Patents

Literature

35 results about "Failure strain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

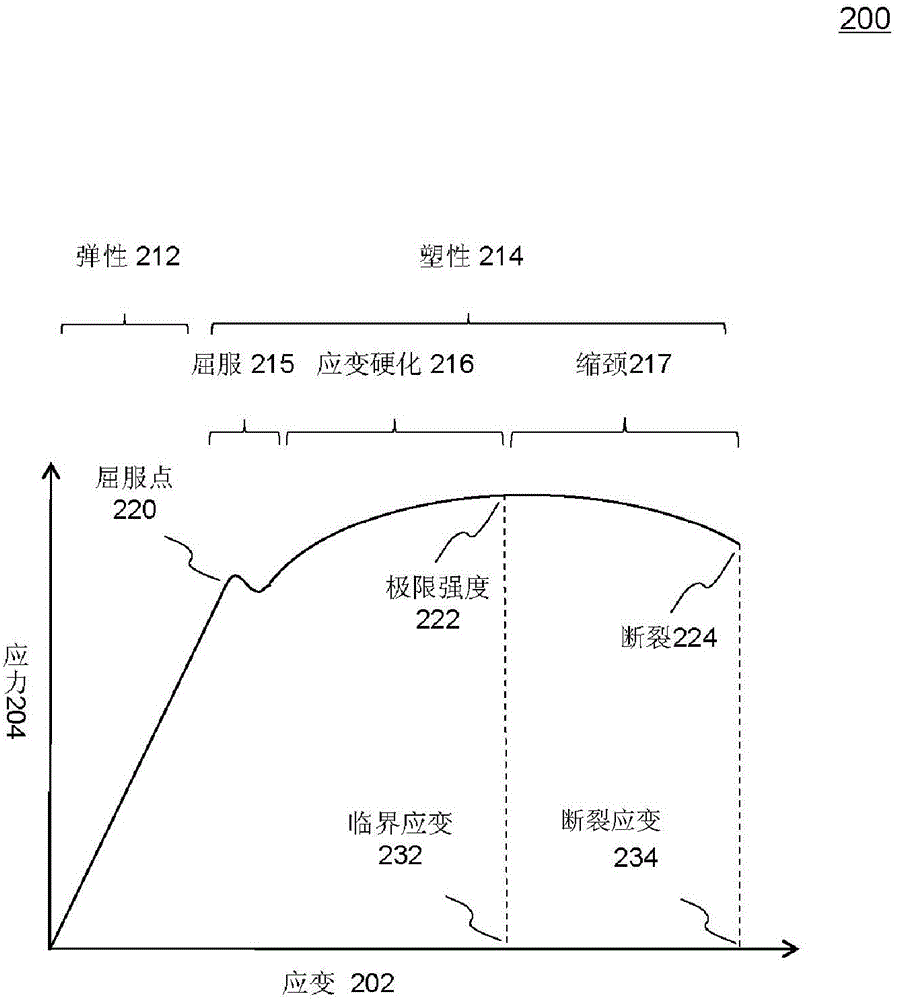

Strain to failure gives the measure of how much the specimen is elongated to failure. By this it means that, it you have strain to failure of 3% measured in specimen of length 100 mm, the material will fail when it it elongated 3 mm, as experimented in tensile test.

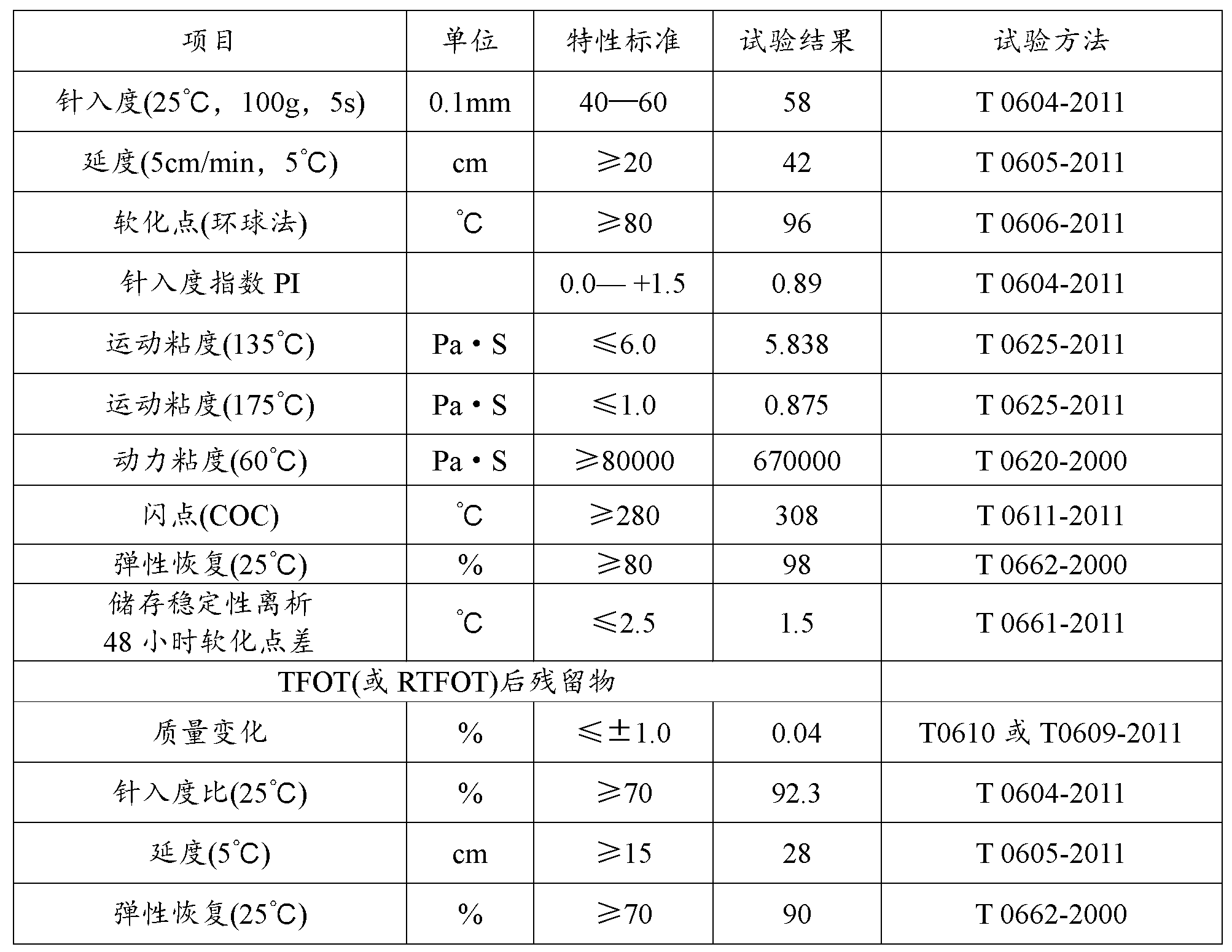

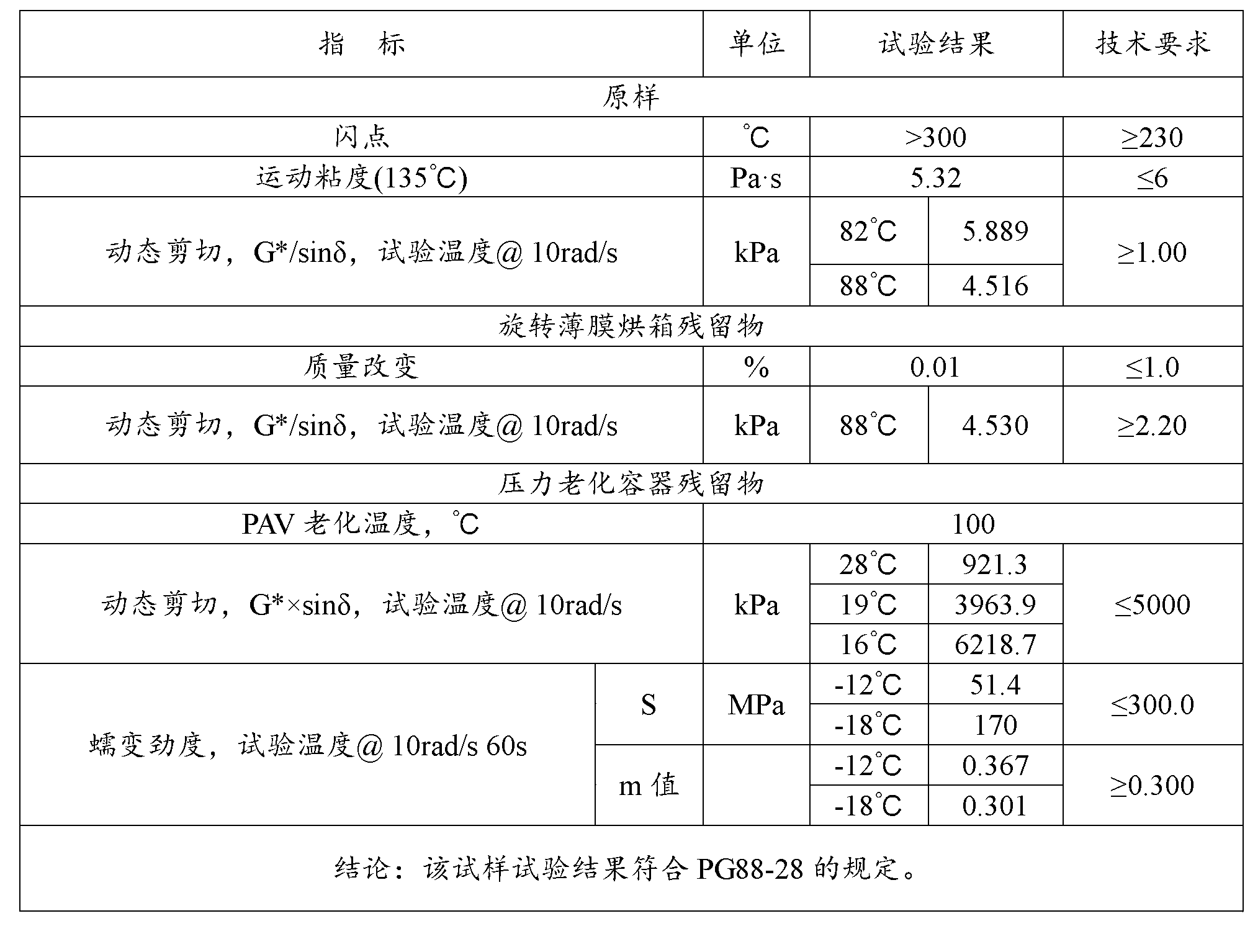

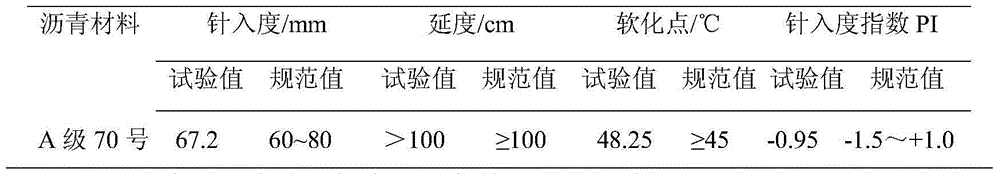

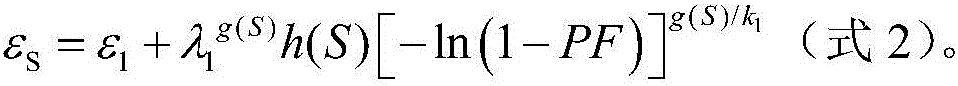

Asphalt modifier, modified asphalt and asphalt mixture

ActiveCN102838874AExcellent Adhesive PropertiesImprove low temperature 60°C viscosityIn situ pavingsBuilding insulationsRoad engineeringBridge deck

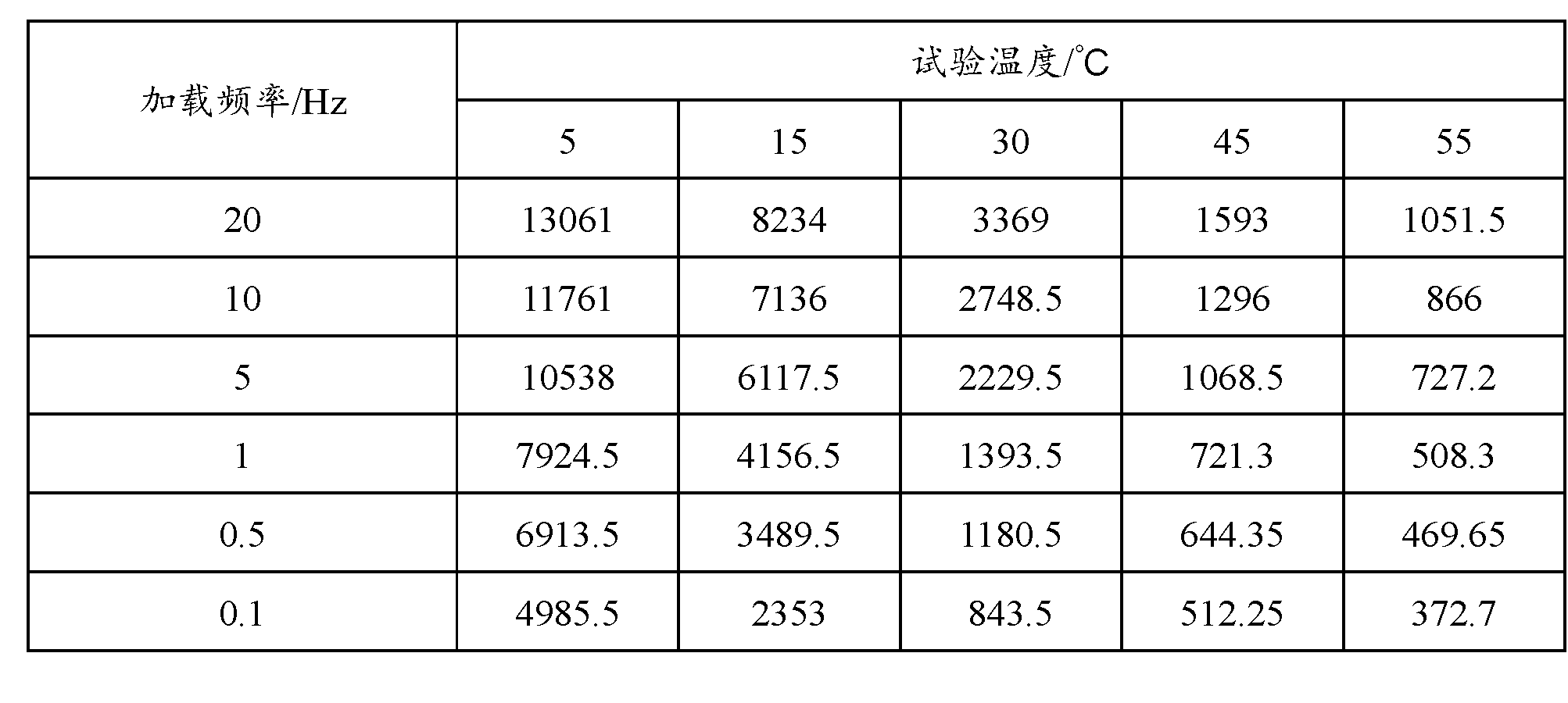

The invention belongs to the field of road engineering, and particularly relates to a hyperviscous and high-elastic asphalt modifier applicable to steel bridge deck pavement. The asphalt modifier comprises the following raw materials in parts by weight: 3-10 parts of junked tire rubber powder, 3-10 parts of polyethylene wastes, 3-8 parts of styrene-butadiene-styrene block copolymer, 1-5 parts of styrene-isoprene-styrene block copolymer, 1-5 parts of terpene resin, 5-10 parts of solvent naphtha, and 0.3-0.7 part of alcohol ether carboxylate adhesion agent. In addition, a modified asphalt and amodified asphalt mixture are prepared on the basis of the modifier, the 60 DEG C dynamic viscosity of the modified asphalt prepared by applying the modifier can reach more than 300000Pa.s, and the performance grading reaches PG 88-28; and the asphalt mixture has favorable water stability, higher dynamic modulus, higher track dynamic stability and low temperature failure strain, and can resist complicated mechanics and temperature environment of a steel bridge deck.

Owner:山东高速交通建设集团股份有限公司

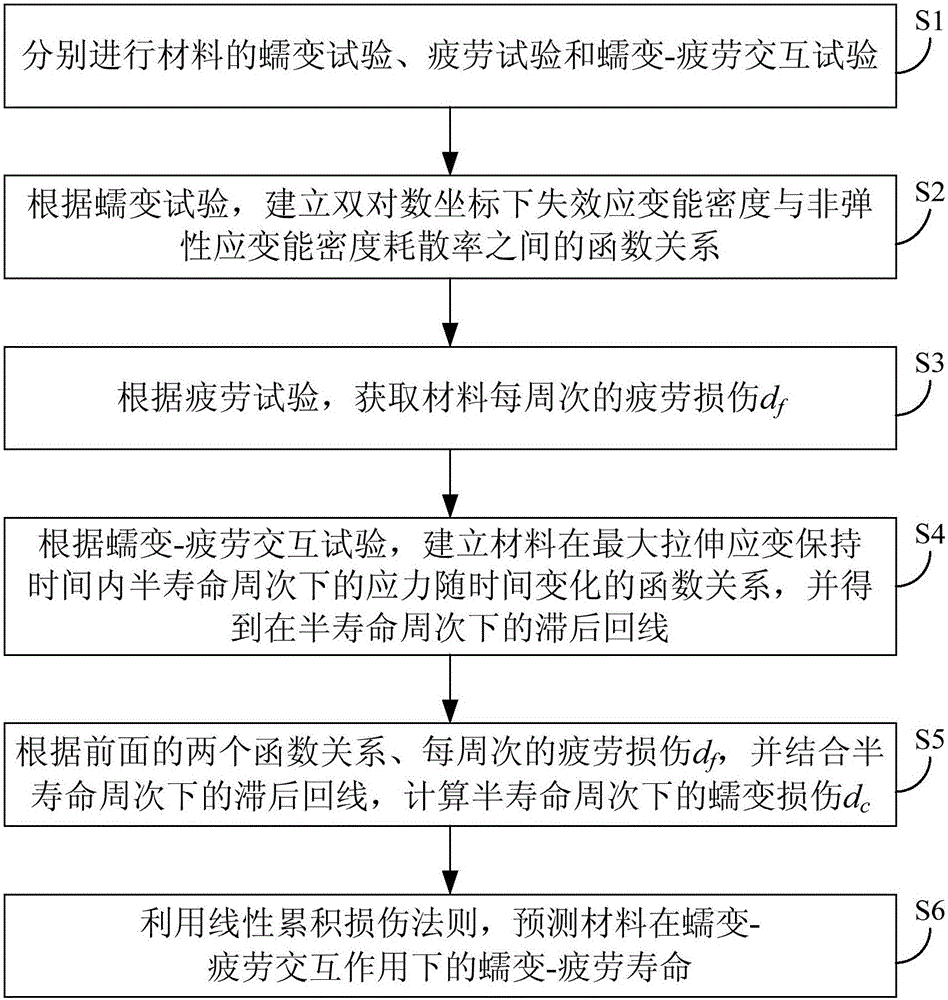

Forecasting method for creep-fatigue life of material

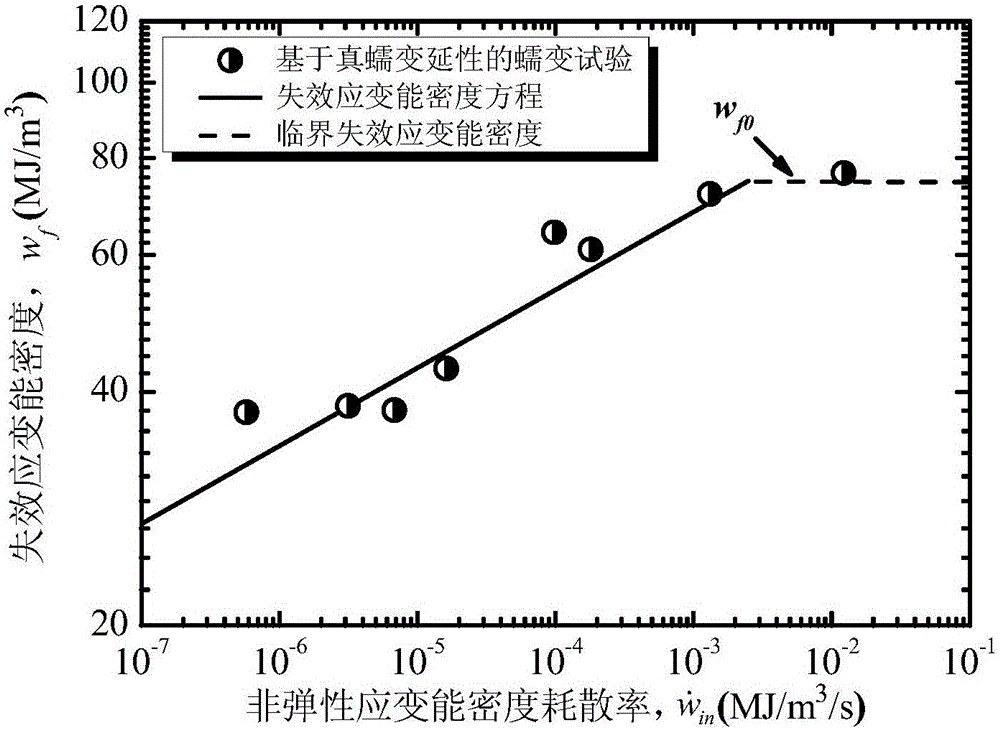

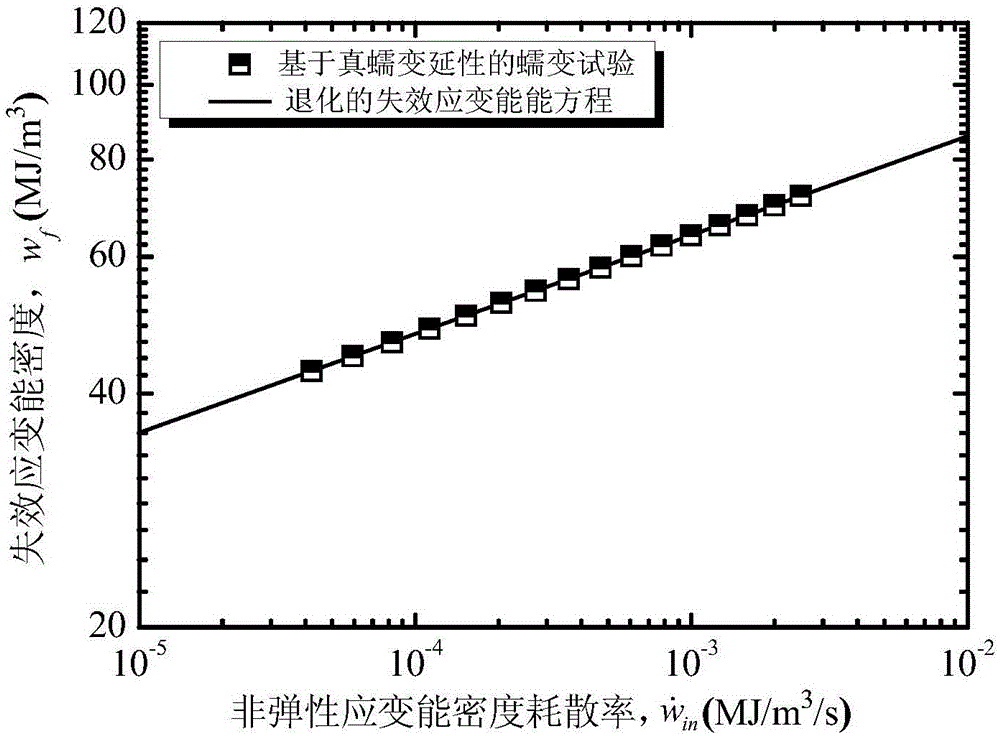

ActiveCN105158084ALife expectancyReal-time Damage DetectionMaterial strength using tensile/compressive forcesFatigue damageHysteresis

