Negative-Poisson ratio multifunctional sponge and preparation method thereof

A multifunctional sponge, negative Poisson's ratio technology, applied in the field of new materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

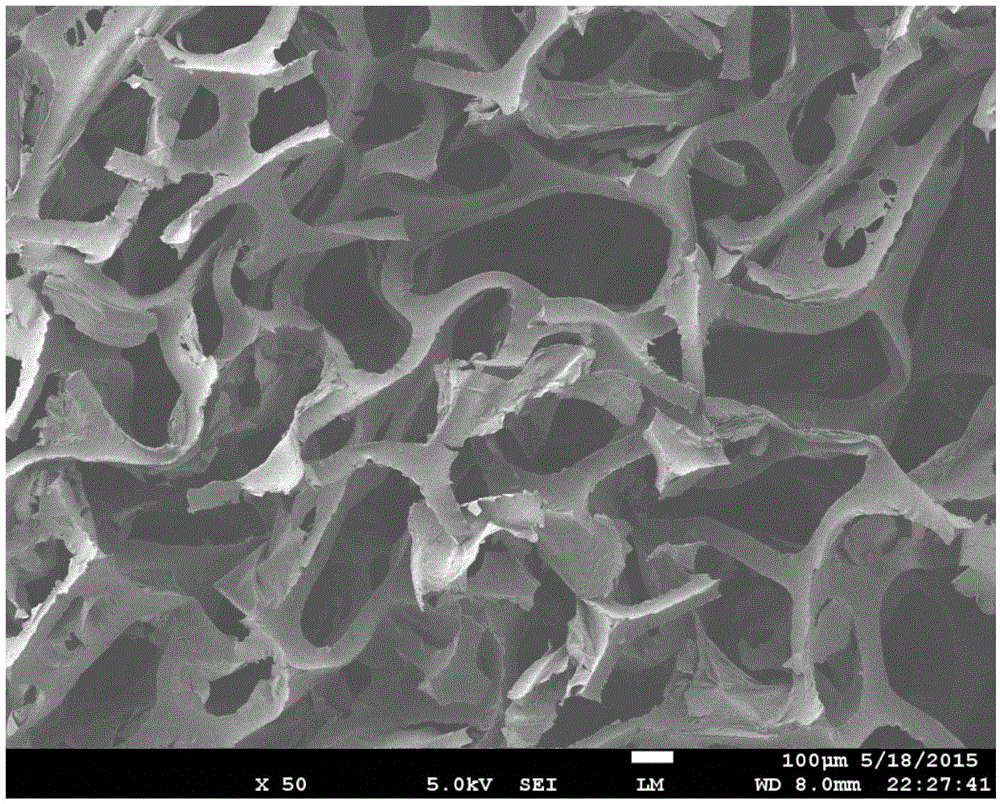

[0060] The present embodiment adopts the following method to prepare negative Poisson's ratio multifunctional sponge:

[0061] (1) Set the density to 23mg / cm 3 Polyurethane sponge cut into 3 x 3 x 10cm 3 The cuboid was cleaned with ethanol by ultrasonic for 30min, then washed with sufficient water, and dried at 80°C;

