Selective naphtha hydrodesulfurization with high temperature mercaptan decomposition

a technology of mercaptan decomposition and hydrodesulfurization, which is applied in the petroleum industry, hydrotreatment process, hydrocarbon oil treatment, etc., can solve the problems of unfavorable loss of olefins through hydrogenation, increase the complexity of overall refinery operations, and add significantly to production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

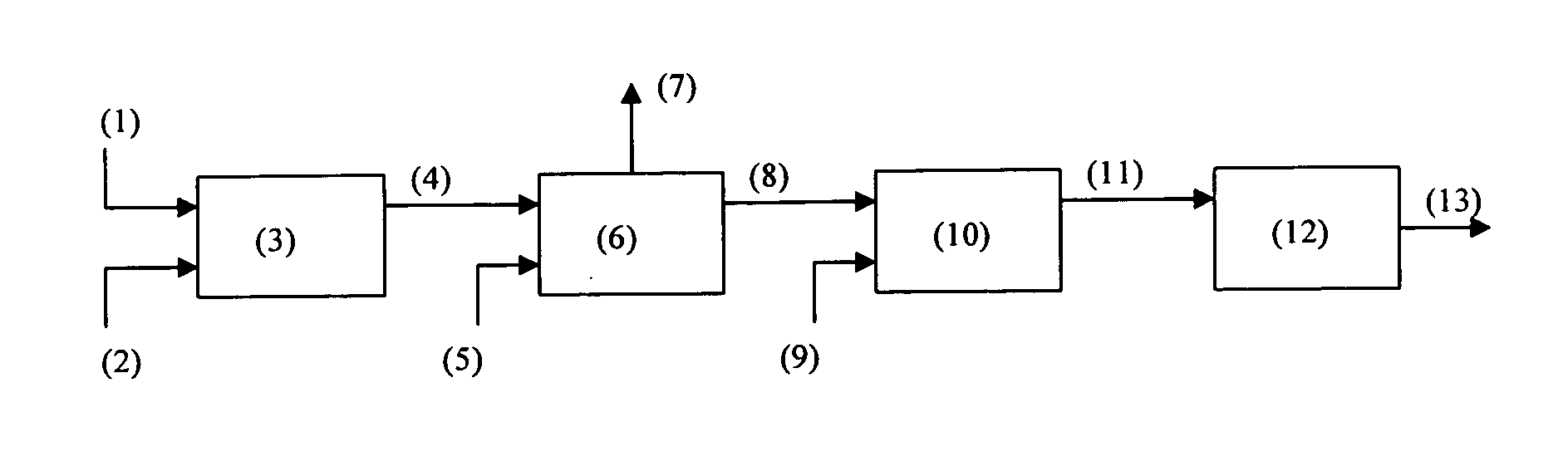

[0043] In this example, the process configuration utilized is shown in FIG. 1. The hydrogen treat gas rates, shown as streams (2) and (9) in FIG. 1, are 2,000 standard cubic feet per barrel (scf / b). The amount of H2S removal in the H2S reaction zone (6) is modeled utilizing an H2S removal step to remove free and dissolved H2S from the process stream at the first hydrodesulfurization reaction pressures (327 psig). Any stripping agent utilized in the art to facilitate H2S removal, such as steam or an amine solution, can be utilized and is shown as stream (5). The H2S or H2S rich compound is then removed from the process via stream (7). The conditions and resulting product qualities are predicted based on a kinetic model developed from a pilot plant database are shown in Tables 1 and 2 below.

TABLE 11st HDS2nd HDSMercaptan RemovalStageStageStage(3)(10)(12)Temperature (° F.)535525625Pressure (psig)327327327

[0044]

TABLE 2FirstSecondThirdReactorStrippedReactorReactorOlefinicEffluentEfflue...