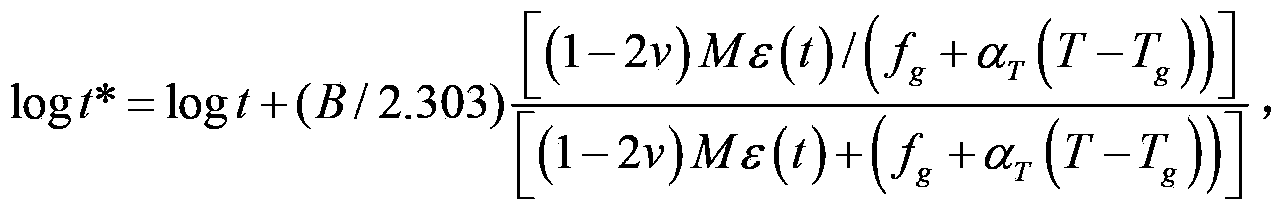

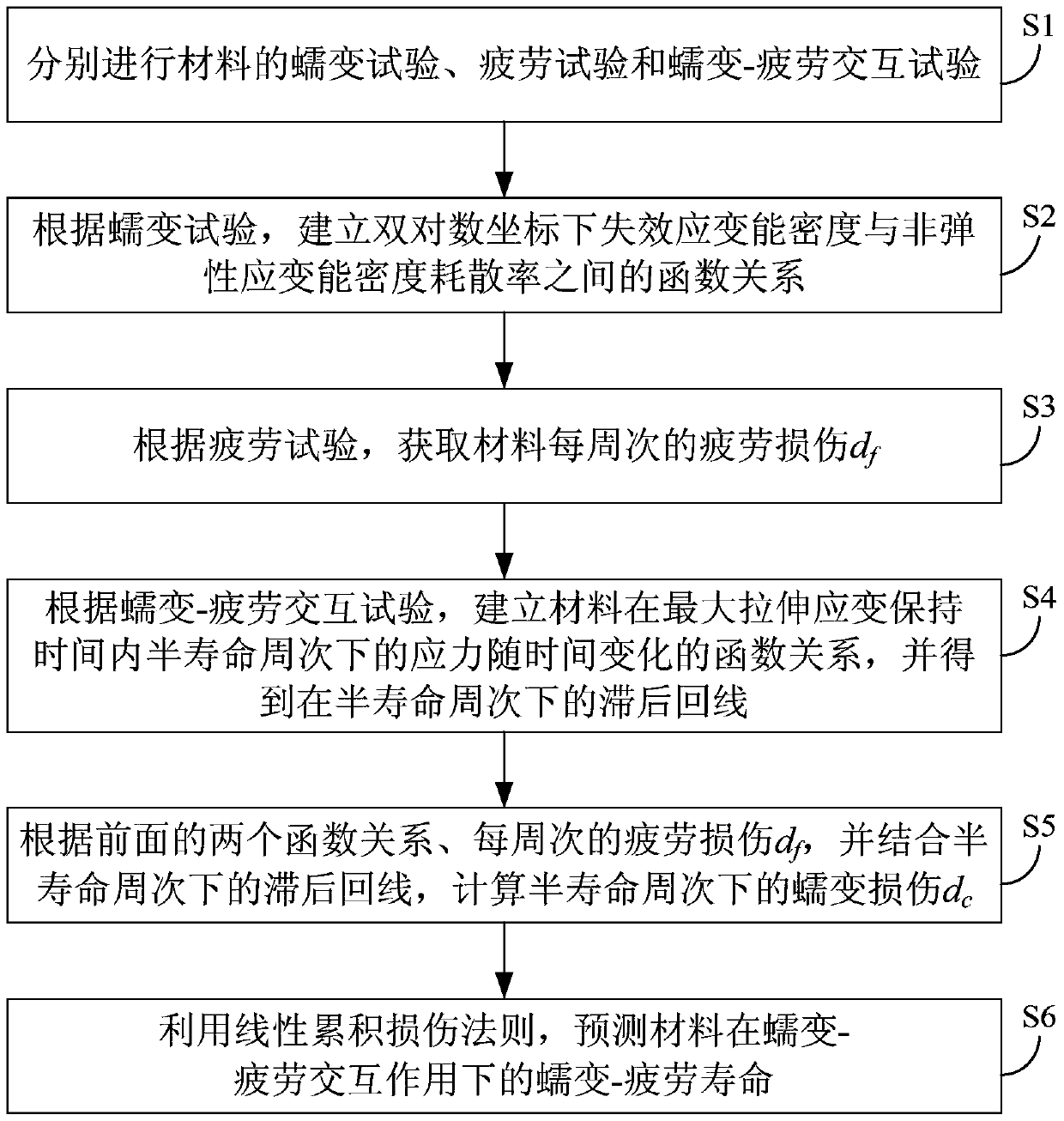

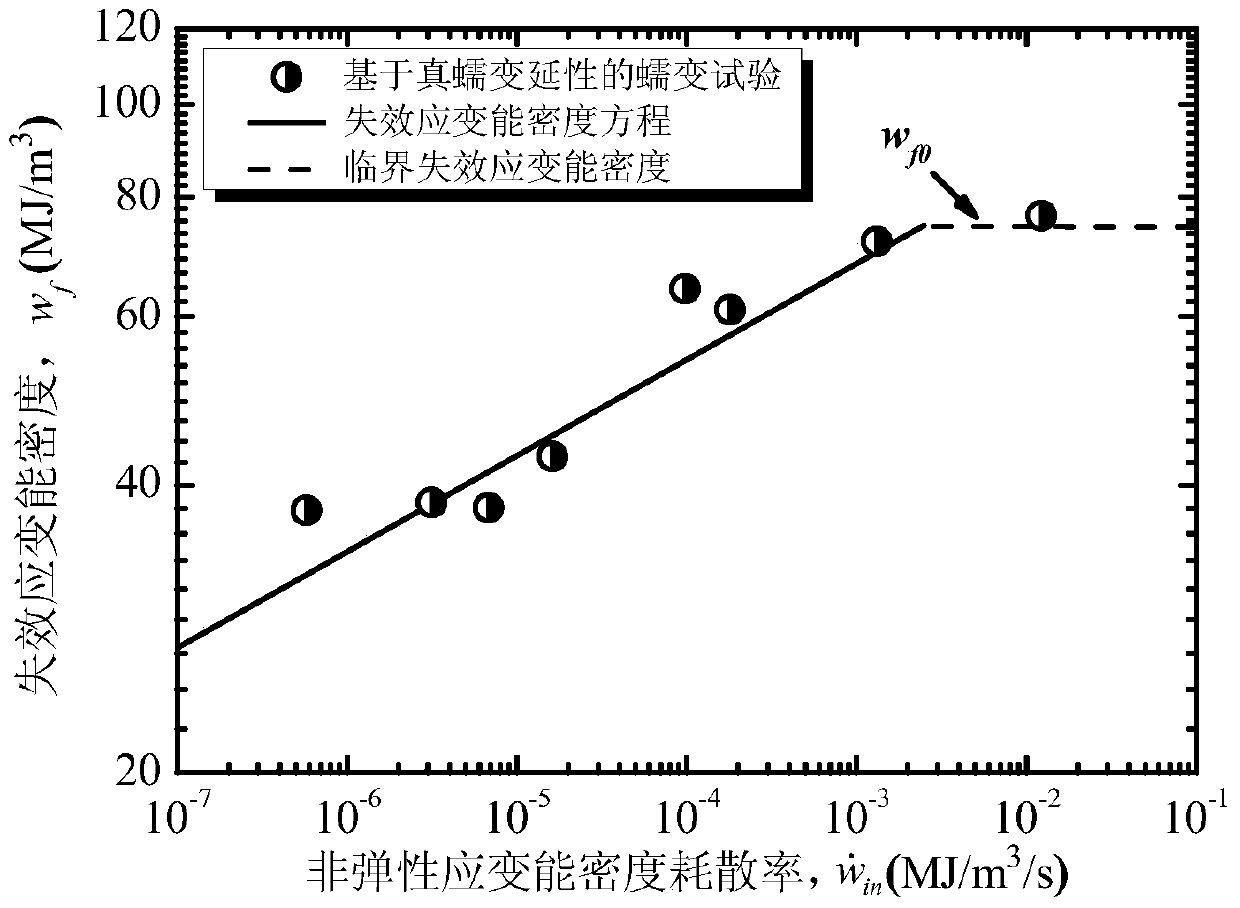

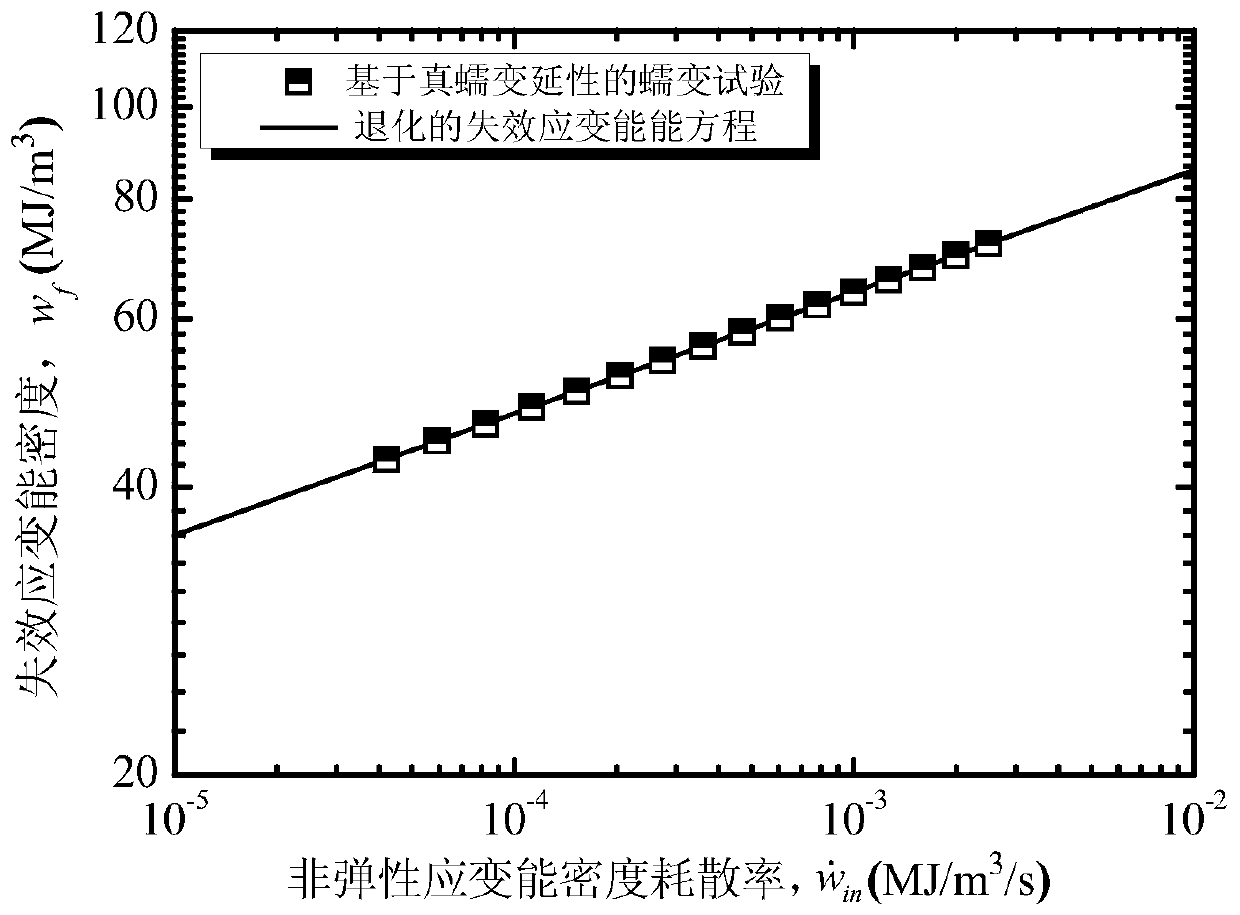

The invention provides a forecasting method for creep-fatigue life of a material. The method comprises the following steps: respectively performing a creep test, a fatigue test and a creep-fatigue interaction test for the material at a same test temperature; establishing a relation between the failure strain energy density wf and a non-elastic strain energy density dissipation rate of the material under a log-log coordinate according to the creep test; acquiring the fatigue damage df of the material per period according to the fatigue test; acquiring a hysteresis loop under a half-life period according to the creep-fatigue interaction test and establishing a function relation of the change of the stress Sigma (t) of the material under the half-life period within the maximum tensile strain maintaining time along with the change of time t; calculating the creep damage dc under the half-life period by combining with the hysteresis loop and based on the relation between wf and the function as shown in the specification and the relation of change of the fatigue damage df and the stress Sigma (t) along with the change of time t; and utilizing a linear accumulating damage rule to forecast the creep-fatigue life of the material under a creep-fatigue interaction. According to the method provided by the invention, the life of the material under the creep-fatigue interaction can be accurately forecasted.

Owner:EAST CHINA UNIV OF SCI & TECH

Prediction method for fatigue life of complex braided structure ceramic-based composite material

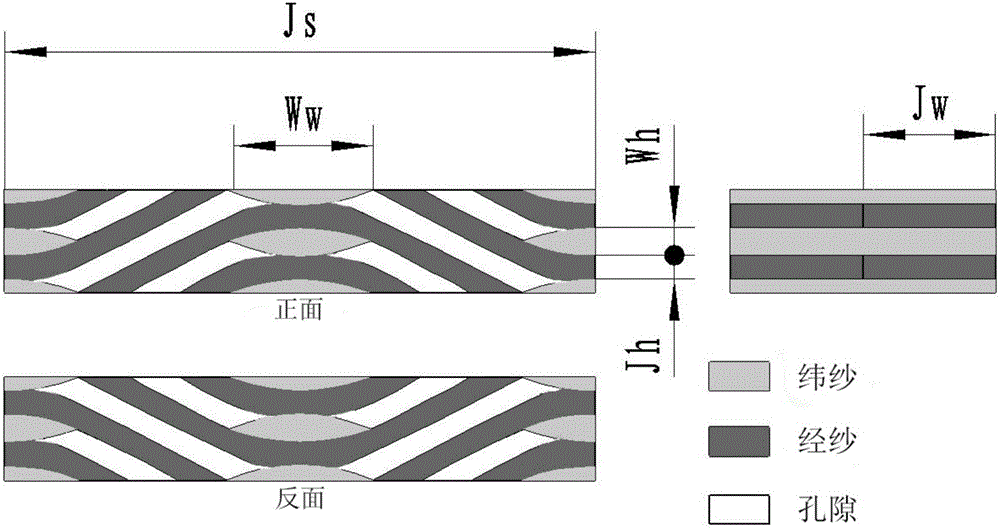

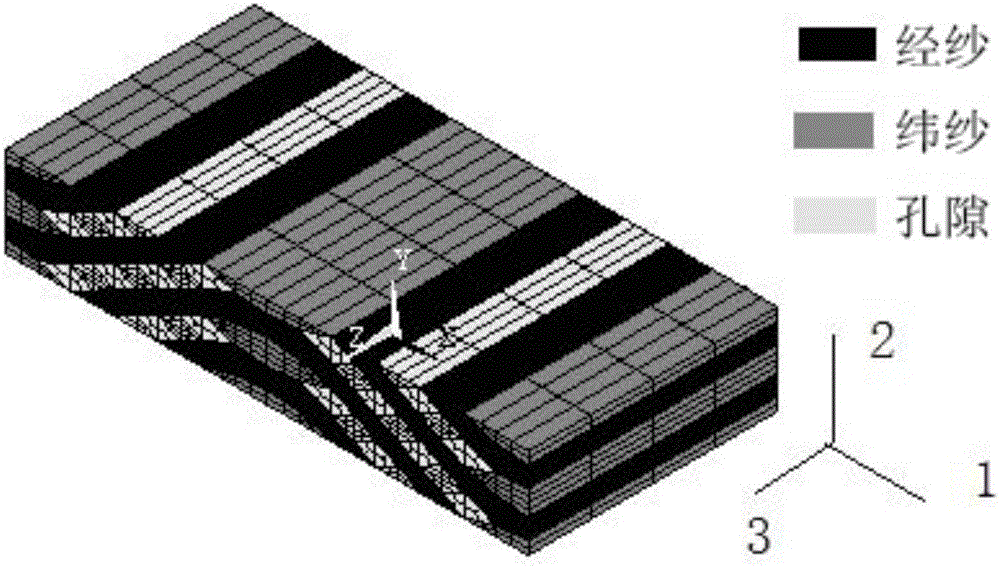

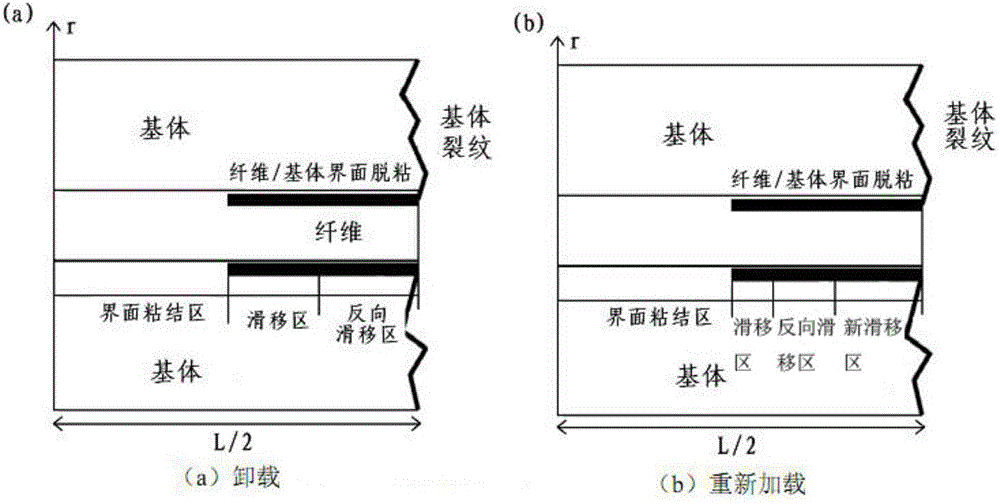

InactiveCN105760605APredict fatigue lifeDesign optimisation/simulationSpecial data processing applicationsFiberFailure strain

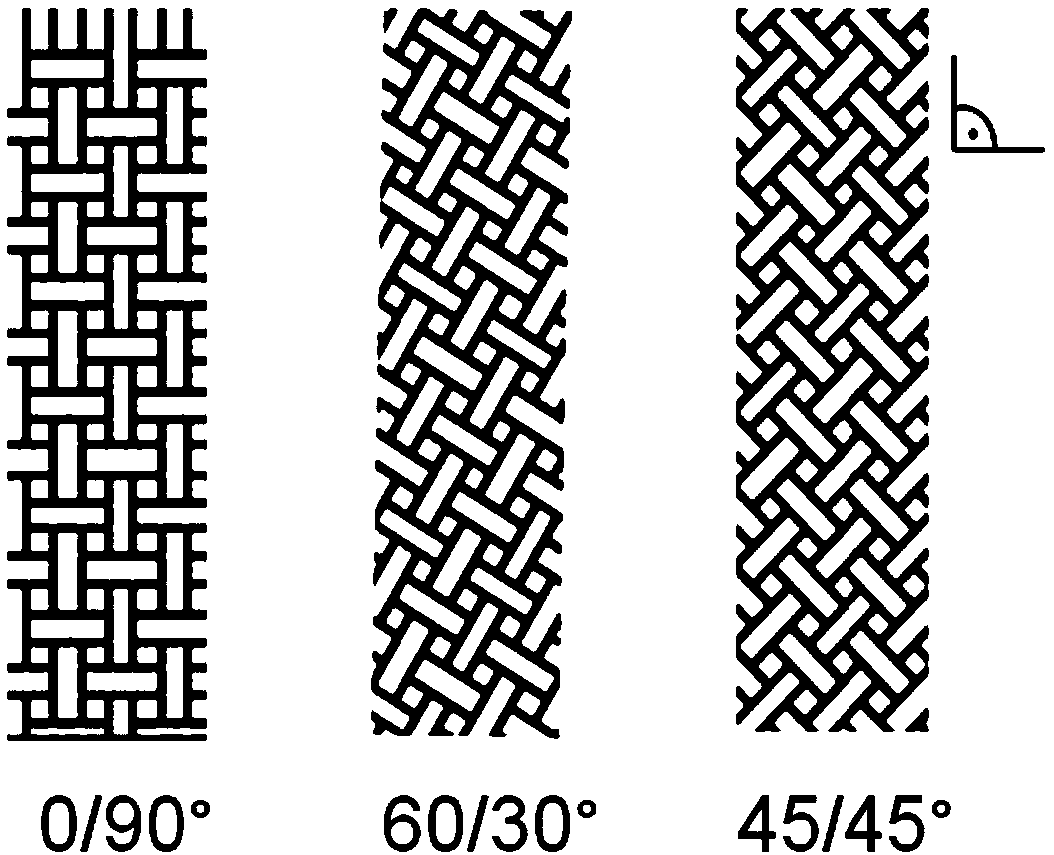

The invention discloses a prediction method for the fatigue life of a complex braided structure ceramic-based composite material.The prediction method comprises the steps that the fatigue performance under a cycle number and the fiber failure percentage under the cycle number are calculated; the relationship between the fiber failure percentage and a fiber failure critical value is determined; the unit-cell scale fatigue performance is calculated to obtain the maximum strain epsilon'max under the cycle; the relationship between the maximum strain epsilon'max and the maximum failure strain epsilonmax is determined; a fatigue life curve of the material is obtained.According to the prediction method, a microscale model taking account of fibers, a base body and pores and a unit-cell multi-scale prediction model taking account of warp yarn, weft yarn and holes are presented and overcome the defects that a micromechanical method cannot be directly applied to the braded material with the complex structure, and a macroscopic phenomenological method depends on a large quantity of tests and only can achieve prediction on the fatigue life of a special material, macromechanics and micromechanics are combined, a micromechanical stress strain field of a complex braided structure is supplied, and the application range of the material is widened while the fatigue life curve of the material is precisely predicted.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

