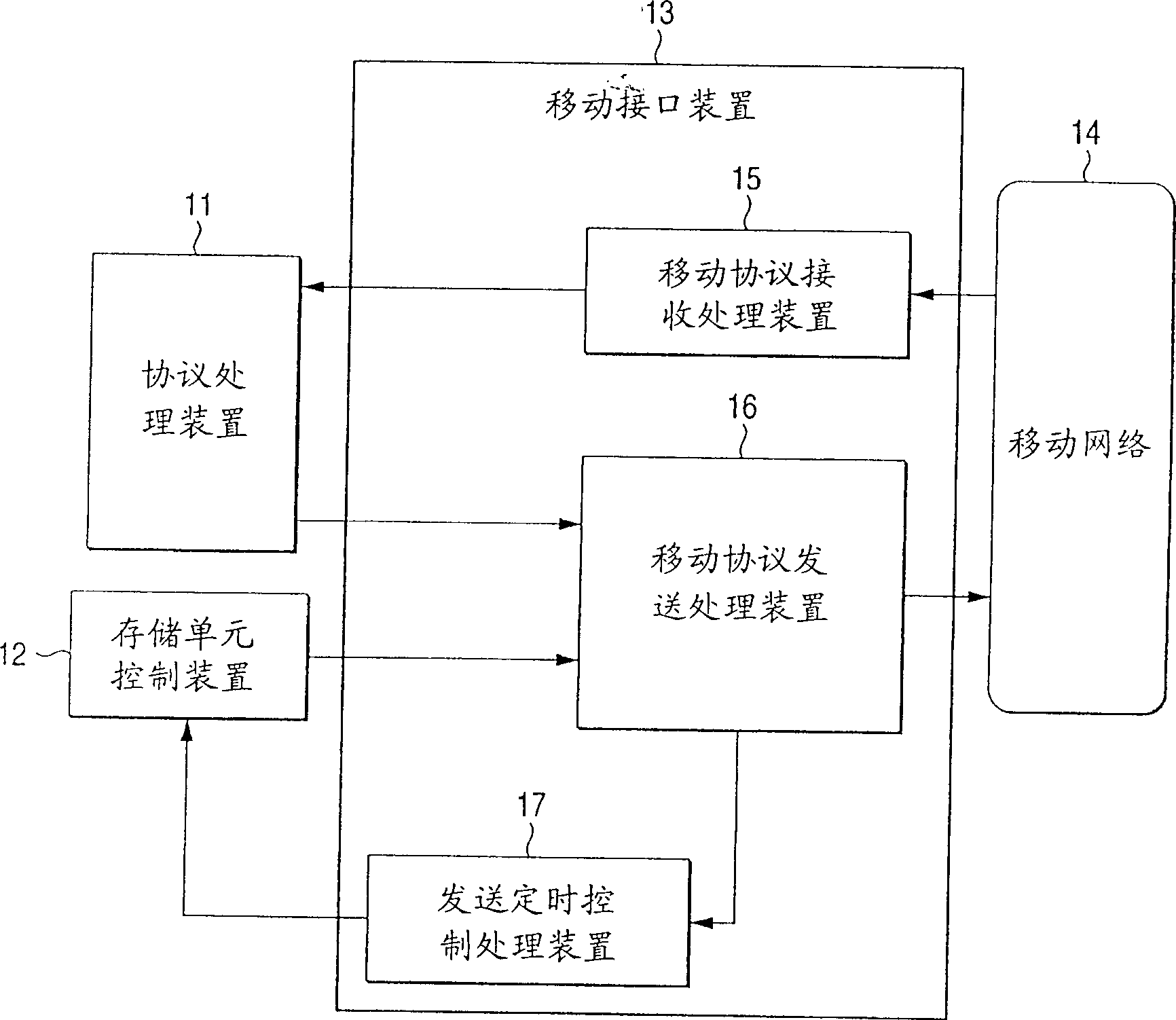

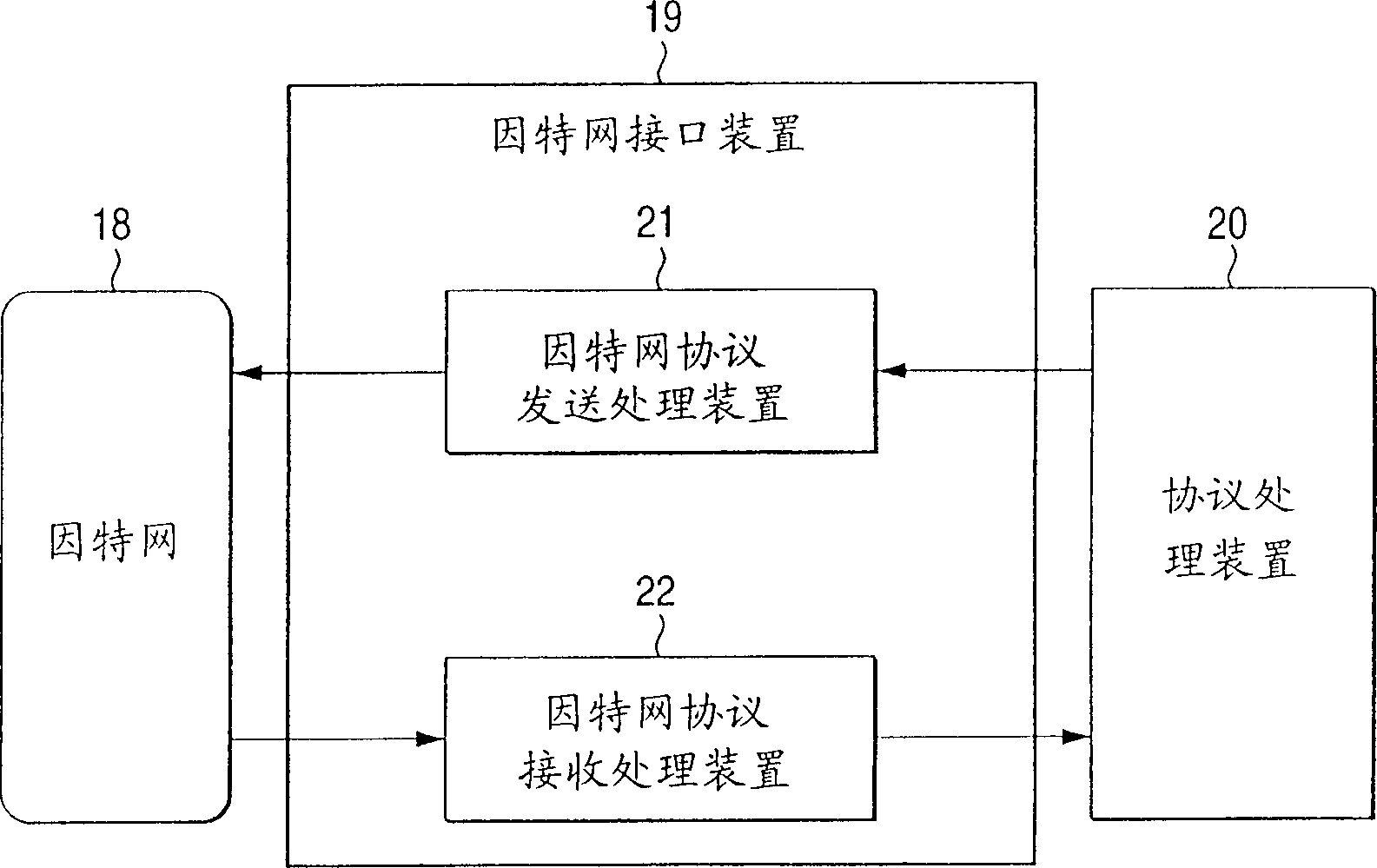

Network device and network communication method

InactiveCN1138387CGuaranteed high-speed transmissionRealize the broadcast functionTelevision system detailsNetwork traffic/resource managementMass storageProtocol processing

A network apparatus which enables continuous reproduction of image information without a necessity of a high performance CPU and a large capacity memory in mobile terminals, comprises: an Internet interface means 5 for establishing an interface with the Internet 1, a mobile interface means 7 for establishing an interface with a mobile network 4, a protocol processing means 6 for applying a protocol process to information which are processed by the Internet interface means and the mobile interface means, an image information edit processing means 8 for editing image information which are extracted by the protocol processing means into image information suitable for a mobile communication, a storage unit 10 for storing the image information which are edited by the image information edit processing means, and a storage unit controlling means 9 for controlling to store / read the image information into / from the storage unit.