example 2

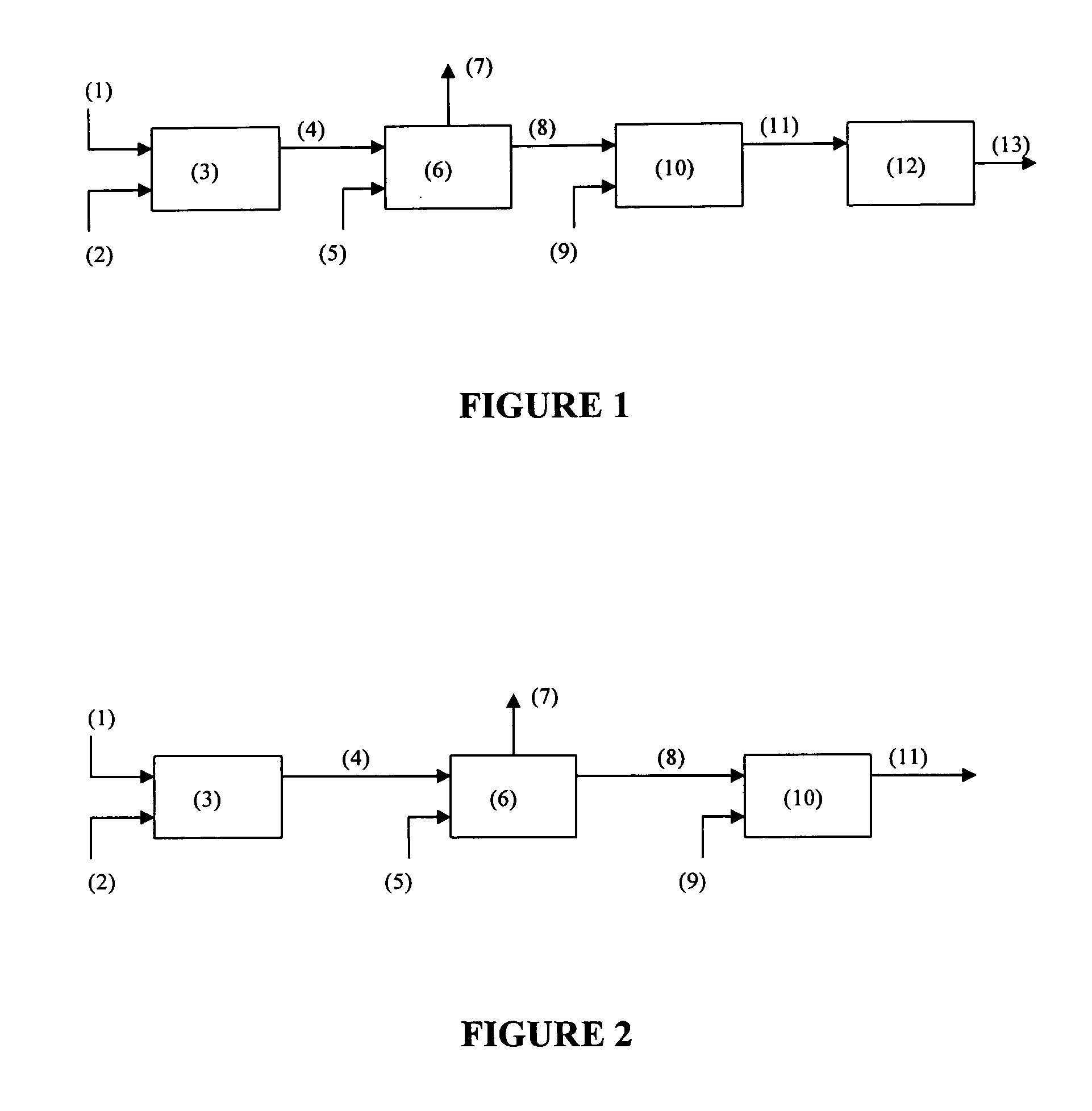

[0045] In this example, the process configuration utilized is shown in FIG. 2. The hydrogen treat gas rates, shown as streams (2) and (9) in FIG. 2, are 2,000 standard cubic feet per barrel (scf / b). The amount of H2S removal in the H2S reaction zone (6) is modeled utilizing an H2S removal step to remove free and dissolved H2S from the process stream at the hydrodesulfurization reaction pressures (327 psig). Any stripping agent utilized in the art to facilitate H2S removal, such as steam or an amine solution, can be utilized and is shown as stream (5). The H2S or H2S rich compound is then removed from the process via stream (7). The conditions and resulting product qualities are predicted based on a kinetic model developed from a pilot plant database are shown in Tables 3 and 4 below.

TABLE 31st HDSMercaptan RemovalStageStage(3)(12)Temperature (° F.)535625Pressure (psig)327327

[0046]

TABLE 4FirstSecondReactorStrippedReactorOlefinicEffluentEffluentProductFeedstreamStreamStreamStream(1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com