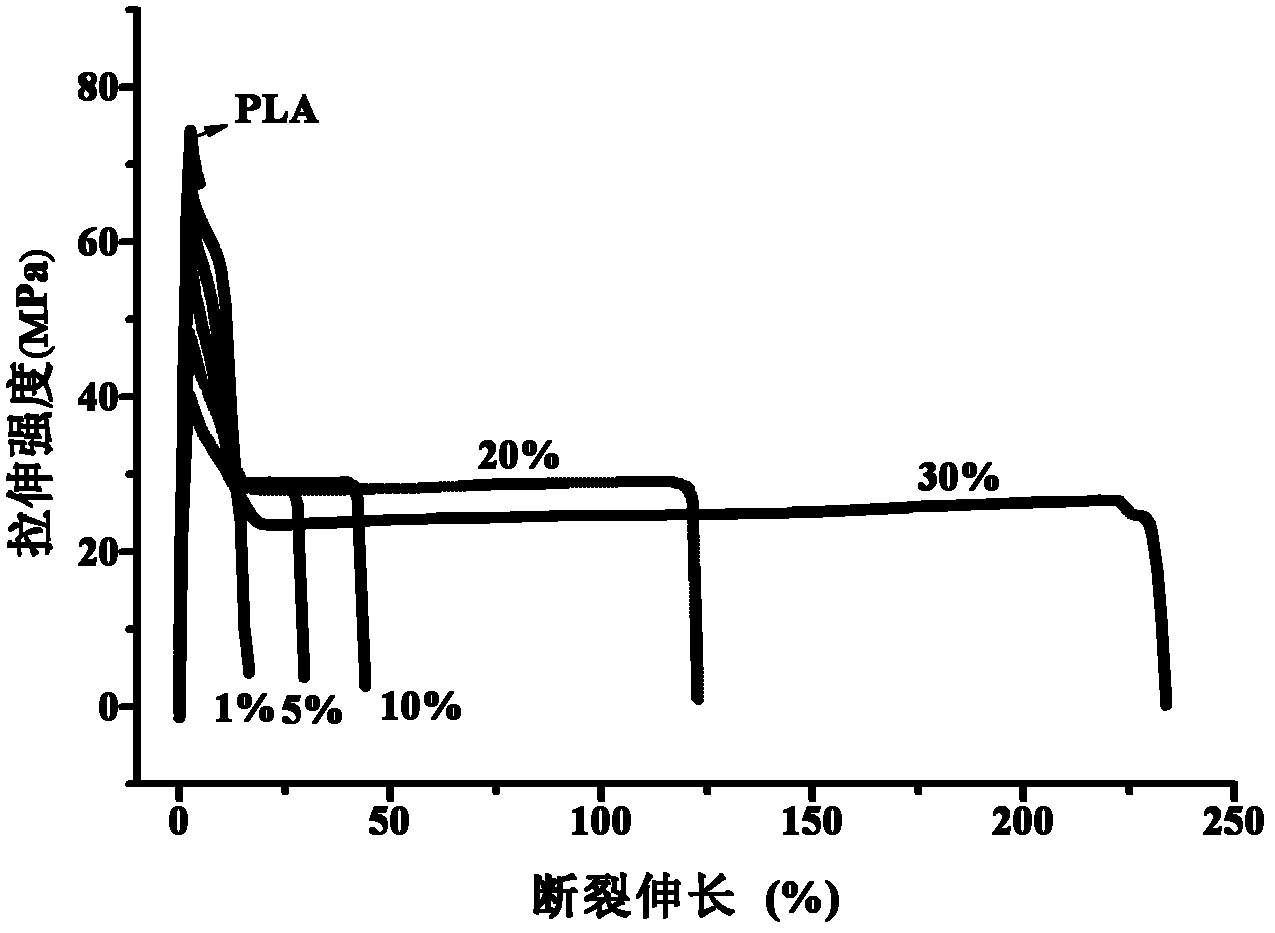

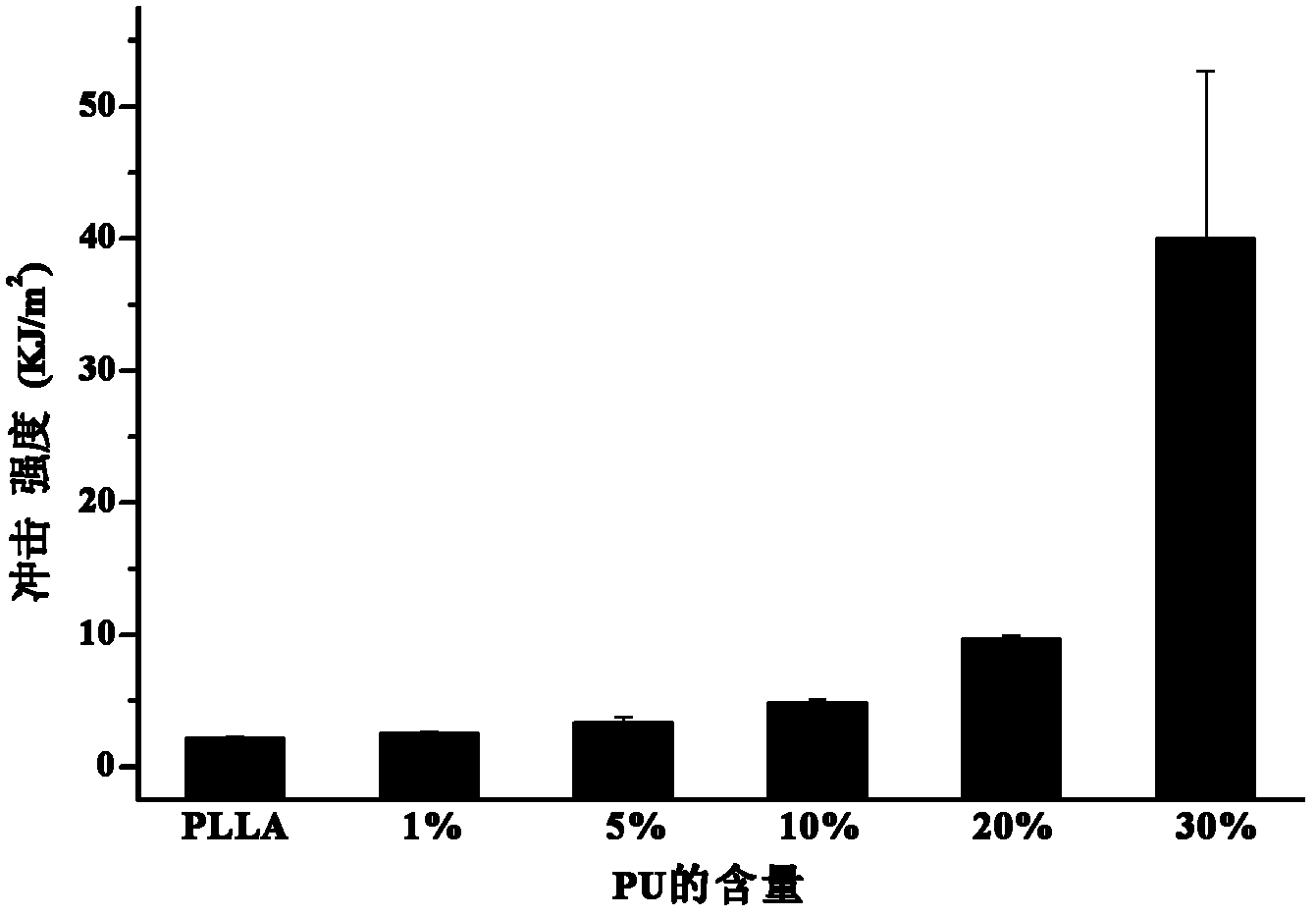

Polylactic acid / polyurethane blend and preparation method thereof

The present invention relates to a polylactide blend, especially a polylactic acid / polyurethane blend and a preparation method thereof. The method provided by the invention comprises steps of: evenly mixing 70- 99wt% of a polylactic acid homopolymer and 1-30 wt% of polyester type polyurethane to obtain a mixture; and then subjecting the mixture to melt blending extrusion, casting and granulating by a twin-screw extruder at 190-220 DEG C to obtain the polylactic acid / polyurethane blend provided by the invention. The polylactic acid / polyurethane blend provided by the invention has significantly increased toughness and tensile failure strain compared with pure PLA; meanwhile, the tensile strength of the blend only decreases a little compared with that of the pure PLA.

Owner:INST OF CHEM CHINESE ACAD OF SCI

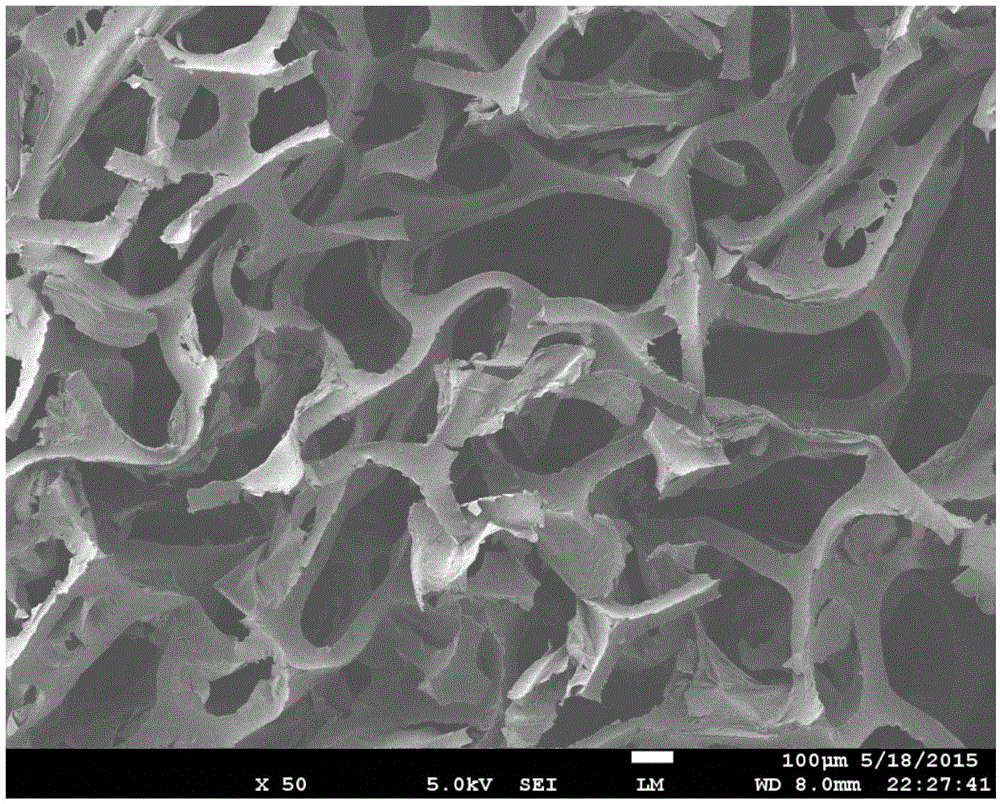

Negative-Poisson ratio multifunctional sponge and preparation method thereof

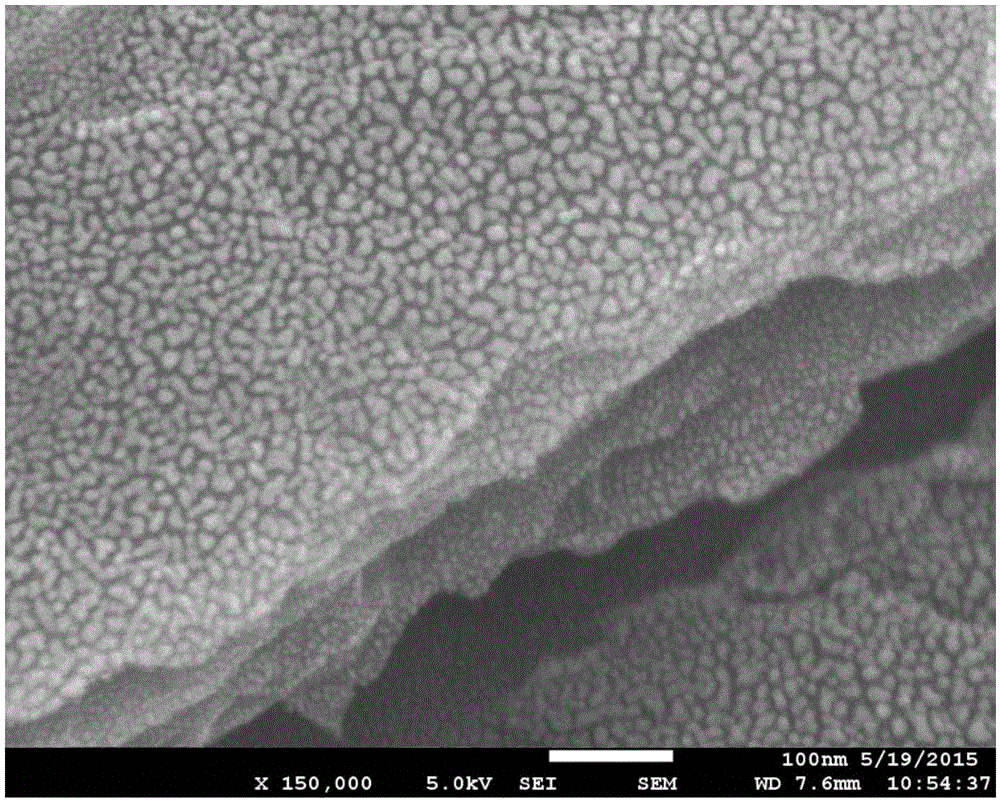

ActiveCN105001622AImprove conductivityHigh energy lossFailure strainElectrical resistivity and conductivity

The invention relates to a negative-Poisson ratio multifunctional sponge and a preparation method thereof. The negative-Poisson ratio multifunctional sponge is loaded with a nano material, and the negative-Poisson ratio multifunctional sponge has a pore structure composed of bent fiber; the curved fiber is sunken inward. The preparation method comprises the steps that a sponge substrate is loaded with the nano material, and then the negative-Poisson ratio multifunctional sponge is obtained through hot pressing. The negative-Poisson ratio multifunctional sponge has the advantages of being high in conductivity, high in energy dissipation, excellent in hydrophobicity, and high in piezoresistive sensitivity; in addition, the inward-sunken bent fiber structure of the negative-Poisson ratio multifunctional sponge enables the negative-Poisson ratio multifunctional sponge to achieve a negative Poisson ratio and higher tensile failure strain, lateral expansion can be achieved in tension, lateral contraction can be achieved in compression, and the application prospect is wide.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Preparation method of shape memory composite material

InactiveCN104589672AImprove mechanical propertiesHigh retention rate of mechanical propertiesThermoplasticFailure strain

The invention belongs to the technical field of shape memory materials, and relates to a preparation method of a shape memory composite material applied to the aerospace field. The shape memory composite material is obtained by compounding discontinuous orientation fibers and shape memory thermoplastic or thermoset resin substrates; the fibers are in a height orientation state in the composite material and the mechanical property and the retention rate of the fibers are higher than the mechanical property and the retention rate of a continuous fiber reinforced composite material; meanwhile, the fibers are discontinuous, and the average length of the fibers and the volume fraction of the fibers can be adjusted, so that the failure strain of the material reaching more than the shape memory transformation temperature can be improved through collaborative optimization, the relatively high deformation property and high folding rate are achieved, and the shape fixed rate is improved at the same time. According to the preparation method, the comprehensive optimization of the mechanical performance and the shape memory performance of the shape memory composite material can be realized, and the preparation method has wide application potential in the application field of aerospace shape memory composite materials.

Owner:AVIC COMPOSITES

Cold-mixed and cold-laid anion emulsified asphalt and preparation method and application thereof

The invention relates to cold-mixed and cold-laid anion emulsified asphalt and a preparation method and application thereof. The cold-mixed and cold-laid anion emulsified asphalt comprises mineral aggregate, cement, mixing water and modified emulsified asphalt and is characterized in that the optimal asphalt-aggregate ratio of the emulsified asphalt mixture is 4-5%, the use amount of the mixing water is 1-2% of the mass of the mineral aggregate and the cement, and the use amount of the cement is 1-2% of the total mass of the mineral aggregate and the cement; the modified emulsified asphalt isprepared by emulsified asphalt and modifier waterborne epoxy resin, the use amount of the modifier waterborne epoxy resin is 10-15% of the mass of the emulsified asphalt, and the modifier waterborne epoxy resin is prepared by waterborne epoxy resin and a curing agent; the emulsified asphalt is prepared by an emulsifier, water, a stabilizer solution and matrix asphalt, and the use amount of the emulsifier is 1.2-4.0% of the mass of the emulsified asphalt. The dynamic stability, residual stability and maximum flexural-tensile failure strain of the cold-mixed and cold-laid anion emulsified asphalt meet Technical Specification for Construction of Highway Asphalt Pavements (JTG F40-2004) and corresponding engineering technical requirements.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE +1

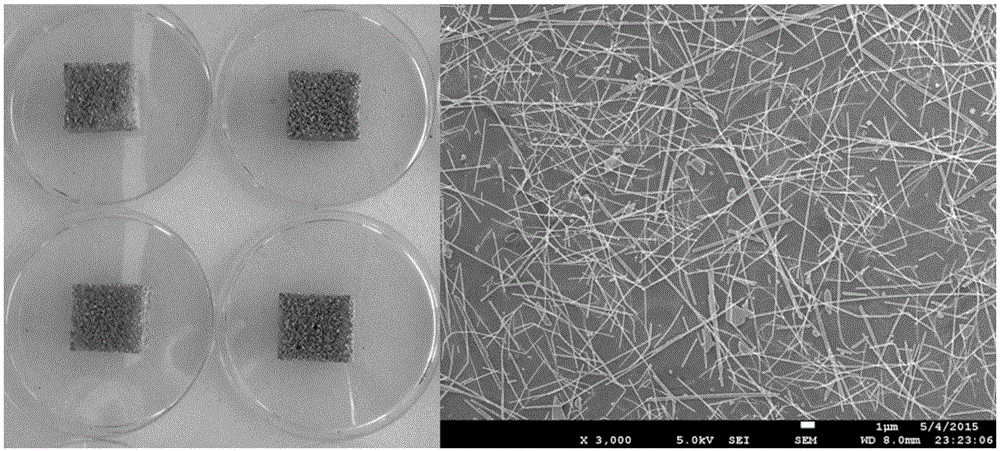

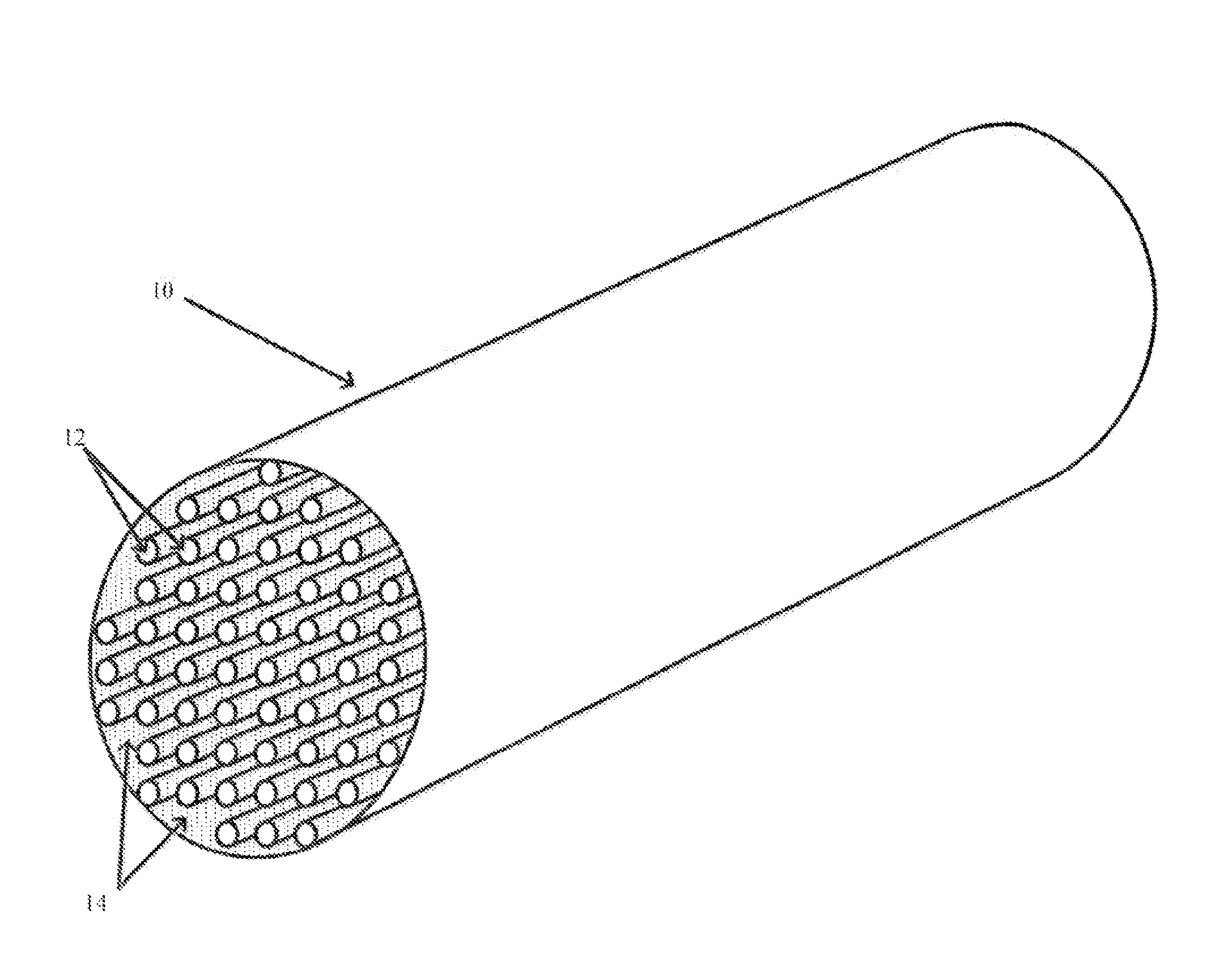

Composite Material

InactiveUS20160288453A1Lower the volumeLow stowed volumeVehicle componentsElectrical equipmentFiberElastomer