Owner:PANASONIC CORP

A diesel engine exhaust purification treatment device and method

ActiveCN112901312BIncrease axial lengthOptimize layoutInternal combustion piston enginesExhaust apparatusCatalytic transformationControl system

Owner:湖南万鼎智能科技有限公司

A kind of regeneration method of alkylation waste sulfuric acid

ActiveCN108069406BAvoid gasification and decompositionConducive to accumulation and coking carbonizationSulfur-trioxide/sulfuric-acidHeat carrierContinuous use

The invention discloses a regeneration method of waste sulfuric acid from alkylation. The regeneration method comprises the following contents: the waste sulfuric acid generated in alkylation reactionis firstly subjected to heat exchange by a heat exchanger, mixed with partially recycled regenerated sulfuric acid at the bottom of a regeneration reactor, and a mixed liquid material enters the regeneration reactor from the top, flows through a first filler layer filled with a heat carrier, is uniformly dispersed in the first filler layer and absorbs mass transfer; then the material flows through a second filler layer filled with the heat carrier, organic matter in the liquid phase material is coked and carbonized on the surface of the high-temperature heat carrier and adhered to the surfaceof the heat carrier, regenerated sulfuric acid with the organic matter removed is discharged through the bottom of the regeneration reactor, part of the regenerated sulfuric acid is recycled back tothe regeneration reactor, part of the regenerated sulfuric acid is cooled and filtered and mixed with oleum, and the mixture returns to an alkylation production unit for continuous use. Aiming at defects in the prior art, the invention provides the regeneration method of waste sulfuric acid from alkylation. The method has the advantages of low operating temperature, mild reaction conditions, safereaction process, low energy consumption and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

A treatment method for fluorine-containing reused water

ActiveCN110451704BImprove recycling ratesHigh removal rateWater/sewage treatment by irradiationWater contaminantsFlocculationFiltration

The invention discloses a method for treating fluorine-containing reuse water. The method comprises the following specific steps: (1) pretreatment; (2) flocculation precipitation; (3) filtration-reverse osmosis membrane filtration; (4) total organic carbon (TOC) degradation and ultraviolet sterilization; (5) electrodeionization (EDI) treatment; (6) TOC degradation and ultraviolet sterilization; and (7) precise filtration. The invention has the advantages that water quality of an effluent can reach a standard of ultra-pure water, fluorine removal efficiency is high, the recycling rate of wastewater is high, and operation cost is low.

Owner:NANJING UNIV +1

Method for producing propylene from methanol or dimethyl ether

ActiveCN101811923BAvoid Burnout SituationsRealize continuous regenerationMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sievePtru catalyst

The invention relates to a method for producing propylene from methanol or dimethyl ether, and mainly solves the problems that a catalyst is easily inactivated due to short reaction residence time and the reaction conditions are frequently fluctuated and the operation is unstable caused by frequent switch and reproduction in the prior art. The method for producing the propylene from the methanol or the dimethyl ether comprises the following steps of: a) making oxygen-containing compounds and a diluent enter a fluid bed reactor from the bottom; b) performing contact reaction on the raw materials and a ZSM-5 molecular sieve catalyst at the temperature of between 400 and 550 DEG C under the pressure of between 0.02 and 0.5 MPa; c) separating gas-phase material flow out of the top of the fluid bed reactor to obtain the propylene; d) extracting the reaction heat by using a heat exchanger; e) controlling the inactivated catalyst with a sliding valve and feeding the catalyst into a regenerator through a catalyst spending inclined tube, reacting the inactivated catalyst with air at the temperature of between 480 and 700 DEG C to burn off carbon deposit, and exhausting waste gas; and f) controlling the regenerated catalyst by using the sliding valve and feeding the regenerated catalyst to the upper part of the fluid bed reactor for circulation through a catalyst regenerating inclined tube. The technical scheme of the invention better solves the problems, and can be applied to the industrial production of the propylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

