Catalytic cracking gasoline adsorption desulfurizing agent as well as preparation method and application thereof

A technology for adsorption desulfurization and desulfurization agent, applied in chemical instruments and methods, inorganic chemistry, treatment of hydrocarbon oil, etc., can solve the problems of poor selectivity and desulfurization effect of adsorption desulfurization agent, and reduce chemical hydrogen consumption and octane number loss. , The effect of high sulfur capacity and low wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The present invention provides an adsorption desulfurizer, comprising powder and a binder; wherein, the raw material components of the powder, in parts by weight, include: 25 parts by weight of silicon dioxide, 25 parts by weight of aluminum oxide, and 20 parts by weight of zinc oxide , 20 parts by weight of iron oxide, 10 parts by weight of reduced nickel (derived from basic nickel carbonate); the raw material components of the adhesive are by weight, including: 15 parts by weight of silica sol, 25 parts by weight of aluminum sol, polyethylene 5 parts by weight of diol PEG600 and 5 parts by weight of methyl cellulose, and the mass of the binder accounts for 20% of the mass of the powder.

[0048] According to the above-mentioned raw material components, adopt the preparation method of the adsorption desulfurizer provided by the present invention to prepare the required adsorption desulfurizer of the present invention:

[0049] S101: Mixing other raw material components...

Embodiment 2

[0064] The present invention provides an adsorbent desulfurizer, comprising powder and binder; wherein, the raw material components of the powder, in parts by weight, include: 20 parts by weight of silicon dioxide, 30 parts by weight of aluminum oxide, and 10 parts by weight of zinc oxide , 30 parts by weight of iron oxide, 10 parts by weight of reduced nickel (derived from nickel acetate); the raw material components of the adhesive are by weight, including: 40 parts by weight of silica sol, 10 parts by weight of aluminum sol and polyethylene glycol 10003 parts by weight of PEG, 5 parts by weight of citric acid and 10 parts by weight of methyl cellulose, and the mass of the binder accounts for 5% of the mass of the powder.

[0065] According to the above-mentioned raw material components, adopt the preparation method of the adsorption desulfurizer provided by the present invention to prepare the required adsorption desulfurizer of the present invention:

[0066] S101: Mixing ...

Embodiment 3

[0073] The invention provides an adsorption desulfurization method for gasoline, comprising the following steps:

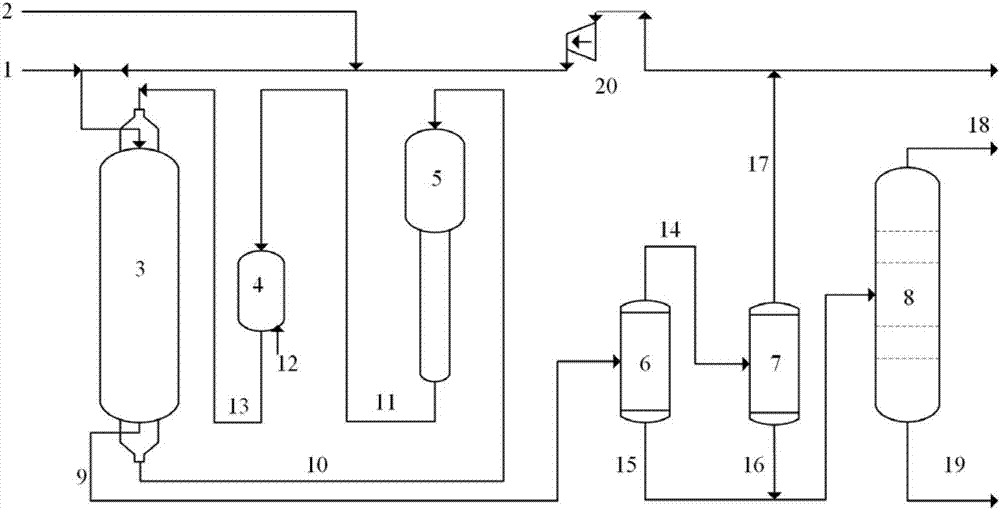

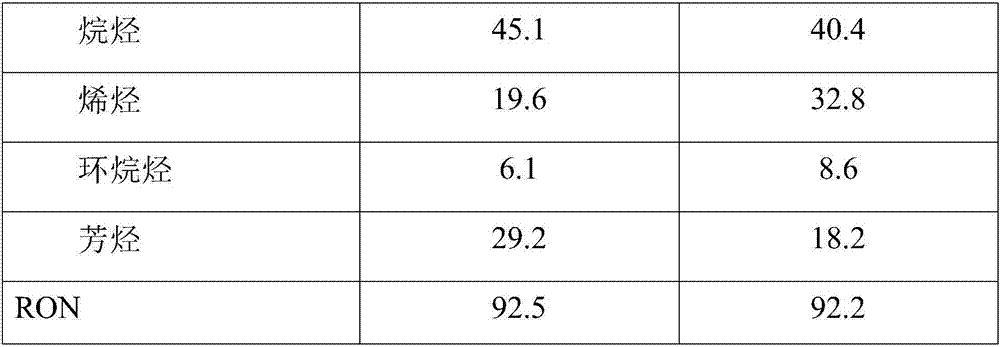

[0074] S201 : performing an adsorption desulfurization reaction on raw material catalytically cracked gasoline, hydrogen, and the adsorption desulfurizer prepared in Example 1 under hydrogen conditions, and then to obtain a desulfurization product and a deactivated desulfurizer. The main properties of the feedstock catalytically cracked gasoline (feedstock 1) in this example are shown in Table 1. Specifically, the catalytically cracked gasoline from the pipeline 1 is mixed with hydrogen and the adsorption desulfurization agent 13 after regeneration, and then enters the moving bed reactor 3 to carry out the adsorption desulfurization reaction. The reaction conditions are: the hydrogen partial pressure in the reactor is 1MPa, and the reaction temperature is 400 ℃, the liquid hour volume space velocity is 2h -1 , the volume ratio of hydrogen to mixture is 100Nm 3 / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com