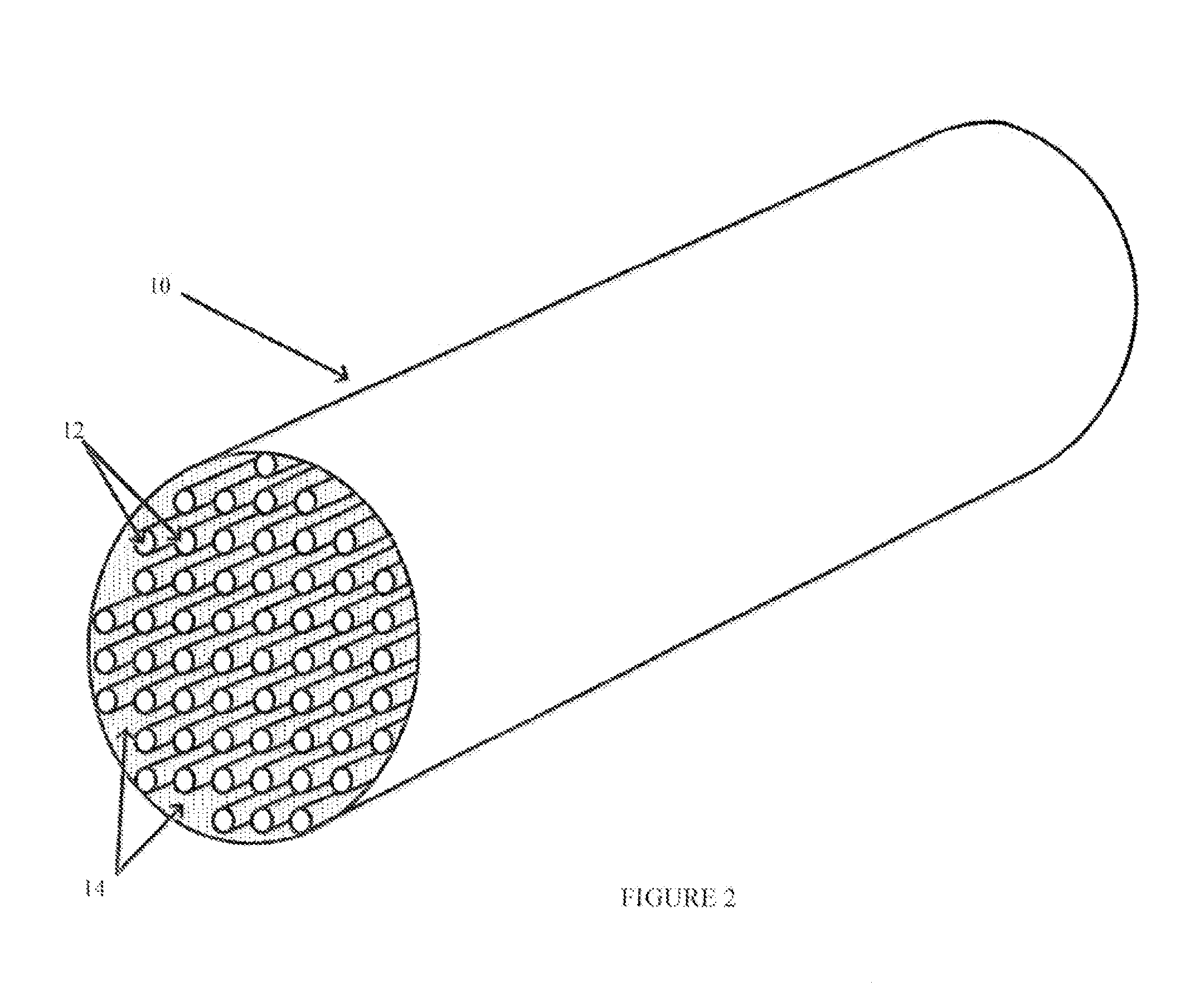

A unidirectional elastomeric composite comprises a plurality of fibers generally aligned in a first direction with an elastomer filling the space between fibers. The plurality of fibers may comprise an intermediate modulus carbon fiber. Preferably, the plurality of fibers have an ultimate elongation at failure or tensile failure strain of 1% or greater, a tensile modulus between 200-400 GPa and tensile strength greater than 4 GPa. The resin or matrix may be a passive elastomer that will maintain its mechanical and chemical properties at a specific operational temperature range. Elastomers are polymers with viscoelasticity, generally having low Young's modulus and high failure strain. Methods of manufacturing the unidirectional elastomeric composite include apply the resin to fibers maintained in tension to maintain the fiber alignment.

Owner:LGARDE

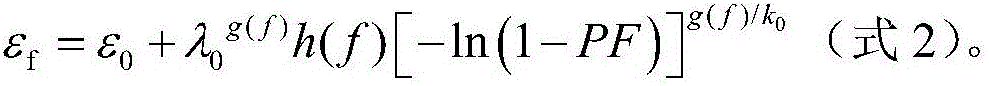

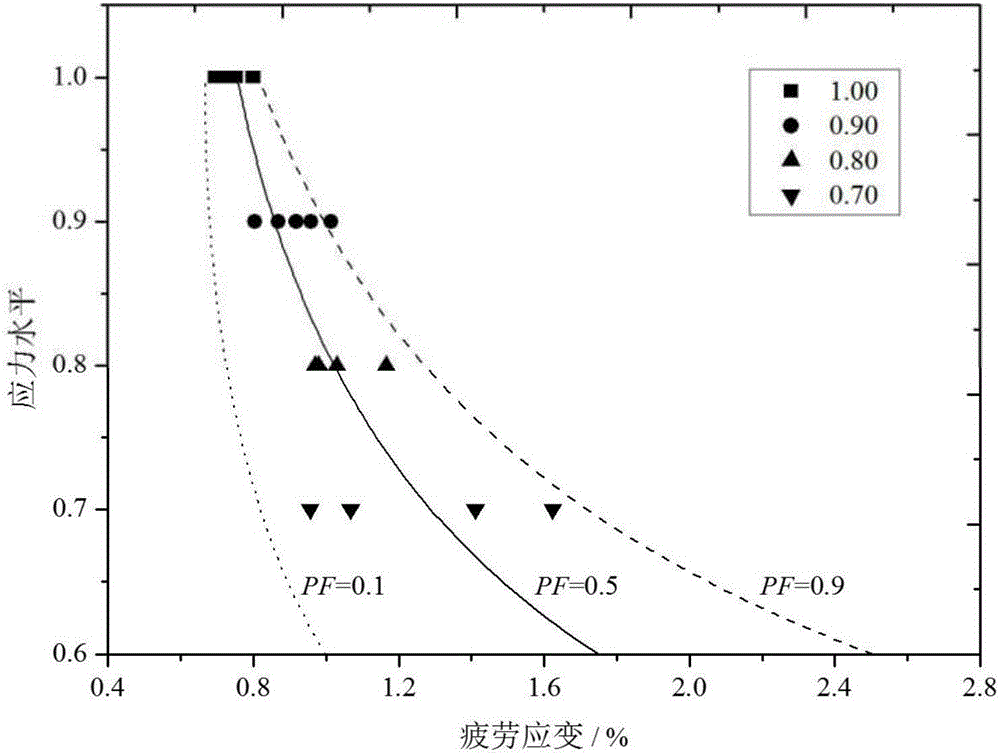

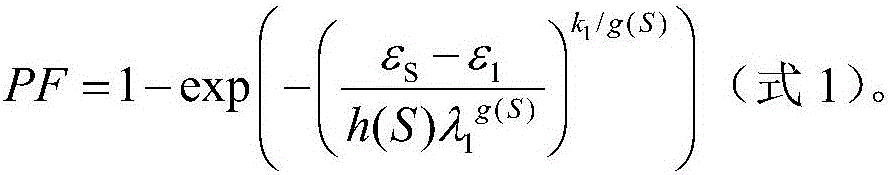

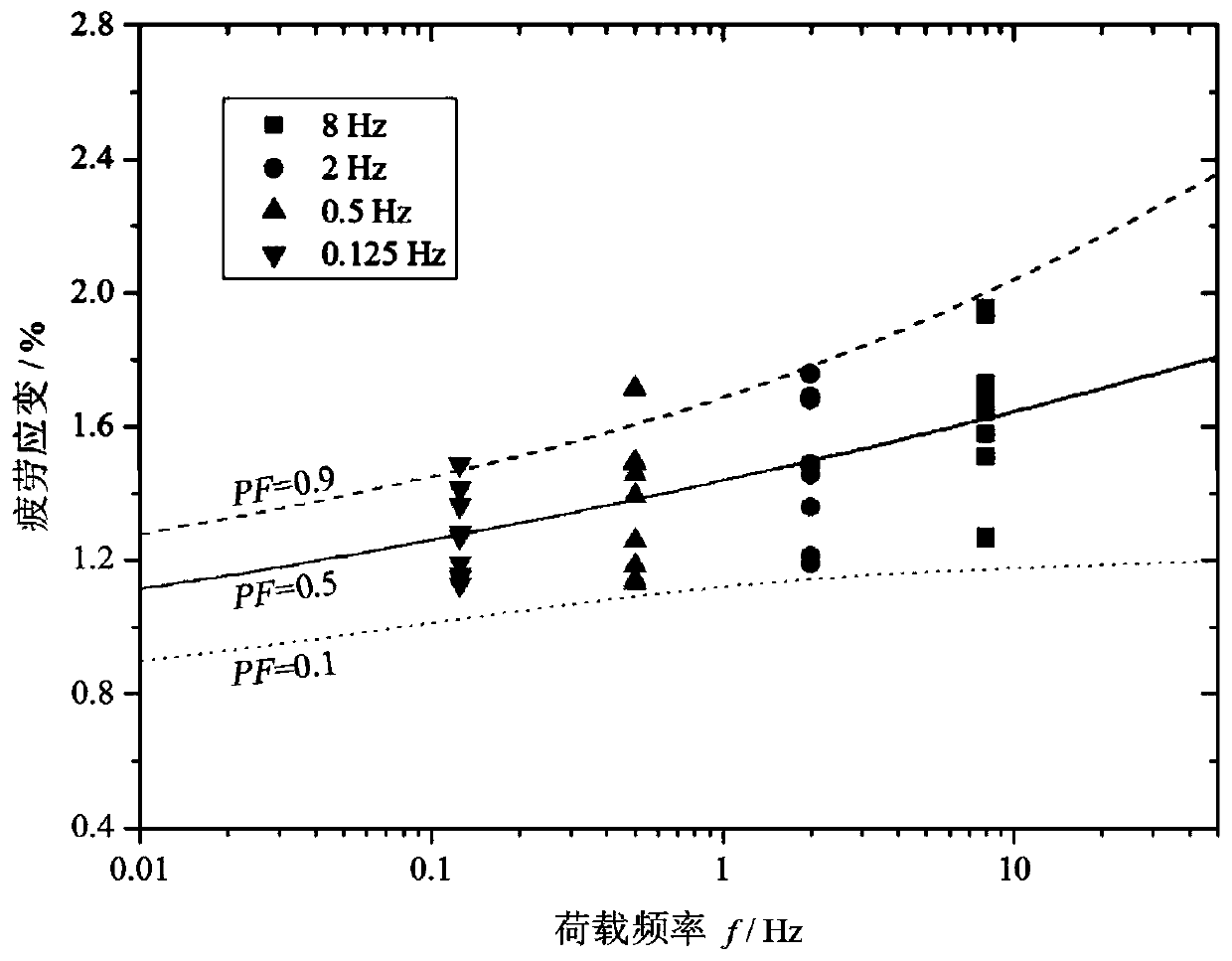

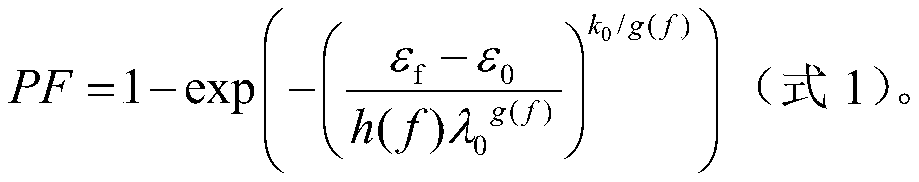

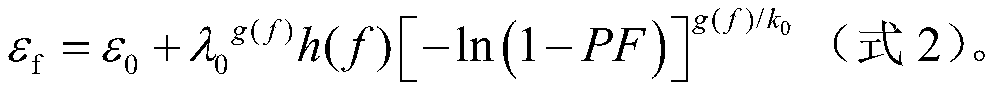

Method for establishing cement-based material fatigue failure probability and fatigue strain probability model capable of considering loading frequency

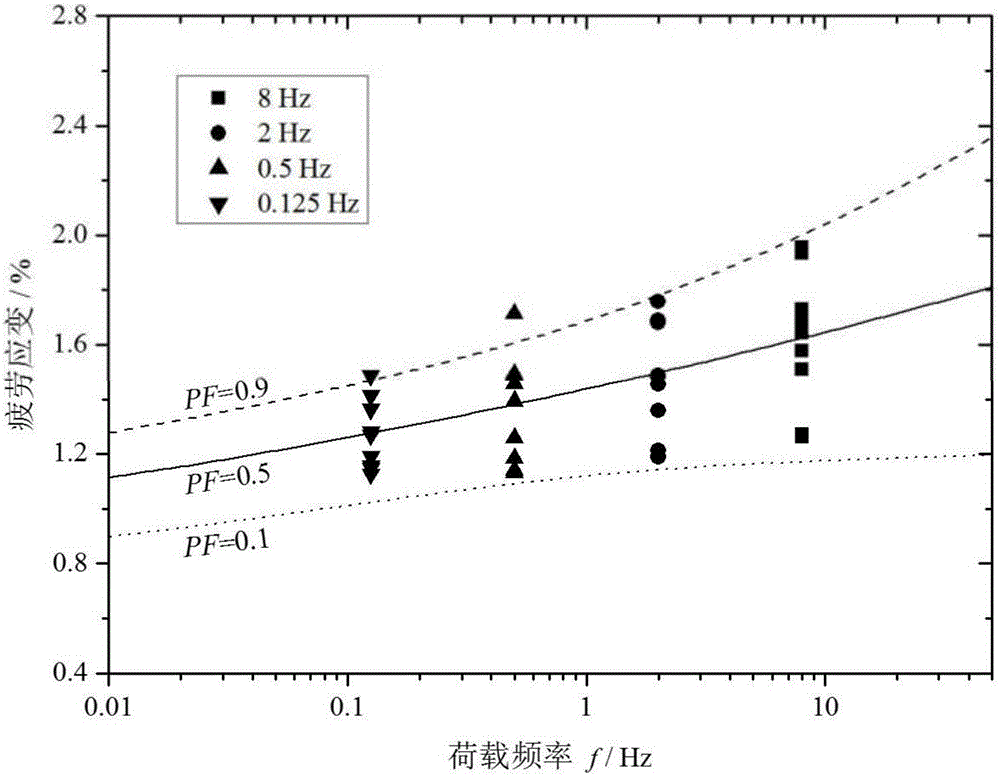

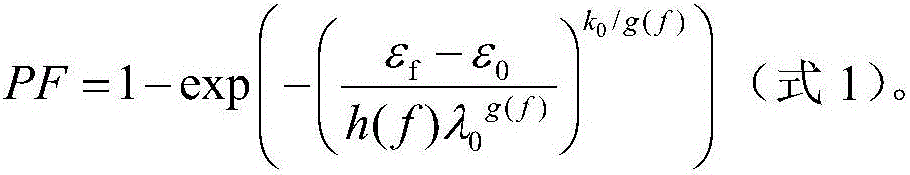

ActiveCN106294967ADesign optimisation/simulationSpecial data processing applicationsFatigue loadingFailure strain

The invention discloses a method for establishing a cement-based material fatigue failure probability and fatigue strain probability model capable of considering loading frequency. On the basis of the quasi-static loading failure strain of the cement-based material and the fatigue failure strain of the cement-based material under different loading frequencies, the cement-based material fatigue strain probability model can be conveniently and quickly obtained. On one hand, the model can predict the cement-based material and the fatigue failure probability of a structure which uses the cement-based material through fatigue strain, on the other hand, the fatigue strain of the cement-based material and the fatigue strain of the structure are calculated through the setting of the fatigue failure probability, and a new approach and a new method are provided for the service condition detection and assessment of the structure under the fatigue performance design and the fatigue loading of the corresponding structure.

Owner:ZHEJIANG UNIV

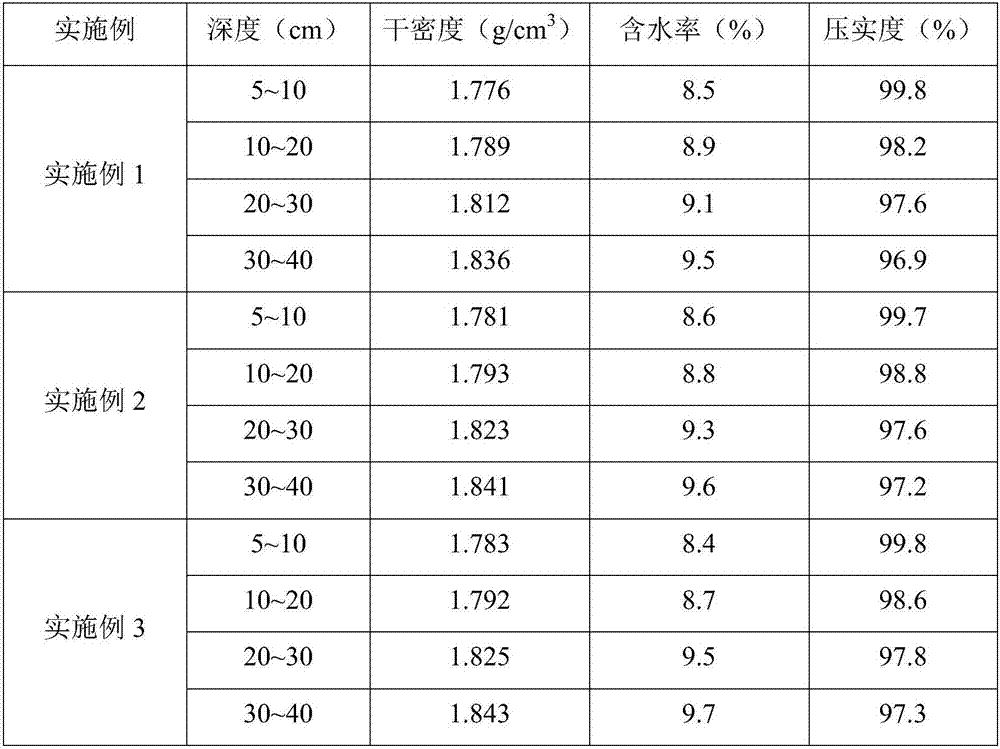

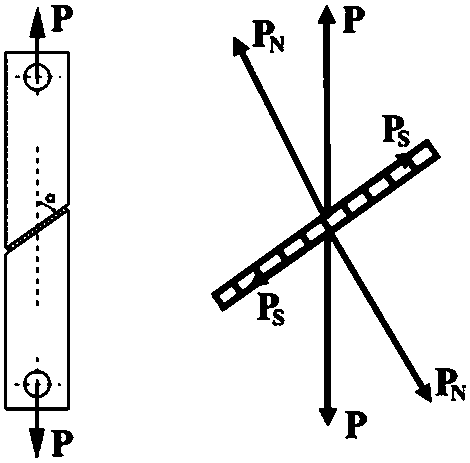

Aeolian sand subgrade construction method

ActiveCN107012755AImprove stabilityImprove reinforcementRoadwaysBuilding constructionsFailure strainEngineering

The invention provides an aeolian sand subgrade construction method. The method comprises the following steps that surveying and setting out are conducted; a base layer is laid; padding is loaded and unloaded; a reinforcing layer is laid; a reinforcing layer is laid on the surface of aeolian sand, wherein the reinforcing layer comprises limestone, polypropylene fibers, loose filling and the balance coal ash; tilling is conducted, specifically, watering is conducted on the reinforcing layer, and tilling is conducted on a subgrade multiple times in the length direction; riffle watering is conducted; rolling compaction is conducted through a bulldozer; rolling compaction is conducted through a road roller; compaction detection is conducted, specifically, the compaction coefficient Kof the compacted aeolian sand is detected in a sand filling mode or a water filling mode; and the step that padding is loaded and unloading to the step that compaction detection is conducted are conducted repeatedly until the subgrade reaches a design elevation, and construction is completed. According to the aeolian sand subgrade construction method provided by the invention, the reinforcing layer is laid on the aeolian sand, the reasonable rolling compaction mode is adopted, the strength of the vibrated and compacted subgrade meets design requirements, the compressive strength is high, the failure strain resistance and tension resistance of the subgrade are greatly improved, and the stability of the subgrade is improved.

Owner:CHINA FOURTH ENG OF CHINA RAILWAY SEVENTH GROUP

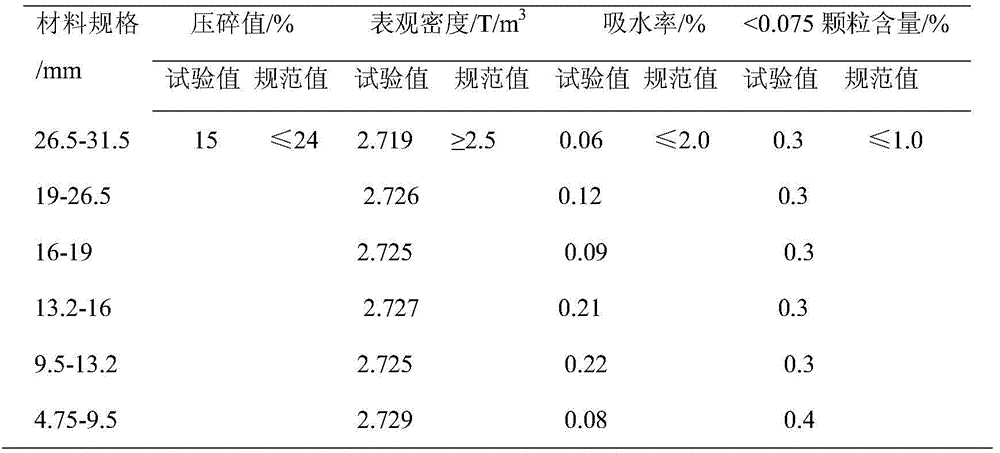

Detection method of water stability of cold region large-grain-size asphalt mixture

InactiveCN105699208AAvoid duplication of experimentsReduce testing workloadPreparing sample for investigationMaterial strength using steady bending forcesFailure strainRoad engineering

The invention belongs to the road engineering technical field, and in particular, relates to a detection method of water stability of a cold region large-grain-size asphalt mixture. The detection method comprises the steps: firstly, carrying out rolling compaction on the large-grain-size asphalt mixture into two plate block specimens, and cutting each plate block specimen into 6 small prismoid beam specimens; randomly selecting 3 specimens from the 6 small prismoid beam specimens of each plate block specimen, and forming an A group and a B group; making 6 specimens of the A group not soaked in water, making 6 specimens of the B group placed under freeze-thaw conditions, carrying out bending tests on the two groups of specimens, measuring the freeze-thaw flexural-tensile strength ratio BSR[dr] and the freeze-thaw flexural-tensile failure strain ratio FSR[dr] of the specimens, and when the average freeze-thaw flexural-tensile strength ratio BSR[dr] and the average freeze-thaw flexural-tensile failure strain ratio FSR[dr] of the two groups of specimens are both greater than or equal to 85%, considering that the water stability of the large-grain-size asphalt mixture is good. The method solves the problems of specimens molded by a traditional Marshall compaction testing method, and puts forward a new water stability testing method integrating the low temperature stability and the water stability of the asphalt mixture.