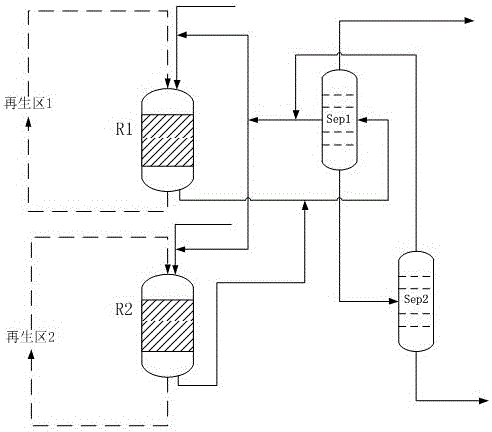

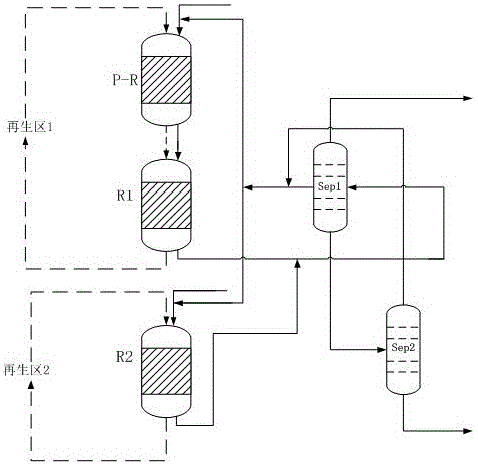

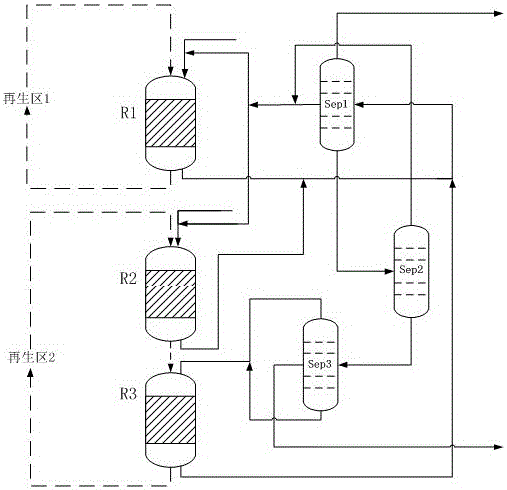

A reaction process for converting oxygenates to aromatics using moving bed technology

ActiveCN103664482BRealize continuous regenerationHigh activityHydrocarbon from oxygen organic compoundsHydrocarbon by hydrocarbon and non-hydrocarbon condensationPtru catalystAromatization

The invention discloses a reaction technology for converting an oxygen-containing compound into aromatic hydrocarbons by using a moving bed process. The technology comprises the following steps: preheating the oxygen-containing compound and a diluent, carrying out mixing preheating, reacting in the presence of an aromatization catalyst in an aromatization reactor in order to generate a mixed effluent, sending the mixed effluent to a cooling separation unit, carrying out dehydration and oxide removal, separating to obtain main products comprising benzene, toluene, xylene and other byproducts; circulating the other byproducts, benzene and toluene to the aromatization reactor as return hydrocarbons for a reaction; removing carbon-deposited aromatization catalyst particles from the aromatization reactor when the conversion rate of the oxygen-containing compound under the catalyst in the aromatization reactor is lower than 99%, regenerating in a regenerator, and adding the regenerated catalyst to the aromatization reactor. The technology improves the stability and the activity of the catalyst, and improves the selectivity of the aromatic hydrocarbons especially xylene through recycling product hydrocarbons.

Owner:ZHEJIANG UNIV

Visible light micro-nano reactor membrane for selective removal of ammonia nitrogen, its preparation method and application

ActiveCN110862176BAchieve continuous operationStable waterSemi-permeable membranesWater/sewage treatment by irradiationAmmoniacal nitrogenPtru catalyst