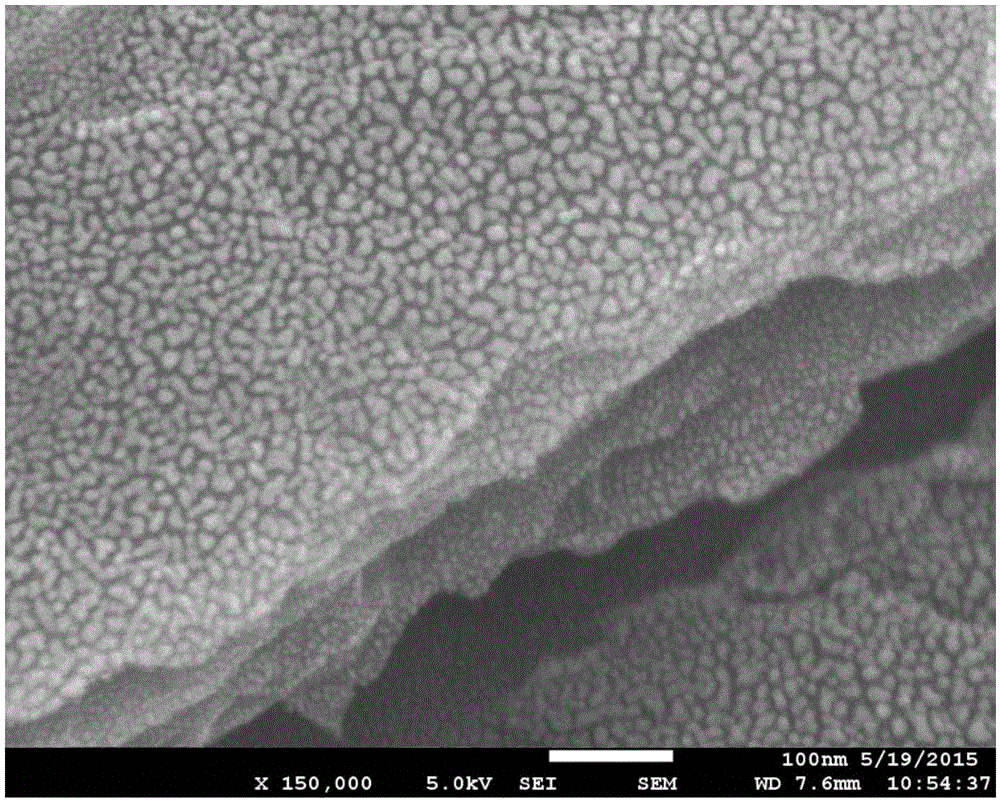

[0062] (2) Take 100 mL of graphene oxide aqueous solution with a density of 1 mg / mL, mix it evenly with 300 μL (0.3% by volume) of hydrazine hydrate, put it into a mold, and extract air bubbles;

[0063] (3) Soak the dried sponge in a mould. After the whole sponge is filled with the blending solution, put it into a well-sealed 99°C incubator and keep it warm for 12 hours to obtain a graphene sponge;

[0064] (4) Take out the graphene sponge, and clean it with ethanol, then dry it at 60°C;

[0065] (5) The dried graphene sponge is uniformly compressed in three directions in the mold, and the uniformly compressed volume is 0.45 times of the initial volume; and ...

Embodiment 2

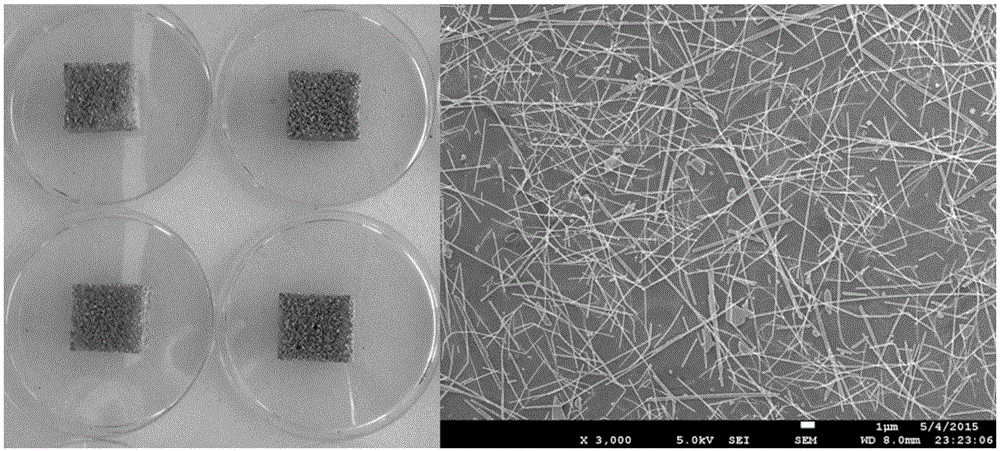

[0069] The present embodiment adopts the following method to prepare negative Poisson's ratio multifunctional sponge:

[0070] (1) Set the density to 5mg / cm 3 Polyurethane sponge cut into 3 x 3 x 10cm 3 The cuboid was cleaned with ethanol by ultrasonic for 30min, then washed with sufficient water, and dried at 80°C;

[0071] (2) get 100mL density and be that the silver nanowire dispersion liquid of 10mg / mL is put into the mould, extract air bubble;

[0072] (3) Soak the dried sponge in a mould, and dry it at 100°C for 4 hours after the whole sponge is fully absorbed with the dispersion liquid to obtain a silver nanowire sponge;

[0073] (4) The dried nano-silver wire sponge is uniformly compressed in three directions in the mold, and the uniformly compressed volume is 0.13 times the initial volume; and kept at 220° C. for 10 minutes;

[0074] (5) After naturally cooling to room temperature, the negative Poisson's ratio multifunctional sponge is obtained, and the loaded nano...

Embodiment 3

[0077] The present embodiment adopts the following method to prepare negative Poisson's ratio multifunctional sponge:

[0078] (1) Set the density to 27.5mg / cm 3 A melamine sponge cut into 3 x 3 x 10cm 3 The cuboid was cleaned with ethanol by ultrasonic for 30min, then washed with sufficient water, and dried at 80°C;

[0079] (2) get 100mL density and put into the mould, take out the air bubble;

[0080] (3) Soak the dried sponge in a mould, and dry it at 140°C for 2 hours after the whole sponge is fully absorbed with the dispersion liquid to obtain a silver nanowire sponge;

[0081] (4) uniformly compress the dried nano-silver wire sponge in three directions in the mold, and the uniformly compressed volume is 0.8 times of the initial volume; and keep warm at 185° C. for 100 min;

[0082] (5) After naturally cooling to room temperature, the negative Poisson's ratio multifunctional sponge was obtained, and the mass ratio increased by 145% compared with that without treatment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com