Owner:SHENYANG JIANZHU UNIVERSITY

Method for establishing cement-based material fatigue failure model and fatigue strain probability model by considering stress level

ActiveCN106250636ADesign optimisation/simulationSpecial data processing applicationsFatigue loadingFailure strain

The present invention discloses a method for establishing a cement-based material fatigue failure model and a fatigue strain probability model by considering a stress level. A fatigue strain probability model of a cement-based material may be conveniently and fast obtained based on quasi-static loading failure strain of the cement-based material and fatigue failure strain at different stress levels. On one hand, the model may be used to predict, by using fatigue strain, a fatigue failure probability of the cement-based material and a structure using the cement-based material, and on the other hand, fatigue strain of the cement-based material and a structure may be calculated by setting the fatigue failure probability, to provide a new approach and a new method for a fatigue performance design of a corresponding structure and service condition detection and assessment of a fatigue loading structure.

Owner:ZHEJIANG UNIV

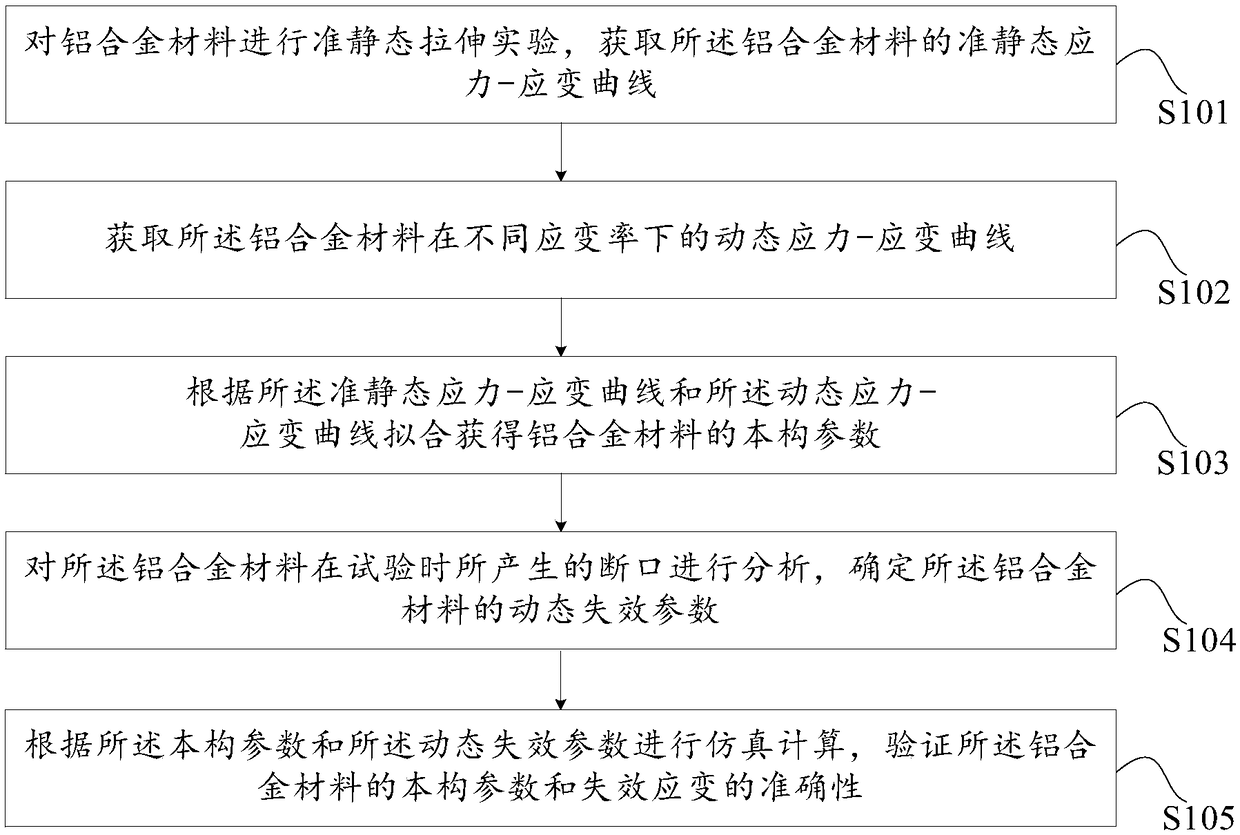

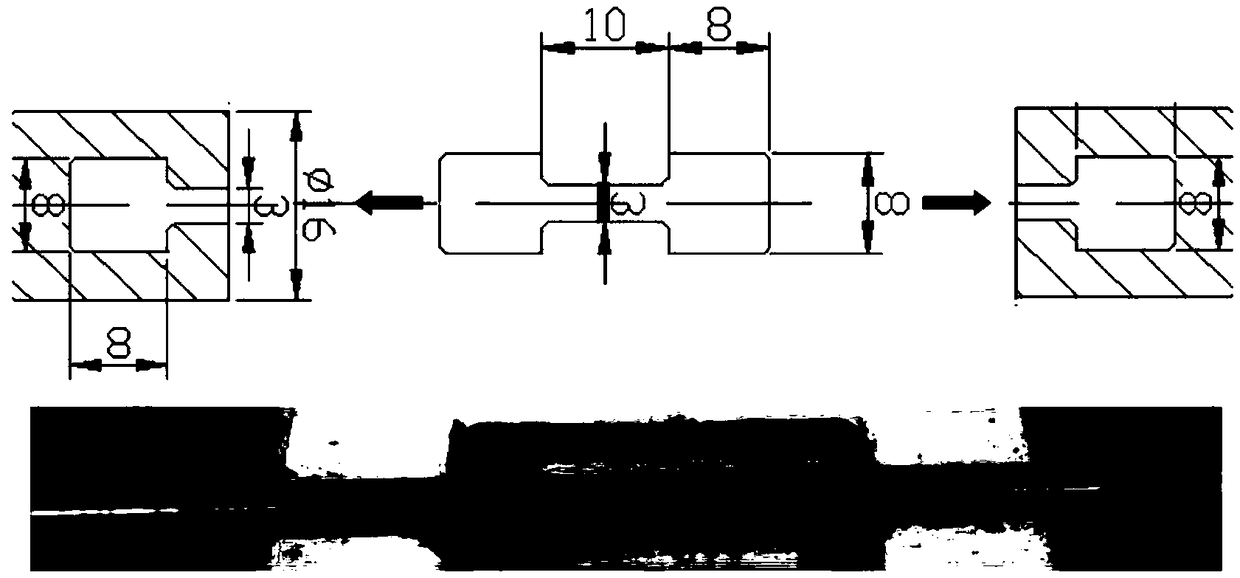

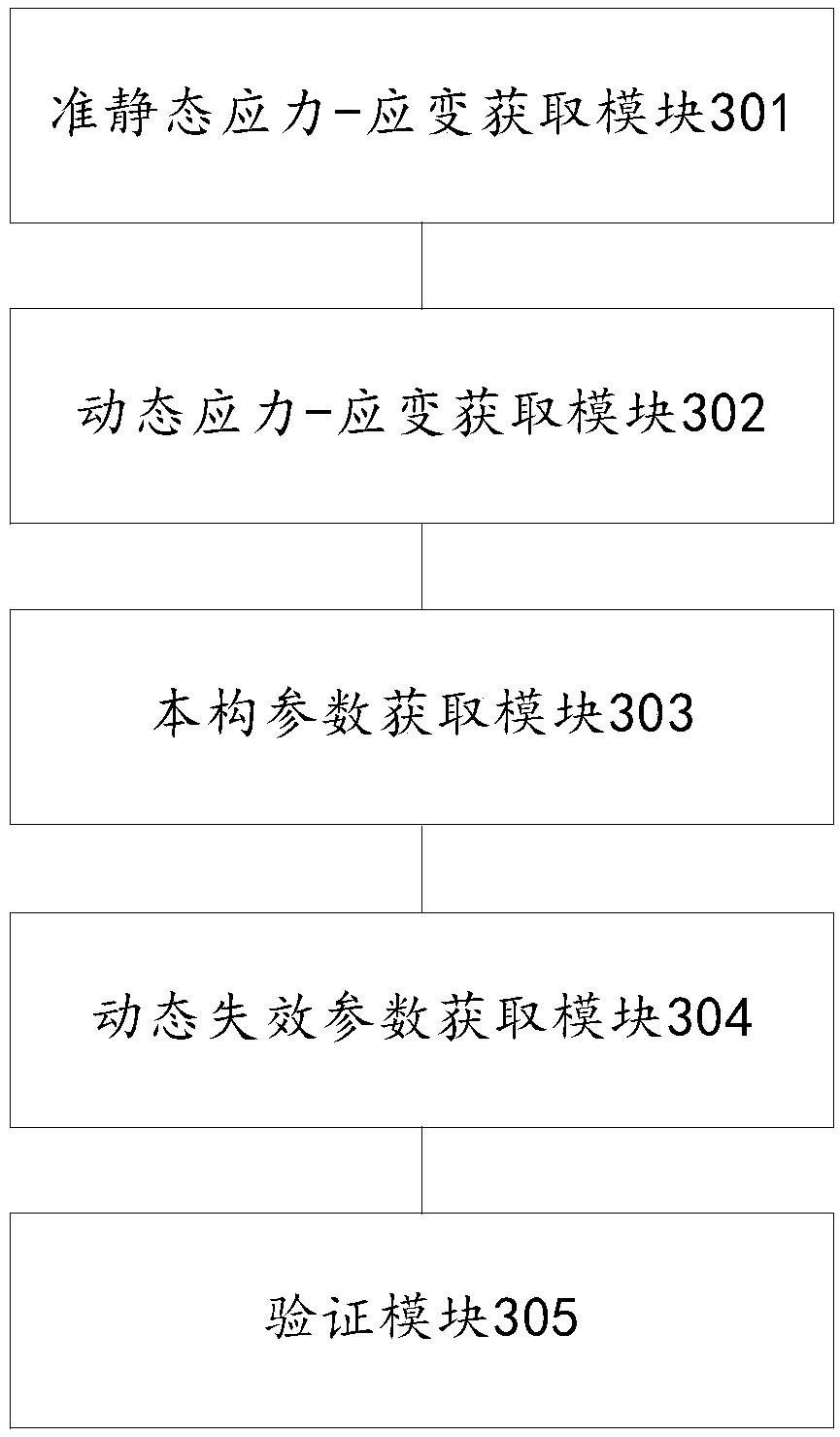

Method and device for obtaining and verifying constitutive parameters and dynamic failure parameters

InactiveCN109238855AVerify accuracyMaterial strength using tensile/compressive forcesMetallurgyFailure strain

The embodiment of the invention relates to a method and device for obtaining and verifying constitutive parameters and dynamic failure parameters. The method comprises the steps of: performing a quasi-static tensile experiment of an aluminium alloy material, and obtaining the quasi-static stress-strain curve of the aluminium alloy material; obtaining the dynamic stress-strain curve of the aluminium alloy material in different strain rates; obtaining the constitutive parameters of the aluminium alloy material by fitting according to the quasi-static stress-strain curve and the dynamic stress-strain curve; analyzing the fracture generated when the aluminium alloy material is tested, and determining the dynamic failure parameters of the aluminium alloy material; and, performing simulation calculation according to the constitutive parameters and the dynamic failure parameters, verifying the accuracy of the constitutive parameters and failure strain of the aluminium alloy material, simulating quasi-static stress-strain and dynamic stress-strain of the aluminium alloy material, then, obtaining the constitutive parameters and the dynamic failure parameters of the aluminium alloy material,and finally, verifying the constitutive parameters and the dynamic failure parameters.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI +1

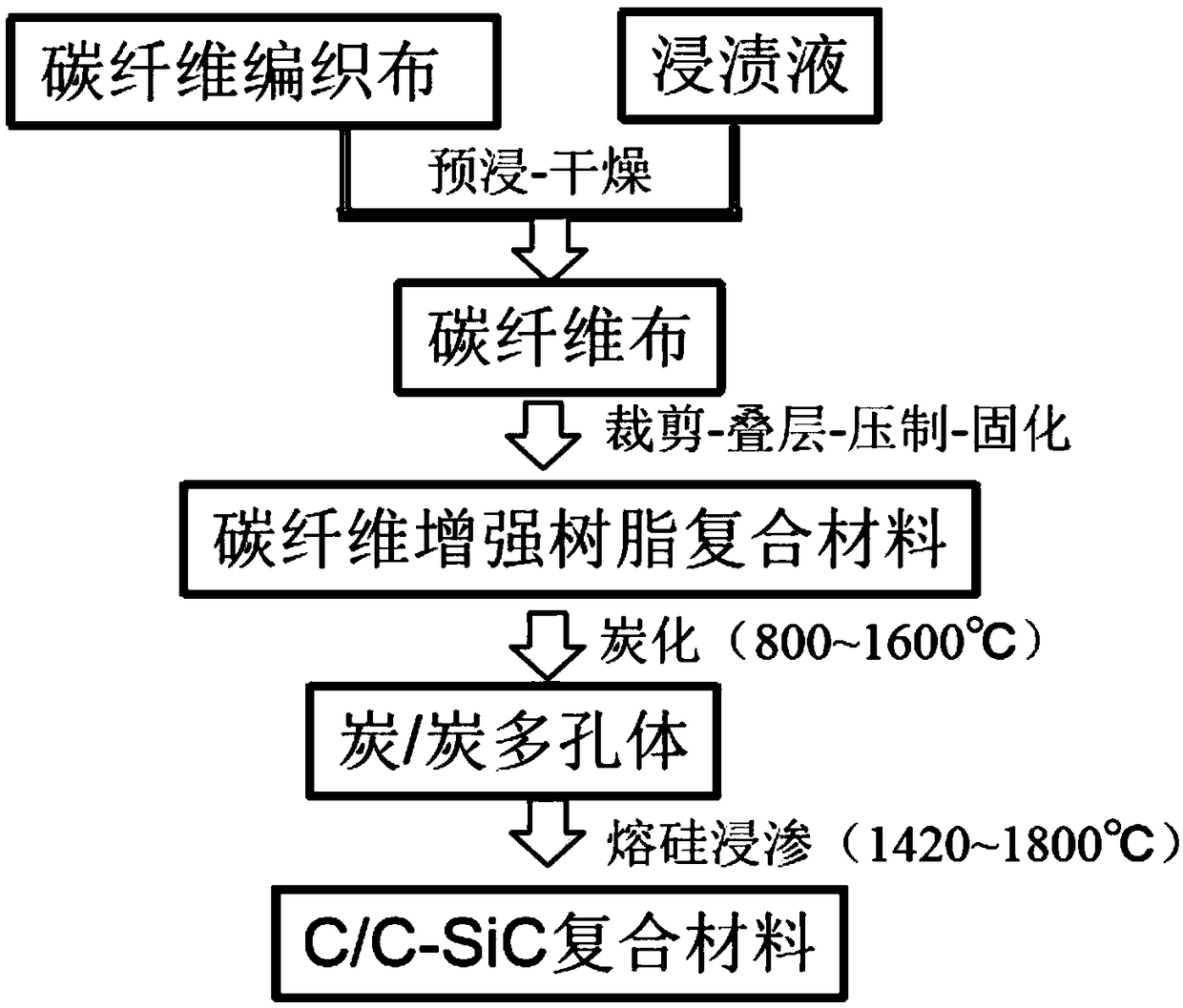

High-damage tolerance C/C-SiC composite material as well as preparation method and regulation and control method thereof

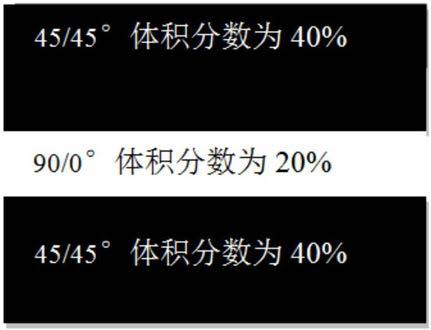

The invention relates to the technical field of C / C-SiC composite materials and discloses a high-damage tolerance C / C-SiC composite material as well as a preparation method and a regulation and control method thereof. According to the preparation method, the composite material is prepared from carbon fiber cloth, as well as high-molecular polymers and silicon powder serving as raw materials through processes of pre-dipping, clipping, stacking, compression, curing, carbonization, melt infiltration and the like; the carbon fiber cloth comprises carbon fiber cloth units which are stacked in different layers, and each carbon fiber cloth unit is one or more of carbon fiber cloth with the fiber bundle arrangement angle of 0-15 degrees / 75-90 degrees, and / or one or more of carbon fiber cloth withthe fiber bundle arrangement angle of 15-30 degrees / 60-75 degrees and / or carbon fiber cloth with the fiber bundle arrangement angle of 45 degrees / 45 degrees. The high-damage tolerance C / C-SiC composite material has high compactness, excellent mechanical property, extremely high failure strain and high damage tolerance and is suitable for the fields of high-speed and high-energy carrier transportation, friction braking materials, space structures and the like.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

ZrB2-SiC-Cf ultra-high temperature ceramic composite material and preparation method thereof

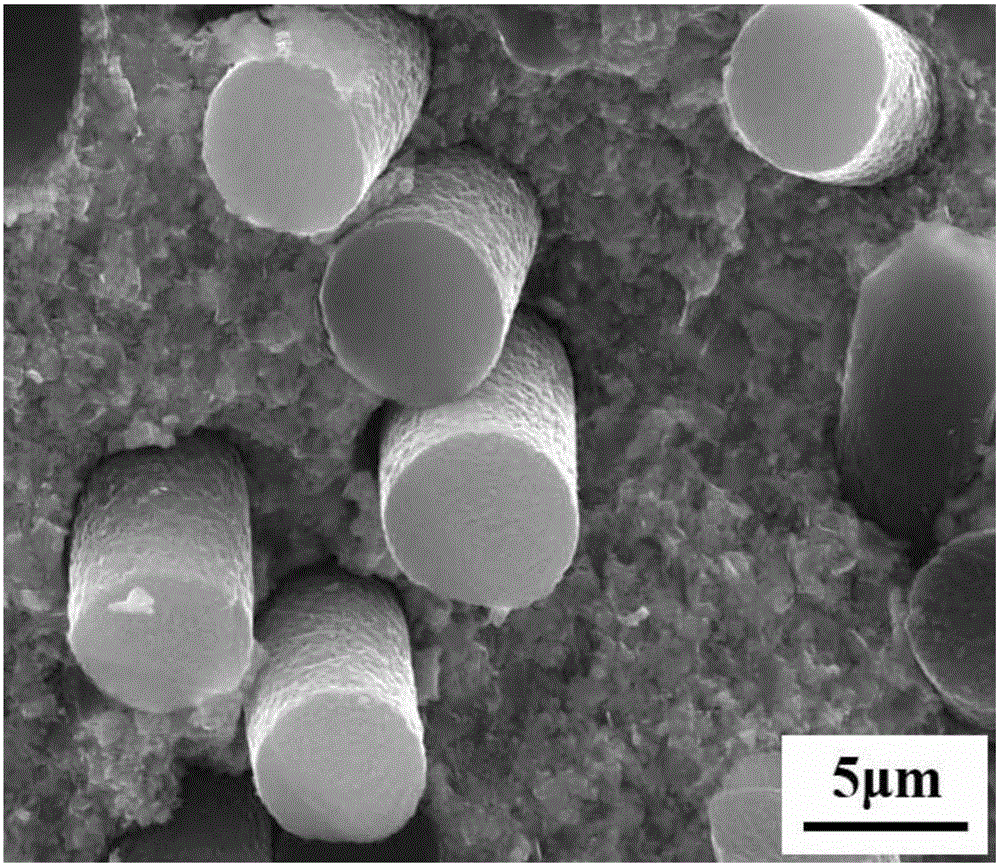

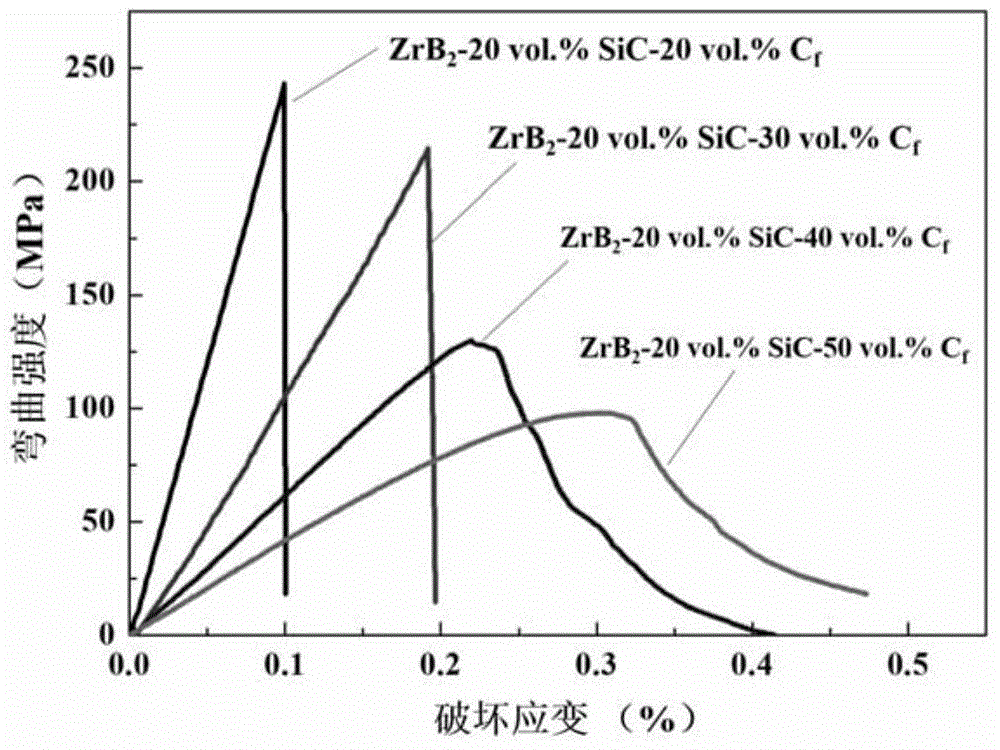

The invention discloses a ZrB 2 -SiC-C f The invention relates to an ultra-high temperature ceramic composite material and a preparation method thereof, belonging to the field of ultra-high temperature ceramic composite materials. The present invention aims to overcome ZrB 2 Intrinsic brittleness of base ultra-high temperature ceramics. The composite material of the present invention is composed of 30% to 60% ZrB with a particle size of 100 to 200 nm by volume fraction 2 Powder, 15% to 30% SiC powder with a particle size of 100 to 500nm and 20% to 50% carbon fiber. Method: 1. ZrB 2 Add the powder, SiC powder and carbon fiber into absolute ethanol, and perform ultrasonic cleaning; 2. Then ball mill and dry; Pressing and sintering, and then cooling to room temperature, ZrB 2 -SiC-C f Ultra-high temperature ceramic composite materials. The invention has the characteristics of low sintering temperature, small fiber damage, high damage strain of composite material, etc.; the sintering temperature of the invention is 1400-1500 DEG C. The ultra-high temperature ceramic composite material of the invention can be applied to the fields of ultra-high temperature heat-resistant structural materials and the like.