Owner:BEIJING ORIGIN WATER FILM TECH

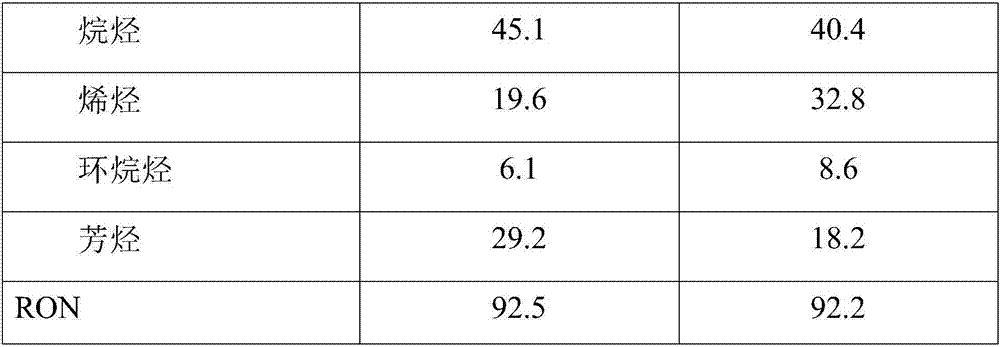

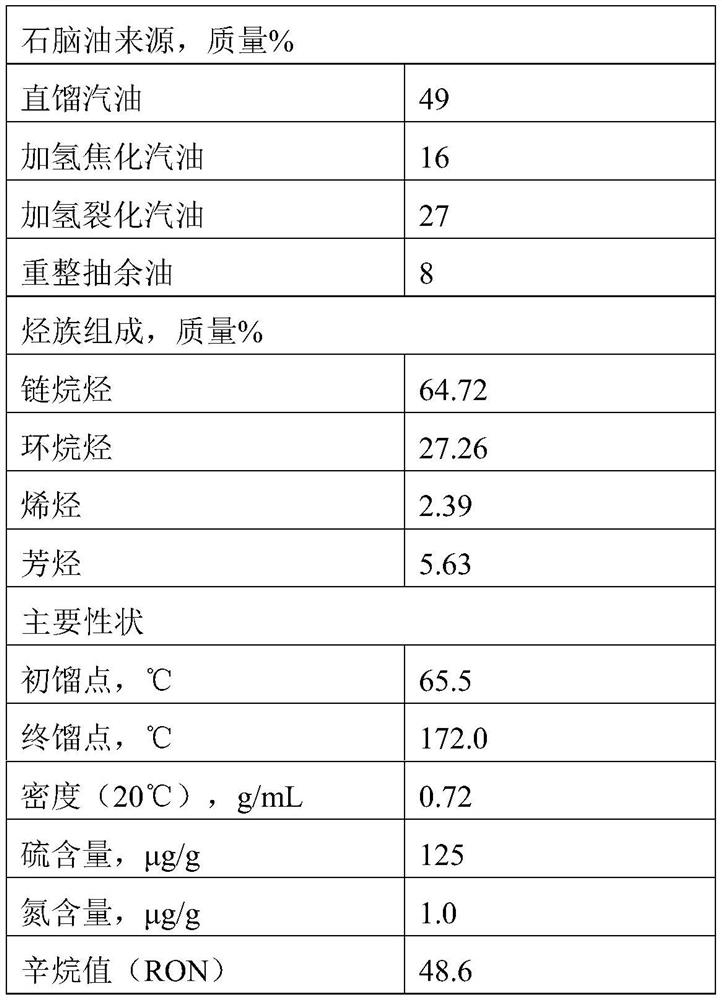

A kind of naphtha and light hydrocarbon upgrading method

ActiveCN111073694BHigh yieldBoost octaneNaphtha treatmentHydrocarbon oils treatmentLiquid productPtru catalyst

