Asphalt modifier, modified asphalt and asphalt mixture

A technology of asphalt modifier and raw material, applied in the field of high-viscosity and high-elastic asphalt modifier, modified asphalt and asphalt mixture, it can solve complex stress and deformation, large vibration amplitude deformation of steel box girder, engineering maintenance cycle long-term issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

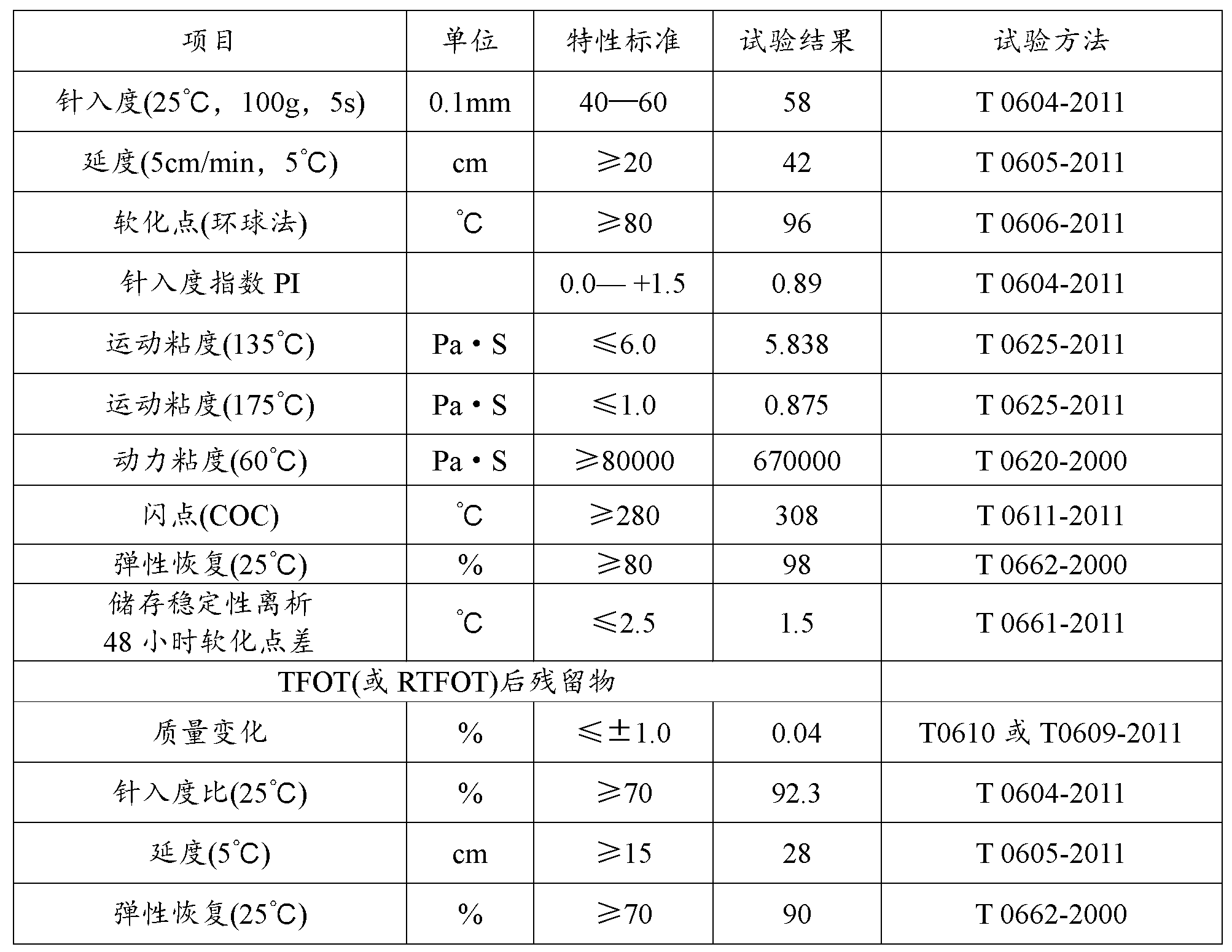

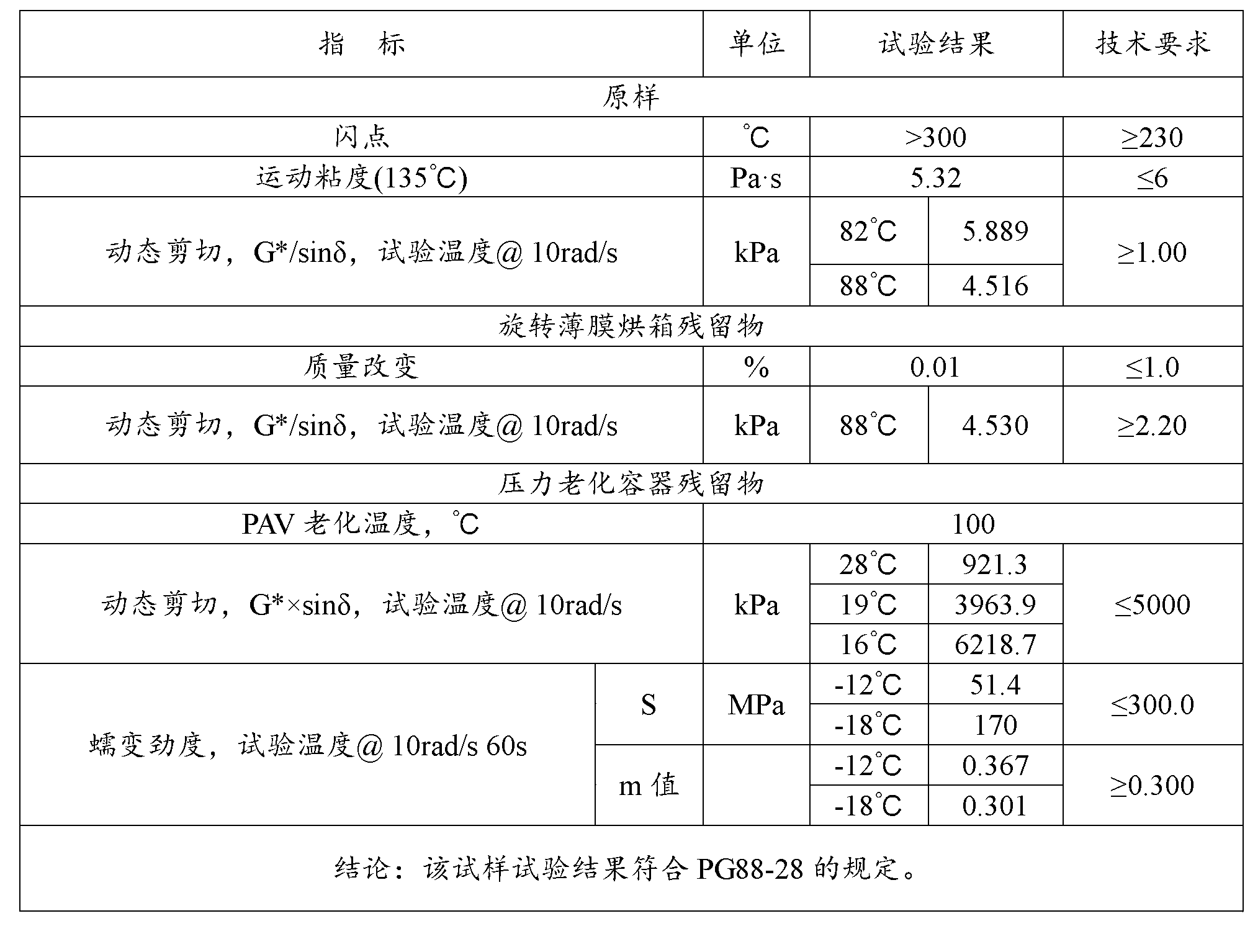

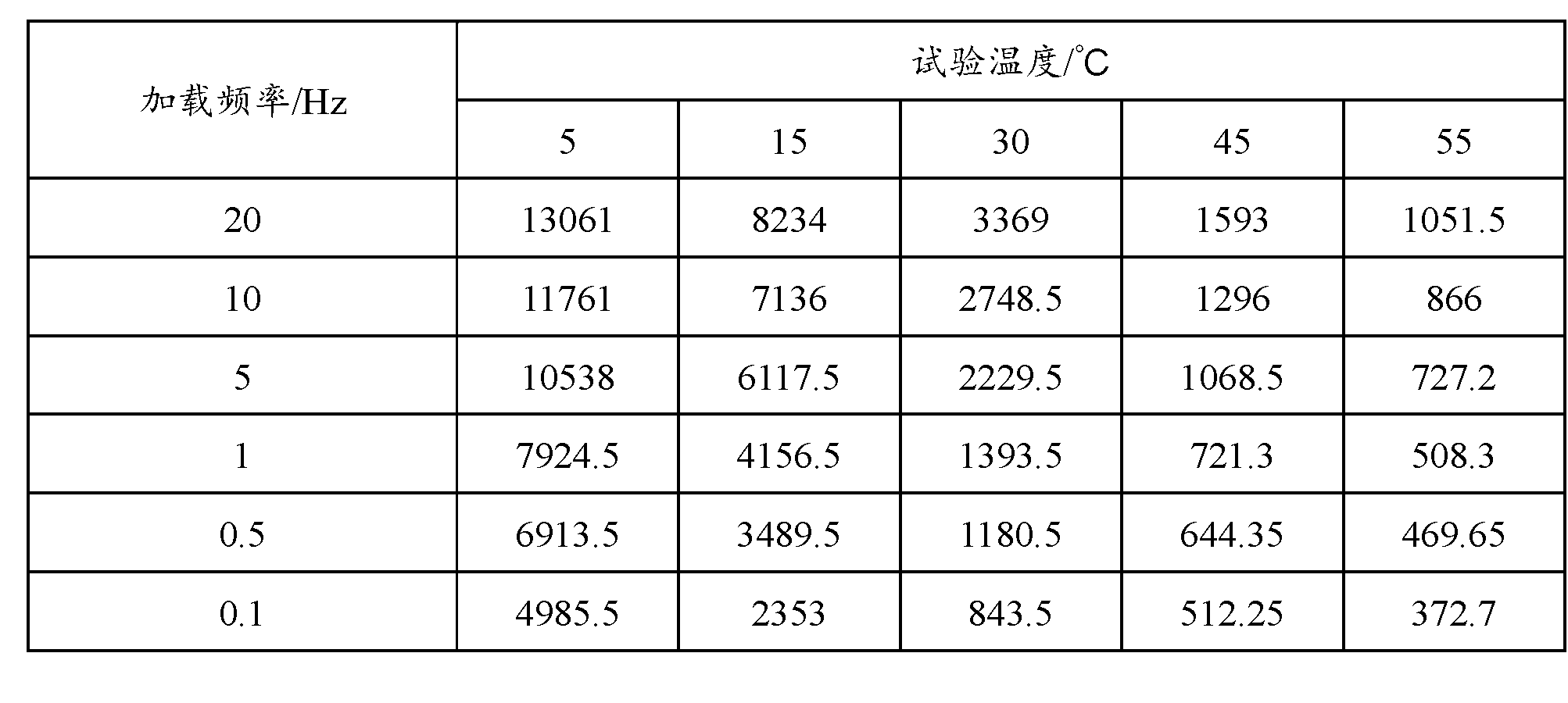

Embodiment 1

[0047] A kind of bitumen modifier, by weight, its raw material is composed of: 10 parts of waste tire rubber powder, 6 parts of polyethylene waste, 3 parts of styrene-butadiene-styrene block copolymer, styrene- 3 parts of isoprene-styrene block copolymer, 3 parts of terpene resin, 6 parts of solvent naphtha, 0.6 part of alcohol ether carboxylate interface agent. Wherein, the softening point of the terpene resin is 90-110° C., and the acid value is less than 20 mgKOH / g. The solvent oil is a compound of waste edible oil and furfural oil, and its weight ratio is 1:1; the alcohol ether carboxylate interface agent is AEC-9Na.