Owner:HARBIN INST OF TECH

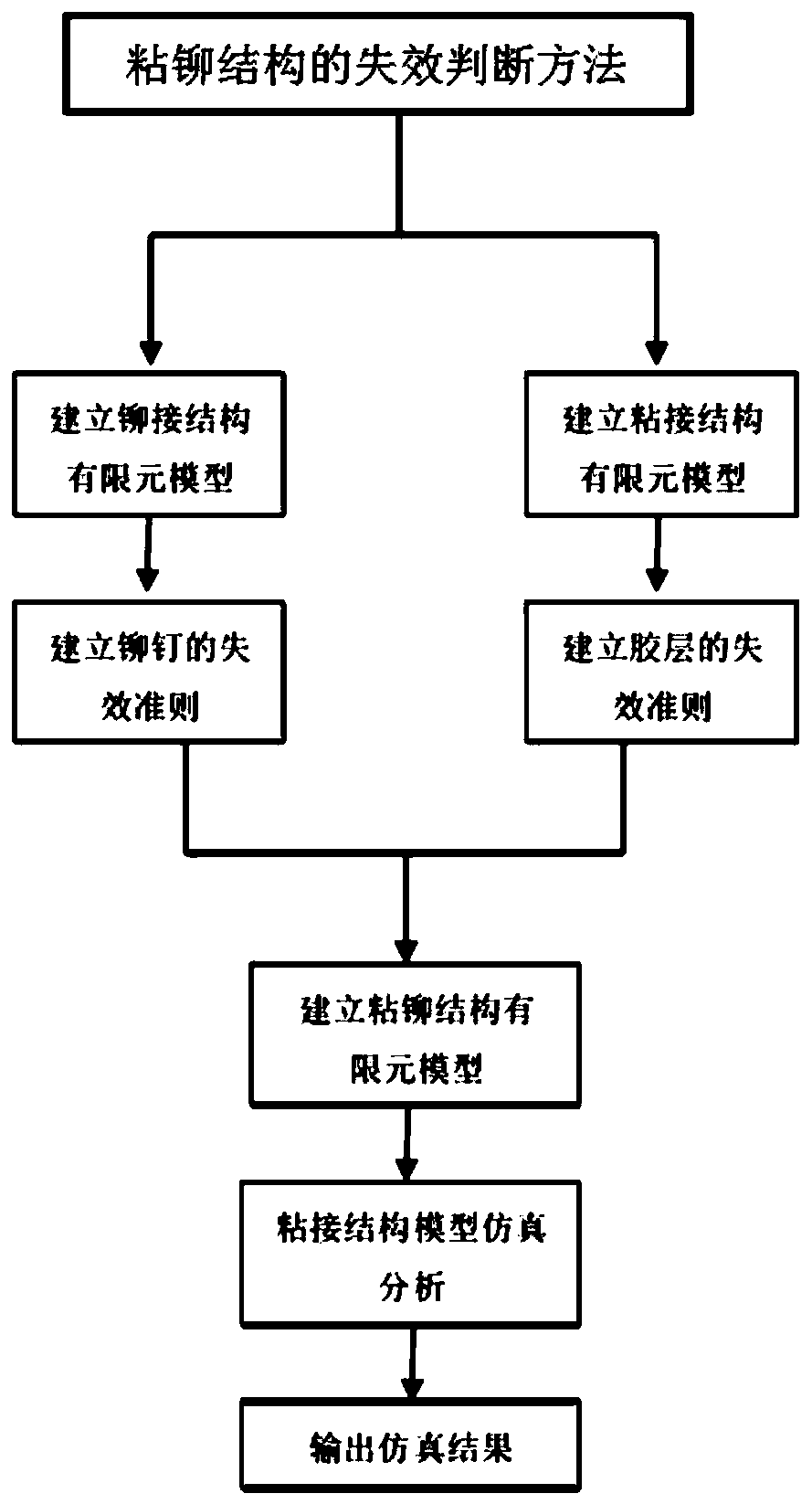

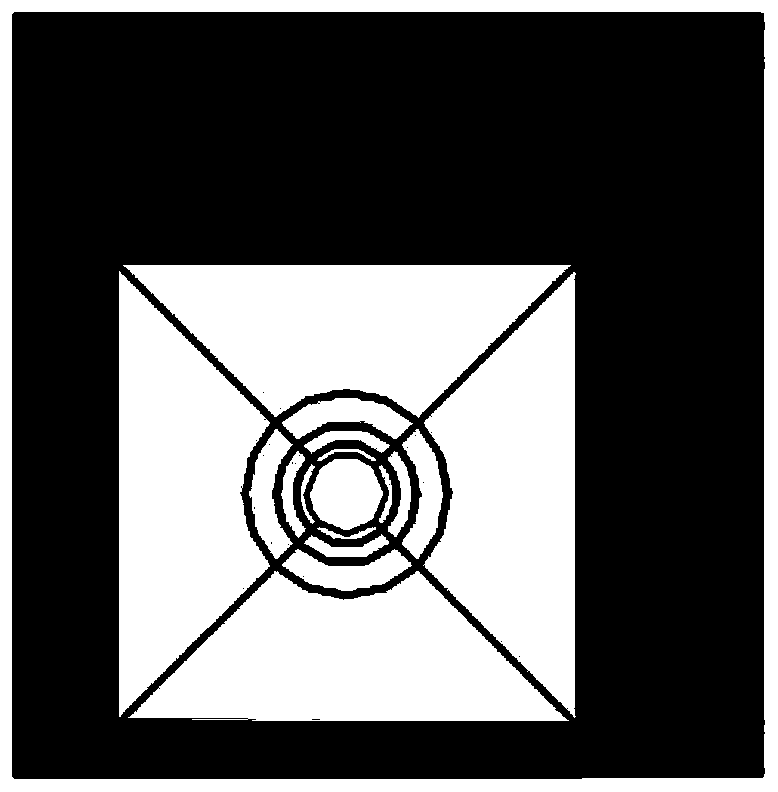

Failure judgment method for bonding-riveting connection structure

InactiveCN110222420ASmall cell sizeImprove simulation accuracyGeometric CADDesign optimisation/simulationFailure strainRivet

The invention discloses a failure judgment method for a bonding-riveting connection structure. The failure judgment method comprises the following steps of firstly, establishing a finite element simulation model of the bonding-riveting connection structure; step 2, determining a rivet failure judgment equation and a glue layer failure judgment equation; step 3, applying a displacement load to thefinite element simulation model, judging whether the rivet is invalid or not through the failure judgment equation, and judging whether the glue layer is invalid or not through the glue layer failurejudgment equation; when the strain of the rivet is greater than or equal to the failure strain, judging that the rivet fails; and when the adhesive layer failure judgment index s is greater than or equal to 1, judging that the adhesive layer fails. According to the failure judgment method for the adhesive-riveting connection structure, failure judgment is conducted on the adhesive-riveting connection structure according to the rivet failure judgment equation and the adhesive layer failure judgment equation, and the accuracy of failure judgment of the adhesive-riveting connection structure canbe improved.

Owner:JILIN UNIV

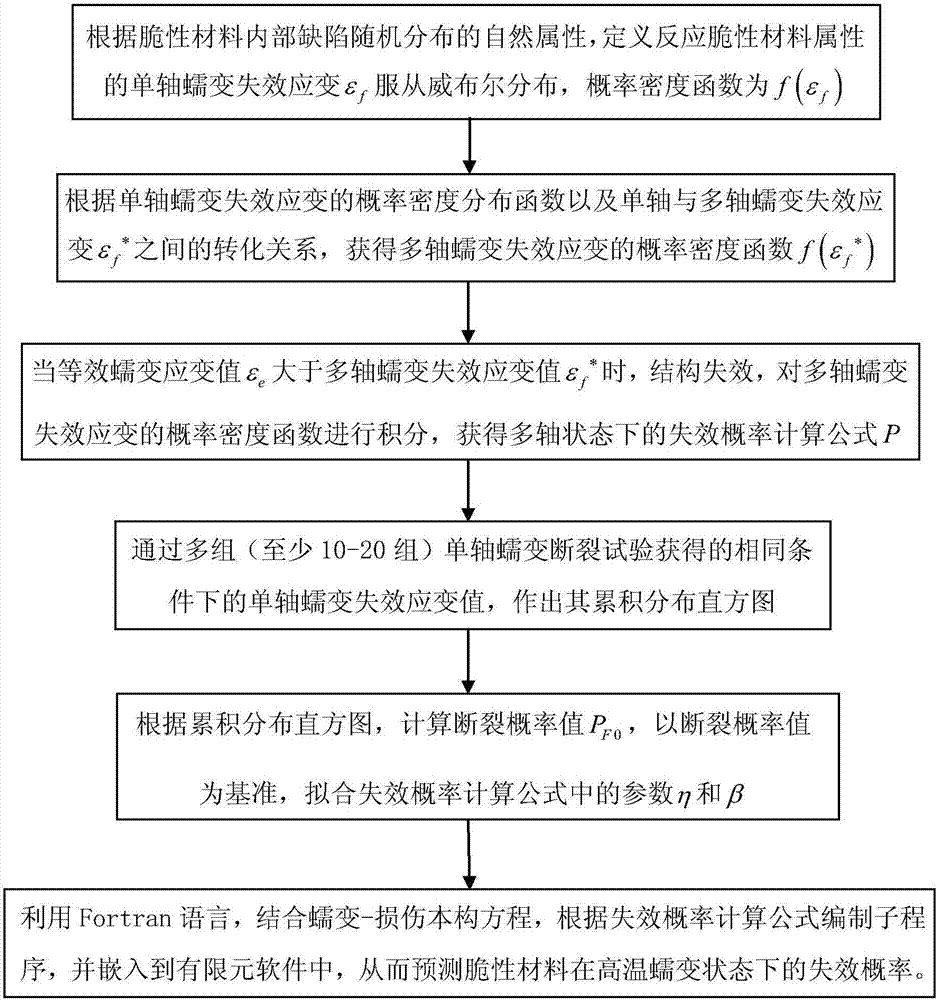

Prediction method for failure probability of fragile material under high-temperature creep state

ActiveCN107273649ASolve the technical problem that the reliability prediction of brittle materials under high temperature creep state cannot be performedSolve technical problems of reliability predictionMathematical modelsDesign optimisation/simulationFinite element softwareHuman language

The invention discloses a prediction method for failure probability of fragile material under a high-temperature creep state. Based on the prior art, uniaxial creep failure strain is assumed to Weibull distribution in combined with the natural attribute that internal defects of the fragile material are randomly distributed, a probability density distribution curve of the uniaxial creep failure strain is acquired by using uniaxial creep experiments, a probability density function of multiaxis creep failure strain is acquired via a conversion relation between a single axis and the multiaxis creep failure strain, and thus integration is performed to acquire a failure probability computing model; on such the base, a sub-program is compiled by using a Fortran language in combination with a creep-damage constitutive equation, and thus a prediction result of the failure probability of the fragile material under the high-temperature creep state is acquired. According to the method provided by the invention, the technical problem that in the prior art, reliability prediction of the fragile material under the high-temperature creep state cannot be performed is solved, and the acquired prediction result is real, accurate, reasonable and reliable.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Diatomite asphalt mixture modification agent and modified asphalt mixture

InactiveCN105907115AImprove high temperature stabilityImprove wear resistanceBuilding insulationsFailure strainUltrasonic vibration

The invention discloses a diatomite asphalt mixture modification agent and a modified asphalt mixture. The diatomite asphalt mixture modification agent is prepared from activated diatomite and polyethylene wax, wherein the mass percent of the polyethylene wax is 2%-22%; the activated diatomite is diatomite obtained by carrying out an activation step on diatomite raw ores; the activation step comprises the following steps of crushing the diatomite raw ores, scrubbing, grading and carrying out ultrasonic vibration; the fineness of the activated diatomite is 325-800 meshes. Compared with an asphalt mixture modified by SBS (Styrene Butadiene Styrene), the dynamic stability DS of the asphalt mixture modified by the modification agent is increased by at least 30%, the water stability (residue stability) is increased by at least 3% and the low-temperature anti-cracking performance (low-temperature failure strain) is improved by at least 1%.

Owner:SICHUAN HONGHUI TECH

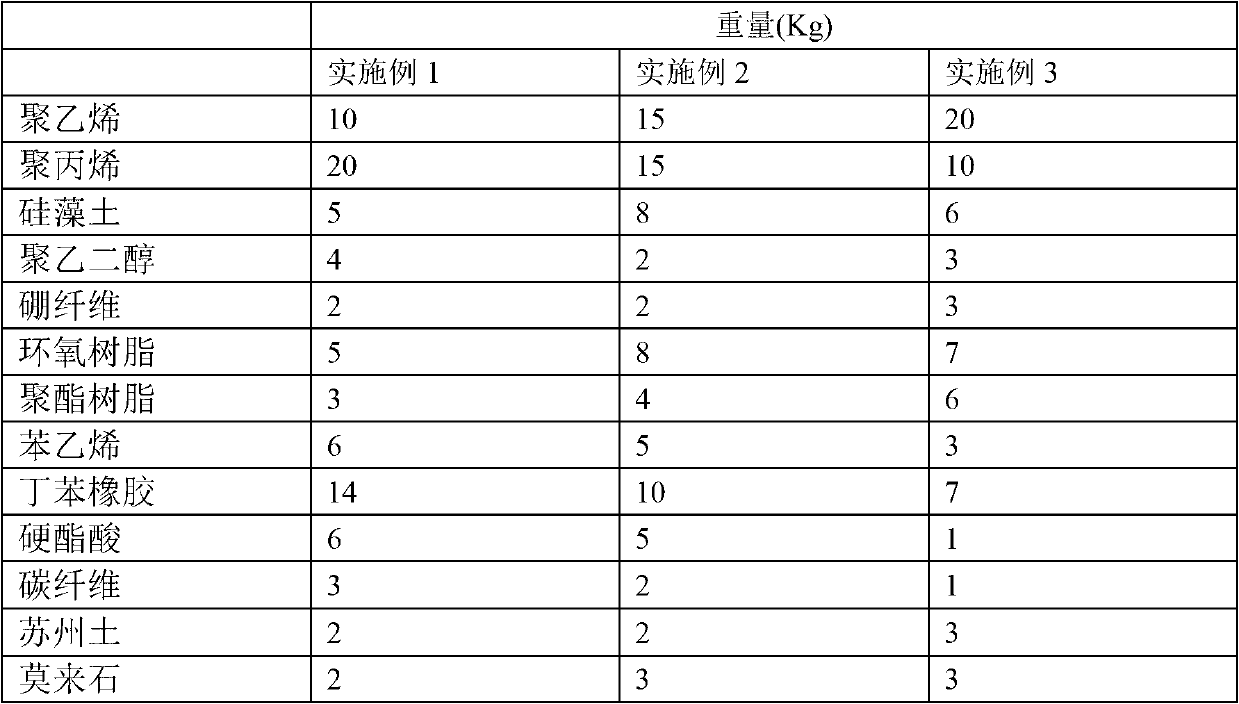

Anti-rutting additive

The invention provides an anti-rutting additive, which belongs to the technical field of building materials. The anti-rutting additive comprises 10 to 20 parts of polyethylene, 10 to 20 of parts polypropylene, 5 to 8 parts of diatomite, 2 to 4 parts of polyethylene glycol, 2 to 3 parts of boron fibers, 5 to 8 parts of epoxy resin, 3 to 6 parts of polyester resin, 3 to 6 parts of styrene, 7 to 14 parts of butadiene styrene rubber, 3 to 6 parts of stearic acid, 1 to 3 parts of carbon fibers, 2 to 3 parts of Suzhou soil and 2 to 3 parts of mullite. When added into a conventional asphalt material, the anti-rutting additive provided by the invention can significantly improve the strength of an asphalt pavement; an obtained asphalt mixture accords with requirements of relevant specification and has dynamic stability DS of up to 7500 times / mm and failure strain of more than 2500 mu epsilon.