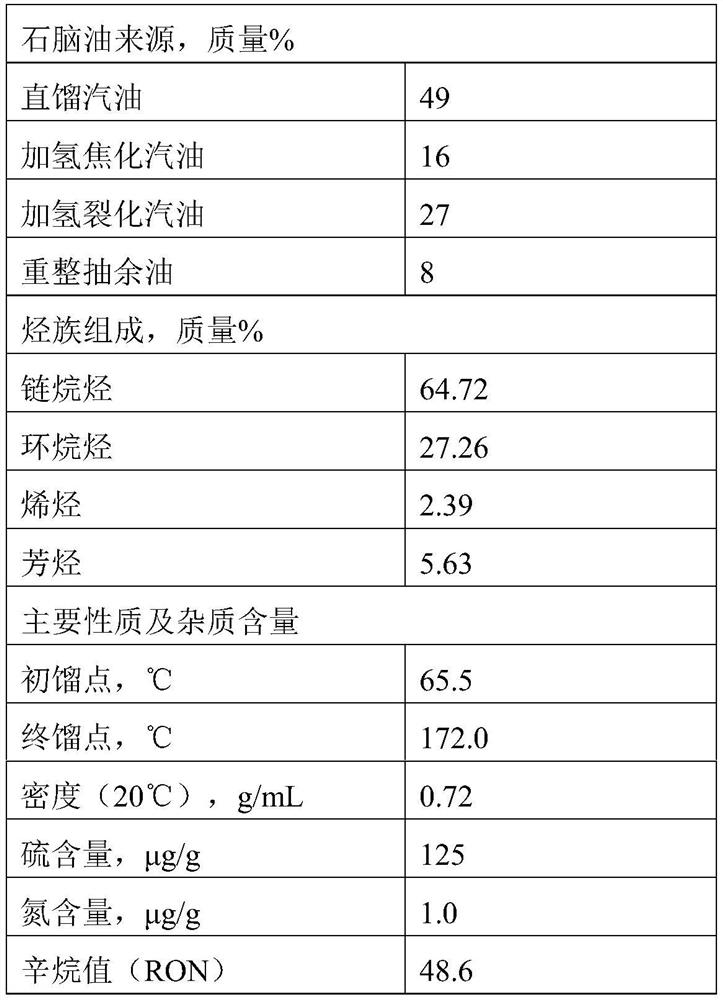

The invention relates to a method for upgrading naphtha and light hydrocarbons, comprising: introducing naphtha into a fixed-bed reaction zone to contact with a dehydrogenation catalyst and performing a dehydrogenation reaction under dehydrogenation reaction conditions, so that part of the naphtha Naphthenic hydrocarbons are converted into aromatic hydrocarbons; wherein, the dehydrogenation catalyst includes a carrier and chlorine elements and Group VIII metals loaded on the carrier; the reaction product obtained in the fixed bed reaction zone is mixed with light hydrocarbons and then introduced into the moving bed reaction zone and the modified catalyst Contact and carry out upgrading reaction to obtain the reaction product and the unused catalyst; the reaction product obtained in the moving bed reaction zone is cooled and separated to obtain the gas phase product and the liquid phase product, and at least part of the gas phase product is returned to the fixed bed reaction zone; the unused catalyst is It is introduced into a regenerator for coke regeneration, and the resulting regenerated catalyst is returned to the moving bed reaction zone. The liquid product yield and octane number of the upgrading method of the present invention are high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and system for recycling petrochemical wastewater

ActiveCN114212914AAchieve removalAchieve reuseFatty/oily/floating substances removal devicesWater contaminantsProcess engineeringPre treatment

The invention discloses a method and a system for recycling petrochemical wastewater. Comprising the following steps: (1) introducing raw petrochemical wastewater into an adjusting tank device, and adjusting the water quality and water quantity by using an adjusting tank; (2) the effluent of the adjusting tank enters an oil removal tank through a lifting pump, compressed air and an oil removal agent are added, and oil substances are removed; (3) enabling effluent of the oil removal tank to enter a neutralization coagulative precipitation tank, adding quick lime, NaOH, and flocculants PAC and PAM, removing substances such as AlCl3, BF3, suspended solids and colloids, filtering out solid substances, and enabling filtered water to enter an intermediate water tank; (4) feeding filtered water in the middle water tank into a precision filter by using a lifting pump, and removing residual non-ionic impurities and part of ionic substances as pretreatment for deep treatment; and (5) the effluent treated by the precision filter enters a membrane-free electrodeionization device, residual heavy metal plasma substances in the wastewater are removed, and the treated clear water meets the recycling requirement.