[0048] The specific preparation method of asphalt modifier is: solvent oil, alcohol ether carboxylate interface agent, styrene-butadiene-styrene block copolymer, polyethylene waste, waste tire rubber powder, styrene-iso Pentadiene-styrene block copolymer and terpene resin are sheared and ground at 180°C according to the weight ratio and mixed uniformly, ext...

Embodiment 2

[0057] A kind of bitumen modifier, by weight, its raw material is composed of: 3 parts of waste tire rubber powder, 10 parts of polyethylene waste, 5 parts of styrene-butadiene-styrene block copolymer, styrene- 4 parts of isoprene-styrene block copolymer, 2 parts of terpene resin, 9 parts of solvent naphtha, 0.4 part of alcohol ether carboxylate interface agent. Wherein, the softening point of the terpene resin is 90-110° C., and the acid value is less than 20 mgKOH / g. The solvent oil is furfural extract oil; the alcohol ether carboxylate interface agent is AEC-10Na.

[0058] The specific preparation method of asphalt modifier is: solvent oil, alcohol ether carboxylate interface agent, styrene-butadiene-styrene block copolymer, polyethylene waste, waste tire rubber powder, styrene-iso Pentadiene-styrene block copolymer and terpene resin are sheared and ground at 190°C according to the weight ratio and mixed uniformly, extruded and granulated by a twin-screw extruder, and pell...

Embodiment 3

[0067] A kind of asphalt modifier, by weight, its raw material is composed of: 6 parts of waste tire rubber powder, 8 parts of polyethylene waste, 4 parts of styrene-butadiene-styrene block copolymer, styrene- 2 parts of isoprene-styrene block copolymer, 4 parts of terpene resin, 7 parts of solvent naphtha, 0.3 part of alcohol ether carboxylate interface agent. Wherein, the softening point of the terpene resin is 90-110° C., and the acid value is less than 20 mgKOH / g. The solvent oil is a compound of waste edible oil and furfural oil, and its weight ratio is 1:1; the alcohol ether carboxylate interface agent is AEC-9Na.

[0068] The specific preparation method of asphalt modifier is: solvent oil, alcohol ether carboxylate interface agent, styrene-butadiene-styrene block copolymer, polyethylene waste, waste tire rubber powder, styrene-iso Pentadiene-styrene block copolymer and terpene resin are sheared and ground at 185°C according to the weight ratio and mixed uniformly, extr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com