Owner:苏州市德莱尔建材科技有限公司

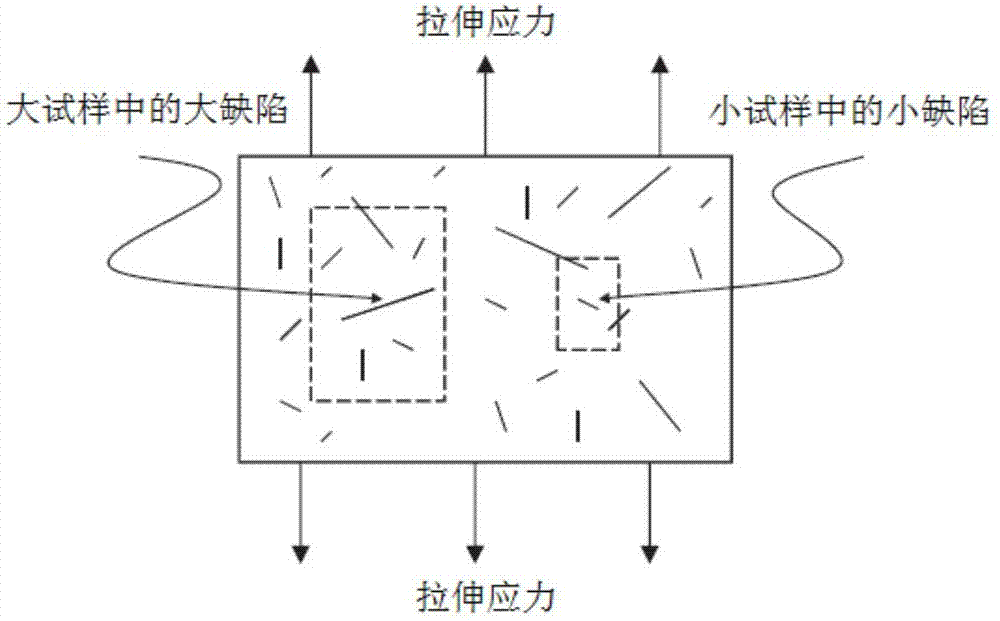

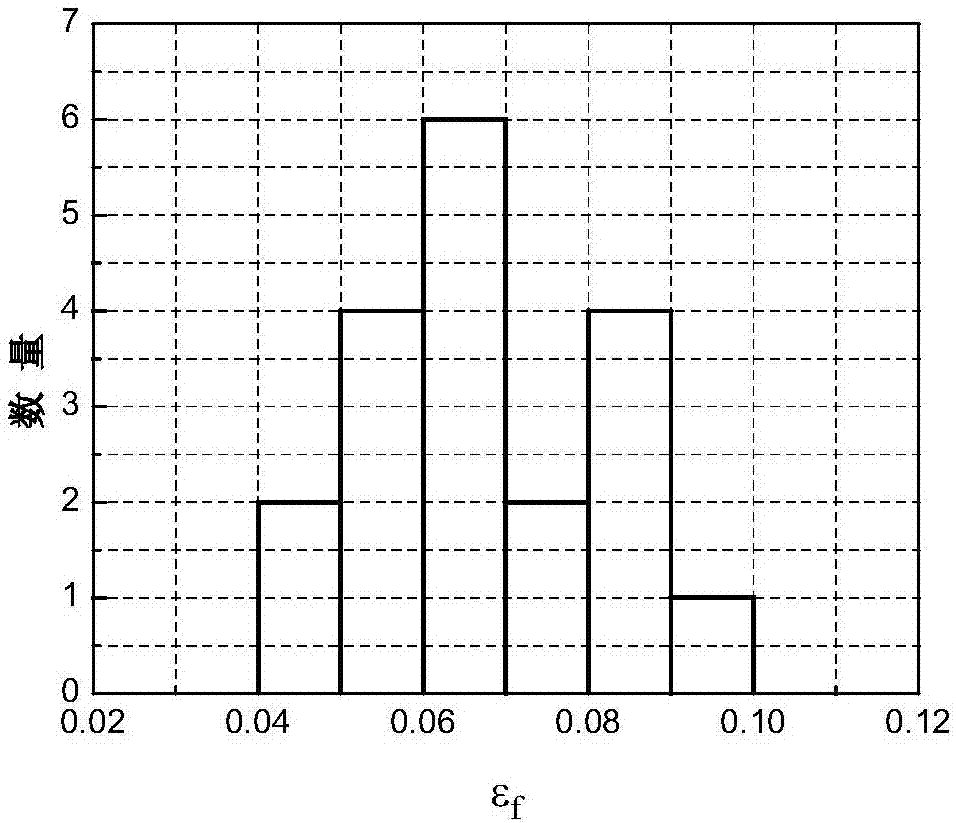

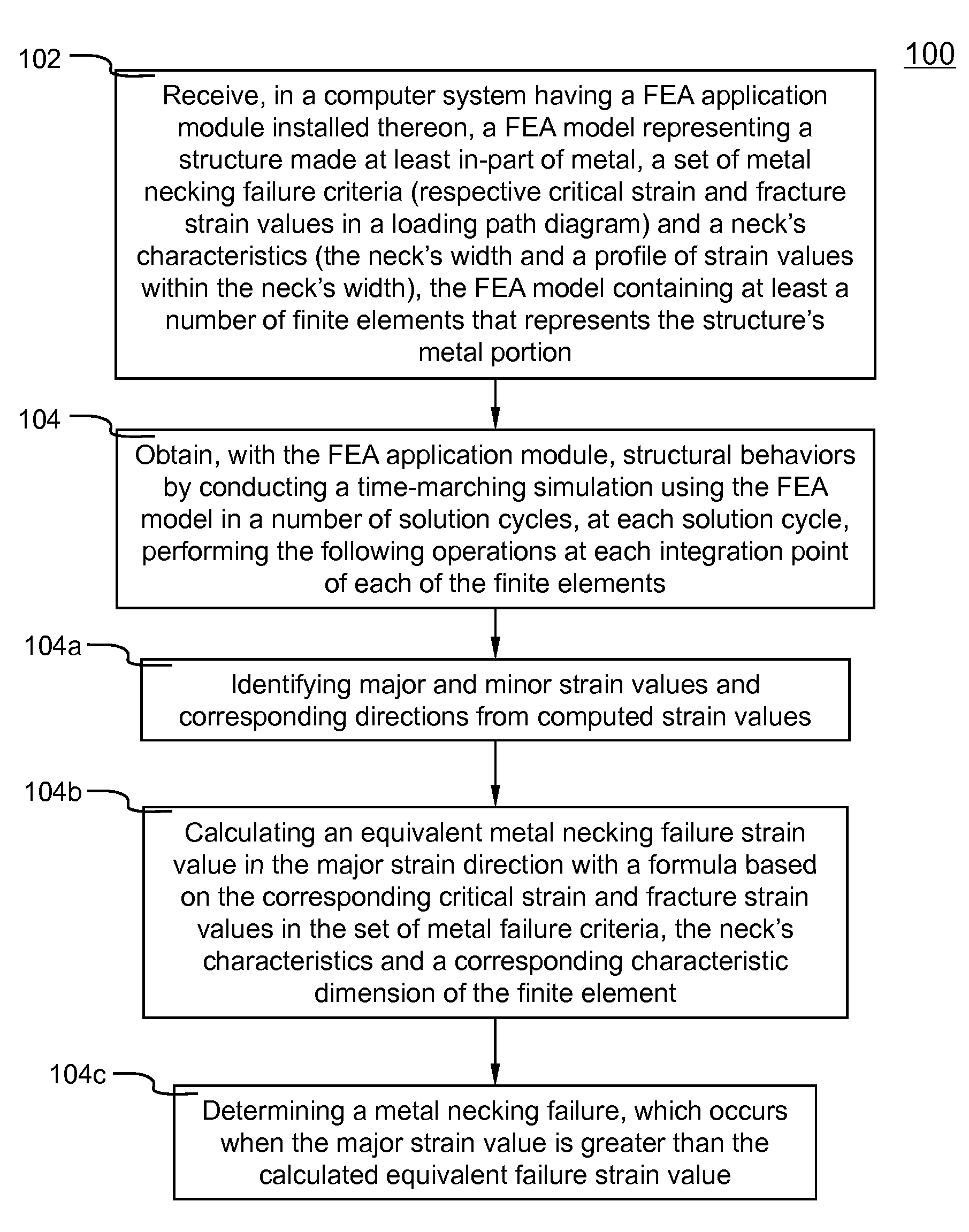

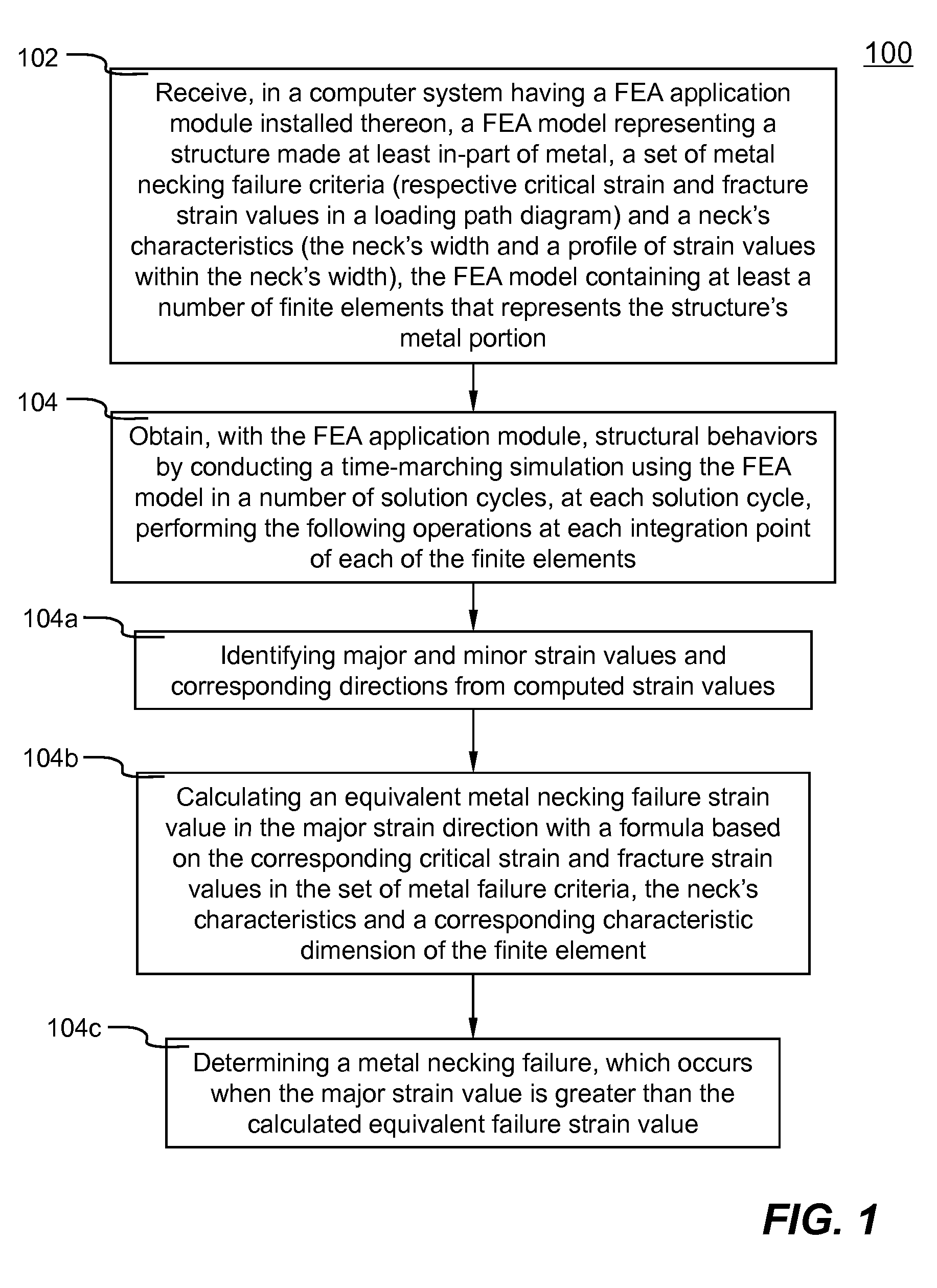

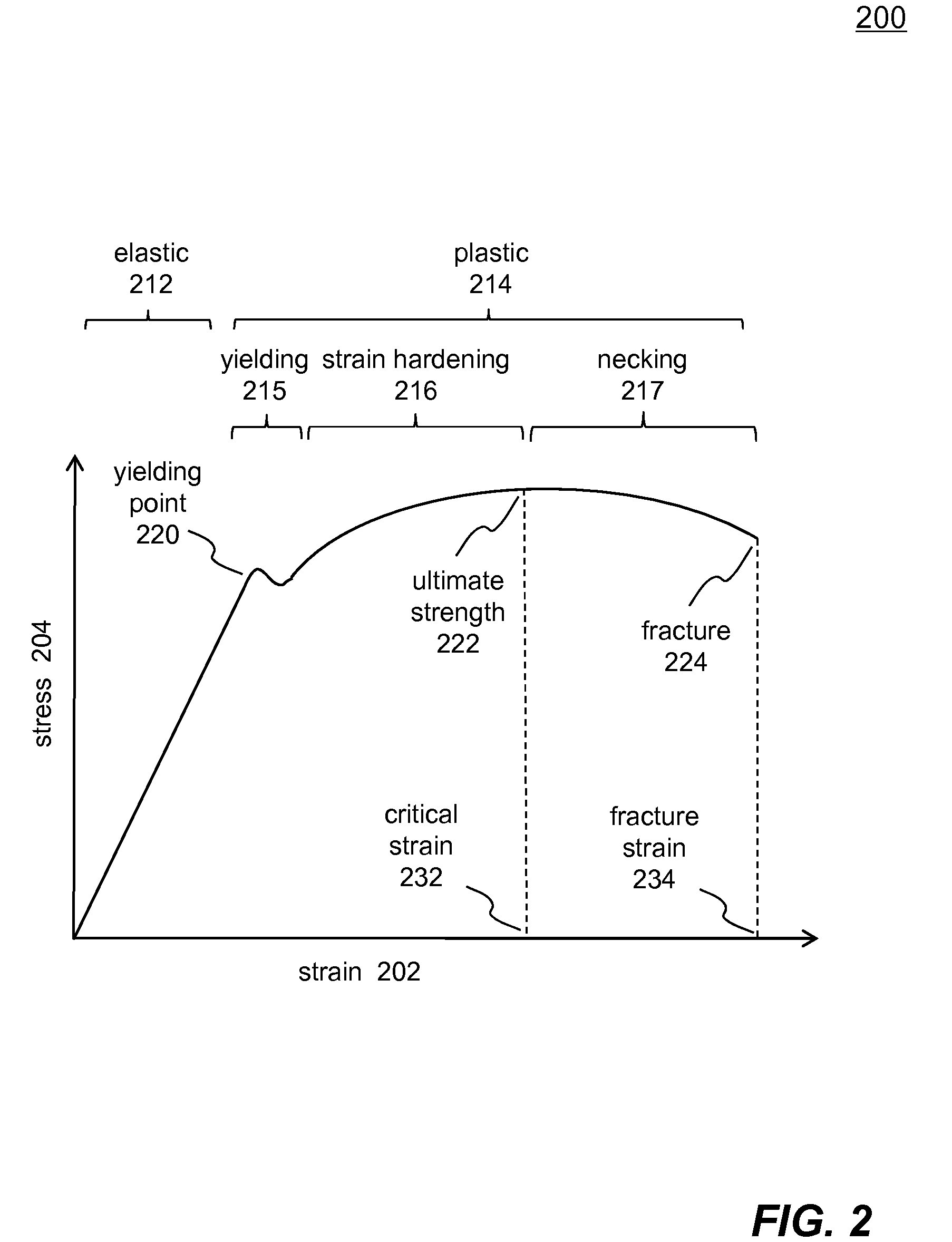

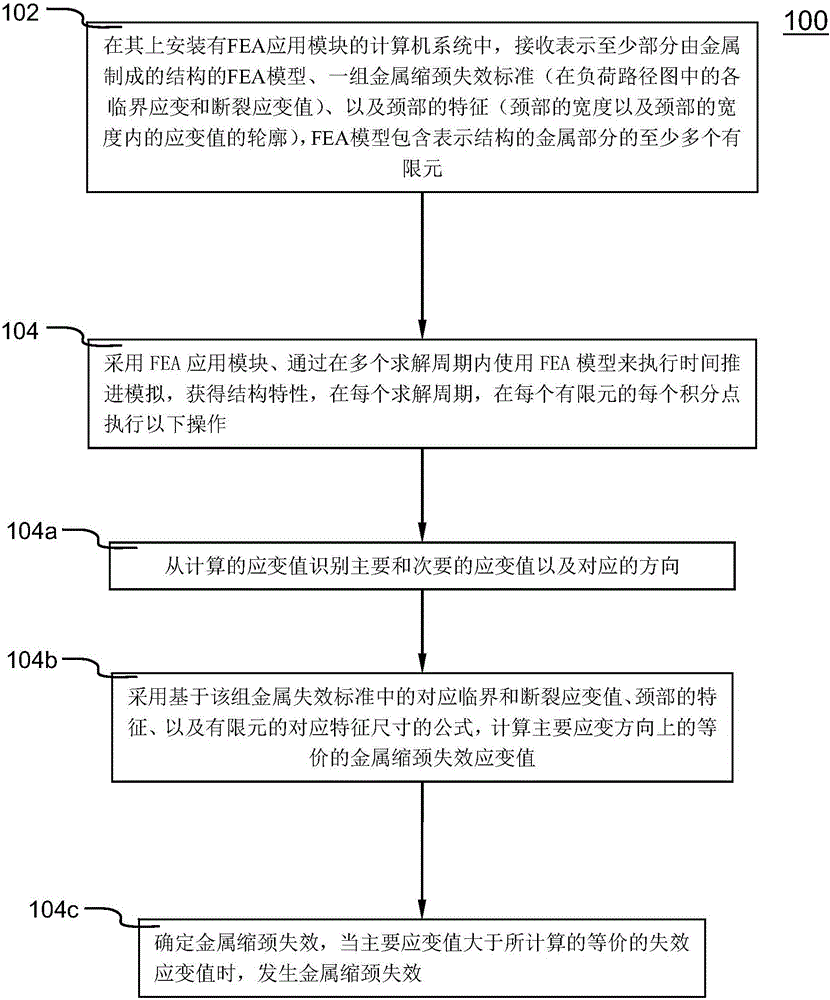

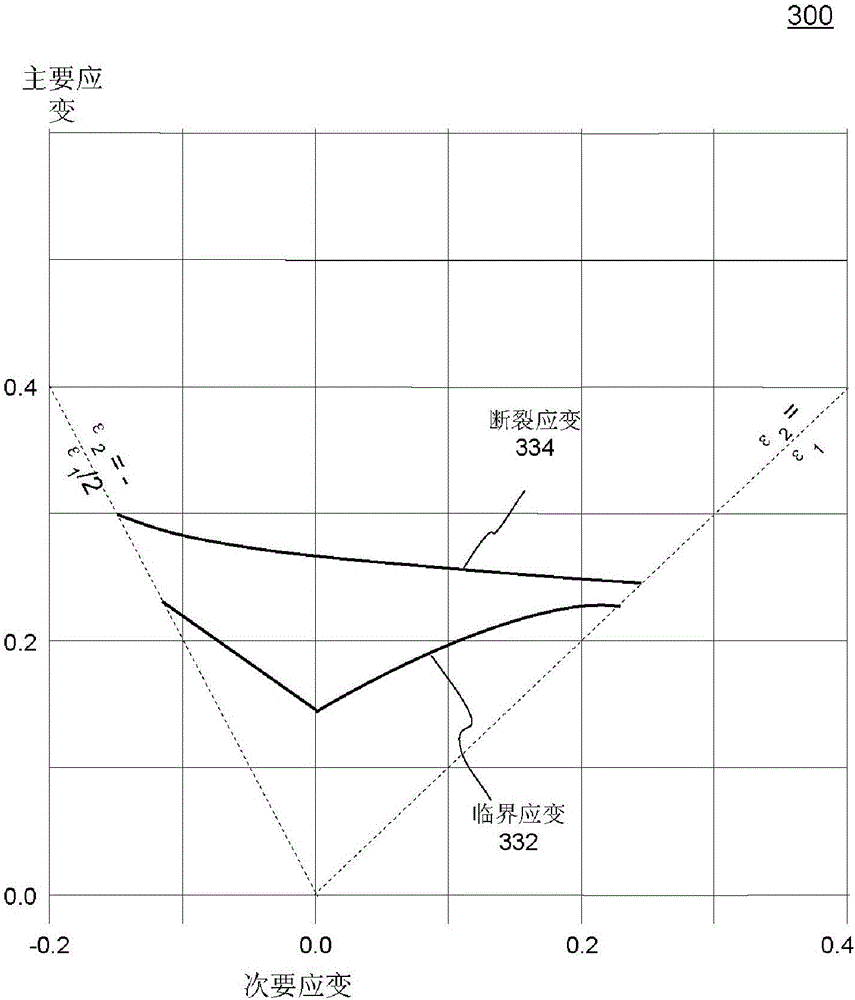

Methods And Systems For Conducting A Time-Marching Numerical Simulation Of A Structure Expected To Experience Metal Necking Failure

InactiveUS20160328503A1Avoid obscuring purposeDesign optimisation/simulationSpecial data processing applicationsFailure strainIntegration point

A FEA model, representing a structure, contains at least many finite elements for metal portion, a set of metal necking failure criteria (critical and fracture strain values defined in form of a loading path diagram) and the neck's characteristics (neck's width and a profile of strain values within the width) are received in a computer system. At each solution cycle of a time-marching simulation using the FEA model, following operations are performed at each integration point of every finite element: identifying major and minor strain values and corresponding directions from the computed strain values, calculating an equivalent metal necking failure strain value (εe) in the major strain direction with a formula based on corresponding critical and fracture strain values, the neck's characteristics and a characteristic dimension with respect to the major strain direction, and determining metal necking failure, which occurs when the major strain value is greater than εe.

Owner:LIVERMORE SOFTWARE TECH

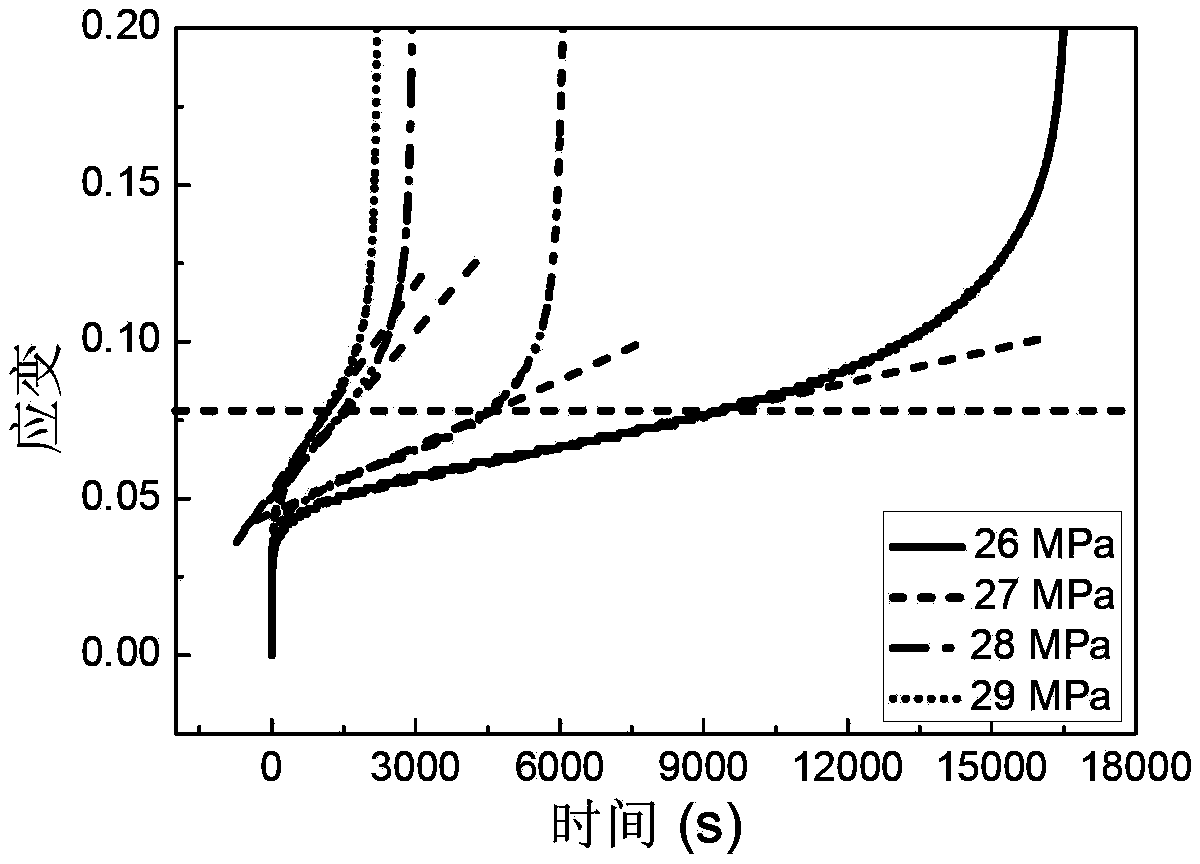

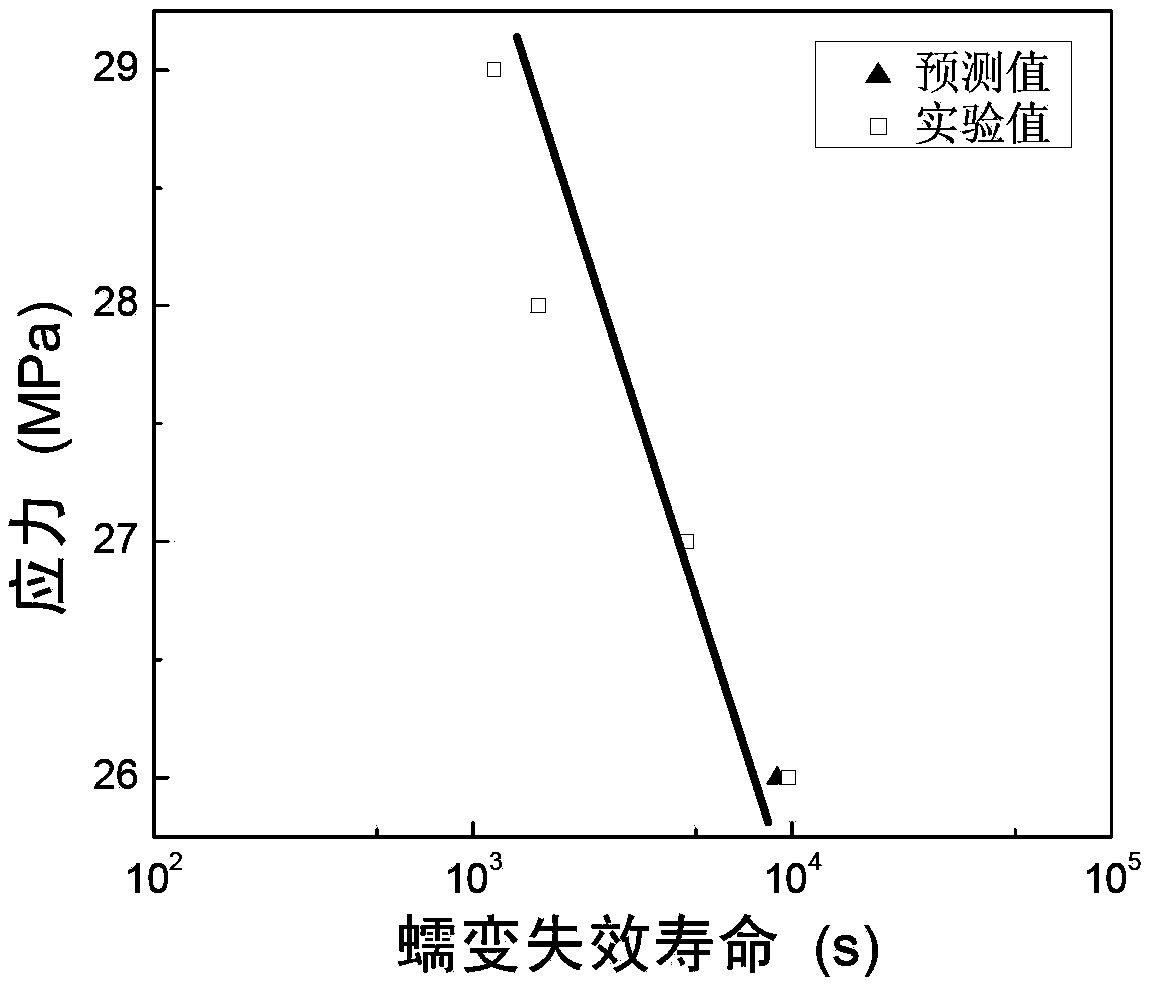

Judgment method and prediction method for creep failure life of polymer material

ActiveCN103323343BDetermination of Creep Failure LifeEasy and intuitive accessInvestigating material ductilityPolymer scienceCreep strain

The invention relates to a judgment method and a prediction method for the creep failure life of a polymer material at a pressure lower than the yield stress of the polymer material, and belongs to the field of polymer materials. The invention provides a judgment method for the creep failure life of a polymer material, and the judgement method comprises the following specific steps: determining a creep strain-time relation of the polymer material through a creep experiment under at least three groups of different test stresses so as to obtain a corresponding creep strain-time curve; then, carrying out straight line fitting on a curve section with a slope which is constant with the increasing of time in the curve, thereby obtaining a critical point at which the polymer material has creep rupture, wherein a strain corresponding to the point is a creep failure strain of the polymer material, and the corresponding time is the creep failure life of the polymer material. The judgment method for the creep failure life of the polymer material, disclosed by the invention, is simple, intuitive and accurate.