Owner:NINGBO POLYTECHNIC +1

Oxidative desulfurization process with continuously regenerated desulfurizer

ActiveCN104548934BWide variety of sourcesImprove solubilityDispersed particle separationFixed bedProcess engineering

The invention discloses an oxidative desulfurization process in which the desulfurizer can be continuously regenerated, which is characterized in that it comprises the following content: in a fixed bed reactor, hydrogen sulfide-containing gas, oxygen-containing gas and the desulfurizer are in contact with the desulfurizer bed to perform oxidative desulfurization And the desulfurization agent regeneration reaction, the purified gas is discharged from the top of the reactor, and the catalytic cracking diesel oil is introduced during the reaction process to dissolve the elemental sulfur generated by the regeneration reaction, and the catalytic cracking diesel oil dissolved in the elemental sulfur flows out of the reactor, and after solid-liquid separation recycle. The process has high desulfurization precision, long service life of desulfurizer, simple operation and low cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of naphtha upgrading method

ActiveCN111073693BHigh yieldBoost octaneNaphtha treatmentHydrocarbon oils treatmentLiquid productPtru catalyst

The invention relates to a method for upgrading naphtha, comprising: introducing naphtha into a fixed bed reaction zone, contacting with a dehydrogenation catalyst, and performing a dehydrogenation reaction under dehydrogenation reaction conditions, so as to convert part of the naphthenes in the naphtha It is an aromatic hydrocarbon; wherein, the dehydrogenation catalyst includes a carrier and chlorine elements and Group VIII metals loaded on the carrier; the reaction product obtained in the fixed bed reaction zone is introduced into the moving bed reaction zone to contact with the reforming catalyst and carry out the reforming reaction to obtain Reaction products and unused catalysts, the reaction products are cooled and separated to obtain gas phase products and liquid phase products, and at least part of the gas phase products are returned to the fixed bed reaction zone; in the bed reaction zone. The liquid product yield and octane number of the upgrading method of the present invention are high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for increasing production of propylene and aromatics using moving bed technology

ActiveCN104557401BRealize continuous regenerationHigh activityHydrocarbon from oxygen organic compoundsBulk chemical productionMolecular sieveHydrogen

The invention discloses a method for increasing the yield of propylene and aromatic hydrocarbon by adopting a moving bed technology. The method for increasing the yield of propylene and aromatic hydrocarbon by adopting the moving bed technology comprises the following steps: (1) introducing raw materials for a first reaction zone and a diluent into the first reaction zone to be contacted and reacted with an A-type molecular sieve based catalyst, wherein a first reaction zone material flow comprises hydrogen, C1-C5 hydrocarbon, an aromatic hydrocarbon component and a C5 or above non-aromatic hydrocarbon component; (2) treating the first reaction zone material flow, then introducing the treated first reaction zone material flow into a separation zone 1 to be separated, mixing one part of return material of the separation zone 1 with the first reaction zone raw materials in ratio, and introducing feedstock for a separation zone 2 into a separation zone 2 to be separated; and (3) introducing raw materials for a second reaction zone, a diluent and the rest return material, obtained in the step (2), of the separation zone 1 into the second reaction zone to be contacted with a molecular sieve based catalyst B, carrying out aromatization reaction for producing a second reaction zone material flow, and mixing the second reaction zone material flow with the first reaction zone material flow. The method for increasing the yield of propylene and aromatic hydrocarbon by adopting the moving bed technology has the advantages that on one hand, the catalyst stability is improved, and on the other hand, flexible yield increase of propylene and aromatic hydrocarbon is realized through multi-reaction zone regulation and circular hydrocarbon selective reprocessing.

Owner:ZHEJIANG UNIV

Diesel engine exhaust aftertreatment device

InactiveCN113047934AEmission reductionStrong oxidation abilityExhaust apparatusSilencing apparatusParticulatesCatalytic transformation

The invention discloses a diesel engine exhaust aftertreatment device. The diesel engine exhaust aftertreatment device comprises an insulating cylinder, a plasma discharging body, a porous disc, an external insulator and a catalyst carrier which are arranged in a left sleeve to form a plasma auxiliary catalytic conversion purification device, and further comprises a diesel engine exhaust particulate matter catcher arranged in a right sleeve, wherein the left sleeve and the right sleeve are connected through a flange, an outlet of the plasma auxiliary catalytic conversion purification device is in butt joint with an inlet of the particulate matter catcher, an air inlet is formed in the left end of the left sleeve, and an exhaust port is formed in the right end of the right sleeve. The diesel engine exhaust aftertreatment device has the beneficial technical effects that emission of carbon monoxide, hydrocarbon, nitric oxide and particulate matter in diesel engine exhaust is reduced, continuous regeneration of the particulate matter catcher is achieved, and the size of an aftertreatment device system is reduced.

Owner:HEBEI NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com