Owner:SICHUAN UNIV

A Creep-Fatigue Life Prediction Method for Materials

ActiveCN105158084BLife expectancyReal-time Damage DetectionMaterial strength using tensile/compressive forcesHysteresisFatigue damage

The invention provides a creep-fatigue life prediction method of a material, which includes respectively performing a creep test, a fatigue test and a creep-fatigue interaction test of the material at the same test temperature; The relationship between the failure strain energy density wf of the material and the dissipation rate of the inelastic strain energy density; according to the fatigue test, the fatigue damage df of the material per cycle is obtained; according to the creep-fatigue interaction test, the half-life cycle is obtained Hysteresis loop, and establish the functional relationship of the stress σ(t) under the half-life cycle of the material within the maximum tensile strain holding time as a function of time t; according to the relationship between wf and wf, the fatigue damage df, and the stress σ( t) the relationship with time t, and combined with the hysteresis loop, calculate the creep damage dc under the half-life cycle; use the linear cumulative damage rule to predict the creep-fatigue of the material under the creep-fatigue interaction Lifetime The present invention enables accurate prediction of material life under creep-fatigue interactions.

Owner:EAST CHINA UNIV OF SCI & TECH

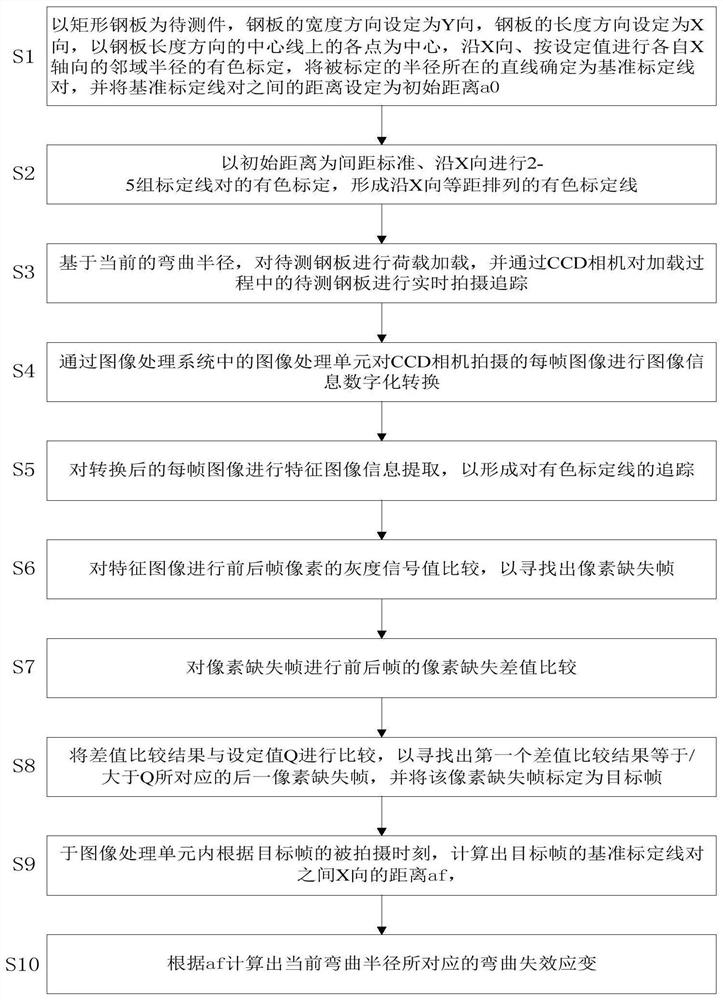

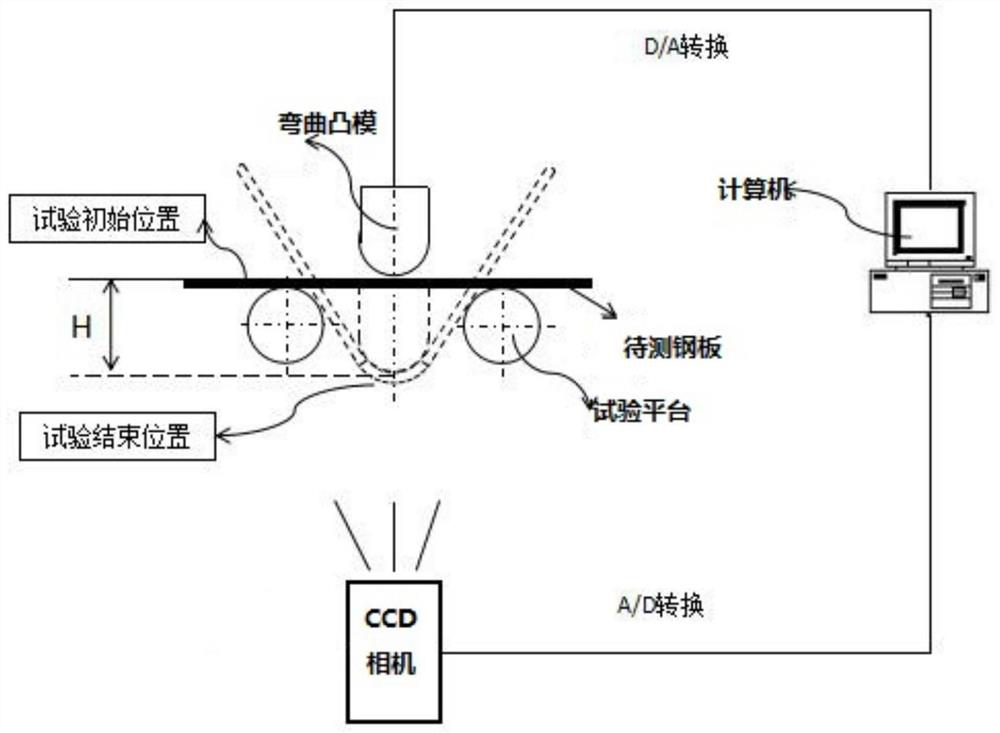

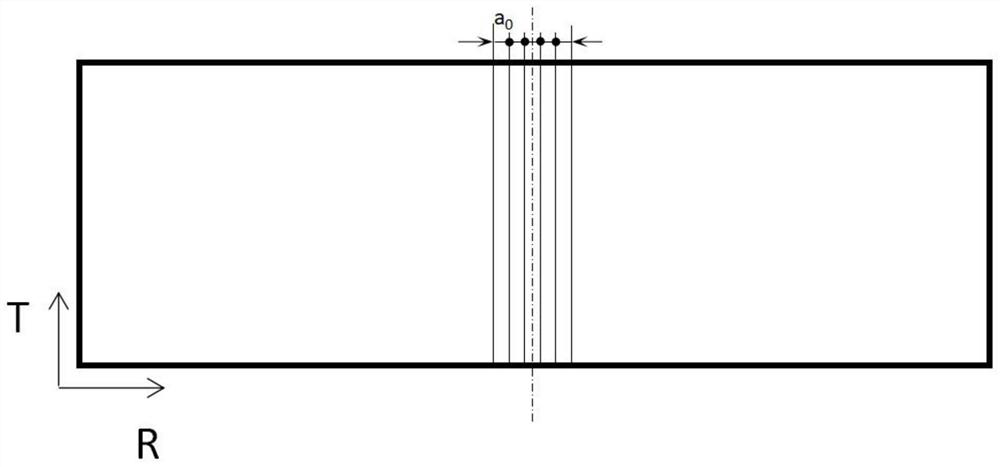

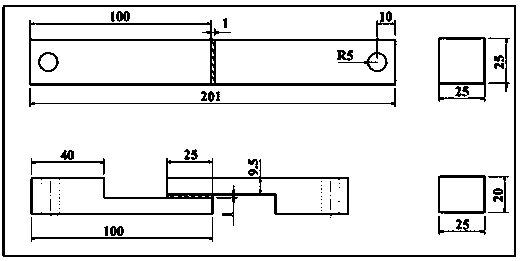

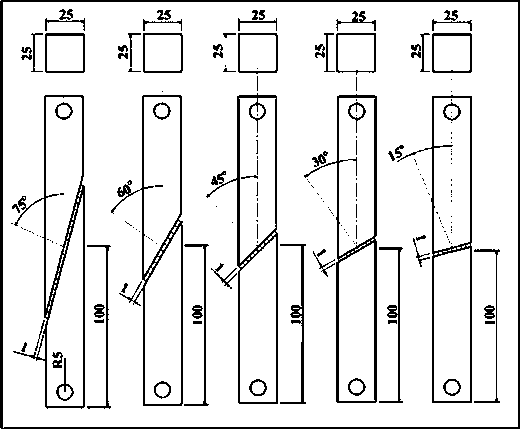

Bending failure strain measurement method

A bending failure strain measurement method is used for finding out bending failure strains corresponding to different bending radiuses through using an arranged image processing system based on a CCD camera. According to the bending failure strain measurement method, on the basis of an original test system, the image processing system based on the CCD camera is additionally arranged, and bending failure strains corresponding to different bending male die radiuses are found out through cooperation of the image processing system and the original test system, thereby establishing a corresponding data set of radius-bending failure strain, and forming an index for predicting the formability of the bending deformation of a part.

Owner:BAOSHAN IRON & STEEL CO LTD

Methods and systems for conducting a time-marching numerical simulation of a structure expected to experience metal necking failure

InactiveCN106126764ADesign optimisation/simulationSpecial data processing applicationsFailure strainIntegration point

A FEA model, representing a structure, contains at least many finite elements for metal portion, a set of metal necking failure criteria (critical and fracture strain values defined in form of a loading path diagram) and the neck s characteristics (neck s width and a profile of strain values within the width) are received in a computer system. At each solution cycle of a time-marching simulation using the FEA model, following operations are performed at each integration point of every finite element: identifying major and minor strain values and corresponding directions from the computed strain values, calculating an equivalent metal necking failure strain value (E e) in the major strain direction with a formula based on corresponding critical and fracture strain values, the neck s characteristics and a characteristic dimension with respect to the major strain direction, and determining metal necking failure, which occurs when the major strain value is greater than E e.

Owner:LIVERMORE SOFTWARE TECH

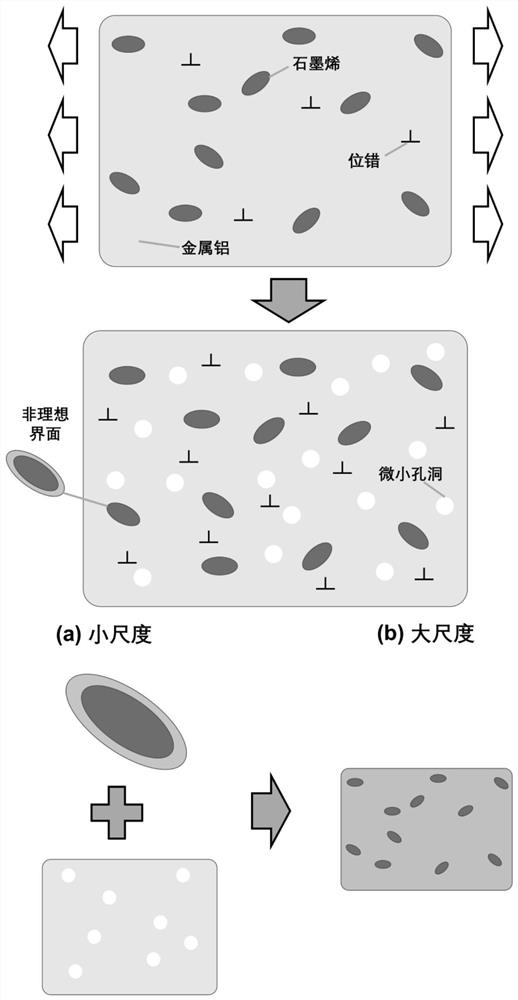

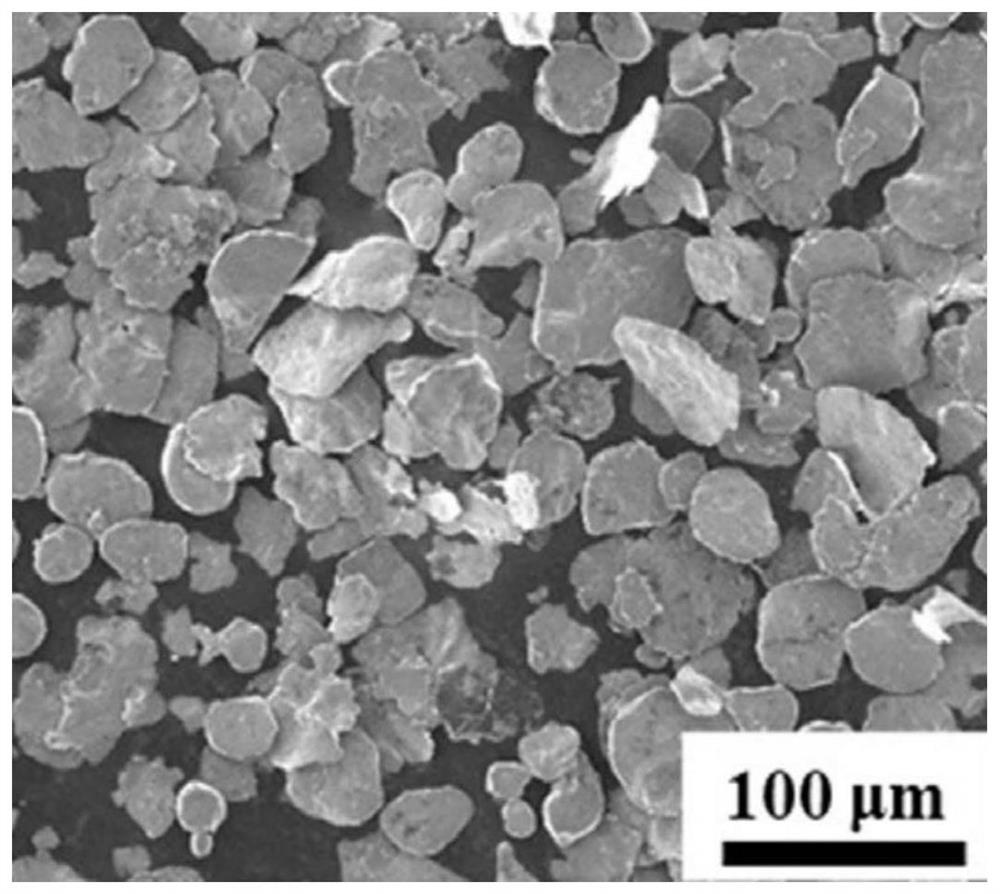

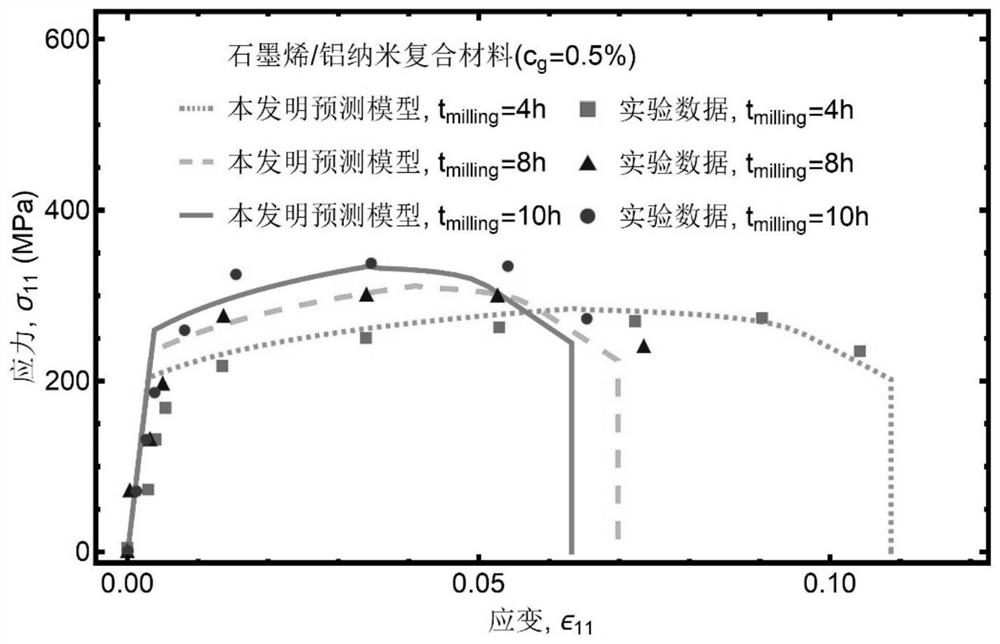

Method for predicting ball-milling related tensile strength of graphene/aluminum nano composite material

ActiveCN112945729AShorten the duration of the experimentSave design economic costMaterial strength using tensile/compressive forcesMicro structureFailure strain

The invention discloses a method for predicting the ball-milling related tensile strength of a graphene / aluminum nano composite material. According to the prediction method provided by the invention, microstructure parameters such as the grain size of the graphene / aluminum nano composite material and mechanical properties such as macroscopic tensile strength and failure strain are closely linked, the experiment time is obviously shortened, and the design economic cost is saved. Model parameters in the prediction method are determined through a small number of experimental data, and the equivalent tensile strength and failure strain of the graphene / metal aluminum nanocomposite under different ball milling time are predicted. The method can guide the graphene / metal aluminum nano composite material to carry out material mechanical property design and check by regulating and controlling material microscopic parameters and ball milling time, and has a wide engineering application prospect.

Owner:CENT SOUTH UNIV

Method for Determining Optimum Asphalt Consumption of Large Particle Size Asphalt Mixture

The invention discloses a method for determining the optimum asphalt dosage of a large particle size asphalt mixture, which is realized by the following method: firstly, the initial asphalt dosage is estimated ; Take it as the median value, and change at an interval of ±0.3%, (a) Carry out rutting test and freeze-thaw cycle rutting test to determine the optimal amount of asphalt , ;(b) Conduct low-temperature bending test and freeze-thaw cycle bending test to determine the optimal amount of asphalt , ; (c) take , , , The arithmetic mean value of the four is used as the optimum asphalt dosage . When failure strain cannot be accurately determined

Owner:SHENYANG JIANZHU UNIVERSITY

A Method for Establishing Fatigue Failure Probability and Fatigue Strain Probability Models of Cement-Based Materials Considering Load Frequency

ActiveCN106294967BDesign optimisation/simulationSpecial data processing applicationsProbit modelFatigue loading

Owner:ZHEJIANG UNIV

Intensity check method of vehicle bonding structure in full temperature field environment

The invention discloses an intensity check method of a vehicle bonding structure in a full temperature field environment. The method is characterized in that the conclusion is as follows that(1) the influence law of the environment temperature on the mechanical properties of an ISR-7008 adhesive main body shows that along with the rise of temperature, the Young modulus, the tensile strength and the failure strain of the adhesives are all on a declining curve; and (2) the test on seven different groups of temperature points on a lap joint, an inlay joint and a butt joint shows that the failurestrength of the joints gradually decreases along with the rise of the temperature, the failure strength of the joints gradually increases along with the fall of the temperature, the rigidity of the joints gradually decreases when the temperature raises from the normal temperature 25 DEG C to 80 DEG C, and the rigidity of the joints gradually increases when the temperature falls from the normal temperature 25 DEG C to -40 DEG C. The intensity check method disclosed by the invention has the advantages that the study of the performance change law of the bonded joint at different temperatures is of great significance in guiding the design of the bonding structure.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

A diatomite asphalt mixture modifier and modified asphalt mixture

InactiveCN105907115BImprove high temperature stabilityImprove wear resistanceBuilding insulationsFailure strainUltrasonic vibration

Owner:SICHUAN HONGHUI TECH

Construction Method of Aeolian Sand Subgrade

ActiveCN107012755BImprove stabilityImprove reinforcementRoadwaysBuilding constructionsFailure strainEngineering

The invention provides an aeolian sand subgrade construction method. The method comprises the following steps that surveying and setting out are conducted; a base layer is laid; padding is loaded and unloaded; a reinforcing layer is laid; a reinforcing layer is laid on the surface of aeolian sand, wherein the reinforcing layer comprises limestone, polypropylene fibers, loose filling and the balance coal ash; tilling is conducted, specifically, watering is conducted on the reinforcing layer, and tilling is conducted on a subgrade multiple times in the length direction; riffle watering is conducted; rolling compaction is conducted through a bulldozer; rolling compaction is conducted through a road roller; compaction detection is conducted, specifically, the compaction coefficient Kof the compacted aeolian sand is detected in a sand filling mode or a water filling mode; and the step that padding is loaded and unloading to the step that compaction detection is conducted are conducted repeatedly until the subgrade reaches a design elevation, and construction is completed. According to the aeolian sand subgrade construction method provided by the invention, the reinforcing layer is laid on the aeolian sand, the reasonable rolling compaction mode is adopted, the strength of the vibrated and compacted subgrade meets design requirements, the compressive strength is high, the failure strain resistance and tension resistance of the subgrade are greatly improved, and the stability of the subgrade is improved.

Owner:CHINA FOURTH ENG OF CHINA RAILWAY SEVENTH GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com